Page 1

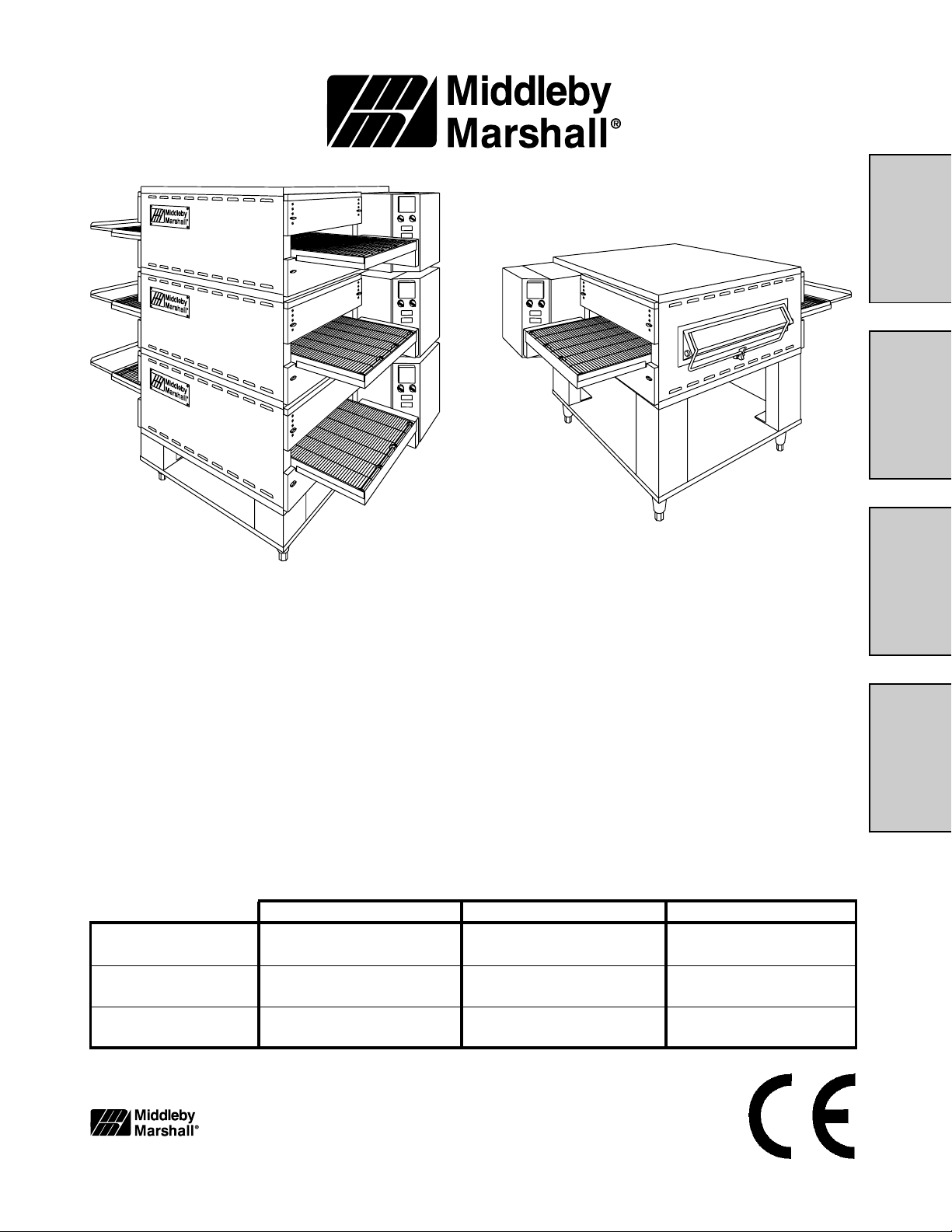

PS536 Gas and Electric

Europe

ENGLISH/German/

French/Spanish

P/N 46525

Rev. B V1 9/01

page 1

ENGLISH

Seite 35

DEUTSCH

PS536 Gas and Electric Ovens

Models:

PS536

OWNER'S OPERATING AND

INSTALLATION MANUAL

for European export ovens

Single Oven Double Oven Triple Oven

Rated Heat Input, Natural Gas 14.6kW-hr. Natural Gas 2x14.6kW-hr. Natural Gas 3x14.6kW-hr.

Gas Ovens Propane 13.2 kW-hr. Propane 2x13.2 kW-hr. Propane 3x13.2 kW-hr.

Rated Heat Input, 17kW 2x17kW 3x17kW

Electric Ovens

Heating Zones 1 controlled 2 controlled 3 controlled

heat zone heat zones heat zones

Combinations:

Single Oven

Double Oven (Two-Stack)

Triple Oven (Three-Stack)

page 69

FRANÇAIS

página 103

ESPAÑOL

© 2001 Middleby Marshall, Inc.

is a registered trademark of Middleby Marshall, Inc. All rights reserved.

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 (847)741-3300 FAX (847)741-4406

1

Page 2

NOTICE:

Owner's Operating and Installation Manual should be given to the user. The operator of the oven should

This

be familiar with the functions and operation of the oven.

This manual must be kept in a prominent, easily reachable location near the oven.

ENGLISH

Gas ovens are designed for use with EITHER natural gas OR liquid propane gas, as specified on the serial plate.

Where permitted by local and national codes, the oven can be converted from natural gas to propane operation,

or from propane to natural gas operation. This conversion is described in the Installation section of this Manual.

The conversion requires the installation of the appropriate Middleby Marshall Gas Conversion Kit.

It is suggested to obtain a service contract with a Middleby Marshall Authorized Service Agent.

WARNING

POST, IN A PROMINENT LOCATION, THE EMERGENCY TELEPHONE NUMBER OF YOUR LOCAL GAS

SUPPLIER AND INSTRUCTIONS TO BE FOLLOWED IN THE EVENT YOU SMELL GAS.

Instructions to be followed in the event the user smells gas shall be obtained by consulting the local gas

supplier. If the smell of gas is detected, immediately call the emergency phone number of your local Gas

Company. They will have personnel and provisions available to correct the problem.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of

this or any other appliance.

WARNING:

Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death. Read the installation,

operating and maintenance instructions thoroughly before installing

or servicing this equipment.

IMPORTANT

An electrical wiring diagram for the oven is located inside the machinery

compartment.

IMPORTANT

It is the customer's responsibility to report any concealed or non-concealed damage

to the freight company. Retain all shipping materials until it is certain that the

equipment has not suffered concealed shipping damage.

NOTICE: CONTACT YOUR MIDDLEBY MARSHALL AUTHORIZED SERVICE AGENT TO PERFORM MAINTENANCE

AND REPAIRS. AN AUTHORIZED SERVICE AGENCY DIRECTORY IS SUPPLIED WITH YOUR OVEN.

NOTICE: Using any parts other than genuine Middleby Marshall factory manufactured parts relieves the manufacturer of

all warranty and liability.

NOTICE: Middleby Marshall (Manufacturer) reserves the right to change specifications at any time.

NOTICE: The equipment warranty is not valid unless the oven is installed, started and demonstrated under the supervision

of a factory certified installer.

Retain This Manual For Future Reference

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 USA (847)741-3300 FAX (847)741-4406

24-Hour Service Hotline: 1-(800)-238-8444

www.middleby.com

2

Page 3

TABLE OF CONTENTS

page page

SECTION 1 - DESCRIPTION ................................................... 4

V. GAS SUPPLY .......................................................... 17

I. OVEN USES ............................................................. 4

II. OVEN COMPONENTS ............................................. 4

A. Window ............................................................. 4

B. Conveyor Exit Tray ............................................ 4

C. Eyebrows .......................................................... 4

D. End Plugs ......................................................... 4

E. Control Panel .................................................... 4

F. Machinery Compartment Access Panel .......... 4

G. Serial Plate ....................................................... 4

H. Conveyor Drive Motor ....................................... 4

I. Crumb Pans ..................................................... 4

J. Conveyor ........................................................... 4

K. Heating Elements ............................................ 4

L. Blow ers ............................................................. 4

M. Air Fingers ........................................................ 4

III. OVEN SPECIFICATIONS ......................................... 4

A. Dimensions ...................................................... 4

B. General Specifications ..................................... 4

C. Electrical Specifications for Electric Ovens ..... 5

D. Electrical Specifications for Gas Ovens .......... 5

E. Gas Orifice and Pressure Specifications........ 5

A. Connection ...................................................... 17

B. Preparation for Use with Various Gases ....... 18

C. Replacing the Gas Orifices ............................. 18

D. Checking the Gas Supply (Inlet) Pressure .... 19

E. Adjusting the Orifice (Manifold) Pressure

and Heat Input ................................................. 19

SECTION 3 - OPERATION ..................................................... 21

I. LOCATION AND DESCRIPTION OF CONTROLS . 21

A. BLOWER (

B. CONVEYOR (

C. Conveyor Speed Controller ............................. 21

D. RESET ( ) Switch ...................................... 21

E. Digital Temperature Controller .......................21

F. Machinery Cpt. Access Panel Safety Switch .. 21

II. NORMAL OPERATION, STEP-BY-STEP ................22

A. Daily Startup Procedure .................................. 22

B. Daily Shutdown Procedure ............................. 23

III. QUICK REFERENCE: DIGITAL TEMPERATURE

CONTROLLERS ..................................................... 24

IV. QUICK REFERENCE: TROUBLESHOOTING ....... 26

) Switch ......................................21

) Switch ............................... 21

ENGLISH

SECTION 2 - INSTALLATION .................................................. 6

I. INSTALLATION KIT .................................................. 7

II. VENTILATION SYSTEM ........................................... 8

A. Requirements .................................................. 8

B. Recommendations .......................................... 8

C. Other Ventilation Concerns .............................. 8

III. ASSEMBLY ............................................................... 9

A. Base Pad Assembly ......................................... 9

B. Stacking ........................................................... 10

C. Conveyor Installation ....................................... 1 1

IV. ELECTRICAL SUPPLY ........................................... 16

A. Additional Information - Gas Ovens ................ 16

B. Additional Information - Electric Ovens .......... 16

C. Connection ...................................................... 16

SECTION 4 - MAINTENANCE ................................................. 27

I. MAINTENANCE - DAILY ..........................................27

II. MAINTENANCE - MONTHLY .................................. 28

III. MAINTENANCE - EVERY 3 MONTHS .................... 28

IV. MAINTENANCE - EVERY 6 MONTHS .................... 32

V. KEY SPARE PARTS KIT ......................................... 3 2

SECTION 5 - ELECTRICAL WIRING DIAGRAMS ................... 33

I. WIRING DIAGRAM, PS536 ELECTRIC OVEN,

380V, 50 Hz, 3 Ph ................................................... 3 3

II. WIRING DIAGRAM, PS536 GAS OVEN,

220-230V, 50 Hz, 1 Ph ............................................ 34

3

Page 4

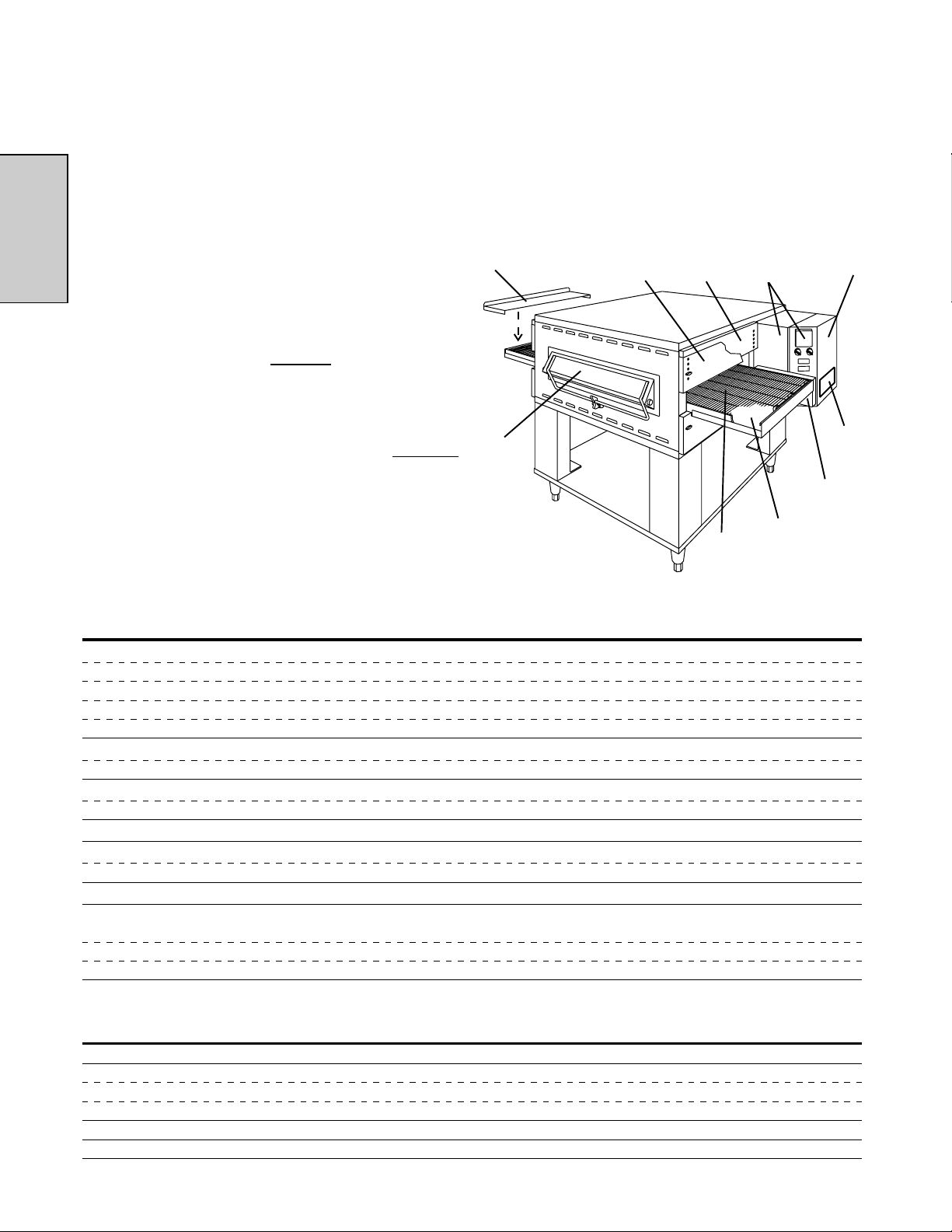

SECTION 1 - DESCRIPTION

I. OVEN USES

PS536 Ovens can be used to bake and/or cook a wide

variety of food products, such as pizza, pizza-type products,

cookies, sandwiches and others.

ENGLISH

II. OVEN COMPONENTS - see Figure 1-1.

A. Window (on ovens so equipped): Allows the user to see

and access food products inside the baking chamber.

B. Conveyor Exit Tray: Prevents food products from falling off

the end of the moving conveyor.

C. Eyebrows (on ovens so equipped): Can be adjusted to

various heights to prevent heat loss into the environment.

D. End Plugs: Allow access to the oven's interior.

E. Control Panel: Location of the operating controls for the

oven. Refer to Section 3,

F. Machinery Compartment Access Panel: Allows access

to the oven's interior components. No user-servicable

parts are located inside the machinery compartment.

G. S e r i a l P l a t e : Provides specifications for the oven that affect

installation and operation. Refer to Section 2,

for details.

H. Conveyor Drive Motor: Moves the conveyor.

I. Crumb Pans: Catch crumbs and other material that drop

through the conveyor belt. One crumb pan is located

underneath each end of the conveyor.

