Page 1

PS770 Series

Gas

Domestic

ENGLISH

P/N 59026

August 18, 2006

PS770 Series Gas Ovens

Model:

• PS770G Gas

Combinations:

• Single Oven

• Double Oven (Two-Stack)

• Triple Oven (Three-Stack)

OWNER'S OPERATING AND

INSTALLATION MANUAL

for domestic and standard export ovens

©2006 Middleby Marshall Inc.

is a registered trademark of Middleby Marshall, Inc. All rights reserved.

Middleby Cooking Systems Group • 1400 Toastmaster Drive • Elgin, IL 60120 • (847)741-3300 • FAX (847)741-4406

Page 2

234

Page 3

Page 4

Model No.

Modéle No.

Serial No.

Serié No.

Installation Date

Date d'installation

MIDDLEBY MARSHALL

PAPA JOHN’S No Quibble Limited

Warranty

Middleby Marshall will repair the equipment 24

hours a day, 365 days a year

(U.S.A. Only) PS770 WOW Oven

MIDDLEBY MARSHALL, HEREINAFTER REFERRED TO

AS “THE SELLER”, WARRANTS EQUIPMENT MANUFACTURED BY THEM TO BE FREE FROM DEFECTS IN

MATERIAL AND WORKMANSHIP FOR WHICH IT IS RESPONSIBLE. THE SELLER’S OBLIGATION UNDER

THIS WARRANTY SHALL BE LIMITED TO REPLACING

OR REPAIRING, AT SELLER’S OPTION, WITHOUT

CHARGE, ANY PART FOUND TO BE DEFECTIVE AND

ANY LABOR AND MATERIAL EXPENSE INCURRED BY

SELLER IN REPAIRING OR REPLACING SUCH PART.

SUCH WARRANTY SHALL BE LIMITED TO THE ORIGINAL PURCHASER ONLY AND SHALL BE EFFECTIVE

FOR A PERIOD OF THREE YEARS FROM DATE OF

ORIGINAL INSTALLATION OR 42 MONTHS FROM DATE

OF PURCHASE, WHICHEVER IS EARLIER, PROVIDED

THAT TERMS OF PAYMENT HAVE BEEN FULLY MET.

This warranty is valid only if the equipment is installed,

started, and demonstrated under the supervision of a

factory-authorized installer.

Normal maintenance functions, including lubrication,

cleaning, or customer abuse, are not covered by this

quibble warranty.

Seller shall be responsible only for repairs or replacements of defective parts performed by seller’s authorized

service personnel. Authorized service agencies are

located in principal cities throughout the contiguous

United States, Alaska, and Hawaii. This warranty is valid

in the 50 United States and is void elsewhere unless the

product is purchased through Middleby International with

warranty included.

The foregoing warranty is exclusive and in lieu of all other

warranties, expressed or implied. There are no implied

warranties of merchantability or of fitness for a particular

purpose.

The foregoing shall be seller’s sole and exclusive obligation and buyer’s sole and exclusive remedy for any

action, including breach of contract or negligence. In no

event shall seller be liable for a sum in excess of the

purchase price of the item. Seller shall not be liable for

any prospective or lost profits of buyer.

This warranty is effective on Middleby Marshall equipment sold on or after April 1, 2006.

no

MIDDLEBY MARSHALL INC.

OVEN LIMITED WARRANTY

(Non U.S.A.)

The Seller warrants equipment manufactured by it to be free from

defects in material and workmanship for which it is responsible. The

Seller’s obligation under this warranty shall be limited to replacing

or repairing, at Seller’s option, without charge, F.O.B. Seller’s

factory, any part found to be defective and any labor and material

expense incurred by Seller in repairing or replacing such part. Such

warranty is limited to a period of one year from date of original

installation or 15 months from date of shipment from Seller’s factory,

whichever is earlier, provided that terms of payment have been fully

met. All labor shall be performed during regular working hours.

Overtime premium will be charged to the Buyer.

This warranty is not valid unless equipment is installed,

started, and demonstrated under the supervision of a factory-authorized installer.

Normal maintenance functions, including lubrication, adjustment of

airflow, thermostats, door mechanisms, microswitches, burners

and pilot burners, and replacement of light bulbs, fuses and

indicating lights, are not covered by warranty.

Any repairs or replacements of defective parts shall be performed

by Seller’s authorized service personnel. Seller shall not be

responsible for any costs incurred if the work is performed by other

than Seller’s authorized service personnel.

When returning any part under warranty, the part must be intact and

complete, without evidence of misuse or abuse, freight prepaid.

Seller shall not be liable for consequential damages of any kind

which occur during the course of installation of equipment, or which

result from the use or misuse by Buyer, its employees or others of

the equipment supplied hereunder, and Buyer’s sole and exclusive

remedy against Seller for any breach of the foregoing warranty or

otherwise shall be for the repair or replacement of the equipment

or parts thereof affected by such breach.

The foregoing warranty shall be valid and binding upon Seller if and

only if Buyer loads, operates and maintains the equipment supplied

hereunder in accordance with the instruction manual provided to

Buyer. Seller does not guarantee the process of manufacture by

Buyer or the quality of product to be produced by the equipment

supplied hereunder and Seller shall not be liable for any prospective

or lost profits of Buyer.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF

ALL OTHER EXPRESS AND IMPLIED WARRANTIES WHATSOEVER. SPECIFICALLY THERE ARE NO IMPLIED WARRANTIES

OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR

PURPOSE.

The foregoing shall be Seller’s sole and exclusive obligation and

Buyer’s sole and exclusive remedy for any action, whether in

breach of contract or negligence. In no event shall seller be liable

for a sum in excess of the purchase price of the item.

© 2003 - Middleby Marshall, A Middleby Company.

The Middleby Marshall logo is a registered trademark of Middleby Marshall, A Middleby Company.

Middleby Marshall Inc. • 1400 Toastmaster Drive • Elgin, Illinois 60120-9272 U.S.A. • (847) 741-3300 • FAX: (847) 741 4406

