Page 1

Electric

PN

April 2013

Series Electric Oven

E

Page 2

NOTICE:

This Owner’s Operating and Installation Manual should be given to the user. The operator of the oven

should be familiar with the operation of the oven.

This manual must be kept in a prominent, easily reachable location near the oven.

It is suggested to obtain a service contract with a Middleby Marshall Authorized Service Agent.

WARNING

FOR YOUR SAFETY, DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

Improper installation, adjustment, alteration service or maintenance can cause property damage, injury or

death. Read the installation, operation and maintenance instructions thoroughly before installing or

servicing this equipment.

IMPORTANT

An electrical wiring diagram for the oven is located inside the machinery compartment of the oven.

IMPORTANT

It is the customer’s responsibility to report any concealed or non-concealed damage to the freight company.

Retain all shipping materials until it is certain that the equipment has not suffered concealed shipping damage.

NOTICE

CONTACT YOUR MIDDLEBY MARSHALL AUTHORIZED SERVICE AGENT TO INSTALL AND PERFORM

MAINTENANCE AND REPAIRS. AN AUTHORIZED SERVICE AGENT DIRECTORY IS SUPPLIED WITH YOUR OVEN.

NOTICE

Using any parts other than genuine Middleby Marshall factory manufactured parts relieves the manufacturer

of all warranty and liability.

NOTICE

Middleby Marshall (Manufacturer) reserves the right to change specifications at any time.

NOTICE

The equipment warranty is NOT VALID unless the oven is installed, started and demonstrated under the

supervision of a factory certified installer.

NOTICE

THIS EQUIPMENT IS FOR PROFESSIONAL USE AND SHALL BE USED BY QUALIFIED PERSONNEL.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

