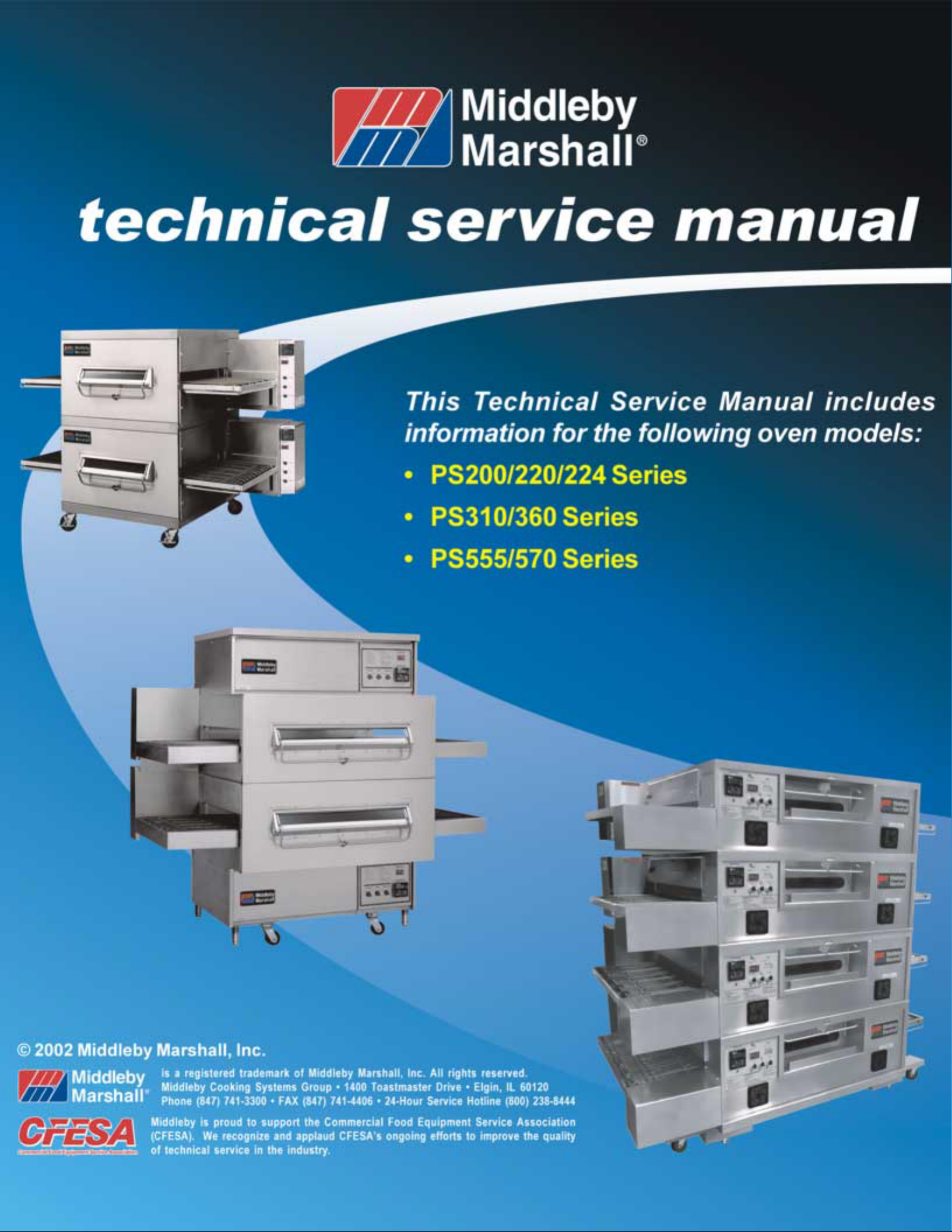

Page 1

Page 2

technical service

manual

This Technical Service Manual includes information

for the following oven models:

PS200/220/224 Series

PS310/360 Series

PS555/570 Series

P/N 47829 Rev. C V1 4/02

Middleby is proud to support the

Commercial Food Equipment Service Association (CFESA).

We recognize and applaud CFESAs ongoing efforts

to improve the quality of technical service in the industry.

© 2002 Middleby Marshall, Inc.

is a registered trademark of Middleby Marshall, Inc. All rights reserved.

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 (847) 741-3300 FAX (847) 741-4406 24-Hour Service Hotline (800) 238-8444

1

Page 3

W ARNING

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

W ARNING

DISCONNECT THE OVEN FROM ITS ELECTRICAL

POWER SUPPLY

During the warranty period, ALL parts replacement and servicing should be performed by your

Middleby Marshall Authorized Service Agent. Service that is performed by parties other than

your Middleby Marshall Authorized Service Agent may void your warranty.

Using any parts other than genuine Middleby Marshall factory manufactured parts relieves the

manufacturer of all warranty and liability.

Middleby Marshall reserves the right to change specifications at any time.

BEFORE SERVICING.

NOTICE

NOTICE

NOTICE

TABLE OF CONTENTS

Section 1 - Sequence of Operation .................................................... 4

I. Gas Oven Sequence of Operation ............................................. 4

II. Electric Oven Sequence of Operation ....................................... 6

Section 2 - Air Flow and Heat Transfer ............................................. 7

