Page 1

PS670 “WOW” SERIES GAS FIRED:

SPL031707-PF-BD

A MIDDLEBY COMPANY

Parts Manual

with Wiring Diagrams

for domestic ovens

Serial # Code (Ten Digit Code)

First 5 digits - order of production

Sixth digit - model specific

Seventh and Eighth digit- month of production

Ninth and Tenth digit - year of production

March 17, 2007

For Production After April, 2007

XXXXXX0407

Table of Contents: Page 2

email: techsupport@middleby.com

1400 Toastmaster Drive

1-847-741-3300 fax 1-847-741- 4406

© 2006 Middleby Marshall Inc.

www.middleby.com

Elgin, IL 60120

Page 2

Table of Contents

Spec Sheet ...................................................................................................................... 3

Key Parts ........................................................................................................................ 7

Cross Reference of Wiring Diagram Symbols and Part Number(s) .............................. 8

View of Installation Kit(s) and Base Kit(s) ....................................................................9

Parts for Installation Kit(s) and Base Kit(s) .................................................................. 10

Standard Finger Conguration and Part Numbers 60188B ........................................... 11

View of Oven Panels, End Plugs and Window ............................................................. 12

Parts for Oven Panels, End Plugs and Window ............................................................ 13

View of Gas Piping ....................................................................................................... 14

Parts for Gas Piping ...................................................................................................... 15

View(s) of Burner/Blower Motor Assembly ................................................................. 16

Parts for Burner/Blower Motor Assembly .................................................................... 17

View(s) of Front Control Area(s) .................................................................................. 18

Parts for Front Control Area(s) ..................................................................................... 19

View of Rear Compartment and Blowers (Conveyor Drive End Shown) .................... 20

Parts for Rear Compartment and Blowers (Conveyor Drive End Shown) ................... 21

View of “Single” Belt Conveyor ................................................................................... 22

Parts for “Single” Belt Conveyor .................................................................................. 23

View of “Split” Belt Conveyor .....................................................................................24

Parts for “Split” Belt Conveyor .................................................................................... 25

Wiring Diagram, G208-240, 50/60Hz, 1 Phase 54745 Rev. I ....................................... 26

2

Page 3

Principle

Middleby Marshall PS Series Conveyor ovens bake both

faster and at a lower temperature than other ovens. Patented vertical columns of hot air move heat aerodynamically instead of using high temperatures. The streams of

hot air remove the boundary layers of cool heavy air which

tend to insulate the product. This gives very rapid baking

without burning. All PS670WOW ovens are designed to

cook pizza 30% faster than other conveyor ovens.

Cleanability

PS670 ovens are designed for easy cleaning. Removable

parts include: crumb pans, end panels, air fingers, and a

folding conveyor belt assembly.

Easily Serviced

Control compartment is designed for quick and easy access. All electrical controls are door-mounted.

Warranty

All PS670 models have a one year parts and labor warranty. Oven start-up and demonstration are included at

no additional charge (USA only).

Ventilation

For installation under a ventilation hood only.

WOW OVEN

A MIDDLEBY COMPANY

1400 Toastmaster Drive

Elgin, Illinois 60120 USA

(847) 741-3300 Fax: (847) 741-0015

www.middleby.com

Direct Gas Fired Conveyor Oven

A/A File No.: _____________

Item No.: ________________

Standard Features

• Impingement PLUS! low oven profile and dual air

return

• Patented EMS Energy Management System re-

duces gas consumption and increases cooking efficiency

• 70”/1778mm-long cooking chamber

• 32”/813mm-wide, 106”/2692mm-long conveyor belt

Speed

• Advanced technology air delivering system bakes up

to 30% faster than standard conveyor ovens.

Energy Management System

* The PS670 features an Energy Management System

(EMS) that automatically reduces gas consumption.

Touch Screen Control can be programmed in one energy

saving mode.

* Automatic “energy eye” saves gas when no pizza’s are

in the oven.

