Page 1

PS300 Series

Gas and Electric (AGA/UL)

ENGLISH/French/Spanish

P/N 41823

Rev. B V3 5/00

page 1page 25página 49

ENGLISHFRANÇAISESPAÑOL

PS300 Series Gas and Electric Ovens

Models:

PS310

PS314

PS360/360Q/360S

PS360WB

PS360EWB

PS360WB70

Combinations:

Single Lower Oven

Single Upper Oven on Stand

Double Oven (Two-Stack)

Tandem Oven

Double (Two-Stack) Tandem Oven

OWNER'S OPERATING

& INSTALLATION

MANUAL

© 2000 Middleby Marshall, Inc.

is a registered trademark of Middleby Marshall, Inc. All rights reserved.

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 (847)741-3300 FAX (847)741-4406

1

Page 2

NOTICE:

This Owner's Operating and Installation Manual should be given to the user. The operator of the oven should

be familiar with the functions and operation of the oven.

This manual must be kept in a prominent, easily reachable location near the oven.

ENGLISH

Gas ovens are designed for use with EITHER natural gas OR liquid propane gas, as specified on the serial plate.

Where permitted by local and national codes, the oven can be converted from natural gas to propane operation,

or from propane to natural gas operation. This conversion requires the installation of the appropriate Middleby

Marshall Gas Conversion Kit by an Authorized Service Agent.

It is suggested to obtain a service contract with a Middleby Marshall Authorized Service Agent.

WARNING

POST, IN A PROMINENT LOCATION, THE EMERGENCY TELEPHONE NUMBER OF YOUR LOCAL GAS

SUPPLIER AND INSTRUCTIONS TO BE FOLLOWED IN THE EVENT YOU SMELL GAS.

Instructions to be followed in the event the user smells gas shall be obtained by consulting the local gas

supplier. If the smell of gas is detected, immediately call the emergency phone number of your local Gas

Company. They will have personnel and provisions available to correct the problem.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of

this or any other appliance.

WARNING:

Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death. Read the installation,

operating and maintenance instructions thoroughly before installing

or servicing this equipment.

IMPORTANT

An electrical wiring diagram for the oven is located inside the machinery

compartment or control compartment.

IMPORTANT

It is the customer's responsibility to report any concealed or non-concealed damage

to the freight company. Retain all shipping materials until it is certain that the

equipment has not suffered concealed shipping damage.

NOTICE: CONTACT YOUR MIDDLEBY MARSHALL AUTHORIZED SERVICE AGENT TO PERFORM MAINTENANCE

AND REPAIRS. AN AUTHORIZED SERVICE AGENCY DIRECTORY IS SUPPLIED IN YOUR INSTALLATION KIT.

NOTICE: Using any parts other than genuine Middleby Marshall factory manufactured parts relieves the manufacturer of

all warranty and liability.

NOTICE: Middleby Marshall (Manufacturer) reserves the right to change specifications at any time.

NOTICE: The equipment warranty is not valid unless the oven is installed, started and demonstrated under the supervision

of a factory certified installer.

Retain This Manual For Future Reference

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 USA (847)741-3300 FAX (847)741-4406

24-Hour Service Hotline: 1-(800)-238-8444

www.middleby.com

2

Page 3

TABLE OF CONTENTS

page page

SECTION 1 - DESCRIPTION .................................................... 4

IV. THERMOCOUPLE INSTALLATION .......................... 9

I. OVEN USES ............................................................. 4

II. OVEN COMPONENTS ............................................. 4

A. Crumb Pans ..................................................... 4

B. Conveyor Drive Motor ........................................ 4

C. Conveyor ........................................................... 4

D. End Plugs ......................................................... 4

E. Serial Plate........................................................ 4

F. Window ............................................................. 4

G. Machinery Compartment Access Panel ........... 4

H. Control Compartment Access Panel ............... 4

I. Control Panel .................................................... 4

J. Eyebrows .......................................................... 4

K. Conveyor End Stop ........................................... 4

L. Gas Burner ........................................................ 4

M. Blowers ............................................................. 4

N. Air Fingers ......................................................... 4

III. OVEN SPECIFICATIONS ......................................... 4

V. TANDEM OVEN ASSEMBLY .................................... 10

VI. CONVEYOR INSTALLATION ................................... 12

A. All Non-Tandem Ovens ................................... 12

B. Tandem Oven Models ..................................... 13

VII. FINAL ASSEMBLY ................................................... 13

VIII. ELECTRICAL SUPPLY ........................................... 14

A. Electric Ovens .................................................. 14

B. Gas Ovens .......................................................14

C. Ovens with External Transformers .................. 14

D. Connection.......................................................14

IX. GAS SUPPLY .......................................................... 15

A. Gas Utility Rough-In Recommedations .......... 15

B. Connection .......................................................15

C. Gas Conversion ............................................... 15

SECTION 3 - OPERATION ...................................................... 1 6

I. LOCATION AND DESCRIPTION OF CONTROLS .. 16

ENGLISH

A. Dimensions ...................................................... 4

B. General Specifications ..................................... 5

C. Gas Orifice and Pressure Specifications ......... 5

D. Electrical Specifications - Gas Ovens .............. 5

E. Electrical Specifications - Electric Ovens ......... 5

SECTION 2 - INSTALLATION .................................................. 6

I. INSTALLATION KIT .................................................. 7

A. Components ..................................................... 7

B. Additional Components - Gas Ovens .............. 7

C. Additional Components - Tandem Ovens ........ 7

II. VENTILATION SYSTEM ............................................ 8

A. Requirements ................................................... 8

B. Recommendations ........................................... 8

C. Other Ventilation Concerns .............................. 8

III. ASSEMBLY ............................................................... 9

A. Stacking ............................................................ 9

A. BLOWER ( ) Switch ...................................... 16

B. HEAT ( ) Switch ............................................ 16

C. CONVEYOR ( ) Switch ............................... 16

D. Conveyor Speed Controller ............................. 16

E. Digital Temperature Controller ........................ 16

F. Machinery Cpt. Access Panel Safety Switch .... 16

II. NORMAL OPERATION, STEP-BY-STEP ................. 17

A. Daily Startup Procedures ................................. 17

B. Daily Shutdown Procedures ............................ 17

III. QUICK REFERENCE: DIGITAL TEMP CONTROL . 18

IV. QUICK REFERENCE: TROUBLESHOOTING ........ 19

SECTION 4 - MAINTENANCE .. ............................................... 20

I. MAINTENANCE - DAILY .......................................... 21

II. MAINTENANCE - MONTHLY ................................... 2 2

III. MAINTENANCE - EVERY 3 MONTHS ..................... 23

IV. MAINTENANCE - EVERY 6 MONTHS ..................... 23

B. Stands ............................................................... 9

V. KEY SPARE PARTS KIT .......................................... 24

3

Page 4

SECTION 1 - DESCRIPTION

I. OVEN USES

PS300 Series Ovens can be used to bake and/or cook a

wide variety of food products, such as pizza, pizza-type

ENGLISH

products, cookies, sandwiches and others.