Page 5

Table of Contents

Page

SECTION 1

DESCRIPTION .................................................................... 6

I. OVEN USES .................................................................... 6

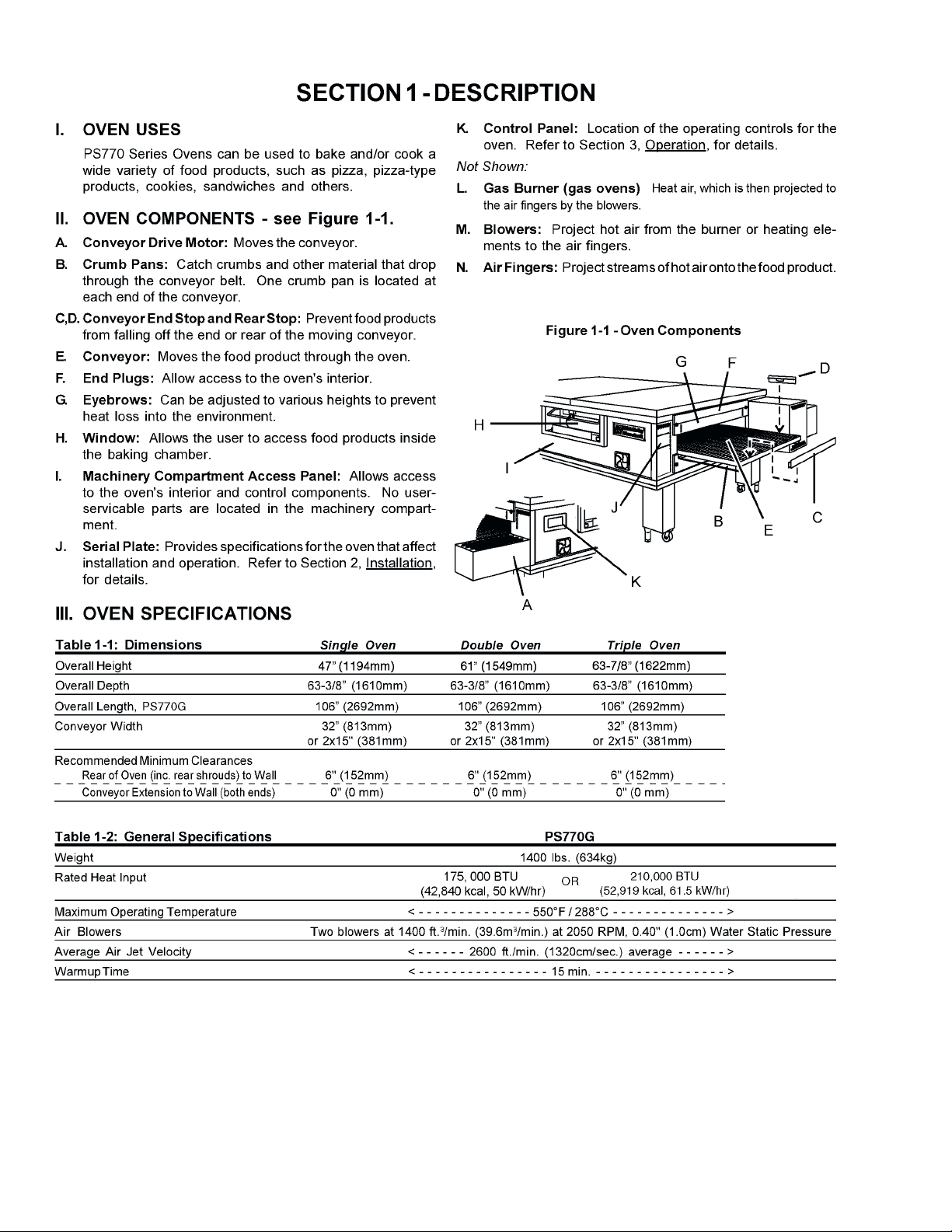

II. OVEN COMPONENTS .................................................... 6

A. Conveyor Motor Drive .............................................. 6

B. Crumb Pans ............................................................... 6

C. Conveyor End Stop and Rear Stop .......................... 6

D. Conveyor End Stop and Rear Stop .......................... 6

E. Conveyor .................................................................... 6

F. End Plugs .................................................................... 6

G. Eyebrows ................................................................... 6

H. Window ....................................................................... 6

I. Machinery Compartment Access Panel ................... 6

J. Serial Plate ................................................................. 6

K. Control Panel ............................................................. 6

L. Gas Burner ................................................................. 6

M. Blowers ...................................................................... 6

N. Air Fingers ................................................................. 6

III. OVEN SPECIFICATIONS ................................................. 6

