Middleby Marshall Oven PS570S Installation Manual

PS570S

Gas (USA & Std. Export)

English

P/N 39141

Rev. C V1 10/00

page 1

ENGLISH

page 49

FRANÇAIS

PS570S Gas Oven

Model:

PS570S

Combinations:

Single Oven

Double Oven (Two-Stack)

Triple Oven (Three-Stack)

Quad Oven (Four-Stack)

OWNER'S OPERATING

& INSTALLATION

MANUAL

página 73

ESPAÑOL

© 2000 Middleby Marshall, Inc.

is a registered trademark of Middleby Marshall, Inc. All rights reserved.

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 (847)741-3300 FAX (847)741-4406

1

NOTICE:

Owner's Operating and Installation Manual should be given to the user. The operator of the oven should

This

be familiar with the functions and operation of the oven.

This manual must be kept in a prominent, easily reachable location near the oven.

ENGLISH

Gas ovens are designed for use with EITHER natural gas OR liquid propane gas, as specified on the serial plate.

Where permitted by local and national codes, the oven can be converted from natural gas to propane operation,

or from propane to natural gas operation. This conversion requires the installation of the appropriate Middleby

Marshall Gas Conversion Kit by an Authorized Service Agent.

It is suggested to obtain a service contract with a Middleby Marshall Authorized Service Agent.

WARNING

POST, IN A PROMINENT LOCATION, THE EMERGENCY TELEPHONE NUMBER OF YOUR LOCAL GAS

SUPPLIER AND INSTRUCTIONS TO BE FOLLOWED IN THE EVENT YOU SMELL GAS.

Instructions to be followed in the event the user smells gas shall be obtained by consulting the local gas

supplier. If the smell of gas is detected, immediately call the emergency phone number of your local Gas

Company. They will have personnel and provisions available to correct the problem.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of

this or any other appliance.

WARNING:

Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death. Read the installation,

operating and maintenance instructions thoroughly before installing

or servicing this equipment.

IMPORTANT

An electrical wiring diagram for the oven is located inside the machinery

compartment.

IMPORTANT

It is the customer's responsibility to report any concealed or non-concealed damage

to the freight company. Retain all shipping materials until it is certain that the

equipment has not suffered concealed shipping damage.

NOTICE: CONTACT YOUR MIDDLEBY MARSHALL AUTHORIZED SERVICE AGENT TO PERFORM MAINTENANCE

AND REPAIRS. AN AUTHORIZED SERVICE AGENCY DIRECTORY IS SUPPLIED WITH YOUR OVEN.

NOTICE: Using any parts other than genuine Middleby Marshall factory manufactured parts relieves the manufacturer of

all warranty and liability.

NOTICE: Middleby Marshall (Manufacturer) reserves the right to change specifications at any time.

NOTICE: The equipment warranty is not valid unless the oven is installed, started and demonstrated under the supervision

of a factory certified installer.

Retain This Manual For Future Reference

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 USA (847)741-3300 FAX (847)741-4406