PATENTS PENDING

PS670

3

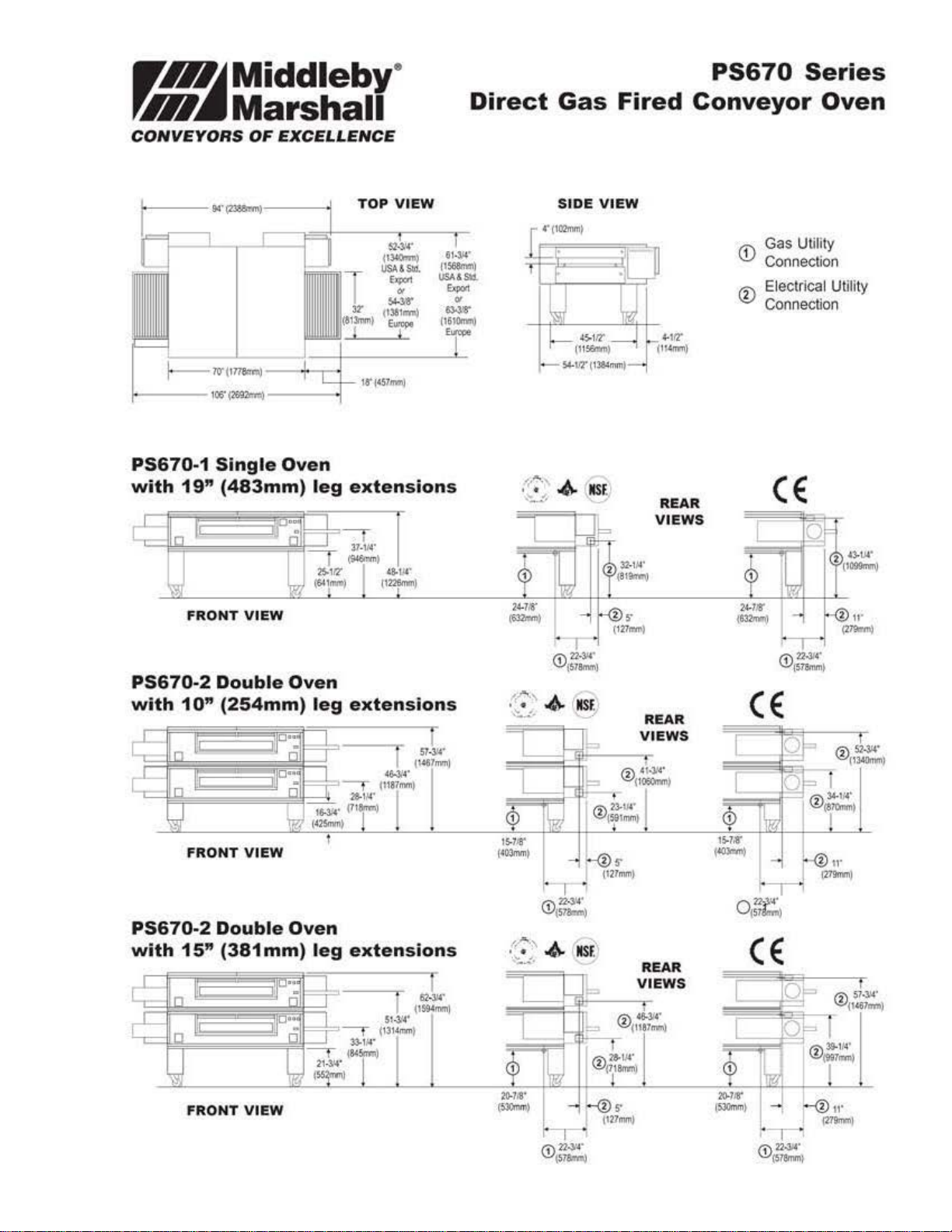

Page 4

WIHJMiddleby•

~~Marshall

CONVEYORS

OF

EXCELLENCE

TOP

VIEW

Direct

Gas

SIDE

VIEW

Fired

PS670

Conveyor

Series

Oven

PS670-1

with

PS670-2

with

19"

FRONT

10"

Single

(483mm)

Double

(254mm)

Oven

VIEW

leg

Oven

leg

extensions

extensions

1C'(1~~

I h

1)

i=

II

1,.,

I~ t'

·

,-

r.. 22·ll4'

~

IS7Bmtrll

"""'~

..,

--Q)_ ..

(1

27tl'nl)

REAR

VIEWS

..

REAR

VIEWS

Gas Utility

1

CD

Connection

<D

El

ectrical UUiity

Connection

CE

CE

FRONT

PS670-2

with

15"

FRONT

VIEW

Double

(381

mm)

VIEW

Oven

leg

extensions

;

,-;

\ 4-

·::-:....:.

4

--..

NS£•

=

REAR

VI

®~··

(11

$7(ml)

EWS

·

CE

[

Page 5

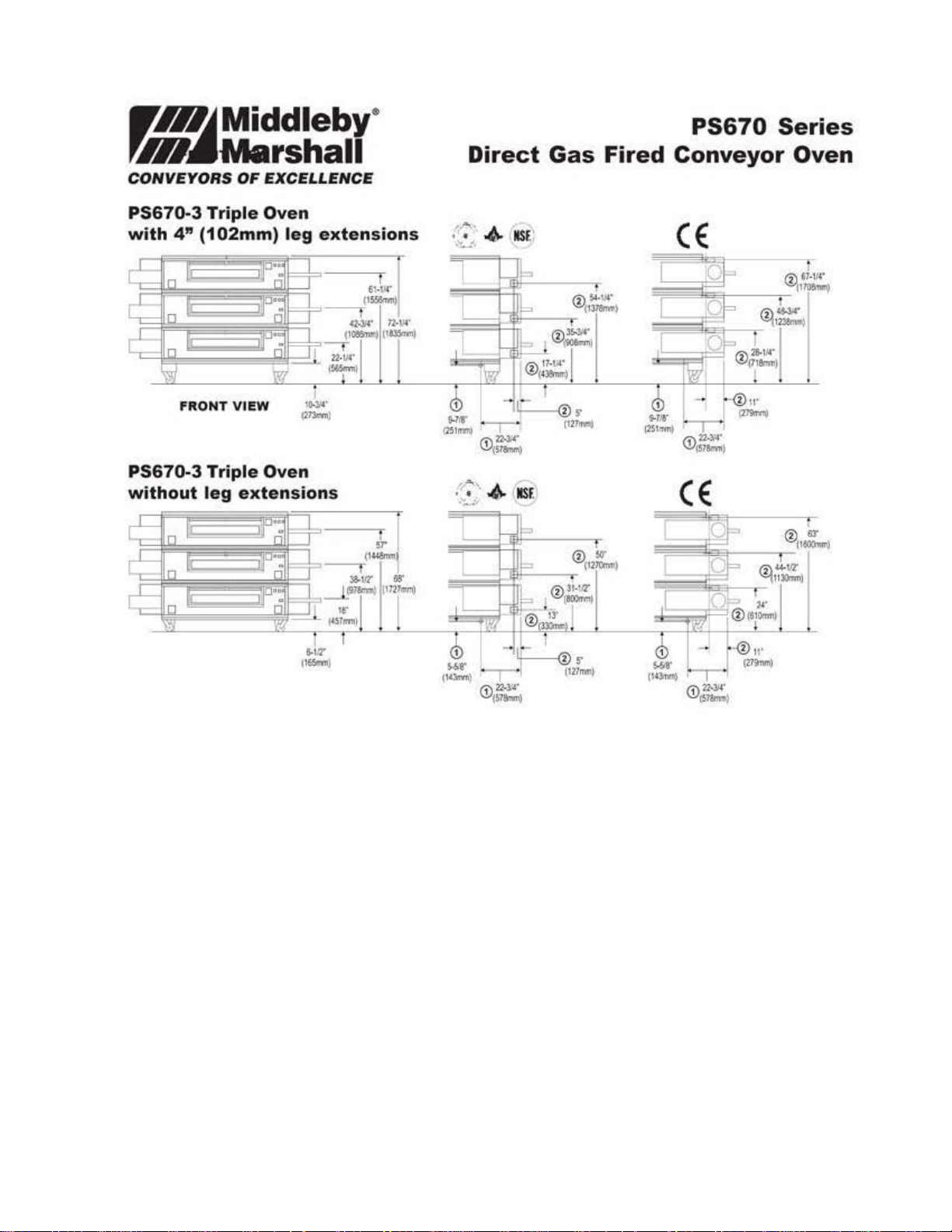

WHI~

Middleby•

PS670

Series

r.III•Marshall

CONVEYORS

PS670-3

with

4"

FRONT

PS670-3

without

OF

EXCEI.I.ENCE

Triple

(102mm)

Triple

leg

Oven

VIEW

Oven

extensions

leg

extensions

I

,,.....