I. Types of Heat Transfer ............................................................... 7

II. Blowers and Blower Speed ....................................................... 7

A. PS200-series ovens ............................................................ 7

B. PS360-series ovens ............................................................ 8

C. PS555/570-series ovens .................................................... 8

III. Air Fingers ................................................................................... 8

A. Description and Function .................................................... 8

B. Configuration and Alignment ............................................... 9

C. Performing a Test Bake ....................................................... 9

D. PS300/350 Air Finger Shutter Adjustment ......................... 10

IV. Oven Capacity ............................................................................12

A. Conveyor Speed and Bake Time ....................................... 12

B. Belt Time ..............................................................................12

C. Time of Delivery (TOD)....................................................... 12

Section 3 - Troubleshooting and Servicing Components

I. Conveyor Speed Controller and Drive Motor.............................13

A. Part Number Reference - Speed Controllers .................... 13

B. Part Number Reference - Pickup Assemblies ...................14

C. Preparing to Service the Speed Controller ........................ 14

D. Controller/Motor Failure ......................................................15

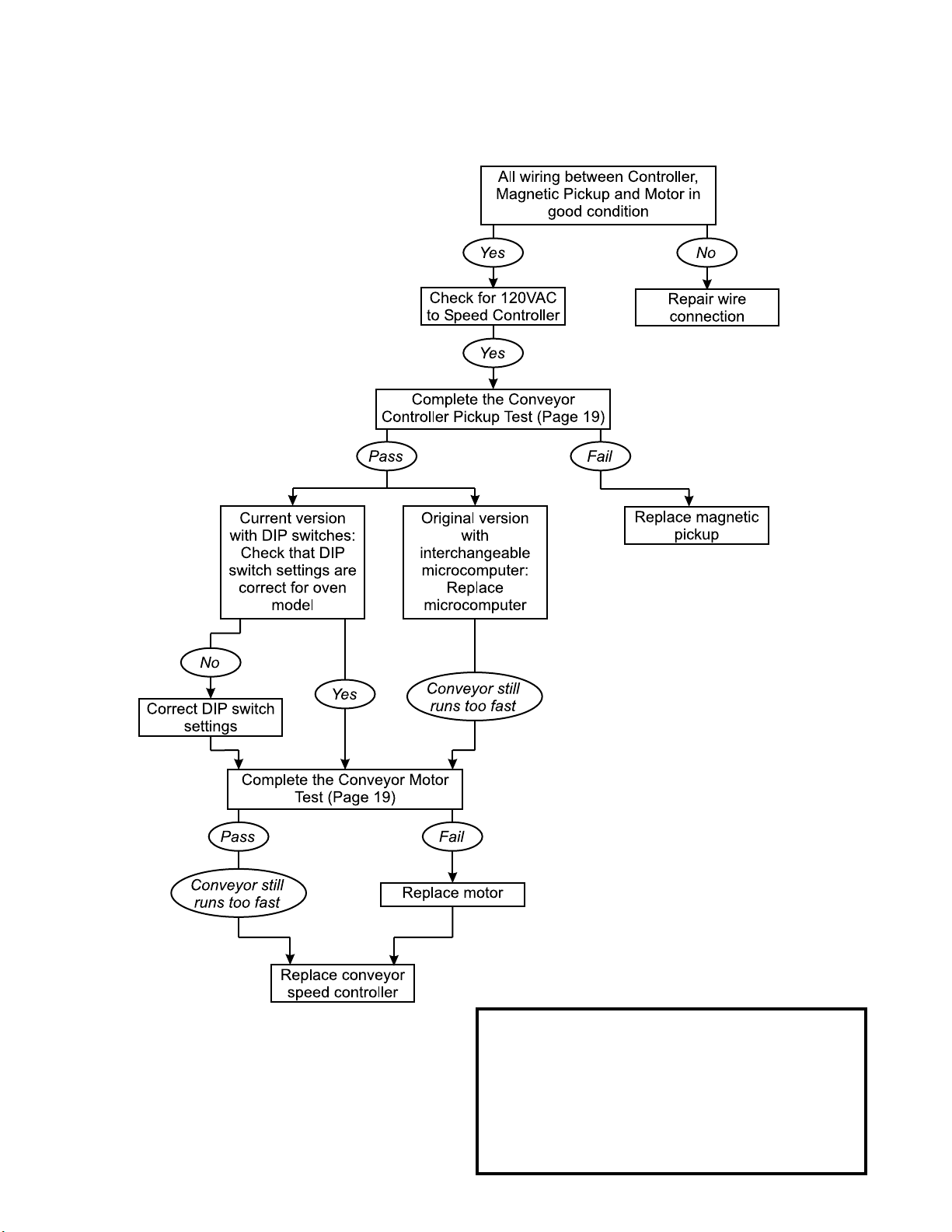

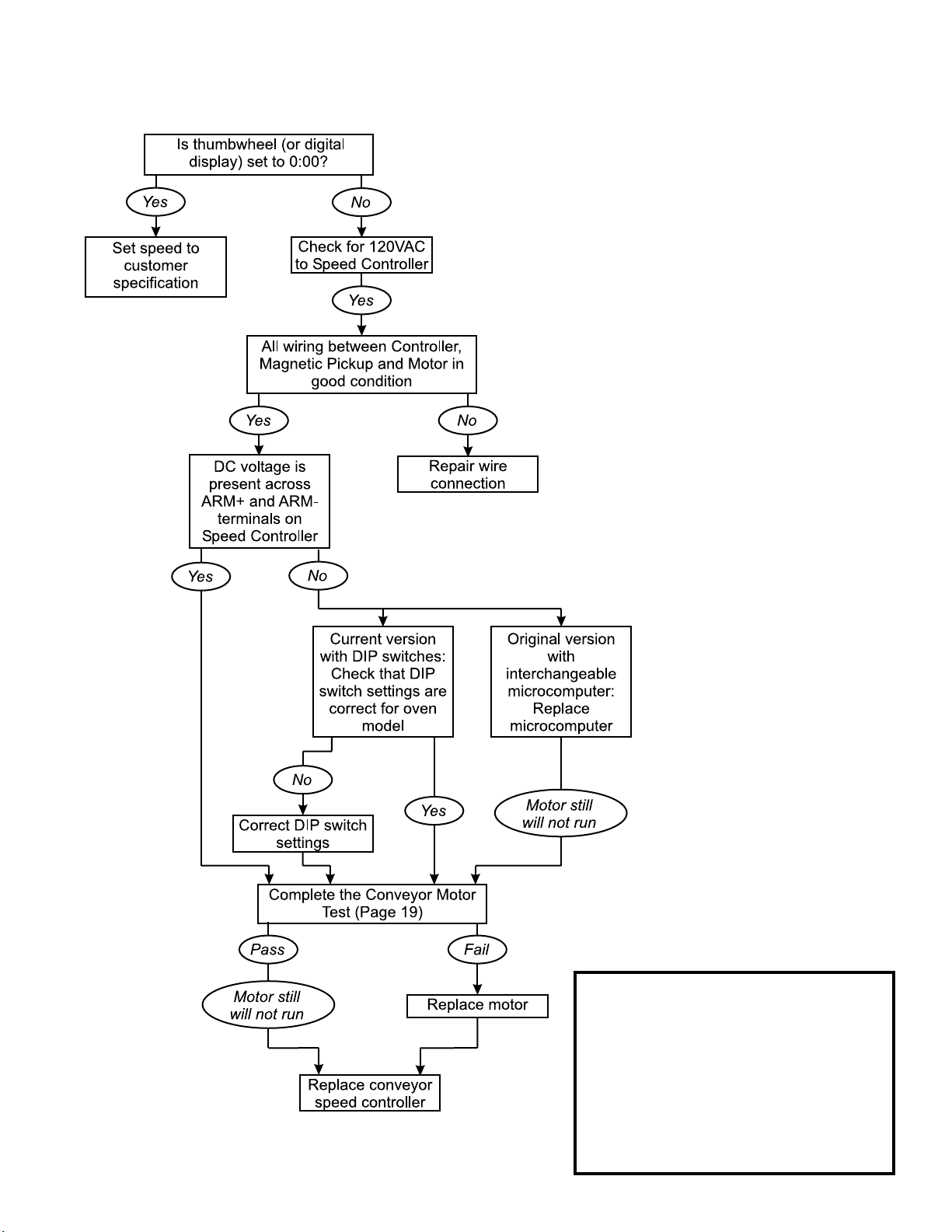

E. Basic Troubleshooting Flowcharts ................................... 16

If the Conveyor Runs at Full Speed ......................... 16

If the Conveyor Will Not Run at All .......................... 17

F. Initial Troubleshooting ......................................................... 18

G. Conveyor Control Pickup Test............................................ 19

H. Conveyor Motor Test ..........................................................19

I. Replacing the Magnetic Pickup .......................................... 19

J. Unshielded Pickup Wires on Early PS360-series Ovens . 19

K. Appendices .........................................................................20

Conveyor sensor wiring changes for PS360-series

and PS570S, 10/95 .................................................... 20

Service Bulletin MM-133B - Installation Instructions

for Conveyor Speed Controller Kit with Thumbwheel,

P/N 42810-0133, 4/95 ................................................ 21

Instructions for Service Kit 42810-0133- Conveyor

Speed Controller Kit with Thumbwheel, 4/95 ..........23

Service Bulletin MM-177 - Introduction and Compat-

ibility of Conveyor Speed Controller with Digital

Display, P/N 37337, 8/00........................................... 27

Instructions for Service Kit 44756 - Conveyor Speed

Controller Kit for PS200R68-series Ovens, 2/02 ...28

Service Bulletin MM-189 - New Conveyor Gear

Motors, Brushes, and Pickup Clamps, 8/01............29

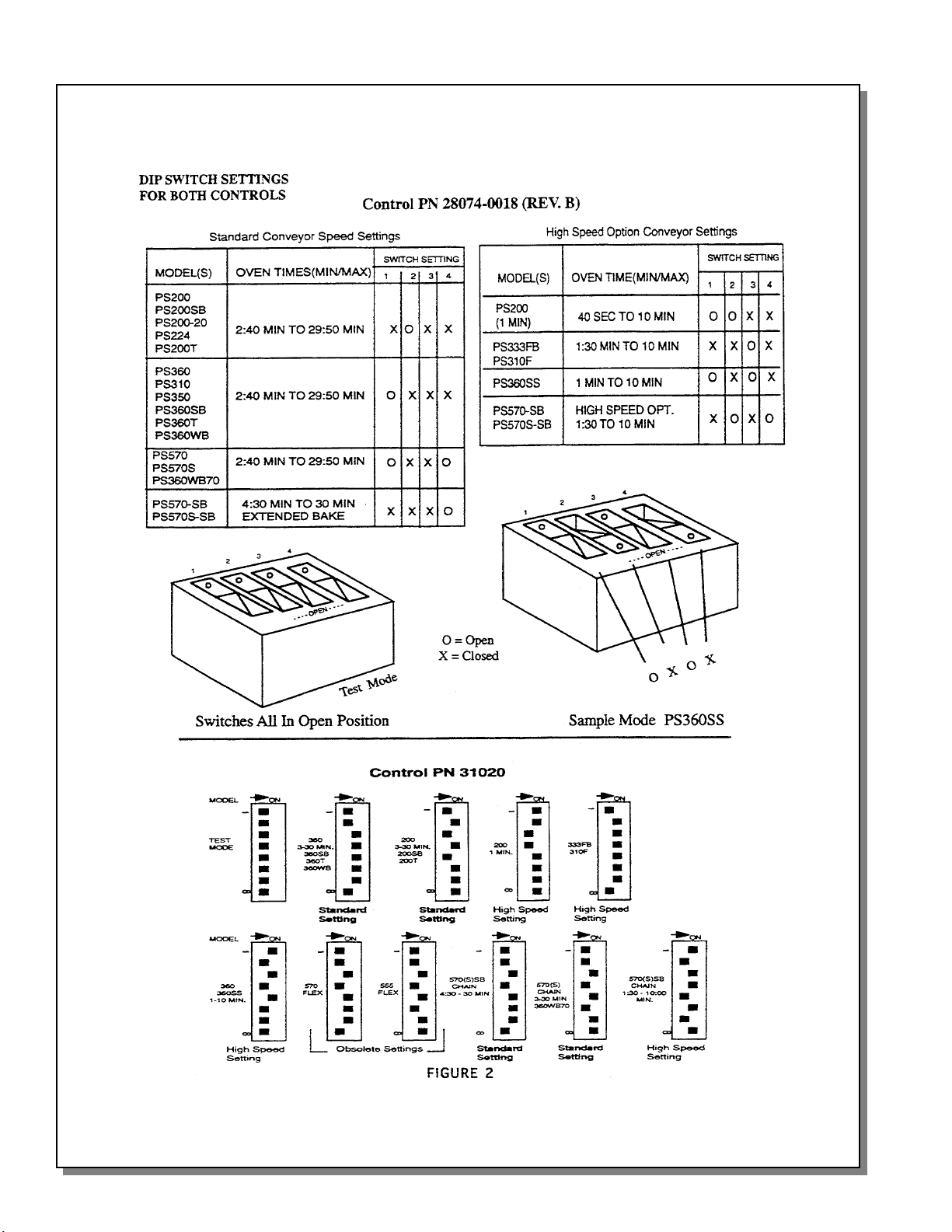

DIP switch settings for Conveyor Speed Controller

with Digital Display (P/N 37337), 4/02 .....................30

II. Temperature Controller ............................................................... 30

A. Part Number Reference - Temperature Controllers ..........31

B. Description ..........................................................................32