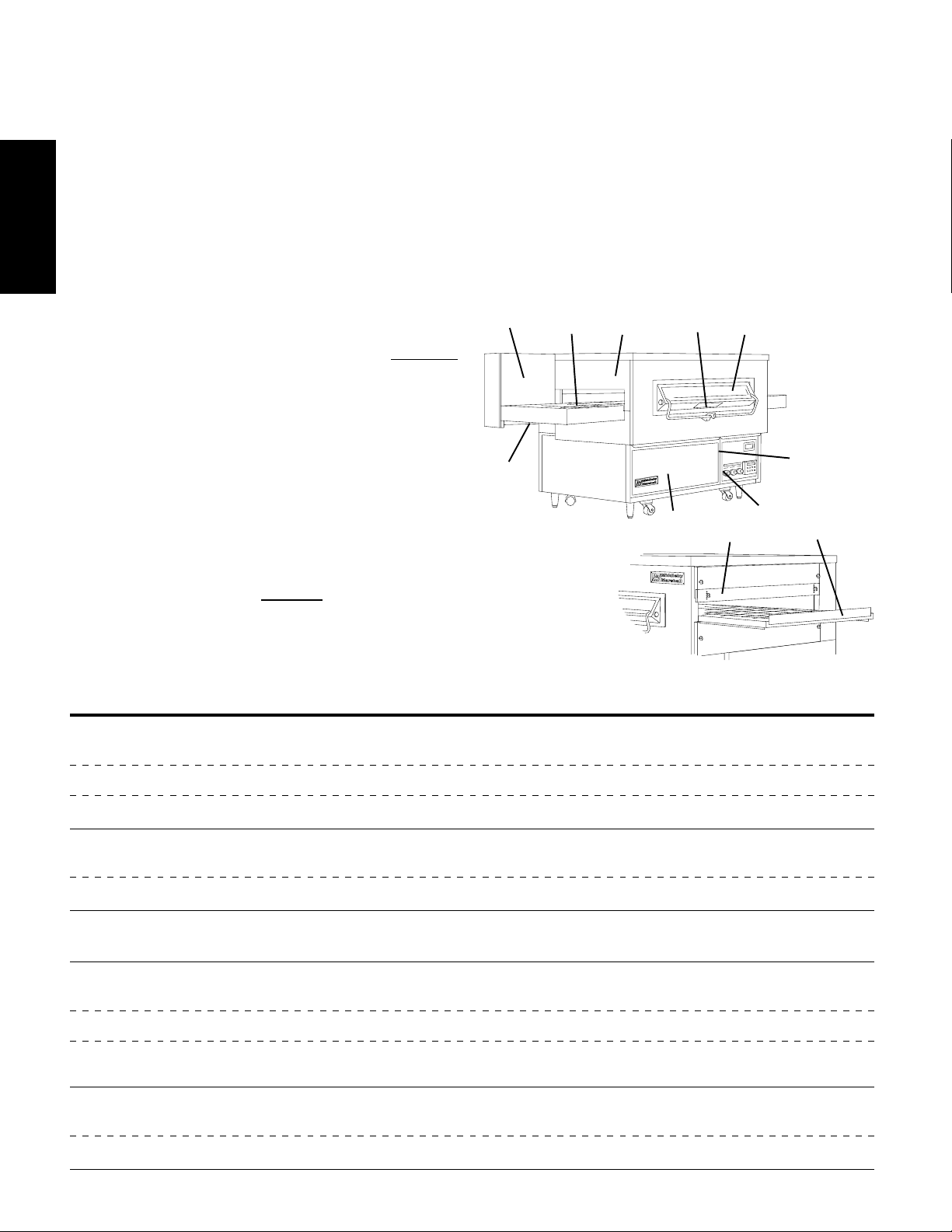

II. OVEN COMPONENTS - see Figure 1-1.

A. Crumb Pans: Catch crumbs and other material that drop

through the conveyor belt. One crumb pan is located

underneath each end of the conveyor.

B. Conveyor Drive Motor: Moves the conveyor.

C. Conveyor: Moves the food product through the oven.

D. End Plugs: Allow access to the oven's interior.

E. Serial Plate: Provides specifications for the oven that affect

installation and operation. Refer to Section 2, Installation,

for details.

F. Window (on ovens so equipped): Allows the user to see

and access food products inside the baking chamber.

G. Machinery Compartment Access Panel: Allows access to

the oven's interior components. No user-servicable parts

are located in the machinery compartment.

H. Control Compartment Access Panel: Allows access to the

control components. This panel is combined with the

Machinery Compartment Access Panel on PS360EWB and

WB70 ovens. No user-servicable parts are located in the

control compartment.

I. Control Panel: Location of the operating controls for the

oven. Refer to Section 3, Operation, for details.

J. Eyebrows (on ovens so equipped): Can be adjusted to

various heights to prevent heat loss into the environment.

K. Conveyor End Stop: Prevents food products from falling off

the end of the moving conveyor.

Not Shown:

L. Gas Burner: Heats air, which is then projected to the air

fingers by the blowers.

M. Blowers: Fans that project hot air from the burner to the air

fingers.

N. Air Fingers: Project streams of hot air onto the food product.

Fig. 1-1 - Oven Components

B

C

D

E

F

H

A

G

I

J

K

III. OVEN SPECIFICATIONS

A. Dimensions

Overall Height

Lower oven,

with top & legs

Upper oven,

with stand and top

Double oven

(two-stack)

Overall Depth

i

nc. rear shrouds

and front window

inc. rear shrouds

(no window)

Overall Length

* NOTE: The PS314 and PS360Q dimensions do NOT include the optional end trays.

Conveyor Width

Single Belt

Split Belt,

identical width

Split Belt,

unequal width

Recommended Minimum Clearances

Rear of oven (inc.

rear shrouds) to wall

Conveyor extension

to wall (both ends)

PS310 PS314 PS360/360Q/360S PS360 Tandem PS360WB PS360WB Tandem PS360EWB PS360WB70

45-1/2 45-1/2 45-1/2 45-1/2 45-1/2 45-1/2 45-1/2 45-1/2

1143mm 1143mm 1143mm 1143mm 1143mm 1143mm 1143mm 1143mm

64-1/2" 64-1/2" 64-1/2" 64-1/2" 64-1/2" 64-1/2" 64-1/2" 64-1/2"

1638mm 1638mm 1638mm 1638mm 1638mm 1638mm 1638mm 1638mm

82-1/4 82-1/4 82-1/4 82-1/4 82-1/4 82-1/4 82-1/4 82-1/4

2089mm 2089mm 2089mm 2089mm 2089mm 2089mm 2089mm 2089mm

39 39 47" 47" 55" 55" 60" 55"

991mm 991mm 1194mm 1194mm 1397mm 1397mm 1524mm 1397mm

36" 36" 44" 44" 52" 52" -- --

914mm 914mm 1118mm 1118mm 1321mm 1321mm -- --

90-1/2" 70-3/4"

2299mm 1797mm

24" 24" 32" 32" 40" 40" 44" 40"

610mm 610mm 813mm 813mm 1016mm 1016mm 1118mm 1016mm

-- -- 2x15" 2x15" 2x19" 2x19" 2x21" 2x19"

-- -- -- -- 1x13"/330mm 1x13"/330mm 1x14"/356mm 1x13"/330mm

1" 1" 1" 1" 1" 1" 1" 1"

25mm 25mm 25mm 25mm 25mm 25mm 25mm 25mm

0" 0" 0" 0" 0" 0" 0" 0"

0mm 0mm 0mm 0mm 0mm 0mm 0mm 0mm

*

90-1/2" * 144-1/2" 90-1/2" 144-1/2" 90-1/2" 106"

*

2299mm * 3670mm 2299mm 3670mm 2299mm 2692mm

381mm 381mm 483mm 483mm 533mm 483mm

4

AND AND AND AND

1x26"/660mm 1x26"/660mm 1x28"/711mm 1x26"/660mm

Page 5

SECTION 1 - DESCRIPTION

B. General specifications (per oven cavity)

PS310 PS314 PS360/360Q/360S PS360WB PS360EWB PS360WB70

Weight

Shipping Weight

Shipping Carton Vol.

1165 lbs./529kg 1165 lbs./529kg 1285 lbs./583kg 1485 lbs./674kg 1620 lbs./733kg 1825 lbs./829kg

1241 lbs./563kg 1241 lbs./563kg 1360 lbs./617kg 1560 lbs./708kg 1695 lbs./767kg 1900 lbs./863kg

105 ft.3/2.98m

3

105 ft.3/2.98m

3

106 ft.3/3.00m

3

129 ft.3/3.65m

3

129 ft.3/3.65m

3

164 ft.3/4.65m

3

Rated Heat Input

Gas

135,000 BTU 135,000 BTU 135,000 BTU 170,000 BTU 175,000 BTU 175,000 BTU

34,020kcal,40kw/hr. 34,020kcal,40kw/hr. 34,020kcal, 40kw/hr. 42,840kcal, 50kw/hr. 44,100kcal, 52kw/hr. 44,100kcal, 52kw/hr.

Electric

26kw/hr. 26kw/hr. 26kw/hr. -- -- --

Max. Operating Temp. < - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 550°F/288°C - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - >

Air Blowers

Air Jet Velocity (avg.)

Warmup Time

< - - - - - - - - - - - - - - - - 2 blowers at 1550 ft.3 (43.9m3)/min. at 1700 RPM, 0.88"/2.2cm water static pressure - - - - - - - - - - - - - - - >

< - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2600 ft./min. (1320cm/sec.) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - >

< - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15 minutes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - >

C. Gas orifice and pressure specifications - for gas-fired ovens (per oven cavity)

Natural Gas

PS310 PS314 PS360/360Q/360S PS360WB PS360EWB PS360WB70 Orifice I.D. Orifice I.D.

Main Orifice I.D.

0.219 0.219 0.219 0.250 0.250 0.250 0.028 0.065/#53 drill 6-12" W.C. 3-1/2" W.C.

5.56mm 5.56mm 5.56mm 6.35mm 6.35mm 6.35mm 0.71mm 1.65mm 14.9-29.9mbar 8.7mbar

Pilot Bypass Supply (inlet) Manifold

*

pressure pressure

ENGLISH

Propane

0.134" 0.134" 0.134" 0.152" 0.165" 0.165" 0.018" 0.034"/#62 drill 11-14" W.C. 10" W.C.

3.40mm 3.40mm 3.40mm 3.86mm 4.19mm 4.19mm 0.46mm 0.86mm 27.4-34.9mbar 24.9mbar

* NOTE: The PS360EWB gas oven does not use a bypass orifice.

