Page 1

PS570G SERIES GAS FIRED:

A MIDDLEBY COMPANY

Parts Manual

with Wiring Diagrams

for domestic and standard export ovens

SPL 102406-PF-BD

October 24, 2006

Replaces

SPL 071406-PF-BD

July 14, 2006

Serial # Code (Nine Digit Code)

(for units produced prior to mid-July, 2006)

First 4 digits - order of production

Fifth digit - model specific

Sixth and Seventh digit - month of production

Eighth and Ninth digit - year of production

Serial # Code (Ten Digit Code)

(for units produced after mid-July, 2006)

First 5 digits - order of production

Sixth digit - model specific

Seventh and Eighth digit - month of production

Ninth and Tenth digit - year of production

The PS570G replaced the PS570S.

They are different!

The PS570G requires a 208/240V, 1Phase Power Supply.

Therefore the Control Circuit is 208/240V.

A Modulating Gas Valve and Signal Amplifier Board were

incorporated to reduce energy consumption and increase

cooking efficiency.

We call this our Energy Management System (EMS).

Serial Tag Location

©2005 Middleby Marshall Inc.

PS570G Single

Oven Shown

Table of Contents: Page 2

www.middleby.com

email: techsupport@middleby.com

1-847-741-3300 fax 1-847-741-4406

1400 Toastmaster Drive • Elgin, IL 60120

Page 2

Table of Contents

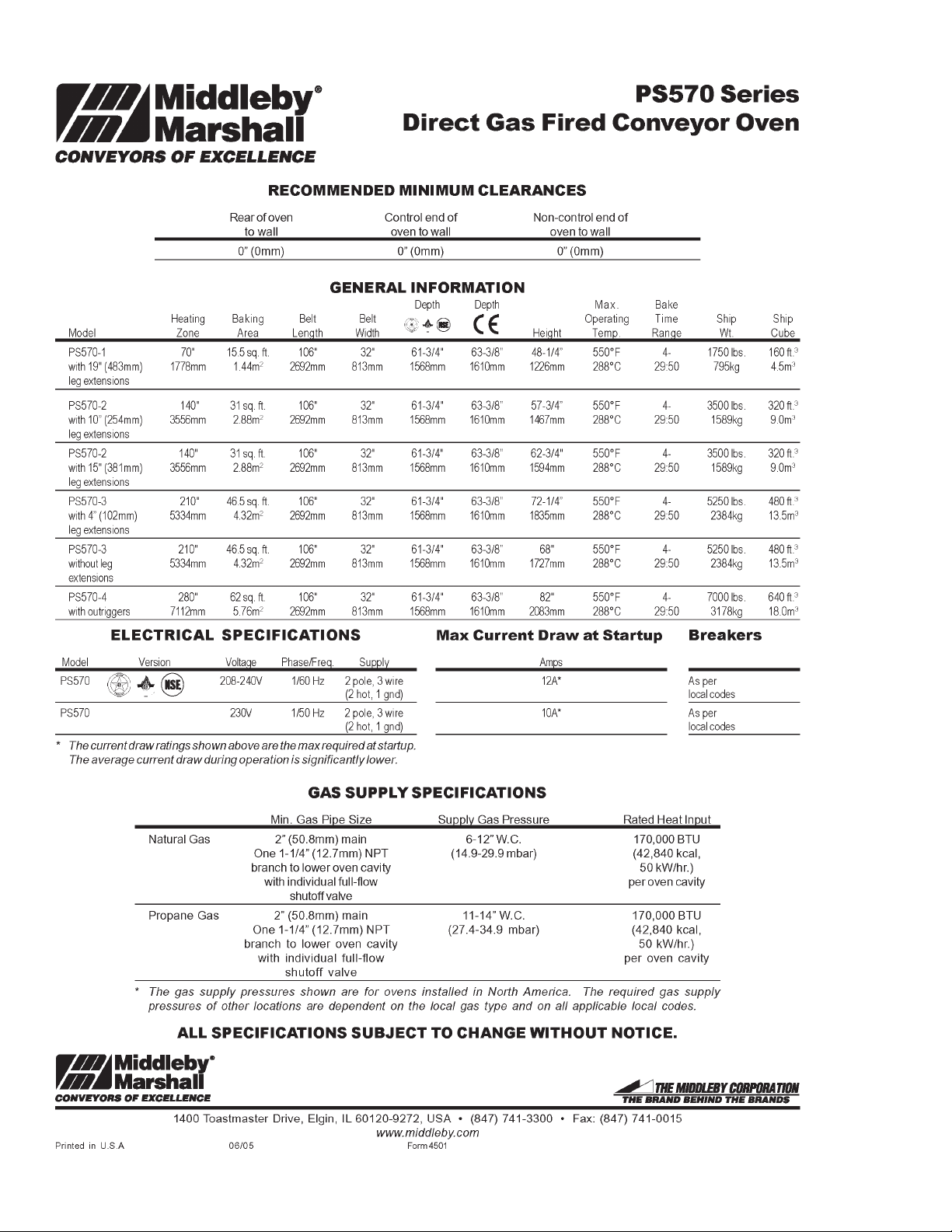

Specification Sheet ............................................................................................. 3

Key Parts ............................................................................................................. 7

View of Installation and Base Pad Kit(s) ............................................................. 8

Parts for Installation and Base Kit(s)................................................................... 9

View of Oven Panels, End Plugs, Window and Legs ...................................... 10

Parts for Oven Panels, End Plugs, Window and Legs ..................................... 11

View of Front Control Area ................................................................................12

Parts for Front Control Area .............................................................................. 13

View of Gas Piping and Burner Assembly ....................................................... 14

Parts for Gas Piping and Burner Assembly...................................................... 15

View of Rear Blower/Motor Assembly ..............................................................16

Parts for Rear Blower/Motor Assembly............................................................. 17

View of Rear Capacitor Area ............................................................................ 18

Parts for Rear Capacitor Area........................................................................... 19

View of “Single” Belt Conveyor ......................................................................... 20

Parts for “Single” Belt Conveyor ........................................................................21

View of “50-50” Split Belt Conveyor ..................................................................22

Parts for “50-50” Split Belt Conveyor .................................................................23

Standard Finger Configuration 31257 and Part Numbers ............................... 24

Wiring Diagram, G208-240 volt 50/60 Hz, 1 Phase, US,

45520 Rev E 2 of 2............................................................................................25

Ladder Diagram, G208-240 volt 50/60 Hz, 1 Phase, US,

45520 Rev E 1 of 2............................................................................................26

Wiring Diagram, G208-240 volt 50/60 Hz, 1 Phase, AU, 46978 Rev D............ 27

Wiring Diagram, G208-240 volt 50/60 Hz, 1 Phase, CAN, 47285 Rev C ......... 28

Wiring Diagram, G230 volt 50 Hz, 1 Phase, CE, DN 47263 Rev C .................. 29

Wiring Diagram, G230 volt 50 Hz, 1 Phase, CE, DUT 47265 Rev C ...............30

Wiring Diagram, G230 volt 50 Hz, 1 Phase, CE, FR 47257 Rev C .................. 31

Wiring Diagram, G230 volt 50 Hz, 1 Phase, CE, GM 47255 Rev C ................. 32

Wiring Diagram, G230 volt 50 Hz, 1 Phase, CE, GK 47261 Rev C .................. 33

Wiring Diagram, G230 volt 50 Hz, 1 Phase, CE, IT 47253 Rev C .................... 34

Wiring Diagram, G230 volt 50 Hz, 1 Phase, CE, SP 47259 Rev C .................. 35

