Page 1

PS740 Series

Electric

Domestic & Std. Export

ENGLISH

P/N 60254

November 18, 2008 Rev. B

PS740 Series Electric Ovens

Model:

• PS740E Electric

Combinations:

• Single Oven

• Double Oven (Two-Stack)

• Triple Oven (Three-Stack)

OWNER'S OPERATING AND

INSTALLATION MANUAL

for domestic and standard export ovens

©2007 Middleby Marshall Inc.

is a registered trademark of Middleby Marshall, Inc. All rights reserved.

Middleby Cooking Systems Group • 1400 Toastmaster Drive • Elgin, IL 60120 • (847)741-3300 • FAX (847)741-4406

Page 2

NOTICE:

This Owner's Operating and Installation Manual should be given to the user. The operator of the oven should be

familiar with the functions and operation of the oven.

This manual must be kept in a prominent, easily reachable location near the oven.

It is suggested to obtain a service contract with a Middleby Marshall Authorized Service Agent.

WARNING

FOR YOUR SAFETY, DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

Improper installation, adjustment, alteration, service, or maintenance can cause

property damage, injury, or death. Read the installation, operation, and maintenance instructions

thoroughly before installing or servicing this equipment.

IMPORTANT

An electrical wiring diagram for the oven is located inside the machinery compartment.

IMPORTANT

It is the customer’s responsibility to report any concealed or non-concealed damage to the

freight company. Retain all shipping materials until it is certain that the equipment has

not suffered concealed shipping damage.

NOTICE

CONTACT YOUR MIDDLEBY MARSHALL AUTHORIZED SERVICE AGENT TO PERFORM

MAINENANCE AND REPAIRS. AN AUTHORIZED SERVICE AGENCY DIRECTORY IS

SUPPLIED WITH YOUR OVEN.

NOTICE

Using any parts other than genuine Middleby Marshall factory manufactured parts relieves the

manufacturer of all warranty and liability.

NOTICE

Middleby Marshall (Manufacturer) reserves the right to change specifications at any time.

NOTICE

The equipment warranty is not valid unless the oven is installed, started and demonstrated under the

supervision of a factory certified installer.

NOTICE

A Middleby Marshall certified installer must be used to install and service this appliance.

NOTICE

This equipment is only for professional use and shall be used by qualified people.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Middleby Cooking Systems Group • 1400 Toastmaster Drive • Elgin, IL 60120 USA • (847)741-3300 • FAX (847) 741-4406

www.middleby.com

ii

Page 3

Model No.

Modéle No.

Serial No.

Serié No.

Installation Date

Date d'installation

MIDDLEBY MARSHALL

NO QUIBBLE LIMITED WARRANTY

(U.S.A. ONLY)

MIDDLEBY MARSHALL, HEREINAFTER REFERRED TO

AS “THE SELLER”, WARRANTS EQUIPMENT MANUFACTURED BY IT TO BE FREE FROM DEFECTS IN MATERIAL AND WORKMANSHIP FOR WHICH IT IS RESPONSIBLE. THE SELLER’S OBLIGATION UNDER THIS WARRANTY SHALL BE LIMITED TO REPLACING OR REPAIRING, AT SELLER’S OPTION, WITHOUT CHARGE, ANY

PART FOUND TO BE DEFECTIVE AND ANY LABOR AND

MATERIAL EXPENSE INCURRED BY SELLER IN REPAIRING OR REPLACING SUCH PART. SUCH WARRANTY

SHALL BE LIMITED TO THE ORIGINAL PURCHASER

ONLY AND SHALL BE EFFECTIVE FOR A PERIOD OF

ONE YEAR FROM DATE OF ORIGINAL INSTALLATION, OR

18 MONTHS FROM DATE OF PURCHASE, WHICHEVER

IS EARLIER, PROVIDED THAT TERMS OF PAYMENT HAVE

BEEN FULLY MET.

This warranty is valid only if the equipment is installed, started,

and demonstrated under the supervision of a factory-authorized installer.

Normal maintenance functions, including lubrication, cleaning, or customer abuse, are not covered by this

warranty

Seller shall be responsible only for repairs or replacements

of defective parts performed by Seller’s authorized service

personnel. Authorized service agencies are located in principal cities throughout the contiguous United States, Alaska,

and Hawaii. This warranty is valid in the 50 United States

and is void elsewhere unless the product is purchased

through Middleby International with warranty included.

.

The foregoing warranty is exclusive and in lieu of all other

warranties, expressed or implied. There are no implied

warranties of merchantability or of fitness for a particular purpose.

The foregoing shall be Seller’s sole and exclusive obligation

and Buyer’s sole and exclusive remedy for any action, including breach of contract or negligence. In no event shall

Seller be liable for a sum in excess of the purchase price of

the item. Seller shall not be liable for any prospective or lost

profits of Buyer.

This warranty is effective on Middleby Marshall equipment sold on, or after, February 15, 1995.

no quibble

MIDDLEBY MARSHALL INC.

OVEN LIMITED WARRANTY

(Non U.S.A.)

The Seller warrants equipment manufactured by it to be free from

defects in material and workmanship for which it is responsible. The

Seller’s obligation under this warranty shall be limited to replacing or

repairing, at Seller’s option, without charge, F.O.B. Seller’s factory,

any part found to be defective and any labor and material expense

incurred by Seller in repairing or replacing such part. Such warranty

is limited to a period of one year from date of original installation or

15 months from date of shipment from Seller’s factory, whichever is

earlier, provided that terms of payment have been fully met. All labor

shall be performed during regular working hours. Overtime premium

will be charged to the Buyer.

This warranty is not valid unless equipment is installed, started,

and demonstrated under the supervision of a factory-authorized installer.

Normal maintenance functions, including lubrication, adjustment of

airflow, thermostats, door mechanisms, microswitches, burners and

pilot burners, and replacement of light bulbs, fuses and indicating

lights, are not covered by warranty.

Any repairs or replacements of defective parts shall be performed by

Seller’s authorized service personnel. Seller shall not be responsible for any costs incurred if the work is performed by other than

Seller’s authorized service personnel.

When returning any part under warranty, the part must be intact and

complete, without evidence of misuse or abuse, freight prepaid.

Seller shall not be liable for consequential damages of any kind

which occur during the course of installation of equipment, or which

result from the use or misuse by Buyer, its employees or others of

the equipment supplied hereunder, and Buyer’s sole and exclusive

remedy against Seller for any breach of the foregoing warranty or

otherwise shall be for the repair or replacement of the equipment or

parts thereof affected by such breach.

The foregoing warranty shall be valid and binding upon Seller if and

only if Buyer loads, operates and maintains the equipment supplied

hereunder in accordance with the instruction manual provided to

Buyer. Seller does not guarantee the process of manufacture by

Buyer or the quality of product to be produced by the equipment

supplied hereunder and Seller shall not be liable for any prospective

or lost profits of Buyer.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF

ALL OTHER EXPRESS AND IMPLIED WARRANTIES WHATSOEVER. SPECIFICALLY THERE ARE NO IMPLIED WARRANTIES

OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR

PURPOSE.

The foregoing shall be Seller’s sole and exclusive obligation and

Buyer’s sole and exclusive remedy for any action, whether in breach

of contract or negligence. In no event shall seller be liable for a sum

in excess of the purchase price of the item.

© 2003 - Middleby Marshall, A Middleby Company.

The Middleby Marshall logo is a registered trademark of Middleby Marshall, A Middleby Company.

Middleby Marshall Inc. • 1400 Toastmaster Drive • Elgin, Illinois 60120-9272 U.S.A. • (847) 741-3300 • FAX: (847) 741 4406

iii

Page 4

TABLE OF CONTENTS

Page

SECTION 1 – DESCRIPTION ............................................ 1

I. OVEN USES ............................................................ 1

II. OVEN COMPONENTS ............................................ 1

A. Conveyor Motor Drive ................................... 1

B. Crumb Pans .................................................. 1

C. Conveyor ....................................................... 1

D. End Plugs ...................................................... 1

E. Eyebrows ...................................................... 1

F. Window ......................................................... 1

G. Machinery Compartment Access Panel ........ 1

H. Serial Plate .................................................... 1

I. Control Panel ................................................ 1

J. Photo Cell ..................................................... 1

K. Blowers ......................................................... 1

L. Air Fingers ..................................................... 1

III. OVEN SPECIFICATIONS ........................................ 2

A. Dimensions ................................................... 2

B. General Specifications .................................. 2

C. Electrical Specifications for

PS740 Electric Ovens ................................... 2

SECTION 2 – INSTALLATION ........................................... 3

I. BASE PAD KIT ......................................................... 4

II. INSTALLATION KIT ................................................. 6

III. VENTILATION SYSTEM ........................................ 12

A. Requirements .............................................. 12

B. Recommendations ...................................... 12

C. Other Ventilation Concerns ......................... 12

IV. ASSEMBLY ............................................................ 13

A. Base Pad, Legs, Casters ............................ 13

B. Stacking ....................................................... 14

C. Restraint Cable Installation ......................... 14

D. Conveyor Installation .................................. 15

E. Standoff Installation .................................... 15

V. FINAL ASSEMBLY ................................................. 16

VI. ELECTRICAL SUPPLY .......................................... 17

Connection ....................................................... 17

UTILITY ROUGH-IN DIMENSIONS AND

POSITIONING FOR PS840-SERIES OVENS ........ 18

Circuit Breaker ................................................. 18

Electrical Specifications ................................... 18

Electrical Rating ............................................... 18

Supply Wire ...................................................... 18

Suggested ........................................................ 18

Page

SECTION 3 – OPERATION .............................................. 19

I. LOCATION AND DESCRIPTION OF CONTROLS 19

II. NORMAL OPERATION, STEP-BY-STEP .............. 20

A. Main Screen ................................................ 20

B. Daily Startup Procedure .............................. 20

C. Daily Shutdown Procedure ......................... 20

III. QUICK REFERENCE: TROUBLESHOOTING ...... 21

IV. SCREEN ALERTS ................................................. 21

SECTION 4 – MAINTENANCE ........................................ 22

I. MAINTENANCE – DAILY ....................................... 22

II. MAINTENANCE – MONTHLY ............................... 23

III. MAINTENANCE – EVERY 3 MONTHS ................. 24

IV. MAINTENANCE – EVERY 6 MONTHS ................. 25

V. KEY SPARE PARTS KIT ....................................... 26

SECTION 5 – TROUBLESHOOTING .............................. 27

SECTION 6 – ELECTRICAL WIRING DIAGRAM ............ 28

WIRING DIAGRAM, 740 Electric Oven, E208/240V,

50/60 Hz, 3 Ph.............................................................. 28

WIRING DIAGRAM, 740 Electric Oven, E380-480V,

50/60 Hz, 3 Ph.............................................................. 29

NOTE

Wiring Diagrams are in Section 6 of this Manual.

The diagram for each oven is also on the lower

inner surface of its Control Console.

iv

Page 5

SECTION 1 – DESCRIPTION

I. OVEN USES

PS740 Series Ovens can be used to bake and/or cook a wide

variety of food products, such as pizza, pizza –type products,

cookies, sandwiches and others.

