Page 1

PS528G

Direct Gas Fired Countertop Conveyor Oven

Principle

Middleby Marshall PS Series conveyor ovens bake both faster and at a lower temperature

than other ovens. Vertical columns of hot air move heat aerodynamically instead of using high

temperatures. The streams of hot air remove the boundary layers of cool heavy air which tend to

insulate the product. All Middleby ovens are designed to cook a multitude of products including

pizza, seafood, sandwiches, bagels, ethnic foods and more.

General Information

The PS528 conveyor oven is ideally suited for Kiosk and

express-style locations where smaller ovens are required.

Standard Features

• Patented EMS Energy Management System* reduces

gas consumption and increases cooking efciency

• 28” (711mm) long cooking chamber with 18”(457.2mm)

belt

• 50”(1270mm) long, 40-3/4”(1035mm) deep, and

21-3/4”(552.4mm) high overall dimensions

• Furnished with 4”(101.6mm) legs

• Stackable up to three high.

• Microprocessor-controlled bake time/conveyor speed

• Stainless steel front, sides, top and interior

• Reversible conveyor direction

• 6”(152.4mm) Extension Tray

• 12”(304.8mm) Extension Tray

• 15”(381mm) wide front window

Optional Features

• Stand with casters

• Extended warranty available

Conserves Energy

Unit incorporates a patented Energy Management System - EMS.

Middleby ovens provide very efcient heat transfer to product.

Energy is conserved as air is recycled from heater to product,

with minimum loss. Oven is cool to the touch.

Cleanability

PS528 Ovens are designed for easy cleaning. Removable parts

include: crumb pans, end panels, air ngers, exit tray, and a

removable conveyor belt assembly.

Easily Services

Control compartment is designed for quick and easy access.

Warranty

All PS528 models have a one year parts and labor warranty.

Ventilation

Use of a ventilation hood is required.

Rev 1 (09/09)