ii

Page 3

Page 4

Page 5

Page 6

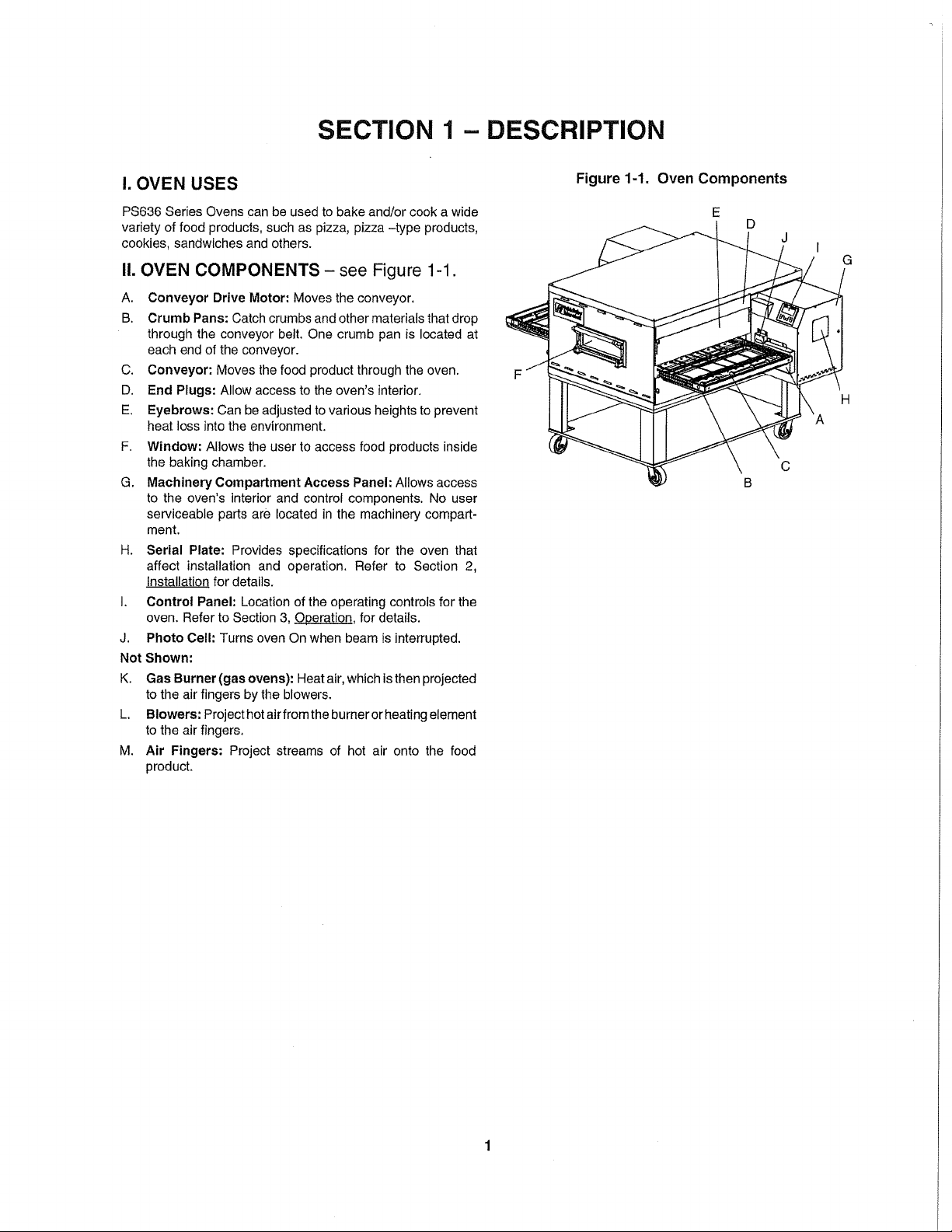

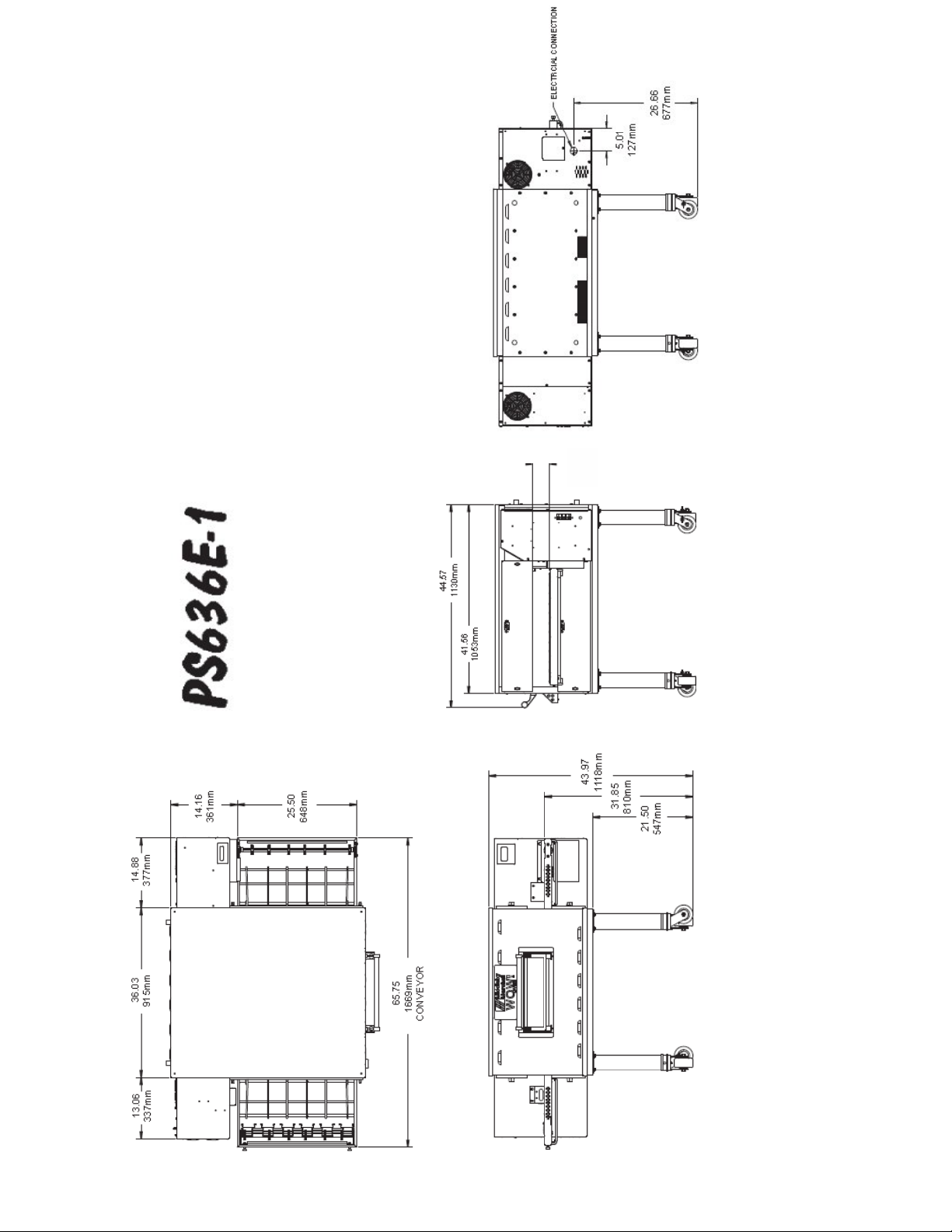

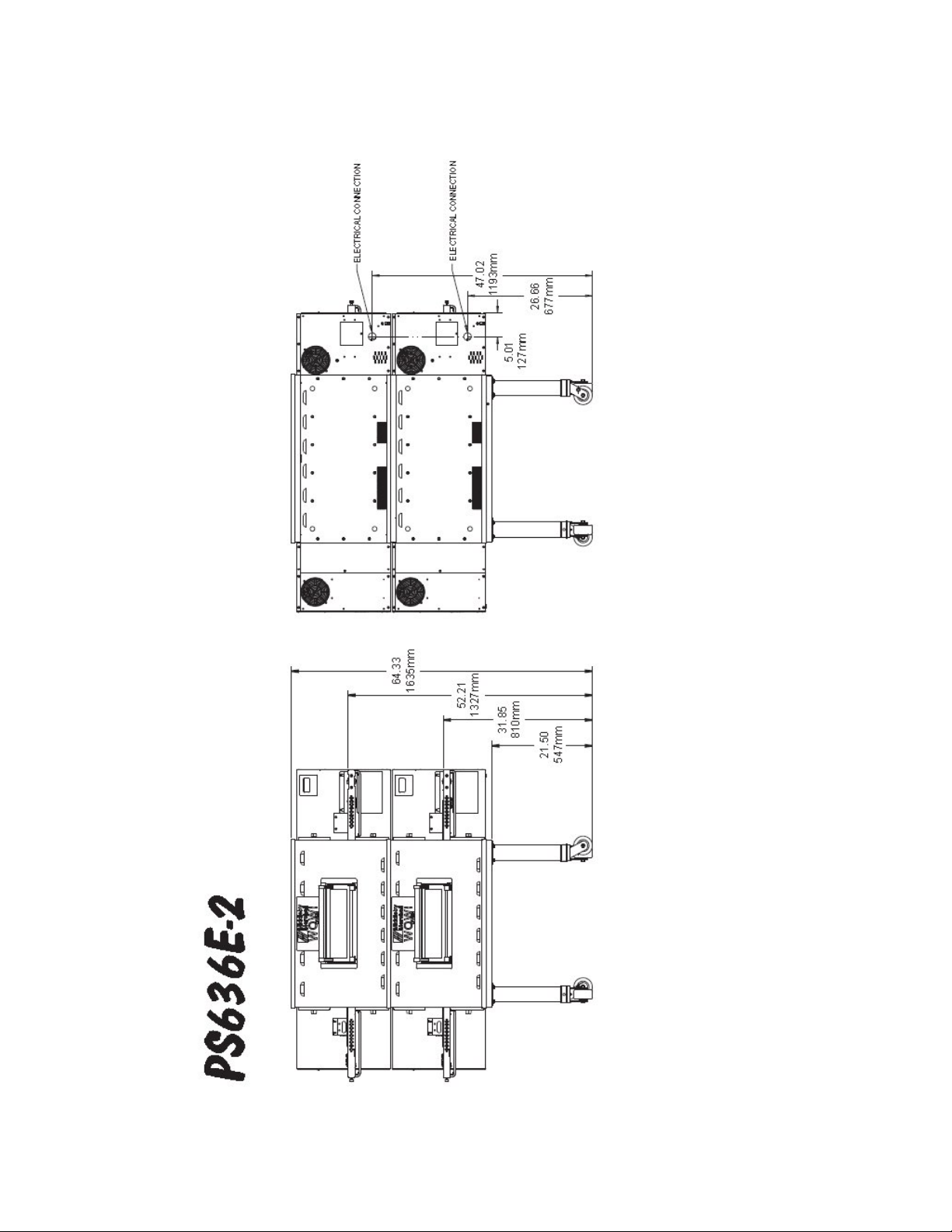

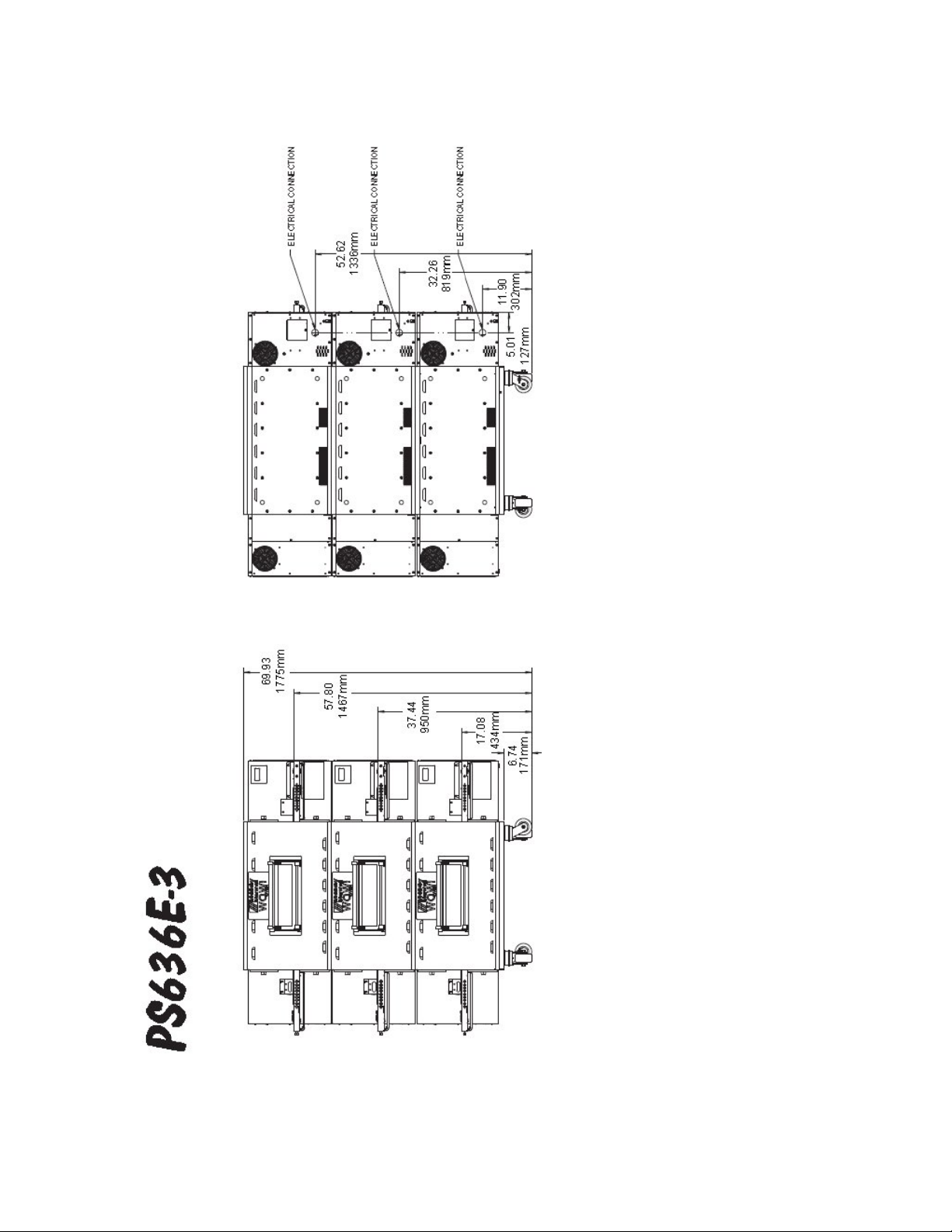

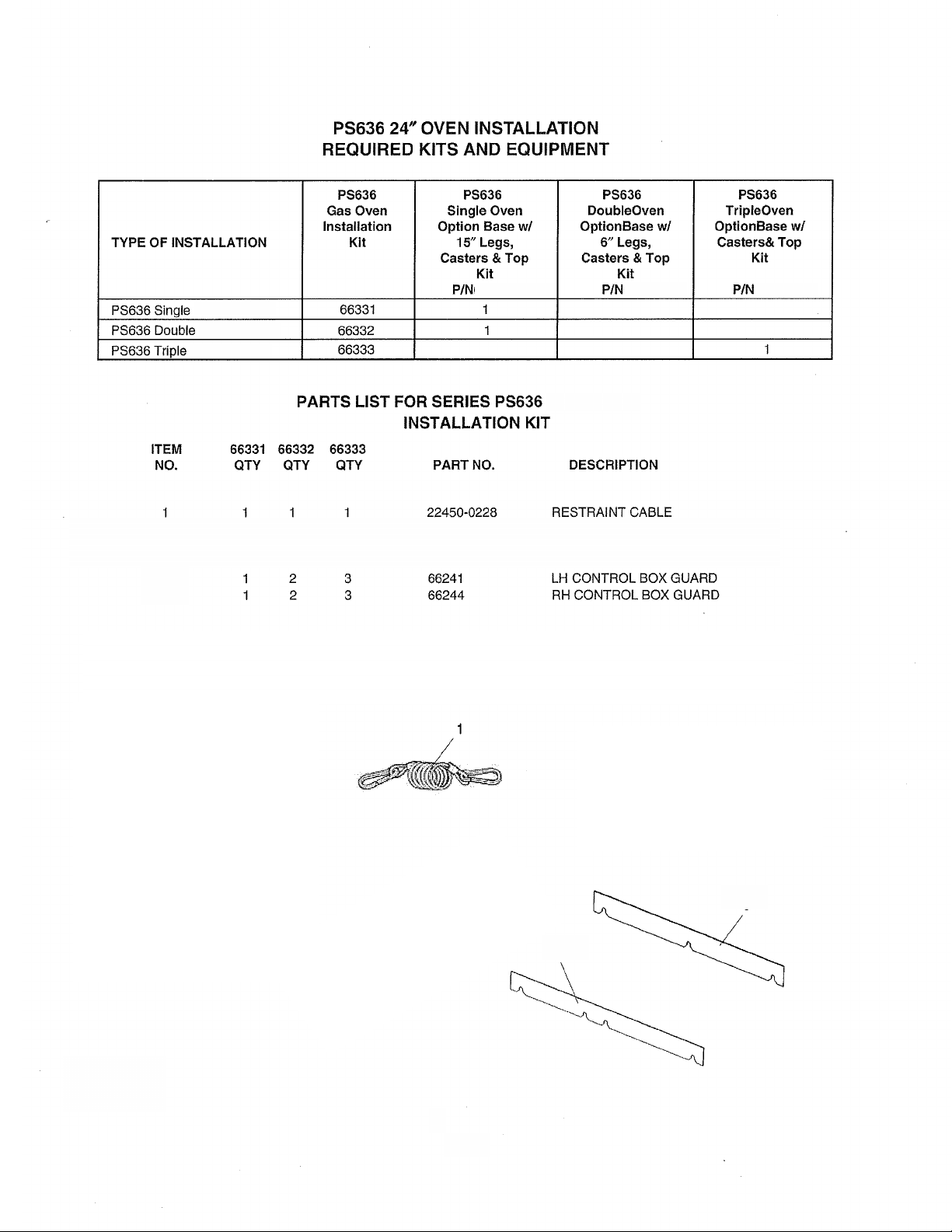

I. PS636E OVEN SPECIFICATIONS

Table 1 -1 Dimensions Single Oven Double Oven Triple Oven

Overall Height 44” (1118 mm) 64-3/8” (1635 mm) 69-3/4” (1772 mm)

Overall Depth 44-1/2” (1130 mm) 44-1/2” (1130 mm) 44-1/2” (1130 mm)