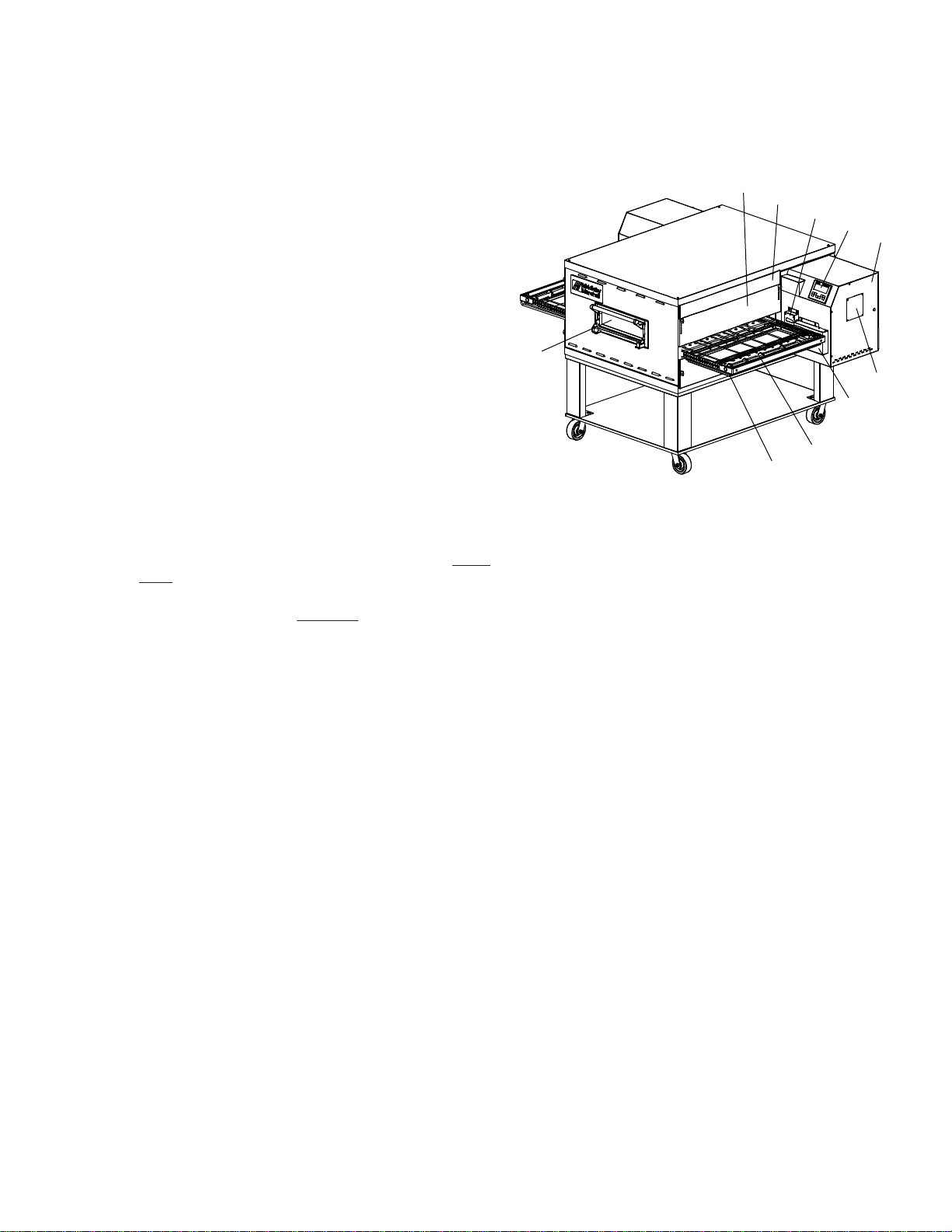

II. OVEN COMPONENTS – see Figure 1-1.

A. Conveyor Drive Motor: Moves the conveyor.

B. Crumb Pans: Catch crumbs and other materials that drop

through the conveyor belt. One crumb pan is located at

each end of the conveyor.

C. Conveyor: Moves the food product through the oven.

D. End Plugs: Allow access to the oven’s interior.

E. Eyebrows: Can be adjusted to various heights to prevent

heat loss into the environment.

F. Window: Allows the user to access food products inside

the baking chamber.

G. Machinery Compartment Access Panel: Allows access

to the oven’s interior and control components. No user

serviceable parts are located in the machinery compartment.

H. Serial Plate: Provides specifications for the oven that

affect installation and operation. Refer to Section 2,

lation for details.

I. Control Panel: Location of the operating controls for the

oven. Refer to Section 3, Operation, for details.

J. Photo Cell: Turns oven On when beam is interrupted.

Not Shown:

K. Blowers: Project hot air from the heating element to the air

fingers.

L. Air Fingers: Project streams of hot air onto the food

product.

Instal-

Figure 1-1. Oven Components

E

D

J

I

G

F

H

A

C

B

1

Page 6

I. OVEN SPECIFICATIONS

Table 1-1 Dimensions

Overall Height 48-3/16″ (1219mm) 62-3/4″ (1575mm) 78-11/16″ (1981mm)

Overall Depth 60″ (1524mm) 60″ (1524mm) 60″ (1524mm)

Overall Length 76-1/2″ (1930mm) 76-1/2″ (1930mm) 76-1/2″ (1930mm)

″″

32

″ Conveyor Model 33-1/2″ (838mm) 33-1/2″ (838mm) 33-1/2″ (838mm)

″″

″ ″

24

″ Conveyor Model

″ ″

Overall Depth 52.75″ (1340mm) 52.75″ (1340mm) 52.75″ (1340mm)

Overall Length 69″ (1753mm) 69″ (1753mm) 69″ (1753mm)

* All other dimension are the same

Recommended Minimum Clearances

Rear of Oven to Wall 3″ (76mm) 3″ (76mm) 3″ (76mm)

Control end of conveyor to Wall 1″ (25.4mm) 1″ (25.4mm) 1″ (25.4mm)

Non-control end of conveyor to Wall) 1″ (25.4mm) 1″ (25.4mm) 1″ (25.4mm)

Table 1-2: General Specifications PS740 ELECTRIC

Weight 1150 lbs. (522kg)

Rated Heat Input 27.0 kW/hr (92,128 BTU, 23,216 kcal)

Maximum Operation Temperature 600°F / 315°C

Air Blowers Two Blowers at 1900 RPM

Warmup Time 15 min.

Single Oven Double Oven Triple Oven

or 2 × 15″ (381mm) or 2 × 15″ (381mm) or 2 × 15″ (381mm)

Single Oven Double Oven Triple Ove

SERIES PS740 ELECTRICAL SPECIFICATIONS

Main Blower & Control Circuit Phase Frequency Amperage Poles Wires

Elements Voltage Voltage Draw

208-240V

208-240V 3 Ph 50/60 Hz 100 Amp 3 Pole 4 Wire

HEATER AMPERAGE

Voltage kW Average Amps

L1 L2 L3

208 27 85 75 75

240 27 75 75 65

(3 hot, 1 grd)

208-240V 3 Ph 50/60 Hz 75 Amp 4 Pole

380V

208-240V 3 Ph 50/60 Hz 60 Amp 4 Pole

480V

IMPORTANT –

Additional electrical information is provided on the oven’s serial plate, and on the wiring diagram

inside the machinery compartment.

Wiring Diagrams are contained in Section 6 of this Manual

HEATER AMPERAGE

Voltage kW Average Amps N

L1 L2 L3

380-480 27 51 41 41 10

HEATER AMPERAGE

Voltage kW Average Amps N

L1 L2 L3

480 27 43 33 33 10

NOTE

and are also located inside the oven at the

bottom of the Control Panel

This Manual Must Be Kept For Future Reference

2

5 Wire

(3 hot, 1neut, 1 grd)

5 Wire

(3 hot, 1neut, 1 grd)

Page 7

SECTION 2 – INSTALLATION

WARNING – After any conversions, readjustments, or service work on the oven:

• Check that the ventilation system is in operation.

WARNING - Keep the appliance area free and clear of combustibles.

WARNING – The oven must be installed on an even (level) non-flammable flooring and any adjacent walls

must be non-flammable. Recommended minimum clearances are specified in the Description section of

this manual.

WARNING – Do not obstruct the flow of ventilation air to and from your oven. There must be no

obstructions around or underneath the oven. Constructional changes to the area where the oven is

installed shall not affect the air supply to the oven.

CAUTION: To reduce the risk of fire, the appliance is to be mounted on floors of noncombustible construction with

noncombustible flooring and surface finish and with no combustible material against the underside thereof, or on

noncombustible slabs or arches having no combustible material against the underside thereof, such construction

shall in all cases extend not less than 12 inches (304mm) beyond the equipment on all sides.

CAUTION: For additional installation information, contact your local Authorized Service Agent.

NOTE – There must be adequate clearance between the oven and combustible construction. Clearance must also

be provided for servicing and for proper operation.

NOTE – An electrical wiring diagram for the oven is located inside the machinery compartment.

NOTE: All aspects of the oven installation, including placement, utility connections, and ventilation requirements,

must conform with any applicable local, national, or international codes. These codes supersede the requirements

and guidelines provided in this manual.

NOTE: In the USA, the oven installation must conform to local codes. Electric ovens, when installed, must be

electrically grounded in accordance with local codes, or in the absence of local codes, with the National Electrical

Code (NEC), or ANSI/NFPA70.

NOTE: In Canada, the oven installation must conform with local codes. Electric ovens, when installed, must be

electrically grounded in accordance with local codes, or in the absence of local codes, with the Canadian Electrical

Code CSA C22.2.