24-Hour Service Hotline: 1-(800)-238-8444

www.middleby.com

2

TABLE OF CONTENTS

page page

SECTION 1 - DESCRIPTION ................................................... 4

V. FINAL ASSEMBLY ................................................... 11

I. OVEN COMPONENTS ............................................. 4

A Conveyor Drive Motor ....................................... 4

B. Crumb Pans ..................................................... 4

C. Conveyor End Stop ........................................... 4

D. Conveyor Rear Stop ......................................... 4

E. Conveyor ........................................................... 4

F. End Plugs ......................................................... 4

G. Eyebrows .......................................................... 4

H. Window ............................................................. 4

I. Machinery Compartment Access Panel .......... 4

J. Control Panel .................................................... 4

K. Serial Plate ....................................................... 4

L. Gas Burner ....................................................... 4

M. Blowers ............................................................. 4

N. Air Fingers ........................................................ 4

II. OVEN SPECIFICATIONS ......................................... 4

A. Dimensions...................................................... 4

VI. ELECTRICAL SUPPLY ........................................... 11

VII. GAS SUPPLY .......................................................... 11

A. Gas Utility Rough-In Recommendations ....... 12

B. Connection ...................................................... 12

C. Gas Conversion .............................................. 12

SECTION 3 - OPERATION AND TROUBLESHOOTING .......... 13

I. LOCATION AND DESCRIPTION OF CONTROLS . 13

A. BLOWER ( ) Switch ...................................... 13

B. HEAT ( ) Switch ............................................ 13

C. CONVEYOR ( ) Switch ............................... 13

D. Conveyor Speed Controller ............................. 13

E. Digital Temperature Controller ....................... 13

F. Machinery Cpt. Access Panel Safety Switch .. 13

II. NORMAL OPERATION, STEP-BY-STEP ................ 14

A. Daily Startup Procedure .................................. 14

B. Daily Shutdown Procedure ............................. 14

ENGLISH

B. General Specifications ..................................... 4

C. Gas Orifice and Pressure Specifications ........ 4

D. Electrical Specifications ................................... 4

SECTION 2 - INSTALLATION .................................................. 5

I. INSTALLATION KIT .................................................. 7

II. BASE PAD KIT .......................................................... 7

III. VENTILATION SYSTEM ........................................... 8

A. Requirements .................................................. 8

B. Recommendations .......................................... 8

C. Other Ventilation Concerns .............................. 8

IV. ASSEMBLY ............................................................... 9