Wiring Diagram, G230 volt 50 Hz, 1 Phase, CE, UK 45587 Rev F 2 of 2 ........ 36

Ladder Diagram, G230 volt 50 Hz, 1 Phase, CE, UK 45587 Rev F 1 of 2....... 37

2

Page 3

WHI.-4

Middleby"

UIIJIMarshaU

CONVEYORS

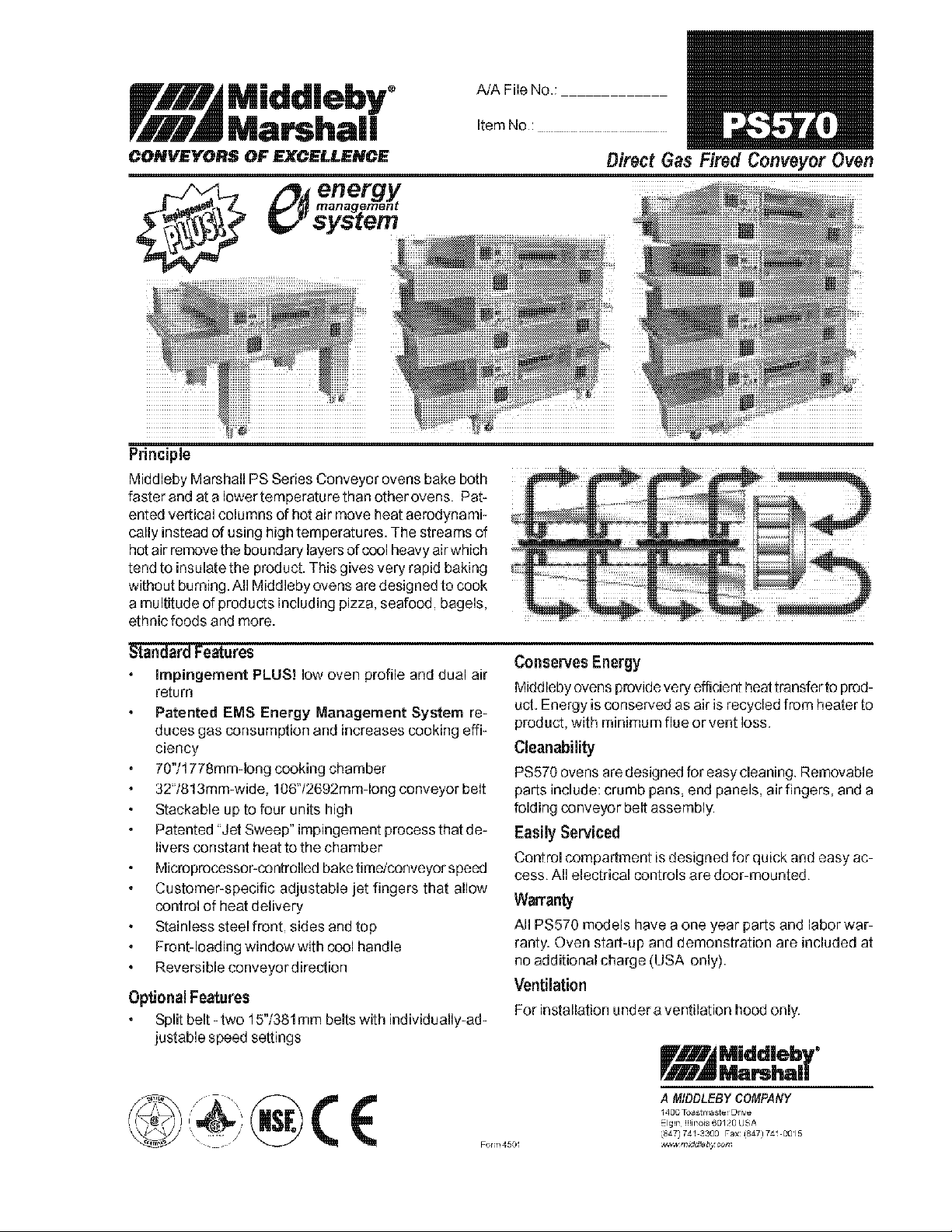

Middleby Marshall PS Series Conveyor ovens bake both

faster and at a lower temperature than other ovens. Patented vertical columns

cally instead

hot air remove the boundary layers

to

tend

without burning.AII Middleby ovens are designed

a multitude

ethnic foods and more.

insulate the product. This gives very rapid baking

OF

EXCELLENCE

of

hot air move heat aerodynami-

of

using high temperatures. The streams of

of

oool

heavy air which

of

products including pizza, seafood, bagels,

A/A File No.: ____________ _

Item No.:

to

cook

Standard

Optional

Features

Impingement

return

Patented EMS Energy Management System re-

duces gas consumption and increases cooking efficiency

70"/1778mm-long cooking chamber

32"1813mm-wide, 106"/2692mm-long conveyor belt

Stackable up to four units high

Patented "Jet Sweep" impingement process that de-

livers constant heat to the chamber

Microprocessor-oontrolled bake time/conveyor speed

Customer-specific adjustable jet fingers that allow

control

Stainless steel front. sides and top

Front-loading window with cool handle

Reversible conveyor direction

of

PLUS! low oven profile and dual air

heat delivery

Features

Split

belt-

two 15"/381 mm belts with individually-ad-

justable speed settings

Conse!Ves

Middleby ovens provide very efficient heat transfer to product. Energy is conserved as air

product, with minimum flue

Clean

PS570 ovens are designed for easy cleaning. Removable

parts include: crumb pans, end panels, air fingers, and a

folding oonveyor belt assembly.

Easily

Control compartment

cess. All electrical controls are door-mounted.

Energy

ability

SeiViced

is

recycled from heater to

or

vent loss.

is

designed for quick and easy ac-

Warranty

All PS570 models have a one year parts and labor warranty. Oven start-up and demonstration are included at

no additional charge (USA only).

Ventilation

For installation under a ventilation hood only.

Fom-,4501

r111.4

WI

A

MIDDLEBY

140C Toastmaster Drrve

Elg'r.

~847)7;:.

M.VNmiddlsbyoom

Middlebr·

AI

Marshal

COMPANY

'''II'OIS 60120 USA

1-33o::l Fax

1,8.17)