(213m>)

Direct

..

...

.

•

~

.

..

·-·

$.111'

--

!l'lml

"'

w

::;,'

·--

#=~

Gas

...

.._,.. tiiS

F.

·

i,.,;,

.

<sr~

4 INS['

@ liT

~---;~

Fired

Conveyor

CE

CE

(12~1

Oven

5

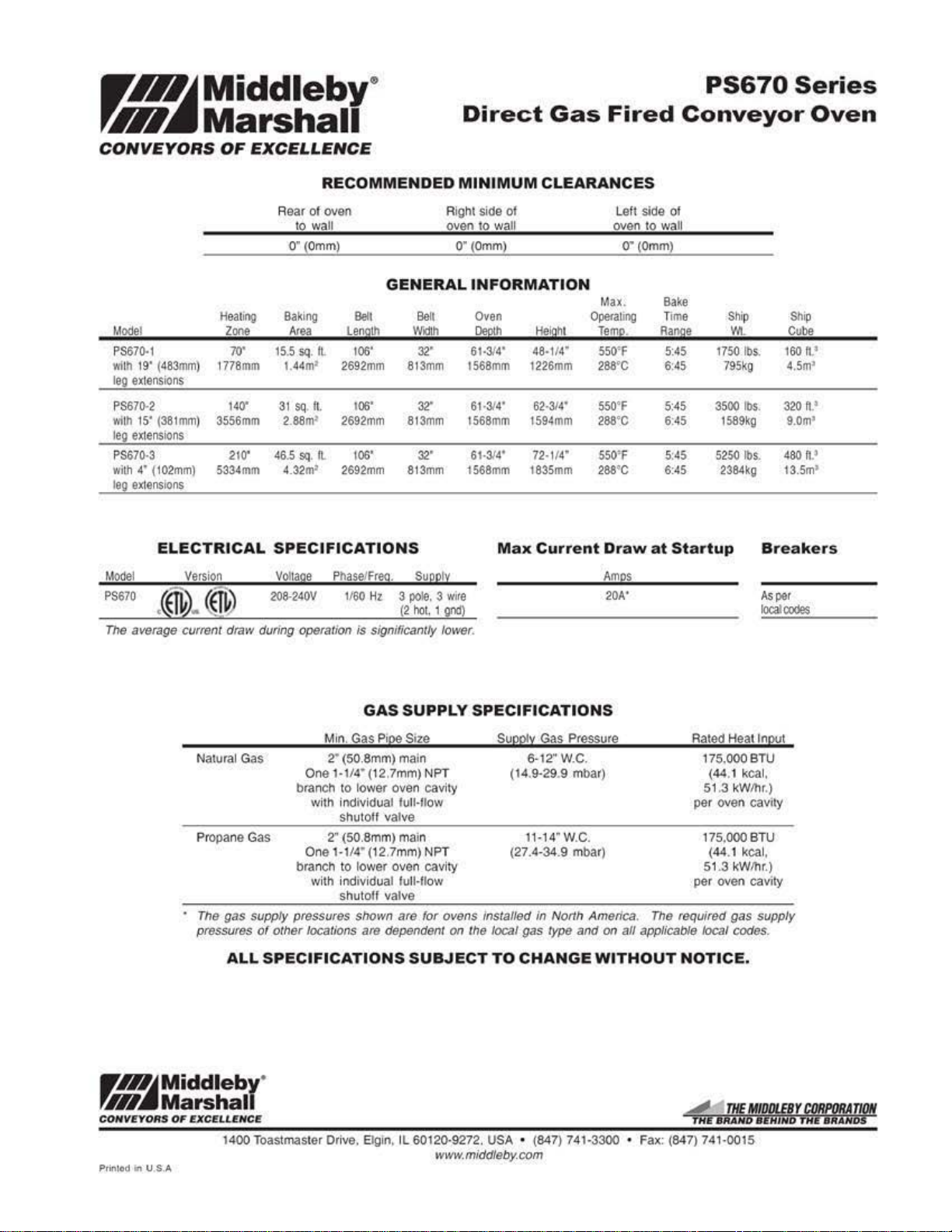

Page 6

WIHJMiddleby

'711

CONVEYORS

..

Marshall

OF

EXCEI.I.ENCE

$

Direct

Gas

Fired

PS670

Conveyor

Series

Oven

RECOMMENDED

Rear

of

oven Right side ol Loll side

to wall oven

O"(Omm

mm

Baking

Area

15.5

L44m

81

2.

46

.5 sq.

4.32m

VO!la

208-240V

Mode

l

PS670.1

wllh

t9'

(483mm)

leg

extensions

PS670.2

wt

lh 15'

(381mm)

leo

extensions

PS670·3

with

4'

(102mm)

leg

eXIenslons

EL

Model

P$670

The average current draw during operation

HeaiJI"'Q

Zone

70'

177B

140'

3556mm

210'

5334mm

ECTRICAL SPECIFICATIONS

version

sq.

sq

86m

pe

1

ft.

1

2

IL

IL

)

2692mm

2692mm

2692mm

P

haseJF

GENERAL

Belt Belt

Le

nolh

106'

813mm

106'

813mm

106'

1160

is

813mm

reo

.

Ht

3

pole.

(2

significantly lower.

Vild1h

32'

32"

32'

su

pply

hot

, 1

MINIMUM

10

wall

Omm)

0" (

INFORMATION

Oven

!lep!h

61·314'

1568mm 1226mm

61·314'

1568mm 1594mm

61·314'

1588mm 1835mm

Max

3

wire

gnd)

CLEARANCES

oven

O"(Omm)

Max

.

Helehl

48·114"

62·314'

72·114'

Current

Ope<aung

Tem

p.

550'F

286\)C

550

'F

286()C

550

'F

288

'C

Draw

Am

20A'

s

to

at

waJI

Bake

Time

Ranoe

6:

5:45

6:

6:45

ol

5:45

45

45

5:

45

Startup

Ship

v~

1750

795kg

3500

1589kg

5250

2384kg

.

lbs

.

lbs

.

lbs.

Breaker

Asper

localoodes

Shi

p

Cube

160

n.~

4.5m'

320 ft.'

