Page 1

A/A File No.: _____________

Principle

Middleby Marshall PS Series Conveyor ovens bake both

faster and at a lower temperature than other ovens. Patented vertical columns of hot air move heat aerodynamically instead of using high temperatures. The streams of

hot air remove the boundary layers of cool heavy air which

tend to insulate the product. This gives very rapid baking

without burning. All Middleby ovens are designed to cook

a multitude of products including pizza, seafood, bagels,

ethnic foods and more.

Item No.: ________________

Direct Gas Fired Conveyor Oven

PS570

Standard Features

• Impingement PLUS! low oven profile and dual air

return

• Patented EMS Energy Management System reduces gas consumption and increases cooking efficiency

• 70”/1778mm-long cooking chamber

• 32”/813mm-wide, 106”/2692mm-long conveyor belt

• St ackable up to four units high

• Patented “Jet Sweep” impingement process that delivers constant heat to the chamber

• Microprocessor-controlled bake time/conveyor speed

• Customer-specific adjustable jet fingers that allow

control of heat delivery

• St ainless steel front, sides and top

• Front-loading window with cool handle

• Reversible conveyor direction

Optional Features

• Split belt - two 15”/381mm belt s with individually-adjustable speed settings

Conserves Energy

Middleby ovens provide very efficient heat transfer to product. Energy is conserved as air is recycled from heater to

product, with minimum flue or vent loss.

Cleanability

PS570 ovens are designed for easy cleaning. Removable

parts include: crumb pans, end panels, air fingers, and a

folding conveyor belt assembly .

Easily Serviced

Control compartment is designed for quick and easy access. All electrical controls are door-mounted.

Warranty

All PS570 models have a one year parts and labor warranty . Oven start-up and demonstration are included at

no additional charge (USA only).

Ventilation

For installation under a ventilation hood only .