C. High Limit/Cooldown Functions..........................................32

D. Troubleshooting .................................................................. 32

E. Appendices.........................................................................32

Temperature Controller Terminal

Cross-Reference, 4/02 .............................................. 32

Instructions for Service Kit 47321 - Digital

Temperature Controller Kit, 2/02 .............................. 33

Service Bulletin MM-136 - Electrical Noise Filter

Capacitor Assembly on Temperature Controllers,

2

9/93 ............................................................................. 43

Page 4

TABLE OF CONTENTS (continued)

III. Hig h L i mit Control Module ...........................................................45

A. Part Number Reference - High Limit Control Modules ...... 45

B. Location ..............................................................................45

C. Troubleshooting ..................................................................45

D. Appendices ......................................................................... 46

Instructions for Service Kit 39733 -

High Limit Conversion Kit for PS300, 310,

350 & 360 Ovens, 5/99 ..............................................46

IV. Thermocouples ........................................................................... 54

A. Part Number Reference - Thermocouples ........................ 54

B. Thermocouple Functions ....................................................54

C. Troubleshooting ..................................................................54

D. Appendices ......................................................................... 56

Instructions for Service Kits 33984 and 33985 -

Oven Thermocouple Kit, 11/01 ................................. 56

V. B lo wer s ....................................................................................68

A. PS200-series ovens...........................................................68

B. PS360-series ovens...........................................................74

C. PS555/570-series ovens ................................................... 76

VI. Blower Motor Centrifugal Safety Switch (PS360-series) .......80

A. Part Number Reference - Blower Centrifugal Switch ......80

B. Troubleshooting .................................................................. 80

VII. Burner Blower Motor Centrifugal Safety Switch (PS200-

series gas, PS310, PS314, PS360, PS360WB, PS570S) .........80

VIII. Ai r Pr essure Safety Switch (PS200-series, PS555/570-

series, PS360EWB, PS360WB70) .............................................81

A. Part Number Reference - Air Switches ............................81

B. Troubleshooting .................................................................. 82

C. Appendices ......................................................................... 83

Instructions for Service Kits 35624 and 35625 -

Air Pressure Switch Replacement Kits, 1/97 ..........83

Instructions to Replace an Alternate Air Switch

P/N 36194 with Service Kit P/N 35624, 3/97 ...........85

IX. PS570/570S Flame Gate............................................................. 87

A. Part Number Reference - Flame Gate ...............................87

B. Flame Gate Orientation .......................................................87

X. Gas Train and Burner System ...................................................88

A. Part Number Reference - Gas Train Components............88

B. Part Number Reference - Gas Orifices and Gas

Conversion Kits ..................................................................91