J. Conveyor: Moves the food product through the oven.

Operation, for details.

Installation,

Not Shown:

K. Gas Burner (gas ovens) or Heating Elements (electric

ovens): Heat air, which is then projected to the air fingers

by the blowers.

L. Blowers: Fans that project hot air from the burner or

heating elements to the air fingers.

M. Air Fingers: Project streams of hot air onto the food

product.

Fig. 1-1 - Oven Components

B

A

EDC

G

H

I

J

F

Ovens with Ovens with Ovens with Ovens with

III. OVEN SPECIFICATIONS

Table 1-1: Dimensions

Overall Height: single oven w/standard 446mm legs 1105mm 1105mm 1105mm --

single oven w/custom 597mm legs -- 1256mm 1256mm --

double oven w/standard 446mm legs 1549mm 1549mm 1549mm - -

double oven w/custom 521mm legs -- 1624mm 1624mm 1624mm

triple oven w/standard 152mm legs 1702mm 1702mm 1702mm - -

Overall Depth: without optional front window 1010mm 1010mm 1010mm 1010mm

with optional front window 1092mm 1092mm 1092mm 1092mm

Overall Length: without exit tray installed 1422mm 1524mm 1537mm 1943mm

with exit tray installed -- 1734mm 1734mm 2140mm

Baking Chamber Length < - - - - - - - - - - - - - - - - - - 914mm - - - - - - - - - - - - - - - - - - >

Conveyor Width:Si ngle Be lt < - - - - - - - - - - - - - - - - - - 508mm - - - - - - - - - - - - - - - - - - >

Split Belt < - - - - - - - - - - - - - - - - - 2 x 241mm - - - - - - - - - - - - - - - - - >

Conveyor Length 1422mm 1524mm 1524mm 1930mm

Recommended Minimum Clearances:

Rear of oven to wall < - - - - - - - - - - - - - - - - - - 76mm - - - - - - - - - - - - - - - - - - >

Control end of conveyor to wall < - - - - - - - - - - - - - - - - - - 457mm - - - - - - - - - - - - - - - - - - >

Non-control end of conveyor to wall < - - - - - - - - - - - - - - - - - - 76mm - - - - - - - - - - - - - - - - - - >

* Refer to Figures 2-9 and 2-10 in the Installation section for illustrations of Type 1 and Type 2 conveyors.

1422mm-long 1524mm-long 1524mm-long 1930mm-long

Type 1 conveyor* Type 1 conveyor* Type 2 conveyor* Type 2 conveyor*

(custom) (standard) (standard) (custom)

Table 1-2: General specifications (per oven cavity)

Weight 182kg

Rated Heat Input: Gas Ovens, Natural Gas 14.6kW-hr.

Gas Ovens, Propane 13.2kW-hr.

Electric Ovens 17kW

Operating Temperature 93-316°C

Warmup Time 25 minutes

4

Page 5

SECTION 1 - DESCRIPTION

Table 1-3: Electrical specifications for electric ovens (per oven cavity)

Main Blower Control Current kW

Voltage Circuit Voltage Phase Freq. Draw Rati ng Poles Wires

230V 120V conv. speed control, 3 Ph 50 Hz 25A 17.0 kW at 380V 4 Pole 5 Wire (3 hot,

drive motor, contactor, 1 neutral, 1 ground)

& temp. control; all others 230V

IMPORTANT: Additional electrical information is provided on the oven's serial plate, and on the wiring diagram inside the

machinery compartment.

CAUTION: The current draw shown in the chart above is an average value for normal operation. The initial amperage draw on

oven startup may exceed the listed value.

Table 1-4: Electrical specifications for gas ovens (per oven cavity)

Main Blower Control Circuit Current draw Poles Wires

Vo lta g e Vo lta g e Phase Freq (avg.) *

220-230V 120V conveyor speed controller 1 Ph 50Hz 4.0-4.6A * 2 Pole 3 Wire (1 hot,

(with transformer); 1 neutral,

all other control circuits 230V 1 ground)

IMPORTANT: Additional electrical information is provided on the oven's serial plate, and on the wiring diagram inside the

machinery compartment.

CAUTION: The current draw shown in the chart above is an average value for normal operation. The initial amperage draw on

oven startup may exceed the listed value.

ENGLISH

Table 1-5: Gas orifice and pressure specifications (per oven cavity)

Supply (Inlet) Pressure

Gas Ori fice DK,FI,GB NL DE BE,FR FI,DE,NL ES,GB (Manifold) Heat

Main UK,CH,IT,AT, SE,CH,AT,DK, BE,IE,IT,PT, Orifice Rated

Type dia .

G20 2.3749 20 -- 20 20 -- -- 11.21 14.6

mm mbar mbar mbar mbar kW-hr.

G25 2.3749 -- 25 - - -- -- -- 16.19 14.6

mm mbar mbar kW-hr.

G30 2.3749 -- -- -- -- 29 or 50 28, 30, 37, 26.15 13.2

mm mbar or 50 mbar mbar kW-hr.

IT,PT,ES,SE,

I

2H

I

2L

I

2E

I

2E+

I

3B/P

I

3+

Pressure Input

5

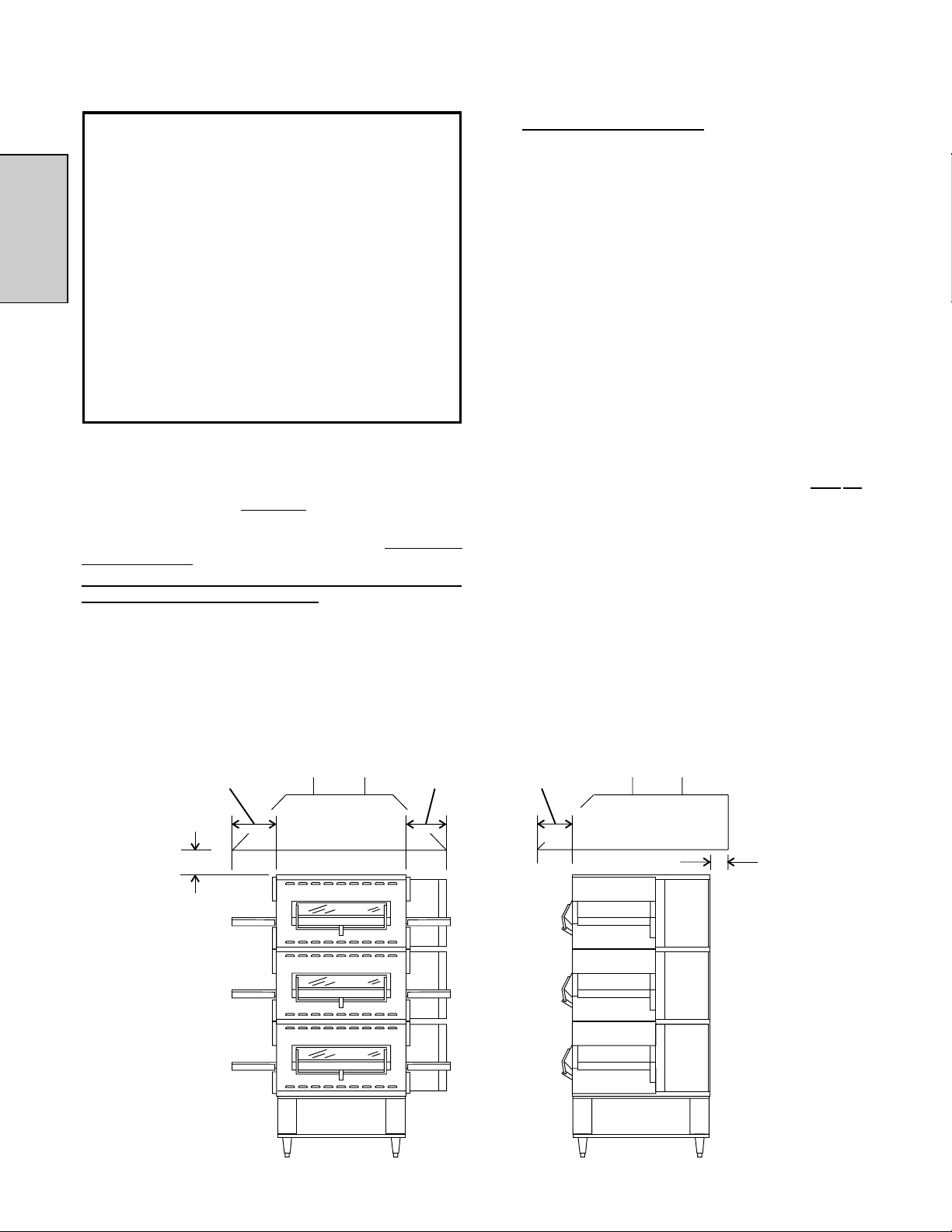

Page 6

WARNING - For gas ovens, after any conversions, readjustments, or service work on the oven:

ENGLISH

For electric ovens, after any conversions, readjustments, or service work on the oven, check that the

The oven must be installed on an even (level) non-flammable flooring and any adjacent walls must

be non-flammable. Recommended minimum clearances are specified in the Description section of

Do not obstruct the flow of combustion and ventilation air to and from your oven. There must be no

obstructions around or underneath the oven. Constructional changes to the area where the oven is

SECTION 2 - INSTALLATION

Perform a gas leak test.

Test for correct air supply.

Test for proper combustion and gas supply.

Check that the ventilation system is in operation.

WARNING

ventilation system (if so equipped) is in operation.

WARNING

Keep the appliance area free and clear of combustibles.

WARNING

this Manual.

WARNING

installed shall not affect the air supply to the oven.

CAUTION

For additional installation information, contact your local Authorized Service Agent.

NOTE

There must be adequate clearance between the oven and combustible construction. Clearance

must also be provided for servicing and for proper operation.

NOTE

An electrical wiring diagram for the oven is located inside the machinery compartment.

NOTE

Four casters are provided to allow the oven to be more easily moved to the installation location. These

casters are intended to simplify pre-installation movement only, and are NOT suitable for use as part of the

oven installation. During the installation procedure, the casters MUST be removed, so that the oven can be

supported by the supplied 152mm adjustable legs.

NOTE

All aspects of the oven installation, including placement, utility connections, and ventilation requirements,

must conform with any applicable local, national, or international codes. These codes supercede the require-

ments and guidelines provided in this manual.

6

Page 7

SECTION 2 - INSTALLATION

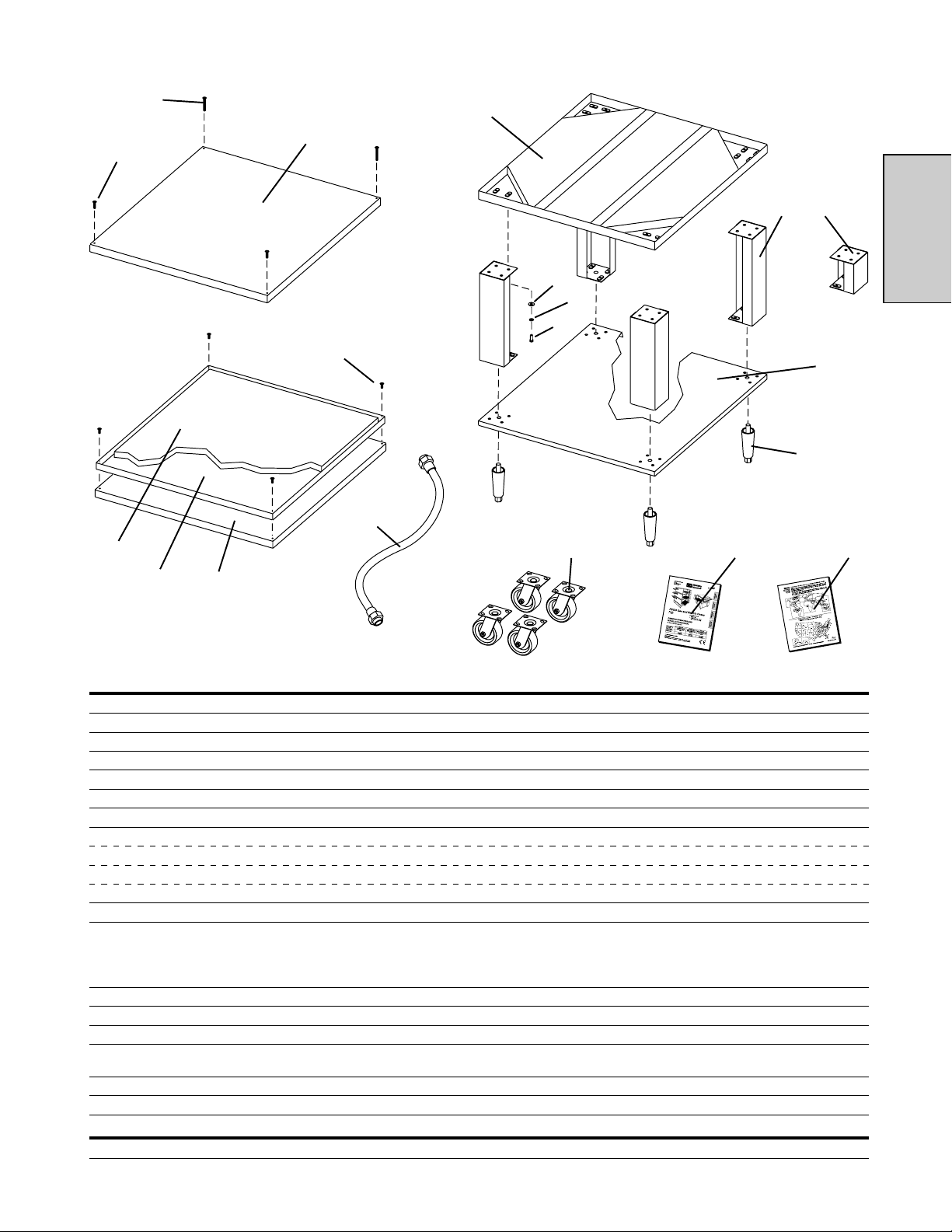

Figure 2-1 - Installation Kit

3

7

1

2

8a 8b

13

12

11

6

17

9

16

5

4

1

10

14

I. INSTALLATION KIT - see Figure 2-1

Item Single Oven Double Oven Triple Oven Part No. Description

1 1 2 3 42882 Top panel

2 2 2 2 220352 Screw, pan head #10 x 1" (top panel - front)

3 2 2 2 3A80A8801 Screw, pan head #10 x 2" (top panel - rear)

4 -- 1 2 44837 Stacking panel

5 -- 1 2 44918 Insulation, stacking panel, pre-cut

6 -- 4 8 4111A8815 Screw, hex head #10-32 x 1/2" (stacking panels)

7 1 1 1 42893 Base pad

8a 4 4 - - 42890 445mm leg extension (standard), for single and double ovens

8b 4 -- - - 45329 597mm leg extension (custom), for single ovens

8c 4 4 -- 45360 521mm leg extension (custom), for single and double ovens

8b - - -- 4 44799 152mm leg extension (standard), for triple ovens

9 4 4 4 22450-0028 Leg, adjustable, 152mm

10 4 4 4 22290-0010 Caster, with flat plate (no brake)

11 32 32 32 220373 Hex bolt, 3/8"-16 x 1"

12 32 32 32 21416-0001 Flat washer, 3/8"

13 32 32 32 21422-0001 Lockwasher, 3/8"

14 1 1 1 46525 Owner's Operating Manual, PS536 Gas and Electric Ovens (European

15 1 1 1 1002040 Middleby Marshall Authorized Service Agency Listing

16 1 2 3 22361-0001 Gas hose (gas ovens only)

Optional components (available separately):

17 1 1 1 46393 Lower shelf

Qty. Qty. Qty.