A. Dimensions ................................................................ 6

B. General Specifications ............................................. 6

C. Electrical Specifications for PS770 Gas Ovens ..... 7

D. Gas Orifice and Pressure Specifications

for PS770 Gas Ovens .............................................. 7

SECTION 2

INSTALLATION .................................................................. 7

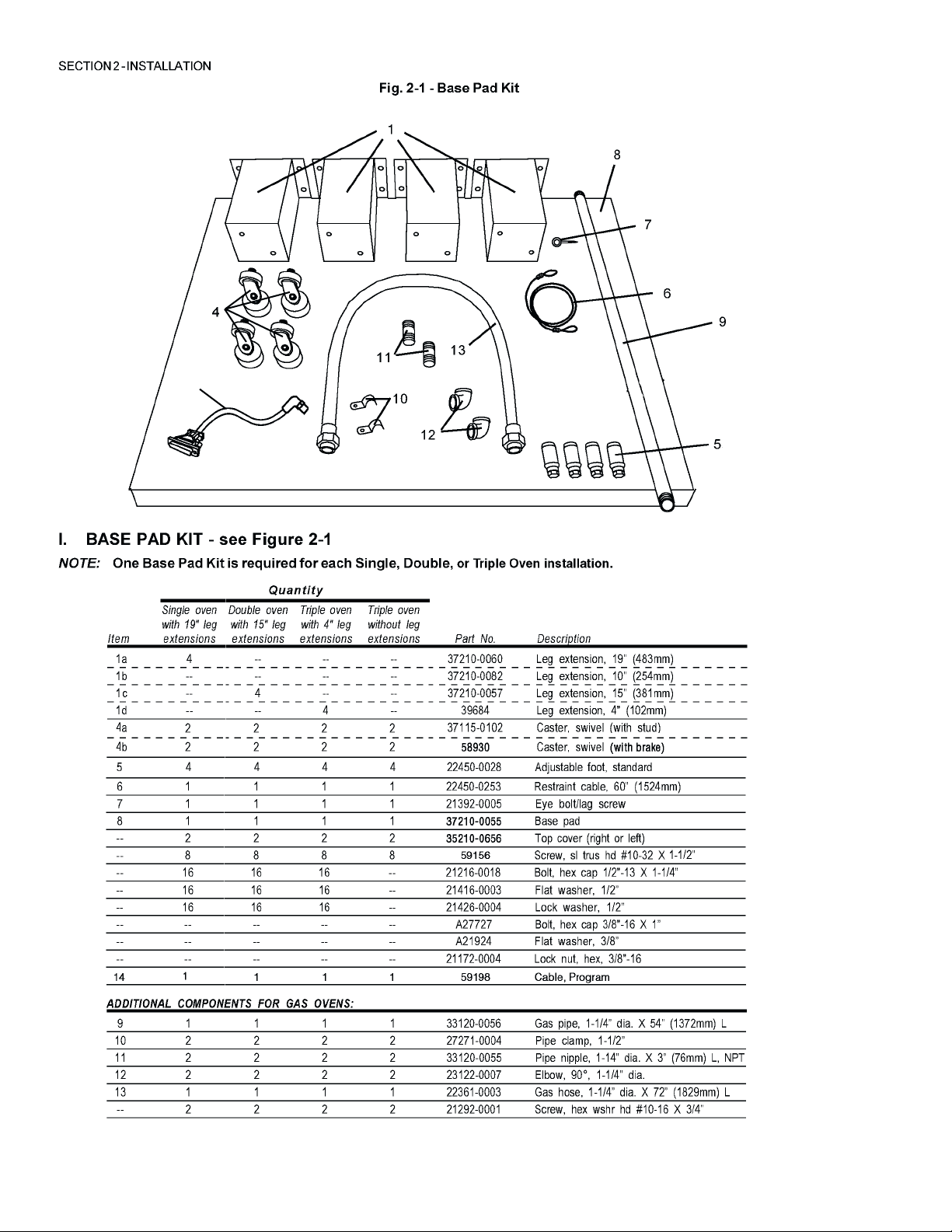

I. BASE PAD KIT ............................................................... 8

II. INSTALLATION KIT ........................................................ 9

III.VENTILATION SYSTEM ................................................. 9

A. Requirements ............................................................ 9

B. Recommendations .................................................... 9

C. Other Ventilation Concerns ...................................... 9

Page

IV. ASSEMBLY .................................................................... 10

A. Base Pad, Legs, Casters, and Stacking ................ 10

B. Restraint Cable Installation .................................... 10

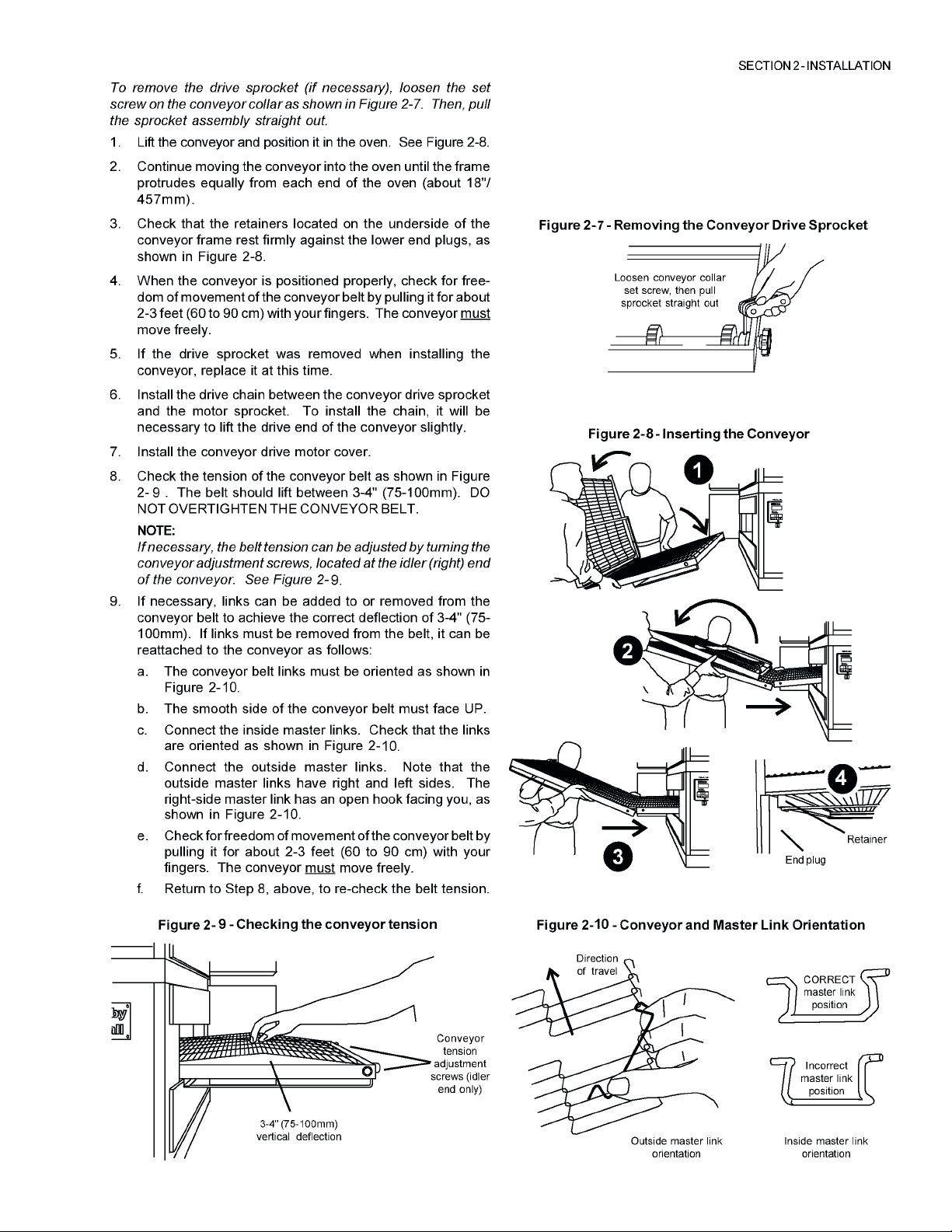

C. Conveyor Installation .............................................. 10

D. Standoff Installation ............................................... 11

V. FINAL ASSEMBLY ....................................................... 12

VI. ELECTRICAL SUPPLY ............................................... 12

Connection .................................................................. 1 3