Overall Length (w/o exit trays) 65-3/4” (1670 mm) 65-3/4” (1670 mm) 65-3/4” (1670 mm)

Conveyor Width (belt is 24”)

25-1/2” (648 mm) or,

2 x 11” (279 mm)

25-1/2” (648 mm) or,

2 x 11” (279 mm)

25-1/2” (648 mm) or,

2 x 11” (279 mm)

Baking Area 6.0 sq. ft. (.557m2)

Recommended Minimum Clearances

Rear of Oven to Wall 0” (0 mm) 0” (0 mm) 0” (0 mm)

Control end of conveyor to wall 2” (50.8 mm) 2” (50.8 mm) 2” (50.8 mm)

Non-control end of conveyor to wall 2” (50.8 mm) 2” (50.8 mm) 2” (50.8 mm)

Table 1-2 General Specifications PS636E Electric Oven

Weight of Single Oven 734 lbs. (333 kg)

Max Operating Power 19.8 kW

Operating Temperature Range 350-600ºF (177 - 316ºC)

Warm-up Time 25 minutes

Belt Speed (Time)

0:30 – 20:00 (STD)

0:30 – 15:00 (SPECIAL)

Table 1-3 Electrical Specifications for PS636E electric ovens

DOMESTIC OVENS

VOLTAGE PHASE HZ kW BREAKER WIRING

208 3 50-60 19.8 70 4-WIRE / L1,L2,L3 & GROUND

240 3 50-60 19.8 60 4-WIRE / L1,L2,L3 & GROUND

INTERNATIONAL OVENS

VOLTAGE PHASE HZ kW BREAKER WIRING

208 3 50-60 19.8 70 4-WIRE / L1,L2,L3 & GROUND

240 3 50-60 19.8 60 4-WIRE / L1,L2,L3 & GROUND

380 3 50-60 19.8 40 5-WIRE / L1,L2,L3,N & GROUND

400-416 3 50-60 18.3 - 19.8 5-WIRE / L1,L2,L3,N & GROUND

230 3 50-60 18.2 5-WIRE / L1,L2,L3,N & GROUND

(400 WYE)

30

30

NOTE

Wiring Diagrams are contained in Section 5 of this manual

and are also located inside the right hand oven control box.