NOTE: These casters are provided to allow the oven to be more easily

moved to the installation location, and are NOT suitable for use as part

of the oven installation. Refer to the notice on the preceding page.

Export models), English/German/French/Spanish

7

ENGLISH

15

Page 8

SECTION 2 - INSTALLATION

II. VENTILATION SYSTEM

IMPORTANT

ENGLISH

Where national or local codes require the

installation of fire suppression equip-

ment or other supplementary equipment,

DO NOT mount the equipment directly to

the oven.

MOUNTING SUCH EQUIPMENT ON

THE OVEN MAY:

VOID AGENCY CERTIFICATIONS

RESTRICT SERVICE ACCESS

LEAD TO INCREASED SERVICE EX-

PENSES FOR THE OWNER

A. Requirements

CAUTION

Gas oven installations

ventilation system with electrical exhaust air sensing control.

A mechanically driven ventilation system is

RECOMMENDED for electric oven installations.

PROPER VENTILATION OF THE OVEN IS THE

RESPONSIBILITY OF THE OWNER.

REQUIRE a mechanically driven

STRONGLY

B. Recommendations

NOTE THAT THE HOOD DIMENSIONS SHOWN IN FIGURE 2-

RECOMMENDATIONS ONLY. LOCAL, NATIONAL AND

2 ARE

INTERNATIONAL CODES MUST BE FOLLOWED WHEN

INSTALLING THE VENTILATION SYSTEM. ANY APPLICABLE

CODES SUPERSEDE THE RECOMMENDATIONS SHOWN IN

THIS MANUAL.

The rate of air flow exhausted through the ventilation system

may vary depending on the oven configuration and hood design.

Consult the hood manufacturer or ventilation engineer for these

specifications.

To avoid a negative pressure condition in the kitchen area,

return air must be brought back to replenish the air that was

exhausted. A negative pressure in the kitchen can cause heatrelated problems to the oven components as if there were no

ventilation at all. The best method of supplying return air is

through the heating, ventilation and air conditioning (HVAC)

system. Through the HVAC system, the air can be temperaturecontrolled for summer and winter. Return air can also be

brought in directly from outside the building, but detrimental

effects can result from extreme seasonal hot and cold

temperatures from the outdoors.

NOTE: Return air from the mechanically driven system

blow at the opening of the baking chamber. Poor oven baking

performance will result.

C. Other ventilation concerns

Special locations, conditions, or problems may require the

services of a ventilation engineer or specialist.

Inadequate ventilation can inhibit oven performance.

It is recommended that the ventilation system and duct

work be checked at prevailing intervals as specified by the

hood manufacturer and/or HVAC engineer or specialist.

must not

51mm

minimum

305mm

minimum

Fig. 2-2 - Ventilation System

305mm

minimum

8

203mm

minimum

25mm

minimum

Page 9

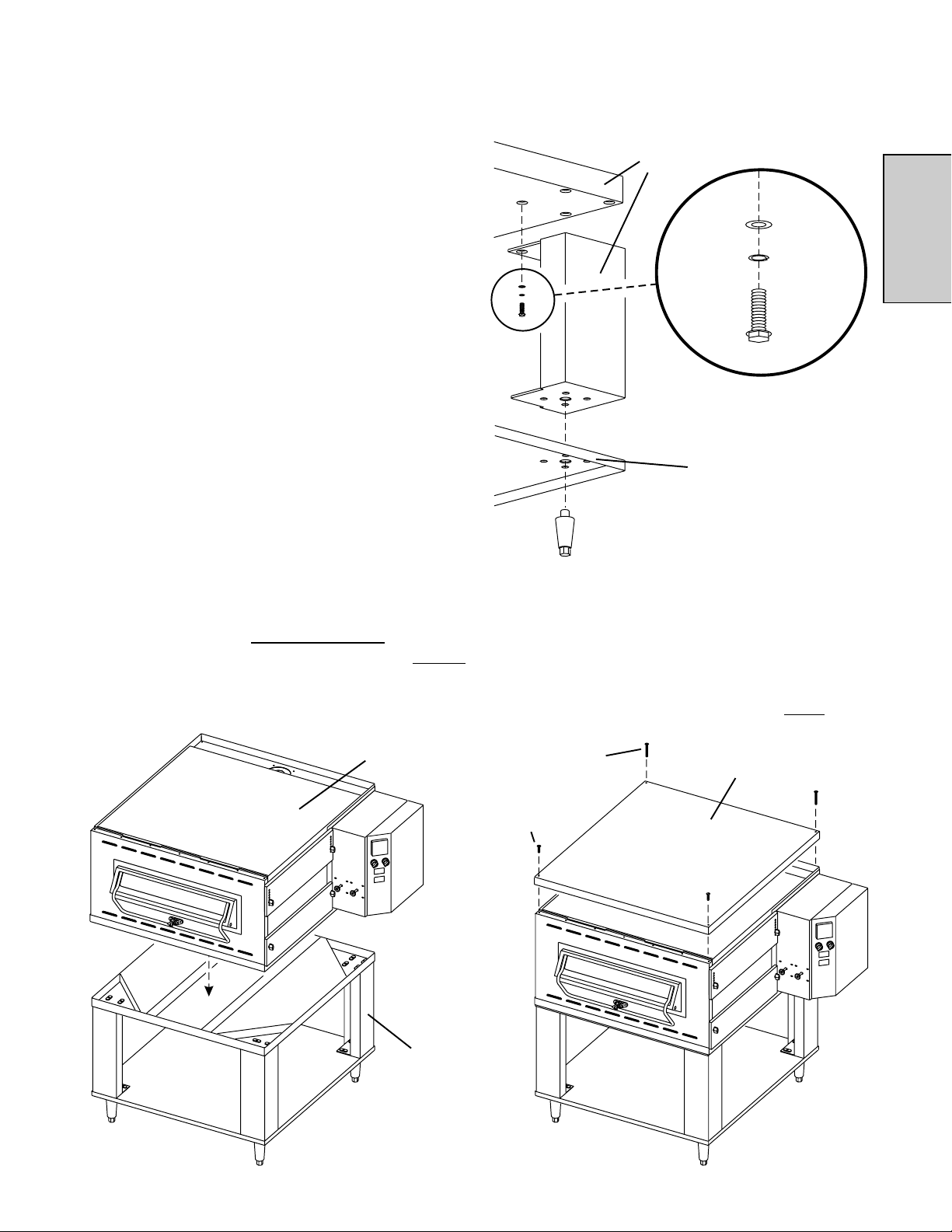

III. ASSEMBLY

A. Base Pad Assembly

1. Install the four leg extensions onto the base pad using the

3/8"-16x1" screws, 3/8" flat washers, and 3/8" lockwashers

supplied in the Base Pad Kit. See Figure 2-3. Check that

the finished sides of each leg extension face OUTWARDS.

2. If desired, position the optional lower shelf in place as

shown in Figure 2-3. Check that the lip on the shelf faces

DOWN. The shelf is available separately, and is NOT

included with the Installation Kit.

3. The Installation Kit includes four casters AND four 152mm

adjustable legs. The casters are provided to allow the oven

to be more easily moved to the installation location, and are

NOT suitable for use as part of the oven installation. Refer

to the notice at the beginning of this Section.

If the oven is already at the installation location, install

one 152mm adjustable leg into the center hole on the

bottom of each leg extension, as shown in Figure 2-4.

If it is necessary to move the oven to the installation

location, TEMPORARILY install the casters using the

remaining 3/8"-16x1" screws, 3/8" flat washers, and 3/

8" lockwashers. Move the oven to its final location, and

remove the casters. Then, install the 152mm adjustable

legs as described in the previous step. The threaded

studs on the adjustable legs extend through the lower

shelf and into the leg extensions. This holds the lower

shelf firmly in place.

4. Install the lower oven cavity onto the base pad. See Figure

2-4.

5. For single ovens ONLY, install the top panel using the screws

included in the base pad kit, as shown in Figure 2-5. Then,

skip ahead to Part C,

For double or triple ovens, continue on to Part B,

Note that the top panel should NOT be installed for double

and triple ovens until after stacking the oven cavities.

Figure 2-4 - Base pad installation

Conveyor Installation.

Stacking.

Bottom oven

cavity

SECTION 2 - INSTALLATION

Figure 2-3 - Leg extension and casters installation

Finished sides of

leg extension

face corner of

base pad

3/8" lock

washer

Lower

shelf

152mm adjustable

leg MUST be used

for installation

Figure 2-5 - Top panel installation

NOTE: DO NOT install top panel onto double or triple ovens

until AFTER stacking the oven cavities. See Part B,

#10 x 2" screws

attach rear of

top panel

#10 x 1" screws

attach front of

top panel

Top

panel

3/8" flat

washer

ENGLISH

3/8"-16 x 1"

hex screw

Stacking.

Assembled

base pad

9

Page 10

SECTION 2 - INSTALLATION

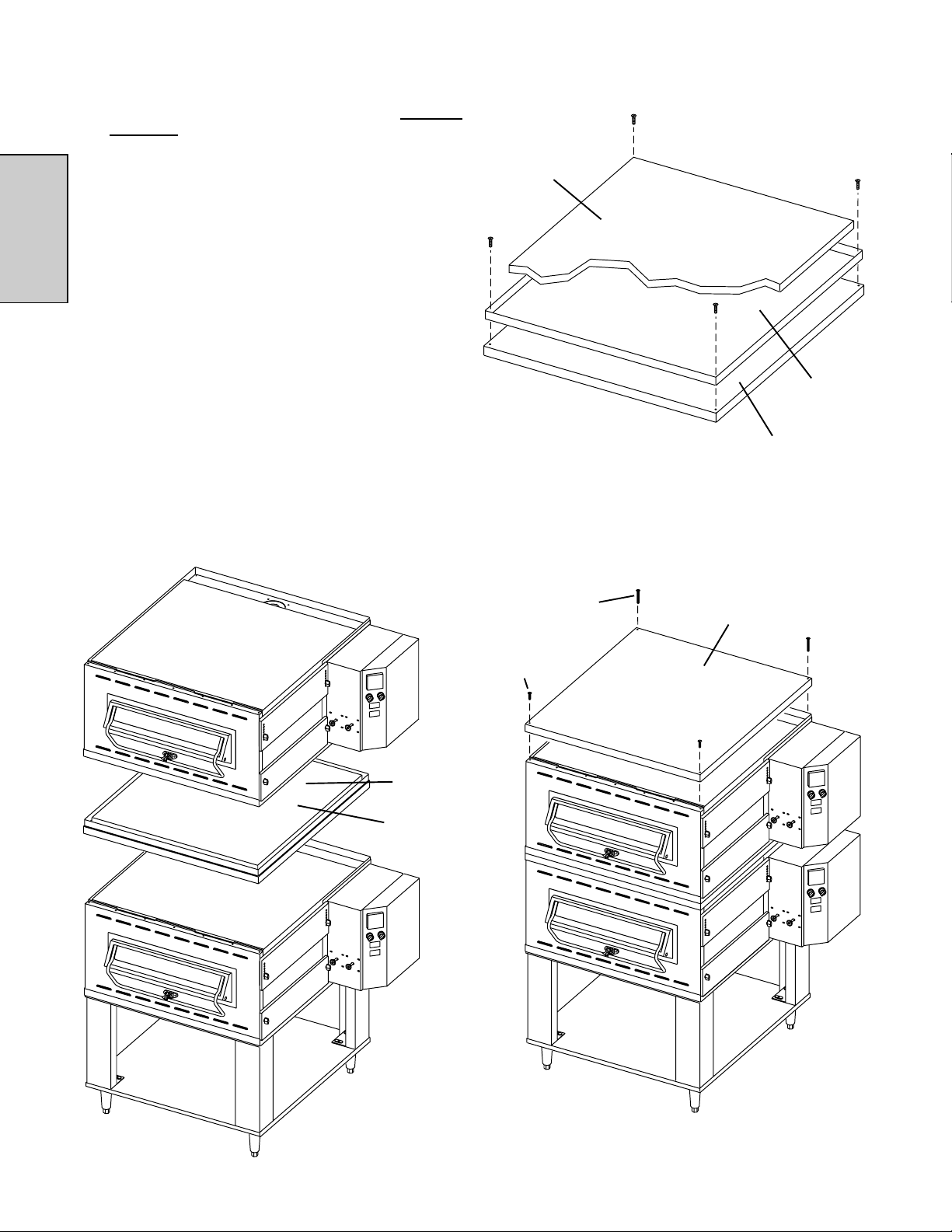

B. Stacking

Figure 2-6 - Assembling the stacking spacers

For single ovens, skip ahead to Part C,

Installation.

IMPORTANT

Middleby Marshall STRONGLY RECOMMENDS that PS536

ENGLISH

oven cavities be stacked using the following:

PS500 Series Stacking Lift Kit, P/N 30580

PS536 Stacking Hardware Kit, P/N XXXXX

Contact your Middleby Marshall Authorized Service Agent for

complete stacking instructions.

1. Assemble the stacking spacer(s) as shown in Figure 2-6.

One spacer assembly is supplied for a double oven, while

two are supplied for a triple oven.

2. Place one of the assembled spacers on top of the lower

oven cavity, making sure that the insulation faces up.

3. Stack an oven cavity on top of the spacer. Check that all four

sides of the spacer overlap the base of the oven, and that

the oven is level and firmly seated. See Figure 2-7.

4. For triple ovens, repeat Steps 2 and 3 to install the top oven

cavity.

5. Install the top panel using the screws included in the base pad

kit, as shown in Figure 2-8.