A. Base Pad, Legs, Casters, and Stacking ......... 9

B. Restraint Cable Installation ............................. 9

C. Conveyor Installation ........................................ 9

III. QUICK REFERENCE: DIGITAL TEMPERATURE CON-

TROLLER ................................................................ 15

IV. QUICK REFERENCE: TROUBLESHOOTING ....... 16

SECTION 4 - REGULAR MAINTENANCE ............................... 17

I. MAINTENANCE - DAILY.......................................... 17

II. MAINTENANCE - MONTHLY .................................. 18

III. MAINTENANCE - EVERY 3 MONTHS .................... 19

IV. MAINTENANCE - EVERY 6 MONTHS ....................20

V. KEY SPARE PARTS KIT ......................................... 21

SECTION 5 - ELECTRICAL WIRING DIAGRAM ...................... 22

3

SECTION 1 - DESCRIPTION

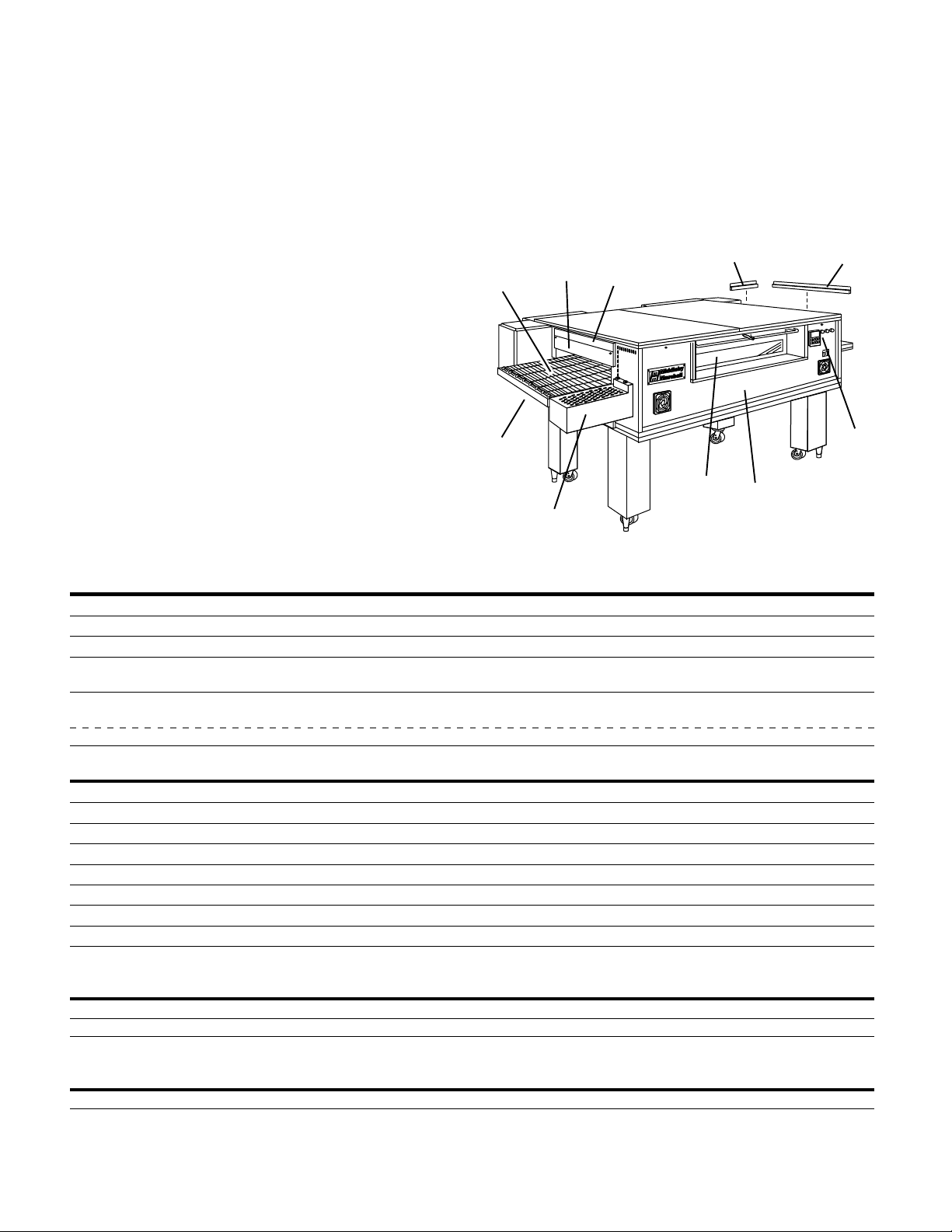

I. OVEN COMPONENTS - see Figure 1-1.

A. Conveyor Drive Motor: Moves the conveyor.

B. Crumb Pans: Catch crumbs and other material that drop

ENGLISH

through the conveyor belt. One crumb pan is located at

each end of the conveyor.

C,D. Conveyor End Stop and Rear Stop: Prevent food products

from falling off the end or rear of the moving conveyor.

E. Conveyor: Moves the food product through the oven.

F. End Plugs: Allow access to the oven's interior.

G. Eyebrows: Can be adjusted to various heights to prevent

heat loss into the environment.

H. Window: Allows the user to see and access food products

inside the baking chamber.

I. Machinery Compartment Access Panel: Allows access

to the oven's interior and control components. No userservicable parts are located in the machinery compartment.

J. Control Panel: Location of the operating controls for the

oven.

Not Shown:

K. Serial Plate: Provides specifications for the oven that affect

installation and operation.

L. Gas Burner: Heats air, which is then projected to the air

fingers by the blowers.

M. Blowers: Project hot air from the burner to the air fingers.

N. Air Fingers: Project streams of hot air onto the food product.

Figure 1-1 - Oven Components

D

E

G

F

B

H

I

C

J

A

II. OVEN SPECIFICATIONS

Table 1: Dimensions Single Oven Double Oven Triple Oven Quad Oven

Overall Height (inc. top and legs, as appropriate) 46-1/8 (1172mm) 60-1/8 (1527mm) 62-1/2 (1588mm) 78 (1981mm)

Overall Depth (inc. rear shrouds) 61-3/4 (1568mm) 61-3/4 (1568mm) 61-3/4 (1568mm) 61-3/4 (1568mm)

Overall Length 106 (2692mm) 106 (2692mm) 106 (2692mm) 106 (2692mm)

Conveyor Width 32 (813mm) 32 (813mm) 32 (813mm) 32 (813mm)

Recommended Minimum Clearances

Rear of Oven (inc. rear shrouds) to Wall 0 mm 0 mm 0 mm 0 mm

Conveyor Extension to Wall (both ends) 0 mm 0 mm 0 mm 0 mm

Table 2: General Specifications (per oven cavity)

Weight 1400 lbs. (634kg)

Shipping Weight 1750 lbs. (780kg)

Shipping Cube 160.3 ft3 (4.53m3)

Rated Heat Input 170,000 BTU (42,840 kcal, 50 kW/hr)

Maximum Operating Temperature 550°F / 288°C

Air Blowers Two blowers at 1400 ft.3/min. (39.6m3/min.) at 2050 RPM, 0.40" (1.0cm) Water Static Pressure

Average Air Jet Velocity 2600 ft./min. (1320cm/sec.) average

Warmup Time 15 min.