VII. GAS SUPPLY ............................................................. 1 3

A. Gas Utility Rough-In Recommendations ............... 13

B. Connection ............................................................... 1 4

C. Gas Conversion ....................................................... 14

D. Propane Conversion ............................................... 14

SECTION 3

OPERATION ........................................................................ 15

I. LOCATION AND DESCRIPTION OF CONTROLS ....... 15

II. NORMAL OPERATION, STEP-BY-STEP ..................... 16

A. Daily Startup Procedure ......................................... 16

B. Daily Shutdown Procedure ..................................... 16

III. ENERGY MODE ........................................................... 17

IV. SCREEN ALERTS ....................................................... 17

SECTION 4

MAINTENANCE .................................................................. 18

I. MAINTENANCE - DAILY .............................................. 1 8

II. MAINTENANCE - MONTHLY ....................................... 19

III. MAINTENANCE - EVERY 3 MONTHS ........................ 20

IV. MAINTENANCE - EVERY 6 MONTHS ....................... 21

V. KEY SPARE PARTS KIT ............................................. 22

SECTION 5

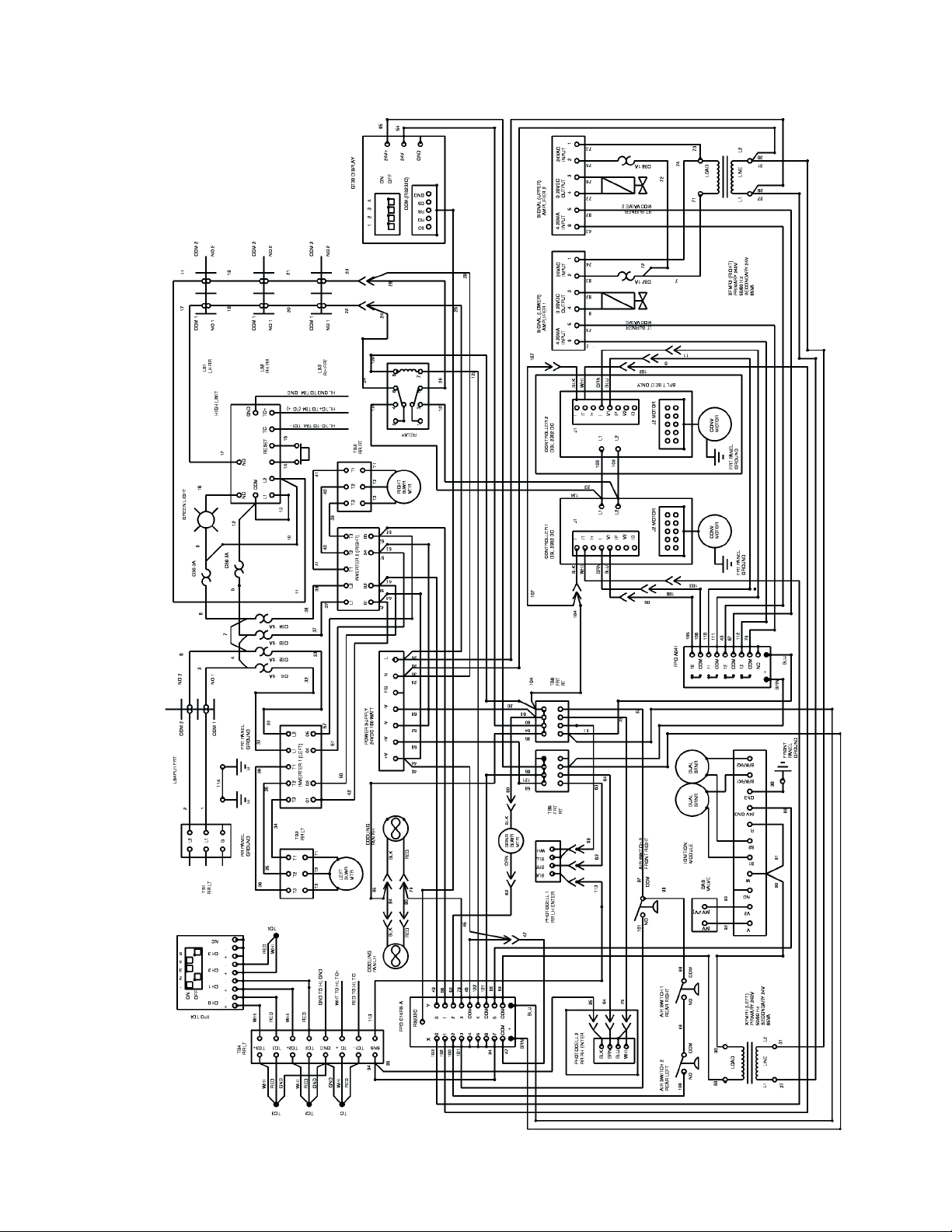

ELECTRICAL WIRING DIAGRAM ...................................... 23

I. WIRING DIAGRAM, 770 GAS OVEN, 208/240V,

50/60 Hz, 1 Ph ............................................................... 23

5

Page 6

678

Page 7

Page 8

14

Page 9

ITEM QTY P/N DESCRIPTION

1 1 55028 STOP,BACK SIDE CONV EXT

2 1 55027 STOP,SIDE END CONV EXT

3 1 59026

4 1 42612 KIT,SUPPLEMENT SVC AGENCY LIST

5 1 33120-0056 PIPE,BLK 1-1/4" X 54"

6 1 22450-0130 BAG,POLY4MIL 9" X 12"W/MINI-GRIP

7 1 59155 BUSHING,HEYCO SB 1500-18

8 1 59099 Reflector

9 1 59098 Bracket, Reflector

10 1 59226 WLDMT, Bracket Reflector

11 2 48522 Spacer, 1.5" Dia X 1.125" H

12 2 19A15144 SCR, MS HH 10-32 X 1-1/4 18-8

OWNER'S OPERATING &

INSTALLATION MANUAL

9

Page 10

10

Page 11

D. STANDOFF INSTALLATION

1 Place screw, P/N 19A15144, through counter-bored hole in

standoff, P/N 48522, and screw into weld nut on rear shroud.

2. Repeat procedure for both sides.

11

Page 12

ATTACHING THE POINT OF SALE CABLE

Remove the cable (P/N 59198) from the Kit. Attach the 90

degree plug to the rear of the touchscreen display and route

the serial connector out the grommetted bottom hole and

along the gas pipe. Connect the serial connector with the

cable supplied by the customer.

Mount the new reflector bracket to the provided holes on the

front right-hand side of the oven. The reflector should be

positioned just above the conveyor belt.

Using an assistant, hold both back cover switches in the

closed position. This will allow power to the photo-eye, and

it will provide a red beam for aiming. Loosen one of the screws

holding the photo detector gimbal tight, allowing it to be

reaimed at the reflector. The beam should hit exactly in the

center of the reflector, then tighten the screw back down.

Note: This is MUCH easier in reduced light.

Replace all covers.

CONVEYOR BELT REVERSAL

Conveyor belt reversal consists of three steps:

1. Physically reversing the conveyor belt

2. Resetting direction jumper on the conveyor control board.

3. Switching the photo detector.

REVERSING THE CONVEYOR BELT

Remove the conveyor from the oven and find the master link

location. Remove master links and remove the belt from the

conveyor frame. Reassemble the belt back onto the frame (in

the reverse direction) and reinstall the master links. Replace

the conveyor assembly in the oven.

RESETTING DIRECTION JUMPER

Locate Jumper P1 on the conveyor control board. Move jumper

from terminals 1 and 2, and replace onto terminals 2 and 3.

SWITCHING PHOTO DETECTOR

Remove both rear fan belt covers, then remove the motor cover

assembly from both sides of the oven. The photo eye is located

on the front side of the left motor bracket. Disconnect the three

connecting wires, noting which color wires assemble to the

associated wires on the photo-detector. Remove the entire

photo detector bracket. Replace the assembly to the righthand side of the unit, mirroring the way it was assembled on

the left. Reconnect the detector wiring in the same order it was

on the left.

Incoming electrical power lines are fed through the strainrelief fitting, shown in Figure 2-12. The electrical supply

connections are made inside the electrical junction box. The

power lines then connect to the oven circuits through safety

switches located inside the machinery compartment and

each blower motor compartment. These switches interrupt

electrical power to the oven when the Machinery Compartment Access Panel is opened, OR when either of the blower

or rear shrouds is removed.

12

Page 13

Connection

Refer to the wiring diagram inside the machinery compartment of the oven to determine the correct connections for the

electrical supply lines. Connect the supply as indicated on the

wiring diagram.

CAUTION

The terms of the oven's warranty require all start-ups, conversions and service work to be performed by a Middleby Marshall

Authorized Service Agent.

13

Page 14

Certain safety code requirements exist for the installation of

gas ovens; refer to the beginning of Section 2 for a list of the

installation standards. In addition, because a the oven is

equipped with casters, the gas line connection shall be made

with a connector that complies with the Standard for Connectors for Movable Gas Appliances, ANSI Z21.69 (in U.S.A.), as

well as a quick-disconnect device that complies with the

Standard for Quick-Disconnect Devices for Use With Gas Fuel,

ANSI Z21.41 (in U.S.A.).