9.0m

480 ft.'

t3.5m,

1

s

NaMal

Gas

Propane Gas 2" (50.8mm) main

The

gas

pressures

supply pressures shown

or

ALL

rmjMiddleby

rHI~Marshal

C

OHV~Y

Oif$

Prinlod

OF EXC!

tn U S.A

U.LHCI!

1400 Toastmaster

One 1-114' (12.7mm) NPT

branch to

wi

One

branch

wi

other

locations are dependent

SPECIFICATIONS

·

GAS

SUPPLY

Min.

Gas

Pioo Srz

2'

(50.8mm) main

lower

lower

oven cavity

oven cavity

al

full-flow

valve

are

th

individual fun-now

shutolf valve

Hl4"(12.7mm) NPT

to

th

individu

shutoff

SUBJECT

Dr

ive.

8gin.

IL 60120·9272. USA • (847) 741·3300 • Fax: (847) 741·0015

SPECIFICATIONS

e

for

ovens installed

on

Supoty

(1

(27.4·34.9 mbar)

lhe

local

TO

www.middlsby.com

6

Gas

Ptessute

6-12"W.C.

4.9-29.9 mnar)

w.c.

11-14"

in

Nol1h America. The required

gas

type

and

on

all

applicabl.s

CHANGE

WITHOUT

Rated Heat

175.000BTU

(44

.1 kcal.

51.3 kW/Ilr.)

pe

r

over\

175.000BTU

(44.1 kcal.

51.3

kWfllr.)

pe

r oven cavity

gas

/oc81

codes.

NOTICE.

Input

cavcty

supply

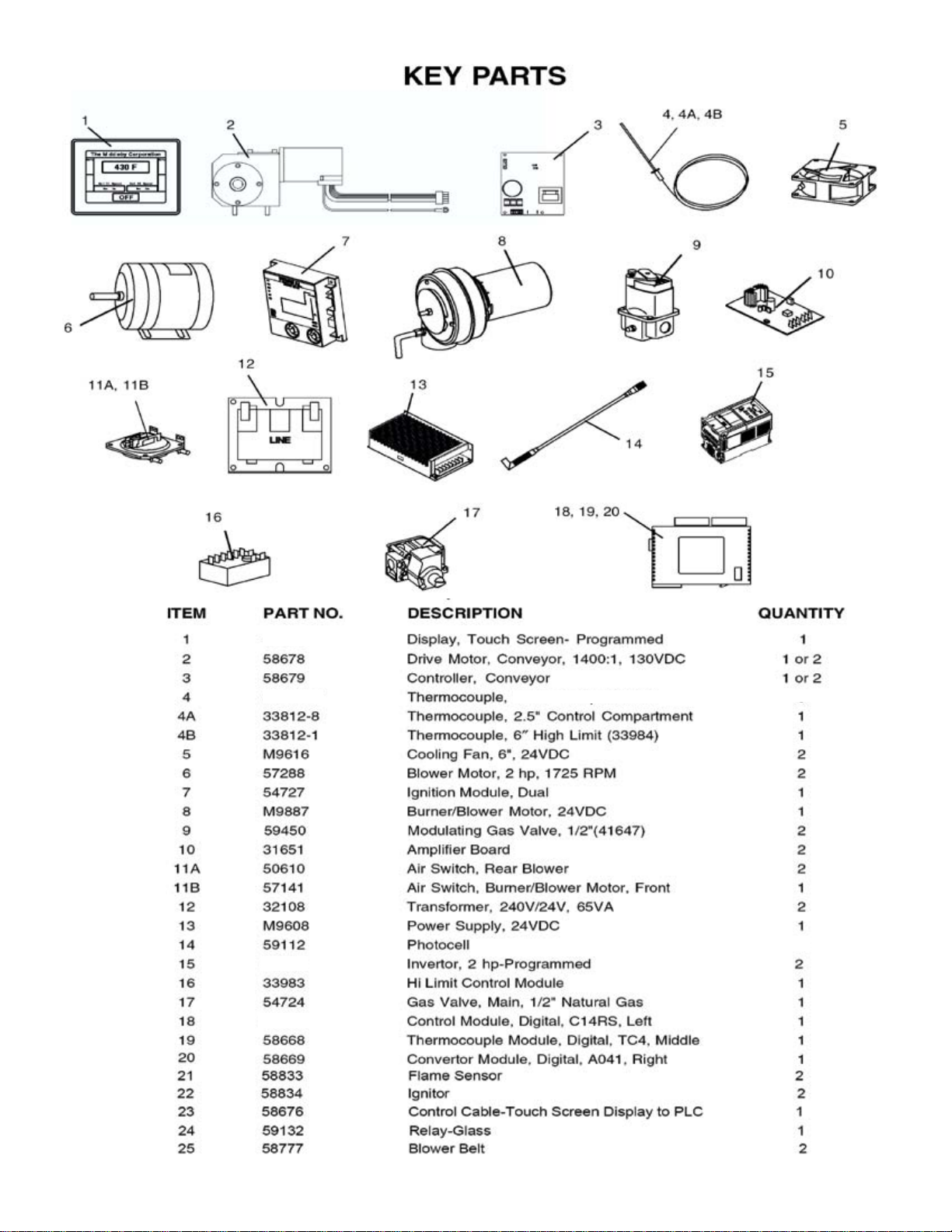

Page 7

60088

33812-6

60126

60128

12" Temp. Control

4

1

7

Page 8

CROSS REFERENCE of WIRING DIAGRAM SYMBOLS and PART NUMBERS

• Air Switch 1 -Rear Right .........................................50610

• Air Switch 2 - Rear Left ..........................................50610

• Air Switch 3 - Front Right .......................................57141

• Blower Motor–Left ..................................................57288

• Blower Motor–Right ................................................57288

• Burner Blower Motor ............................................ M9887

• Circuit Breakers

• CB1 - 15A ...............................................................45037

• CB2 - 15A ...............................................................45037

• CB3 - 15A ...............................................................45037

• CB4 - 15A ...............................................................45037

• CB5 - 3A .................................................................45036

• CB6 - 3A .................................................................45036

• CB7 - 1A .................................................................45644

• CB8 - 1A .................................................................45644

• Cooling Fan LH .....................................................M9616

• Cooling Fan RH .....................................................M9616

• Controller 1 DC ......................................................58679

• Controller 1 DC (split belt) ......................................58679

• Conveyor Motor ......................................................58678

• Conveyor Motor (split Belt) .....................................58678

• Dual Burner ............................................................54719

• Converter Module - Digital A041, Right ..................58669

• Control Module - Digital C14RS-A, Left .................60088

• Thermocouple Module - Digital TC4, Middle ..........58668

• Gas Valve ...............................................................54724

• Green Light (Reset Button) ....................................35145

• GT30 Display .........................................................60128

• Ignition Module, Dual .............................................54727

• Inverter - 1 Left, 2HP ..............................................60126

• Inverter - 2 right, 2 HP ............................................60126

• Switch(es)