Figure 2-7 - Stacking

Conveyor

#10-32 x 1/2"

hex screws

38mm-thick

insulation, pre-cut

Stacking panel,

P/N 44837

Top panel,

P/N 42882

Figure 2-8 - Top panel installation

Assembled

spacer

Insulation

faces up

#10 x 2" screws

attach rear of

top panel

#10 x 1" screws

attach front of

top panel

Top

panel

10

Page 11

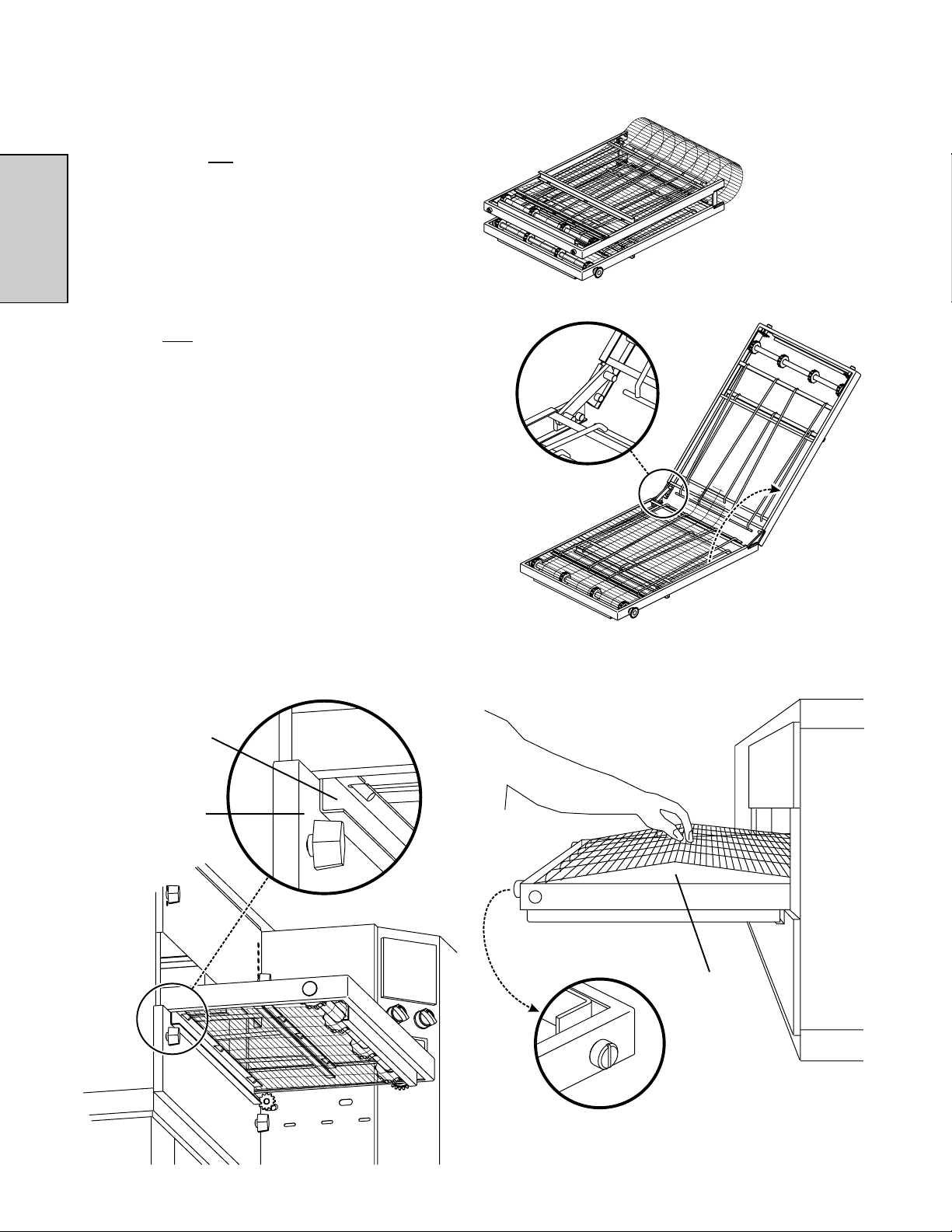

C. Conveyor Installation

SECTION 2 - INSTALLATION

PS536 ovens may be equipped with either of two different

conveyor designs. Both designs are available in single belt and

split belt configurations. Refer to Figures 2-9 and 2-10 to

determine which conveyor was shipped with your oven.

Figure 2-9 - Identifying the Type 1 conveyor

Pins on frame

fit into slots

on bracket

Some conveyors MAY be

equipped with external

bearings on drive shaft

If your oven uses the Type 1 Conveyor, continue on to Step

1 in this section, "Type 1 Conveyor Installation."

If your oven uses the Type 2 Conveyor, skip ahead to Step

2 in this section, "Type 2 Conveyor Installation."

ENGLISH

Tensioning screws

(2 per side)

Figure 2-10 - Identifying the Type 2 conveyor

Hinge plates at

center of conveyor

frame

Conveyor frame made of

rectangular steel sections

Tension adjustment

screws (2) on idler

end of conveyor

Conveyor frame made of

"C"-section stainless steel

11

Page 12

SECTION 2 - INSTALLATION

1. Type 1 Conveyor Installation

a. Unfold the conveyor frame so that it lies flat on the floor.

As you unfold the frame, check that the locator pins

shown in Figure 2-11 lock into the slots on the bracket.

ENGLISH

b. Refer to Figure 2-11. Note the locations of the four

tensioning screws (2 per side) in the slotted holes on

the brackets. Loosen these screws to allow the

conveyor to be properly tensioned.

c. Lift the conveyor belt away from the frame, as shown

in Figure 2-11, to check the belt tension. The belt

should lift between 25-50mm.

Figure 2-11 - Assembling and tensioning the conveyor

Folded

frame

If it is necessary to adjust the belt tension, gently push

the two conveyor frame sections closer together, or

further apart, as required. Then, re-check the tension

of the conveyor belt. Repeat this step as necessary

until the proper belt tension is achieved.

d. When the belt tension is correctly adjusted, tighten the

two tensioning screws on each side of the conveyor

frame. This fastens the two frame sections together

at the correct belt tension.

e. If it is necessary to add or remove conveyor links to

achieve the correct tension, OR if it is necessary to

reverse the conveyor belt for correct orientation, the

belt will need to be removed from the conveyor frame.

If this is necessary, perform the following procedure:

Remove the master links using long-nose pliers.

Then, roll up the belt along the length of the

conveyor frame.

Add or remove belt links as necessary to achieve

the correct belt tension.

Replace the belt on the conveyor frame. Check

that the conveyor belt links are oriented as shown

in Figure 2-12, and that the smooth side of the

conveyor belt faces UP.

f. Connect the inside master links. Check that the links

are oriented as shown in Figure 2-12.

g. Connect the outside master links. Note that the

outside master links each have an open hook on one

side. This hook aligns with the hooks along the sides

of the other conveyor links. See Figure 2-12.

Pins on frame

fit into slots

on bracket

Tensioning

screws in slotted

holes (2 per side)

With tensioning

screws loosened,

frame sections can

be moved to adjust

belt tension

1-2" (25-50mm)

vertical deflection

Figure 2-12 - Conveyor and master link orientation

Direction

of travel

Incorrect

master link

position

12

CORRECT

master link

position

Page 13

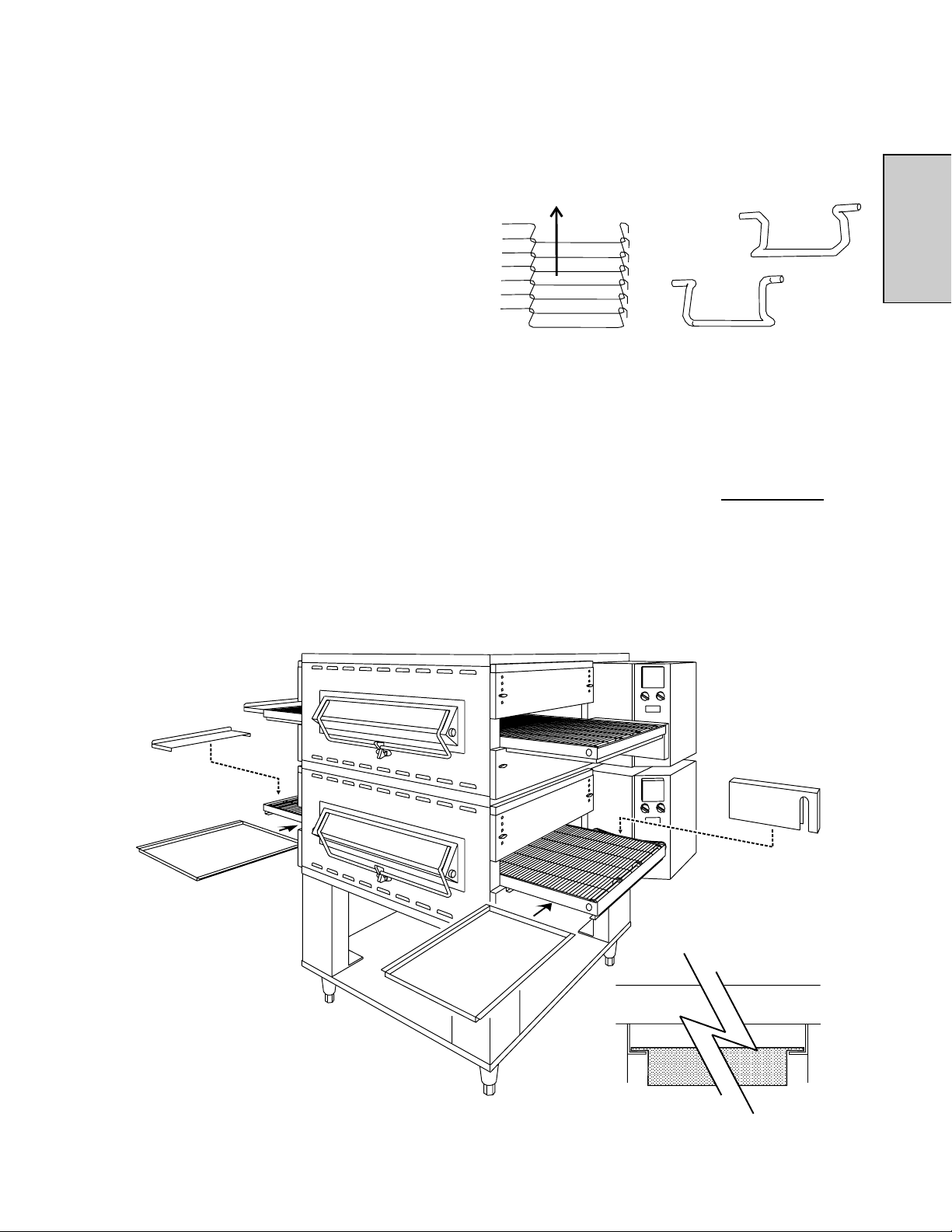

h. Lift the conveyor and position it in the oven. The

conveyor can only be installed from the end of the oven

with the drive motor.

i. Continue moving the conveyor into the oven until the

conveyor frame is positioned properly. The inside

supports for the crumb trays should rest firmly against

the lower end plugs, as shown in Figure 2-13.

j. When the conveyor is positioned properly, check for

freedom of movement of the conveyor belt by pulling it

for about 60 to 90 cm with your fingers. The conveyor

must move freely.

k. Install the drive chain between the conveyor drive

sprocket and the motor sprocket. To install the chain,

it will be necessary to lift the drive end of the conveyor

slightly.

l. Install the conveyor drive motor cover as shown in

Figure 2-15.

m. Some ovens are shipped with BOTH perforated AND

solid crumb trays, as shown in Figure 2-14. For these

ovens, the solid crumb trays should be used for the

lower (or a single) oven, while the perforated trays

should be used for all upper ovens.

Install the crumb trays as shown in Figure 2-15. First,

place the inside edge of each tray onto its support

bracket. Then, hook the outside edge of the tray over

the end of the conveyor frame.

n. Press the conveyor exit tray down over the edge of the

conveyor frame at the exit end of the oven. See Figure

2-15. Then, skip ahead to Section V,

Electrical Supply.

SECTION 2 - INSTALLATION

Figure 2-13 - Conveyor placement

Crumb tray

support

bracket

End plug

ENGLISH

Figure 2-14 - Crumb trays

Crumb trays WITH openings

(if oven is so equipped) - all

upper ovens

Crumb trays

WITHOUT openings -

lower oven only

Press conveyor

exit tray down over

end of conveyor

Figure 2-15 - Final assembly

Crumb trays

Place chain cover

down over

conveyor sprocket

2. Hook outside

edge over

conveyor frame

1. Place inside

edge on support

bracket

13

Page 14

SECTION 2 - INSTALLATION

2. Type 2 Conveyor Installation

a. Partially unfold the conveyor as shown in Figure 2-16.

Then, begin to slide the conveyor into the end of the

oven. The conveyor can only be installed from the end

of the oven

ENGLISH

b. Continue moving the conveyor into the oven until the

frame protrudes equally from each end of the oven.

Check that the crumb tray supports located on the

underside of the conveyor frame rest firmly against the

lower end plugs, as shown in Figure 2-16.

c. When the conveyor is positioned properly, check for

freedom of movement of the conveyor belt by pulling it

for about 2-3 feet (0.75-1.00m) with your fingers. The

drive and idler shafts must rotate smoothly, and the

must move freely without rubbing on the inside of

belt

the oven.

d. Check the tension of the conveyor belt as shown in

Figure 2-17. The belt should lift about 25mm. DO NOT

OVERTIGHTEN THE CONVEYOR BELT.

NOTE:

If necessary, the belt tension can be adjusted by

turning the conveyor adjustment screws, located at the

idler (non-control) end of the conveyor. See Figure 2-

18.

with the drive motor.

Figure 2-16 - Conveyor installation

Folded

frame

Conveyor

placed in

oven

Figure 2-17 - Conveyor placement

Crumb tray

support

bracket

End plug

Figure 2-18 - Conveyor belt tension

25mm

vertical

deflection

Adjustment

screws (2) on

idler end of

conveyor

14

Page 15

e. If it is necessary to add or remove conveyor links to

achieve the correct tension, OR if it is necessary to

reverse the conveyor belt for correct orientation, the

belt will need to be removed from the conveyor frame.

If this is necessary, perform the following procedure:

Remove the conveyor assembly from the oven

and place it flat on the floor.

Remove the master links using long-nose pliers.

Then, roll up the belt along the length of the

conveyor frame.

Add or remove belt links as necessary to achieve

the correct belt tension.

Replace the belt on the conveyor frame. Check

that the conveyor belt links are oriented as shown

in Figure 2-19, and that the smooth side of the

conveyor belt faces UP.

Connect the inside master links. Check that the

links are oriented as shown in Figure 2-19.

Connect the outside master links. Note that the

outside master links each have an open hook on

one side. This hook aligns with the hooks along

the sides of the other conveyor links. See Figure

2-19.

Replace the conveyor into the oven.

SECTION 2 - INSTALLATION

f. Install the drive chain between the conveyor drive

sprocket and the motor sprocket. To install the chain,

it will be necessary to lift the drive end of the conveyor

slightly.

Figure 2-19 - Conveyor and master link orientation

Direction

of travel

Incorrect

master link

position

CORRECT

master link

position

g. Install the conveyor chain cover as shown in Figure 2-

20. Check that the chain cover does not bind on the

conveyor sprocket or drive shaft.

h. Slide the crumb trays into place as shown in Figure 2-

20.

i. Press the conveyor exit tray down over the edge of the

conveyor frame at the exit end of the oven. See Figure

2-20. Proceed to Section V,

Electrical Supply.

ENGLISH

Press conveyor

exit tray down over

end of conveyor

Slide crumb trays

into place from

front of oven

Figure 2-20 - Final assembly

Place chain cover

down over

conveyor sprocket

15

Crumb trays rest in

support rails underneath

conveyor

Page 16

SECTION 2 - INSTALLATION

IV. ELECTRICAL SUPPLY

WARNING

Authorized supplier personnel normally accomplish

the connections for the ventilation system, electric supply,

and gas supply, as arranged by the customer. Following

ENGLISH

these connections, the factory-authorized installer can

perform the initial startup of the oven.

NOTE: All aspects of the electrical supply connection must

comply with current IEC/CEE requirements and with all

applicable local, national, and international codes.

Check the oven serial plate before making any electric supply

connections. Electric supply connections must agree with data

on the oven serial plate. The location of the serial plate is shown

in Figure 1-1 (in Section 1,

A fused disconnect switch or a main circuit breaker (customer

furnished)

MUST be installed in the electric supply line for each

oven cavity. The circuit breaker/disconnect must have a minimum

of 3mm contact separation breaking all poles of the supply. It

is recommended that this circuit breaker/disconnect have

lockout/tagout capability.

The supply conductors are to be 90°C-rated copper wiring.

Additional wiring information is shown on the wiring diagrams

in Section 5,

Electrical Wiring Diagrams and inside the machin-

ery compartment of the oven.

The oven requires a ground connection to the oven ground

screw located in the electrical junction box. (The box is shown

in Figure 2-21.) The ground connection must comply with

current IEC/CEE requirements and with all applicable local,

national, and international codes. If necessary, have the

electrician supply the ground wire. Do NOT use the wiring

conduit or other piping for ground connections!

Description).