3

Page 8

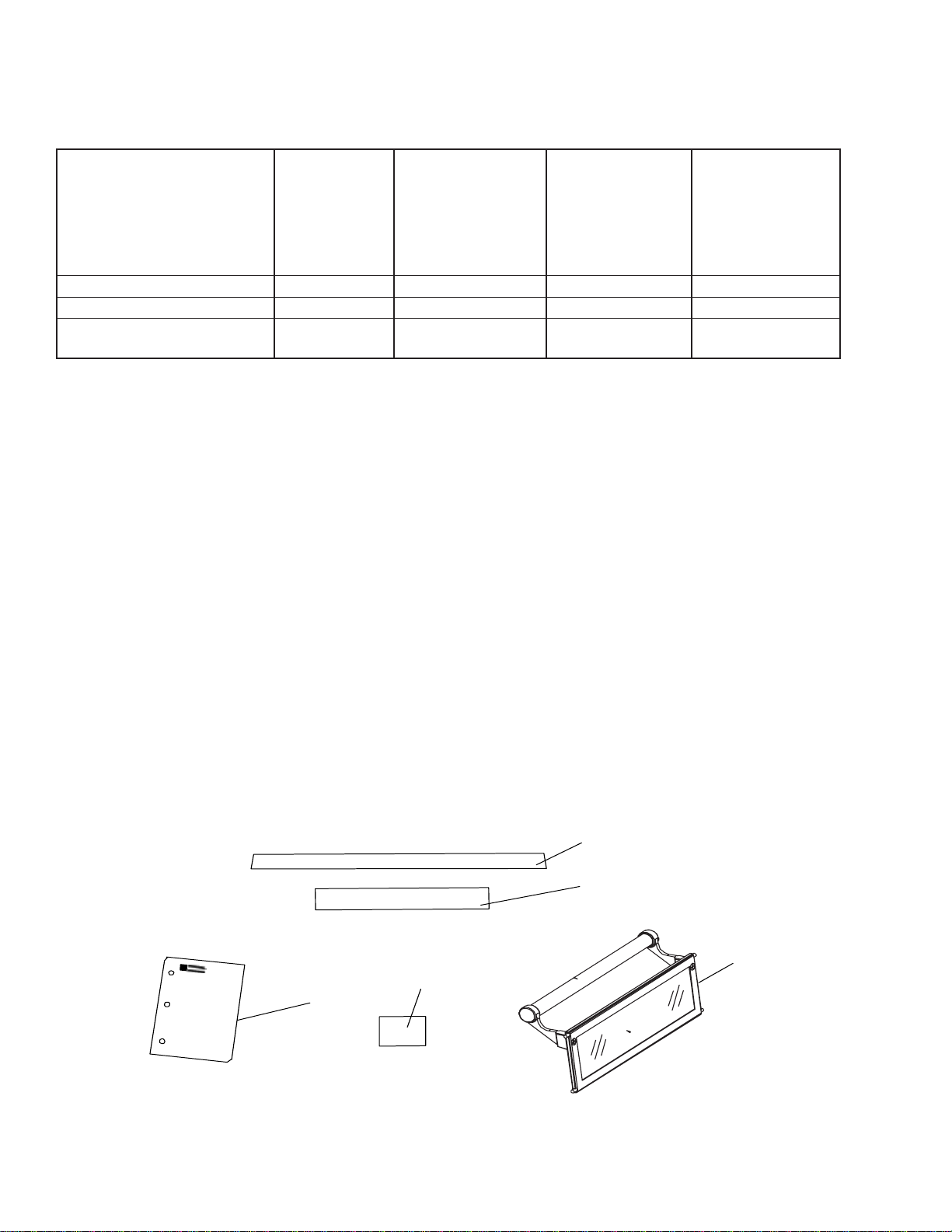

PS740 24

″″

″ OVEN INSTALLATION

″″

REQUIRED KITS AND EQUIPMENT

PS740 PS740 PS740 PS740

Electric Oven Single Oven DoubleOven TripleOven

Installation Option Base w/ OptionBase w/ OptionBase w/

TYPE OF INSTALLATION Kit 15″ Legs, 6″ Legs, Casters& Top

Casters & Top Casters & Top Kit

Kit Kit

P/N47810-0008 P/N61123 P/N61457 P/N61458

PS740 Single Gas Oven 1 1

PS740 Double Gas Oven 2 1

PS740 Triple Gas Oven 3 1

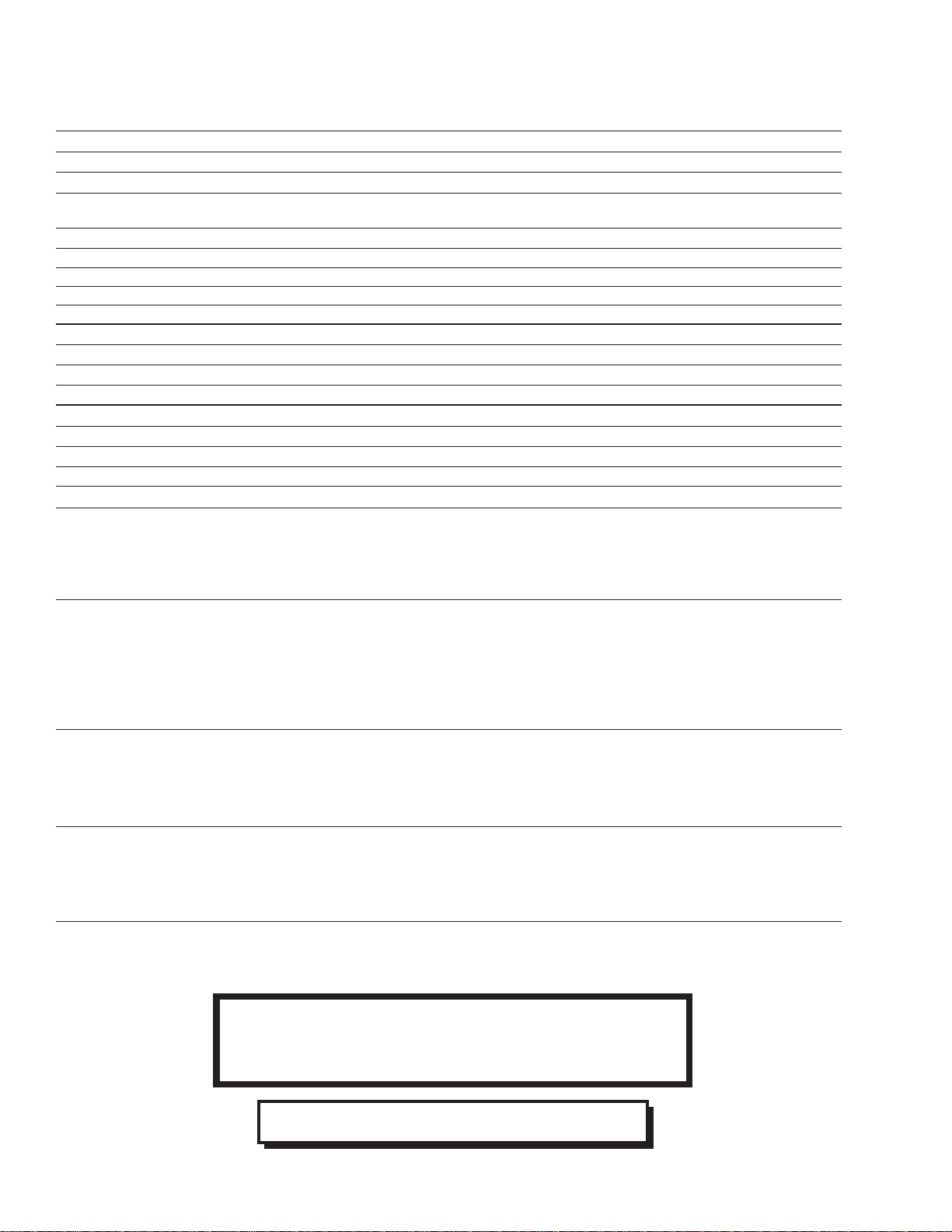

PARTS LIST FOR SERIES PS740 ELECTRIC OVEN

INSTALLATION KIT

P/N 47810-0008

(Two required for double oven)

(Three required for triple oven)

ITEM

NO. QTY PART NO. DESCRIPTION

1 1 55028 CONVEYOR END STOP

2 1 31461 CONVEYOR LEFT REAR STOP

3 1 42612 SERVICE AGENCY DIRECTORY

4 1 22500-0080 LABEL, MM

5 1 51054 ASSY, HANDLE & DOOR

Figure 2-1A. PS740-Series Electric Oven Installation Parts

1

2

4

3

4

5

Page 9

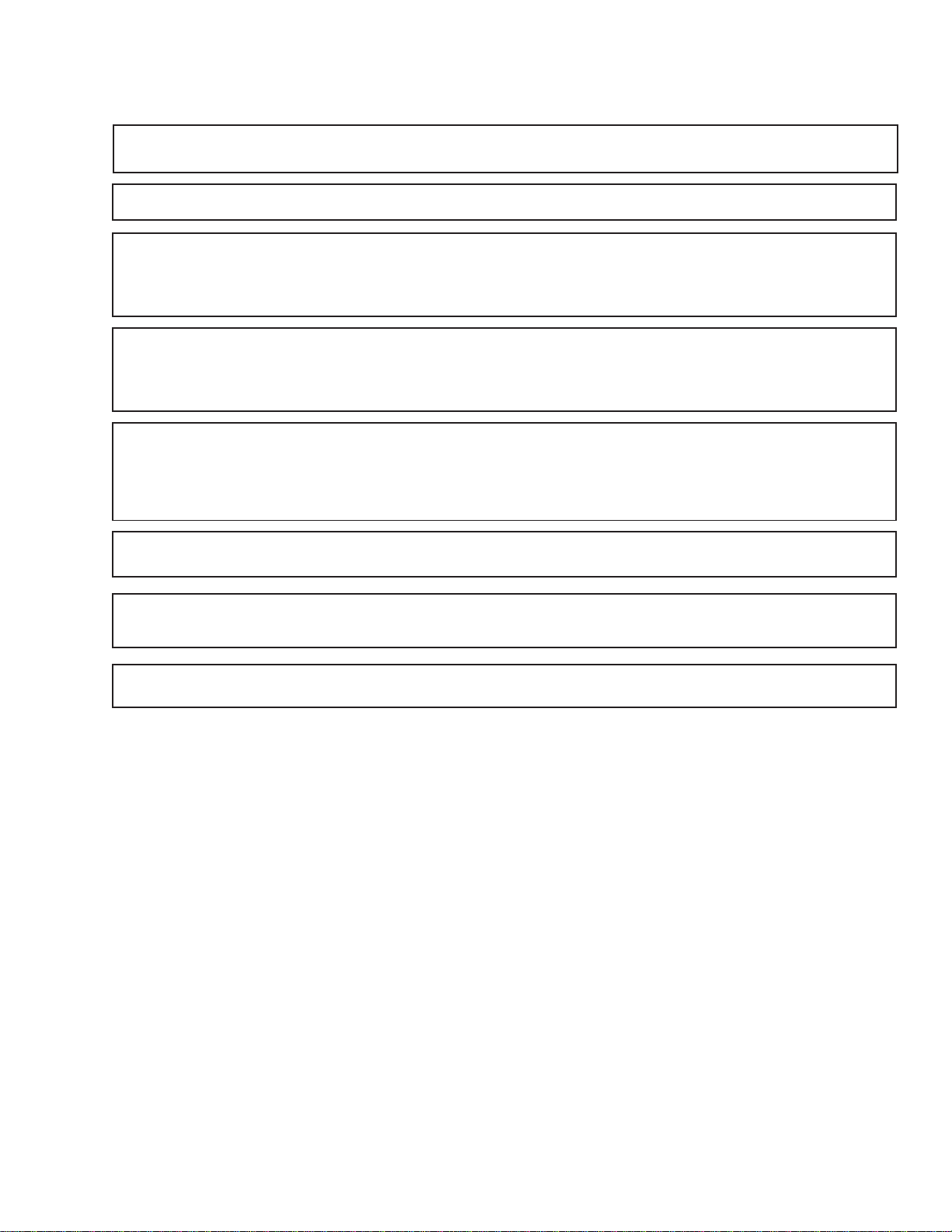

PS740 OVEN INSTALLATION

REQUIRED KITS AND EQUIPMENT

PS740 PS740 PS740 PS740

Electric Oven Single Oven DoubleOven TripleOven

Installation Option Base w/ OptionBase w/ OptionBase w/

TYPE OF INSTALLATION Kit 15″ Legs, 6″ Legs, Casters& Top

Casters & Top Casters & Top Kit

Kit Kit

P/N47810-0008 P/N59720 P/N59725 P/N59726

PS740 Single Electric Oven 1 1

PS740 Double Electric Oven 2 1

PS740 Triple Electric Oven 3 1

PARTS LIST FOR SERIES PS740 ELECTRIC OVEN

INSTALLATION KIT

P/N 47810-0008

(Two required for double oven)