• LS1 (LH RR), Momentary ............................. 28021-0061

• LS2 (RH RR), Momentary ............................ 28021-0061

• LS3 (RH Front), Inter Lock ........................... 28021-0047

• LS4 (LH Front), Inter Lock ............................ 28021-0047

• Reset Button ..........................................................35145

• Mod Valve 1 (41647) ..............................................59450

• Mod Valve 2 (41647) ..............................................59450

• Photocell 1 Entrance ..............................................59112

• Photocell 2 Exit ......................................................59112

• Power Supply ........................................................M9608

• Relay ......................................................................59132

• Signal Amplier 1 ...................................................31651

• Signal Amplier 2 ...................................................31651

• TB1 RR LT (3 Pole) ................................................44390

• TB2 RR LT (3 Pole) ................................................44390

• TB3 RR RT (3 Pole) ...............................................44390

• TB4 RR LT (8 Pole) ................................................31047

• TB5 Comp Brkt (4 Pole) ........................................M0593

• TB6 Comp Brkt (4 Pole) ........................................M0593

• TC1 - 6” High Limit (33984) ................................ 33812-1

• TC2 - 12”, Oven Temp. ....................................... 33812-6

• TC3 - 12”, Oven Temp. ....................................... 33812-6

• TC4 - 2.5”, Control Compartment ....................... 33812-8

• XFMR1 - 240V/24V 65 VA ......................................32108

• XFMR2 - 240V/24V 65 VA ......................................32108

• High Limit ...............................................................33983

Wiring Diagram on Page 26

8

Page 9

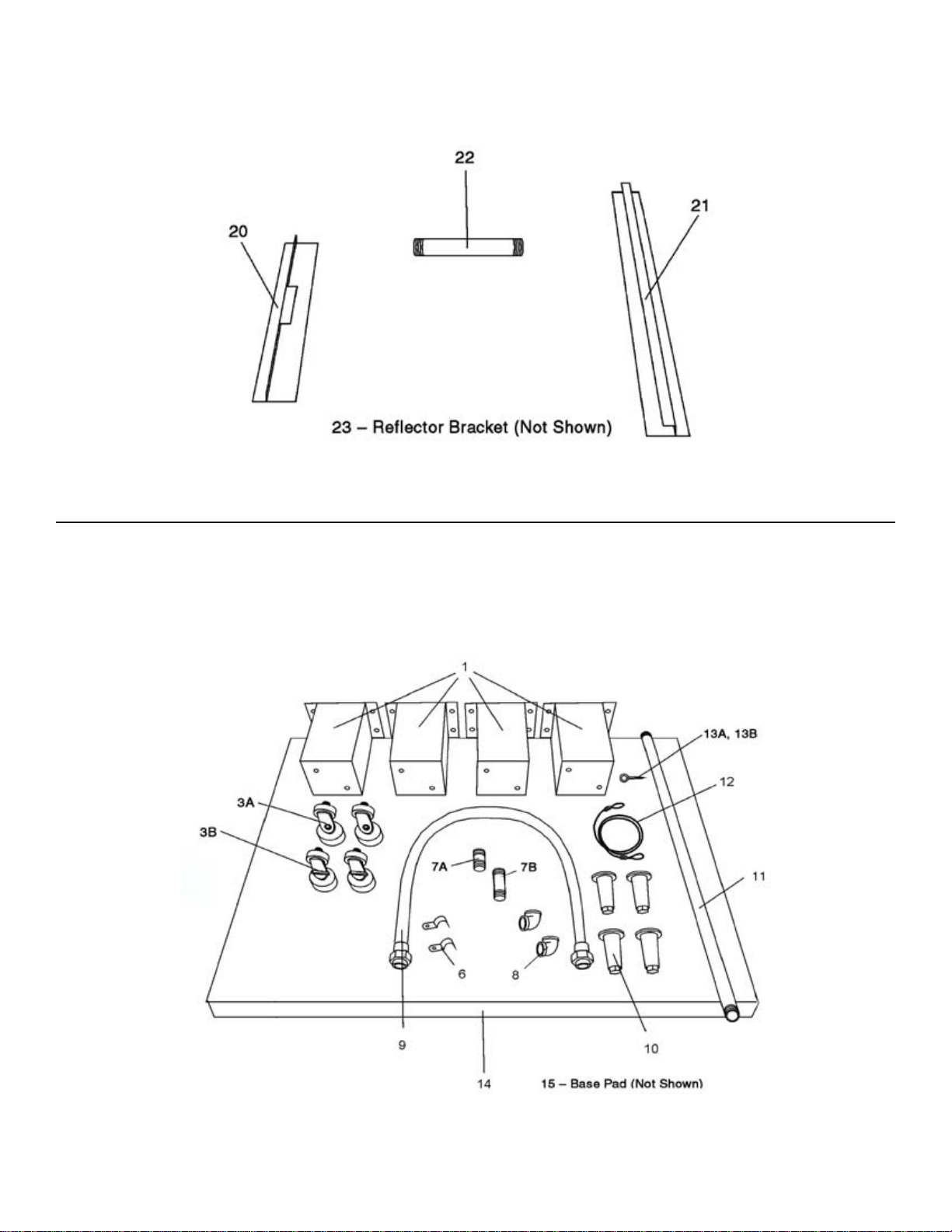

VIEW OF INSTALLATION KIT (PART NUMBER 59057)

VIEW OF BASE PAD KIT

9

Page 10

Parts for INSTALLATION KIT (Part Number 59057)

59419

10

Page 11

IAIAIBIEIXIEIBIAIAI

I I I

45084

A=

WLDMT,OTR

35000-1366

45083 WLDMT,RAISED MANF W/PERF

PLA

PL T W/EXT

TE,INNER PERF L6

TAB

Sll4

ALUZ

BAF

11

11

< '>

I I

.

