Page 1

WOW2 Principle with exclusive VAF (Variable Air Flow)

22

22

The Middleby Marshall WOW!2 conveyor series oven utilizes

advanced VAF impingement technology that allows the

user full control of the air ow on the top and bottom of

the baking chamber, resulting in optimal results in cooking

product. Top and bottom zone air ow is modied through

the main control, allowing instant results and full control of

air movement, time, and temperature settings. The exterior

of the oven is cool to the touch, safely giving users cooler

working conditions in the immediate area. The WOW!2 oven

is designed to cook an endless amount of food products

including pizza, chicken, seafood, sandwiches and more.

PS636G

Direct Gas Fired Conveyor Oven

Standard Features

• Impingement PLUS! low oven prole and dual air

return

• Patented EMS energy Management System

reduces gas consumption and increases cooking

efciency

• 36” (914mm) long cooking chamber

• 24” (610mm) wide,

65-3/4” (1670mm) long conveyor belt

• Conveyor speed (Range of 1:00 - 30:00)

• Two 5-1/2” exit trays

Speed

• Advanced technology air delivery system bakes up

to 30% faster than standard conveyor ovens

Energy Management System

The PS636 WOW!

Management System (EMS) that automatically

reduces gas consumption. Electronic control can be

programmed in one energy saving mode.

Automatic “energy eye” saves gas when food product

is not present in the oven.

2

Oven

features an Energy

TM

Middleby Marshall reserves the right to change specications and product design without notice. Such revisions do not entitle the buyer to corresponding changes, improvements, additions, or replacements for previously purchased equipment.

PS636G Rev 2 (04/11)

Optional Features

• Split belt - two 12” (305mm) belts with individually

adjustable speed settings

• Stainless steel lower shelf for double oven

Cleanability

PS636 Ovens are designed for easy cleaning. Removable

parts include: crumb pans, end panels, air ngers, and a

folding conveyor belt assembly.

Easily Serviced

Control compartment is designed for quick and easy

access.

Warranty

All PS636 WOW!

and labor warranty. Oven start-up and demonstration are

included at no additional charge (USA Only)

2

Oven

models have a one year parts

TM

Ventilation

For installation under a ventilation hood only.

