Page 1

Application

CTX heavy-duty, energy-efficient

conveyor ovens are designed for direct

baking on the conveyor belt, thereby

producing a hearth bake product with

distinctive results, which are excellent for

pizza, pita breads and rolls.

General Information

Heavy-duty, electric, conveyor oven is

designed to be mounted on a modular

base up to four decks high. Oven

chamber is equipped with 18" wide, highcarbon steel, wire mesh hearth belt. The

oven is equipped with pre-programmed

self-cleaning cycle. Overall dimensions

are 92"W x 35

1

⁄2"D x 14"H. The oven

chamber is 50"W x 18"D x 5

1

⁄2"H.

Construction

The frame is constructed of 14-gauge

steel and reinforced structural steel

welded together. Walls and supporting

structure are built of 16-gauge aluminized

steel. The base assembly is constructed

of 10-gauge steel. The frame and base

assembly have a black enamel finish.

Infrared heat emitters are enclosed in high

strength thermal conductive steel plates

and are placed above and below the oven

chamber. The high temperature bearings

have excellent wear characteristics, and

are self-lubricating and self-aligning.

Insulation

The oven is fully insulated with 3" of

insulation.

Electrical

Ovens can be ordered for 208VAC or

230VAC electrical utilities. The total power

input on 208VAC is 18.0kW; 230VAC is

18.0kW. The average operating power

input is 8.4kW for 208VAC and 6.45kW

for 240VAC. Ovens are wired for 3-phase

electrical connection on 208 and 230VAC.

An electrical cord knock-out is provided at

the rear on the exit side of the oven along

with an access panel for making electrical

connections.

Heating

Heating is accomplished with six far

infrared emitters, three above and three

below the oven chamber.

Controls

A programmable microprocessor controls

the temperature from 200° to 950°F, and

the cook time from 1.2 to 240 minutes.

The oven can be controlled in three upper

and three lower zones. Thermal sensors,

located on the contactor and control panel

compartments, will give a warning if either

control gets too warm. The solid state

relays are specially designed for this

application and are high temperature

controls. The control areas have a fan

filter to keep the area around the motor

clean. There is also a standby mode for

energy conservation.

MenuSelect

®

The patented MenuSelect®feature allows

the operator to preset up to six different

time and temperature combinations into

the control that can be recalled by

pressing the appropriate preset key, then

the computer automatically adjusts time

(belt speed) and temperatures. A ready

message is displayed when the desired

temperatures are reached.

Agency Data

The Hearth Bake 4 (HB4) is listed by

Underwriters’ Laboratories, Inc., and NSF.

Warranty

Warranted for one year covering parts

and labor under the “No Quibble

Warranty”. USA only.

Electrical Ordering Information*

❐ 208VAC, 3-Phase

❐ 230VAC, 3-Phase

❐ 380-415V, 3-Phase, Non-agency

available

*Consult the electrical data on the rear

side of this specification sheet for

connected kW and amperage loading

representing your electrical utility.

Accessories

❐ ACST40SH - Base Assembly, 24"

❐ ACST40TL - Base Assembly, 36"

❐ ACHCCTXZ - Set of Two Heat Curtains

❐ ACET - Exit Tray, 15"

❐ ACETL - Exit Tray, 22

1

⁄2"

❐ ACSKZ4 - Service Kit

❐ ACSKHBI - Service Kit HB International

❐ ACSBHB4 - Stacking Bracket/Insulating

Panel

Foodservice Equipment

Job_________ Item#_________

Conveyor Oven

Hearth Bake 4 (HB4) with MenuSelect

®

Form 2204

HB4 - Two Decks

On Optional 24" Base.

Infrared Conveyor Ovens

A MIDDLEBY COMPANY

1400 Toastmaster Drive

Elgin, Illinois 60120 USA

(847) 741-3300 Fax: (847) 741-0015

www.middleby.com

Middleby

Marshall

Page 2

We reserve the right to change specifications and product design

without notice. Such revisions do not entitle the buyer to

corresponding changes, improvements, additions or replacements

for previously purchased equipment.

Conveyor Oven

Hearth Bake 4 (HB4)