11!1

'

SYMMETRICAL FINGER CONFIG.

AVG CONTROL TICS: 4 USED

ENT: TOP INNER

EXIT:

RPM= 2100RPM, INVERTERS

BOTH SIDES END PLUGS

PARTITION K

lclolxlolcl

TOP

& OUTER LOCATIONS: 12" PROBES

INNER & OUTER LOCATIONS: 12" PROBES

IT

RAISED PIN 59834

HAVE

SET@

63HZ

.DIVERTERS

I I I I I

39225

B=

C=

D=

. . 3521 0-0520 PLA

Ea

WLOMT

35000-1366 PLATE,INNER PERF L6

45083 WLDMT,RAISED MANF

37900-0051 PLATE,OUTER S/L6

35000-1366 PLATE,INNER PERF L6

36449 WLDMT,MANF

44476 WLOMT,OTR PLATE L 18

43034 WLDMT,MANF W/PERF BAF

35210-0535 PLATE,BLANK PRTL 2.75

,PLT

OTR

W/PERF

TE

,INNER PERF L

S/L6

W/EXT

ALUZ

W/PERF

BAFFLE

W/14

18

ALUZ

TAB

BAF

ALUZ

ALUZ

ROWS

ALUZ

l18

UPR

l===i=

=}="

----==

=

=~

~==

=========-

-,

+

~~

~~~~~~~~~~

-~"~

--~~--

---

ICONFIG,FNG.RPS670G

'

~

·

.

188

·· · B I

_·_,~~·

,___,,

~~'------=-

· ·:

rs

·~·

·

'--'.

.. · . _

·

lr-~Middleby-

U.~Marshall

_j

CONVI!YOIIB

S!D

OF

Bt:ai.EIICa

.

_j

Page 12

47

48 FILTER-ONLY

46

12

Page 13

49 1 59834 Partition Kit

50 1 59456 Partition Raised

51 2 59464 Bottom Partition

59838

59049

13

Page 14

View

of G.AS

CONTROLS RIGHT HAND BURNER

PIPING

14

6

2

CONTROLS LEFT H

I

4

DUAL BURNER ASSE

FITS HERE

4

AND

BURNER

MBLY

Page 15

QlY

ITEM

1 4 23051-0003

2

. P/N

1 23051-0012

Parts for

DESCRIPTION

UNION, 1

UNION,

GAS

1-1W

PIPI

/2"

NG

15

3

4

5

5A 1 28092-0018 SPRING FOR LPCONVERSION

----

6 1

1 23115-0009

2

1 54724

59450

----------------

42410-0016 BRACKET/CLAMP

MANUALONIOFFGASVALVE,1/2", BALL

MODULATINGGASVALVE.

VALVE, COMBINATION,

------------

112" (4164

112"

-NATURAL GAS

---------

7)

Page 16

(1/8” GAP)

16

Page 17

.118

17

Page 18

26

1, 1A, 9

1, 1A, 9

View(s) of FRONT CONTROL AREA(S)

27

18

Page 19

Parts for FRONT CONTROL AREA(s)

ITEM QTY. P/N DESCRIPTION

1 2 310-2458 FILTER/GUARD, FAN

2 2 31651 AMPLIFIER BOARD

3 2 32108 TRANSFORMER, 240/24V, 65VA

4 1 60128 TOUCH SCREEN DISPLAY

5 1 54727 DUAL IGNITION MODULE

6 1or 2 58679 CONTROLLER, CONVEYOR

8 2 M0593 TERMINAL BLOCK, 2-POLE

9 2 M9616 COOLING FAN, 24VDC

10 1 33983 HI-LIMIT CONTROL

11 1 57141 AIR SWITCH, FRONT, BURNER/BLOWER

12 1 60088 CONTROL, (LEFT-HAND), DIGITAL, C14RS -PROGRAMMED

13 1 58668 THERMOCOUPLE (MIDDLE), CONTROL, TC4

14 1 58669 CONVERTER, (RIGHT-HAND), A041

15 1 M9608 POWER SUPPLY, 24VDC

16 1 35145 RESET SWITCH W/GREEN LIGHT, HI-LIMIT

17 2 60126 INVERTOR -PROGRAMMED

18 2 45644 CIRCUIT BREAKER, 1 AMP

19 2 28021-0047 SWITCH, INTERLOCK

20 4 45037 CIRCUIT BREAKER, 15 AMP

21 2 45036 CIRCUIT BREAKER, 3 AMP

22 1 33812-8 THERMOCOUPLE, 2.5″ x 60″, CONTROL COMPARTMENT

23 4 33812-6 THERMOCOUPLE, 12″x120″ REAR OF OVEN

24 1 33812-1 THERMOCOUPLE 6″ (HIGH LIMIT) REAR OF OVEN (33984)

25 1 59132 RELAY, DPDT, 24VDC COIL

1A 2 310-2468 FILTER ONLY

26 1 58764 MIDDLEBY LOGO

27 1 59085 LABLE - MIDDLEBY MARSHALL WOW OVEN

19

Page 20

20

View(s)

of

REAR

COMPARTMENT

AND

BLOWER

(CONVEYOR

DRIVE

END

SHOWN)

2

ITEM 39

ITE

ITEM

ITEM

ITEM 43

ITEM 44

ITEM 47 PHOTO

ITEM

MOME

NTAR

M 40

AIR

SWI

TCH. NOT SHOW

41

ALUMINUM

42

TUBING. SILICONE. N

THERMOCOUPLE. NOT

THER

MOCOUPLE. N

CELL

48

MOUNTING

Y SWI

TCH

. N

TUBING. NOT

OT

OT

BRACKET.

PHOTO

OT

SHO

WN

N

SHOWN

SHOWN

SHOWN·12'"

SHOWN·6"

CELL

NOTE: IDENTIFY THE DEFECTIVE INNER FROM THE DEFECTIVE OUTER BEARING ITEM 14 PER ENGINEERING’S REQUEST

(THESE PARTS ARE TO BE RETURNED FOR OUR INSPECTION)

Page 21

28 4 A3682 LOCKWASHER, SPLIT 5/16″

ITEM QTY. P/N DESCRIPTION

Parts for EACH REAR COMPARTMENT AND BLOWER

31 1 57296 PULLEY, 5.6″

32 1 57297 INSERT, 5/8″

33 1 43024 EXTENDER, FAN

34A 1 27399-0008 FAN BLADE, CW, 8″, CONVEYOR DRIVE END

34B 1 27399-0009 FAN BLADE, CCW, 8″, IDLER END

35 1 57316 BRACKET, MOTOR SUPPORT

SHAFT SEAL, PTFE

36 1 57298 INSERT, 1-7/16″

37 1 Contact Factory KEY, 5/8 x 1

38 2 57325 RING

39 1 28021-0061 SWITCH, MOMENTARY

40 1 50610 AIR SWITCH

41 A/R 15125-0002 ALUMINUM TUBING

42 A/R 22450-0297 TUBING, SILICONE