C. Component Identification ....................................................92

D. Pilot/Ignitor Assembly .......................................................... 93

E. Burner Blower Motor .......................................................... 95

F. Air Shutter...........................................................................95

G. Burner Transformer ...........................................................96

H. Burner Motor Relay ............................................................ 96

I. High Flame Solenoid Valve ................................................. 96

J. Bypass (Low Flame) Orifice .............................................96

K. Modulating Gas Valve ......................................................... 97

L. Amplifier Board ................................................................... 97

M. Combination Gas Control Valve .........................................98

N. Ignition Module .................................................................... 99

O. Gas Conversion Kits ....................................................... 100

P. Burner and Gas Train Troubleshooting .......................... 100

Q. Checking the Gas Pressures .......................................... 102

R. Troubleshooting Flowcharts ........................................... 103

Intermittent Pilot System Troubleshooting Table 103

No Spark, System Does Not Work........................ 104

Spark is Present, Pilot Will Not Light ................... 105

Pilot Lights, Main Valve Will Not Come On ......... 106

S. Appendices ...................................................................... 107

Instructions for Service Kit 42810-0117 -

Pilot/Ignitor Kit, 7/91 ............................................... 107

Instructions for Service Kit 30185 - Pilot Tee, 3/94 . 108

Instructions for Service Kit 42810-0121 -

Combination Gas Valve, 1/92 ................................ 112

Instructions for Service Kit 42810-0114 -

Ignition Module, 11/90 ............................................. 116

Position of Combination Gas Valve Components

during Burner Operation, 4/02 ................................ 118

Instructions for All Gas Conversion Kits

for Ovens with Wayne Burner, Natural Gas to

Propane, 8/00 ........................................................... 119

Instructions for All Gas Conversion Kits

for Ovens with Wayne Burner, Propane to

Natural Gas, 8/00 ................................................... 125

Instructions for Service Kit 36856 - Gas

Conversion Kit for PS360EWB/WB70 with

Midco Burner, Natural Gas to Propane, 1/98 ....... 131

Instructions for Service Kit 36863 - Gas

Conversion Kit for PS360EWB/WB70 with

Midco Burner, Propane to Natural Gas, 1/98 ....... 135

Equivalent Orifice Sizes at High Altitudes, 4/02 . 139

XI. Electric Oven Heating System ................................................ 140

A. PS200-series ovens ........................................................ 140

B. PS310/360-series ovens ................................................ 142

C. PS555 ovens .................................................................... 144

D. Electric Oven Mercury Contactor Replacement ............ 146

Section 4 - Electrical Wiring Diagrams ............................................ 149

I. Component Wiring.................................................................... 149

A. Temperature Controllers .................................................. 149

B. Ignition Modules ............................................................... 150

II. PS200-series Ovens ............................................................... 151

III. PS310/360-series Ovens ........................................................ 160

IV. PS555/570-series Ovens ........................................................ 166

Section 5 - Reference ..................................................................... 172

25-point preventative maintenance checklist ....................... 172

Fractional inches to decimal and millimeter equivalents ... 173

Decimal equivalents of drill sizes ......................................... 173

General conversion factors ................................................... 174

Pressure conversions ............................................................ 174

Pressure conversion chart ..................................................... 175

Ohms Law equation wheel .................................................... 175

Common electrical wiring diagram symbols ........................ 176

3

Page 5

SECTION 1 - SEQUENCE OF OPERATION

SEQUENCE OF OPERATION

SECTION 1

I. GAS OVEN SEQUENCE OF OPERATION

A. Electrical Supply

Gas heated ovens operate on 208/240V, single phase.

Standard incoming power configurations are:

1. 4-wire system (PS200 series, PS310/360 series,

PS570, PS570S) - 2 single phase 208/240V supply (hot) lines, 1 neutral and 1 ground.

2. 3-wire system (PS360WB70, PS360EWB, PS555,

PS570G, PS536) - 2 single phase 208/240V supply (hot) lines and 1 ground.

For all wiring configurations, the voltage when measured

from either hot line to neutral should never exceed 130V.

B. Door Switch

Closing the control cabinet door (or machinery compartment door, as appropriate for the oven model) will

close the door switch and allow the oven to operate.

Note that the electrical systems will still be live

if the switch is open, although the oven cannot

operate.

The door switch has a bypass position to enable service operation with the door opened. When the door is

open, grasp the switch actuator and pull it out as far as

possible. This will close the door switch and permit

troubleshooting. Closing the control cabinet door will

reset the switch.

1. Closing the door switch permits a circuit to go

through a fuse (or circuit breaker, as appropriate

for the oven model) to one side of the conveyor

switch, blower motor switch, cooldown relay and

heat switch.

2. Closing the door switch permits a circuit to go

through the motor fuse (two 9A or 15A fuses per

motor).

C. Conveyor Switch

Closing the conveyor switch permits a circuit to go to

the Conveyor Speed Control Module, which:

1. Sends power to the gear motor (conveyor drive motor). The 120VAC signal to the Conveyor Speed

Control Module is rectified to a 90VDC signal which

is then sent to the gear motor.

2. Allows regulation of conveyor speed. Adjusting the

thumbwheel (or digital pushbutton display unit, as

appropriate) to the desired conveyor belt speed instructs the Conveyor Speed Control Module to regulate the output to the gear motor. This increases

or decreases the conveyor speed as necessary to

match the speed setting shown on the thumbwheel

or display unit.

D. Blower Switch

Closing the blower switch energizes:

1. The cooling (axial) fan(s).

2. The blower motor contactor (s).

Closing this contactor starts the blower motor(s). When

both blower motors are up to speed, centrifugal switches

located inside the blower motors (or air switches detecting blower operation, as appropriate for the oven

model) will close, setting up the heat circuit.

3. The Temperature Controller.

E. Heat Switch

Closing the heat switch completes a circuit:

1. Through the heat switch.

2. Through the blower motor centrifugal switches (or

air switches, as appropriate for the oven model).

3. Through the high limit switch.

4. One circuit then goes to the:

a. Burner (L1).

b. Transformer (110V to 24V).

c. Motor relay coil. On a cold start the heater on

this relay takes about 30 seconds to warm up

before the relay will energize. This gives an

additional prepurge. The relay is not used on

ovens with 208/240V burner blower motors.

d. Burner blower motor. As the motor reaches full

operating speed, the centrifugal switch (or air

flow switch, as appropriate for the oven model)

closes and applies voltage to the burner control. This energizes the ignitor control spark

transformer and the pilot valve. The spark then

lights the pilot. The flame sensor proves the

presence of the pilot flame, and the ignitor control then shuts off the spark. At the same time,

the main burner valve is opened. The main

burner is then ignited.

If the pilot does not light within approximately

90 seconds, the oven will shut down.

The pilot and main gas valve will stay on (open)

as long as the heat switch is ON and the flame

is proven. If the flame goes out for any reason,

the pilot will try to light for 90 seconds, and

then go into automatic lockout. To relight the

pilot after it has gone into automatic lockout,

the burner

and then turned ON again.

must be turned OFF for 5 minutes

4

Page 6

SECTION 1 - SEQUENCE OF OPERATION

e. For ovens with an On-Off gas regulation sys-

tem (with solenoid valve): Temperature Controller

terminals 4 & 5 (power for the primary relay

contacts for the high flame solenoid valve).

For PS360EWB ovens with a modulating gas

system and Temperature Controller P/N 32571:

Temperature Controller terminals 4 & 5 (input

signal to amplifier board).

For all other ovens with a modulating gas system: Temperature Controller terminals 15 & 16

(input signal to amplifier board).

In all ovens, the temperature-sensing thermocouple(s)

send a millivolt signal to the temperature controller. As

long as the temperature inside the oven is below the

set point of the Temperature Controller, the Controller

will do the following:

1. For ovens with an On-Off gas regulation system: If

the temperature sensed by the thermocouple(s) is

below the set point on the Temperature Controller,

the Controller energizes the high flame solenoid.

When the solenoid is energized, the solenoid valve

permits 100% gas flow. Power to the solenoid is

cut when the temperature reaches the set point,

which closes the valve. This permits on-off gas

flow to the burner.

When power is cut to the high flame solenoid, the

burner will remain ON in the low flame mode. When

the temperature drops a few degrees, the Temperature Controller will again energize the high flame

solenoid, which opens the valve and restores gas

flow to 100%.

An indicator on the Temperature Controller will

show whether the high flame solenoid is energized

(or whether the burner is activated, which is effectively the same). This indicator varies by Temperature Controller model. Refer to the instructions for

the appropriate Temperature Controller for an illustration and description of this indicator.

2. For ovens with a modulating gas system: In response to the signal from the thermocouple(s), the

Temperature Controller sends a 4-20mA signal to

the amplifier board. The amplifier board converts

this to a 0-20VDC signal which is sent to the modulating gas valve. The valve opens or closes in proportion to the signal from the amplifier board, allowing the gas flow to be regulated as required from

0-100%.