with MenuSelect

®

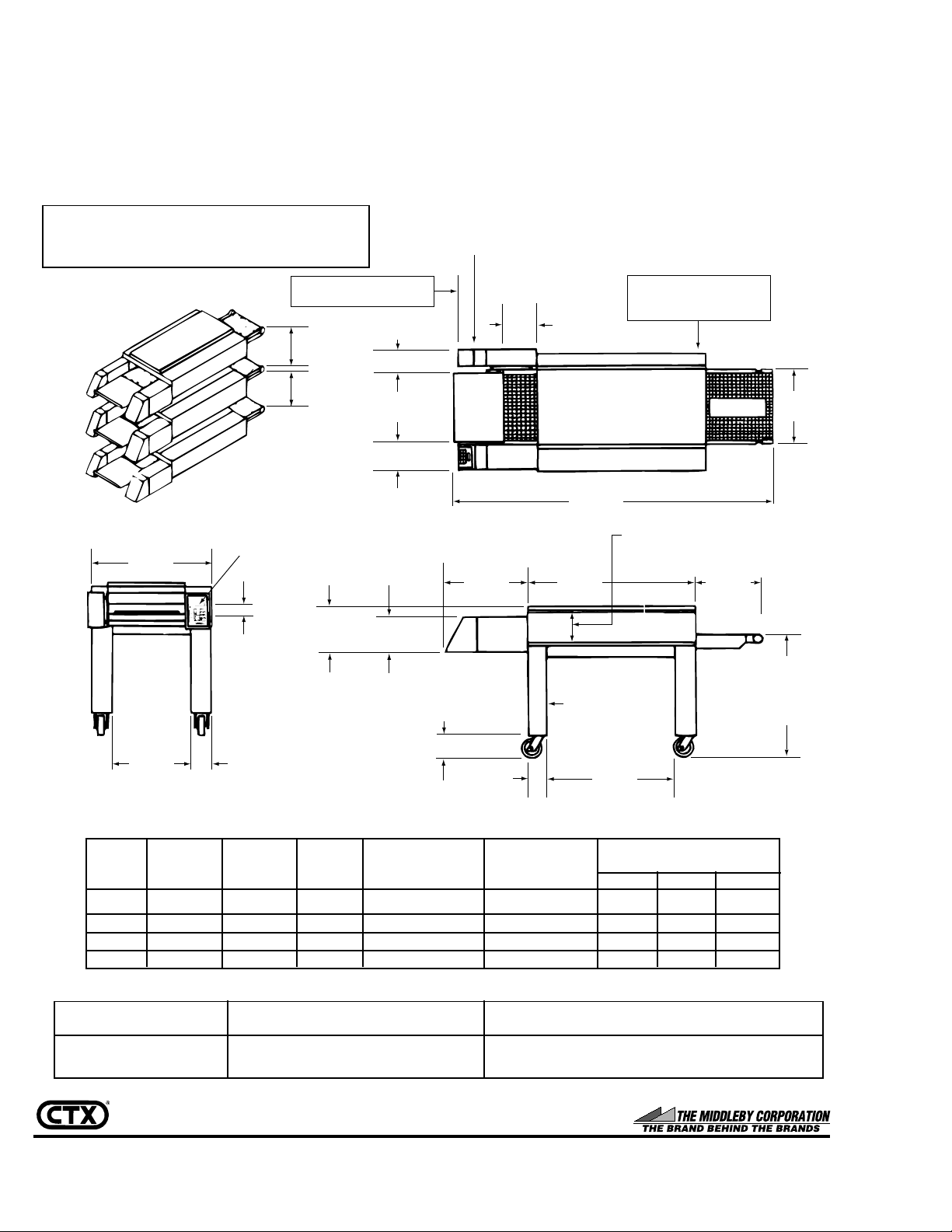

ALLOW 33" (838.2) FROM

THIS END TO SIDE WALL

FIELD

WIRING

BOX

7.5"

(190.5)

ALLOW 8.5" (215.9)

MINIMUM FROM THIS

SURFACE TO BACK WALL

18"

(457.2)

INFEED

BELT LENGTH

77"

(1955.8)

92"

(2336.8)

EXIT

22.5"

(571.5)

7.5"

(190.5)

{

11.75" WITH

(298.45) INSULATED PANEL

10.75" WITHOUT

(273.05) INSULATED PANEL

24"

(609.6)

OR

36"

(914.4)

BELT LINE

BASE

19"

(482.6)

50"

(1270)

22.5"

(571.5)

14"

(355.6)

10.5"

(266.7)

6.5"

(165.1)

6"

(152.4)

37.5"

(952.5)

23"

(584.2)

6"

(152.4)

2.703"

(68.658)

WITH

CURTAIN

IN

PLACE

CONTROL

PANEL

35.5"

(901.7)

5.5"

(139.7)

11"

(279.4)

11"

(279.4)

END VIEW

SIDE VIEW

TOP VIEW

NOTE: ALL FIGURES IN PARENTHESES ARE IN MILLIMETERS

1400 Toastmaster Drive, Elgin, IL 60120-9272 USA • (847) 741-3300 • Fax: (847) 741-0015

www.middleby.com

Printed in U.S.A. 5/99 Form 2204

AVG

MODEL CONNECTED OPERATING CONNECTED LOAD

NO. VOLTS PHASE Hz kW kW L1 L2 L3

HB4 208 3 50/60 18.0 8.40 52 52 52

HB4 230 3

50/60

17.0 6.45 45 45 45

HB4Y 380 3

50

13.3 5.7 25.0 27 25.0

HB4Y 415 3

50

20.1 12 27.5 30 27

ELECTRICAL DATA

SHIPPING WEIGHTS OVEN - SHIPPING DIMENSIONS

NET WEIGHT OVEN OVEN 24" BASE 36" BASE LENGTH WIDTH HEIGHT (without base)

500 lbs. 620 lbs. 160 lbs. 190 lbs. 92" 35.5" 14"

(2336.8) (901.7) (355.6)

DIMENSIONS

Loading...

Loading...