7~~-oo·ts

3

Page 4

456

Page 5

Page 6

Page 7

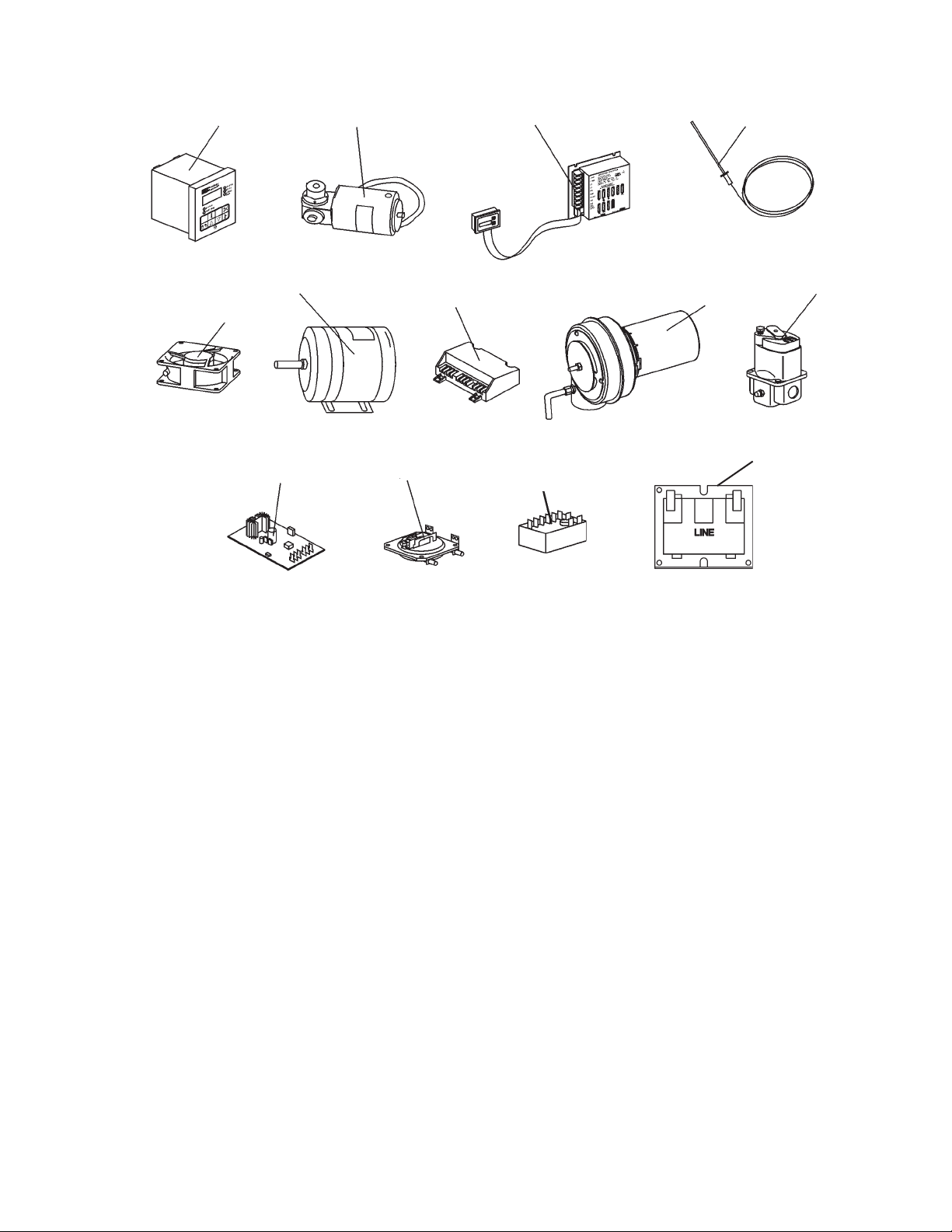

KEY PARTS

12

34

6

5

10

ITEM PART NO. DESCRIPTION QUANTITY

1 47321 Kit, Digital Temperature Control (58504) 1

2 See Below Motor, Drive 1 or 2

47796 1400:1 (provided Standard)

51059 600:1 (Hi-speed application)