D. Electrical specifications - for gas-fired ovens (per oven cavity)

Main Blower Control Current

Voltage Circuit Voltage Phase Freq. Draw Poles Wires

PS310/314/360/360Q/

360S/360WB

208-240V 120V 1 Ph 60 H z 10A 3 Pole 4 Wire (2 hot, 1 neut, 1 gnd)

208-240V (export) 120V (transformer) 1 Ph 50/60 Hz 10A 2 Pole 3 Wire (2 hot, 1 gnd)

200-220V (export) 120V (transformer) 1 Ph 50/60 Hz 10A 2 Pole 3 Wire (2 hot, 1 gnd)

PS360EWB/WB70

208-240V 120V conveyor speed 1 Ph 60 Hz 12A 2 Pole 3 wire (2 hot, 1 gnd)

controller (transformer);

all other control cicuits

as per line (208-240V)

E. Electrical specifications - for electrically-heated ovens (per oven cavity)

Main Blower Control Current kW

Voltage Circuit Voltage Phase Freq. Draw Rating Poles Wires

208-240V 120V 3 Ph 60 H z 67.3A at 208V 26.0 kW at 208V 4 Pole 5 Wire (3 hot, 1 neut, 1 gnd)

(with 3 Ph blower motors) 58.4A at 240V 26.0 kW at 240V

208-240V 120V 3 Ph 60 H z 67.3A at 208V 26.0 kW at 208V 4 Pole 5 Wire (3 hot, 1 neut, 1 gnd)

(with 1 Ph blower motors) 58.4A at 240V 26.0 kW at 240V

200-220V (export) 120V (transfomer) 3 P h 50/60 Hz 67.3A at 208V 24.3 kW at 208V 3 Pole 4 Wire (3 hot, 1 gnd)

53.5A at 220V 20.4 kW at 220V

240V (export) 120V (transformer) 3 Ph 50/60 Hz 58.4A 26.0 kW 3 Pole 4 Wire (3 hot, 1 gnd)

380V (export) 120V (transformer) 3 Ph 50/60 Hz 36.8A 24.3 kW 3 Pole 4 Wire (3 hot, 1 gnd)

400-416V (export) 120V (transfomer) 3 P h 50/60 Hz 33.8A 24.3 kW 3 Pole 4 Wire (3 hot, 1 gnd)

480V 120V (transformer) 3 P h 60 Hz 29.2A 26.0 kW 3 Pole 4 Wire (3 hot, 1 gnd)

IMPORTANT

Additional electrical information is provided on the oven's serial plate, and on the wiring diagram inside the machinery

compartment.

5

Page 6

ENGLISH

The oven must be installed on an even (level) non-flammable flooring and any adjacent walls must

be non-flammable. Recommended minimum clearances are specified in the Description section of

Do not obstruct the flow of combustion and ventilation air to and from your oven. There must be no

obstructions around or underneath the oven. Constructional changes to the area where the oven is

SECTION 2 - INSTALLATION

WARNING - After any conversions, readjustments, or service work on the oven:

Perform a gas leak test.

Test for correct air supply, particularly to the burner blower.

Test for proper combustion and gas supply.

Check that the ventilation system is in operation.

WARNING

Keep the appliance area free and clear of combustibles.

WARNING

this Manual.

WARNING

installed shall not affect the air supply to the oven.

CAUTION

For additional installation information, refer to the following documents:

PS360 Pre-Installation Procedures Manual (Middleby Marshall P/N 88210-0024)

PS360 Installation Manual (Middleby Marshall P/N 88210-0025)

Or, contact your local Authorized Service Agent.

NOTE

There must be adequate clearance between the oven and combustible construction. Clearance

must also be provided for servicing and for proper operation.

NOTE

An electrical wiring diagram for the oven is located inside the machinery compartment or control

compartment.

NOTE

All aspects of the oven installation, including placement, utility connections, and ventilation requirements,

must conform with any applicable local, national, or international codes. These codes supercede the require-

ments and guidelines provided in this manual.

NOTE

In U.S.A., the oven installation must conform with local codes, or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1. The oven, when installed, must be electrically grounded in accor-

dance with local codes, or in the absence of local codes, with the National Electrical Code (NEC), or ANSI/

NFPA70.

NOTE

In Canada, the oven installation must conform with local codes, or in the absence of local codes, with the

Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Gas Installation Code, CAN/CGA-B149.2,

as applicable. The oven, when installed, must be electrically grounded in accordance with local codes, or in

the absence of local codes, with the Canadian Electrical Code CSA, C22.2, as applicable.

NOTE

For Australian installation, the oven installation must conform with AGA Code, AG601, and with any require-

ments of the appropriate statutory authority.

6

Page 7

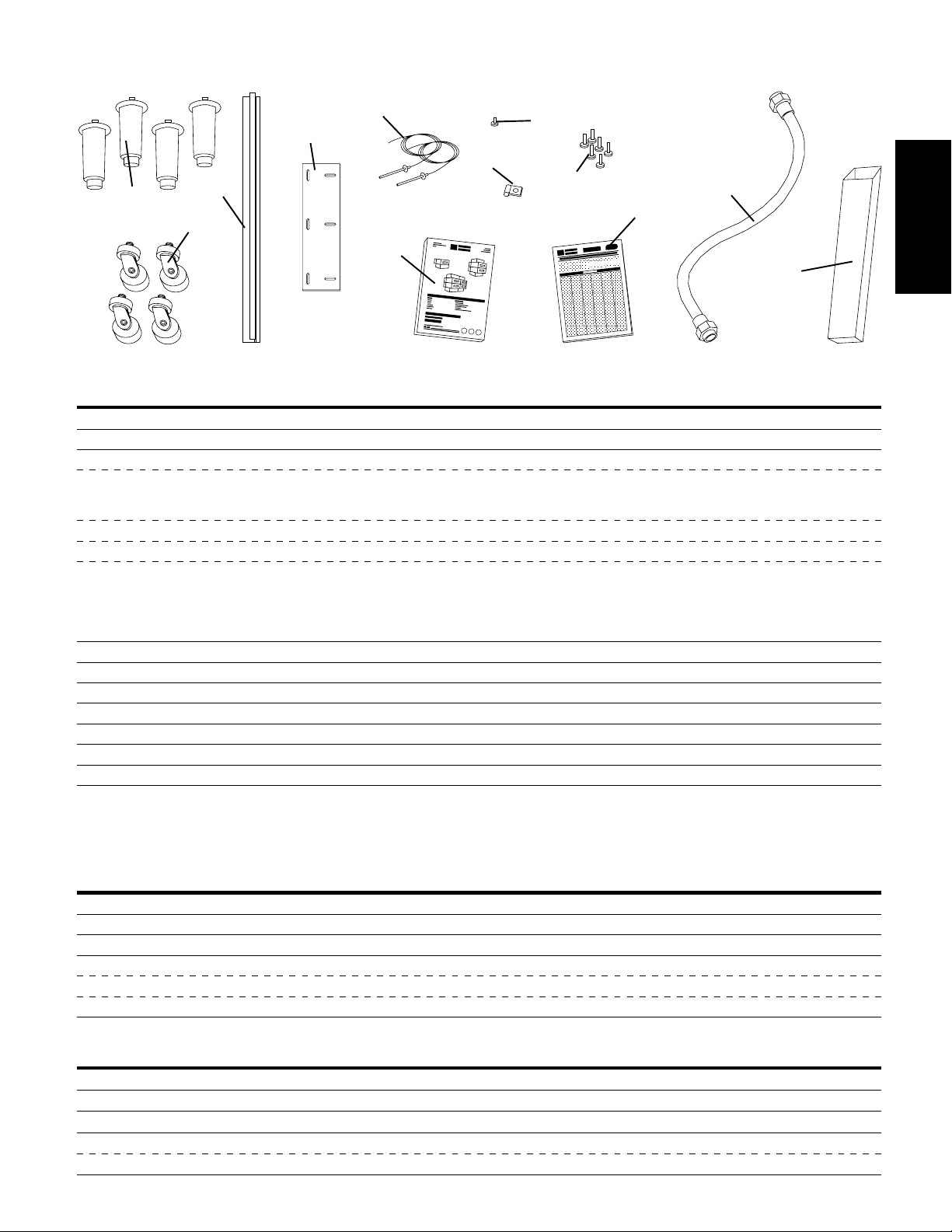

I. INSTALLATION KIT

1

3

2

SECTION 2 - INSTALLATION

Fig. 2-1 - Installation Kit

5

4

6

7

8

11

10

9

12

A. Installation kit components (one kit required per cavity)

Item Description Part Number Lower Oven w/o Top Lower Oven w/Top Upper Oven

1 Legs, adjustable 22450-0028 4 4 -2* Caster, Swivel (with stud) 37115-0102 4* 4* 4*

3a Conveyor End Stop - PS310/314 35000-1099 1 1 1

3b Conveyor End Stop - PS360/360S

Single Belt 35000-1103 1 1 1

Split Belt 35509222

3c Conveyor End Stop - PS360Q 37000-0524 1 1 1

3c Conveyor End Stop - PS360WB/WB70 (Single or Split Belt) 36526111

3d Conveyor End Stop - PS360EWB

Single Belt 35900-0370 2 2 2

Split Belt: 2x21"/533mm belts 35900-0370 2 2 2

Split Belt: 1x14"/356mm belt + 35509111

1x28"/711mm belt 35000-1099 1 1 1

4 Attachment Plate, upper oven 35122-0049 -- -- 2

5 Thermocouple 33812-1 2 2 2

6 Screw, #10-32 x 3/8" 21256-0008 2 2 2

7 Cable Clamp 27276-0001 1 1 1

8 Screw, #2PT 10-16 x 3/4" HWH 21292-0001 2 2 14

9 Owner's Operating and Installation Manual 41823111

10 Authorized Service Agency Listing 1002040 1 1 1

ENGLISH

NOTE

* The 4 swivel casters (Item 2) are pre-attached to each oven cavity for ease of movement during installation.

B. Additional installation kit components for gas ovens

Item Description Part Number Lower Oven w/o Top Lower Oven w/Top Upper Oven

6 Screw, #10-32 x 3/8" 21256-0008 1 1 1

8 Screw, #2PT 10-16 x 3/4" HWH 21292-0001 2 2 2

11 Gas hose, flexible 22361-0001 1 1 1

12a Flue vent, 14" (356mm) 30773 -- 1 - 12b Flue vent, 29-1/2" (749mm) 30759 -- -- 1

12c Flue vent, 50" (1270mm) 30758 1 -- - -

C. Additional installation kit components for tandem ovens (not shown)

Item Description Part Number Tandem Oven Double (2-stack) Tandem Oven

--

-- Front Gasket Spacer 35000-1456 2 4

-- Rear Gasket Spacer 35000-1457 2 4

--

--

Machinery Compartment Trim Strip

Baking Chamber Gasket and Frame - PS360

Baking Chamber Gasket and Frame - PS360WB

35000-1454 1 2

37200-0013 1 2

32483 1 2

7

Page 8

SECTION 2 - INSTALLATION

II. VENTILATION SYSTEM

IMPORTANT

ENGLISH

Where national or local codes require the

installation of fire suppression equipment or other supplementary equipment,

DO NOT mount the equipment directly to

the oven.