1400 Toastmaster Drive

Elgin, IL 60120 USA

(847) 741-3300 Fax: (847) 741-0015

www.middleby-marshall.com

Page 2

Direct Gas Fired Conveyor Oven

22

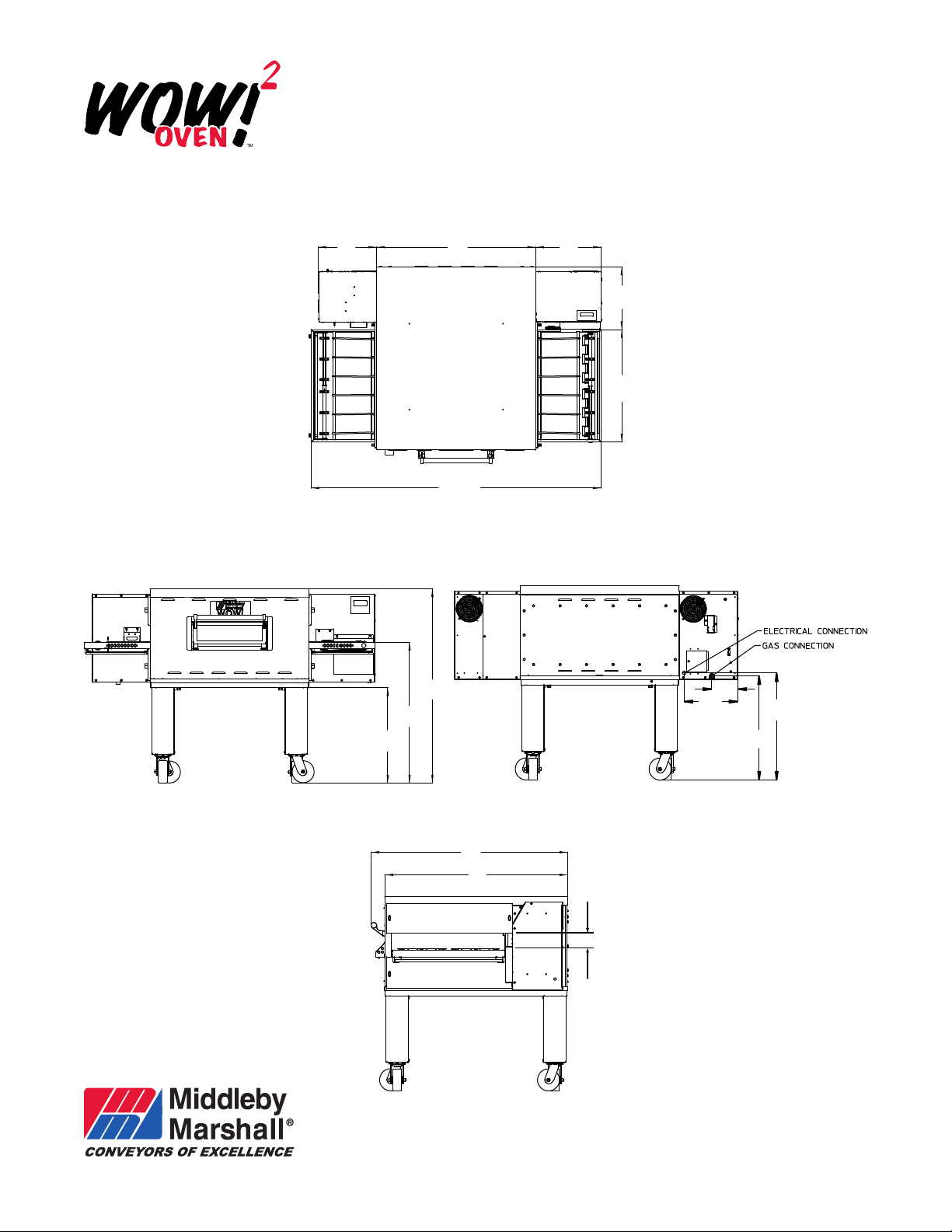

NOTE: Height dimensions are shown for standard leg extensions.

Customer-specic leg extensions will affect these dimensions.

NOTE: All units are shown with casters. CE-approved ovens use

6”/152mm adjustable feet instead of casters.

PS636G-1

13.27

(337)

TOP VIEW

44.02

(1118)

31.89

(810)

21.55

(547)

36.03

(915)

65.75

(1670)

CONVEYOR

14.86

(377)

14.22

(361)

25.50

(648)

12.05

(309)

5.90

(150)

23.57

(599)

24.24

(616)

FRONT VIEW

PS636G Rev 2 (04/11)

44.50

(1130)

41.46

(1053)

SIDE VIEW

BACK VIEW

3.57 (91) Opening

Page 3

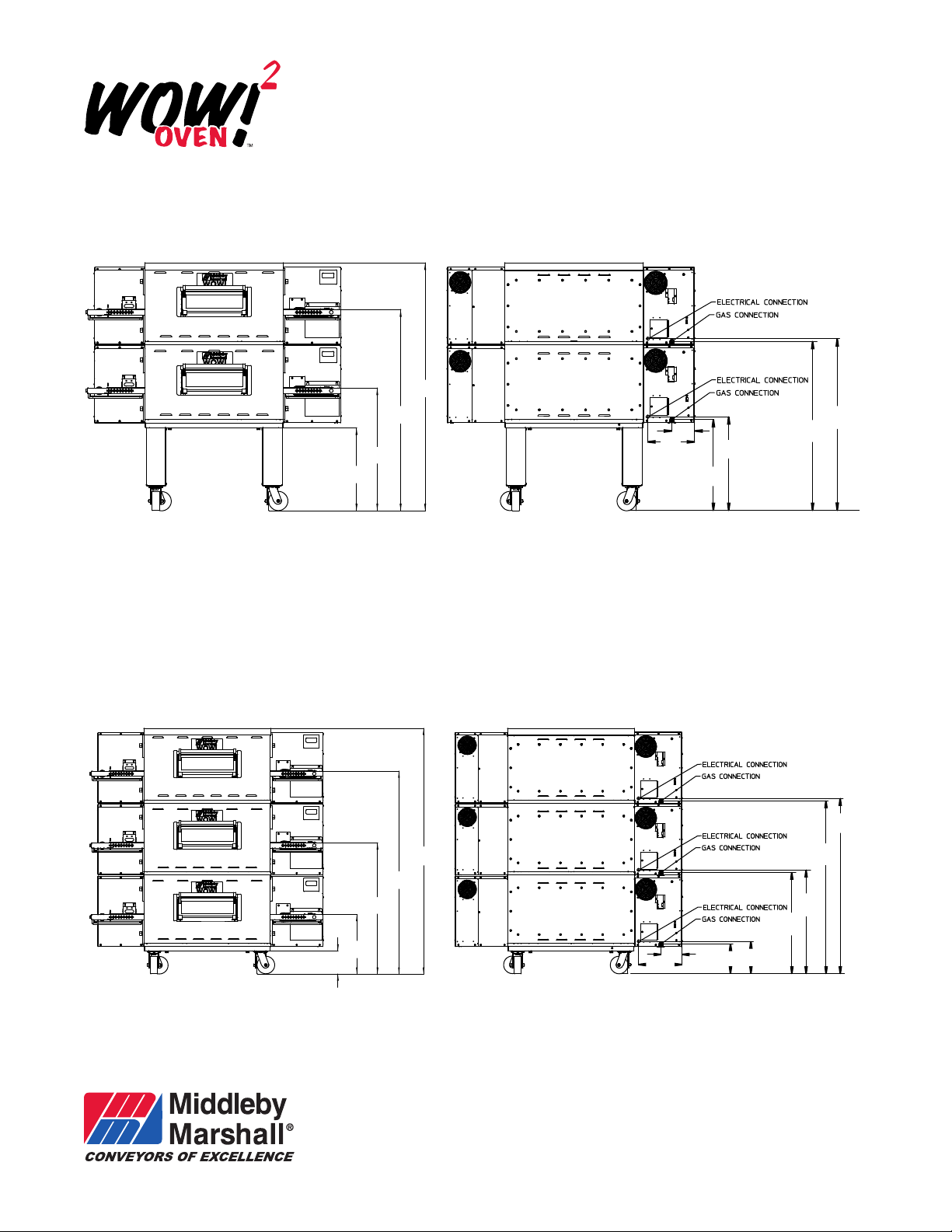

PS636G-2

22

Direct Gas Fired Conveyor Oven

NOTE: Height dimensions are shown for standard leg extensions.