3 58323 Kit, Conveyor Speed Controller 1 or 2

4 33984 Kit, Thermocouple (33812-1) 4

5 97525 Fan, Cooling 2

6 27381-0069 Motor, Blower, 1HP 2

7A 42810-0114 Ignition Module, US Version 1

7B 30872 Ignition Module, CE Version 1

7C 44676 Ignition Module, Australian Version 1

8 38811 Burner Blower/Motor Assembly 1

9 59450 Valve, Modulating Gas, 1/2″ (41647) 1

10 31651 Amplifier, Modulating Valve 1

11 50610 Air Switch, Rear Blower(s) 2

12 57141 Air Switch, Front, Burner/Blower 1

13 33983 Hi Limit Control Module 1

14 31504 Transformer, 240/120V Conveyor System 1

15 41872 Transformer, 240/24V, 25VA 1

16 32108 Transformer, 240/24V, 65VA 1

7A, 7B, 7C

11, 12

with Digital Display

8

14, 15, 16

13

9

7

Page 8

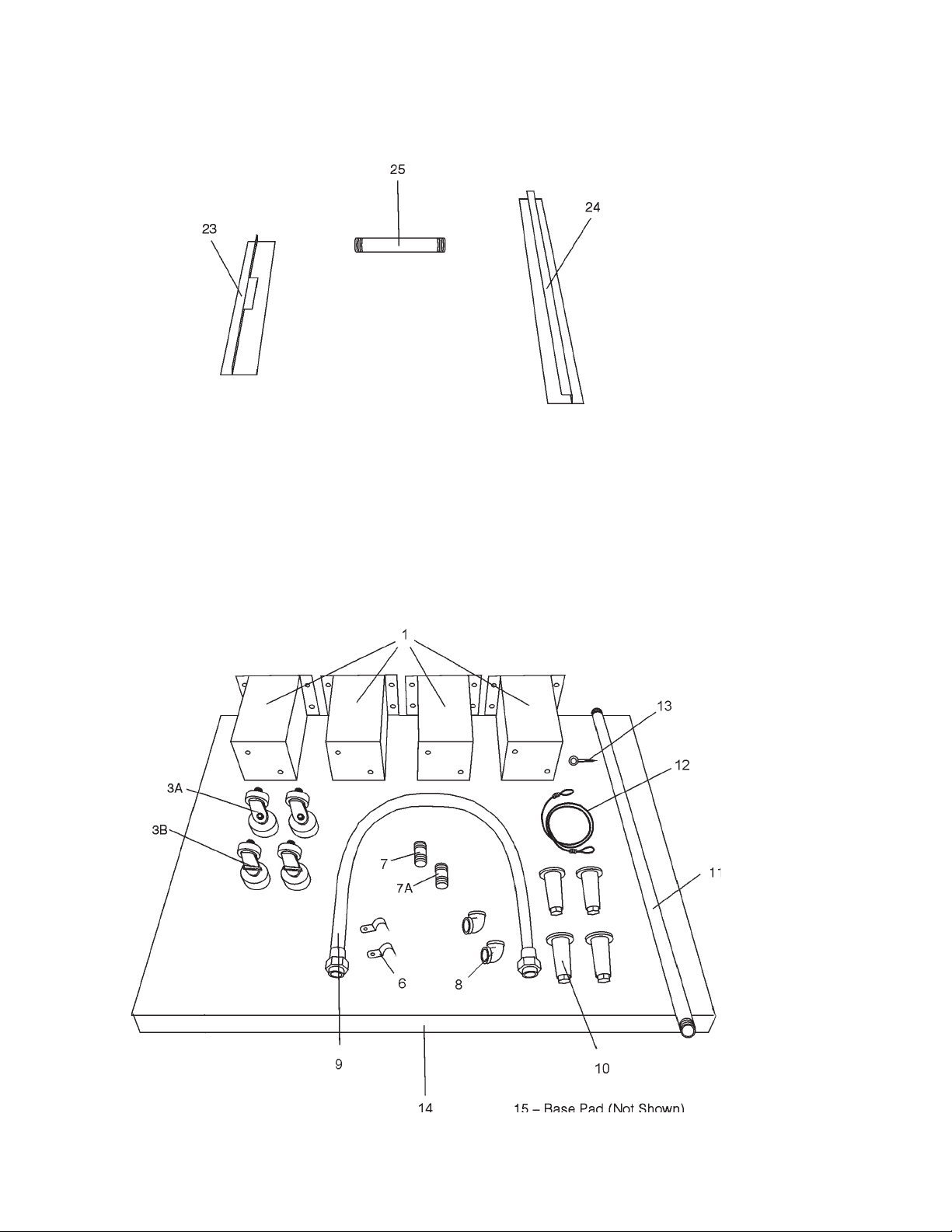

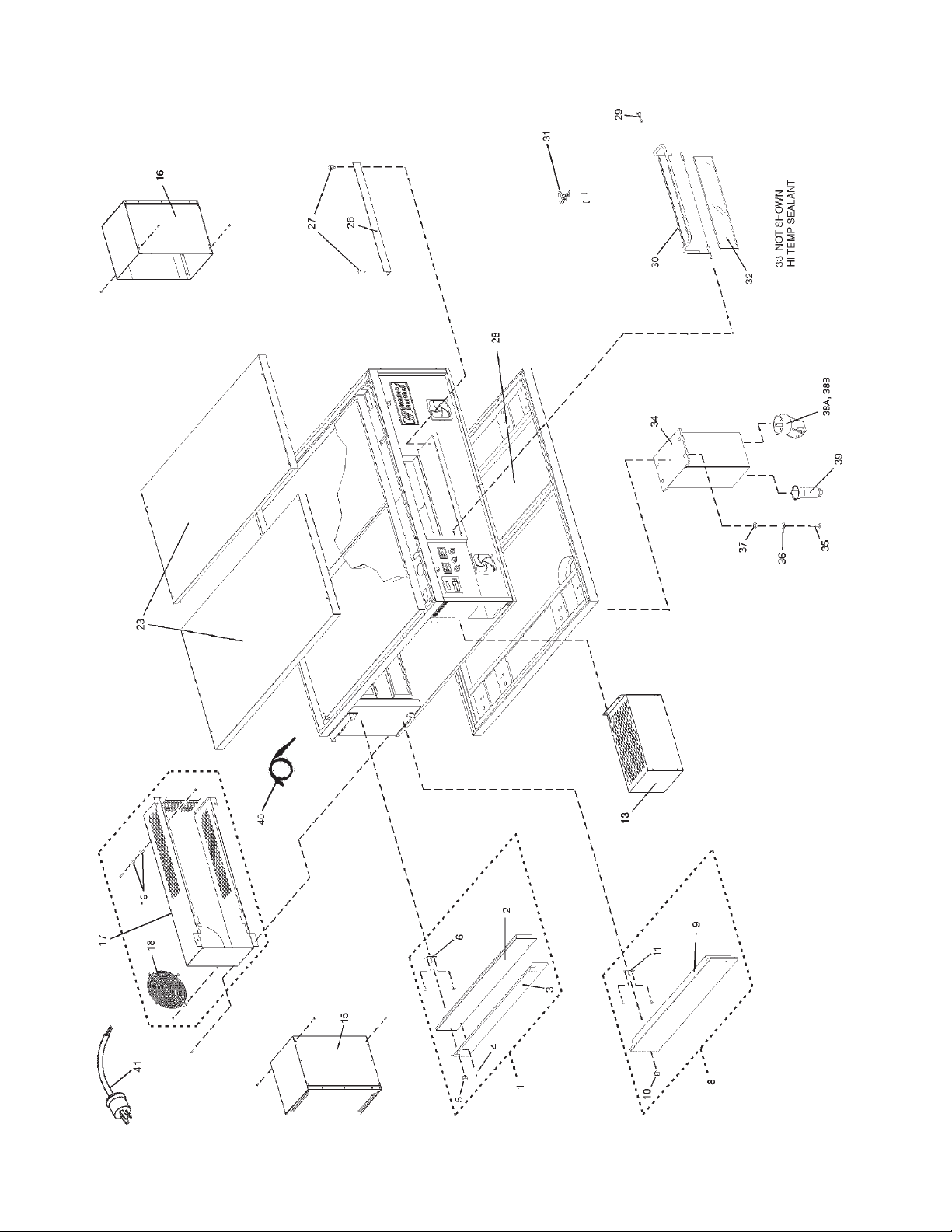

View of INSTALLATION KIT

View of BASE PAD KIT

8

Page 9

Parts for INSTALLATION KIT

QTY. – SGL.

ITEM BELT P/N DESCRIPTION

23 1 55028 CONVEYOR REAR STOP, 18″

24 1 55027 CONVEYOR END STOP, 29-1/4″

25 1 33120-0054 GAS PIPE NIPPLE, 1-1/4″ X 6″

Parts for BASE PAD KIT

QTY. QTY. QTY. QTY.

SGL. SGL./DBL. SGL./DBL. TRIPLE

OVEN OVEN/W OVEN/W OVEN

ITEM 19

1A 4 — — — 37210-0060 LEG, 19″ (483mm) (OPTIONAL)

1B — 4 — — 37210-0082

1C — 4 — 37210-0057 LEG, 15″ (381mm)

1D — — — 4 39684 LEG, 4″ (102mm) (43158, set of 4)

3A 2 2 2 2 37115-0102 CASTER, SWIVEL WITH 3/4″ STUD

3B 2 2 2 2 58930 CASTER, SWIVEL WITH BRAKE

6 2 2 2 2 27271-0004 PIPE CLAMP, 1-1/2″

7 2 2 2 2 33120-0055 NIPPLE, 1-1/4″ DIA. X 3″ L, NPT

7A 1 1 1 1 33120-0054 PIPE, 1-1/4″ DIA. X 6″ L

8 2 2 2 2 23122-0007 ELBOW, 90°, 1-1/4″ DIA.

9 1 1 1 1 22361-0003 GAS HOSE, 1-1/4″ DIA. x 72″ L

10 4 4 4 4 22450-0028

11 1 1 1 1 33120-0056 GAS PIPE, 1-1/4″ DIA. x 54″ L

12 1 1 1 1 22450-0253 RESTRAINT CABLE, 60″ (1524mm)

13 1 1 1 1 37699 EYE BOLT, BASE PAD

14 2 2 2 2 35210-0656 TOP COVER (RIGHT OR LEFT)

15 1 1 1 1 37210-0055 BASE PAD

NOT SHOWN:

— 8 8 8 8 59156 SCREW, TEKS HD #10-32 x 1-1/4″

— 2 2 2 2 21292-0001 SCREW, TEKS HWH #2PT #10-16 x 3/4″

— 16 16 16 — 21216-0018 BOLT, HEX CAP 1/2″-13 x 1-1/4″

— 16 16 16 — 21416-0003 FLAT WASHER, 1/2″

— 16 16 16 — 21426-0004 LOCK WASHER, 1/2″

— 1 1 1 1 21392-0005 EYE BOLT, WALL

″″

″ LEGS 10

″″

″″

″ LEGS 15

″″

″″

″ LEGS P/N DESCRIPTION

″″

LEG, 10″ (254mm), No Longer Available

LEG, 6″ (152mm) ADJUATABLE WITH 3/4″ STUD

9

Page 10

View of PANELS, END PLUGS, WINDOW and LEGS

10

Page 11

″

- SINGLE &

″

STUD - SINGLE,

STUD - SINGLE,

″

3-1/2″ x 32″

(381mm)

″

(483mm)

″

(254mm),

″

-13 X 1-1/4

- SGL & DBL OVENS

″

- SGL & DBL OVENS

″

″

″

(33812-1)

″

26 1 41768 WINDOW GUARD

ITEM QTY. P/N DESCRIPTION

27 2 30927 BUMPER, WINDOW

(INC. ITEMS 2-6)

28 1 37210-0055 BASE PAD

29 1 34121-0003 SCREW, THUMB

30 1 45457 WINDOW ASSEMBLY WITH HATCH

″

(INCLUDED IN ITEM 30)

