Page 1

CONVEYORS OF EXCELLENCE

AIA File No.:

PS220-R68

Item No.:

PS220-R68 Double Unit

Principle

Middleby Marshall PS Series Conveyor ovens bake both

faster and at a lower temperature than other ovens.

Patented vertical columns of hot air move heat

aerodynamically instead of using high temperatures.

The streams of hot air remove the boundary layers of

cool heavy air which tend to insulate the product. This

gives very rapid baking without burning. All Middleby

ovens are designed to cook a multitude of products,

including pizza, seafood, bagels, Mexican, etc.

Double Models Direct Gas Fired

Conveyor Oven

General Information

PS220 conveyor ovens feature a 40.5" cooking

chamber, and a patented “Jet Sweep” convection

process that delivers constant heat to the chamber. All

ovens feature microprocessor controlled bake

time/conveyor speed. Six adjustable jet fingers and

front-loading window are standard. Ovens have

stainless steel front, sides and top. All ovens include

extra fan belt, installation kit, restraining cable, and 4'

AGA flex hose. Heating is controlled in 8" adjustable

zones. Top and bottom are independently adjustable.

The conveyor drive is reversible. Conveyor belt provides

automatic delivery when product is finished. Front

loading window with cool handle design allows product

with different bake times to be cooked consistently

regardless of loading.

Special Features

PS220 Units are stackable two high, with tandem options

available. Split belt option and left hand controls are also

available upon request.

Conserves Energy

Middleby ovens provide very efficient heat transfer to

product. Energy is conserved as air is recycled from

heater to product, with minimum flue or vent loss.

Cleanability

PS220 ovens are designed for easy cleaning.

Removable parts include: crumb pans, end panels, air

fingers and a folding conveyor belt assembly for easy

removal.

Easily Serviced

Control compartment is designed for quick and easy

access. All electrical controls are door mounted.

Warranty

All PS220 Models have a one year parts and labor

warranty . Oven start-up and demonstration are included

at no additional charge (USA only).

Ventilation

For installation under a ventilation hood only .