(Three required for triple oven)

ITEM

NO. QTY PART NO. DESCRIPTION

1 1 55028 CONVEYOR END STOP

2 1 55027 CONVEYOR LEFT REAR STOP

3 1 42612 SERVICE AGENCY DIRECTORY

4 1 22500-0080 LABEL, MM

5 1 51054 ASSY, HANDLE & DOOR

Figure 2-1B. PS740-Series Electric Oven Installation Parts

1

2

4

3

5

5

Page 10

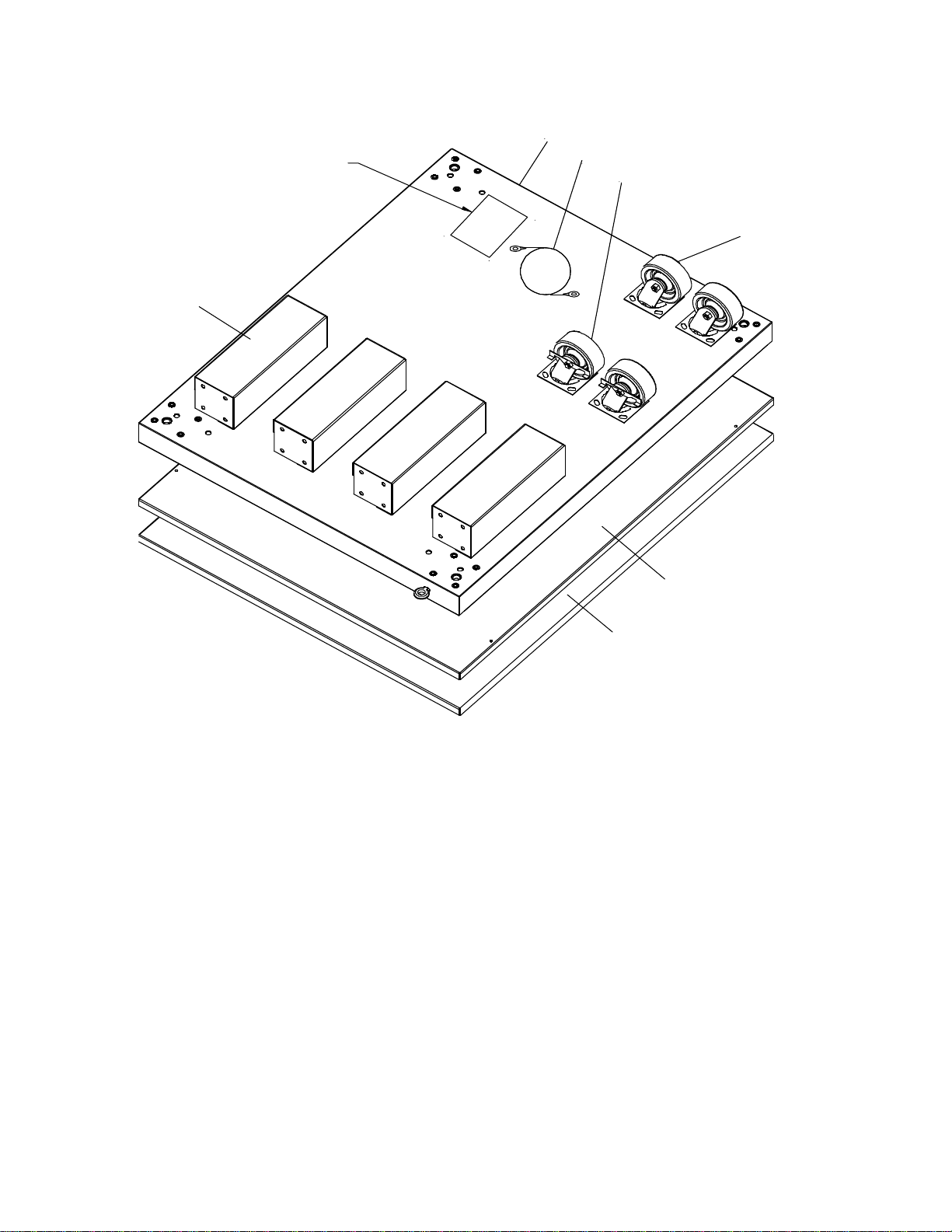

HARD WARE BA G

5, 6, 7, 10 & 11

2

Figure 2-2A. Model PS740 24

Option Base with Legs and Top

″″

″ Single Oven

″″

1

8

3

4

PARTS LIST FOR PS740 SERIES 24

ITEM NO. QTY PART NO. DESCRIPTION

1 1 61126 COMPLETE BASE WELDMENT

2 4 37900-0024 TOP PLATE, LEG WELDMENT

3 2 22290-0009 SWIVEL CASTER W/BRAKE FLAT PLATE

4 2 22290-0010 SWIVEL CASTER FLAT PLATE

5 32 2000531 3/8″-16 × 1″ HEX SCREW, SST

6 32 21416-0001 3/8″ FLAT WASHER, SS

7 32 21422-0001 3/8″ SPLIT LOCK WASHER, ZP

8 1 22450-0228 RESTRAINT CABLE ASSEMBLY

9 1 61125 TOP COVER

10 2 59677 SCR, MS SL TR HD 10-32 × 2-1/2″

11 2 7A2S15 SCR, MS STR TRSHD 10-32 × 3/4″

12 1 61128 SUPPORT, SHELF

9

12

″″

″ SINGLE OVEN OPTION - BASE w/15

″″

P/N 61123

″″

″ LEGS & TOP

″″

6

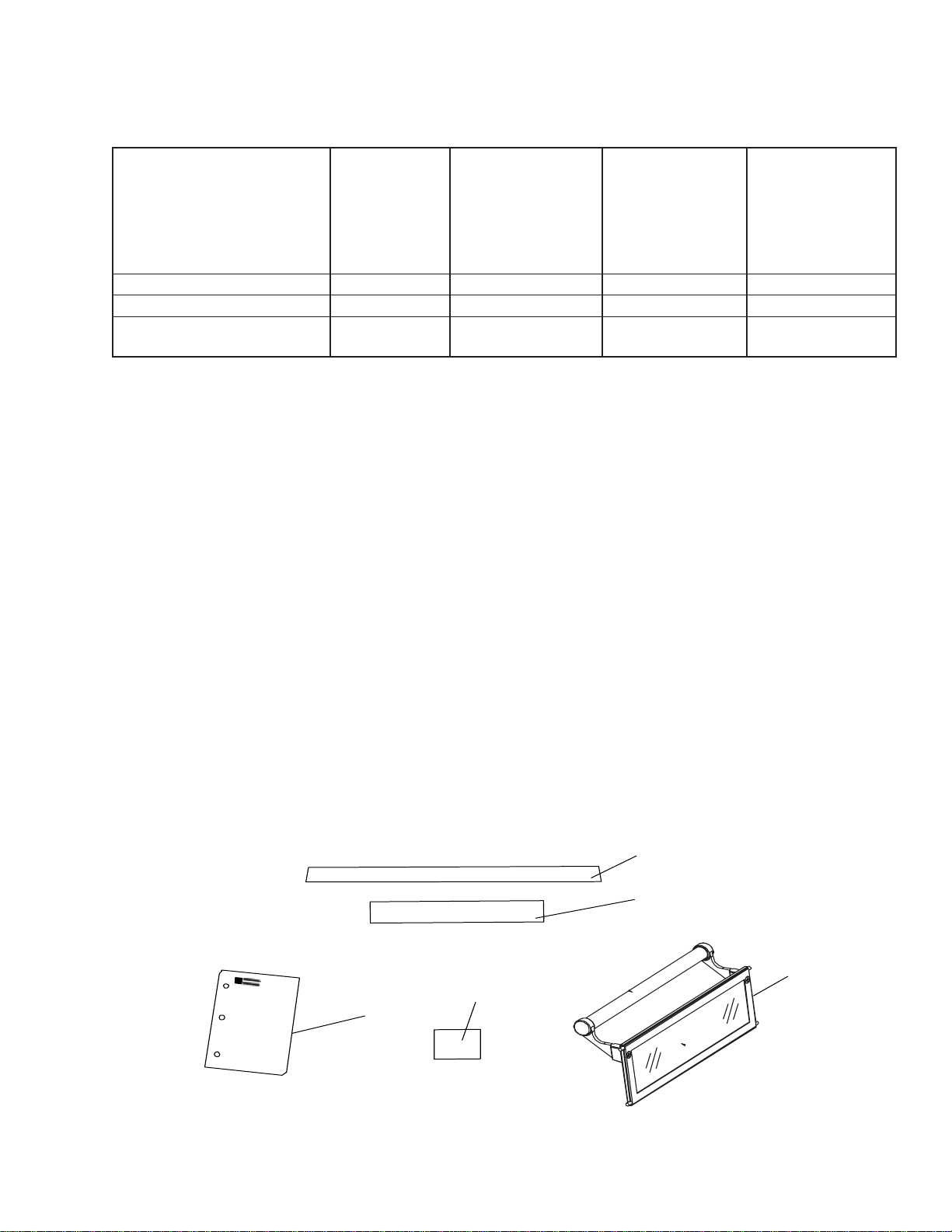

Page 11

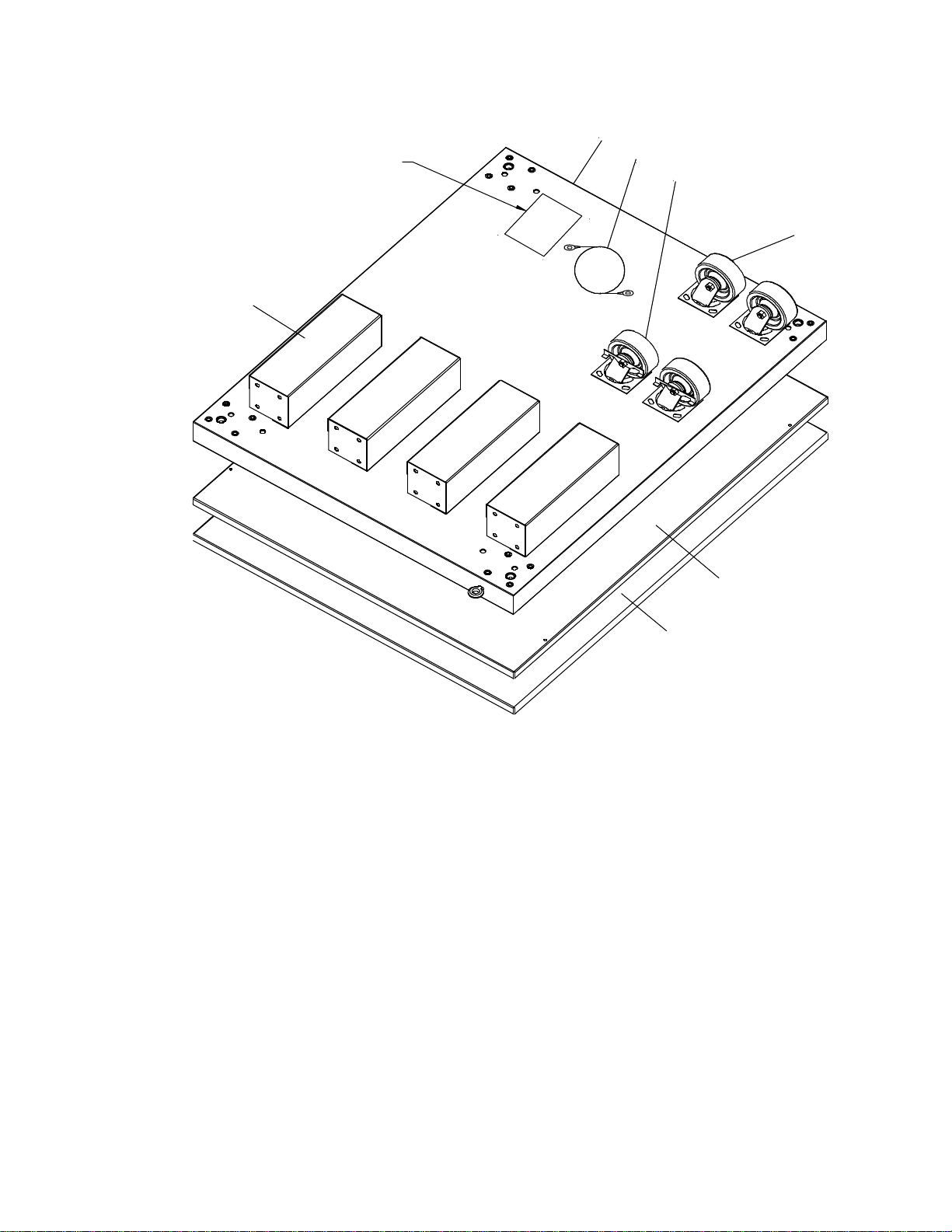

HARD WARE BA G

5, 6, 7, 10 & 11

2

Figure 2-2B. Model PS740 32

Option Base with Legs and Top

″″

″ Single Oven

″″

1

8

3

4

PARTS LIST FOR PS740 32

ITEM NO. QTY PART NO. DESCRIPTION

1 1 60287 COMPLETE BASE WELDMENT

2 4 37900-0024 TOP PLATE, LEG WELDMENT

3 2 22290-0009 SWIVEL CASTER W/BRAKE FLAT PLATE

4 2 22290-0010 SWIVEL CASTER FLAT PLATE

5 32 2000531 3/8″-16 × 1″ HEX SCREW, SST

6 32 21416-0001 3/8″ FLAT WASHER, SS

7 32 21422-0001 3/8″ SPLIT LOCK WASHER, ZP

8 1 22450-0228 RESTRAINT CABLE ASSEMBLY

9 1 59560 TOP COVER

10 2 59677 SCR, MS SL TR HD 10-32 × 2-1/2″

11 2 7A2S15 SCR, MS STR TRSHD 10-32 × 3/4″

12 1 59724 SUPPORT, SHELF

9

12

″″

″ SERIES SINGLE OVEN OPTION - BASE w/15

″″

P/N 59720

″″

″ LEGS & TOP

″″

7

Page 12

5, 6, 7, 10 & 11

2

Figure 2-3A. Model PS740 24

Option Base with Legs and Top

HARDWARE BA G

″″

″ Double Oven

″″

1

8

3

4

PARTS LIST FOR PS740 SERIES 24

ITEM NO. QTY PART NO. DESCRIPTION

1 1 61126 COMPLETE BASE WELDMENT

2 4 37900-0102 TOP PLATE, LEG WELDMENT

3 2 22290-0009 SWIVEL CASTER W/BRAKE FLAT PLATE

4 2 22290-0010 SWIVEL CASTER FLAT PLATE

5 32 2000531 3/8″-16 × 1 HEX SCREW, SST

6 32 21416-0001 3/8″ FLAT WASHER, SS

7 32 21422-0001 3/8″ SPLIT LOCK WASHER, ZP

8 1 22450-0228 RESTRAINT CABLE ASSEMBLY

9 1 61125 TOP COVER

10 2 59677 SCR, MS SL TR HD 10-32 × 2-1/2″

11 2 7A2S15 SCR, MS STR TRSHD 10-32 × 3/4″

12 1 61128 SUPPORT, SHELF

9

12

″″

″ DOUBLE OVEN OPTION - BASE w/6

″″

P/N 61457

″″

″ LEGS & TOP

″″

8

Page 13

HARD WARE BA G

5, 6, 7, 10 & 11

2

Figure 2-3B. Model PS740 32

Option Base with Legs and Top

″″

″ Double Oven

″″

1

8

3

4

PARTS LIST FOR PS740 SERIES 32

ITEM NO. QTY PART NO. DESCRIPTION

1 1 60287 COMPLETE BASE WELDMENT

2 4 37900-0102 TOP PLATE, LEG WELDMENT

3 2 22290-0009 SWIVEL CASTER W/BRAKE FLAT PLATE

4 2 22290-0010 SWIVEL CASTER FLAT PLATE

5 32 2000531 3/8″-16 × 1 HEX SCREW, SST

6 32 21416-0001 3/8″ FLAT WASHER, SS

7 32 21422-0001 3/8″ SPLIT LOCK WASHER, ZP

8 1 22450-0228 RESTRAINT CABLE ASSEMBLY

9 1 59560 TOP COVER

10 2 59677 SCR, MS SL TR HD 10-32 × 2-1/2″

11 2 7A2S15 SCR, MS STR TRSHD 10-32 × 3/4″

12 1 59724 SUPPORT, SHELF

9

12

″″

″ DOUBLE OVEN OPTION - BASE w/6

″″

P/N 59725

″″

″ LEGS & TOP

″″

9

Page 14

Figure 2-4A. Model PS740 24

″″

″ Triple Oven

″″

Option Base with Outriggers and Top