(INCLUDED IN ITEM 30),

31 1 45087 LATCH

32 1 44514 GLASS, WINDOW, PRE-CUT

33 1 17130-0006 SEALANT

34A 4 37210-0060 LEG, SINGLE OVEN, 19

34B 4 37210-0057 LEG, DOUBLE OVEN, 15

(INC. ITEMS 9-11)

(43158, SET OF 4)

″

NO LONGER AVAILABLE

34C 4 37210-0082 LEG, DOUBLE OVEN, 10

DOUBLE OVENS

36 16 21426-0004 LOCKWASHER, 1/2

35 16 21216-0018 BOLT, HEX CAP 1/2

34D 4 39684 LEG, 4

37 16 21416-0003 FLAT WASHER, 1/2

(152mm) ADJUSTABLE WITH 3/4

″

DOUBLE, & TRIPLE OVENS

DOUBLE, & TRIPLE OVENS WITH BRAKE

STUD - SINGLE, DOUBLE, & TRIPLE OVENS

40 4 33984 KIT, THERMOCOUPLE, 6

38A 2 37115-0102 CASTER, SWIVEL WITH 3/4

39 4 22450-0028 LEG, 6

38B 2 58930 CASTER, SWIVEL WITH 3/4

41A 1 49975 CORD AND PLUG, L6-20P

41B 1 49976 CE CORD

-20 W/PLASTIC GRIP

″

-20 W/PLASTIC GRIP

″

Parts for PANELS, END PLUGS, WINDOW and LEGS

(INC. ITEM 18 and 19)

1 2 39539 ASSY, UPPER END PLUG

2 2 41778 WELDMENT, UPPER END PLUG PS500

3 1 50834 EYEBROW

4 8 220295 SCREW, “AB” HEX WSHR HD #10 X 3/4

ITEM QTY. P/N DESCRIPTION

5 4 36452 WING NUT, 1/4

8 2 39569 ASSY, LOWER END PLUG

6 4 41708 PLATE, END PLUG MOUNTING

9 2 41779 WELDMENT, LOWER END PLUG PS500

10 4 36452 WING NUT, 1/4

11 4 41708 PLATE, END PLUG MOUNTING

13 1 44494 ASSEMBLY, DRIVE MOTOR SHROUD

15 1 44482 ASSEMBLY, LEFT MOTOR SHROUD

11

16 1 44483 ASSEMBLY, RIGHT MOTOR SHROUD

17 2 41679 ASSEMBLY, REAR SHROUD

18 2 31765 GRILL, COOLING FAN

19 2 48522 BUMPER

23 2 35210-0656 TOP COVER

Page 12

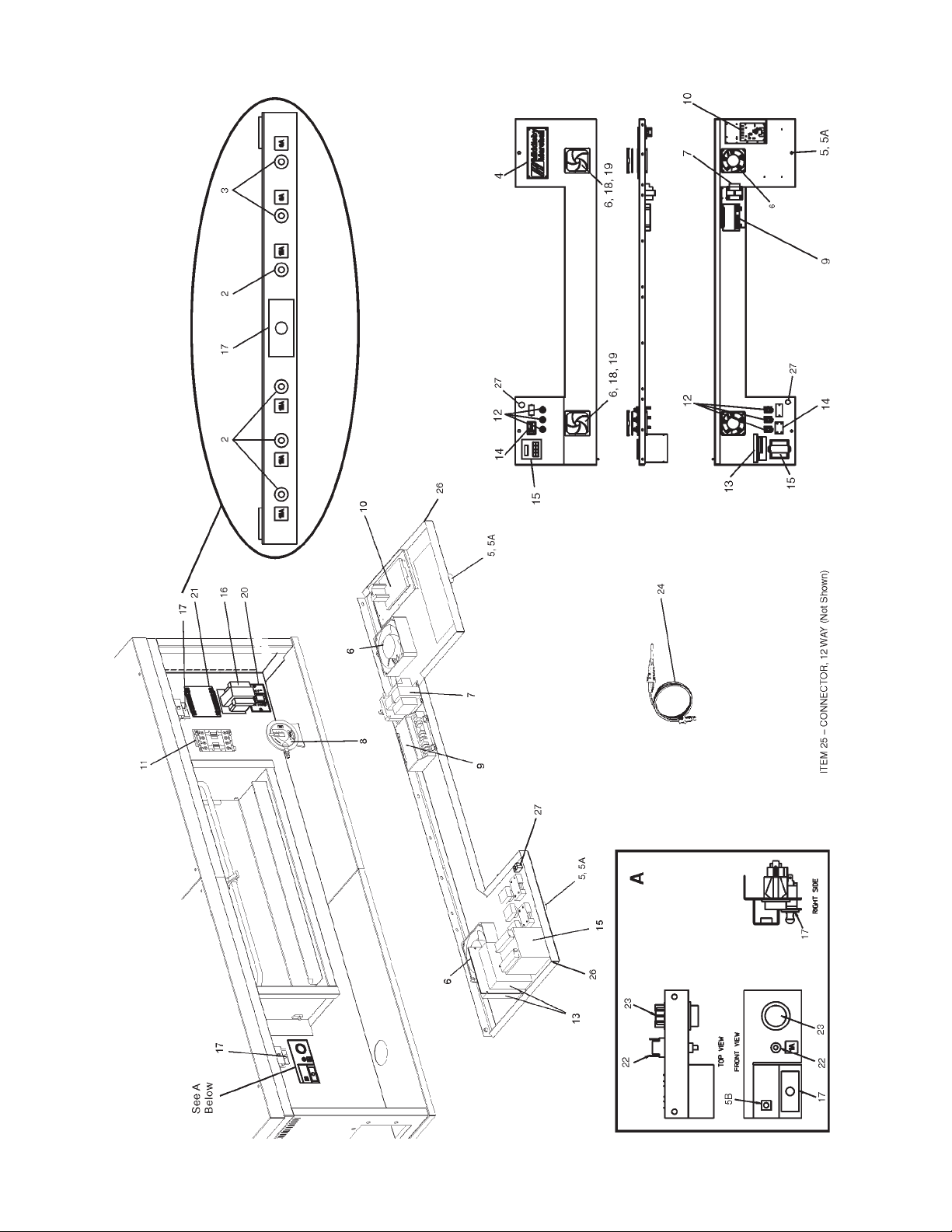

View(s) of FRONT CONTROL AREA(s)

12

Page 13

CONVEYOR

MENT ACCESS PANEL, INTERLOCK

FIER, 25VA

FOR P/N 30872

(CE ONLY)

PACTROL IGNITION MODULE (CE ONLY)

16 1 31504 TRANSFORMER, 230Vp:120Vs, 0.2 KVA,

ITEM QTY. P/N DESCRIPTION

18 2 310-2458 GRILL, COOLING FAN, WITH FILTER

19 2 310-2468 FILTER ONLY

20 1 33983 HI-LIMIT CONTROL

21 1 41872 TRANSFORMER, 240/24V, SIGNAL AMPLI-

22 1 45644 CIRCUIT BREAKER, 1 AMP

23 1 35145 RESET BUTTON WITH GREEN LIGHT

17 2 28021-0047 SAFETY SWITCH, MACHINERY COMPART-

24 4 33894 KIT, THERMOCOUPLE, 6″ x 120″ (33812-1)

Parts for FRONT CONTROL AREA(s)

FRONT

25 1 32001 CONNECTOR, 12 WAY

26 2 45020 CATCH, DOOR

27 1 28201-0016 LIGHTED RESTART SWITCH

27A 1 27073-0007 BULB, 220V

CE ONLY

27B 1 30204 PUSH BUTTON

27C 1 30205 ADAPTER

27E 1 30207 SOCKET FOR BULB

27D 1 30206 CONTACT BLOCK

WITH SELECTOR AND DIGITAL DISPLAY

(INC. ITEM 14)