An indicator on the Temperature Controller will

show whether the burner is activated. This indicator varies by Temperature Controller model. Refer

to the instructions for the appropriate Temperature

Controller for an illustration and description of this

indicator.

F. High Limit

NOTE: Most PS200-Series and PS360-series gas ovens use the high limit feature of the Temperature Controller. All other oven models use a separate High Limit

Control Module. Refer to the wiring diagram for the

appropriate oven model to check whether a separate

High Limit Control Module is used.

The high limit relay will shut the oven burner OFF:

1. If the high limit thermocouple senses an oven temperature above 650°F.

2. If the signal from the high limit thermocouple is

lost.

An indicator on the Temperature Controller will show a

high limit condition. This indicator varies by Temperature Controller model. Refer to the instructions for the

appropriate Temperature Controller for an illustration and

description of this indicator.

G. Cooldown

NOTE: PS200VL-series ovens do not include a

cooldown feature.

When the heat and blower Switches are turned OFF

the cooldown relay will allow the blowers to remain ON

until the oven temperature falls to 200°F (93°C).

During cooldown, the Temperature Controller will continue to show the oven temperature.

5

Page 7

SECTION 1 - SEQUENCE OF OPERATION

ll. ELECTRIC OVEN SEQUENCE OF OPERATION

A. Electrical Supply

Most electrically heated ovens operate on a 208/230/

380/440V, 3 phase, 4 wire system. The fourth wire is

for a 120 V neutral ground. This 120 V neutral ground

eliminates the need for a control transformer. Where a

neutral is not available, a 240/110V transformer is supplied.

B. Door Switch

Closing the control cabinet door (or machinery compartment door, as appropriate for the oven model) will

close the door switch and allow the oven to operate.

Note that the electrical systems will still be live

if the switch is open, although the oven cannot

operate.

The door switch has a bypass position to enable service operation with the door opened. When the door is

open, grasp the switch actuator and pull it out as far as

possible. This will close the door switch and permit

troubleshooting. Closing the control cabinet door will

reset the switch.

Closing the door switch permits a circuit to go through

a fuse (or circuit breaker, as appropriate for the oven

model) to one side of the conveyor switch, blower motor switch and to the heat switch.

C. Conveyor Switch

Closing the conveyor switch permits a circuit to go to

the Conveyor Speed Control Module, which:

1. Sends power to the gear motor (conveyor drive motor). The 120VAC signal to the Conveyor Speed

Control Module is rectified to a 90VDC signal which

is then sent to the gear motor.

2. Allows regulation of conveyor speed. Adjusting the

thumbwheel (or digital pushbutton display unit, as

appropriate) to the desired conveyor belt speed instructs the Conveyor Speed Control Module to regulate the output to the gear motor. This increases

or decreases the conveyor speed as necessary to

match the speed setting shown on the thumbwheel

or display unit.

D. Blower Switch

Closing the blower switch energizes:

1. The cooling (axial) fan(s).

2. The blower motor contactor (s).

Closing this contactor starts the blower motor(s). When

both blower motors are up to speed, centrifugal

switch(es) located inside the rear end of the motor(s)

(or air flow switch[es], as appropriate for the oven model)

will close, setting up the heat circuit.

3. The Temperature Controller.

E. Heat Switch

Closing the heat switch completes a circuit:

1. Through the heat switch.

2. Through the blower motor centrifugal switch.

3. Through the high limit switch.

4. For ovens with on On-Off heater activation mode:

To the primary relay contacts of the Temperature

Controller (terminals 4 and 5 for digital controllers,

terminals 5 and 6 for analog controllers).

When the temperature-sensing thermocouple(s)

indicate that the oven temperature is below the set

point on the Temperature Controller, the Temperature Controller will energize the contactor(s) which

in turn energize the heaters.

When the oven temperature reaches the set point

of the Temperature Controller, the Temperature Controller will cut power to the heaters. When the temperature drops a few degrees, the Temperature Controller will again energize the heaters.

An indicator on the Temperature Controller will

show whether the Controller is calling for heat. This

indicator varies by Temperature Controller model.

Refer to the instructions for the appropriate Temperature Controller for an illustration and description of this indicator.

5. For ovens with a Variable Pulse heater activation

system: To terminals 15 and 16 on the temperature controller. In response to the signal from the

thermocouple(s), Terminals 15 and 16 send a 420mA signal to a controller module that contains

an amplifier board and two solid state relays. The

relays activate the heating elements at 100% power

on a fixed cycle time, for a length of time proportional to the signal from the temperature controller.

A HEAT ON indicator on the Temperature Controller will light to show whether the Controller is

calling for heat.

F. High Limit

NOTE: Electric oven models use a separate High Limit

Control Module.

The High Limit relay will shut the oven burner OFF:

1. If the high limit thermocouple senses an oven temperature above 650°F.

2. If the signal from the high limit thermocouple is

lost.

An indicator on the Temperature Controller will show a

high limit condition. This indicator varies by Temperature Controller model. Refer to the instructions for the

appropriate Temperature Controller for an illustration and

description of this indicator.

G. Cooldown

When the heat and blower switches are turned OFF

the cooldown relay will allow the blowers to remain ON

until the oven temperature falls to 200°F (93°C).

During cooldown, the Temperature Controller will continue to show the oven temperature.

6

Page 8

SECTION 2 - AIR FLOW AND HEAT TRANSFER

SECTION 2

AIR FLOW AND HEAT TRANSFER

I. TYPES OF HEAT TRANSFER

Heat constantly moves from a warm object to a cold object. Heat moves in three different ways: thorough conduction, through radiation, and through convection.

Middleby Marshall conveyor ovens use all three of these

paths to cook the product.

Conduction - Heat is transferred through surface con-

tact (such as pizza dough in contact with a pan).

Radiation - Heat is transferred from light-colored ob-

jects to dark-colored objects. The darker the color of

an object, the greater the amount of heat that it absorbs. The lighter the color of an object, the greater

the amount of heat that it reflects. Middleby ovens use

light-colored interiors (aluminized or stainless steel,

depending on the oven model) to reflect as much heat

as possible to the product.

Convection - Heated air will transfer heat to objects

with which it comes into contact. Unless the air flow is

controlled, hot air will rise and be replaced by cooler

air. Middleby Marshall ovens use blowers (one or two

large fans, depending on the oven model) to force air

through adjustable air fingers onto the product.

The intensity of the heat at the point at which it is sensed is

called temperature. The difference in temperature between

the food product and the heat source - that is, the pan,

oven interior, or heated air, as described above - determines

the speed at which the heat flows. The greater the difference in temperature, the faster the heat flows to the product.

In Middleby Marshall conveyor ovens, the heat transfer from

conduction is greatly dependent on the customers product

and cooking surface (pans, etc.). Likewise, the heat transfer from radiation is effectively constant, because the color

of the oven interior cannot be changed. For these reasons,

the best way to optimize heat transfer is by regulating the

convection air. This can be done in two ways:

Adjusting the

quantity and velocity of air delivered onto the product.

Adjusting the air finger configuration to change the pat-

tern in which the vertical columns of air are delivered to

the product.