Form 4106

A MIDDLEBY COMPANY

P.O. Box 1820

Elgin, Illinois 60121 USA

1-800-323-5575 Fax 800-635-4725

Page 2

Middleby Marshall

PS220-R68 Series

Double Models

Direct Gas Fired

Conveyor Oven

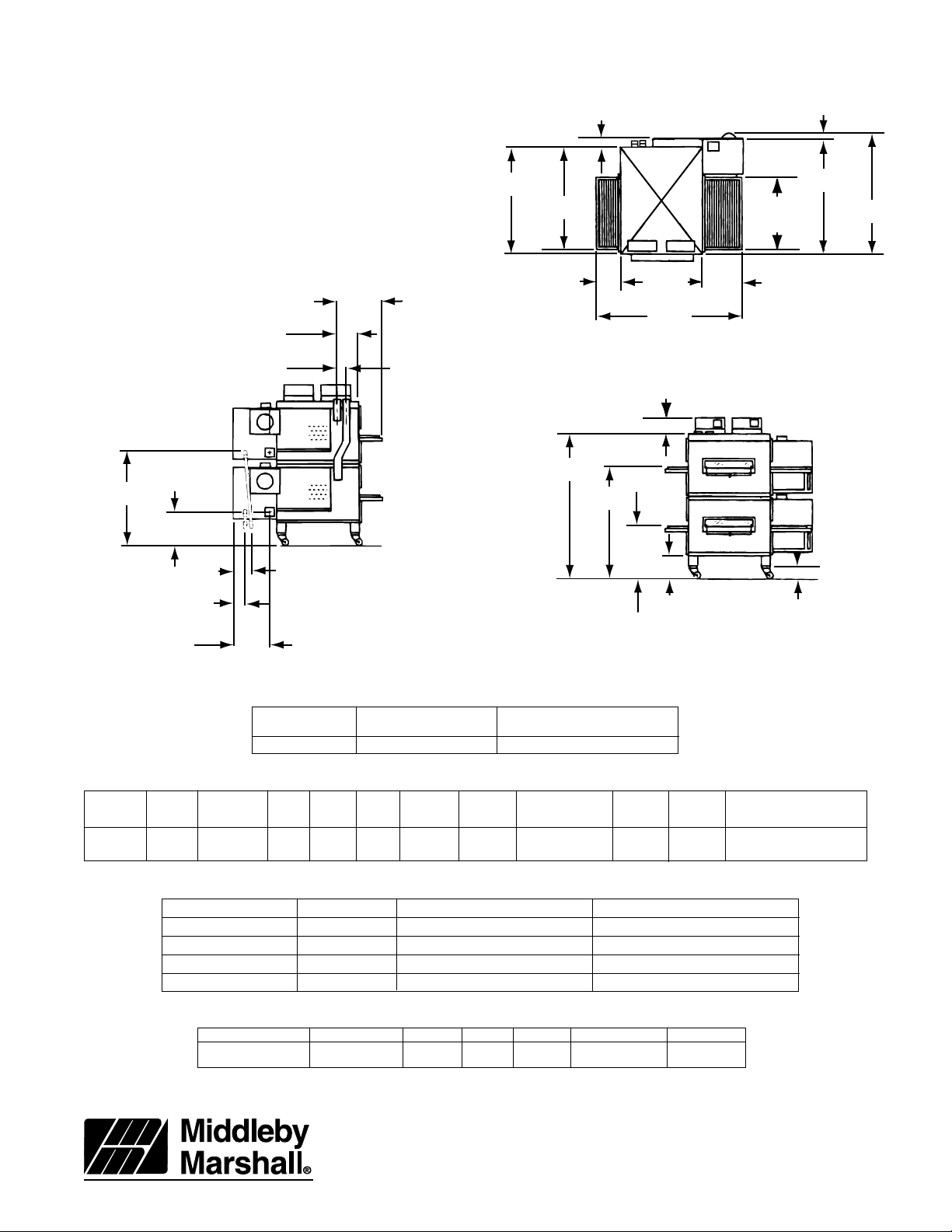

Baking chamber opening: 3.5" (88.9 mm).

Scale .25" (6.35 mm) = (304.8 mm) approx.

NOTE: All Figures In Parentheses Are In Millimeters

All models also available with left hand controls.

*

38.5"

(977.9)

36.5"

(927.1)

3"

(76.2)

Top View

20"(508)

Cooking

Zone

1"

(25.4)

44.75"

(1136.65)

45.75"

(1162.5)

47"

(1193.8)

Rear View

20"

(508)

7"

(177.8)

5"

(127)

10"

9.75"

(247.65)

(368.3)

14.5"

19.75"

(501.65)

3.125"

(79.375)

(254)

69.5"

(1765.3)

58"

(1473.2)

27.5"

(698.5)

RECOMMENDED MINIMUM CLEARANCES

Rear of Oven Left Conveyor Right Conveyor Extension

to Wall Extension to Wall to Wall (control panel side)

1" (25.4) 0" 18" (457.2)

68"

(1727.2)

40.5"

(1028.7)

Front View

9.5"

(241.3)

12.5"

(317.5)

17.5"

(444.5)

(165.1)

6.5"

Heating Bake Belt

Zone Chamber Width

PS220R68

40.5" 5.5 sq. ft. 20" 77" 68" 45.75" 550° 2 min., 40 sec.

(1028.7) (.? sq. m) (508) (1955.8) (1727.2) (1162.05) (287°C) to 29 min., 50 sec.

Natural Gas 1 or 2 ovens 2" (508) NPT .75" (19.05) NPT each oven 6" (152.4) to 14" (355.6) water column

Gas 3 or 4 ovens 2.5" (63.5) NPT .75" (19.05) NPT each oven 6" (152.4) to 14" (355.6) water column

Propane Gas 1 or 2 ovens 1.5" (38.1) NPT .75" (19.05) NPT each oven 11.5" (292.1) to 14" (355.6) water column

Propane Gas 3 or 4 ovens 2" (50.8) NPT .75" (19.05) NPT each oven 11.5" (292.1) to 14" (355.6) water column

A MIDDLEBY COMPANY

GENERAL INFORMATION

Height Length Depth Operating Time Wt. Cube Per

Max. Bake Ship Ship Power

Temp. Range Per Cavity Per Cavity Cavity

925 lbs. 132 ft.

3

GAS SUPPLY PROVIDED BY CUSTOMER

Min. Gas Pipe Size Gas Valves (full flow gas shut-off valve) Req'd Supply Gas Pressure

ELECTRICAL RATINGS

Electric Rating

(Gas Fired Ovens) (each oven)

Voltage Phase HZ Amps Grounding Breakers

208 or 240 1 50/60 4.1 3 pole, 4 wire

Above specifications subject to change without notice.

*

15 amp,

Middleby Marshall Inc.

P.O. Box 1820

Elgin, IL 60121 USA

1-800-323-5575

Form 4106 (1/96) FAX (800) 635-4725

120,000 BTU/HR per cavity

Loading...

Loading...