(58504)

2 4 45037 CIRCUIT BREAKER, 15 AMP

3 2 45036 CIRCUIT BREAKER, 3 AMP

4 1 22500-0021 NAMEPLATE, “MIDDLEBY MARSHALL”

ITEM QTY. P/N DESCRIPTION

5 2 A6153 BOLT

6 2 97525 COOLING FAN, BLOWS IN

7 1 32108 TRANSFORMER, 240Vp:24Vs, 65VA

5A 2 21182-0005 KEEPER

5B 2 21182-0006 SELF RETAINING NUT

8 1 57141 AIR SWITCH, BURNER/BLOWER MOTOR,

9A 1 42810-0114 IGNITION MODULE, US VERSION

9B 1 30872 IGNITION MODULE, CE VERSION

10 1 31651 SIGNAL AMPLIFIER, BOARD

11 1 28041-0011 CONTACTOR, BLOWER MOTORS

9C 1 44676 IGNITION MODULE, AUSTRALIAN VERSION

12 3 46521 KIT, SELECTOR SWITCH, CONTACT BLOCK

12A 3 44697 CONTACT BLOCK

13 1 58323 KIT, CONVEYOR SPEED CONTROLLER

12B 3 44696 SELECTOR SWITCH

13

14 1 37503 DIGITAL DISPLAY

15 1 47321 KIT, DIGITAL TEMPERATURE CONTROLLER

Page 14

View of GAS PIPING AND BURNER ASSEMBLY

14

Page 15

, NATURAL GAS

(INCLUDES CAP

(CE ONLY)

22 1 30185 KIT, PILOT TEE 1/4″/6.4mm

23 A/R 15125-0002 TUBING, ALUMINUM, 1/4″/6.4mm O.D.

24 1 59450 VALVE, MODULATING GAS, 1/2″ (41647)

ITEM QTY. P/N DESCRIPTION

(INCLUDES ITEMS 1-12)

25A 1 45688 COMBINATION GAS VALVE (SAFETY

2-4)

REGULATOR), 1/2″, NATURAL GAS

25B 1 43085 COMBINATION GAS VALVE & GAS PRES-

NATURAL GAS TO LP,

SURE SWITCH

25C 1 28092-0018 KIT, COMBINATION VALVE, CONVERT

AND LP SPRING)

SCREW, O-RING, ADJUSTING SCREW

26 1 23115-0009 VALVE, SHUTOFF 1/2″

27 1 42410-0016 BRACKET, PIPE MOUNTING 1-1/4″

28 1 23051-0003 UNION, PIPE 1/2″

AND 25C)

PROPANE (INCLUDES ITEMS 14B, 15B

29 1 23051-0012 UNION, PIPE 1-1/4″

30B 1 42810-0124 KIT, CONVERSION FROM NATURAL GAS TO

32 1 35210-0053 TUBE BLOWER EXTENSION (NOT SHOWN)

Parts for GAS PIPING AND BURNER ASSEMBLY

(INCLUDES ITEMS

2 1 38811 ASSEMBLY, BURNER BLOWER AND MOTOR

1 1 38126 ASSEMBLY, BURNER

ITEM QTY. P/N DESCRIPTION

ORIFICE

5 1 38127 VENTURI

6 1 27363-0002 PILOT IGNITOR WITH NATURAL GAS

7 1 27170-0204 PILOT SHIELD

8 1 27170-0264 BRACKET, PILOT MOUNTING

(6.35mm)

12 1 38279 ORIFICE HOLDER/INLET CONNECTOR

14A 1 22176-0014 MAIN ORIFICE, NATURAL GAS, 0.250″

USE ITEM 6 FOR NATURAL GAS

15A

14B 1 22176-0015 MAIN ORIFICE, PROPANE, 0.152″ (3.86mm)

17 2 22450-0259 HOSE CLAMP

15B 1 22174-0010 PILOT ORIFICE, PROPANE, 0.018″ (0.46mm)

15

18 1 37210-0026 BRACKET, HOSE AND BURNER MOUNTING

19 1 22450-0255 AIR DUCT, FLEXIBLE

20 A/R 22450-0297 TUBING, SILICONE RUBBER, 1/4″/6.4mm DIA.

21 1 27159-0019 IGNITION/SENSOR WIRE

Page 16

View(s) of REAR BLOWER/MOTOR ASSEMBLY (CONVEYOR DRIVE END SHOWN)

ITEM 40 RFI FILTER – NOT SHOWN

16

ITEM 37 GREASE CARTRIDGE

(17110-0015) – NOT SHOWN

Page 17

(SOME MODELS

(SEE BELOW)

21 1 46452 BELT, STANDARD

25 1 27381-0069 MOTOR, BLOWER 1HP

ITEM QTY. P/N DESCRIPTION

26 1 41666 BRACKET, MOTOR MOUNTING

(33812-1)

(SEE BELOW)

(5 x 5 x 19mm), MOTOR

31 1 47267 PULLEY, (BK65) STANDARD, MOTOR

32 1 220026 KEY, PULLEY, 3/16″ x 3/16″ x 3/4″

33 1 43024 EXTENDER, FAN

34A 1 27399-0008 FAN BLADE, CW, IDLER END

34B 1 27399-0009 FAN BLADE, CCW, CONVEYOR, DRIVE END

HAVE A QTY OF 4)

(FOR 22072-0017 BEARING)

35 1 41667 BRACKET, MOTOR SUPPORT

37 A/R 17110-0015 GREASE CARTRIDGE

36 4 33984 KIT, THERMOCOUPLE, 6″

(CE & AUSTRALIAN ONLY)

38 1 41575 MOUNTING BRACKET

39 1 44550 SUPPORT BRACKET

40 1 33813 RFI FILTER

Parts for EACH REAR BLOWER/MOTOR ASSEMBLY

BLOWER WHEEL-CW, IDLER END

BLOWER WHEEL-CCW – DRIVE END

DESCRIPTION

1A 1 22521-0005

ITEM QTY. P/N

PLATE, INLET RING

2 1 37210-0124

1B 1 22521-0006

SCREW, CAP HEX HD 3/8″-16 x 3″

LOCKWASHER, SPLIT 3/8″

SPACER

3 4 21211-0001

5 10 21422-0001

6 4 35210-0576

PLATE, SHAFT SEAL INNER

SHAFT BLOWER

KEY, BLOWER WHEEL

BEARING (22072-0017)

SHAFT SEAL, PTFE

7 1 35210-0541

8 1 37210-0101

12 1 41899

13 1 35210-0286

SPACER, BEARING

14 2 57321

15 4 39411

FLATWASHER, 7/16″

SCREW, CAP HEX HD

16 4 2000535

17 4 A6235

17

LOCKWASHER

HEX NUT, 1/2″-13

PULLEY, BLOWER, STANDARD, 6-1/2″

18 4 21121-0013

17A 4 21422-0016

19 1 39587

BUSHING, 2-1/2″ DIAMETER

P/N W/SPLIT BUSHING SPLIT BUSH P/N DESCRIPTION P/N FAN

RPM KIT HERTZ MOTOR PULLEY MTR PULLEY P/N DIAMETER BELT SIZE BELT RPM OF

20 1 22031-0018

47214 60 BK70 44977 6-3/4″ BX67 46452 1780

Production

No Longer in

47215 60 BK80 39586 7-3/4″ BX68 46453 2057

47215 50 BK80 39586 7-3/4″ BX68 46453 1733

47216 60 BK90H 46455 8-3/4″ BX70 46454 2300

Hi-Altitude W/BUSHING 50222

47216 50 BK90H 46455 8-3/4″ BX70 46454 1917

Hi-Altitude W/BUSHING 50222

47268 60 BK65 47267 6-1/4″ BX67 46452 1692

Standard

Page 18

View of REAR CAPACITOR AREA

ITEM 20 RFI FILTER, CE & AUSTRALIAN – NOT SHOWN

18

Page 19

(CE & AUSTRALIAN ONLY)

SHROUD, MOMENTARY

Parts for REAR CAPACITOR AREA

11 2 50610 AIR SWITCH

12 A/R 22450-0297 TUBING, SILICONE BULK 1/4"/6.4mm O.D.

13 2 15125-0002 TUBING, ALUMINUM BULK 1/4″/6.4mm O.D.