1

HARDWARE BAG

7, 8, 9, 10, 11, 12,

13, 14, & 17

5

6

2

15

3

4

PARTS LIST FOR PS740 SERIES 24

ITEM NO. QTY PART NO. DESCRIPTION

1 1 61126 COMPLETE BASE WELDMENT

2 4 45209 QUAD OUTRIGGER WELDMENT

3 2 22290-0009 SWIVEL CASTER, W/BRAKE FLAT PLATE

4 2 22290-0010 SWIVEL CASTER, FLAT PLATE

5 4 45206 INSERT,QUAD ADJUSTMENT FOOT

6 4 45205 SPACER,QUAD CASTER

7 32 A27727 3/83 -16x1-1/4 HEX BOLT

8 32 A21924 3/83 FLAT WASHER, SS

9 32 21422-0001 3/83 SPLIT LOCK WASHER, ZP

10 16 21172-0004 3/83 -16 NYLON INSULATED LOCKNUT, ZC

11 8 2001048 1/23 -13 x 1-3/8 18-8 HEX CAPSCREW

12 8 A27750 1/23 18-8 FLAT WASHER

13 8 21422-0016 1/23 18-8 LOCK WASHER

14

15 1 22450-0228 RESTRAINT CABLE ASSEMBLY

16 1 61125 TOP COVER

17 2 7A2S15 SCR, MS STR TRSHD 10-32X3/4″

2

16

″″

″ TRIPLE OVEN OPTION - BASE w/CASTERS & TOP

″″

P/N 61458

59677 SCR, MS SL TR HD 10-32X2-1/2

10

Page 15

Figure 2-4B. Model PS740 32

″″

″ Triple Oven

″″

Option Base with Outriggers and Top

1

HARDWARE BAG

7, 8, 9, 10, 11, 12,

13, 14, & 17

5

6

2

15

3

4

PARTS LIST FOR PS740 SERIES 32

ITEM NO. QTY PART NO. DESCRIPTION

1 1 60287 COMPLETE BASE WELDMENT

2 4 45209 QUAD OUTRIGGER WELDMENT

3 2 22290-0009 SWIVEL CASTER, W/BRAKE FLAT PLATE

4 2 22290-0010 SWIVEL CASTER, FLAT PLATE

5 4 45206 INSERT,QUAD ADJUSTMENT FOOT

6 4 45205 SPACER,QUAD CASTER

7 32 A27727 3/83 -16x1-1/4 HEX BOLT

8 32 A21924 3/83 FLAT WASHER, SS

9 32 21422-0001 3/83 SPLIT LOCK WASHER, ZP

10 16 21172-0004 3/83 -16 NYLON INSULATED LOCKNUT, ZC

11 8 2001048 1/23 -13 x 1-3/8 18-8 HEX CAPSCREW

12 8 A27750 1/23 18-8 FLAT WASHER

13 8 21422-0016 1/23 18-8 LOCK WASHER

14

15 1 22450-0228 RESTRAINT CABLE ASSEMBLY

16 1 59560 TOP COVER

17 2 7A2S15 SCR, MS STR TRSHD 10-32X3/4″

2

16

″″

″ TRIPLE OVEN OPTION - BASE w/CASTERS & TOP

″″

P/N 59726

59677 SCR, MS SL TR HD 10-32X2-1/2

11

Page 16

III. VENTILATION SYSTEM

IMPORTANT

Where national or local codes re-

quire the installation of fire sup-

pression equipment or other

supplementary equipment, DO NOT

mount the

equipment directly to the oven.

MOUNTING SUCH EQUIPMENT ON

THE OVEN MAY:

• VOID AGENCY CERTIFICATIONS

• RESTRICT SERVICE ACCESS

• LEAD TO INCREASED SERVICE

EXPENSES FOR THE OWNER

B. Recommendations

NOTE THAT THE HOOD DIMENSIONS SHOWN IN

FIGURE 2-5 ARE RECOMMENDATIONS ONLY.

LOCAL, NATIONAL AND INTERNATIONAL CODES

MUST BE FOLLOWED WHEN INSTALLING THE

VENTILATION SYSTEM. ANY APPLICABLE CODES

SUPERSEDE THE RECOMMENDATIONS SHOWN IN

THIS MANUAL.

The rate of air flow exhausted through the ventilation system

may vary depending on the oven configuration and hood

design. Consult the hood manufacturer or ventilation engineer

for these specifications.

To avoid a negative pressure condition in the kitchen area,

return air must be brought back to replenish the air that was

exhausted. A negative pressure in the kitchen can cause heatrelated problems to the oven components as if there were no

ventilation at all. The best method of supplying return air is

through the heating, ventilation and air conditioning (HVAC)

system. Through the HVAC system, the air can be temperature-controlled for summer and winter. Return air can also be

brought in directly from outside the building, but detrimental

effects can result from extreme seasonal hot and cold temperatures from the outdoors.

A. Requirements

A mechanically driven ventilation system is

RECOMMENDED for electric oven installations.

PROPER VENTILATION OF THE OVEN IS THE RESPONSIBILITY OF THE OWNER.