Additional electrical information is provided on the oven’s serial plate.

This manual must be kept for future reference.

2

Page 7

3.57

91mm

OPENING

PS636E SINGLE OVEN

3

Page 8

PS636E DOUBLE OVEN

4

Page 9

PS636E TRIPLE OVEN

5

Page 10

SECTION 2

SECTION 2

INSTALLATION

INSTALLATION

WARNING

The oven must be installed on an even (level) non-flammable flooring and any adjacent walls must

be non-flammable. Recommended minimum clearances are specified in the Description section of

this Manual.

WARNING

Do not obstruct the flow of combustion and ventilation air to and from your oven. There must be no

obstructions around or underneath the oven. Constructional changes to the area where the oven is

installed shall not affect the air supply to the oven.

CAUTION

For additional installation information, contact your local Authorized Service Agent.

NOTE

There must be adequate clearance between the oven and combustible construction. Clearance

must also be provided for servicing and for proper operation.

NOTE

An electrical wiring diagram for the oven is located inside the machinery compartment.

NOTE

All aspects of the oven installation, including placement, utility connections, and ventilation requirements,

must conform with any applicable local, national, or international codes. These codes supersede the

requirements and guidelines provided in this manual.

NOTE

In the USA, the oven installation must conform with local codes. Installed ovens must be electrically

grounded in accordance with local codes, or in the absence of local codes,

with the National Electrical Code (NEC), or ANSI/NFPA70.

NOTE - CANADA INSTALLATION

In Canada, the oven installation must conform with local codes. Installed ovens must be electrically

grounded in accordance with local codes, or in the absence of local codes, with the Canadian Electrical Code

CSA C22.2.

NOTE - AUSTRALIA INSTALLATION

In Australia, the oven installation must conform with any requirements of the appropriate statutory authority.

NOTE - CE OVEN INSTALLATION

Four casters are provided to allow the oven to be more easily moved to the installation location. These casters

are intended to simplify pre-installation movement only, and are NOT suitable for use as part of a CE oven

installation. During the installation procedure, the casters MUST be removed, so that the oven can be

supported by the supplied 152mm adjustable legs.

NOTE - GROUNDING INSTRUCTIONS

The oven must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric

shock by providing an escape wirdor electric current. This product is equiped with a cord having a grounding wire

and an appropriate grounding plug. This plug must be plugged into a properly installed outlet in accordance with all

local codes and ordinances.

WARNING: Improper installation of the grounding plug can result in the risk of electric shock. The grounding wire

has insulation with an outer surface that is green with or without yellow stripes.

Implementation of the grounding requirements should be carried out by a qualified electrician or service techni-

cian. Do not modify the appliance plug provided. If the appliance plug does not fit the outlet, the outlet should be

replaced by a qualified electrician.

6

Page 11

SECTION 2

INSTALLATION

NOTE: The oven, when installed, must be electrically

grounded in accordance with local codes, or in the absence of local codes, with the National Electrical Code

(NEC), or ANSI/NFPA70.

NOTE

There must be adequate clearance between

the oven and any adjacent combustible construction. Clearance must also be provided

for servicing and for operation.

CAUTION

It is recommended that the oven be placed under

a ventilation hood for adequate air supply and

ventilation.

CAUTION

Do not obstruct the flow of ventilation air to and

from your oven. Do not obstruct the fan holes in

the rear of the unit.

I. UNLOADING

Your Middleby Marshall PS636-Series Oven is shipped

partially assembled. It will arrive in a carton on a crate.

The crate and carton

Bill of Lading. Report any visible damage to the transport

company, and check for the proper number of crates. If

apparent damage is found, make arrangements to file a

claim against the carrier. Surface Interstate Commerce

Regulations (U.S.A.) require that the claim must be

initiated by the consignee within 10 days from the date that

the shipment is received.

Installer should be qualified to install commercial

conveyor ovens, having suitable lifting equipment to

prevent personal injury.

must be examined before signing the

7

Page 12

66955

OPTION

66956

67280

ELECTRIC OVEN

2

3

2

3

8

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Electric Oven

Page 19

UTILITY ROUGH-IN DIMENSIONS AND POSITIONING

FOR PS636-SERIES OVENS

SECTION 2

INSTALLATION

WARNING

DO NOT USE CONDUIT FOR

GROUND CONNECTION.

CAUTION

IT IS RECOMMENDED THAT THE OVEN

BE PLACED UNDER A VENTILATION

HOOD FOR ADEQUATE AIR SUPPLY

AND VENTILATION.

ELECTRIC SUPPLY TO BE

PROVIDED BY CUSTOMER

CIRCUIT BREAKER

A seperate circuit breaker with lockout/tagout electrical

shutoff is required for each, seperately wired oven.