Customer-specic leg extensions will affect these dimensions.

NOTE: All units are shown with casters. CE-approved ovens use

6”/152mm adjustable feet instead of casters.

64.38

(1635)

52.25

21.55

(547)

31.89

(810)

(1327)

12.15

(309)

5.90

(150)

23.57

(599)

24.24

(616)

43.93

(1116)

44.60

(1133)

FRONT VIEW

PS636G-3

6.55

(166)

16.89

(429)

37.25

(946)

57.61

(1463)

69.74

(1171)

BACK VIEW

12.15

(309)

5.90

(150)

8.52

(216)

9.19

(233)

28.88

(734)

29.55

(751)

49.24

(1251)

49.91

(1268)

FRONT VIEW

PS636G Rev 2 (04/11)

BACK VIEW

Page 4

PS636G

22

Direct Gas Fired Conveyor Oven

RECOMMENDED MINIMUM CLEARANCES

Rear of Oven to Wall Control end of conveyor to wall Non-control end of conveyor to wall

0” (0mm) 1” (25.4mm) 1” (25.4mm)

GENERAL SPECIFICATIONS

Overall Length Maximum Bake

Heating Baking Belt Belt (exit trays Operating Time Ship Ship

Zone Area Length Width installed) Height Depth Temp Range Wt Cube

PS636-1 36” 6 ft2 65-3/4” 24” 73” 44” * 44-1/2” 5500F 1-30 min 734lbs 75.1ft

with 17.5” 914mm 0.55 m2 1670mm 610mm 1854mm 1118mm 1130mm 2880C 333kg 2.13m

(446mm) or

leg extensions 2x11”

279mm

PS636-2 72” 12 ft2 65-3/4” 24” 73” 64-3/8” * 44-1/2” 5500F 1-30 min 1468 lbs 150.2 ft

with 17.5” 1828mm 1.1m2 1670mm 610mm 1854mm 1635mm 1130mm 2880C 666 kg 4.25m

(446mm) or

leg extensions 2x11”

279mm

PS636-3 108” 18 ft2 65-3/4” 24” 73” 69-3/4” * 44-1/2” 5500F 1-30 min 2202 lbs 225.3 ft

with 6” 2743mm 1.7 m2 1670 mm 610mm 1865mm 1772mm 1130mm 2880C 999 kg 6.38m

(152mm) or

leg extensions 2x11”

279mm

* Overall height is shown for standard leg extensions. Customer-specic leg extensions will affect the overall height of the oven

3

3

3

3

3

3

ELECTRICAL SPECIFICATIONS

Version Voltage Phase Freq Current Draw Supply Breakers

Domestic and 208/240v 1 50/60 hz 10 Amp 2 pole, 3 wire As per

std. export (2 hot, 1 ground) local codes

* The current draw rating shown above are maximum values for normal operation, amperage draw will be less than the listed value.

NOTE: Each oven includes a 6 ft cord with NEMA# L6-20P plug. Customer to provide NEMA# L6-20R receptacle.

GAS SUPPLY SPECIFICATIONS

Version Gas Type Supply (inlet) Regulated Rated Heat

Pressure Pressure Input

Domestic & Natural 6-12” W.C. 3.5” W.C. 75,000 BTU

std export Gas (14.9-29.9mbar) * (8.7mbar) (21.9 kW-hr)

Domestic & Propane 11-14”W.C. 10” W.C. 75,000 BTU

std export Gas (27.4-34.9mbar) * (24.9mbar) (21.9 kW-hr)

* The required gas supply pressures of other locations are dependent on the local gas type and on all applicable local codes.

Minimum Gas Pipe Sizes:

* Natural Gas - 1 1/2” (50.8 mm) main supply line. One 3/4” (19mm) NPT branch per oven cavity with individual full-ow shutoff valve.

* Propane Gas - 1 1/2” (31.8 mm) main supply line. One 3/4” (19mm) NPT branch per oven cavity with individual full-ow shutoff valve

NOTE: Each oven includes (1) 3/4”(19mm)NPT x 48”(1219mm) exible, vinyl coated stainless steel braided gas hose.

ALL SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE.

Middleby Marshall, in accord with its policy to continually improve its products, reserves the right to

change materials or specications without notice. Such revisions do not entitle the buyer to correspond-

ing changes, improvements, additions, or replacements for previously purchased equipment.

1400 Toastmaster Drive, Elgin, IL 60120-9272, USA • (847) 741-3300 • Fax: (847) 741-0015

www.middleby-marshall.com PS636G Rev 2 (04/11)

© 2011 Middleby Marshall, Inc.

Loading...

Loading...