STRONGLY

Figure 2-5. Ventilation System

18″ (458mm)

minimum

(Typical - both

ends of oven)

2″ (51mm)

minimum

NOTE:

C. Other ventilation concerns

• Special locations, conditions, or problems may require

• Inadequate ventilation can inhibit oven performance.

• It is recommended that the ventilation system and duct

Return air from the mechanically driven system must

not blow at the opening of the baking chamber. Poor

oven baking performance will result.

the services of a ventilation engineer or specialist.

work be checked at prevailing intervals as specified by the

hood manufacturer and/or HVAC engineer or specialist.

8″ (203mm)

minimum

3″ (76mm)

minimum

12

Page 17

IV. ASSEMBLY

m

•

Figure 2-6. Leg extension and casters installation

A. Top Panel and Base Pad Assembly

1. Install the four leg extensions onto the base pad using

the 3/8″-16 × 1″ screws, 3/8″ flat washers, and

3/8″ lockwashers supplied in the Base Pad Kit. See

Figure 2-6. Check that the finished sides of each leg

extension face OUTWARDS. One rear leg should be

attached using three 3/8″-16 × 1″ screws and the 3/4″

eyebolt, as shown in Figure 2-6. This eyebolt acts as the

anchor point for the restraint cable assembly (see Part C,

Restraint Cable Installation).

2. If your oven is equipped with the lower shelf, position it in

place as shown in Figure 2-6. Check that the lip on the

shelf faces DOWN. Seal joint between leg and shelf with

NSF listed silicone.

3. Install one caster onto each leg extension, as shown in

Figure 2-7. Use the 3/8″-16 × 1″ screws, 3/8″ flat washers, and 3/8″ lockwashers supplied in the Installation Kit.

The locking casters should be installed at the FRONT of

the oven. The non-locking casters should be installed at

the REAR of the oven.

4. Install the lower oven cavity onto the base pad.

See Fig 2-7.

5. For single ovens ONLY:

Install the top panel using the screws included in the base

pad kit, as shown in Figure 2-8. Then, skip ahead to Part

C, Restraint Cable Installation.

For double or triple ovens:

Continue on to Part B, Stacking. Note that the top panel

should NOT be installed for double and triple ovens until

after stacking the oven cavities.

Finished sides of

leg extension face

corner of base

pad

Lower

shelf

Domestic and

standard export

ovens:

Locking casters -

FRONT of oven

Non-locking casters -

REAR of oven

3/8″ flat

washer

3/8″ lock

washer

3/8″-16 × 1″

hex screw

Figure 2-7. Base pad Installation

oven

Botto

cavity

Assembled•

base pad

Figure 2-8. Top panel installation

#10-32 × 2-1/2″

screw length

#10-32 × 3/4″

screw length

Top

panel

13

Page 18

NOTE:

DO NOT install top panel onto double or triple

ovens until AFTER stacking the oven cavities. See

Part B, Stacking.

B. Stacking

For single ovens, skip ahead to Part C, Restraint Cable

Installation.

IMPORTANT

Middleby Marshall STRONGLY RECOMMENDS that PS740

Electric oven cavities be stacked BY AUTHORIZED

PERSONEL.

C. Restraint Cable Installation

Because the oven is equipped with casters, a restraint cable

assembly must be installed to limit the movement of the appliance. One end of the cable is anchored to the eyebolt on the rear

surface of the oven’s base pad, while the other is anchored to

the wall. See Figure 2-11.

After connecting the restraint cable, move the oven to its final

location. Adjust the bottom (hex) sections of the feet so that

the casters are off the floor. For quad ovens, lock the two

front casters.

Contact your Middleby Marshall Authorized Service Agent for

complete stacking instructions.

1. Stack an oven cavity on top of the lower oven. Check

the following:

• All four sides of the lower lip (on the bottom edge

of the oven cavity) overlap the top of the lower oven

• The oven is level

• The oven is firmly seated

See Figure 2-9.

2. For triple ovens, repeat Step 1 to install the top

oven cavity.

3. Install the top panel using the screws included in the base

pad kit, as shown in Figure 2-10.

Figure 2-9. Stacking

Figure 2-10. Top panel installation

#10-32 × 2-1/2″

screw length

#10-32 × 3/4″

screw length

Top

panel

3/8″-18 × 1″

eyebolt on

14

Figure 2-11. Installing the Restraint Cable

Restraint cable assembly

rear leg

extension

3/4″ (19mm)

eyebolt

Wall of structure

Page 19

D. Conveyor Installation

1. Unfold the conveyor as shown in Figure 2-12. Then, begin

to slide the conveyor into the end of the oven. The

conveyor can only be installed from the end of the oven

with the drive motor.

2. Continue moving the conveyor into the oven until the

frame protrudes equally from each end of the oven.

Check that the crumb tray supports located on the underside of the conveyor frame rest firmly against the lower

end plugs, as shown in Figure 2-13.

3. When the conveyor is positioned properly, check for

freedom of movement of the conveyor belt by pulling it for

about 2-3 feet (0.6-1.0m) with your fingers. The drive and

idler shafts must rotate smoothly, and the belt must move

freely without rubbing on the inside of the oven.

4. Check the tension of the conveyor belt as shown in

Figure 2-14. The belt should lift about 1″ (25mm).

DO NOT OVERTIGHTEN THE CONVEYOR BELT

.

Figure 2-13. Conveyor placement

Crumb tray

support

bracket

End plug

NOTE:

If necessary, the belt tension can be adjusted by

turning the conveyor adjustment screws, located at

the idler (non-control) end of the conveyor. See

Figure 2-14.

Figure 2-12. Conveyor installation

Folded

frame

Idler end (with belt tension

adjustment screws)

Conveyor

placed in

oven

Figure 2-14. Conveyor Belt tension

Drive end (with

drive sprocket)

1″ (25mm)

vertical

deflection

Adjustment

screws (2) on

idler end of

conveyor

15

Page 20

5. If it is necessary to add or remove conveyor links to

achieve the correct tension, OR if it is necessary to

reverse the conveyor belt for correct orientation, the belt

will need to be removed from the conveyor frame. If this

is necessary, perform the following procedure:

• Remove the conveyor assembly from the oven and

place it flat on the floor.

• Remove the master links using long-nose pliers. Then,

roll up the belt along the length of the conveyor frame.

• Add or remove belt links as necessary to achieve the

correct belt tension.

• Replace the belt on the conveyor frame. Check that the

conveyor belt links are oriented as shown in Figure 2-15,

and that the smooth side of the conveyor belt faces UP.

• Connect the inside master links. Check that the links are

oriented as shown in Figure 2-15.

• Connect the outside master links. Note that the outside

master links each have an open hook on one side. This

hook aligns with the hooks along the sides of the other

conveyor links. See Figure 2-15.

• Replace the conveyor into the oven.

Figure 2-15. Conveyor and Master Link orientation

Direction

of travel

Incorrect

master link

position

E. Final Assembly

1. Install the crumb trays underneath the conveyor as shown

in Figure 2-16.

CORRECT

master link

position

Figure 2-16. Crumb Trays

CONVEYOR BELT REVERSAL

Conveyor belt reversal consists of three steps:

1. Physically reversing the conveyor belt.

2. Resetting direction jumper on the conveyor control board.

3. Switching the photo detector.

REVERSING THE CONVEYOR BELT

Remove the conveyor from the oven and find the master link

location. Remove master links and remove the belt from the

conveyor frame. Reassemble the belt back onto the frame (in

the reverse direction) and reinstall the master links. Replace the

conveyor assembly in the oven.

RESETTING DIRECTION JUMPER

Locate Jumper P1 on the conveyor control board. Move jumper

from terminals 1 and 2, and replace onto terminals 2 and 3.

CAUTION: Shock hazard in compartments electrical filters

are electrically alive.

SWITCHING PHOTO DETECTOR

CAUTION: Disconnect Power Before Switching Photo eye.

Remove the three screws securing the access door to the unit.

Open the access door and disconnect the connector fitting to

the photo eye assembly. Remove the two screws securing the

photo eye assembly to the control box. Remove the four nuts

securing the photo eye to the housing. Rotate the photo eye 180

degrees and resecure the photo eye with the four nuts.

On the opposite control box, remove the two screws holding the

cover where the photo eye assembly will be positioned. Secure

the photo eye assembly in position with the two screws. Place

the photo eye cover on the opposite control box, where the

photo eye assembly was removed, and secure the two screws.

Secure the access door with the three screws.

Remove the three screws securing the access door on the

opposite side. Open the access door, where the photo eye is

now positioned, and connect the photo eye connector fitting.

Secure the access door with the three screws.

Apply power to the unit. Adjust the photo eye height by loosening the two screws securing the photo eye assembly and sliding

the photo eye assembly either up or down, such that the beam

is approximately 1/4 inch above the belt.

Crumb tray

insertion

Note:

This is MUCH easier in reduced light.

Replace all covers.

16

Page 21

III. ELECTRICAL CONNECTION INFORMATION

FOR PS740E-SERIES OVENS.

WARNING

Authorized supplier personnel normally

accomplish the connections for the ventilation

system, electric supply, as arranged by the

customer. Following these connections, the

factory-authorized installer can perform the

initial startup of the oven.

Check the oven data plate (Figure 2-17) before making any

electric supply connections. Electric supply connections must

agree with data on the oven data plate.

NOTE: The electric supply installation must satisfy the requirements of the appropriate statutory authority, such as the National Electrical Code (NEC), ANSI/NFPA70, (U.S.A.); the

Canadian Electrical Code, CSA C22.2; the Australian Code

AG601; or other applicable regulations.

A fused disconnect switch or a main circuit breaker (customer

furnished)

oven; it is recommended that this switch/ circuit breaker have

lockout/tagout capability. The electric supply connection must

meet all national and local electrical code requirements. Copper is the recommended material for the electrical supply

conductors.

MUST be installed in the electric supply line for each

IV. ELECTRIC SUPPLY FOR ELECTRICALLY

HEATED OVENS

Power requirements for electrically heated ovens are usually

208 - 240VAC, 3-phase, 4-wire (3 ‘hot’, 1 ground), although

ovens built for export can have power requirements of 380VAC

and 480VAC. (These ovens have a 5-wire system.) A 2″

(51mm) diameter cutout/hole in the back of the machinery

compartment provides access for the electrical supply connections. Using flexible cable(s) for the electrical power supply

conductors requires a 2″ (51mm) strain-relief fitting (not furnished) to enable safe access to the terminal block from which

oven power is distributed.

The supply conductors must be of the size and material

(copper) recommended to provide the current required; (refer to

the data plate for the ampere specifications). The electric

current rating for each conductor supplying a PS740E-Series

Oven must comply to local and national codes.

Typical specifications for each PS740E-Series Oven

are 208V or 240V, 3-phase, 4-wire, 60-ampere, 34.4kW. A

PS740E-Series Double Oven (Figure 1-2) installation would

require two 60-ampere service connections, one for each oven;

the 34.4kW power consumption also doubles for such an

installation to 68.8kW.

The 208V or 240VAC electrically heated oven uses two legs of

the supplied power to provide 208V or 240VAC power for the

oven control circuitry.