D. PS770 Propane conversion

Four items have to be changed, to change the oven to LP:

1. Adjust internal burner air shutters.

2. Replace main Orifices

3. Replace (and adjust) the spring in the main valve (see LP kit)

4. Adjust modulating valve bypass settings.

Disconnect the manifold unions closest to the main burner,

and remove the manifold assemblies (four screws each).

Remove the addition four screws holding the burner cores and

slide out each burner core (leaving the ignition and sense

wires connected). Adjust the internal air shutters fully open,

and replace the cores.

Replace the main orifices on the manifold assemblies with the

LP units, and replace the manifold assemblies. Reconnect the

unions. Replace the valve spring with the LP spring, and adjust

the downstream pressure to get 7″ WC.

Adjust the bypass screws in the side of each modulating valve

to approximately 1/6 turn from fully closed. If this setting is too low,

the burners will shut off when trying to modulate. If it is too open,

the unit will tend to gradually raise up in temperature at standby.

Figure 2-14 - Gas Burner/Blower Motor and Piping Assembly

Gas Burner

14

Burner/Blower Motor

Page 15

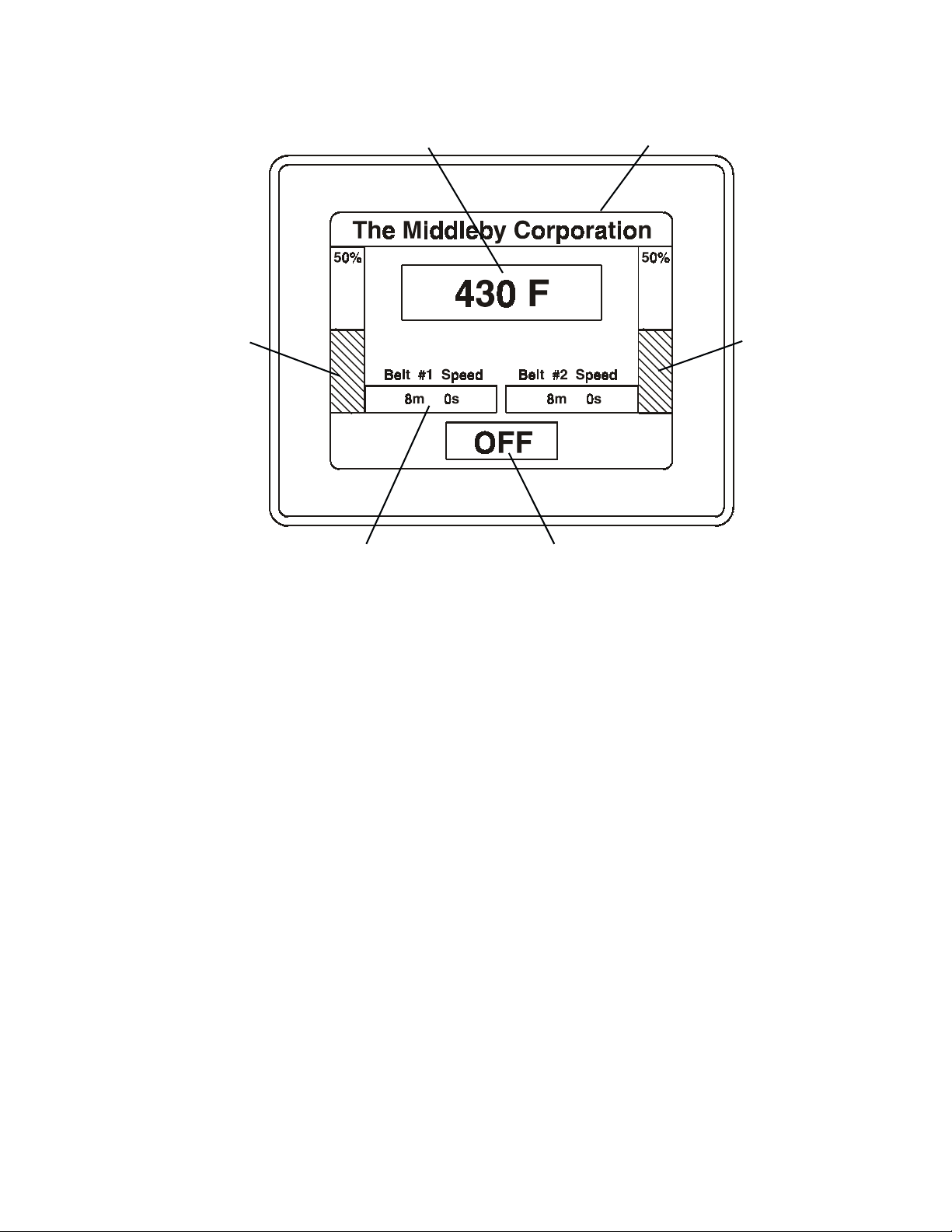

SECTION 3 - OPERATION

E. Energy Level

Indicators

C. Temperature Control/Display

B. Conveyor Time Setting

D. Message Bar

E. Energy Level

Indicators

A. Main On/Off Button

I. LOCATION AND DESCRIPTION OF CONTROLS

A. Main On/Off Button

Turns all oven functions on or off. If the oven is below the set

point, it will rise to the set point and turn the conveyor on.

If it is turned off and the oven is above 200° F, the blowers

will remain on until the oven drops below 200° F.

B. Conveyor Time Setting

Adjusts and displays the conveyor bake time. Dual belt

ovens have two displays, single units have one.

C. Temperature Control/Display

Displays the average set point of both right and left sides

of the oven. Pressing on the display allows individual

temperature displays and adjustments.

D. Message Bar

Displays messages during oven operation.

E. Energy Level Indicators

Displays energy usage on left and right sides of the oven.

15

Page 16

II. NORMAL OPERATION - STEP-BY-STEP-

A. Daily Startup Procedure

1. Check that the circuit breaker/fused disconnect is in

the On position. Check that the window is closed. The

touch panel display should be lit.

2. Adjust the conveyor to the desired bake time.

3. Press the temperature button to display right and left

hand oven settings. Set temperatures as desired.

4. Press the ON button to activate the oven. The conveyor

will not run, until the oven temperature has reached the

set points.

B. Daily Shutdown Procedure

1. Make certain there are no products left on the conveyor

in the oven.

2. Press the ON square to turn the oven off.

3. Open the window to allow the oven to cool faster.

4. After the oven has cooled and the blowers have turned off,

the circuit breaker/fused disconnect may be turned off.

Quick Reference – Touch Screen Controller

A. Main Screen

1. On/Off button - Used to turn oven On and Off.

2. Conveyor speed - Pressing on either the minutes or

seconds allows a new value to be input for the conveyor

speed. Split belt ovens have two inputs (front and rear

belts).

3. Oven temperature - Pressing on the set temperature

shifts the user to the oven temperature set point/

indicator screen.