43 4 33812-6 THERMOCOUPLE, 12″ x 1 2 0 ″, REAR OF OVEN

44 1 33812-1 THERMOCOUPLE 6″ (HIGH LIMIT) (33984)

45 1 41575 MOUNTING BRACKET

46 1 44550 SUPPORT BRACKET

47 1 59112 PHOTO CELL, 24V DC

48 1 59108 MOUNTING BRACKET, PHOTO CELL

2 1 37210-0124 PLATE, INLET RING

1A 1 22521-0005 BLOWER WHEEL, IDLER END

1B 1 22521-0006 BLOWER WHEEL, CONVEYOR DRIVE END

ITEM QTY. P/N DESCRIPTION

3 4 21211-0001 SCREW, CAP HEX HD 3/8″-16 x 3″

5 10 21422-0001 LOCKWASHER, SPLIT 3/8″

6 4 35210-0576 SPACER

7 1 35210-0541

8 1 37210-0101 PLATE, SHAFT SEAL INNER

12 1 57323 SHAFT BLOWER

13 1 35210-0286 KEY, BLOWER WHEEL

14 2 57321 BEARING

15 4 57320 SPACER, BEARING

16 4 2000535 SCREW, CAP HEX HD

17 4 A6235 FLATWASHER, 7/17″

18 4 21121-0013 HEX NUT, 1/2″-13

19 1 57295 PULLEY, 5″

17A 4 21422-0016 LOCKWASHER

21 1 58777 BELT

25 1 57288 MOTOR, BLOWER 2HP

26 1 59133 BRACKET, MOTOR MOUNTING

27 4 6673 SCREW, CAP HEX HD 5/16″-18 x 1″

21

Page 22

\\

II

View of Single-Belt Conveyor

..

. . .

~~·

·\

· .

. . . :

••

V' •••

...

....

·.

..

.:·

. t ·'

·.

. . .

..

.. ··"

•• c ......

(<4

I . . . \

·. = .··

. 2

·.·

. · r, •

.·

··

{

N

-:··

•'

..

. .

. · "· .

t ...

-:·

....

••

.

·

22

Page 23

Parts

for

Single-Belt Conveyor

ITEM

OTY

2 1

3 1

4

s

6 8

7

8

8 8

9A 1

------------------------------------------

9B

10

11

12

4

13

23

14

15

6

17

2

18

2

19

2

20

2

21

PART NO.

37210-0117

37210-0046

37210-0116

35210-0429

35210-0491

F716A8805

21176-0001

22450-0265

33900-0032

51380

350()0..10

22229--0003

22034-{)003

37000-0413

35000-1008

35000-10

11

54947

12

WEL.OMENT.CONVEYORORIVE

WELDMENT.CONVEYORCENTERFRAME

WELOMENT.CONVEYORQ.ERFRAME

PIVOT

PlATE

BUSHING.CONVEYORAIWSTMENT

WASHER.

LOCKNUT, HEX

CONVEYOR

CONVEYOR

MASTERLINKS

SHAFT

SPROCKET,

BUSHING, BRONZE

BRACKET, IDLER SHAFT ADJUST

SC

BRACKET.

SHAFT. DRIVE

EXTERNAL

MASTERUNK.LEFT

MASTERUNK.CENTER

MASTERLINK, RIGHT

, IOlER

REW, CONVEYOR

SHAFT

DESCRIPTION

FRAME

TOOTH

1/4•

114"·20

BELT, COMPLETE.32"Wx206'1.

BEL

T.

32'"W

x 12"l

(0.8

1x

0.30m)

KIT

. 32"

(0.81m)

BELT

(INC.ITEMS

CONVEYOR BEL

SUPPORT

T

3/4" 0.0. x

TENSION

518"

1 .D.

MENT

ADJUSTMENT

11-13)

ITEM OTY

22

27 2

42

24

25

26

28

29

30

31

32

33

35

40

41

43

44

6

1

2

2

1

1

1

1

2

1

PART NO.

22229.0003

22011·0013

22034·0003

3500().1080

54947

35000-10

22152

4240

2227

22152.0018

35210.()640

.()()

0-0164

3.()01)1

58678

55027

55028

13

17

30004

M1

0098

4

5035

DESCRIPTION

SPROCKET, CONVEYOR

COLLAR. SHAFT. WITH

BUSHING,

SPACER.

BRACKET.SHAFTSUPPORT

ADAPTER.

SPROCKET. DRIVE

~

ASSEMBl Y.ROUERCHAIN(62UNKS)WITHMASTERUNK

SPROCKET,ORIVE MOTOR,st8•80Re,

~

AOAPTER.ORIVEMOTORWITHSETSCREW

ORIVEMOTOR.BRUSHL.ESS,1400

ENDSTOP.CONVEYOR,29-1/4"LONG

REARSTOP.CONVEYOR,

CRUMB

HARNE

MOUNTINGBRACKET,DRNEMOTOR

BRONZE

NYLON

DRIVE

MASTERUNK.

PAN

SS, WIRE

BELT

SET

314"

0.0

1-1/4"

0.0. x

SHAFT

SHAFT

ROLLER

SCREW

. x

518"

1 0.

3/4"1.0.

.

518"

BORE. 9T, WITH

CHAIN

:11

18"LONG

1ST,

WITH

30VOC

SET

SET

Page 24

...

0

>-

<1>

>

s:

0

0

r

"""'>70

I

I

I

I

I

I

I

I

I

I

I

/

/

I

I

I

/

I

I

I

/

/

/

./

~

·' .

______

I

_/

24

.

--

/

I

I

/

/

I

/

I

/

/

I

I

I

I

I

/

/

/

I

I

.

.

. .

..

.

..

•

··.

.

·~

Page 25

Qll

ll~Da

1

2 1

1 37210-0

3

4

5

6 8

eaBltUl

3721Q-Q117

37210-0046

11

3§210-Q429 PIVQTPLATE

35210-0491 BUSHING, CONVEYOR ADJUSTMENT

WE

LDMENT,CONVEYORCRIVEFRAME

WEUJMENT,CONVEYORCENTERFRAME

6 WEUJMENT CQNVEYORIOLERFRAME

7 8 F716A8805 WASHER EXTERNAL TOOTH

8 8

9A

----------------J

2

98

10

15 1

16

11

25

20

21 2

22

23

24 21415-0001 FLAT WASHER.

25

2

14 1

1

8

19

2 22034-0003 BUSHING BRONZE 314" O.D. x 518"1.0 .

2

2 54947 BRACKET SHAFTSUPPDRT

1 42400-0355 SHAFT. DRIVE,

.21176-0001 LOCKNUT, HEX 1

22450-0271

33900-Q037 CONVE

51382

4240

0·035

21415·0001 FLAT

3~00Q·1535

22229·0003 SPROCKET CONVEYOR BELT

37000-0413

35000-100~

35000-1536 SH

OONVEYO