1400 Toastmaster Drive

Elgin, IL 60120 USA

(847) 741-3300 Fax: (847) 741-0015

www.middleby.com

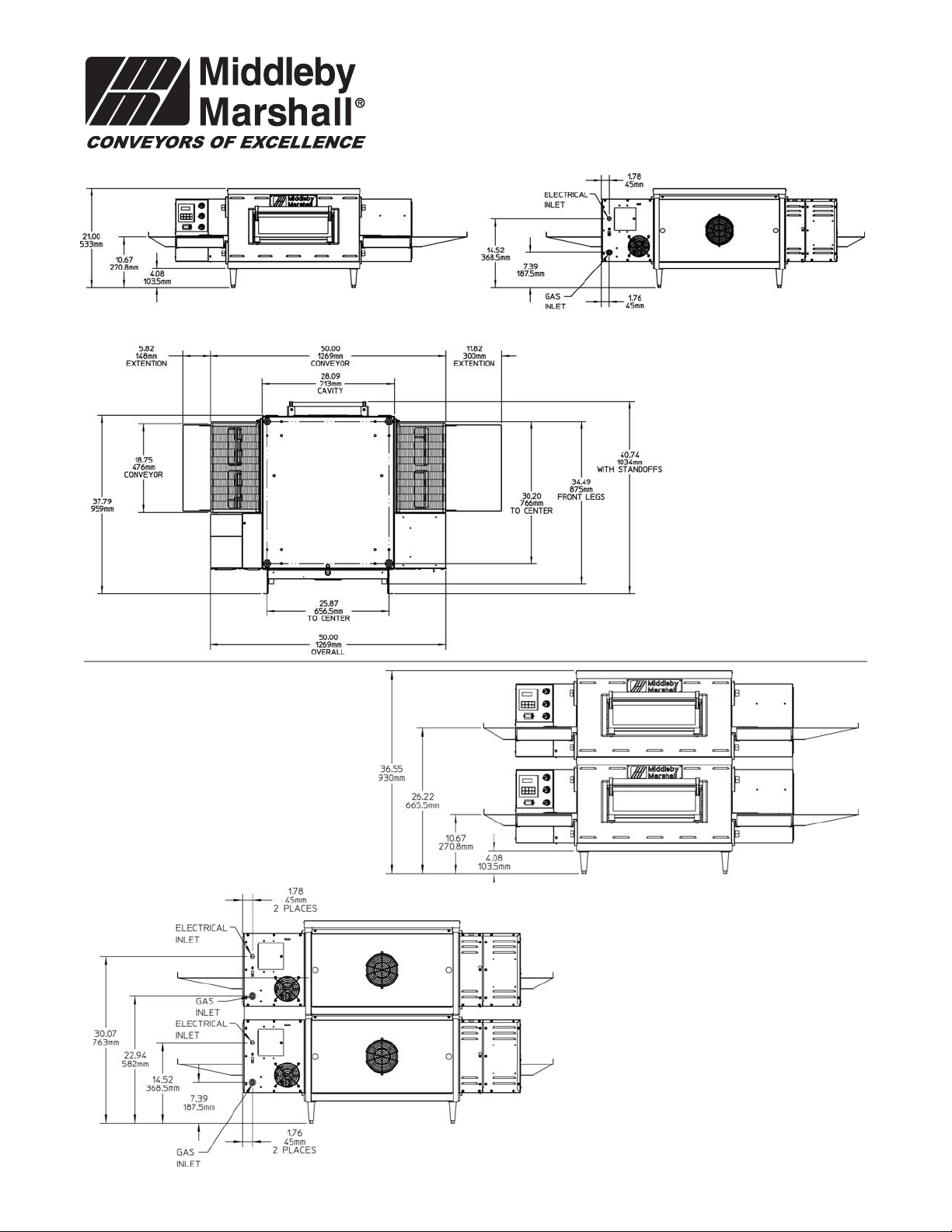

Page 2

PS528G Series

Direct Gas Fired Counter Top Conveyor Oven

PS528-1

Rev 1 (09/09)

PS528-2

Page 3

PS528-3

PS528G Series

Direct Gas Fired Counter Top Conveyor Oven

Optional cart available for PS528G Series

Rev 1 (09/09)

Page 4

PS528G Series

Direct Gas Fired Counter Top Conveyor Oven

RECOMMENDED MINIMUM CLEARANCES

Rear of Oven to Wall Control end of conveyor to wall Non-control end of conveyor to wall

0” 0” 0”

GENERAL SPECIFICATIONS

Overall Length Maximum Bake

Heating Baking Belt Belt (exit trays Operating Time Ship Ship

Zone Area Length Width installed) Height Depth Temp Range Wt Cube

PS528-1 28” 3.5 sq ft 50” 18” 68” 21.10” 40.75” 6000F 1-30 min 325 lbs 22.1 ft

711mm 0.33 sq m 1270 mm 457mm 1727mm 536mm 1035mm 3160C 147.42kg 0.62m

PS528-2 56” 5.0 sq ft 50” 18” 68” 36.55” 40.75” 6000F 1-30 min 650 lbs 44.2 ft

1422mm 0.66 sq m 1270 mm 457mm 1727mm 930mm 1035mm 3160C 294.48 kg 1.24m

PS528-3 84” 7.5 sq ft 50” 18” 68” 52.08” 40.75” 6000F 1-30 min 975 lbs 66.3 ft

2133mm 0.99 sq m 1270 mm 457mm 1727mm 1322mm 1035mm 316

0

C 442.25 kg 1.86m

ELECTRICAL SPECIFICATIONS

Version Voltage Phase Freq Current Draw Supply Breakers

Domestic and 208/240v 1 50/60 hz 2.0 Amp 2 pole, 3 wire As per

std. export local codes

3

3

3

3

3

3

* The current draw rating shown above are maximum values for normal operation, amperage

draw will be less than the listed value.

Each oven includes a 6 ft cord with NEMA# L6-20P plug. Customer to provide NEMA# L6-20R receptacle.

GAS SUPPLY SPECIFICATIONS

Version Gas Type Supply (inlet) Regulated Rated Heat

Pressure Pressure Input

Domestic & Natural 6-8” W.C. 3.5” W.C. 50,000 BTU

std export Gas (14.9-19.9mbar) * (8.72mbar)

Domestic & Propane 6-8” W.C. 3.5” W.C. 50,000 BTU

std export Gas (14.9-19.9mbar) * (8.72mbar)

* The required gas supply pressures of other locations are dependent on the local gas type and on all applicable local codes.

Minimum Gas Pipe Sizes:

* Natural Gas - 1 1/2” (31.8 mm) main supply line. One 3/4” (19mm) NPT branch per oven cavity with individual full-ow shutoff valve.

* Propane Gas - 1 1/2” (31.8 mm) main supply line. One 3/4” (19mm) NPT branch per oven cavity with individual full-ow shutoff valve

Each oven includes (1) 3/4”(19mm)NPT x 36”(914mm) exible, vinyl coated stainless steel braided gas hose.

ALL SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE.

Middleby Marshall, in accord with its policy to continually improve its products, reserves the right to

change materials or specications without notice. Such revisions do not entitle the buyer to correspond-

ing changes, improvements, additions, or replacements for previously purchased equipment.

© 2009 Middleby Marshall, Inc.

1400 Toastmaster Drive, Elgin, IL 60120-9272, USA • (847) 741-3300 • Fax: (847) 741-0015

Rev 1 (09/09) www.middleby.com

Loading...

Loading...