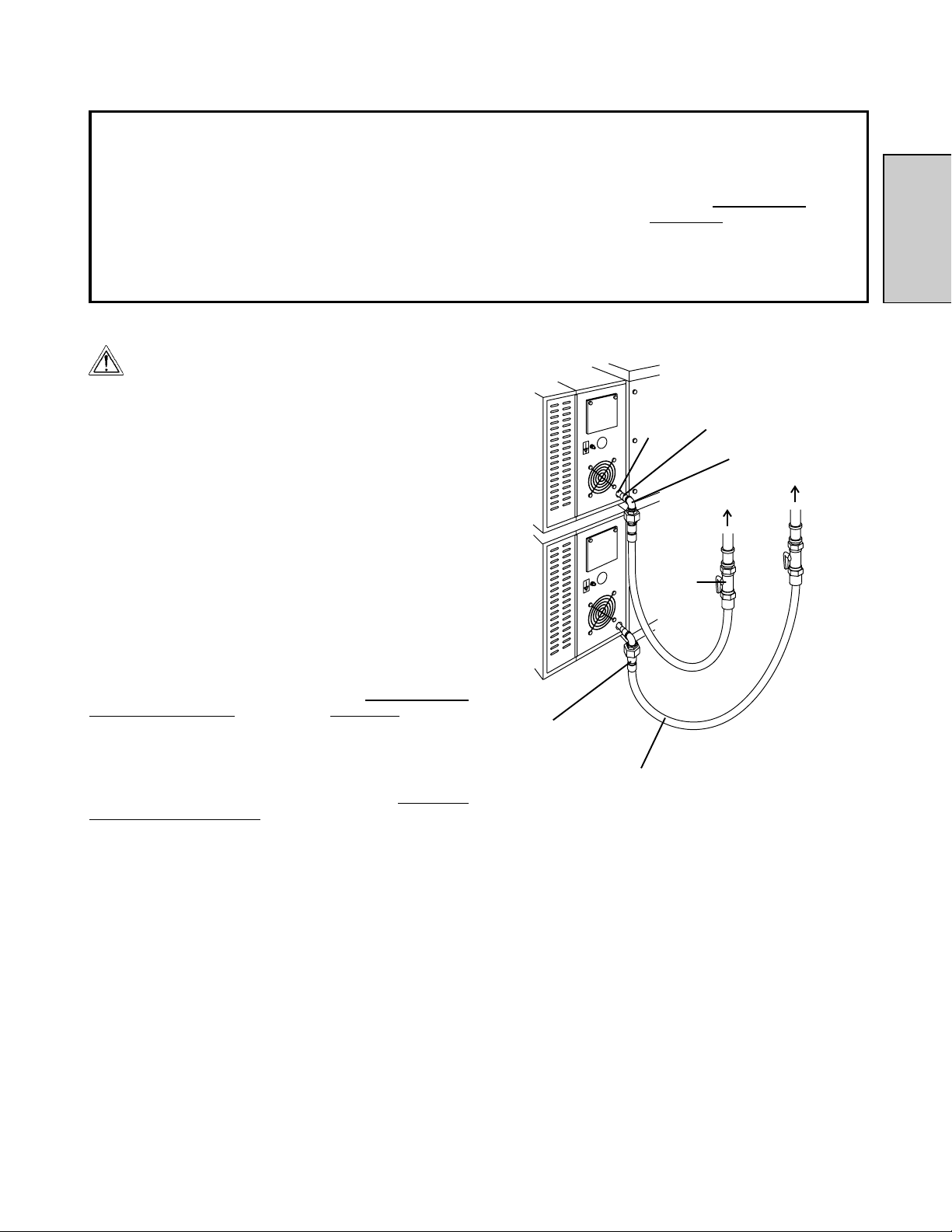

A. Additional Information - Gas Ovens

All electric supply connections are made via the electrical

junction box on the rear of the oven, shown in Figure 2-21. The

power lines then connect to the oven circuits through safety

switches located inside the machinery compartment and each

blower motor compartment. These switches interrupt electric

power to the oven when the Machinery Compartment Access

Panel is opened, OR when either of the blower or rear shrouds

is removed.

B. Additional Information - Electric Ovens

A 33mm dia. cutout in the back wall of the machinery compartment

provides access to the electrical supply connections. The

actual wiring connections are made at the terminal block

located in the electrical junction box. See Figure 2-21.

Using flexible cables for the electric power supply conductors

requires a 33mm strain-relief fitting (not furnished with the

oven) to enable safe access to the terminal block.

C. Connection

Refer to the wiring diagram inside the machinery compartment,

or in Section 5 of this Manual, to determine the correct

connections for the electrical supply lines. Connect the supply

as indicated on the wiring diagram.

If required by national or local codes, connect an equipotential

ground wire to the lug next to the

symbol (shown in Figure

2-21). The equipotential ground connection must meet all

applicable national and local code requirements.

33mm cutout for

electric utility

connection

Figure 2-21 - Utility connection locations

Electrical

Junction Box

Equipotential

ground lug

16

Page 17

V. GAS SUPPLY

SECTION 2 - INSTALLATION

CAUTION

DURING PRESSURE TESTING NOTE ONE OF THE FOLLOWING:

1. The oven and its individual shutoff valve must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressure in excess

of 3.45 kPa.

2. The oven must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at

test pressure equal to or less than 3.45 kPa.

A. Connection

WARNING

Some procedures in this section may require conversions, readjustments, or service on the oven's gas system.

Before performing these procedures, check that the main

gas supply valve and the circuit breaker/fused disconnect

are in the OFF ("O") position. After completing these procedures, perform a gas leak test before operating the oven.

CAUTION

The terms of the oven's warranty require all start-ups, conversions and service work to be performed by a Middleby Marshall

Authorized Service Agent. The installation, start-up and changes

required when changing from one gas type to another can be

performed ONLY by a certified professional.

NOTE: The gas supply connection should be according to

applicable ISO 228-1 or ISO 7-1 recommendations. All aspects

of the gas supply connection must comply with current IEC/CEE

requirements and with all applicable local, national, and international codes.

Check the ovens gas supply requirements before making the

gas utility connection. Gas supply requirements are listed on

the ovens serial plate and in Table 1-5,

Pressure Specifications (in Section 1, Description).

Check the serial plate to determine the type of gas to be used

with the oven. Check that the gas type indicated matches the

local supply at the installation. If the gas type on the serial plate

does NOT match the local supply, directions for converting the

oven for use with other gases are described in Part B,

for Use with Various Gases, in this section.

One 90° elbow equals a 2.13m length of pipe. The recommended

pipe sizes are larger than usually required to eliminate any

operation problems. It is much less expensive to make the

initial installment large enough to do the job rather than redoing

the job later.

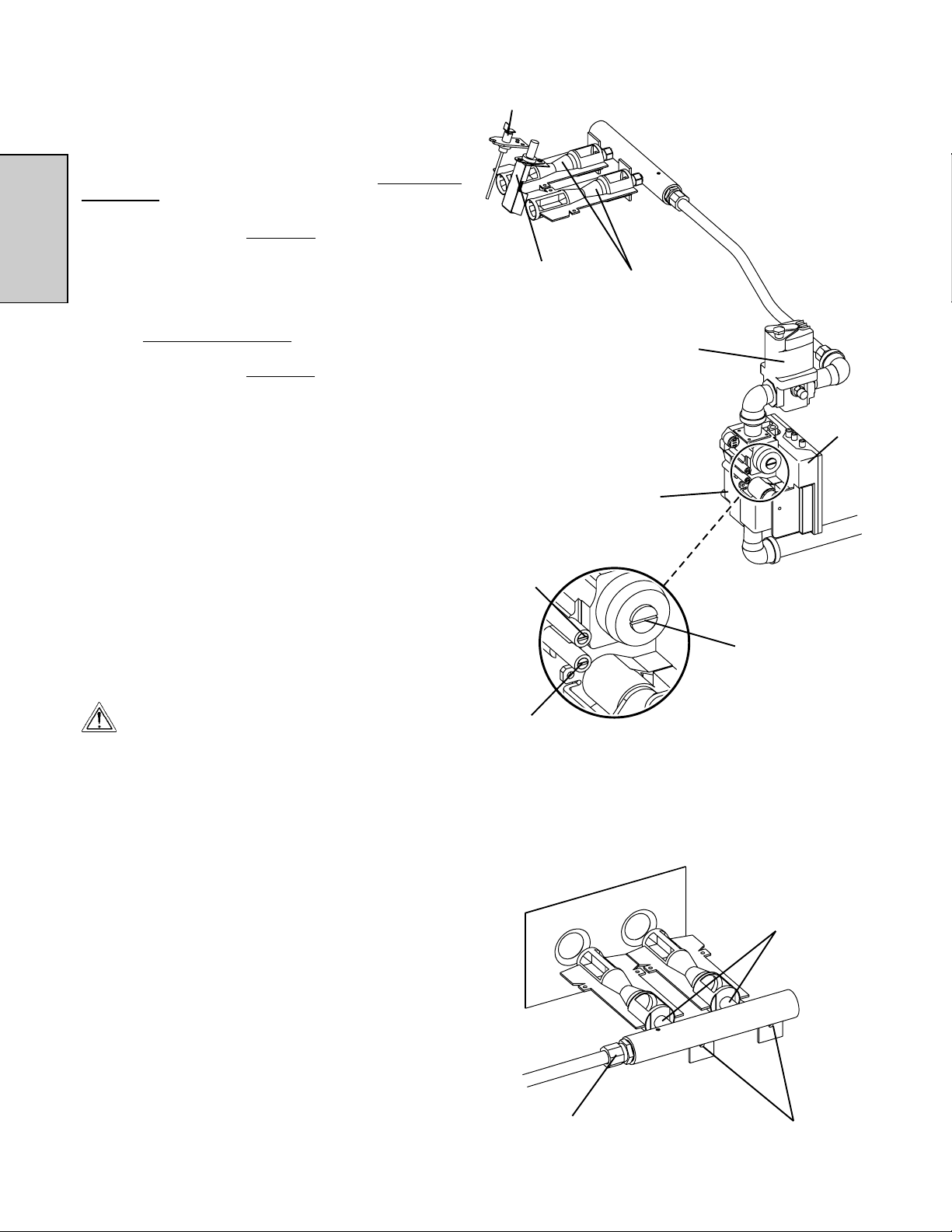

Refer to the instructions in the gas hose package (included in

the Installation Kit) before connecting the gas line. One gas line

connection method is shown in Figure 2-22; however,

compliance with the applicable standards and regulations is

mandatory.

Gas Orifice and

Preparation

3. If incoming pressure is over 50mbar, a separate regulator MUST be installed in the line BEFORE the individual

shutoff valve for the oven.

WARNING: To prevent damage to the control valve regulator during initial turn- on of gas, it is

the manual shutoff valve

very slowly.

very important to open

After the initial gas turn-on, the manual shutoff valve must

remain open except during pressure testing as outlined in

the above steps or when necessary during service maintenance.

Figure 2-22 - Flexible Gas Hose Installation

3/4"-1/2"

gas pipe

reducer

Full-Flow

Shutoff

Quick-

disconnect

device

Flexible

Gas Hose

Gas

Valve

3/4" gas

pipe nipple

Elbow

90°

Individual gas

connection for

each oven

cavity

To Gas

Supply Pipe

ENGLISH

17

Page 18

SECTION 2 - INSTALLATION

B. Preparation for Use with Various Gases

Before proceeding to set up the oven for a specific gas, check

that the main gas supply valve and the circuit breaker/fused

disconnect are in the OFF ("O") position.

The main orifices must match the sizes shown in Table 1-5. If

ENGLISH

necessary, replace the orifices. Refer to Part C,

Gas Orifices.

The orifice (manifold) pressure should be adjusted to the value

shown in Table 1-5 (in the

Description section) for the specific

gas type and location.

The actual heat input to the oven must match the rated heat

input. The input to the burner can be determined using the

orifice (manifold) pressure data or by the volume supplied

using the gas meter. Both of these procedures are described

in Part E,

Checking the Heat Input.

If the measured input does not correspond with the rated input

(shown in Table 1-5 in the

Description section of this Manual),

check first that the correct orifices are installed. If the orifices

are correct, check and correct the supply and orifice pressures

to obtain the correct input based on the gas meter reading.

C. Replacing the Gas Orifices (if so required)

1. Check that the main gas supply valve and the circuit

breaker/fused disconnect are in the OFF ("O") position.

2. Remove AND RETAIN the hex screws that hold the rear

wall in place. Then, remove the rear wall panel.

3. Loosen the burner tube fitting, shown in Figure 2-24.

4. Remove AND RETAIN the two screws that hold the mani-

fold in place. Remove the manifold from the oven.

5. Remove and discard the two main orifices.

6. Install the two new main orifices into the manifold.

7. Replace the manifold into the oven. Fasten it in place with

the two original mounting screws, and tighten the burner

tube fitting.

WARNING

After completing these procedures, perform a gas

leak test before operating the oven.

Replacing the

Flame

sensor

Ignitor

Manifold

pressure tap

(under cap

screw)

Inlet

pressure tap

(under cap

screw)

Figure 2-23

In-shot

burners (2)

Modulating

gas valve

Ignition

module

Gas

control

valve

Pressure

adjustment screw

(governor - under

cap screw)

18

Burner

tube fitting

Figure 2-24

Main orifices

(2)

Screws (2)

Page 19

D. Checking the Gas Supply (Inlet) Pressure

1. Remove the supply (inlet) pressure cap screw from the gas

control valve. Attach a manometer to the stud.

2. Depress the safety switches to allow the oven to operate.

3. Open the main gas supply valve. Switch the circuit breaker/

fused disconnect to the ON ("I") position.

4. Start the oven according the directions in the

Operation

section of this Manual. Adjust the temperature controller to

the maximum setting (316°C).

5. Measure the supply (inlet) pressure.

6. Switch the oven off. Close the main gas supply valve, and

switch the circuit breaker/fused disconnect to the OFF ("O")

position. Remove the manometer, and replace the cap

screw onto the gas control valve.

7. Compare the measured supply (inlet) pressure to the

nominal pressures shown in Table 1-5 (in the Description

section of this Manual).

If the supply pressure is lower or higher than the nominal

pressure, the reason should be investigated and the gas

supplier contacted.

For natural gas ovens, if the measured supply pressure is lower

than 17mbar, or higher than 25mbar, contact the gas supplier.

DO NOT OPERATE THE OVEN or adjust the oven controls.

E. Adjusting the Orifice (Manifold) Pressure and Heat Input

To use the orifice pressure method, you must know the specific

gas type and quality used. If using the orifice pressure method,

you should double-check the input using the volumetric method.

To use the volumetric method, you must know the heat value

(HuB) of the gas used. This information is available from your

gas supplier.

During these measurements, do not operate any other

appliances that use the same gas meter as the oven.

1. Orifice (Manifold) Pressure Method

a. Check that the main gas supply valve and the circuit

breaker/fused disconnect are in the OFF ("O") position.

b. Remove the regulated (manifold) pressure cap screw

from the gas control valve. Attach a manometer to the

stud.

c. Remove the cap screw from the pressure adjustment

screw (governor) on the gas control valve.

d. Depress the safety switches to allow the oven to

operate.

e. Open the main gas supply valve. Switch the circuit

breaker/fused disconnect to the ON ("I") position.

f. Start the oven according the directions in the

Operation

section of this Manual. Adjust the temperature controller

to the maximum setting (316°C).

g. Adjust the pressure adjustment screw as necessary

to match the correct pressure for the oven's specific

gas type. Refer to Table 1-5 in the

Description section

of this Manual. Turning the adjustment screw clockwise

increases the flow, while turning it counterclockwise

reduces the flow.

h. Switch the oven off. Close the main gas supply valve,

and switch the circuit breaker/fused disconnect to the

OFF ("O") position. Remove the manometer, and

replace the cap screws onto the gas control valve.