Form 4501

A MIDDLEBY COMPANY

1400 Toastmaster Drive

Elgin, Illinois 60120 USA

(847) 741-3300 Fax: (847) 741-0015

www.middleby.com

Page 2

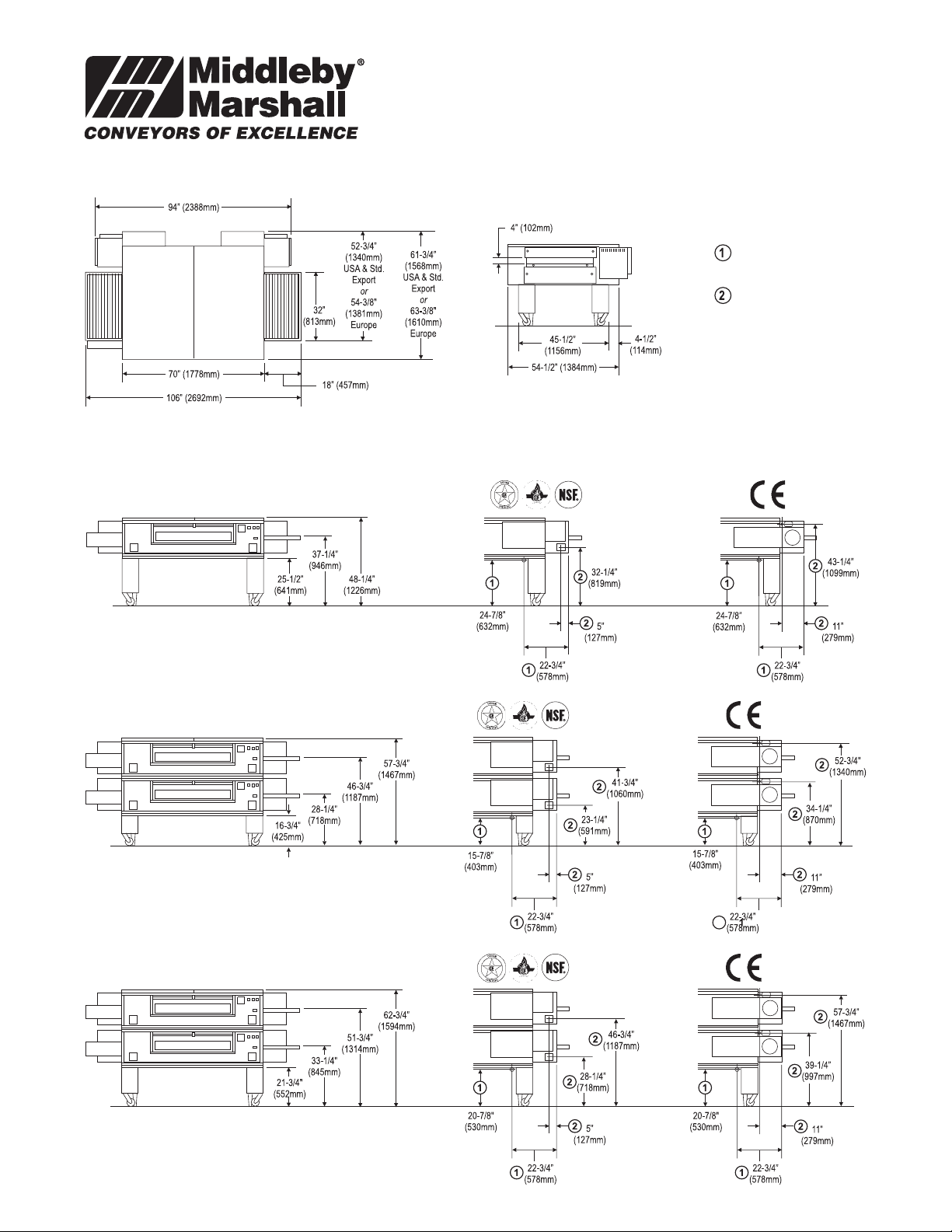

TOP VIEW SIDE VIEW

PS570-1 Single Oven

with 19” (483mm) leg extensions

PS570 Series

Direct Gas Fired Conveyor Ov en

Gas Utility

Connection

Electrical Utility

Connection

REAR

VIEWS

FRONT VIEW

PS570-2 Double Oven

with 10” (254mm) leg extensions

FRONT VIEW

PS570-2 Double Oven

with 15” (381mm) leg extensions

REAR

VIEWS

REAR

VIEWS

FRONT VIEW

Page 3

PS570-3 Triple Oven

with 4” (102mm) leg extensions

FRONT VIEW

PS570-3 Triple Oven

without leg extensions

PS570 Series

Direct Gas Fired Conveyor Ov en

REAR

VIEWS

REAR

VIEWS

FRONT VIEW

PS570-4 Quad Oven

with outriggers

FRONT VIEW

REAR

VIEWS

Page 4

PS570 Series

Direct Gas Fired Conveyor Ov en

RECOMMENDED MINIMUM CLEARANCES

Rear of oven Control end of Non-control end of

to wall oven to wall oven to wall

0” (0mm) 0” (0mm) 0” (0mm)

GENERAL INFORMA TION

Model Zone Area Length Width Height Temp. Range Wt. Cube

Heating Baking Belt Belt Operating Time Ship Ship

PS570-1 70" 15.5 sq. ft. 106" 32" 61-3/4" 63-3/8” 48-1/4” 550°F 4- 1750 lbs. 160 ft.

with 19" (483mm) 1778mm 1.44m

2

2692mm 813mm 1568mm 1610mm 1226mm 288°C 29:50 795kg 4.5m

leg extensions

PS570-2 140" 31 sq. ft. 106" 32" 61-3/4" 63-3/8” 57-3/4” 550°F 4- 3500 lbs. 320 ft.

with 10” (254mm) 3556mm 2.88m

2

2692mm 813mm 1568mm 1610mm 1467mm 288°C 29:50 1589kg 9.0m

leg extensions

PS570-2 140" 31 sq. ft. 106" 32" 61-3/4" 63-3/8” 62-3/4" 550°F 4- 3500 lbs. 320 ft.

with 15" (381mm) 3556mm 2.88m

2

2692mm 813mm 1568mm 1610mm 1594mm 288°C 29:50 1589kg 9.0m

leg extensions

PS570-3 210" 46.5 sq. ft. 106" 32" 61-3/4" 63-3/8” 72-1/4” 550°F 4- 5250 lbs. 480 ft.

with 4” (102mm) 5334mm 4.32m

2

2692mm 813mm 1568mm 1610mm 1835mm 288°C 29:50 2384kg 13.5m

leg extensions

PS570-3 210" 46.5 sq. ft. 106" 32" 61-3/4" 63-3/8” 68" 550°F 4- 5250 lbs. 480 ft.

without leg 5334mm 4.32m

2

2692mm 813mm 1568mm 1610mm 1727mm 288°C 29:50 2384kg 13.5m

extensions

PS570-4 280" 62 sq. ft. 106" 32" 61-3/4" 63-3/8” 82" 550°F 4- 7000 lbs. 640 ft.

with outriggers 7112mm 5.76m

2

2692mm 813mm 1568mm 1610mm 2083mm 288°C 29:50 3178kg 18.0m

ELECTRICAL SPECIFICATIONS

Depth Depth Max. Bake

Max Current Draw at Startup

Breakers

3

3

3

3

3

3

3

3

3

3

3

3

Model Version Voltage Phase/Freq. Supply

PS570 208-240V 1/60 Hz 2 pole, 3 wire

(2 hot, 1 gnd)

PS570 230V 1/50 Hz 2 pole, 3 wire

(2 hot, 1 gnd)

* The current draw ratings shown above are the max required at startup.

The average current draw during operation is significantly lower.

GAS SUPPL Y SPECIFICATIONS

Min. Gas Pipe Size Supply Gas Pressure Rated Heat Input

Natural Gas 2” (50.8mm) main 6-12” W .C. 170,000 BTU

One 1-1/4” (12.7mm) NPT (14.9-29.9 mbar) (42,840 kcal,

branch to lower oven cavity 50 kW/hr.)

with individual full-flow per oven cavity

shutoff valve

Propane Gas 2” (50.8mm) main 11-14” W.C. 170,000 BTU

One 1-1/4” (12.7mm) NPT (27.4-34.9 mbar) (42,840 kcal,

branch to lower oven cavity 50 kW/hr.)

with individual full-flow per oven cavity

shutoff valve

* The gas supply pressures shown are for ovens installed in North America. The required gas supply

pressures of other locations are dependent on the local gas type and on all applicable local codes.

ALL SPECIFICA TIONS SUBJECT TO CHANGE WITHOUT NOTICE.

Amps

12A*

10A*

As per

local codes

As per

local codes

1400 Toastmaster Drive, Elgin, IL 60120-9272, USA • (847) 741-3300 • Fax: (847) 741-0015

Printed in U.S.A 06/05

www.middleby.com

Form 4501

Loading...

Loading...