Table 3: Gas orifice and pressure specifications (per oven cavity)

Gas Type Main Orifice I.D. Pilot Orifice I.D. Supply (Inlet) Pressure Pressure

Natural 0.250 (6.35mm) 0.028 (0.71mm) 6-12 W.C. (14.9-29.9mbar) 3.5 W.C. (8.7mbar)

Propane 0.152 (3.86mm) 0.018 (0.46mm) 11-14 W.C. (27.4-34.9mbar) 10 W.C. (24.9mbar)

or 2x15" (381mm) or 2x15" (381mm) or 2x15" (381mm) or 2x15" (381mm)

Orifice (Manifold)

Table 4: Electrical specifications (per oven cavity)

Main Blower Voltage Control Circuit Voltage Phase Freq Current Draw Poles Wires

208-240V 120V (w/transformer) 1 Ph 50/60Hz 12A 3 Pole 4 Wire (2 hot, 1 neut, 1 gnd)

IMPORTANT: Additional electrical information is provided on the oven's serial plate, and on the wiring diagram inside the

machinery compartment.

4

SECTION 2 - INSTALLATION

WARNING - For gas ovens, after any conversions, readjustments, or service work on the oven:

Perform a gas leak test.

Test for correct air supply.

Test for proper combustion and gas supply.

Check that the ventilation system is in operation.

WARNING

Keep the appliance area free and clear of combustibles.

WARNING

The oven must be installed on an even (level) non-flammable flooring and any adjacent walls must

be non-flammable. Recommended minimum clearances are specified in the Description section of

this Manual.

WARNING

Do not obstruct the flow of combustion and ventilation air to and from your oven. There must be no

obstructions around or underneath the oven. Constructional changes to the area where the oven is

installed shall not affect the air supply to the oven.

CAUTION

For additional installation information, contact your local Authorized Service Agent.

ENGLISH

NOTE

There must be adequate clearance between the oven and combustible construction. Clearance

must also be provided for servicing and for proper operation.

NOTE

An electrical wiring diagram for the oven is located inside the machinery compartment.

NOTE

All aspects of the oven installation, including placement, utility connections, and ventilation requirements,

must conform with any applicable local, national, or international codes. These codes supercede the require-

ments and guidelines provided in this manual.

NOTE

In the USA, the oven installation must conform with local codes. In the absence of local codes, gas oven

installations must conform with the National Fuel Gas Code, ANSI Z223.1. Gas ovens, when installed, must

be electrically grounded in accordance with local codes, or in the absence of local codes, with the National

Electrical Code (NEC), or ANSI/NFPA70.

NOTE

In Canada, the oven installation must conform with local codes. In the absence of local codes, gas oven

installations must conform with the Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Gas

Installation Code, CAN/CGA-B149.2, as applicable. Gas ovens, when installed, must be electrically grounded

in accordance with local codes, or in the absence of local codes, with the Canadian Electrical Code CSA

C22.2.

NOTE

In Australia, the oven installation must conform with any requirements of the appropriate statutory authority.

Gas oven installtions must conform with AGA Code, AG601.