SECTION 2 - INSTALLATION

2. Volumetric Method

3

a. Determine the time of 0.1m

(100 liters) of gas usage

as follows.

Consumption (m

3

/hr.) =

NB (Rated input in kW)

HuB (Heat [Calorific] value

of gas in kW/m3)

Time (in minutes) of

0.1m3 of gas usage

=

6

Consumption

b. Check that the main gas supply valve and the circuit

breaker/fused disconnect are in the OFF ("O") position.

c. Remove the cap screw from the pressure adjustment

screw (governor) on the gas control valve.

d. Depress the safety switches to allow the oven to

operate.

e. Open the main gas supply valve. Switch the circuit

breaker/fused disconnect to the ON ("I") position.

f. Start the oven according the directions in the

section of this Manual. Adjust the temperature controller

to the maximum setting (316°C).

g. Adjust the pressure adjustment screw as necessary

to match the calculated volume using the time (in

minutes) of 0.1m

3

of gas usage. Turning the

adjustment screw clockwise increases the flow, while

turning it counterclockwise reduces the flow.

h. Record the reading obtained from the gas meter and

calculate the obtained gas flow. Compare this value

to the information in Table 1-4 in the

Description

section of this Manual.

i. Switch the oven off. Close the main gas supply valve,

and switch the circuit breaker/fused disconnect to the

OFF ("O") position. Replace the cap screw onto the

gas control valve.

ENGLISH

Operation

19

Page 20

SECTION 2 - INSTALLATION

ENGLISH

NOTES:

20

Page 21

SECTION 3 - OPERATION

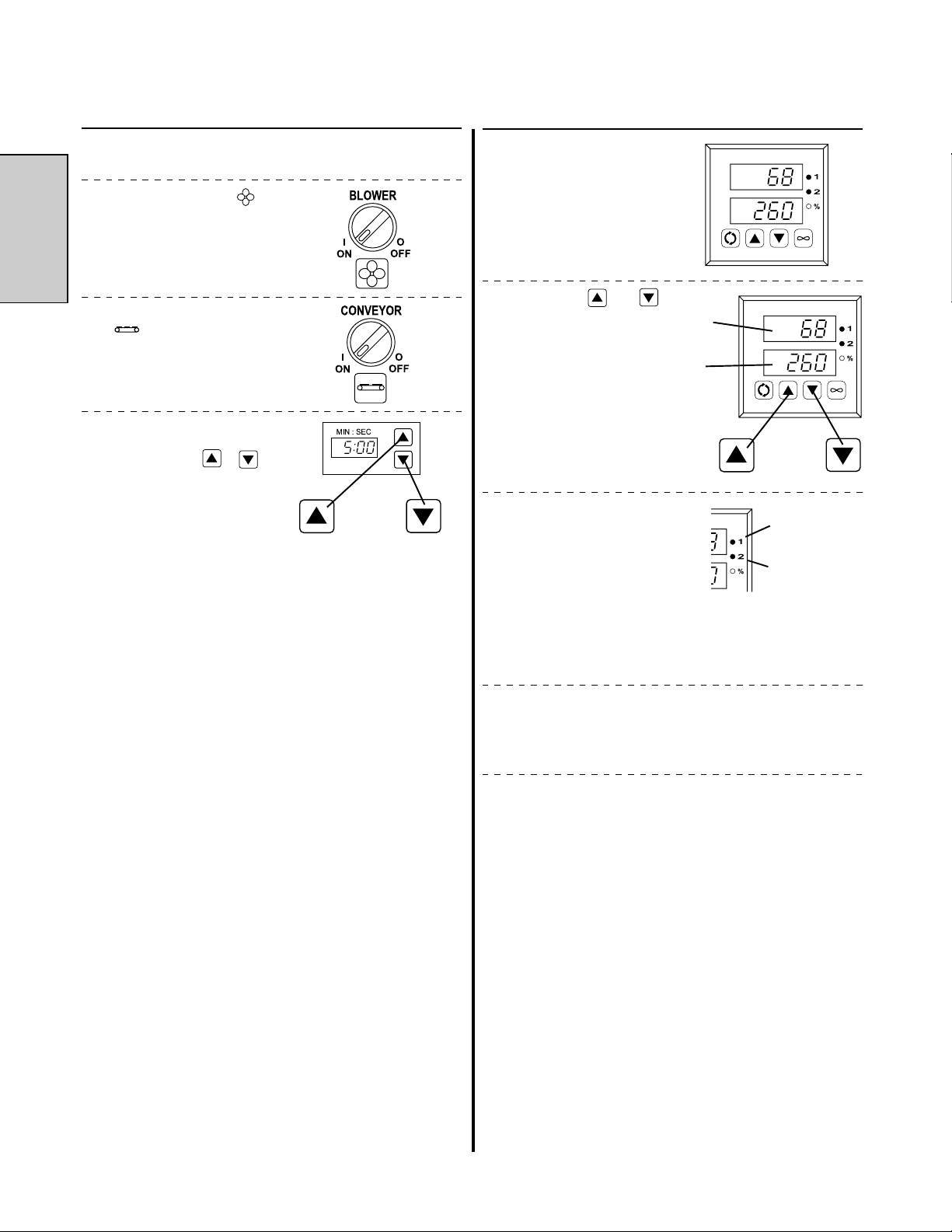

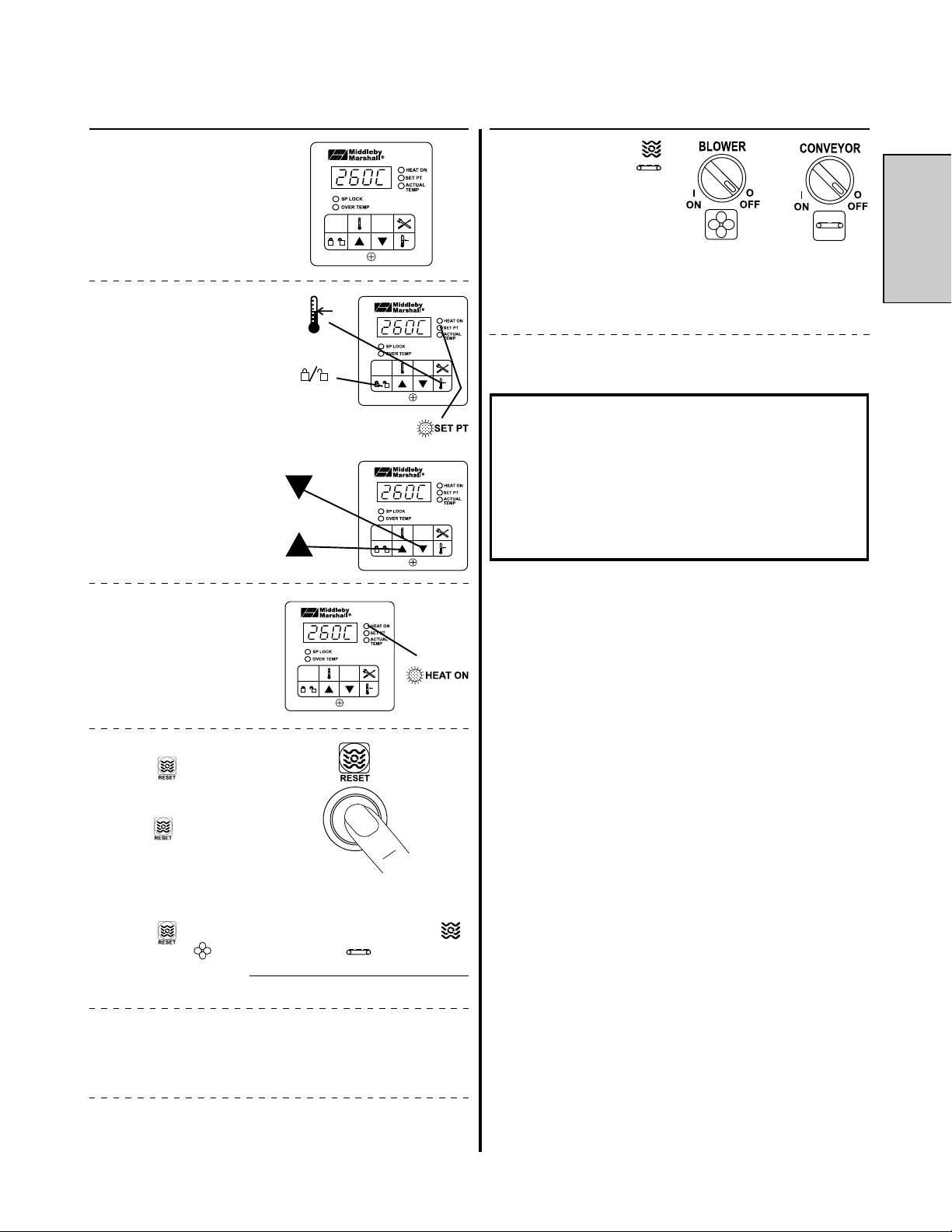

I. LOCATION AND DESCRIPTION OF CONTROLS

Fig. 3-1 - Control Panel

E

ENGLISH

E

A

B

C

D

A.

B.

C.

D.

"BLOWER" Switch: Turns the blowers and

cooling fans on and off. When set to the "ON" (I)

position, it also allows the heating elements to

activate. Activation is determined by the settings on the Digital Temperature Controller.

"CONVEYOR" Switch: Turns the conveyor drive

motor on and off.

Conveyor Speed Controller: Adjusts and displays the bake time. Single-belt ovens have one

controller. Split belt ovens have one controller

for each conveyor belt, labeled "FRONT" and

"BACK."

"RESET" Switch: Gas ovens only. Illuminates

if the gas burner does not light. The switch can

be pressed repeatedly to attempt to light the

burner. If the burner does not light within 15

minutes, the "RESET" (

) switch is locked out.

E.

NOT SHOWN:

F. Machinery Compartment Access Panel Safety Switch:

Disconnects electrical power to the controls and the blowers when the machinery compartment access panel is

opened. The panel should only be opened by authorized

service personnel.

Digital Temperature Controller: Continuously

monitors the oven temperature. Settings on the

Digital Temperture Controller control the activation of the burner or heating elements. Keypad

controls allow the operator to select the cooking

temperature and monitor oven operation.

Note that two different models of Digital Temperature Controller are used on PS536 ovens.

This section provides instructions specific to

each controller.

21

Page 22

SECTION 3 - OPERATION

II. NORMAL OPERATION - STEP-BY-STEP

A. DAILY STARTUP PROCEDURE

1. Check that the circuit breaker/fused disconnect is in the on

ENGLISH

position. Check that the window (if so equipped) is closed.

2. Turn the "BLOWER" ( )

switch to the ON ("I")

position.

3. Turn the "CONVEYOR"

(

) switch to the ON

("I") position.

4. If necessary, adjust the

conveyor speed setting

by pressing the

pushbuttons on the conveyor speed controller to

change the displayed

bake time.

o r

or

If the oven uses this

Digital Temperature

Controller:

5a. Press the

pushbuttons on the digital temperature controller to adjust the set temperature, if necessary.

Note that the set temperature is shown in the lower

window of the display,

while the actual oven

temperature is shown in

the upper window.

6a. Check that the "1" light

illuminates. This shows

that the burner or heating

elements have been

turned on.

The "2" light will illuminate while the oven heats

to its minimum normal

operating temperature of

93°C.

or

Actual

temp

Set

temp

or

Heating

elements on

Oven

temperature

under 200°F/

93°C

7a. Wait for the oven to heat to the set point temperature. Higher

set point temperatures will require a longer wait. The oven

can reach a temperature of 232°C in approximately 15

minutes.

8a. Allow the oven to preheat for 10 minutes after it has reached

the set point temperature.

22

Page 23

B. DAILY SHUTDOWN PROCEDURE

SECTION 3 - OPERATION

If the oven uses this

Digital Temperature

Controller:

5b. Adjust the temperature

controller to a desired set

temperature, if necessary.

Press the Set Point

and Unlock keys at

the same time. Wait

for the "SET PT" light

to turn on.

Press the Up Arrow

and Down Arrow

Keys as necessary

to adjust the setpoint.

or

+

wait

for

1. Turn the "BLOWER" ( )

and "CONVEYOR" (

switches to the "OFF"

("O") position. Open the

window (if so equipped)

to allow the oven to cool

faster.

Note that the blowers will

remain in operation until

the oven has cooled to

below 93°C.

2. After the oven has cooled and the blowers are off, switch the

circuit breaker/fused disconnect to the off position.

)

+

CAUTION

In case of power failure, turn all switches to the OFF ("O")

position, open the oven window, and remove the product.

After the power has been restored, perform the normal

startup procedure.

On gas ovens, the burner will not operate and gas will not

flow through the burner without electric power. No

attempt should be made to operate the oven during a

power failure.

ENGLISH

6b. Check that the "HEAT ON"

light illuminates. This

shows that the burner or

heating elements have

been turned on.

7b. (Gas ovens only) If the "RE-

SET" (

nates, the gas burner did

not light. Press the "RESET" (

edly if necessary) to attempt to light the burner.

NOTE: If the burner does not light within 15 minutes, the

oven enters a safety lockout mode that disables the "RESET" (

"BLOWER" (

"OFF" ("O") position.

Then, repeat the Daily Startup procedure.

8b. Wait for the oven to heat to the setpoint temperature. Higher

setpoint temperatures will require a longer wait. The oven

can reach a temperature of 232°C in approximately 5

minutes.

) switch illumi-

) switch (repeat-

) switch. If this occurs, turn the "HEAT" ( ),

), and "CONVEYOR" ( ) switches to the

Wait for AT LEAST FIVE MINUTES.

wait

for

9b. Allow the oven to preheat for 10 minutes after it has reached

the set point temperature.