Electrical Junction Box

(One per oven cavity)

Figure 2-17. Typical Electric Oven Data Plate

Figure 2-18. Utility Connection Locations for

Electric Ovens

17

Page 22

UTILITY ROUGH-IN DIMENSIONS AND POSITIONING

FOR PS740-SERIES OVENS

WARNING

DO NOT USE CONDUIT FOR GROUND

CONNECTION.

CAUTION

IT IS RECOMMENDED THAT THE OVEN

BE PLACED UNDER A VENTILATION

HOOD FOR ADEQUATE AIR SUPPLY

AND VENTILATION.

ELECTRIC SUPPLY TO BE

PROVIDED BY CUSTOMER

CIRCUIT BREAKER

Separate circuit breaker with lockout/tagout electrical shutoff

for each oven. Wire each oven separately.

100 Amp circuit breaker for 208-240V, or 50 Amp circuit

breaker for 380-480V.

ELECTRICAL SPECIFICATIONS

DOMESTIC: 208V main blower motors and elements,

3 Ph, 75 Amp draw, 50/60 Hz, 208-240V control circuit,

3 pole, 4 wire system per oven (3 hot, 1 grd).

NOT

Do

or

DOMESTIC: 240V main blower motors and elements,

3 Ph, 65 Amp draw, 50/60 Hz, 208-240V control circuit,

3 pole, 4 wire system per oven (3 hot, 1 grd).

Do

or

EXPORT: 380V elements, 3 Ph, 41 Amp draw, 50/60 Hz,

208-240V control circuit and main blower motor, 4 pole,

5 wire system per oven (3 hot, 1 neutral, 1 grd).

Do

or

DOMESTIC: 480V elements, 3 Ph, 32.5 Amp draw,

50/60 Hz, 208-240V control circuit and main blower motor,

4 pole, 5 wire system per oven (3 hot, 1 neutral, 1 grd).

Do

use conduit for ground.

NOT

use conduit for ground.

NOT

use conduit for ground.

NOT

use conduit for ground.

To Ov en

To Ov en

Suggested dimensions are shown; utility code

requirements supersede any factors shown.

Figure 2-19. Typical PS740-Series Oven(s)

Installation

ELECTRICAL RATING

27.0 kW/hr.

SUPPLY WIRE

Supply wire size must be in accordance with the National

Electrical Code (current edition) and must be in compliance with

local codes.

NOTE: The electrical terminal connection marked “MP” located

inside the control compartment is desiganated for the blue

(neutral) wire to the oven. See the electrical wiring/schematics

in Section 6 of this manual.

SUGGESTED

If space permits, service should be located near the control

console end of the oven(s) to allow convenient access to safety

switches.

18

Page 23

SECTION 3 - OPERATION

E. Energy Level

Indicators

C. Temperature Control/Display

B. Conveyor Time Setting

D. Message Bar

E. Energy Level

Indicators

A. Main On/Off Button

I. LOCATION AND DESCRIPTION OF CONTROLS

A. Main On/Off Button

Turns all oven functions on or off. If the oven is below the set

point, it will rise to the set point and turn the conveyor on. If it is

turned off and the oven is above 200° F, the blowers will remain

on until the oven drops below 200° F.

B. Conveyor Time Setting

Adjusts and displays the conveyor bake time. Dual belt ovens

have two displays, single units have one.

C. Temperature Control/Display

Displays the average set point of both right and left sides of the

oven. Pressing on the display allows individual temperature

displays and adjustments.

D. Message Bar

Displays messages during oven operation.

E. Energy Level Indicators

Displays energy usage on left and right sides of the oven.

19

Page 24

II. NORMAL OPERATION - STEP-BY-STEP-

A. Daily Startup Procedure

1. Check that the circuit breaker/fused disconnect is in the On

position. Check that the window is closed. The touch panel

display should be lit.

2. Adjust the conveyor to the desired bake time.

3. Press the temperature button to display right and left hand

oven settings. Set temperatures as desired.

4. Press the ON button to activate the oven. The conveyor will

not run, until the oven temperature has reached the set

points.

B. Daily Shutdown Procedure

1. Make certain there are no products left on the conveyor in

the oven.

2. Press the ON square to turn the oven off.

3. Open the window to allow the oven to cool faster.

4. After the oven has cooled and the blowers have turned off, the

circuit breaker/fused disconnect may be turned off.

Quick Reference – Touch Screen Controller

A. Main Screen

1. On/Off button - Used to turn oven On and Off.

2. Conveyor speed - Pressing on either the minutes or

seconds allows a new value to be input for the conveyor

speed. Split belt ovens have two inputs (front and rear

belts).

3. Oven temperature - Pressing on the set temperature shifts

the user to the oven temperature set point/indicator screen.

4. Energy level indicators - Indicators to either side of the

screen indicate the energy input to that side of the oven.

5. Message bar - Indicates various messages pertaining to

current oven conditions.

B. Oven Temperature/Set Point/Indicator Screen

1. Right actual temperature - Indicates current average temperature of the right side of the oven.

2. Left actual temperature - Indicates current average temperature of the left side of the oven.

NOTE: Right to Left temperature settings should not exceed

a differential of 20 °F.

3. Right Set point temperature - Pressing on this value allows

the user to adjust the set point for the right side of the oven.

4. Left Set point temperature - Pressing on this value allows

the user to adjust the set point for the left side of the oven.

5. Exit - Returns to the main screen.

C. Energy Modes

Energy Mode One - This mode is automatic, and starts (bake

time +1 minute) after the last product has entered the oven. In

this mode, the main oven blowers will lower to 1500 RPM, while

the oven maintains temperature and belt speed.

Energy Mode Two - The oven lowers its set point by 100° F, and

stops the belt. Anytime that the oven is more than 10 degrees

over its set point, the ovens will completely shut off, allowing the

oven to cool. The main blowers will continue to run at 1500 RPM

in this mode. Placing any article on the input belt will cause

normal operation of the oven to resume, and bring the set point

back to its original level. The belt will resume operation once

both sides of the oven are within 5° F of the set point.

Energy Mode Three - The oven will turn off completely and

shut off the circulation blowers once the oven temperature has

dropped below 200° F. Placing any article on the input belt will

cause normal operation of the oven to resume, and bring the set

point back to its original level. The belt will resume operation

once both sides of the over are within 5° F of the set point.

Energy Mode Four - This is a complete oven shut down.

Placing anything on the belt will NOT return the oven to

Operation. The ON button on the main screen has to be pressed

to restart the oven.

20

Page 25

III. QUICK REFERENCE: TROUBLESHOOTING

SYMPTOM PROBLEM SOLUTION

Oven will not

turn On.

Oven will not

heat.

Oven is operating, but

little or no air is coming

from the fingers.

Conveyor will not move.

No electrical power • Check that the circuit breaker/fused disconnect is on. Make

sure the emergenct stop button is on.

Faulty contactor

Faulty heater element

Air fingers may be assembled incorrectly after

cleaning.

Conveyor may be jammed. • Turn oven off, and allow to cool. Check conveyor for block-

• Replace contactor.

• Replace element.

• Turn oven off, and allow to cool. Reassemble fingers correctly.

age.

SCREEN ALERTS

SYMPTOM PROBLEM SOLUTION

High Control Compartment

Temperature

Combustion Blower

problem.

Clean and replace the front

fan filters.

The computer has detected

a problem with either the

main, or burner blowers.

• Failure to do this will eventually shut down the oven due to

excessive temperature.

• This should be corrected by a qualified service technician.Main Blower problem or

Control Over Temp Front filters are clogged • Clean or replace filters.

Front belt jammed Front belt has stopped • Remove obstruction, and restart oven.

• If no obstruction, call service.

Rear Belt jammed Rear belt has stopped • Remove obstruction, and restart oven.

• If no obstruction, call service.

High Temp Error Thermocouple or • Call service

PLC malfunction

Belt off-Oven not Normal operation until

in temperature Oven reaches operating

temperature

Energy Saving Mode 1 Normal operation

Energy saving mode 2 Normal operation

Energy saving Mode 3 Normal operation

21

Page 26

SECTION 4 - MAINTENANCE

WARNING

Before ANY cleaning or servicing of the oven, perform the following procedure:

1. Switch off the oven and allow it to cool. Do NOT service the oven while it is warm.

2. Turn off the electric supply circuit breaker(s)

When all cleaning and servicing is complete:

1. If the oven was moved for servicing, return the oven to its original location.

2. If the restraint cable was disconnected to clean or service the oven, reconnect it at this time.

3. Reconnect the electrical supply.

4. Turn on the electric supply circuit breaker(s).

5. Perform the normal startup procedure.

Possibility of injury from moving parts and electrical shock exists in this oven. Switch off and lockout/tagout

the electric supply BEFORE beginning to disassemble, clean, or service any oven. Never disassemble or clean

an oven with the BLOWER ( ) switch or any other circuit of the oven switched on.

NEVER use a water hose or pressurized steam-cleaning equipment when cleaning this oven. To avoid saturating the oven

insulation, DO NOT use excessive amounts of water. DO NOT use a caustic oven cleaner, which can damage the bake

chamber surfaces.

and disconnect the electric supply to the oven.

WARNING

CAUTION

NOTE

ANY replacement parts that require access to the interior of the oven may ONLY be replaced by a Middleby Marshall

Authorized Service Agent. It is also strongly recommended that the 3-Month Maintenance and 6-Month Maintenance

procedures in this section be performed ONLY by a Middleby Marshall Authorized Service Agent.

I. MAINTENANCE - DAILY

A. Check that the oven is cool and the power is discon-

nected, as described in the warning at the beginning of

this Section.

B. Clean ALL of the cooling fan grills and vent openings

with a stiff nylon brush. Refer to Figure 4-1 for the

locations of the grills and vents.

C. Clean the outside of the oven with a soft cloth and mild

detergent.

D. Check that ALL cooling fans are operating properly.

CAUTION: If a cooling fan is not operating correctly, it must

be replaced IMMEDIATELY. Operating the oven

without adequate cooling can seriously damage

the oven's internal components.

E. Clean the conveyor belts with a stiff nylon brush. This

is more easily accomplished by allowing the conveyor to

run while you stand at the exit end of the conveyor.

Then, brush the crumbs off the conveyor as it moves.

F. Remove and clean the crumb trays. If necessary, refer

to Figure 2-16 (in Section 2,

the crumb trays into the oven.

G. Clean the window in place.

Installation) when replacing

Figure 4-1. Cooling Vents and Grills

Vents on

front panel

of oven

Fan grills (3) on rear

of oven and control

compartment

Vent (2) on rear

of machinery

compartment

22

Page 27

II. MAINTENANCE – MONTHLY

Figure 4-2. Removing Air Fingers and Plates

NOTE:

A. Check that the oven is cool and the power is disconnected,

B. Remove the crumb trays from the oven.

C. Lift the drive end of the conveyor slightly, and push it

D. Slide the conveyor out of the oven, folding it as it is removed.

E. Remove the end plugs from the oven. The end plugs are

F. Slide the air fingers and blank plates out of the oven, as

When removing the conveyor, refer to Figure 2-12 (in

Section 2,

as described in the warning at the beginning of this Section.

forward into the oven. This removes the tension from the

drive chain. Then, remove the drive chain from the conveyor sprocket.

shown in Figure 1-1 (in Section 1,

shown in Figure 4-2. AS EACH FINGER OR PLATE IS

REMOVED, WRITE A “LOCATION CODE” ON IT WITH A

MARKER to make sure that it can be reinstalled correctly.