14 2 28021-0061 SAFETY SWITCH, BLOWER MOTOR

ITEM QTY. P/N DESCRIPTION

15 2 27170-0269 ASSEMBLY START CAPACITOR (BLACK)

16 2 27170-0270 CAPACITOR, RUN (SILVER)

17 2 44465 INSULATOR CAP, RUN CAPACITOR

15A 1 44469 BRACKET & END CAP, START CAPACITOR

18 4 22450-0259 HOSE CLAMP

(SOME MODELS HAVE A QTY OF 4)

19 3 33984 KIT, THERMOCOUPLE, 6″ x 120″ (33812-1)

20 1 33813 RFI FILTER

19

Page 20

View of “SINGLE” BELT CONVEYOR

ITEM 44 HEYCO PLIERS, NOT SHOWN

20

Page 21

(WITH OPENINGS)

SCREW

(STANDARD SPEED)

25 2 22034-0003 BUSHING, BRONZE 3/4" O.D. x 5/8" 1.D.

26 2 35000-1080 SPACER, NYLON 1-1/4" O.D. x 3/4" I.D.

27 2 54947 BRACKET, SHAFT SUPPORT

28 1 35000-1013 ADAPTER, DRIVE SHAFT

29 1 22152-0017 SPROCKET, DRIVE SHAFT, 5/8" BORE, 9T, WITH SET

ITEM OTY PART NO. DESCRIPTION

30 1 42400-0164 ASSEMBLY, ROLLER CHAIN (62 LINKS) WITH MASTERLINK

SCREW (STANDARD SPEED)

(HIGH SPEED)

31 1 22273-0001 MASTERLINK, ROLLER CHAIN

32A 1 22152-0018 SPROCKET, DRIVE MOTOR, 5/8" BORE, 15T, WITH SET

33 1 35210-0640 ADAPTER, DRIVE MOTOR WITH SET SCREW

32B 1 57319 SPROCKET, DRIVE MOTOR, 5/8″, BORE, 20T

(INC.ITEMS 11-13)

Parts for “SINGLE” BELT CONVEYOR

DRIVE MOTOR ITEM 35B ITEM 36

MOTOR RATIO BRUSHES PICKUP SENSOR

CONVEYOR

35 1 47796 DRIVE MOTOR, 1/8 HP, 1400:1 (STANDARD)

36 1 SEE BELOW ASSEMBLY, PICKUP, DRIVE MOTOR

40 1 55027 END STOP, CONVEYOR, 29-1/4″ LONG

41 1 55028 REAR STOP, CONVEYOR, 18″ LONG

43 2 30004 CRUMB PAN, ALUMINIZED

35B 1 SEE BELOW BRUSHES, DRIVE MOTOR,

35A 51059 DRIVE MOTOR, 1/8 HP, 600:1 (HIGH SPEED)

44 1 50795 TOOL, HEYCO PLIERS

46444 1400:1 46658 46451

CURRENT 47796 1400:1 45017 50265

46603 1400:1 46658 46451

27384-0008 1400:1 22450-0052 46451

CURRENT 51059 600:1 45017 50265

46446 600:1 46658 46451

46605 600:1 46658 46451

27384-0003 600:1 22450-0052 46451

1 1 37210-0117 WELDMENT, CONVEYOR DRIVE FRAME

2 4 37210-0046 WELDMENT, CONVEYOR CENTER FRAME

3 1 37210-0116 WELDMENT, CONVEYOR IDLER FRAME

5 4 35210-0429 PIVOT PLATE

6 8 35210-0491 BUSHING, CONVEYOR ADJUSTMENT

7 8 F716A8805 WASHER, EXTERNAL TOOTH 1/4"

8 8 21176-0001 LOCKNUT, HEX 1/4"-20

ITEM OTY PART NO. DESCRIPTION

9A 1 22450-0265 CONVEYOR BELT, COMPLETE, 32"W x 206"L (0.81 x 5.23m)

10 1 42400-0089 MASTERLINKS KIT, 32" (0.81m) BELT

12 4 - - MASTERLINK, CENTER

9B -- 33900-0032 CONVEYOR BELT, 32"W x 12"L (0.81 x 0.30m)

13 1 - - MASTERLINK, RIGHT

11 1 - - MASTERLINK, LEFT

15 6 22229-0003 SPROCKET, CONVEYOR BELT

17 2 22034-0003 BUSHING, BRONZE 3/4" O.D. x 5/8" 1.D.

18 2 37000-0413 BRACKET, IDLER SHAFT ADJUSTMENT

19 2 35000-1008 SCREW, CONVEYOR TENSION ADJUSTMENT

14 1 35000-1011 SHAFT, IDLER

20 2 54947 BRACKET, SHAFT SUPPORT

21

21 1 35000-1012 SHAFT, DRIVE

22 6 22229-0003 SPROCKET, CONVEYOR BELT

24 1 22011-0013 COLLAR, SHAFT, WITH SET SCREW

Page 22

View of “50-50” Split Belt Conveyor

ITEM 49 HEYCO PLIERS, NOT SHOWN

22

Page 23

(WITH OPENINGS)

SCREW

(STANDARD SPEED)

(STANDARD SPEED)

31 2 54947 BRACKET, SHAFT SUPPORT

32 1 35900-0023 BUSHING, SPLIT BELT DRIVE SPROCKET

33 2 22152-0017 SPROCKET, DRIVE SHAFT, 5/8" BORE, 9T, WITH SET

34 1 42400-0164 ASSEMBLY, ROLLER CHAIN COMPLETE (62 LINKS)

ITEM OTY PART NO. DESCRIPTION

35 1 42410-0128 ASSEMBLY, ROLLER CHAIN COMPLETE (48 LINKS)

SCREW

(HIGH SPEED)

36 2 22273-0001 MASTERLINK, ROLLER CHAIN

37B 2 57319 SPROCKET, DRIVE MOTOR, 5/8″, BORE, 20T

37A 2 22152-0018 SPROCKET, DRIVE MOTOR, 5/8" BORE, 15T, WITH SET

(INC.ITEMS 11-13)

Parts for “50-50” Split Belt Conveyor

CONVEYOR

38 1 35210-0640 ADAPTER, DRIVE MOTOR WITH SET SCREW

40 2 47796 DRIVE MOTOR, 1/8 HP, 1400:1 (STANDARD)

40A 2 51059 DRIVE MOTOR, 1/8 HP, 600:1 (HIGH SPEED)