23

Page 24

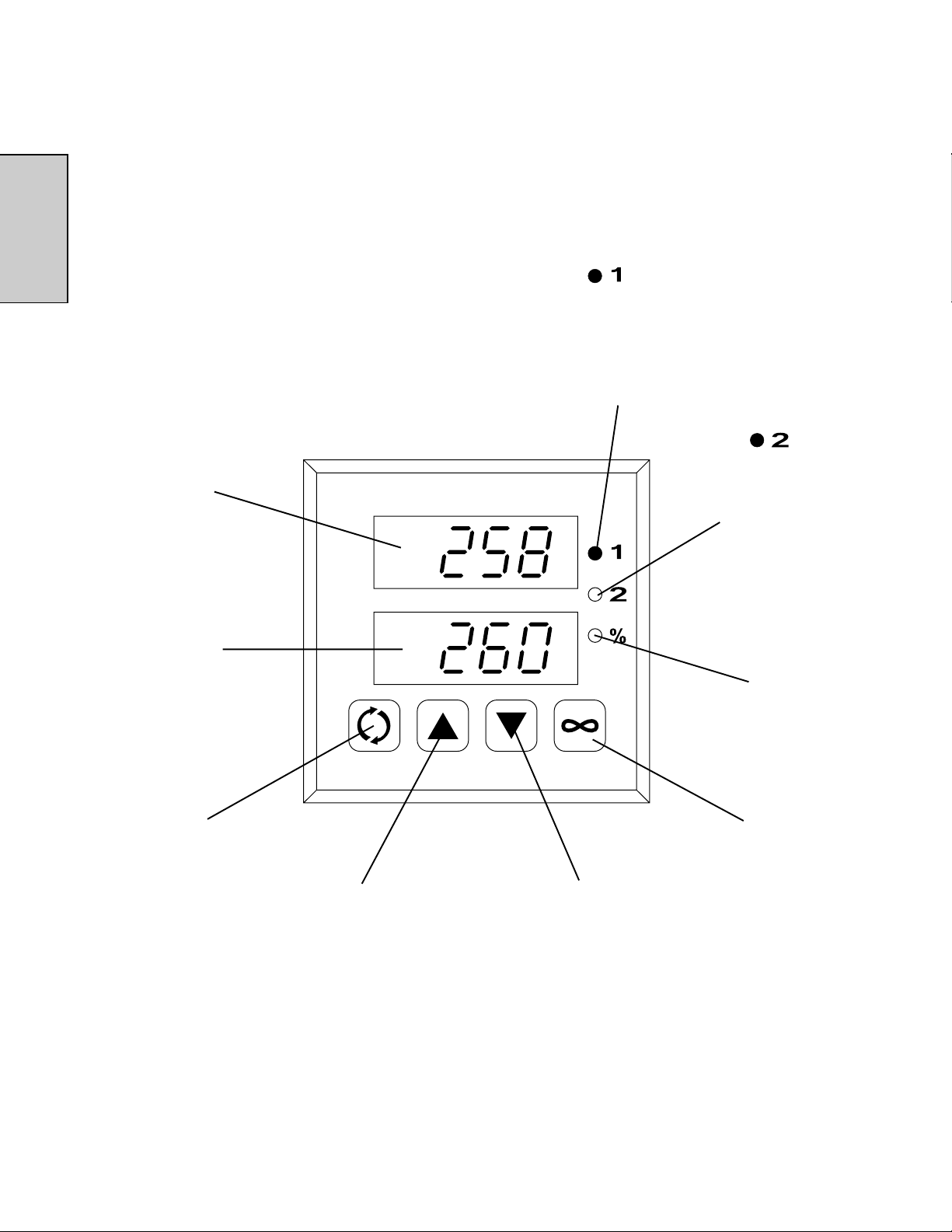

SECTION 3 - OPERATION

III. QUICK REFERENCE: DIGITAL TEMPERATURE CONTROLLERS

ENGLISH

Upper display

Shows the actual

oven temperature.

Lower display

Shows the set

point temperature.

Illuminates when the burner

light

or heating elements are on.

This light will flicker during

normal operation after the

oven reaches the set point

temperature.

light

Illuminates when

oven temperature is

EITHER below 93°C

OR above 316°C.

Percent

indicator

light

Service use only.

Advance key

Service use only.

Up Arrow key

Increases the set

point temperature.

Press the key once

to change the set

point by one degree.

Hold the key down

for larger changes.

Infinity key

Service use only.

Down Arrow key

Decreases the set point

temperature. Press the

key once to change the

set point by one degree.

Hold the key down for

larger changes.

24

Page 25

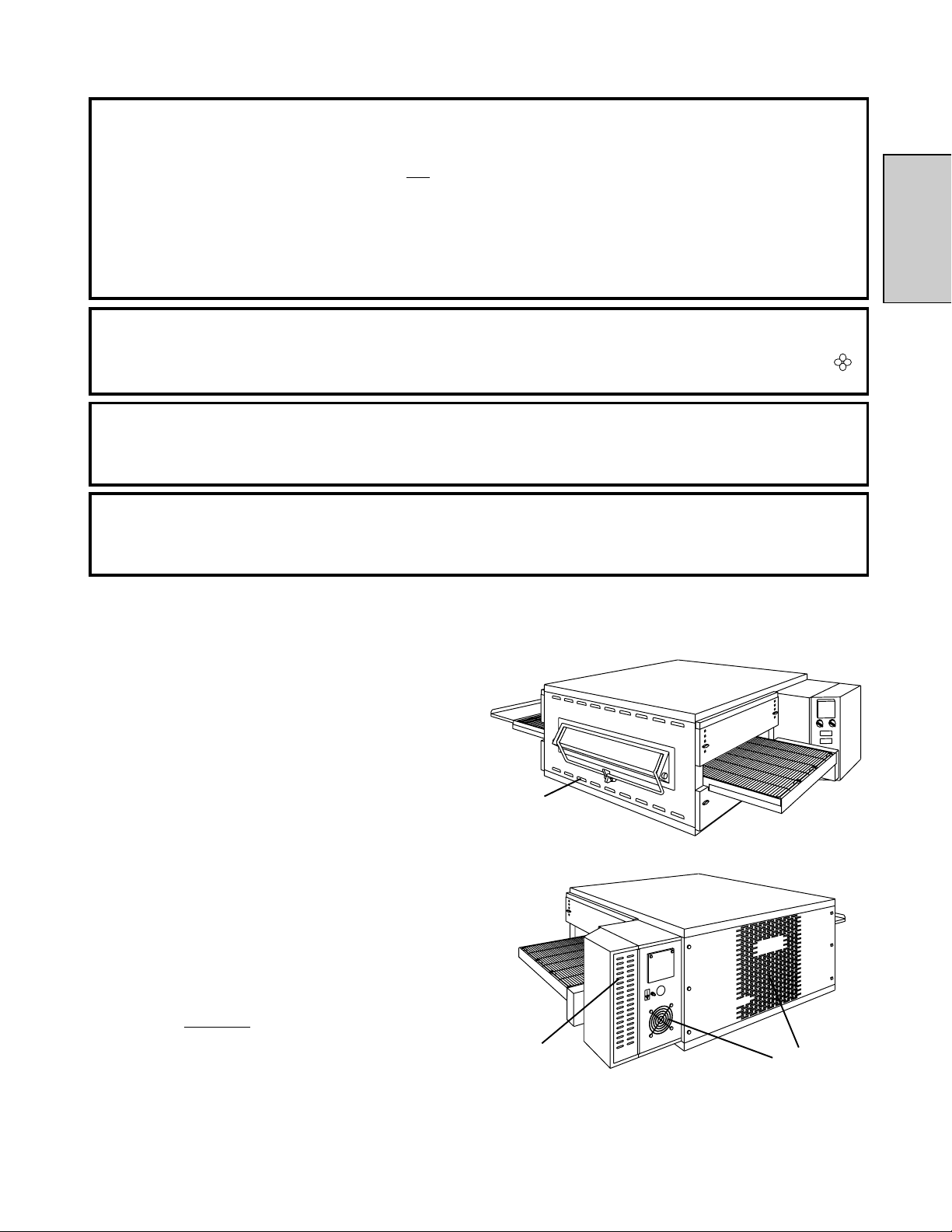

SECTION 3 - OPERATION

"SP LOCK"

Light

Lights when the

set point is locked

out from changes.

This setting can

only be changed by

service personnel.

OVERTEMP

Light

Lights when the oven

temperature is

greater than 343°C.

Refer to

Reference: Trouble-

shooting in this

Quick

section.

Display

Shows the Set Point

or the Actual Tem-

perature in degrees

Fahrenheit (F) or

Celsius (C).

"HEAT ON"

Light

Lights when the

burner or heating

elements, as

appropriate for the

oven model, are in

operation.

ENGLISH

"SET PT"

(setpoint)

Light

Lights when the

set point is shown

in the display.

"ACTUAL

TEMP" Light

Lights when the

Actual Temperature is shown in

the display.

Temperature

Key

Press this key once

to view the Actual

Temperature in the

Display.

together with the Set

Point Key to allow the

changed. Changes

can only be made for

Unlock Key

Press this key

Set Point to be

60 seconds.

Up Arrow and Down

Arrow Keys

Press these keys to

adjust the Set Point up or

down. If the Set Point will

not change, refer to

Point Key and Unlock Key

in this section.

25

Set

Service Key

Service use

only.

Set Point Key

Press this key

together with the

Unlock Key to allow

the Set Point to be

changed.

Changes can only be

made for 60 sec-

onds.

Page 26

SECTION 3 - OPERATION

IV. QUICK REFERENCE: TROUBLESHOOTING

SYMPTOM PROBLEM SOLUTION

The oven temperature is in

excess of 316°C. If the oven

is left in operation, the temperature may rise to 343°C

and cause a shutdown.

The oven temperature exceeded 343°C, and the oven

was automatically shut

down.

ENGLISH

light illuminates

oven has been

operating normally

Oven shuts down

completely during operation

light is lit, oven will

not heat

after

Turn the oven off according to the

Allow the oven to cool. Regardless of the time that is required

for the oven to cool, wait for AT LEAST FIVE MINUTES before

restarting the oven.

Repeat the

Turn the oven off according to the Daily Shutdown Procedure.

Contact your Middleby Marshall Authorized Service Agent to

determine and correct the cause of the condition to prevent

damage to the oven.

Daily Startup Procedure.

Daily Shutdown Procedure.

The oven did not reach

appears in display, oven is not

heating

"RESET" (

illuminated, oven will not

(gas ovens only)

Oven will not

turn on at all

Oven will not heat Controls may be set incor-

Oven is operating, but

little or no air is blowing

from air fingers

) switch is

heat

93°C within 15 minutes of

startup, and has stopped

heating.

The gas burner did not light

within 90 seconds of turning the "HEAT" (

to the ON ("I") position.

Electrical power may not be

reaching the oven, or the

controls may be set incorrectly.

rectly.

Air fingers may have been

reassembled incorrectly

after cleaning.

Blower belt may be broken.

) Switch

Turn the "BLOWER"

the "OFF" ("O") position.

Wait for AT LEAST FIVE MINUTES before restarting the oven.

Repeat the Daily Startup procedure.

Press the "RESET" (

attempt to light the burner.

If the burner does not light within 15 minutes, the oven will enter

a safety lockout mode that disables the "RESET" (

If this occurs, turn the "HEAT" (

"CONVEYOR" (

for AT LEAST FIVE MINUTES before restarting the oven. Then,

repeat the Daily Startup procedure.

Check that the circuit breaker/fused disconnect is turned on.

Check that the "BLOWER"

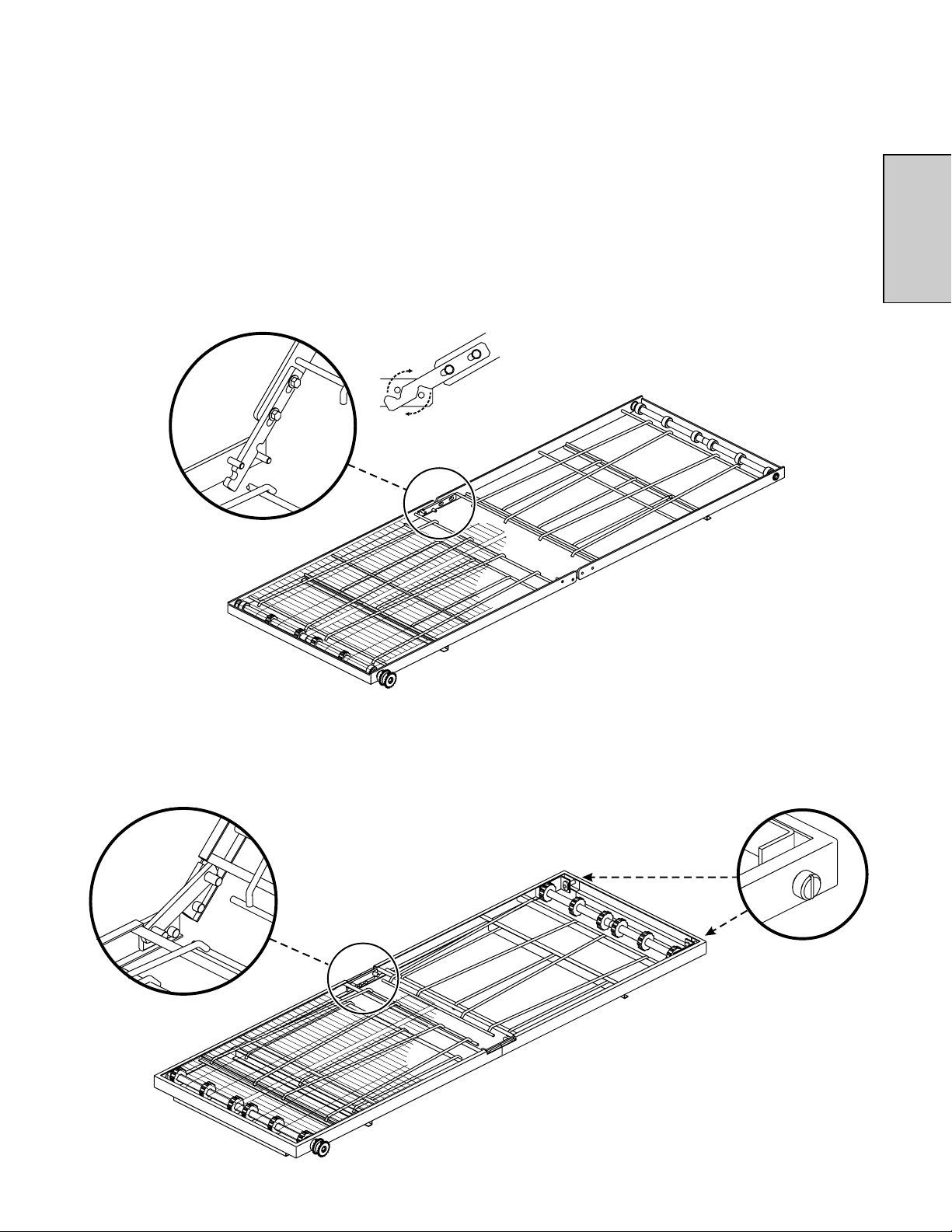

position. The burner cannot engage until the blowers are in

operation.

Check that the Set Point is correctly set.

Check that the "BLOWER"

position.

If the oven still will not heat, turn the oven off according to the

instructions in the

Wait for AT LEAST FIVE MINUTES before restarting the oven.

Repeat the

is above 93°C.

Turn the oven off according to the

Refer to Section 4,

bling the air fingers.

Turn the oven off according to the

Contact your Middleby Marshall Authorized Service Agent to

correct the problem.

Daily Startup Procedure. Check that the Set Point

( ) and "CONVEYOR" ( )switches to

) switch (repeatedly if necessary) to

) switch.

), "BLOWER" ( ), and

)switches to the "OFF" ("O") position. Wait

( ) Switch is in the ON ("I")

( ) Switch is in the ON ("I")

Daily Shutdown Procedure.

Daily Shutdown Procedure.

Maintenance, for instructions on reassem-

Daily Shutdown Procedure.

Conveyor moves with a

jerky motion, or will not

move at all

Food products are

overcooked or

undercooked

IF THESE STEPS FAIL TO RESOLVE THE PROBLEM, CONTACT YOUR LOCAL MIDDLEBY MARSHALL AUTHORIZED

SERVICE AGENT. A SERVICE AGENCY DIRECTORY IS SUPPLIED WITH YOUR OVEN.

Conveyor may be jammed

on an object in the oven, or

conveyor belt or drive chain

may be overtightened.

Controls may be set incorrectly.

Turn the oven off according to the

Check if the conveyor is blocked by an object inside the oven.

Check that the conveyor drive chain is not overtightened.

Refer to Section 4,

the conveyor belt tension.

Check that the set temperature and bake time settings are

correct.

26

Maintenance, for instructions on checking

Daily Shutdown Procedure.

Page 27

SECTION 4 - MAINTENANCE

WARNING

Before ANY cleaning or servicing of the oven, perform the following procedure:

1. Switch off the oven and allow it to cool. Do NOT service the oven while it is warm.

2. Turn off the electric supply circuit breaker(s)

3. If it is necessary to move a gas oven for cleaning or servicing, disconnect the gas supply connection before moving the oven.

and disconnect the electric supply to the oven.