II. BLOWERS AND BLOWER SPEED

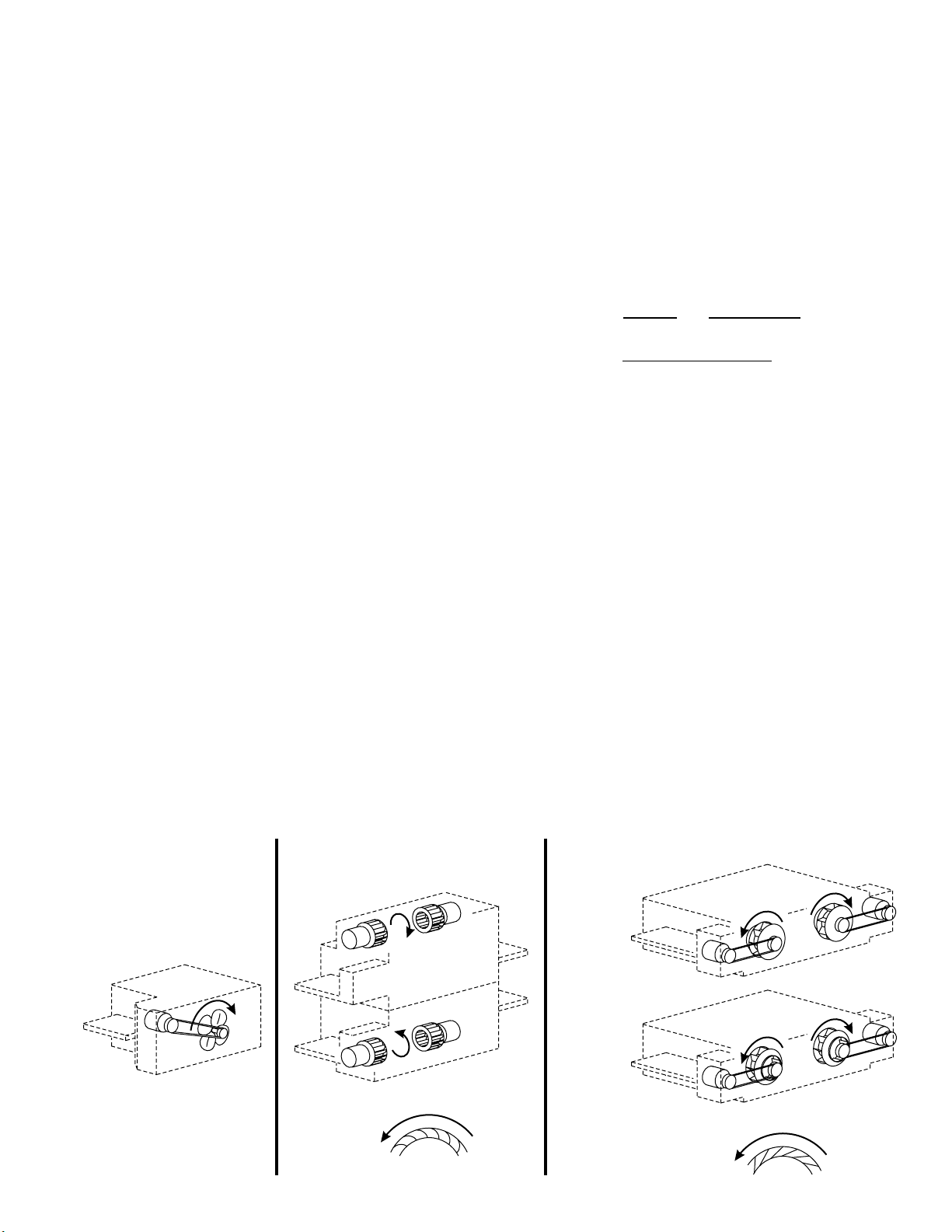

A. PS200-series ovens

PS200-series ovens have a single blower motor mounted

inside the machinery compartment, with a pulley on

the end of the motor shaft. A belt connects this pulley

to another on the shaft of the blower fan. The air velocity can be changed by using a larger or smaller pulley

on the motor shaft, and changing the length of the belt

to match the new pulley. See Figure 1.

However, note that there are only two approved belt/

pulley combinations for PS200-series ovens; one for

60Hz ovens, and one for 50Hz ovens. Field modifications to these approved combinations are not permitted unless under the specific directions of the Middleby

Technical Service Department. Any changes to convection air delivery MUST be made using the air fingers.

blowers and blower speed to change the

PS200-series

PS360-series PS555/570-series

Blower

Wheel

Orientation

Figure 1

Blowers, belts and pulleys

Early

(PS570)

Current

(PS570S,

PS570G, all

PS555)

Blower Wheel

Orientation

7

Page 9

SECTION 2 - AIR FLOW AND HEAT TRANSFER

B. PS360-series ovens

PS360-series ovens feature two blower motors. A blower

wheel is fastened onto the end of the motor shaft. In

order to adjust the amount and speed of heated air that

is directed by the blower wheels, it is necessary to

change the size of the wheels and/or change the speed

of the motor. See Figure 1.

Each PS360-series oven model has a specific combination of blower motor and blower wheel. Field modifications to these approved combinations are not permitted unless under the specific directions of the

Middleby Technical Service Department. Any changes

to convection air delivery MUST be made using the air

fingers.

C. PS555/570-series ovens

PS555/570-series ovens have one blower motor

mounted inside each of the end compartments of the

oven, with a pulley on the end of the motor shaft. The

oven has two blower wheels; a belt connects each motor

pulley to a pulley on the end of one of the blower wheel

shafts. The air velocity can be changed by using a

larger or smaller pulley on the motor shaft, and changing the length of the belt to match the new pulley. See

Figure 1.

Some customers have a specific belt/pulley combination approved by Middleby Marshall, while others use a

standard configuration. Field modifications to these

approved combinations are not permitted unless under

the specific directions of the Middleby Technical Service Department.

III. AIR FINGERS

A. Description and Function

Air fingers direct the heated air from the blowers into

vertical jets that are directed at the top and bottom of

the conveyor belt. Each air finger configuration has

been tested to optimally cook a specific customers

product. As a rule, air finger configurations should NOT

be changed from customer specifications without direct instructions from the Middleby Technical Services

Department.

Middleby uses two main types of air fingers:

PS300/350 and early PS310/360 ovens used a shut-

ter-type air finger assembly. The finger is assembled from a manifold, inner plate and outer

plate. The inner plate is assembled from two separate plates, each with a series of holes, that are

riveted together. The plates can be repositioned

relative to each other to restrict the air flow through

the holes as necessary. These fingers are no longer

in general use, but may still be found in older ovens in the field. See Figure 3.

All current ovens use an air finger which is com-

posed of a manifold, inner plate, and outer plate.

No adjustments are necessary or possible to these

fingers, but a wide variety of styles is available to

meet different customers baking needs. See Figure 4.