5

SECTION 2 - INSTALLATION

ENGLISH

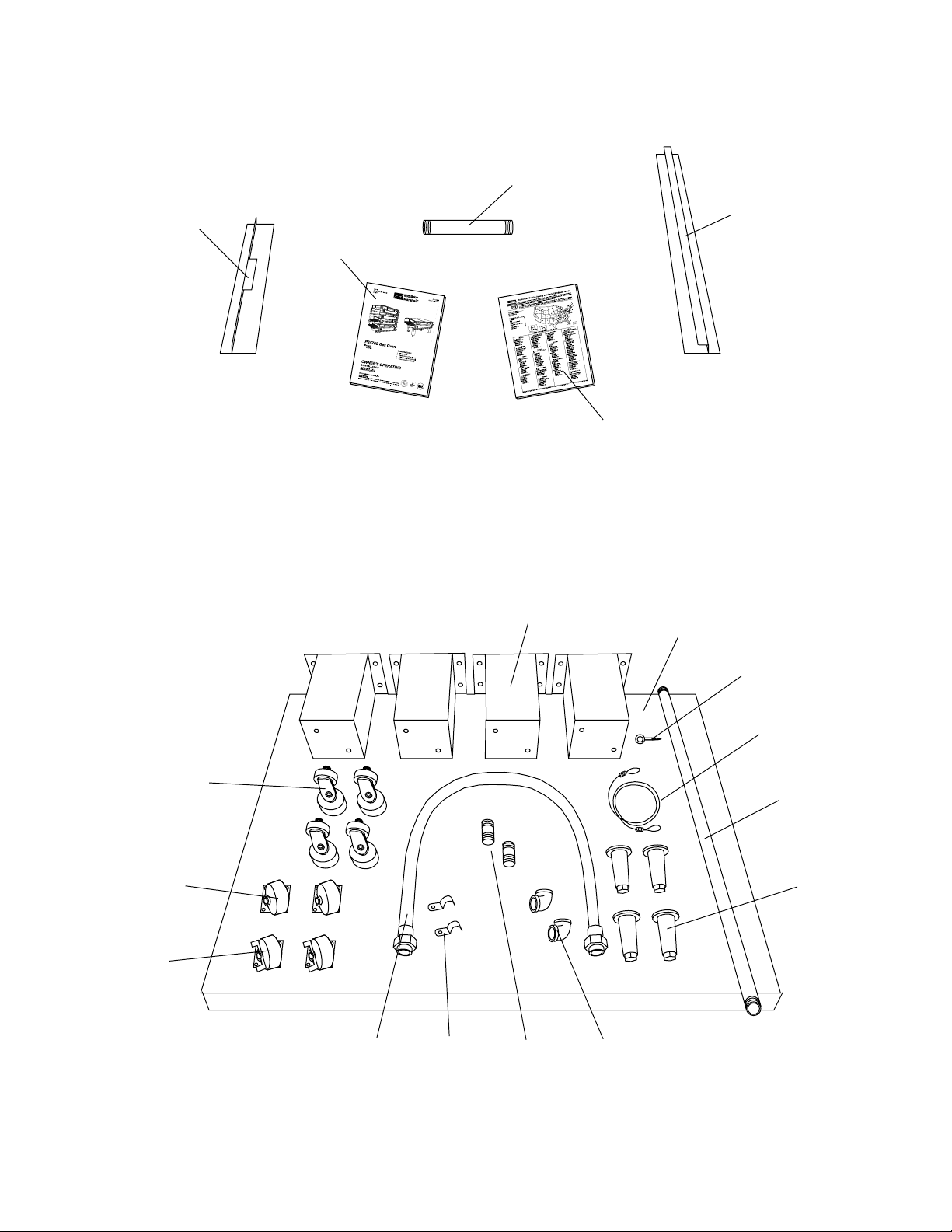

Figure 2-1 - Installation Kit

3

1

2

4

5

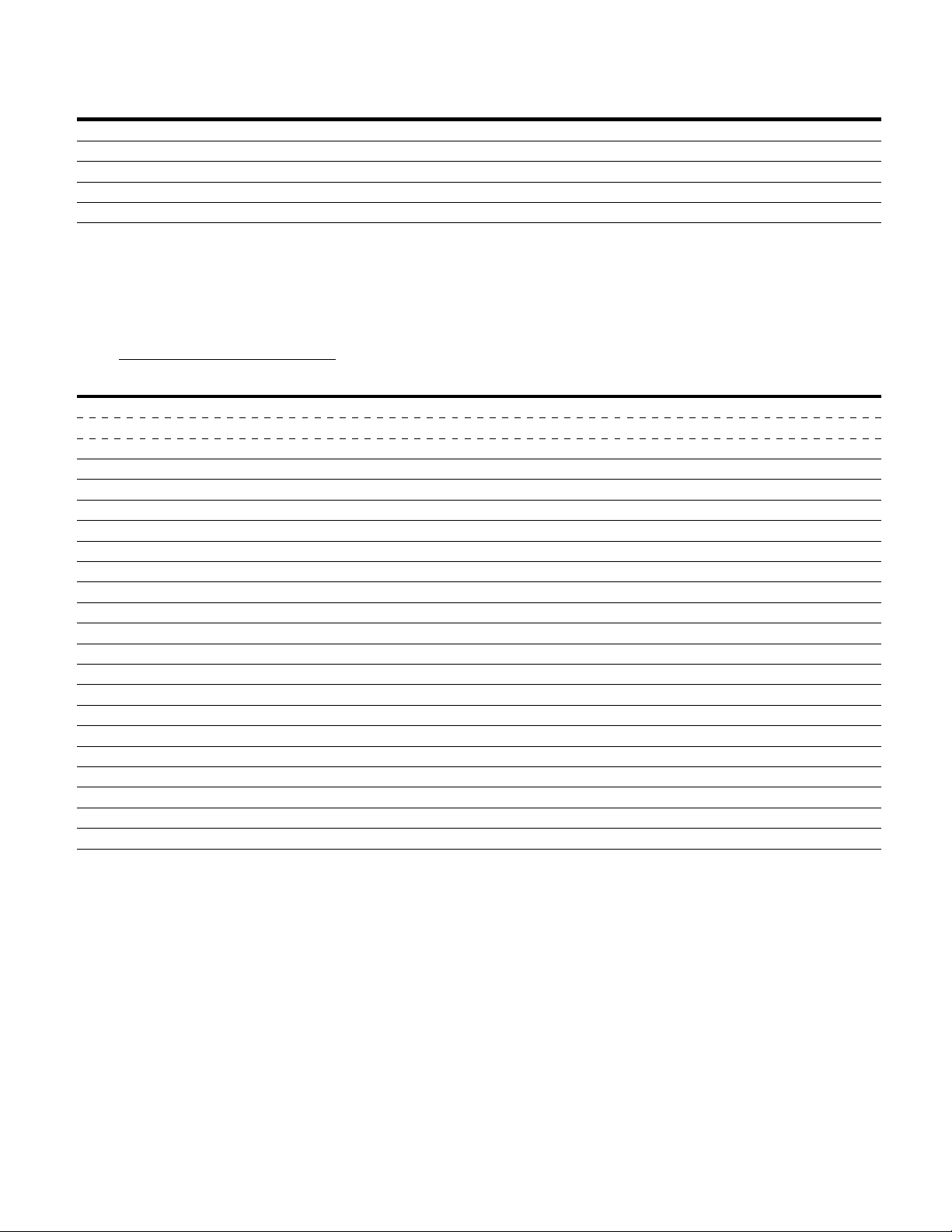

Figure 2-2 - Base Pad Kit

1

13

12

11

2

3

10

9

4

56 78

6

SECTION 2 - INSTALLATION

I. INSTALLATION KIT - see Figure 2-1

NOTE: One Installation Kit is required for each oven cavity.

Item Qty. Part No. Description

1 1 35900-0148 Conveyor rear stop

2 1 35000-1103 Conveyor end stop

3 1 33120-0053 Gas pipe nipple

4 1 39141 Owner's Operating and Installation Manual, PS570S Gas Ovens

5 1 1002040 Middleby Marshall Authorized Service Agency Listing

II. BASE PAD KIT - see Figure 2-2

NOTE: One Base Pad Kit is required for each Single, Double, Triple, or Quad Oven installation.

Qty.

Single Double Double Triple Quad

oven oven with oven with oven oven

Item 10" legs 15" legs Part No. Description

1a 4 -- -- -- -- 37210-0060 Leg extension, 19" (483mm)

1b -- 4 - - -- -- 37210-0082 Leg extension, 10" (254mm)

1c -- - - 4 -- -- 37210-0057 Leg extension, 15" (381mm)