When all cleaning and servicing is complete:

1. If the oven was moved for servicing, return the oven to its

original location.

2. For gas ovens, reconnect the gas supply.

3. Reconnect the electrical supply.

4. For gas ovens, turn on the full-flow gas safety valve. Test

the gas line connections for leaks using approved leak

test substances or thick soap suds.

5. Turn on the electric supply circuit breaker(s).

6. Perform the normal startup procedure.

WARNING

Possibility of injury from moving parts and electrical shock exists in this oven. Switch off and lockout/tagout the electric supply

BEFORE beginning to disassemble, clean, or service any oven. Never disassemble or clean an oven with the BLOWER

switch or any other circuit of the oven switched on.

CAUTION

NEVER use a water hose, water jet, or pressurized steam-cleaning equipment when cleaning this oven. DO NOT use

excessive amounts of water, to avoid saturating the oven insulation. DO NOT use a caustic oven cleaner, which can damage

the aluminized bake chamber surfaces.

NOTE

ANY replacement parts that require access to the interior of the oven may ONLY be replaced by a Middleby Marshall Authorized

Service Agent. It is also strongly recommended that the 3-Month Maintenance and 6-Month Maintenance procedures in this

section be performed ONLY by a Middleby Marshall Authorized Service Agent.

I. MAINTENANCE - DAILY

A. Check that the oven is cool and the power is disconnected,

as described in the warning at the beginning of this Section.

B. Clean ALL of the cooling fan grills and vent openings with a

stiff nylon brush. Refer to Figure 4-1 for the locations of the

grills and vents.

C. Clean the outside of the oven with a soft cloth and mild

detergent.

D. Check that ALL cooling fans are operating properly.

CAUTION

If a cooling fan is not operating correctly, it must be replaced

IMMEDIATELY. Operating the oven without adequate

cooling can seriously damage the oven's internal components.

E. Clean the conveyor belts with a stiff nylon brush. This is

more easily accomplished by allowing the conveyor to run

while you stand at the exit end of the conveyor. Then, brush

the crumbs off the conveyor as it moves.

F. Remove and clean the crumb trays. Be sure to replace the

trays in the same positions from which they were removed,

because they are NOT identical. Refer to Figure 2-11 (in

Section 2,

G. Clean the window (if so equipped) in place.

Installation).

Vents on

front panel

of oven

Vents on rear of

machinery

compartment

access panel

Figure 4-1 -Cooling Vents and Grills

Grills/vents

on rear of

oven

ENGLISH

( )

27

Page 28

SECTION 4 - MAINTENANCE

II. MAINTENANCE - MONTHLY

A. Check that the oven is cool and the power is disconnected,

as described in the warning at the beginning of this Section.

B. Refer to Part C,

ENGLISH

section of this Manual. Then, remove the following components from the oven:

Conveyor exit tray

Crumb trays

Chain cover

End plugs

Conveyor assembly

C. Slide the air fingers and blank plates out of the oven, as

shown in Figure 4-2. AS EACH FINGER OR PLATE IS

REMOVED, WRITE A "LOCATION CODE" ON IT WITH A

MARKER to make sure that it can be reinstalled correctly.

Example of markings:

(Top Row) T1 T2 T3 T4

(Bottom Row) B1 B2 B3 B4

D. Disassemble the air fingers. See Figure 4-3. AS EACH

FINGER IS DISASSEMBLED, WRITE THE "LOCATION

CODE" FOR THE FINGER ON ALL THREE OF ITS PIECES.

This will help you in correctly reassembling the air fingers.

CAUTION

Incorrect reassembly of the air fingers will change the

baking properties of the oven.

E. Clean the air finger components and the interior of the

baking chamber using a vacuum cleaner and a damp cloth.

Refer to the boxed warnings at the beginning of this Section

for cleaning precautions.

F. Reassemble the air fingers. Then, replace them in the

oven, using the "location code" as a guide.

G. Install the end plugs on the oven. Then, reinstall the

conveyor.

H. Reattach the drive chain. Replace the chain cover.

I. Check the tension of the conveyor belt as shown in Figure

2-7 (in Section 2,

25-50mm. If necessary, adjust the belt tension using the

procedure in Part C (

tion section of this Manual.

J. Replace the crumb trays and exit tray onto the oven.

Conveyor Installation, in the Installation

Installation). The belt should lift between

Conveyor Installation) in the Installa-

Figure 4-2 - Removing Air Fingers and Plates

Figure 4-3 - Disassembling the Air Fingers

Outer Plate

Inner plate

Manifold

III. MAINTENANCE - EVERY 3 MONTHS

A. Check that the oven is cool and the power is disconnected,

as described in the warning at the beginning of this Section.

B. Open the machinery compartment access panel. Vacuum

the inside of the compartment using a shop vacuum.

C. Tighten all electrical control terminal screws.

28

Page 29

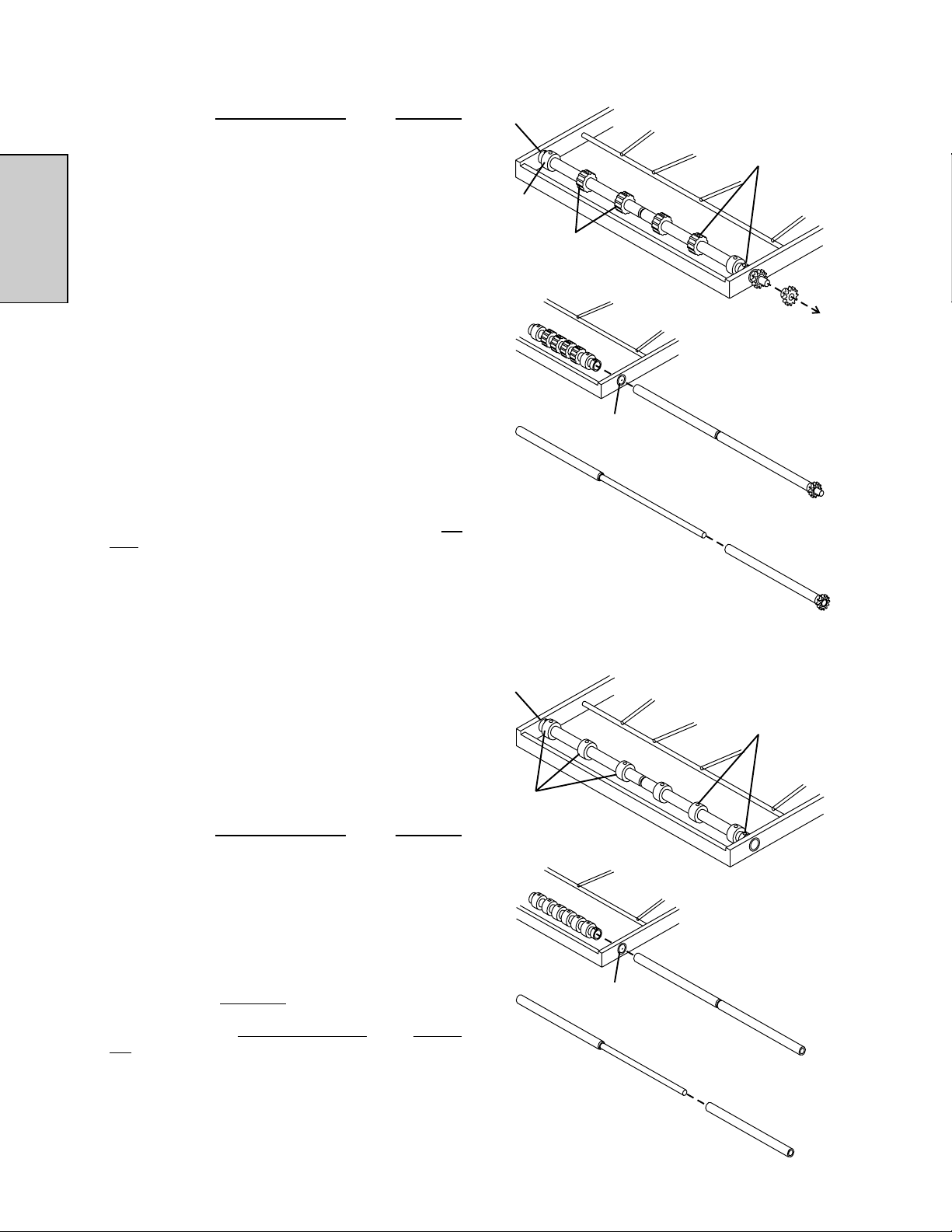

D. Split Belt Disassembly and Cleaning

For split belt ovens ONLY, disassemble, clean and lubricate the

conveyor shaft components as described in this Section.

PS536 ovens may be equipped with either of two different

conveyor designs. Both designs are available in split belt

configurations. Refer to Figures 4-4 and 4-5 to determine which

conveyor was shipped with your oven.

SECTION 4 - MAINTENANCE

If your oven uses the Type 1 Conveyor, continue on to Step

1 in this section, "Type 1 Conveyor Split Belt Cleaning."

If your oven uses the Type 2 Conveyor, skip ahead to Step

2 in this section, "Type 2 Conveyor Split Belt Cleaning."

Figure 4-4 - Identifying the Type 1 split belt conveyor

Pins on frame

fit into slots

on bracket

Tensioning screws

(2 per side)

Conveyor frame made of

rectangular steel sections

ENGLISH

Figure 4-5 - Identifying the Type 2 split belt conveyor

Hinge plates at

center of conveyor

frame

Conveyor frame made of

"C"-section stainless steel

29

Tension adjustment

screws (2) on idler

end of conveyor

Page 30

SECTION 4 - MAINTENANCE

1. Type 1 Conveyor Split Belt Cleaning

Figure 4-6 - Disassembling the drive shaft

a. Refer to Part C,

Conveyor Installation, in the Installation

section of this Manual. Then, remove the following components from the oven:

ENGLISH

Conveyor exit tray

Crumb trays

Chain cover

End plugs

Conveyor assembly

b. Remove the master links from each conveyor belt. Then,

roll the belts up along the length of the conveyor to remove

them from the frame.

c. Loosen (DO NOT REMOVE) the set screw on the outer drive

sprocket. Then, slide the drive sprocket off the end of the

drive shaft. See Figure 4-6.

d. Loosen (DO NOT REMOVE) the set screws on all four steel

spacers (2 per shaft), AND on all twelve conveyor belt

sprockets (6 per shaft).

e. Gently work the shaft sections out of the conveyor frame,

removing the conveyor belt sprockets as necessary. See

Figures 4-6 and 4-7.

f. Slide the two sections of each shaft apart.

g. Clean all of the shaft components thoroughly using a rag.

Then, lubricate each solid inner shaft, AND the interiors of

each hollow shaft, using a light food-grade lubricant.

NOT lubricate the shafts using WD40 or a similar product.

This can cause the shafts to wear rapidly.

h. Slide the hollow shaft sections over the solid inner shafts.

Check that the hollow section that has a drive sprocket

attached is placed at the end of the the drive shaft.

i. Slide the reassembled shafts into the conveyor frame. As

the shafts are replaced, slide the steel spacers and conveyor belt sprockets onto the shafts. Refer to Figures 4-6

and 4-7.

j. After the shafts are properly aligned, position the steel

spacers against the ends of the bushings on the conveyor

frame. Tighten the set screws on the spacers to hold them

in place. Leave the conveyor belt sprockets loose at this

time.

k. Replace the outer drive sprocket. Tighten its set screw to

hold it in place.

l. Refer to Part C,

Conveyor Installation, in the Installation

section of this Manual to replace the conveyor belt. As you

replace the belt, position the conveyor belt sprockets.

m. After the belt is in place and the sprockets are correctly

positioned, tighten the set screws to hold the sprockets in

place.

n. Reinstall the end plugs and conveyor onto the oven.

o. Reattach the drive chains. Replace the chain cover.

p. Check the tension of the conveyor belt as shown in Figure

2-11 (in Section 2,

Installation). The belt should lift between

25-50mm. If necessary, adjust the belt tension using the

procedure in Part C (

Conveyor Installation) in the Installa-

tion section of this Manual.

q. Replace the crumb trays and exit tray onto the oven. Then,

skip ahead to Part E, "Blower Belt."

DO

Spacer (2)

Smooth

sprocket (2)

Spacer (2)

Smooth

sprockets (6)

2. Loosen set

screws on belt

sprockets and

spacers (8)

Sprockets

w/teeth (4)

1. Remove outer

drive sprocket

Bushing

4. Disassemble,

clean, and

lubricate shafts

3. Slide shafts out

of frame

Figure 4-7 - Disassembling the idler shaft

1. Loosen set

screws on belt

sprockets and

spacers (8)

Bushing

2. Slide shafts out

of frame

30

3. Disassemble,

clean, and

lubricate shafts

Page 31

1. Type 2 Conveyor Split Belt Cleaning

SECTION 4 - MAINTENANCE

Figure 4-8 - Split Belt Idler Shaft

a. Refer to Part C,

Conveyor Installation, in the Installation

section of this Manual. Then, remove the following components from the oven:

Conveyor exit tray

Crumb trays

Chain cover

End plugs

Conveyor assembly

b. Remove the master links from each conveyor belt. Then,

roll the belts up along the length of the conveyor to remove

them from the frame.

c. Remove the two conveyor adjustment screws from the idler

end of the conveyor frame, as shown in Figure 4-8.

d. Remove the idler shaft assembly from the conveyor.

e. Pull apart the two sections of the idler shaft.

f. Clean the shafts thoroughly using a rag. Then, lubricate

both the extended shaft and the interior of the hollow shaft

using a light food-grade lubricant.

DO NOT lubricate the

shafts using WD40 or a similar product. This can cause the

shafts to wear rapidly.

g. Before reassembling the shafts into the conveyor frame,

check that they are oriented properly.

h. Reassemble the idler shaft into the conveyor.

Make sure

that the bronze washer is in place between the two sections

of the shaft. See Figure 4-10.

i. Replace the conveyor adjustment screws as shown in

Figure 4-8. To allow the conveyor belt to be reinstalled later,

do not tighten the screws at this time.

j. Loosen the set screw on both of the conveyor drive sprock-

ets. Then, remove the sprockets from the shaft.

k. Loosen the locking collar set screw, as shown in Figure 4-

9.

l. Push the drive shaft towards the drive sprocket, and lift it

free of the conveyor frame. Then, disassemble and lubricate the two sections of the drive shaft as described for the

idler shaft, above.

m. Before reassembling the shafts into the conveyor frame,

check that they are oriented properly.

n. Reassemble the drive shaft into the conveyor.

Check that

the nylon spacer is in place, as shown in Figure 4-10. Also,

check that the bronze washer is in place between the two

sections of the shaft.

o. Replace the drive sprockets. Reassemble the belts and

master links onto the conveyor.

p. Reinstall the end plugs and conveyor onto the oven.

q. Reattach the drive chains. Replace the chain cover.

r Check the tension of the conveyor belt as shown in Figure

2-18 (in Section 2,

Installation). The belt should lift about

25mm. If necessary, adjust the belt tension by turning the

conveyor adjustment screws.

s. Replace the crumb trays and exit tray onto the oven. Then,

skip ahead to Part E, "Blower Belt."

Conveyor

adjustment

screw

ENGLISH

Figure 4-9 - Split Belt Drive Shaft

Locking collar

Figure 4-10 - Washer and Spacer

Bronze washer on

BOTH idler and

drive shafts

Nylon spacer

on drive shaft

ONLY

31

Page 32

SECTION 4 - MAINTENANCE

E. Blower Belt

1. Remove the six screws shown in Figure 4-11. Then,

remove the rear panel from the oven.