MOUNTING SUCH EQUIPMENT ON

THE OVEN MAY:

VOID AGENCY CERTIFICATIONS

RESTRICT SERVICE ACCESS

LEAD TO INCREASED SERVICE

EXPENSES FOR THE OWNER

A. Requirements

CAUTION

A mechanically driven ventilation system is

gas oven installations.

A mechanically driven ventilation system is STRONGLY

RECOMMENDED for electric oven installations.

PROPER VENTILATION OF THE OVEN IS THE

RESPONSIBILITY OF THE OWNER.

REQUIRED for

B. Recommendations

NOTE THAT THE HOOD DIMENSIONS SHOWN IN FIGURE 22 ARE RECOMMENDATIONS ONLY. LOCAL AND NATIONAL

CODES MUST BE FOLLOWED WHEN INSTALLING THE

VENTILATION SYSTEM. ANY APPLICABLE LOCAL AND

NATIONAL CODES SUPERSEDE THE RECOMMENDATIONS

SHOWN IN THIS MANUAL.

The rate of air flow exhausted through the ventilation system may

vary depending on the oven configuration and hood design.

Consult the hood manufacturer or ventilation engineer for these

specifications.

To avoid a negative pressure condition in the kitchen area, return

air must be brought back to replenish the air that was exhausted.

A negative pressure in the kitchen can cause heat- related

problems to the oven components as if there were no ventilation

at all. The best method of supplying return air is through the

heating, ventilation and air conditioning (HVAC) system. Through

the HVAC system, the air can be temperature-controlled for

summer and winter. Return air can also be brought in directly

from outside the building, but detrimental effects can result from

extreme seasonal hot and cold temperatures from the outdoors.

NOTE: Return air from the mechanically driven system must not

blow at the opening of the baking chamber. Poor oven baking

performance will result.

C. Other ventilation concerns

Special locations, conditions, or problems may require the

services of a ventilation engineer or specialist.

Inadequate ventilation can inhibit oven performance.

It is recommended that the ventilation system and duct work

be checked at prevailing intervals as specified by the hood

manufacturer and/or HVAC engineer or specialist.

18"

458mm

Fig. 2-2 - Ventilation System

2"/51mm

minimum

18"

458mm

8

12"

305mm

3"

76mm

Page 9

III. ASSEMBLY

A. Stacking

If the installation will include upper ovens mounted atop lower

ovens:

1. Remove the casters (pre-attached to each oven cavity) from

the upper ovens.

2. Stack the oven cavities. If necessary, refer to the Installation

Manual for Model PS310/360 Ovens (Middleby P/N 88210-

0025).

SECTION 2 - INSTALLATION

Figure 2-3 - Exploded View, Oven Stand

Attachment

plates inc. w/

upper oven

installation kit

B. Stands

If the installation includes ovens that are to be mounted on

stands:

Remove the casters (pre-attached to each oven cavity) and

install them on the stands as shown in Figure 2-3.

Assemble the ovens to the stands. An exploded view of the

stand is shown in Figure 2-3.

C. Flue Vent(s)

For gas ovens, attach one flue vent to the rear wall of each oven

cavity. Use one #10-16 x 3/8" and two #10-32 x 3/4" screws for

each flue vent. These screws are provided in the Installation Kit.

IV. THERMOCOUPLE INSTALLATION

1. Install one thermocouple sensing bulb into each of the two

holes in the rear panel of the oven, as shown in Figure 2-4.

Fasten each thermocouple in place using one of the #1032 x 3/8" screws supplied in the Installation Kit.

2. Thread BOTH sets of thermocouple leads through the

grommet and into the machinery compartment, as shown

in Figure 2-4.

3. Remove the right-side access panel of the machinery

compartment.

4. Thread the thermocouple leads through the side of the

machinery compartment as shown in Figure 2-5, and into

the electrical box (at the right-front of the machinery compartment).

ENGLISH

Casters inc.

w/oven

Figure 2-4 - Thermocouple Installation Locations

Thermocouples

Grommet-protected hole

Figure 2-5 - Placing the Thermocouple Leads

5. Connect BOTH sets of thermocouple leads to the temperature controller as shown in Figure 2-6. Note that the two

thermocouples are now tied together at the temperature

controller.

6. Replace the right-side panel of the machinery compartment.

7. Repeat Steps 1-6 for any other oven cavities in the installation.

8=White=Positive

7=Red=Negative

R=No Connection

Ground=Shielded cable

Figure 2-6 - Thermocouple Lead Connections

9

Page 10

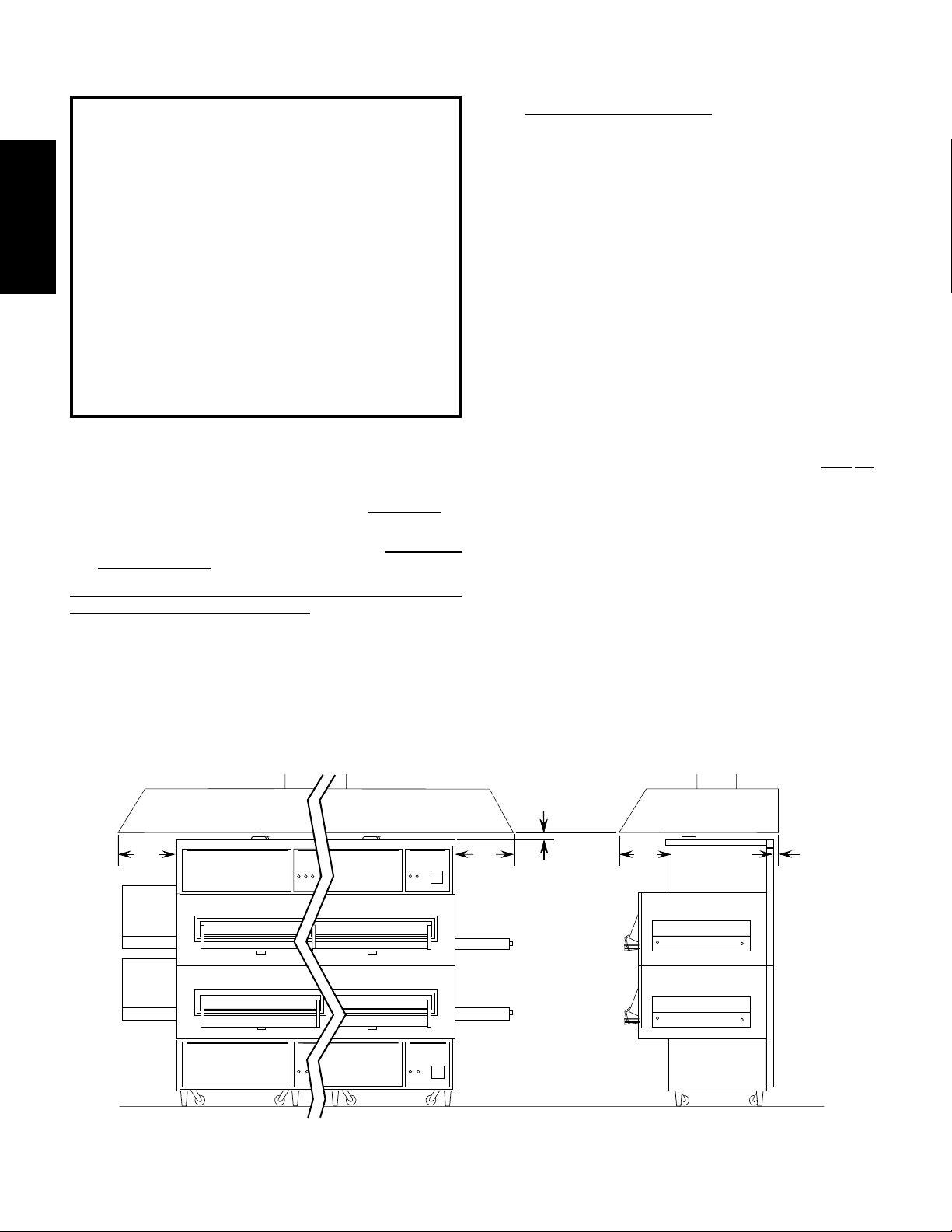

SECTION 2 - INSTALLATION

V. TANDEM OVEN ASSEMBLY

NOTE

For non-tandem oven installations, skip ahead to Section VI,

Conveyor Installation.

ENGLISH

1. Determine the proper position of the ovens by referring to

Figure 2-7. Then, move the ovens to their approximate final

locations.

2. Check that the top and bottom air finger retaining screws are

present on all mating ends of the oven sections. See Figure

2-7. The screws prevent the air fingers from sliding in

between the oven sections.

3. Remove the rear axial cooling fans that are adjacent to the

mating sides of the ovens. The fans may either be completely

disconnected, or left attached by their wiring as shown in

Figure 2-8.