4. Energy level indicators - Indicators to either side of the

screen indicate the energy input to that side of the

oven.

5. Message bar - Indicates various messages pertaining

to current oven conditions.

B. Oven Temperature/Set Point/Indicator Screen

1. Right actual temperature - Indicates current average

temperature of the right side of the oven.

2. Left actual temperature - Indicates current average

temperature of the left side of the oven.

NOTE: Right to Left temperature settings should not

exceed a differential of 20 °F.

3. Right Set point temperature - Pressing on this value

allows the user to adjust the set point for the right side

of the oven.

4. Left Set point temperature - Pressing on this value

allows the user to adjust the set point for the left side

of the oven.

5. Exit - Returns to the main screen.

C. Energy Modes

Energy Mode One - This mode is automatic, and starts

(bake time +1 minute) after the last product has entered the

oven. In this mode, the main oven blowers will lower to 1500

RPM, while the oven maintains temperature and belt

speed.

Energy Mode Two - The oven lowers its set point by 100°

F, and stops the belt. Anytime that the oven is more than

10 degrees over its set point, the burners will completely

shut off, allowing the oven to cool and the burners are on

minimum flow. The main blowers will continue to run at

1500 RPM in this mode. Placing any article on the input

belt will cause normal operation of the oven to resume, and

bring the set point back to its original level. The belt will

resume operation once both sides of the oven are within

5° F of the set point.

Energy Mode Three - The oven will turn off completely and

shut off the circulation blowers once the oven temperature

has dropped below 200° F. Placing any article on the input

belt will cause normal operation of the oven to resume, and

bring the set point back to its original level. The belt will

resume operation once both sides of the over are within

5° F of the set point.

Energy Mode Four - This is a complete oven shut down.

Placing anything on the belt will NOT return the oven to

Operation. The ON button on the main screen has to be

pressed to restart the oven.

16

Page 17

III. QUICK REFERENCE: TROUBLESHOOTING

SYMPTOM PROBLEM SOLUTION

Oven will not

turn On.

Oven will not

heat.

Oven is operating, but

little or no air is coming

from the fingers.

Conveyor will not move.

No electrical power • Check that the circuit breaker/fused disconnect is on. Make

sure the emergenct stop button is on.

No gas pressure

Burner did not light

Air fingers may be assembled incorrectly after

cleaning.

Oven is not up to operating

temperature.

Conveyor may be jammed.

• Make sure main gas is on.

• Turn oven off, and restart. If it still does not light, call for

service.

• Turn oven off, and allow to cool. Reassemble fingers

correctly.

• Allow oven to preheat.

• Turn oven off, and allow to cool. Check conveyor for blockage.

SCREEN ALERTS

SYMPTOM PROBLEM SOLUTION

lower right hand corner

The internal battery needs

to be replaced to retain

energy mode timings.

• A qualified service technician should accomplish this.Battery Symbol in the

High Control Compart-

ment Temperature

Combustion Blower

problem.

Control Over Temp Front filters are clogged • Clean or replace filters.

Front belt jammed Front belt has stopped • Remove obstruction, and restart oven.

Rear Belt jammed Rear belt has stopped • Remove obstruction, and restart oven.

High Temp Error Thermocouple or • Call service

Belt off-Oven not Normal operation until

in temperature Oven reaches operating

Energy Saving Mode 1 Normal operation

Energy saving mode 2 Normal Operation

Clean and replace the

front fan filters.

The computer has

detected a problem with

either the main, or burner

blowers.

PLC malfunction

temperature

• Failure to do this will eventually shut down the oven due to

excessive temperature.

• This should be corrected by a qualified service technician.Main Blower problem or

• If no obstruction, call service.

• If no obstruction, call service.