~~~~=~~~~~ml

MASTERLIN

SHA

4

SHAEI,IOLER, FRONT, 1

BRACKET, IDLERS HAFT ADJUSTMENT

SCREW,CONVEYORTENSIONAOJUSTMENT

RBE

LT,COMPLETE.

YOR

BELT, 1

KS

FT

IDLER REAR 32·314"

WAS

HER, BRQNZE,

REAR

AFT

.DRIVE ,FRONT, 17-

Parts for "SPLIT" Belt Conveyor

c'~~B,E:liCtll

1/4'

14'-20

_____________

5"Wx

12'1. (0.38 x 0.3Qml

KIT, 1

5'

BR

{0.81m} B

, 35-1/

ONZE,

ELT

1"

0.0

. X 1/2" 1.0.

§-~/8

"

3"

1"

0 .0 . X 1/2" 1.0.

3/4"

(INC.ITEMS 11-13!

QD:

II~rd

2§

27

2~

2~

30

31 2 54947 BRACKET SHAFT SUPPORT

32

33

~

2

2 35000-1

1 35900-0023 BUSHING SPLIT BEL TORI

2

eaBitUl

2222~-QllQ~

35000-1531

22Q11

-Qll14

22~·QllQ~

080

22

152-

0017

§PRQI;

SPACER NYLON FfTSBETWEENSPROCKET

I;QLLA!3,

B!,!§HIN!Z, BRQNZ

SPACER NYLON 1-1/

SPROCKET.ORIVESHAFT,5/8" BORE,9T, WITH SET

aE~Bieiic~

KET, I;QNVEY

!2E

LIT LQI;KIN!Z

!:i

QR

~£4"Q,Q

4"

SCREW

RO

34 42400·0164 ASSEMBLY,

35

36

37

2 22273

2

42410-0128 ASSEMBLY, ROLLER CHAIN COMPLETE {48 LINKS)

MASTERLINK

SPROCKET.ORIVE MOTOR,

22

152·

-00

0018

01

LLER CHAIN

RO

LLER CHAIN

SCREW

38

40

45

46

47

48

49

2

2 30004 CRUMB PAN

2

35210-0640 ADAPTER DRIVE MOTOR WITH SET SCR

OR

58678

55027

55028 REARSTOP.CONVEYOR

M10098 HARNESS. WIRE

45035 MOUNTINGBRACKET,ORIVEMOTOR

IVEMOTOR,BRUSHLESS.1/8HP11400

END

STOP CONVEY

OR

BELT

. x ~/~'

0 .

0. x 314"1.0.

VE

SPROCKET

COMPLETE

518

"BORE. 1ST, WlT

29-1/

4"

18'

"

1.0

.

I62LINKS}

HSET

EW

;1

Page 26

•••

~----------------~w

•

Hlii

LKT

COM'! I ,jCDM2

LS1

LHRR

t«ll

"

u

I I

'I

• •

llll2

G_

H_

1

__

lint

.,

DATE

I-

..

_

,_

•••

-CIILGIIIIINTCII

0111111

lmE1BI

111M' I CIU1M

-I'IIIITUMILINI!Ij

0111~

_...._,

CIII'D-

OIIUC

-

REVISION

11-.

DESCRIPTION

Nft.l~llll

I'IIIITIIIN

BY

CHK

IIIII

-

FC

_,

AI-

DATE

~

11'111,..

Dlltv..

26

.

LOAD

kd

=

r"""'""

L1

UIE

L2

!It

27

XFI'R1

LEFTI

PRIMARY

:mY

SDJ60Hz

SE!]JNJARY

6SVA

2'V

FPO-A0'1

["

CDI

[

~

CDI

[c:.~~

[:~~

~

~I

117

CONTRW.ER

IB.-2302

ILIC

1tll

~

f;l

a

~

1

:

111

,

IQ

IL_

IL~~~~----~~---_-_-_-_-_-_-_-_-_-_-_-_-_-_-_-_-_-_-_-_-_-_-_-_~~--~--~

DC

~.n

f-Orr

0~

r-o~

n-

01'

L2

0'12

L...!!..!!._

00000

ooooo

1

Ll

WD

LABEL

PIN

56613

TOIBWj[E

IIATBUIL

l--

---------\

FINI..

- IIEIICED

M

®©

ALL

LILLESS

111"121111

lBI

Ml/21111

WD,G208-240t50!60!1

DI-LONS

w.

IN I NOES

OTIBWII!E SPEtiFIEIJ. 5 4 7 4 5

DO

_!IC!!_

StALf

DIIIIWINii

!PB:IFIIII

MliLES

lEt

.........,

11!1

I

PART

.I

.XI

.1001:

llltl,_

NO

IJUSS

THIS IJIAWIIE IS toiFIDEIITIAL

• 1.0"'

•.IBD

•.01!5

••

oos

THE

UOO

Elgin.

PIICI'EIITY

Toaat•catl!r

llllnalo

147-7~

1-3300

Of

CORPORATION

Dr I we

toll120

MIDDI.EBY

PS870!770

SHT

[

1

OF

AND

IRE¥

1

I_

Page 27

Loading...

Loading...