Figure 2-7

Oven Positioning and Alignment

LEFT OVEN

Sealing gasket

assembly

(pre-mounted)

Alignment

plate

Slot for

alignment

plate

Air finger

NOTE: The Sealing Gasket Assembly may

be pre-mounted to EITHER of the oven

cavities.

Figure 2-8 - Cooling Fan Removal

Mating surface of

ovens (shown

from lower rear)

RIGHT OVEN

retaining

screws

10

Wiring is still

connected

Page 11

4. Insert three of the supplied 1/2 x 5 bolts through the holes

in the frame of the right oven, pointing outward as shown in

Figure 2-9. Then, slide the spacers into place on the bolts.

SECTION 2 - INSTALLATION

Figure 2-9 - Bolts and Spacers

2-1/2" x 2-1/2"

(64x64mm)

spacers

ENGLISH

2-1/2" x 8"

(64x203mm)

spacers

5. Push the ovens together. Check that the mounting bolts,

alignment plate, and sealing gasket are all properly aligned.

See Figure 2-10.

6. Tighten all of the attaching bolts. Check that the mating

edges of the ovens align properly. If gaps appear between

the tops of the ovens, it will be necessary to loosen the

connecting bolts and realign the ovens.

7. Attach the front trim strip between the two ovens, as shown

in Figure 2-11.

8. Replace the rear axial cooling fans. See Figure 2-8.

Figure 2-10 - Aligning the Sections

Figure 2-11 - Trim Strip Installation

11

Trim strip

Page 12

SECTION 2 - INSTALLATION

VI. CONVEYOR INSTALLATION

Refer to either Step A or Step B in this section, as appropriate,

to install the conveyor and belt.

A. Installing the Conveyor - All ovens EXCEPT Tandem models

ENGLISH

NOTE

Split belt conveyors can only be installed from the end of the oven

with the drive motor.

Single-belt conveyor assemblies may be inserted into either

end of the oven. If it is to be installed from the end of the oven

without the drive motor, the drive sprocket assembly must be

removed.

To remove the drive sprocket (if necessary), loosen the set screw

on the conveyor collar as shown in Figure 2-12. Then, pull the

sprocket assembly straight out.

1. Lift the conveyor and position it in the oven as shown in

Figure 2-13.

Figure 2-13 - Inserting the Conveyor

Figure 2-12 - Removing the Conveyor Drive Sprocket

Loosen conveyor collar

set screw, then pull shaft

straight out

1

2. Continue moving the conveyor into the oven until the frame

protrudes equally from each end of the oven (about 18"/

457mm).

3. Check that the retainers located on the underside of the

conveyor frame rest firmly against the lower end plug, as

shown in Figure 2-14.

NOTE:

PS360EWB ovens have a retainer bracket that extends the

full width of the conveyor frame on

All other ovens have retainer clips as shown in Figure 2-14,

located on the drive (left) side of the frame only.

4. When the conveyor is positioned properly, check for freedom of movement of the conveyor belt by pulling it for about

2-3 feet (60 to 90 cm) with your fingers. The conveyor must

move freely.

5. If the drive sprocket was removed when installing the

conveyor, replace it at this time.

6. Install the drive chain between the conveyor drive sprocket

and the motor sprocket. To install the chain, it will be

necessary to lift the drive end of the conveyor slightly. The

drive motor and sprocket are shown in Figure 2-12.

7. Install the conveyor drive motor cover and tighten its hanger

screw (on the rear wall of the oven).

8. Check the tension of the conveyor belt as shown in Figure

2-15. The belt should lift between 3-4" (75-100mm). DO

NOT OVERTIGHTEN THE CONVEYOR BELT.

NOTE:

If necessary, the belt tension can be adjusted by turning the

conveyor adjustment screws, located at the idler (right) end

of the conveyor. See Figure 2-15.

both ends of the frame.

2 3

Figure 2-14 - Conveyor retainers

Retainers on both ends of

PS360EWB, drive side

only for all other ovens

Figure 2-15 - Checking the conveyor tension

3-4"

(75-100mm)

vertical

deflection

Conveyor

tension

adjustment

screws (idler

end only)

12

Page 13

B. Installing the Conveyor and Belt - Tandem oven models

NOTE

For non-tandem oven installations, skip ahead to Section VII,

Final Assembly.

1. Insert the conveyor frame into the oven as follows:

Slide one hinged conveyor frame section into each end of

the oven. The two sections butt against each other at the gap

between the two oven sections. See Figure 2-17.

IMPORTANT

Be sure that the drive section of the conveyor frame is at the

same end of the oven as the conveyor drive motor.

2. Slide the conveyor belt through the support rods underneath

the frame, and thread it through the oven. Then, reach

through the oven window and pull the free end of the belt

through the oven so that it lies atop the conveyor frame.

After the belt has been pulled through the oven, check the

following:

The conveyor belt links must be oriented as shown in

Figure 2-18.

The smooth side of the conveyor belt must face UP.

3. Connect the inside master links. Check that the links are

oriented as shown in Figure 2-18.

4. Connect the outside master links. Note that the outside

master links have right and left sides. The right-side master

link has an open hook facing you, as shown in Figure 2-19.

5. Check for freedom of movement of the conveyor belt by

pulling it for about 2-3 feet (60 to 90 cm) with your fingers. The

conveyor

must move freely.

6. Check the tension of the conveyor belt as shown in Figure

2-15 (on the previous page). The belt should lift between 34" (75-100mm). DO NOT OVERTIGHTEN THE CONVEYOR

BELT. If necessary, the belt tension can be adjusted by

turning the conveyor adjustment screws, located at the idler

(right) end of the conveyor.

7. LOOSELY attach the conveyor drive motor to the end wall of

the oven. Refer to Figure 2-12 (for ovens with standard

conveyor frames) or Figure 2-20 (for ovens with heavy-duty

conveyor frames).

8. Assemble the conveyor drive chain in place on the motor and

conveyor drive sprockets.

9. Position the motor to adjust the deflection of the drive chain

to 3/4 (19mm). DO NOT OVERTIGHTEN THE DRIVE

CHAIN. Then, tighten the bolts to hold the motor in place.

SECTION 2 - INSTALLATION

Figure 2-17 - Tandem Conveyor Installation

Hinged

end section

Hinged

end section

Figure 2-18 - Conveyor and Inside Master Link Orientation

Direction

of travel

Figure 2-19 - Outside Master

Link Orientation

Direction

of travel

Figure 2-20 - Drive Motor for

Tandem Oven Heavy-Duty

Conveyor Frame

CORRECT

master link

position

Incorrect

master link

position

Figure 2-21 - Crumb tray positions

Upper Oven

(Drive End)

Upper Oven

(Idler End)

ENGLISH

VII. FINAL ASSEMBLY

1. Assemble the end plugs and motor housing onto the oven.

These components are shown in Figure 1-1 (on Page 1).

2. Slide the conveyor extensions over the ends of the conveyor

frame. Be sure that the extension with the drive sprocket

opening is placed on the drive end.

NOTE

The PS360EWB oven does not use conveyor extensions.

3. Refer to Figure 2-21 for the correct location of each crumb tray.

Then, install the crumb trays underneath the conveyor as

shown in Figure 2-22. First, place the inside edge of the tray

onto the bracket attached to the end plug. Then, swing the

outside edge of the tray up and into place.

4. Press the end stop down over the edge of the conveyor

extension at the exit end of the oven. See Figure 2-22.

5. After the oven is moved to its final location, adjust the bottom

section of the legs so that the oven is level and the casters

do not touch the floor.

Lower Oven

Figure 2-22 - Crumb trays, extensions, and end stop

End stop

Crumb tray

13

Conveyor extension Conveyor frame

Page 14

SECTION 2 - INSTALLATION

VIII. ELECTRICAL SUPPLY (all ovens)

WARNING

Authorized supplier personnel normally accomplish

the connections for the ventilation system, electric supply,

and gas supply, as arranged by the customer. Following these

ENGLISH

connections, the factory-authorized installer can perform the

initial startup of the oven.

NOTE: The electric supply installation must satisfy the

requirements of the appropriate statutory authority, such as the

National Electrical Code (NEC), ANSI/NFPA70, (U.S.A.); the

Canadian Electrical Code, CSA C22.2; the Australian Code

AG601; or other applicable regulations.

NOTE: The electric supply connection must meet all national

and local electrical code requirements.

Check the oven serial plate before making any electric supply

connections. Electric supply connections must agree with data

on the oven serial plate. The location of the serial plate is shown

in Figure 2-23.

A fused disconnect switch or a main circuit breaker (customer

furnished) MUST be installed in the electric supply line for each

oven cavity. It is recommended that this switch/circuit breaker

have lockout/tagout capability.

The supply conductors must be of the size and material (copper)

recommended. Refer to the wiring diagram inside the machinery compartment or control compartment of the oven. Electrical

specifications are also listed on the oven's serial plate (Figure

2-23) and in the Electrical Specifications table (on Page 5).

The oven requires a ground connection to the oven ground screw

located in the electrical junction box. (The box is shown in Figure

2-24.) If necessary, have the electrician supply the ground wire.

Do NOT use the wiring conduit or other piping for ground

connections!

Figure 2-23 - Oven Serial Plate

Serial plate location

CAUTION

Before connecting incoming power to the oven, measure the

voltage of each input leg to neutral. The expected voltage is

approximately 120V. ANY voltage reading exceeding 130V

indicates that the supply has a high leg. CONNECTING A

HIGH LEG TO THE OVEN VOIDS ALL OVEN WARRANTIES.