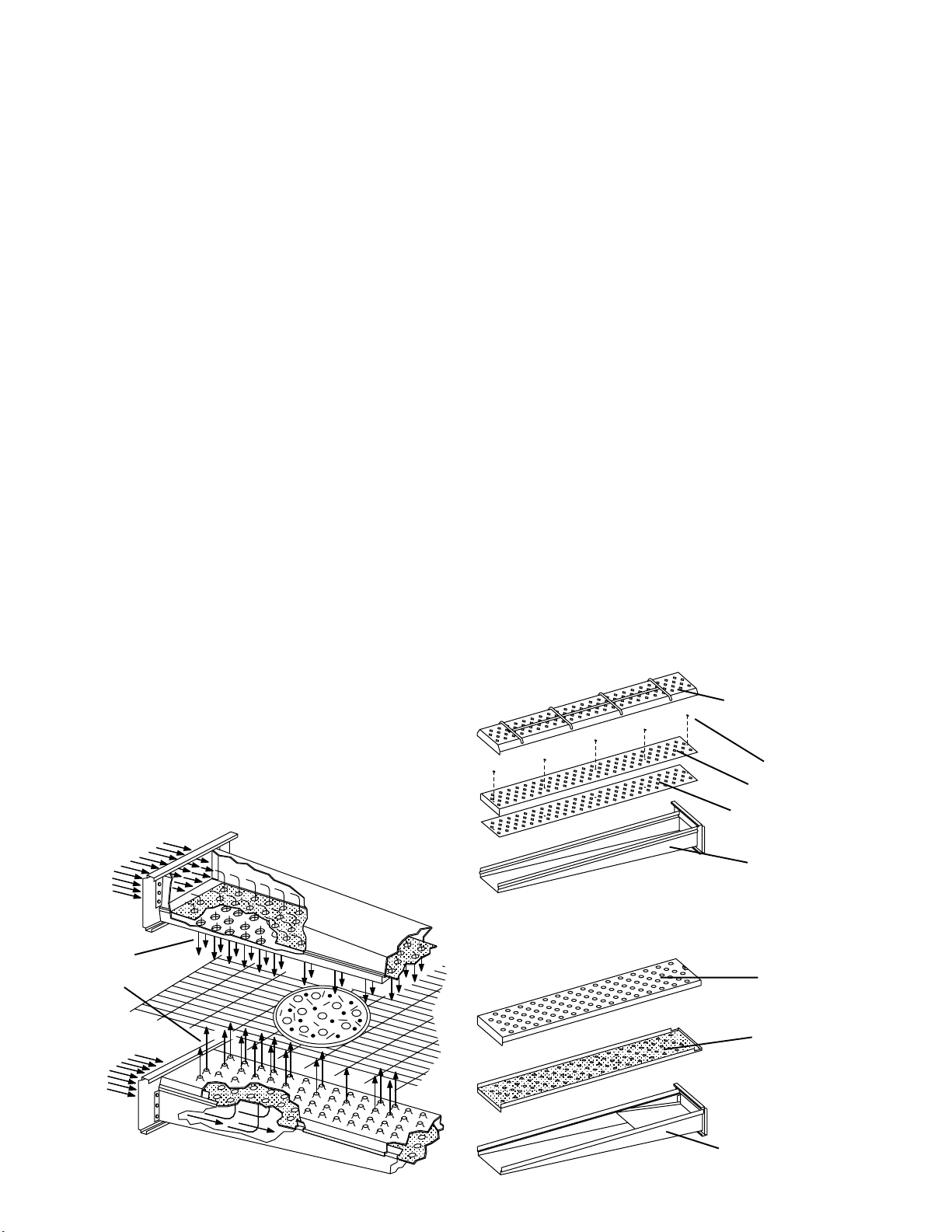

Figure 3

PS300/350 air finger with shutter plate

Outer plate

Lower air fingers have wire

rack as shown to prevent

conveyor belt from rubbing

on outer plate.

Hot air flow

from blower

wheel(s)

Vertical

columns of

high-velocity

hot air

Figure 2

Air finger operation

Rivets

Inner plate

Shutter

Manifold

Figure 4

Current standard air finger (all oven models)

Outer plate

Width and hole

configuration varies.

Inner plate

Width and hole

configuration varies.

May have inner dam.

Manifold

Width varies to match inner

and outer plates. Baffle may

be solid, perforated, partially

perforated, or absent.

Several special shapes are

available to meet specific

8

customer needs.

Page 10

SECTION 2 - AIR FLOW AND HEAT TRANSFER

B. Configuration and Alignment

To ensure proper baking of the product, the air flow

MUST be properly aligned as it exits the air fingers.

Because air finger configurations are tested at the factory for a specific customers product, severe bake problems related to the air fingers are rare. If you encounter a problem, check the following:

1. Check that the air fingers are properly assembled,

cleaned and free of obstructions. For the standard

air fingers shown in Figure 4, a variety of styles are

available for each of the three components. It is

often possible to assemble these components incorrectly, as they are designed to be modular. This

will affect the quality of the bake.

If you need information on the correct air finger configuration of the oven, check the following:

3D air finger label or card. Many current ov-

ens will have a three-dimensional drawing on

the front panel of the oven that shows the correct air finger configuration, as shown in Figure 5. Other ovens may have this information

on a laminated card attached to the oven.

Internal air finger chart. All Middleby ovens

have a chart similar to the one shown in Figure

6 attached inside the machinery compartment

door. Note that if the air finger configuration

has been updated since the oven was installed,

this chart may no longer be correct.

If there is no label present on the oven, and the

chart inside the machinery compartment is incorrect, contact Middleby Technical Service for

assistance.

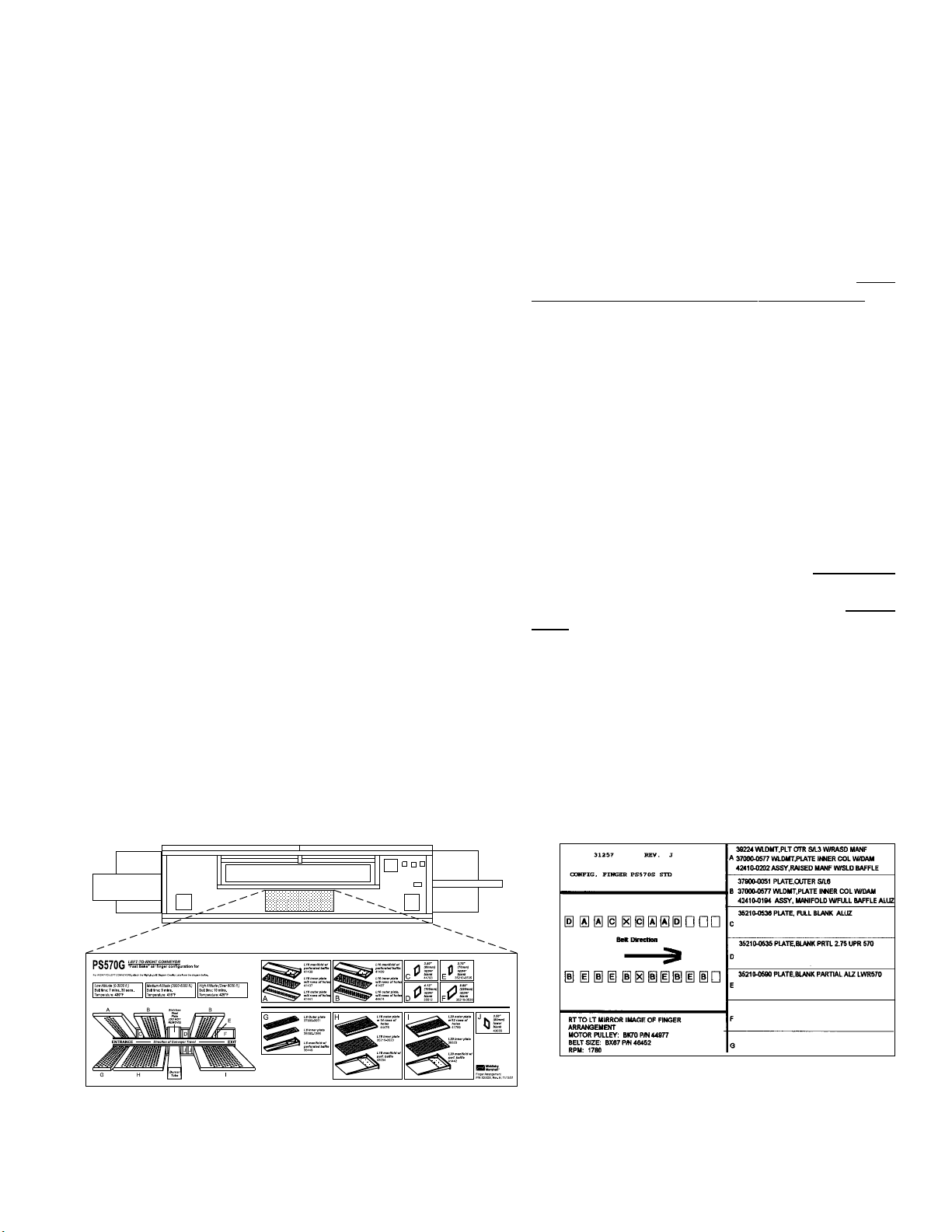

Figure 5

3D air finger label (if present)

2. Check that the bake time and temperature settings

of the oven match the customers specifications.