2 4 4 4 4 -- 37115-0102 Caster, swivel, with 3/4" mounting stud

3 -- -- - - -- 2 22290-0010 Caster, swivel, with flat mounting plate

4 -- -- - - -- 2 22290-0009 Caster, swivel, with flat mounting plate and brake

5 1 1 1 1 1 22361-0003 Flexible gas hose, 1-1/4 dia. X 72 (1829mm) L

6 2 2 2 2 2 27271-0004 Pipe clamp, 1-1/2

7 2 2 2 2 2 33120-0055 Nipple, 1-1/4 dia. X 3 (76mm) L, NPT

8 2 2 2 2 2 23122-0007 Elbow, 90°, 1-1/4 dia.

9 4 4 4 4 -- 22450-0028 Adjustable leg, 6" (152mm)

10 1 1 1 1 1 33120-0056 Gas pipe, 1-1/4 dia. X 54 (1372mm) L

11 1 1 1 1 1 22450-0253 Restraint cable, 60 (1524mm) L

12 1 1 1 1 1 21392-0005 Eyebolt

13 1 1 1 1 1 37210-0055 Base pad

-- 2 2 2 2 2 35210-0656 Top cover (Right or Left)

-- 8 8 8 8 8 21256-0069 Screw, slt trs hd, #10-32 X 1-1/4

-- 2 2 2 2 2 21292-0001 Screw, hex washer hd, #10-16 X 3/4

-- 16 16 16 -- 8 21216-0018 Bolt, hex cap, 1/2"-13 X 1-1/4

-- 16 16 16 -- 8 21416-0003 Flat washer, 1/2

-- 16 16 16 -- 8 21426-0004 Lock washer, 1/2

-- - - -- - - - - 16 21216-0001 Bolt, hex cap, 3/8"-16 X 1

ENGLISH

7

Loading...

Loading...