Connecting a high leg to the black lead of the oven can severely

damage the ovens electrical and electronic components.

CAUTION

DO NOT CONNECT BLACK WIRE TO HIGH LEG.

VOLTAGE OF THE BLACK AND WHITE WIRES MUST

BE NO HIGHER THAN 130 VAC.

A. Additional Information - Electric Ovens

For electric ovens, a 1-1/4" (32mm) dia. cutout in the back

wall of the machinery compartment provides access for the

electrical supply connections. Using flexible cables for the

electric power supply conductors requires a 1-1/4" (32mm)

strain-relief fitting (not furnished with the oven) to enable

safe access to the terminal block from which power is

distributed to the oven.

B. Additional Information - Gas Ovens

All gas oven electric supply connections are made via the

electrical junction box on the rear of the oven, shown in

Figure 2-24. The power lines then connect to the oven

circuits through the Machinery Compartment Access Panel

Safety Switch. This switch interrupts electric power to the

oven when the Machinery Compartment Access Panel is

opened.

C. Additional Information - Ovens with External Transform-

ers (export versions)

Position the transformer on the rear wall of the oven, on the

same side as the control compartment, as space permits.

Fasten it in place using the supplied mounting hardware.

D. Connection

Refer to the wiring diagram inside the machinery

compartment or control compartment of the oven to

determine the correct connections for the electrical supply

lines. Connect the supply as indicated on the wiring

diagram. Be sure to connect the electrical supply ground

wire to the oven ground screw located in the junction box

on the rear of the oven.

Figure 2-24 - Utility Connection Locations

Gas oven:

3/4" (19mm) pipe for

gas utility connection

Electric oven:

1-1/2" (38mm) conduit for

electric utility connection

NOTE: The location of these

components may vary slightly

depending on the oven model.

Electrical

Junction Box

14

Appliance

Connection/Male

Nipple

Figure 2-25 - Flexible Gas

Hose Installation

To Gas

Supply Pipe

90°

Elbow

Full-Flow Gas

Shutoff Valve

Flexible

Gas Hose

Page 15

IX. GAS SUPPLY (gas ovens only)

SECTION 2 - INSTALLATION

CAUTION

DURING PRESSURE TESTING NOTE ONE OF THE FOLLOWING:

1. The oven and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at test pressure in excess of 1/

2 psi (3.45 kPa).

2. The oven must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressure equal to or less than 1/2 psi (3.45 kPa).

A. Gas Utility Rough-In Recommendations

The following gas system specifications are STRONGLY

RECOMMENDED. Deviating from these recommendations

may affect the baking performance of the oven.

Gas Meter

One or two oven cavities: 750 cfh meter

Three or four oven cavities: 1200 cfh meter

Gas Line

DEDICATED LINE from the gas meter to the oven

2" (50.8mm) pipe for natural gas

1-1/2" (38.1mm) pipe for propane

Maximum length: 200' (61m). Each 90° elbow equals 7'

(2.13m) of pipe.

B. Connection

Check the ovens gas supply requirements before making the

gas utility connection. Gas supply requirements are listed on the

ovens serial plate (Figure 2-23) and in the Gas Orifice and

Pressure Specifications table (Page 5 of this manual).

Check the serial plate to determine the type of gas (Propane or

Natural) to be used with the oven.

Refer to the instructions in the gas hose package (included in the

Installation Kit) before connecting the gas line. One gas line

connection method is shown in Figure 2-25; however, compliance

with the applicable standards and regulations is mandatory.

Inlet, regulated, and pilot gas pressure readings can be taken

using a U tube manometer at the tap locations shown in Figure

2-26.

3. If incoming pressure is over 14 W.C. (35mbar), a separate regulator MUST be installed in the line BEFORE the

individual shutoff valve for the oven.

WARNING: To prevent damage to the control valve regulator during initial turn- on of gas, it is

very important to open

the manual shutoff valve very slowly.

After the initial gas turn-on, the manual shutoff valve must

remain open except during pressure testing as outlined in

the above steps or when necessary during service maintenance.

NOTE

The installation must conform with local codes or in the absence

of local codes, with the National Fuel Gas Code, ANSI Z223.1latest edition.

In Australia, the installation must conform with AGA Code AG601

and with any requirements of the appropriate statutory authority.

CANADIAN:

CAN/CGA-B 149.1 Natural Gas Installation Code

CAN/CGA-B 149.2 Propane Installation Code

Certain safety code requirements exist for the installation of gas

ovens; refer to the beginning of Section 2 for a list of the

installation standards. In addition, because the oven is equipped

with casters, the gas line connection shall be made with a

connector that complies with the Standard for Connectors for

Movable Gas Appliances, ANSI Z21.69 (in U.S.A.), or, if applicable, Connectors for Movable Gas Appliances, CAN/CGA-6.16

(in Canada), as well as a quick-disconnect device that complies

with the Standard for Quick-Disconnect Devices for Use With

Gas Fuel, ANSI Z21.41 (in U.S.A.), or, if applicable, QuickDisconnect Devices for Use With Gas Fuel, CAN1-6.9 (in Canada).

C. Gas Conversion

Where permitted by local and national codes, it is possible to

convert ovens from natural to propane gas, or from propane to

natural gas. Use the appropriate Middleby Marshall Gas

Conversion Kit for the specific oven model.

WARNING

The terms of the oven's warranty require all start-ups,

conversions and service work to be performed by a Middleby

Marshall Authorized Service Agent.

ENGLISH

Inlet pressure tap

(where incoming

gas pressure is

measured)

Manual

shutoff valve

On/Off Knob

Always leave in

ON position

Combination Gas

Control Valve

(Safety Regulator)

Manifold pressure tap

(where manifold gas

pressure is measured)

High Flame

Solenoid Valve

Figure 2-26 - Gas Burner and Piping Assembly

Burner

Blower

Gas Burner

Pilot pressure tap

(where pilot gas

pressure is measured)

Low Flame

Bypass Line

15

Model PS360EWB Only

Modulating gas valve

NOTE: PS360EWB ovens use a

modulating gas valve INSTEAD OF

a high flame solenoid valve and

low-flame bypass line.

Page 16

SECTION 3 - OPERATION

I. LOCATION AND DESCRIPTION OF CONTROLS

ENGLISH

All ovens except PS360EWB and PS360WB70 PS360EWB and PS360WB70 only

D.

Conveyor Speed

(or "

")

controller(s)

Fig. 3-1 - Control Panel

D.

Conveyor Speed

(or "

")

controller(s)

E.

Digital Temperature

")

(or "

controller

A.

"BLOWER"

(or "

switch

A.

B.

C.

B.

"HEAT"

(or "

")

")

switch

C.

"CONVEYOR"

(or "

")

switch

"BLOWER" Switch: Turns the blowers and

cooling fans on and off. The HEAT Switch has no

effect unless the BLOWER Switch is in the ON

position.

E.

Digital Temperature

")

(or "

controller

A.

"BLOWER"

")

(or "

switch

D.

Conveyor Speed Controller: Adjusts and dis-

B.

"HEAT"

(or " ")

switch

C.

"CONVEYOR"

(or "

")

switch

plays the bake time. Single-belt ovens have one

controller. Split belt ovens have one controller for

each conveyor belt, labeled "FRONT" and "BACK."

For tandem and double tandem ovens, this

"HEAT" Switch: Allows the gas burner to light.

control is present only on the left oven section(s).

Activation of the gas burner is determined by the

settings on the Digital Temperature Controller.

E.

"CONVEYOR" Switch: Turns the conveyor drive

motor on and off. For tandem and double tandem ovens, this switch is present only on the left

Digital Temperature Controller: Continuously

monitors the oven temperature. Settings on the

Digital Temperture Controller control the activa-

tion of the gas burner.

oven section(s).

NOT SHOWN:

F. Machinery Compartment Access Panel Safety Switch:

Disconnects electrical power to the controls and the blowers when the machinery compartment access panel is

opened. The panel should only be opened by authorized

service personnel.

16

Page 17

II. NORMAL OPERATION - STEP-BY-STEP

A. DAILY STARTUP PROCEDURE

1. Check that the circuit breaker/fused disconnect is in the on

position. If the oven is equipped with a window, check that

the window is closed.

2. Turn the "BLOWER" (or )

switch to the ON (or "I")

position.

or

SECTION 3 - OPERATION

7. Wait for the oven to heat to the setpoint temperature. Higher

setpoint temperatures will require a longer wait. The oven

can reach a temperature of 500°F (232°C) in approximately

5 minutes.

8. (Optional) Press the Temperature ( ) key to show

the Actual Temperature

in the display, and wait for

the "ACTUAL TEMP" light

to turn on. This allows

you to monitor the oven

temperature as it rises to

the setpoint.

wait

for

ENGLISH

3. Turn the "CONVEYOR" (or

) switch to the ON

(or "I") position.

4. If necessary, adjust the

conveyor speed setting

by turning the three

thumbwheels to change

the displayed bake time.

5. Adjust the temperature controller to a desired set tempera-

ture, if necessary.

Press the Set Point

and Unlock keys at

the same time. Wait

for the "SET PT" light

to turn on.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press the Up Arrow

and Down Arrow

Keys as necessary

to adjust the setpoint.

+

or

or

mins secs

thumbwheels

wait

for

9. Allow the oven to preheat for 10 minutes after it has reached

the set point temperature.