Example of markings:

Installation).

Description).

(Top Row) T1 T2 T3 T4 T5 T6

(Bottom Row) B1 B2 B3 B4 B5 B6

G. Disassemble the air fingers as shown in Figure 4-3. AS EACH

FINGER IS DISASSEMBLED, WRITE THE “LOCATION CODE”

FOR THE FINGER ON ALL THREE OF ITS PIECES. This will

help you in correctly reassembling the air fingers.

Figure 4-3. Disassembling the Air Fingers

CAUTION: Incorrect reassembly of the air fingers will change

the baking properties of the oven.

H. Clean the air finger components and the interior of the

baking chamber using a vacuum cleaner and a damp

cloth. Refer to the boxed warnings at the beginning of this

Section for cleaning precautions.

I. Reassemble the air fingers. Then, replace them in the

oven, using the “location guide” as a guide.

J. Replace the end plugs on the oven.

K. Reassemble the conveyor into the oven. If the drive

sprocket was removed when installing the conveyor,

replace it at this time.

L. Reattach the drive chain.

M. Check the tension of the conveyor belt as shown in Figure

2-14 (in Section 2, Installation). The belt should lift

between 3 - 4″ (75-100mm). DO NOT OVERTIGHTEN

THE CONVEYOR BELT. If necessary, the belt tension

can be adjusted by turning the conveyor adjustment

screws, located at the idler (right) end of the conveyor.

N. Replace the crumb trays.

23

Page 28

III. MAINTENANCE – EVERY 3 MONTHS

A. Check that the oven is cool and the power is discon-

nected, as described in the warning at the beginning of

this Section.

B. Vacuum both of the blower mounts, and their surrounding

compartments, using a shop vacuum.

C. Tighten all electrical terminal screws.

D. Split Belt Disassembly and Cleaning

1. Refer to Part D, Conveyor Installation, in the Installation section of this Manual. Then, remove the following

components from the oven:

• Conveyor end stop

• Crumb trays

• Chain cover

• Drive chains

• End plugs

• Conveyor assembly

2. Remove the master links from each conveyor belt.

Then, roll the belts up along the length of the conveyor

to remove them from the frame.

3. Remove the two conveyor adjustment screws from

the idler end of the conveyor frame, as shown in

Figure 4-4.

4. Remove the idler shaft assembly from the conveyor.

5. Pull apart the two sections of the idler shaft.

6. Clean the shafts thoroughly using a rag. Then, lubri-cate

both the extended shaft and the interior of the hollow

shaft using a light food-grade lubricant.

lubricate the shafts using WD40 or a similar product.

This can cause the shafts to wear rapidly.

7. Before reassembling the shafts into the conveyor

frame, check that they are oriented properly.

Figure 4-4. Disassembling the idler shaft

DO NOT

8. Reassemble the idler shaft into the conveyor. Make

sure that the bronze washer is in place between the

two sections of the shaft. See Figure 4-4.

9. Replace the conveyor adjustment screws as shown in

Figure 4-4. To allow the conveyor belt to be reinstalled

later, do not tighten the screws at this time.

10. Loosen the set screw on both of the conveyor drive

sprockets. Then, remove the sprockets from the shaft.

11. Check the conveyor configuration as follows:

High-speed conveyors are equipped with large flange

bearings at both ends of the shaft, as shown in

Figure 4-5. For these conveyors, remove the two

screws that hold each bearing to the conveyor frame.

With the screws removed, lift the end of the shaft at the

front of the oven, and pull the entire assembly free of

the conveyor frame.

Standard conveyors are equipped with bronze bushings mounted on spacers at both ends of the shaft, as

shown in Figure 4-5. For these convey-ors, remove

the two screws that hold the bracket to the conveyor

frame. With the screws removed, lift the end of the

shaft at the front of the oven, and pull the entire

assembly free of the conveyor frame. The brackets

will be removed along with the drive shaft assembly.

12. Disassemble and lubricate the two sections of the

drive shaft as described for the idler shaft, above.

13. Before reassembling the shafts into the conveyor

frame, check that they are oriented properly.

14. Reassemble the drive shaft into the conveyor.

sure that the bronze washer is in place between the

two sections of the shaft. See Figure 4-4.

15. Replace the drive sprockets. Reassemble the belts

and master links onto the conveyor.

16. Reinstall the end plugs and conveyor onto the oven.

17. Reattach the drive chains. Replace the chain cover.

18. Check the tension of the conveyor belt as shown in

Figure 2-14 (in Section 2, Installation). The belt should

lift about 1″ (25mm). If necessary, adjust the belt

tension by turning the conveyor adjustment screws.

19. Replace all components onto the oven.

Make

24

Figure 4-5. Drive shaft configurations

Page 29

Figure 4-6. Disassembling the drive shaft

Figure 4-7. Rear panel access

Remove eight (8)

screws to remove

rear panel

Bearings

(2 total)

Blower belt

E. Blower Belt

1. Remove the eight screws shown in Figure 4-7. Then,

remove the rear panel from the oven.

2. Check the blower belt for the proper 1/4″ (6mm) deflection at the center, and for cracking or excessive wear.

See Figure 4-7. Overtightening the belt will cause premature

bearing failure and possible vibrations. A loose belt may also

cause vibrations.

3. If necessary, adjust the tension of the belt by loosening

the four motor mounting bolts. Reposition the motor as

neccessary until the correct 1/4″ (6mm) deflection is

reached, then tighten the bolts.

Blower motor

Loosen four (4) screws to adjust

motor position and belt tension

IV. MAINTENANCE - EVERY 6 MONTHS

A. Check that the oven is cool and the power is discon-

nected, as described in the warning at the beginning of

this Section.

B. Check for excessive wear on the conveyor drive motor

brushes. The brushes should be replaced if they have

worn to less than

the brushes in exactly the same position.

C. For gas ovens, inspect and clean the burner nozzle and

the spark electrode assembly.

D. Check the conveyor drive shaft bushings and spacers.

Replace the components if they are worn.

1/4"

(6mm) in length. Be sure to replace

25

Page 30

V. KEY SPARE PARTS – Available separately. See Figure 4-8.

1

6

13, 14, 15, 16

23

4

8

18

10

19, 20, 21

7

9

5

11, 12

17

23

24

25

22

Figure 4-8. Key Spare Parts

ITEM QTY. P/N DESCRIPTION

1 1 60190 DIGITAL DISPLAY, PROGRAMMED

2 1 58920 CONVEYOR DRIVE MOTOR W/PICKUP ASSY.

3 1 58679 CONVEYOR SPEED CONTROLER

4 1 60196 KIT, THERMOCOUPLE 6″

5 1 59668 BELT, BLOWER

6 1 57288 MOTOR, BLOWER, 2HP

7 1 33983 HIGH LIMIT CONTROL MODULE, 240V

8 1 51399 COOLING FAN (BACKWALL)

9 1 97525 COOLING FAN (CONTROL COMPARTMENT)

10 1 60598 AIR SWITCH

11 2 44914 CONTROLLER, POWER 208V/240V

12 2 44568 CONTROLLER, POWER 380V/480V

13 1 60750 HEATER 208V 27.0 kW

14 1 60751 HEATER 240V 27.0 kW

15 1 60752 HEATER 380V 27.0 kW

16 1 60753 HEATER 480V 27.0 kW

17 1 60253 PHOTOCELL

18 1 60638 INVERTER, PROGRAMMED

19 1 60684 PLC

20 1 58668 THERMOCOUPLE MODULE

21 1 58669 CURRENT MODULE

22 2 59132 RELAY, DPDT 24V COIL

23 1 M9608 POWER SUPPLY

24 1 60452 CONTACTOR, 24VDC

25 1 60636 BEARING, PB 5/8 B

26

Page 31

SECTION 5

TROUBLESHOOTING

PROBLEM:

PRODUCTS ARE OVERCOOKED

OR UNDERCOOKED

Check for correct

setting of conveyor

speed control.

Set the conveyor speed

control at correct setting.

Verify the food

preparation process.

If products still cook incorrectly,

call your Middleby Marshall

Service Agency.

Check for correct

setting on tempera-

ture controller.

Turn temperature

control to correct

setting.

PROBLEM:

OVEN BLOWER AND CONVEYOR OPERATE,

YET THE OVEN IS NOT HEATING

Reset the temperature controller

to a new setting (above 200°F),

after turning the BLOWER switch

to off for 30 seconds.

Start the oven again. If the oven still does not

heat, call your Middleby Marshall Service Agency.

PROBLEM:

CONVEYOR WILL NOT HOLD PROPER SPEED

OR WILL NOT RUN AT ALL

Check whether the conveyor is

jammed on something in oven.

PROBLEM:

OVEN DOES NOT HEAT

Check to see if both BLOWER

switch and HEAT switch are in

the “ON” or “I” position.

If oven does not heat, call your

Middleby Marshall Service Agency.

PROBLEM:

BLOWER MOTOR IS RUNNING, YET LITTLE

OR NO AIR BLOWS FROM AIR FINGERS

Air fingers reassembled incorrectly,

after cleaning.

Assemble air fingers correctly, after cleaning.

Refer to Section 4 procedure, or call your

Middleby Marshall Service Agency.

Check for proper tension of conveyor drive

chain and conveyor belt. Refer to Section 4 for

correct procedure.

Check that the conveyor

drive sprocket is tight.

If conveyor still does not run correctly, contact

your Middleby Marshall Service Agency.

PROBLEM:

OVEN DOES NOT TURN ON WHEN ITS

SWITCHES ARE TURNED ON

Check that all electric supply switches are set to

the “ON” or “I” position. Then, start the oven.

If oven still will not start, contact your Middleby

Marshall Service Agency.

27

Page 32

SECTION 6 - WIRING DIAGRAM

60739 Rev. F

28

Middleby-Marshall Model Number E208-240 Volt 50/60 Hz, 3 Phase

Page 33

60741 Rev. F

29

Middleby-Marshall Model Number E380-480 Volt 50/60 Hz, 3 Phase

Page 34

NOTES

30

Page 35

NOTES

31

Page 36

WARNING

Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death. Read the installation,

operating and maintenance instructions thoroughly before

installing or servicing this equipment.

NOTICE

During the warranty period, ALL parts replacement and servicing should be performed

by your Middleby Marshall Authorized Service Agent. Service that is performed by

parties other than your Middleby Marshall Authorized Service Agent may void your

warranty.

NOTICE

Using any parts other than genuine Middleby Marshall factory manufactured parts

relieves the manufacturer of all warranty and liability.

NOTICE

Middleby Marshall reserves the right to change specifications at any time.

Middleby is proud to support the Commercial Food Equipment

Service Association (CFESA). We recognize and applaud

CFESA's ongoing efforts to improve the quality of technical

service in the industry.

Middleby Cooking Systems Group • 1400 Toastmaster Drive • Elgin, IL 60120 • USA • (847)741-3300 • FAX (847)741-4406

www.middleby.com

Loading...

Loading...