Energy saving Mode 3 Normal operation

17

Page 18

181920

Page 19

Page 20

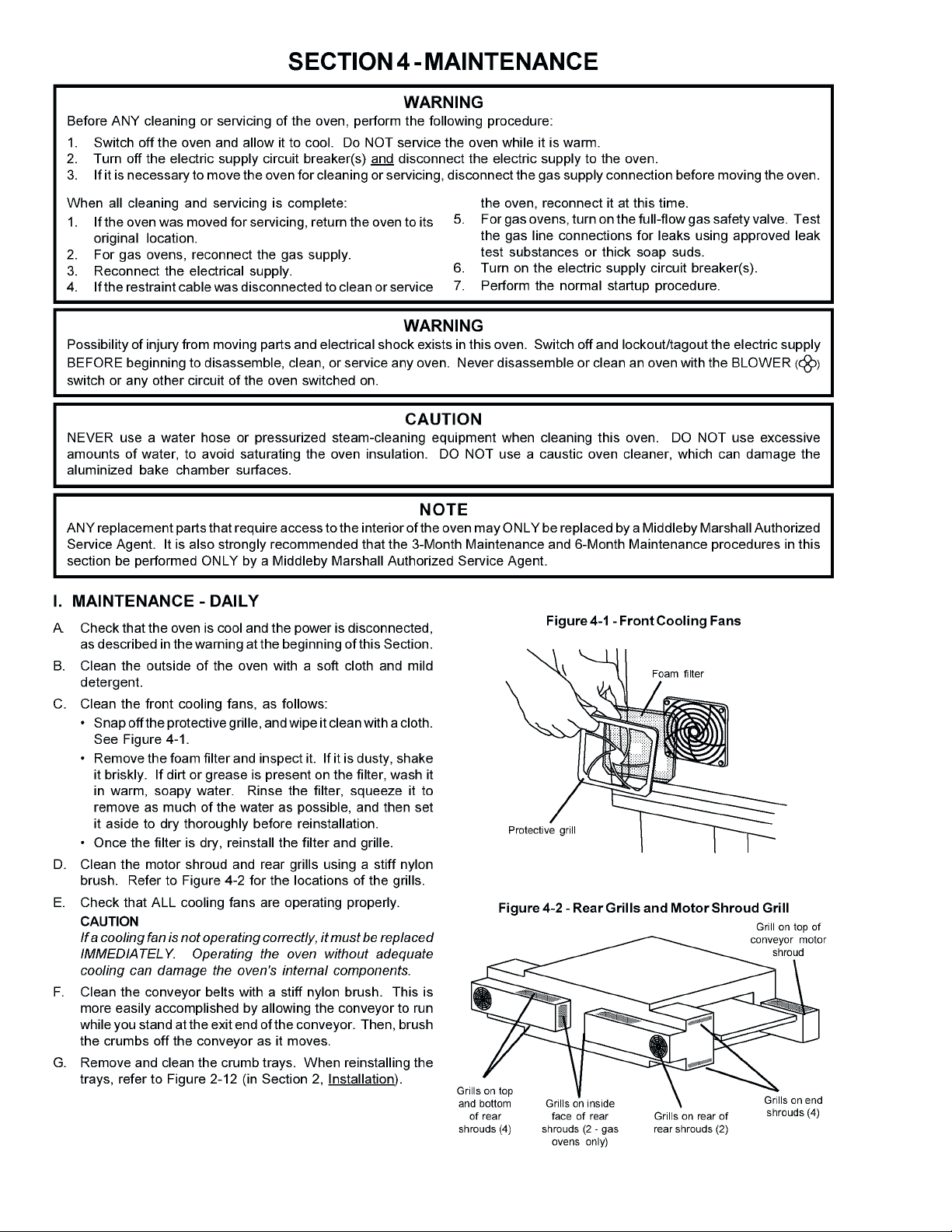

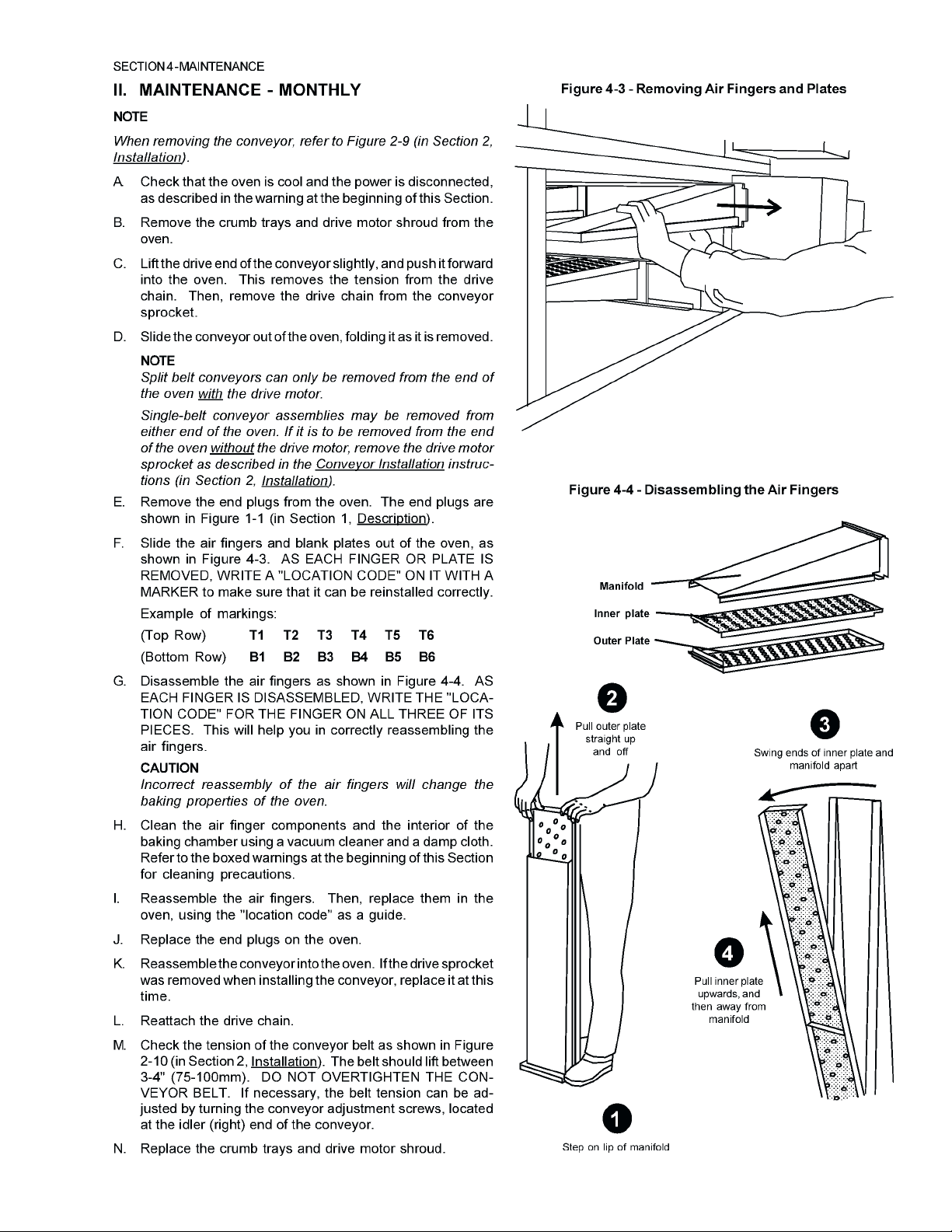

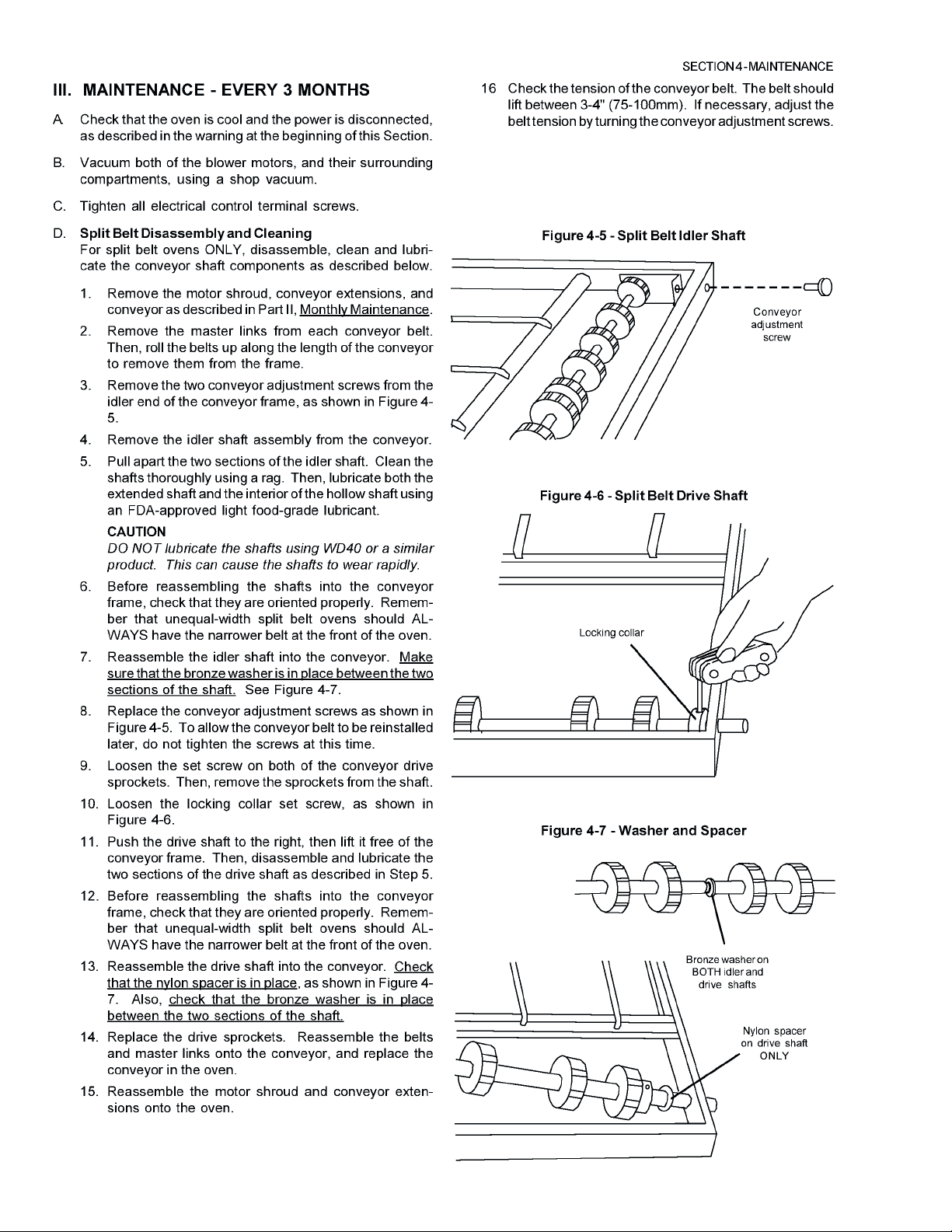

Page 21

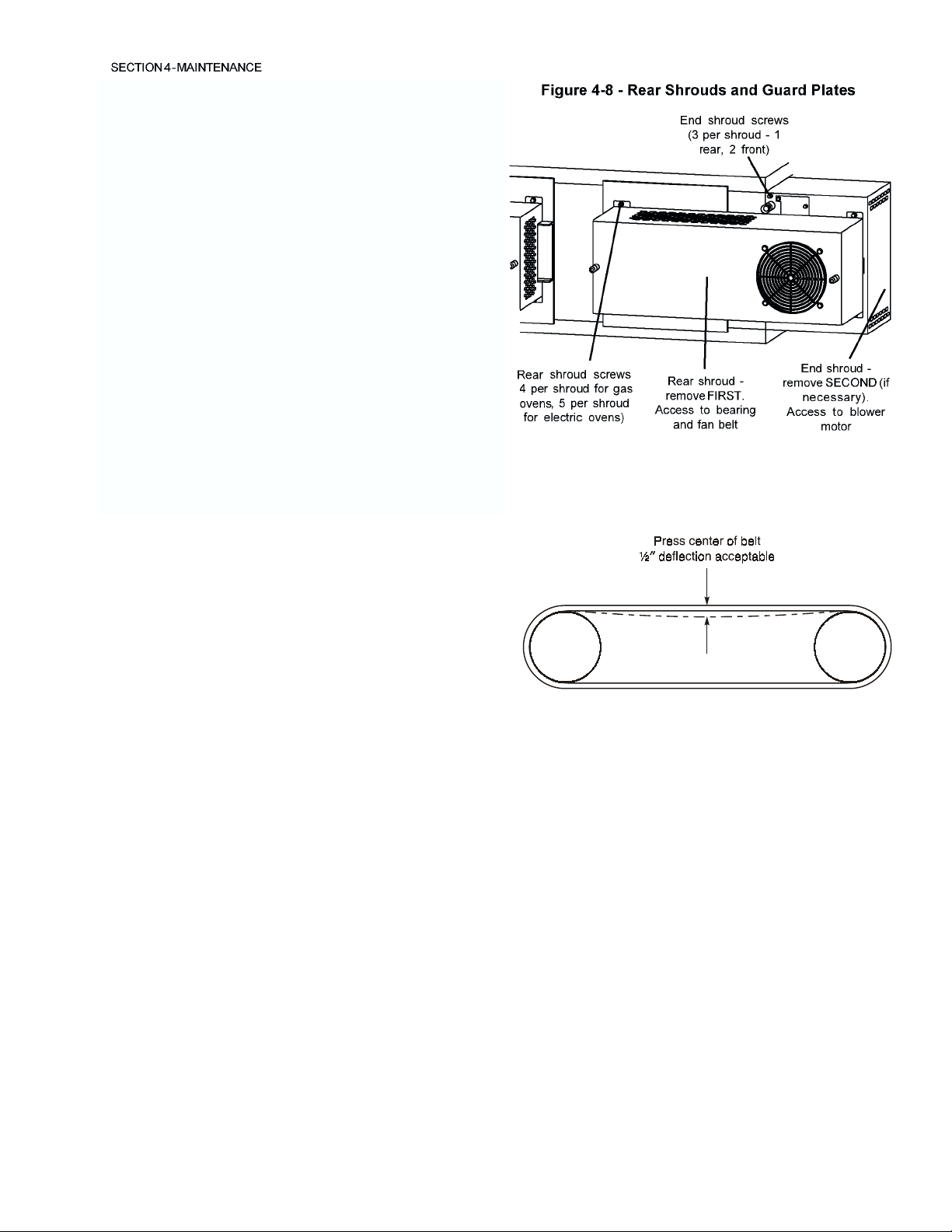

E. Blower Belts

1. To gain access to each blower belt compartment remove

the four screws shown in Figure 4-8. Then, lift the rear

shroud off its hangers.

If access to the blower motors is required, remove the

three mounting screws (two on the front of each shroud

and one on the rear). Then, lift the end shroud straight up

and off its hangers.

2. Check each blower belt for cracking or excessive wear.

3. Check for amount of belt deflection in the center of the belt,

1/2″ deflection is acceptable, see Figure 4-9.

4. If necessary, replace belt.

IV. MAINTENANCE - EVERY 6 MONTHS

A. Check that the oven is cool and the power is disconnected

as described in the warning at the beginning of this Section.

B. For gas ovens, clean and inspect the burner nozzel and

electrode assembly.