B. DAILY SHUTDOWN PROCEDURE

1. Turn the "HEAT" (or

and "BLOWER" (or

switches to the "OFF" (or

"O") position. Note that

the blowers will remain in

operation until the oven

has cooled to below

200°F (93°C).

)

)

+

- - - - - or - - - - -

+

2. Make certain that there

are no products left on the

conveyor inside the oven.

Turn the "CONVEYOR" (or

) switch to the "OFF"

(or "O") position.

3. If the oven is equipped with a window, open the window to

allow the oven to cool faster.

4. After the oven has cooled and the blowers have turned off,

switch the circuit breaker/fused disconnect to the off position.

or

6. Turn the "HEAT" (or )

switch to the "ON" (or "I")

position, and wait for the

"HEAT ON" light to turn

on.

or

wait

for

IMPORTANT

On gas ovens, if the "HEAT ON" light will not illuminate, OR

if the oven does not heat, the gas burner may not have lit.

Turn the "HEAT" (

(

) switches to the "OFF" ("O") position. Wait for AT

LEAST FIVE MINUTES before restarting the oven. Then,

repeat the Daily Startup procedure.

), "BLOWER" ( ), and "CONVEYOR"

CAUTION

In case of power failure, turn all switches to the OFF (or "O")

position, open the oven window, and remove the product.

After the power has been restored, perform the normal

startup procedure.

The burner will not operate and gas will not flow through

the burner without electric power. No attempt should be

made to operate the oven during a power failure.

17

Page 18

SECTION 3 - OPERATION

III. QUICK REFERENCE: DIGITAL TEMPERATURE CONTROLLER

ENGLISH

"HEAT ON" Light

Lights when the

burner is in operation. Note that on all

ovens EXCEPT the

PS360EWB, this light

cycles on and off during normal operation.

"SP LOCK" Light

Lights when the set

point is locked out

from changes. This

setting can only be

changed by service

personnel.

Display

Shows the Set

Point or the Actual

Temperature in

degrees Fahrenheit (F) or Celsius

(C).

"SET PT" (setpoint)

Light

Lights when the set

point is shown in the

display.

OVERTEMP Light

Lights when the

oven temperature is

greater than 650°F

(343°C). Refer to

Quick Reference:

Troubleshooting in

this section.

Temperature Key

Press this key

once to view the

Actual Temperature in the Display.

Unlock Key

Press this key together

with the Set Point Key

to allow the Set Point

to be changed.

Changes can only be

made for 60 seconds.

Up Arrow and Down Arrow

Keys

Press these keys to adjust

the Set Point up or down. If

the Set Point will not

change, refer to

Key and Unlock Key in this

section.

Set Point

"ACTUAL TEMP"

Light

Lights when the

Actual Temperature is shown in

the display.

Service Key

For use by service

personnel only.

Set Point Key

Press this key together with the

Unlock Key to allow the Set Point

to be changed.

Changes can

only be made for

60 seconds.

18

Page 19

V. QUICK REFERENCE: TROUBLESHOOTING

SYMPTOM PROBLEM SOLUTION

SECTION 3 - OPERATION

light is lit, food product is

undercooked

Oven will not

turn on at all

Oven shuts down shortly

after it is turned on

appears in display,

oven is not heating

The oven temperature exceeded 650°F (343°C), and

the burner was automatically shut down.

Electrical power may not be

reaching the oven, or the

controls may be set incorrectly.

The gas burner did not light

within 90 seconds of turning the "HEAT" (or

Switch to the ON (or "I")

position. This automatically

engages a safety lockout

mode.

The oven did not reach

200°F (93°C) within 15 minutes of startup, and the oven

has stopped heating.

Follow the procedures under Daily Shutdown Procedures in

this section to shut down the oven. Contact your Middleby

Marshall Authorized Service Agent to determine and correct the

cause of the condition to prevent damage to the oven.

Check that the circuit breaker/fused disconnect is turned on.

Check that the "BLOWER"

position. The burner cannot engage until the blowers are in

operation.

Turn the "HEAT" (or

(or )switches to the "OFF" (or "O") position.

)

Wait for AT LEAST FIVE MINUTES before restarting the oven.

Repeat the Daily Startup procedure.

Turn the "HEAT" (or

(or )switches to the "OFF" (or "O") position.

Wait for AT LEAST FIVE MINUTES before restarting the oven.

Repeat the Daily Startup procedure.

(or ) Switch is in the ON (or "I")

), "BLOWER" (or ), and "CONVEYOR"

), "BLOWER" (or ), and "CONVEYOR"

ENGLISH

Oven will not heat

Oven is operating, but

little or no air is blowing

from air fingers

Conveyor moves with a

jerky motion, or will not

move at all

Food products are

overcooked or

undercooked.

Controls may be set incorrectly.

Air fingers may have been

reassembled incorrectly

after cleaning.

Conveyor may be jammed

on an object in the oven, or

conveyor belt or drive chain

tension may be incorrect.

Controls may be set incorrectly.

Check that the Set Point is correctly set.

Check that both the "BLOWER" (or ) and "HEAT" (or )

Switches are in the ON (or "I") position.

If the oven still will not heat, turn the "HEAT" (or ) , "BLOWER"

(or ), and "CONVEYOR" (or )switches to the "OFF" (or "O")

position.

Wait for AT LEAST FIVE MINUTES before restarting the oven.

Repeat the Daily Startup procedure. Check that the Set Point

is above 200°F (93°C).

Turn the oven off, and allow it to cool. Disconnect electrical

power to the oven.

Refer to Section 4,

bling the air fingers.

Turn the oven off, and allow it to cool. Disconnect electrical

power to the oven.

Check if the conveyor is blocked by an object inside the oven.

Refer to Section 4,

the conveyor and drive chain tension.

Check that the set temperature and bake time settings are

correct.

Maintenance, for instructions on reassem-

Maintenance, for instructions on checking

IF THESE STEPS FAIL TO RESOLVE THE PROBLEM, CONTACT YOUR LOCAL MIDDLEBY MARSHALL

AUTHORIZED SERVICE AGENT. A SERVICE AGENCY DIRECTORY IS SUPPLIED WITH YOUR OVEN.

19

Page 20

SECTION 4 - MAINTENANCE

ENGLISH

Before ANY cleaning or servicing of the oven, perform the following procedure:

1. Switch off the oven and allow it to cool. Do NOT service the oven while it is warm.

2. Turn off the electric supply circuit breaker(s) and disconnect the electric supply to the oven.

3. If it is necessary to move the oven for cleaning or servicing, disconnect the gas supply connection before moving

the oven.

When all cleaning and servicing is complete:

1. If the oven was moved for servicing, return the oven to its original location. Adjust the legs so that they are seated

properly on the floor.

2. Reconnect the gas supply.

3. Reconnect the electrical supply.

4. Turn on the full-flow gas safety valve. Test the gas line connections for leaks using approved leak test substances

or thick soap suds.

5. Turn on the electric supply circuit breaker(s).

6. Perform the normal startup procedure.

Possibility of injury from moving parts and electrical shock exists in this oven. Switch off and lockout/tagout the electric

supply BEFORE beginning to disassemble, clean, or service any oven. Never disassemble or clean an oven with the

BLOWER switch or any other circuit of the oven switched on.

WARNING

WARNING

CAUTION

NEVER use a water hose or pressurized steam-cleaning equipment when cleaning this oven. DO NOT use excessive

amounts of water, to avoid saturating the oven insulation. DO NOT use a caustic oven cleaner, which can damage the

aluminized bake chamber surfaces.

NOTE

ANY replacement parts that require access to the interior of the oven may ONLY be replaced by a Middleby Marshall

Authorized Service Agent.

NOTE

It is strongly recommended that the 3-Month Maintenance and 6-Month Maintenance procedures in this section be

performed ONLY by a Middleby Marshall Authorized Service Agent.

20

Page 21

I. MAINTENANCE - DAILY

A. Check that the oven is cool and the power is disconnected,

as described in the warning on Page 20.

B. Clean the outside of the oven with a soft cloth and mild

detergent.

C. Clean ALL of the cooling fan grills and vent openings with a

stiff nylon brush. Refer to Figures 4-1, 4-2, and 4-3 for the

locations of the grills and vents.

D. Check that ALL cooling fans are operating properly.

CAUTION

If a cooling fan is not operating correctly, it must be replaced

IMMEDIATELY. Operating the oven without adequate cooling can seriously damage the oven's internal components.

E. Clean the conveyor belts with a stiff nylon brush. This is

more easily accomplished by allowing the conveyor to run

while you stand at the exit end of the conveyor. Then, brush

the crumbs off the conveyor as it moves.

F. Remove and clean the crumb trays. Be sure to replace the

trays in the same positions from which they were removed, because they are NOT identical. Refer to the

drawings on Page 10 in the

Installation section.

SECTION 4 - MAINTENANCE

Figure 4-1 - Cooling Fan/Vent Locations:

All ovens except PS360EWB and PS360WB70

Vents in top rear

edge of upper

oven

FRONT

Vents in floor

of lower oven

2 rear fans,

upper and lower ovens

REAR

Figure 4-2 - Cooling Fan/Vent Locations: PS360EWB

2 front fans,

upper and lower ovens

Vents on each side of

rear panel, upper and

lower ovens

Vents in top rear

edge of upper

ENGLISH

oven

G. OVENS EQUIPPED WITH WINDOWS ONLY: Clean the

window in place.