See breaker sizing requirements below:

ELECTRICAL SPECIFICATIONS

NOTE: Please refer to page 2, Electrical Specifications

chart and your units data plate information, for more

detailed information.

DOMESTIC:

4-WIRE SYSTEM (L1,L2, L3 & GROUND)

208V, 60 Hz, 19.8 kW, 70A Service

240V, 60 Hz, 19.8 kW, 60A Service

Do

NOT

use conduit for ground.

.

/

&

&

/

4O/VEN

MM

/

.

/

&

&

4O/VEN

MM

Suggested dimensions are shown; utility code

3UGGESTEDDIMENSIONSARESHOWNUTILITYCODE

requirements supersede any factors shown.

REQUIREMENTSSUPERSEDEANYFACTORSSHOWN

Figure 2-9. Typical Oven Installation

SUPPLY WIRE

Supply wire size must be in accordance with the

National Electrical Code (current edition) and must be in

compliance with local codes.

SUGGESTED

If space permits, service should be located near the

control console end of the oven(s) to allow convenient

access to safety switches.

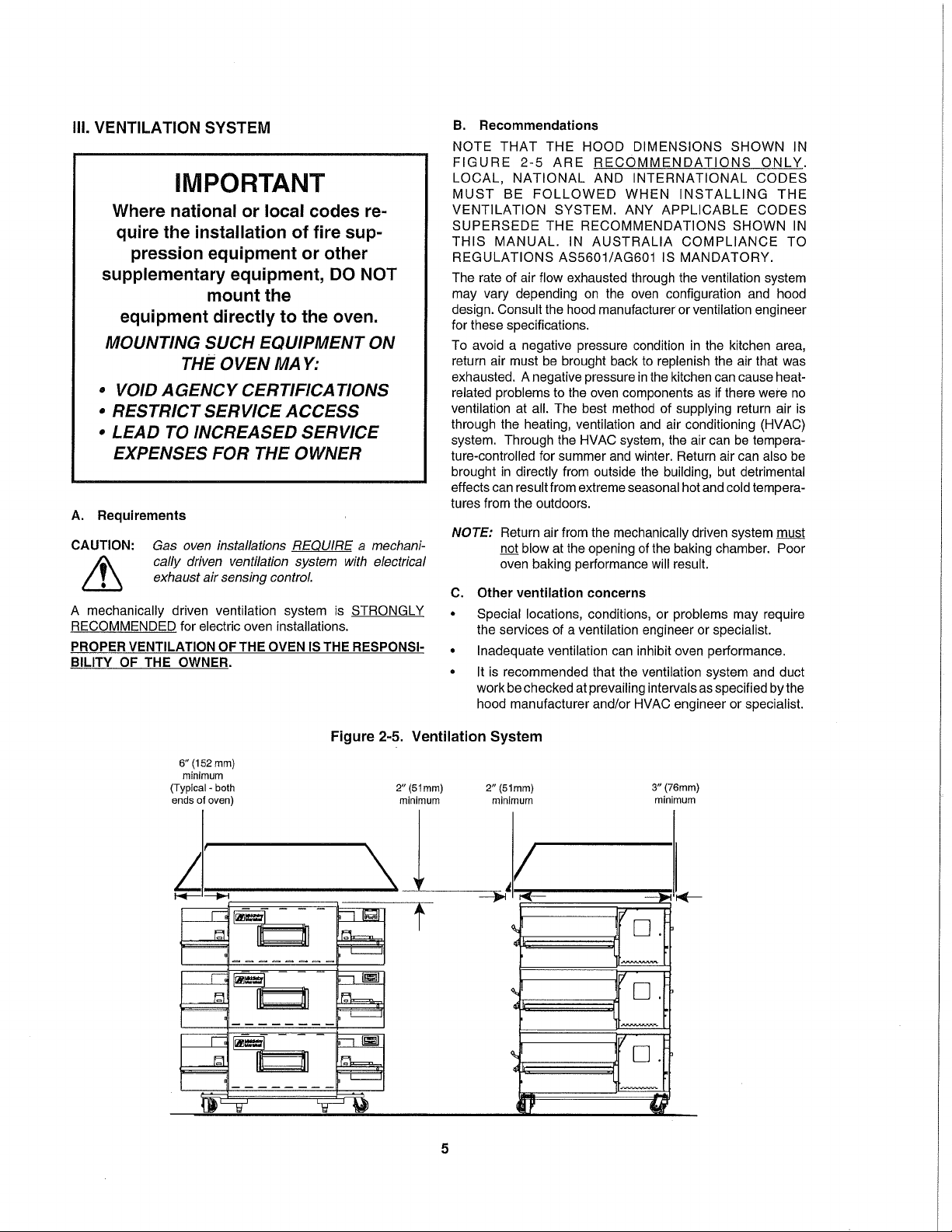

II. VENTILATION GUIDELINES

Use of a ventilation hood is not required for proper

operation, but installation must conform with all local

codes and regulations.