C. Check (and clean, if necessary) the oven venting system.

D. Check the conveyor drive shaft bushings and spacers.

Replace the components if they are worn.

Figure 4-9 - Belt Deflection

21

Page 22

ITEM QTY. P/N DESCRIPTION

1 1 59080 DIGITAL DISPLAY, PROGRAMMED

2 1 58678 MOTOR, CONVEYOR DRIVE

3 1 58679 CONVEYOR CONTROL BOARD

4 2 59169 INVERTER, PROGRAMMED

5 1 M9608 POWER SUPPLY

6 1 59047 KIT, THERMOCOUPLE (5 THERMOCOUPLES)

7 2 M9616 FAN, COOLING

8 2 57288 MOTOR, BLOWER

9A 1 57141 AIR SWITCH BURNER/BLOWER MOTOR

9B 2 50610 AIR SWITCH MAIN BLOWER

10 1 54727 IGNITION MODULE

11 1 M9887 ASSEMBLY, BURNER BLOWER/MOTOR

12 2 41647 VALVE, MODULATING GAS, 1/2"

13 2 31651 AMPLIFIER, MODULATING VALVE

14 1 33983 HIGH LIMIT CONTROL MODULE, 240V

15 2 32108 TRANSFORMER, 240Vp:24Vs

16 1 59082 PLC MODULE, PROGRAMMED

17 1 58668 THERMOCOUPLE MODULE

18 1 58669 CURRENT MODULE

19 1 59112 PHOTOCELL

12 345

10

15

16, 17, 18

22

19

Page 23

Wiring Diagrams (electrical schematics)

54745 Rev. I

23

Middleby-Marshall Model Number G208-240 volt 50/60 Hz, 1 Phase

Page 24

Loading...

Loading...