FRONT

Vents on each side

of floor panel of

lower oven

REAR

Figure 4-3 - Cooling Fan/Vent Locations: PS360WB70

2 front fans,

upper and

lower ovens

2 side vents,

upper and lower ovens

21

FRONT

REAR

Page 22

SECTION 4 - MAINTENANCE

II. MAINTENANCE - MONTHLY

NOTE

When removing the conveyor, refer to the drawings on Pages 1213 in the Installation section.

ENGLISH

A. Check that the oven is cool and the power is disconnected,

as described in the warning on Page 20.

B. Remove the drive motor shroud and conveyor extension

covers from the oven. Disconnect the drive chain from the

sprocket on the drive shaft of the conveyor.

C. Slide the conveyor out of the oven.

NOTE

Split belt conveyors can only be removed from the end of the

oven with the drive motor.

Single-belt conveyor assemblies may be removed from

either end of the oven. If it is to be removed from the end of

the oven without the drive motor, the drive sprocket assembly must be removed.

To remove the drive sprocket (if necessary), loosen the set

screw on the conveyor collar as shown in Figure 2-12 (on

Page 12). Then, pull the sprocket assembly straight out.

D. Remove the end plugs from the oven. The end plugs are

shown in Figure 1-1, on Page 4 of this Manual.

E. Slide the air fingers and blank plates out of the oven, as

shown in Figure 4-4. AS EACH FINGER OR PLATE IS

REMOVED, WRITE A "LOCATION CODE" ON IT WITH A

MARKER to make sure that it can be reinstalled correctly.

Example of markings:

(Top Row) T1 T2 T3 T4 T5 T6

(Bottom Row) B1 B2 B3 B4 B5 B6

F. Disassemble the air fingers as shown in Figure 4-5. AS

EACH FINGER IS DISASSEMBLED, WRITE THE "LOCATION CODE" FOR THE FINGER ON ALL THREE OF ITS

PIECES. This will help you in correctly reassembling the air

fingers.

CAUTION

Incorrect reassembly of the air fingers will change the

baking properties of the oven.

G. Clean the air finger components and the interior of the

baking chamber using a vacuum cleaner and a damp cloth.

Refer to the boxed warnings on Page 20 for cleaning

precautions.

H. Reassemble the air fingers. Then, replace them in the oven,

using the "location code" as a guide.

I. Replace the end plugs on the oven.

J. Reassemble the conveyor into the oven. If the drive sprocket

was removed when installing the conveyor, replace it at this

time.

K. Reattach the drive chain.

L. Check the tension of the conveyor belt as shown in Figure

2-15 (on Page 12). The belt should lift between 3-4" (75100mm). DO NOT OVERTIGHTEN THE CONVEYOR BELT.

If necessary, the belt tension can be adjusted by turning the

conveyor adjustment screws, located at the idler (right) end

of the conveyor.

M. Replace the drive motor shroud and the conveyor exten-

sions.

22

Figure 4-4 - Removing Air Fingers and Plates

Blank Plate

Air Finger

Figure 4-5 - Disassembling the Air Fingers

Manifold

Inner plate

Outer Plate

2

Pull outer plate

straight up

and off

Swing ends of inner plate and

manifold apart

4

Pull inner plate

upwards, and

then away from

manifold

1

Step on lip of manifold

3

Page 23

III. MAINTENANCE - EVERY 3 MONTHS

SECTION 4 - MAINTENANCE

IV. MAINTENANCE - EVERY 6 MONTHS

A. Check that the oven is cool and the power is disconnected,

as described in the warning on Page 20.

B. Vacuum both of the blower motors, and their surrounding

compartments, using a shop vacuum.

C. Tighten all electrical control terminal screws.

D. For split belt ovens ONLY, disassemble, clean and lubricate

the conveyor shaft components as described below.

1. Remove the motor shroud, conveyor extensions, and

conveyor as described in Part II, Monthly Maintenance.

2. Remove the master links from each conveyor belt.

Then, roll the belts up along the length of the conveyor

to remove them from the frame.

3. Remove the two conveyor adjustment screws from the

idler end of the conveyor frame, as shown in Figure 4-

6.

4. For PS360EWB and PS360WB70 ovens, remove the

socket head screw as shown in the inset drawing.

Then, loosen the locking collar set screw. Push the

shaft assembly toward the locking collar until it is free.

5. Remove the idler shaft assembly from the conveyor.

6. Pull apart the two sections of the idler shaft. Clean the

shafts thoroughly using a rag. Then, lubricate both the

extended shaft and the interior of the hollow shaft using

a light food-grade lubricant.

CAUTION

DO NOT lubricate the shafts using WD40 or a similar

product. This can cause the shafts to wear rapidly.

7. Before reassembling the shafts into the conveyor frame,

check that they are oriented properly. Remember that

unequal-width split belt ovens should ALWAYS have

the narrower belt at the front of the oven.

8. Reassemble the idler shaft into the conveyor. For all

ovens except the PS360EWB and PS360WB70,

make

sure that the bronze washer is in place between the two

sections of the shaft. See Figure 4-8.

9. Loosen the set screw on both of the conveyor drive

sprockets. Then, remove the sprockets from the shaft.

10. Loosen the locking collar set screw, as shown in Figure

4-7. For PS360EWB and PS360WB70 ovens, remove

the socket head screw shown in the inset drawing.

11. Push the drive shaft to the right, then lift it free of the

conveyor frame. Then, disassemble and lubricate the

two sections of the drive shaft as described in Step 5.

12. Before reassembling the shafts into the conveyor frame,

check that they are oriented properly. Remember that

unequal-width split belt ovens should ALWAYS have

the narrower belt at the front of the oven.

13. Reassemble the drive shaft into the conveyor. Check

that the nylon spacer is in place, as shown in Figure 4-

8. Also, for all ovens except the PS360EWB and

PS360WB70, check that the bronze washer is in place

between the two sections of the shaft.

14. Replace the drive sprockets. Reassemble the belts

and master links onto the conveyor, and replace the

conveyor in the oven.

15. Reassemble the motor shroud and conveyor extensions onto the oven.

A. Check that the oven is cool and the power is disconnected,

as described in the warning on Page 20.

B. Check for excessive wear on the conveyor drive motor

brushes. The brushes should be replaced if they have worn

to less than 1/4" (6.4mm) in length.

C. Clean and inspect the burner nozzle and electrode assem-

bly.

D. Check (and clean, if necessary) the oven venting system,

including the flue.

E. Check the conveyor drive shaft bushings and spacers.

Replace the components if they are worn.

Figure 4-6 - Split Belt Idler Shaft

Collar

PS360EWB

and

PS360WB70

Only

All ovens

Conveyor adjustment

screw (2)

PS360EWB and

PS360WB70 Only

Screw

Figure 4-7 - Split Belt Drive Shaft

Screw

All ovens

Locking collar

PS360EWB and

PS360WB70 Only

Figure 4-8 - Washers and Spacer

All ovens

Nylon spacer

on drive shaft

ONLY

All ovens

except

PS360EWB and

PS360WB70

Bronze washer on

BOTH idler and

drive shafts

23

ENGLISH

Page 24

SECTION 4 - MAINTENANCE

V. KEY SPARE PARTS KIT - Available separately. See Figure 4-9.

ENGLISH FRANÇAIS ESPAÑOL

page 1 page 25 página 49

A. Key Spare Parts Kit components (all ovens)

Item Description Part Number

1 1 Kit, Digital Temperature Controller 36939

2 1 Conveyor Drive Motor 27384-0008

3 2 Brushes, Conveyor Drive Motor 22450-0052

4 1 Kit, Conveyor Speed Controller 42810-0133

5 1 Conveyor Control Pickup Assembly 27170-0263

6 1 Thermocouple 33984

7a 1 Cooling Fan (PS310, 314, 360, 360Q, 27392-0002

360S, 360WB)

7b 1 Cooling Fan (PS360EWB, WB70) 36451

8a 1 Blwr Mtr, 1 Ph, 1/3 HP (PS310, 314, 360, 360S) 27381-0023

8b 1 Blower Motor, 3 Ph, 1/3 HP (PS310, 314, 360) 27381-0024

8c 1 Blower Motor, 1 Ph, 1/4 HP (PS360Q) 27381-0054

8d 1 Blower Motor, 1 Ph, 1/2 HP (PS360WB) 27381-0075

8e 1 Blower Motor, 1 Ph, 1 HP (PS360EWB, WB70) 31432

Fig. 4-9 - Key Spare Parts Kit

12 34 5 6

B. Additional Key Spare Parts Kit components for gas

ovens

Item Description Part Number

9 1 Kit, Ignition Module 42810-0114

10a 1 Burner Blower/Motor Assembly 27170-0011

(PS310, 314, 360, 360Q, 360S, 360WB)

10b 1 Burner Blower/Motor Assembly (PS360EWB, WB70) 38811

11 1 Solenoid Valve (All ovens EXCEPT PS360EWB) 28091-0017

12 1 Modulating Valve (PS360EWB) 32570

13 1 Amplifier, Modulating Valve (PS360EWB) 31651

14 1 Air Switch (PS360EWB, WB70) 32102

7

91011121314

8

IMPORTANT

An electrical wiring diagram for the oven is located inside the

machinery compartment or control compartment.

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 USA (847)741-3300 FAX (847)741-4406

24-Hour Service Hotline: 1-(800)-238-8444

www.middleby.com

24

Loading...

Loading...