or

EXPORT: CE MODEL

4-WIRE SYSTEM (L1,L2, L3 & GROUND)

208V, 50/60 Hz, 19.8 kW, 30A Service

230-240V, 50/60Hz, 18.2/19.8 kW, 30A Service

5-WIRE SYSTEM (L1, L2, L3, N & GROUND)

380V, 50/60 Hz, 19.8 kW, 40A Service

400-416V, 50/60 Hz, 18.3-19.8 kW, 30A Service

230V (400Y), 50/60 Hz, 18.2 kW, 30A Service

Do NOT

use conduit for ground.

POWER RATING

19.8 kW Standard

Local codes and conditions vary greatly from one area to

another and must be complied with. Following are the

suggested requirements for good ventilation. Please remember these are recommendations or guidelines, you

may have a special condition or problem that will require

the services of a ventilation engineer or specialist. Proper

ventilation is the oven owner’s responsibility. Improper

ventilation can inhibit oven performance.

11

Page 20

SECTION 2

INSTALLATION

III. ELECTRICAL CONNECTION INFORMATION

FOR PS624-SERIES OVENS.

WARNING

Authorized supplier personnel normally accomplish the connections for the ventilation

system, electric and gas supplies, as arranged by the customer. Following these

connections, the factory-authorized installer

can perform the initial startup of the oven.

Check the oven data plate (Figure 2-10) before making any

electric supply connections. Electric supply connections

must agree with data on the oven data plate.

NOTE: The electric supply installation must satisfy the

requirements of the appropriate statutory authority, such

as the National Electrical Code (NEC), ANSI/NFPA70,

(U.S.A.); the Canadian Electrical Code, CSA C22.2; the

Australian Code AG601; or other applicable regulations.

A fused disconnect switch or a main circuit breaker

(customer furnished)

supply line for each oven; it is recommended that this

switch/ circuit breaker have lockout/tagout capability. The

electric supply connection must meet all national and local

electrical code requirements. Copper is the recommended

material for the electrical supply conductors.

MUST be installed in the electric

IV. ELECTRIC SUPPLY

Electrical connection is a fixed conduit connection.

See Electrical Specifications chart on page 2.

The supply conductors must be of the size and

material (copper) recommended to provide the current required; (refer to the data plate for the ampere

specifications).

ELECTRICAL

INLET

International CE Plate

Figure 2-10. Typical Electric Oven Data Plate

Figure 2-11. Junction Connection Box

Domestic Plate

12

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

1 2 3 4 5 6a, b

ITEM

QTY

P/N

DESCRIPTION

7 8 9 10 11a, b, c 12

13 14

19a, b 20

1 1 65564 Digital Display, Programmed

2 1 65756 Motor, Conveyor Drive

3 1 65566 Conveyor Control Board

4 1 66065 Inverter, ½ HP (230V Input)

5 1 61186 Power Supply

6a

6b

7 1 36451 Fan,Cooling

8 2 62044 Air Switch

9 1 65701 Blower Motor, 3/8 HP

10 1 44549 Contactor

11a

11b

11c

12 1 50794 Relay, 30A (240V coil)

13 1 33983 Hi Limit Thermostat

14 1 45036 Circuit Breaker, 3A (Control Circuit)

15 1 65565 Board,Main – I/O

16 2 60520-2 Thermocouple, 2” Grounded

17 1 60185 Photo Sensor

18 1 59132 Relay, DPDT 24VDC Coil

19a 2 66381 Belt, Blower-to-Blower

19b 2 66382 Belt, Blower-to-motor

20 1 45644 Circuit Breaker, 1A (Conveyor Motors)

21 1 59206 Circuit Breaker, 10A (Blower Motors)

22 1 67043 Blower Bearing Assembly

23 1 45019 Circuit Breaker, 3-pole 63A

24 1 58131 RFI Filter, 50A (380V CE Only)

15 16 17 18

21

22 23 24

KEY SPARE PARTS PS636 ELECTRIC

1

1

1

1

44914

44568

68063

68064

68065

Power Relay, 208-240V

Power Relay, 380-415V

Heating Element, 208V, 19.8kW (400-415V)

Heating Element, 240V, 19.8kW

Heating Element, 380V, 19.8kW

22

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Loading...

Loading...