41 2 SEE BELOW ASSEMBLY, PICKUP, DRIVE MOTOR

45 1 55027 END STOP, CONVEYOR, 29-1/4″ LONG

46 1 55028 REAR STOP, CONVEYOR, 18″ LONG

40B 2 SEE BELOW BRUSHES, DRIVE MOTOR,

49 1 50795 TOOL, HEYCO PLIERS

48A 2 30004 CRUMB PAN, ALUMINIZED

DRIVE MOTOR ITEM 40B ITEM 41

46444 1400:1 46658 46451

MOTOR RATIO BRUSHES PICKUP SENSOR

CURRENT 47796 1400:1 45017 50265

46603 1400:1 46658 46451

27384-0008 1400:1 22450-0052 46451

CURRENT 51059 600:1 45017 50265

46446 600:1 46658 46451

46605 600:1 46658 46451

27384-0003 600:1 22450-0052 46451

1 1 37210-0117 WELDMENT, CONVEYOR DRIVE FRAME

2 1 37210-0046 WELDMENT, CONVEYOR CENTER FRAME

3 1 37210-0116 WELDMENT, CONVEYOR IDLER FRAME

5 4 35210-0429 PIVOT PLATE

6 8 35210-0491 BUSHING, CONVEYOR ADJUSTMENT

7 8 F716A8805 WASHER, EXTERNAL TOOTH 1/4"

8 8 21176-0001 LOCKNUT, HEX 1/4"-20

ITEM OTY PART NO. DESCRIPTION

9A 2 22450-0271 CONVEYOR BELT, COMPLETE, 15"W x 206"L (0.38 x 5.23m)

10 2 51382 MASTERLINKS KIT, 15" (0.81m) BELT

12 2 - - MASTERLINK, CENTER

9B -- 33900-0037 CONVEYOR BELT, 15"W x 12"L (0.38 x 0.30m)

13 2 - - MASTERLINK, RIGHT

11 2 - - MASTERLINK, LEFT

15 1 21415-0001 FLAT WASHER, BRONZE, 1″ O.D. X 1/2″ I.D.

16 1 35000-1535 SHAFT, IDLER, FRONT, 16-3/8″

17 8 22229-0003 SPROCKET, CONVEYOR BELT

19 2 22034-0003 BUSHING, BRONZE 3/4" O.D. x 5/8" 1.D.

14 1 42400-0354 SHAFT, IDLER, REAR, 32-3/4″

20 2 37000-0413 BRACKET, IDLER SHAFT ADJUSTMENT

23

21 2 35000-1008 SCREW, CONVEYOR TENSION ADJUSTMENT

22 2 54947 BRACKET, SHAFT SUPPORT

23 1 42400-0355 SHAFT, DRIVE, REAR, 35-1/3″

24 1 21415-0001 FLAT WASHER, BRONZE, 1″ O.D. X 1/2″ I.D.

25 1 35000-1536 SHAFT, DRIVE, FRONT, 17-3/4″

26 8 22229-0003 SPROCKET, CONVEYOR BELT

27 1 35000-1531 SPACER, NYLON FITS BETWEEN SPROCKETS

28 1 22011-0014 COLLAR, SPLIT LOCKING

29 2 22034-0003 BUSHING, BRONZE 3/4" O.D. x 5/8" 1.D.

30 2 35000-1080 SPACER, NYLON 1-1/4" O.D. x 3/4" I.D.

Page 24

Standard Finger Configuration and Parts

37000-0577 WLDMT, PLATE, INNER COL W/DAM

42410-0202 ASSY, RAISED MANF W/SLD BAFFEL

37000-0577 WLDMT, PLATE, INNER COL W/DAM

42410-0194 ASSY, MANIFOLD W/FULL BAFFEL ALUZ

A = 39224 WLDMT, PLT OTR SL3 W/RASD MANF

B = 37900-0051 PLATE, OUTER S/L6

C = 35210-0536 PLATE, FULL BLANK ALUZ

D = 35210-0535 PLATE, BLANK PRTL 2.75 UPR 570

B

E

D

A

A

C

X

C

B

E

B

X

B

E

E = 35210-0590 PLATE, BLANK PARTIAL ALUZ LWR570

F =

G=

A

A

D

B

E

B

Notes

RT TO LT MIRROR IMAGE OF FINGER ARRANGEMENT

MOTOR PULLEY: BK65 P/N 47267

BELT SIZE: BX67 P/N 46452

RPM= 1692

24

Page 25

Wiring Diagrams (electrical schematics)

45520E2

------r~-~--;::)

-~;

------t--oco~--t

---------~J

' '

J:::;

~:--__,,,,,

--_::;-I_,.,

__

-'

----9

~

_j_

MIDDLEBY MARSHALL PS570G WIRING DIAGRAM G208-240 volt 50/60 Hz, 1 Phase

25

Page 26

45520E1

26

MIDDLEBY MARSHALL PS570G LADDER DIAGRAM G208-240 volt 50/60 Hz, 1 Phase

Page 27

46978D

I -

I ill['"""::

I /

I I>-"'""'\ W

I

~

I

Zc

r

i i i = u

i

§l

''

1 c 2 0 J

[-oco

--

I I

"'

"'D

"'

_f

::1

it!

:<'

MIDDLEBY MARSHALL PS570G WIRING DIAGRAM G208-240 volt 50/60 Hz, 1 Phase AU

27

Page 28

47285C

28

MIDDLEBY MARSHALL PS570G WIRING DIAGRAM G208-240 volt 50/60 Hz, 1 Phase CAN

Page 29

------------t";;---

47263C

~

:;;

;:':

--

~I

/

____________

"-------o

__j_

__

"'

_"____

:

E~

s

___

L

"

~

~~

~!

±I

Q

~

j_~

±:

8!

8:

~:

~I

)

O'~H

0~8

!L

~

'

'

.&

'

/

29

l'i

C<.

;f

lBi

~

~!

'

MIDDLEBY MARSHALL PS570G WIRING DIAGRAM G230 volt 50 Hz, 1 Phase CE DN

0

i:'

~

Page 30

47265C

30

MIDDLEBY MARSHALL PS570G WIRING DIAGRAM G230 volt 50 Hz, 1 Phase CE DUT

Page 31

m

'

~

.l

'

:

·~

~·

8

"~

~

'

I)!

d

"

'~

"

c

"'

5

'

".

r

m

'

b

..

----·----

A

"

3~<Bl

GS

47257C

0

~

•

,.

~

e

z

-

,;-

ll:'

,_

.f

~:

'E:

0

~:

.

§:

'

g

!

MIDDLEBY MARSHALL PS570G WIRING DIAGRAM G230 volt 50 Hz, 1 Phase CE FR

31

Page 32

47255C

32

MIDDLEBY MARSHALL PS570G WIRING DIAGRAM G230 volt 50 Hz, 1 Phase CE GM

Page 33

47261C

"'

B

8

'

~:

'

i'<

~:

33

MIDDLEBY MARSHALL PS570G WIRING DIAGRAM G230 volt 50 Hz, 1 Phase CE GK

Page 34

47253C

34

MIDDLEBY MARSHALL PS570G WIRING DIAGRAM G230 volt 50 Hz, 1 Phase CE IT

Page 35

----->_>-----~;;~---

47259C

'

MIDDLEBY MARSHALL PS570G WIRING DIAGRAM G230 volt 50 Hz, 1 Phase CE SP

35

Page 36

45587F2

36

MIDDLEBY MARSHALL PS570G WIRING DIAGRAM G230 volt 50 Hz, 1 Phase CE UK

Page 37

45587F1

37

MIDDLEBY MARSHALL PS570G LADDER DIAGRAM G230 volt 50 Hz, 1 Phase CE

Page 38

NOTES

38

Page 39

NOTES

39

Page 40

40

Loading...

Loading...