Most customers have an acceptable range for bake

time and temperature to allow for local variations in

altitude, humidity, etc.

3. If these checks fail to correct the problem, you

should perform a test bake to pinpoint the type of

baking problem that is present.

C. Performing a Test Bake

Before you attempt to correct any problem, please CONFIRM THAT THERE IS ACTUALLY A PROBLEM. It is

extremely difficult to tell if an oven is baking unevenly

by simply looking at a pizza with ingredients, especially if the pizza is a large combination-type. Often,

the ingredients and toppings themselves can cause an

uneven bake.

The best way to check for an uneven bake is to make a

test bake with a consistent, predictable product and

then read it. We recommend using the customers

dough (for a pizza product) OR a commercially-available pancake mix (for customers with a variety of products). The pancake mix is generally more sensitive to

variations in temperature and thus provides more accurate results than the dough test.

When interpreting the results of the test, consistently

uneven baking on the top of the product may indicate a

problem with the upper air fingers. Likewise, consistently uneven baking on the bottom of the product may

indicate a problem with the lower air fingers.

The most common bake problem is a front-to-back

bake issue. This problem occurs when the front of the

conveyor belt (towards the window) receives more heat

than the rear, or vice-versa. This results in uneven baking for the product based on where it is placed on the

conveyor.

Figure 6

Internal air finger chart

NOTE: Labels of this type are not

used on all ovens. Label placement

and design will vary based on

customer preference.

NOTE: All ovens use a chart of this

type inside the machinery compartment.

Changes to the air finger configuration

after oven installation MAY NOT BE

INDICATED.

9

Page 11

SECTION 2 - AIR FLOW AND HEAT TRANSFER

To perform the test bake:

1. Select identical pans for the test. Choose the pans

based on the width of the conveyor; you should space

the pans in line completely across the conveyor without having them touch each other. For instance, for a

32 /813mm-wide conveyor, you could use three 10/

254mm pans or two 15/381mm pans.

You will need enough pans to have three complete rows.

This eliminates the possibility of a single row distorting

the results. If necessary, the test can be run with only

1 row of pans, but the results are not as reliable.

2. For a pancake batter test, mix the pancake batter as

instructed by the manufacturer. Pour the batter

EVENLY into the test pans to a depth of 1/4 (6mm).

You may use any type of pancake mix that is available,

AS LONG AS YOU USE THE SAME TYPE THROUGHOUT THE TEST.

For a dough test, have the customer make up a thin

crust dough in each pan. The dough should be of a

consistent thickness in each pan and should be no

thicker than 1/4 (6mm). Thicker doughs will provide

too great a cushion and will distort the test results.

3. Place the pans side-by-side on the conveyor. The front

and rear edges of the pans should be aligned so that it

is easier to see if there is a front-to-back bake problem. DO NOT stagger the rows of pans diagonally.

Also, check that the pans do not touch each other;

this can transfer heat to the test product and distort

the results.

4. Run the products through the conveyor at the

customers normal bake time and temperature settings.

5. Read the results of the test. Each pan of product

should have the same coloration.

If you used pancake batter, the sugar in the mix will

brown very rapidly if over-baked. This highlights an outof-balance oven.

If the product lightens or darkens slightly from front-toback in only one row, there is probably not a significant

front-to-back bake problem. If the product is noticeably lighter or darker at the front or back in ALL of the

rows of pans, there is a front-to-back bake problem.

See Figure 7.

Also, remember that

consistently uneven baking on

the top of the product may indicate a problem with the

upper air fingers. Likewise, consistently uneven baking on the bottom of the product may indicate a problem with the lower air fingers.

If the oven has the current standard air finger type,

you should contact Middleby Technical Services

for assistance.

If the oven has the PS300/350-style air fingers with

a shutter plate, it is possible to adjust the positions of the air shutters to correct a front-to-back

bake problem. Proceed to Step D, PS300/350 Air

Figure 7

Front-to-back uneven bake

NOTE: In this example,

the front of the product

is darker than the rear.

The opposite condition

is also possible.

Finger Shutter Adjustment.

D. PS300/350 Air Finger Shutter Adjustment

Before attempting to properly balance a Middleby

Marshall oven equipped with shutter fingers, you should

understand the principles of operation of this type of

finger.

The oven moves approximately 2000 ft.³ of air per minute.

When this large amount of air is moved through the

plenum and fingers it rushes through the plenum and to

the end of the air finger. This creates a back pressure

of air inside the finger and tends to deliver more air onto

the product at the front of the air finger.

The inner plate has a separate shutter plate riveted to it

at a slight angle. Since there is more pressure at the

end of the fingers (front of the oven) than at the plenum

(rear of the oven), the shutter plate is angled to restrict

the air flow near the front of the oven. This creates a

proper balance permitting an even amount of air to exit

out of the holes across the width of the conveyor. See

Figure 8.

Before adjusting the shutters, it is necessary to determine if the finger is providing a balanced air delivery

across the width of the conveyor. This is the purpose

10

Page 12

SECTION 2 - AIR FLOW AND HEAT TRANSFER

of making a test to read the bake.

1. Remove all upper air fingers from the oven.

NOTE: As the air fingers are removed, use a felt pen to

mark all parts of the fingers. This includes the manifold, inner plate and outer plate. If a blank or choke

plate is used, mark that plate also. Fingers are marked

in the order shown below, as viewed from the front of

the oven. If there are upper and lower oven cavities,

you should mark the fingers for the upper oven with a

U and those for the lower oven with a L.

VERY IMPORTANT: When the ovens were shipped

from the factory, all of the shutters were pre-adjusted for their location within the oven. AII parts

of the fingers must be marked as explained above

and reassembled into their original position.

2. Check the size of the openings at the front of the shut-

ter plates by inserting a drill into the opening. The

factory setting is a #46 drill (0.081/2.06mm).

3. Drill out the four 1/8 pop rivets that are located toward

the front of the fingers. See Figure 8.

NOTE: DO NOT drill out the rivet at the back of the air

finger. This is the pivot for the shutter.

4. If the product is lighter at the front of the oven, increase

the opening by 1/16/1.59mm. If the product is darker

at the front of the oven, decrease the opening by 1/16/

1.59mm.

The best way to check the size of the openings is to

use numbered drills as a gauge. An orifice drill set is

ideal for making this adjustment. For example, to increase the opening by 1/16, you would use a #30 drill

(0.1285/3.26mm), which is approximately 1/16 larger

than the original setting measured with the #46 drill

(0.081/2.06mm).

Be sure that the measurement is taken at the largest

point of the opening. See Figure 8.

5. While holding the new adjustment, clamp the two shutter plates together (two pairs of vice grip pliers are ideal)

and drill holes for new pop rivets.

NOTE: Most of the old rivet holes can be reused if the

old hole is simply elongated. However, if the hole is not

properly elongated, the new rivets may pull the plates

out of adjustment when they are installed.

IMPORTANT: Aluminum 1/8 pop rivets are ideal

for use here. They are much easier to drill out

than stainless steel rivets.

6. Repeat these steps to adjust all upper air fingers. Then,

reinstall the fingers into the oven.

7. Perform another test bake.

lMPORTANT: This test bake must be an exact duplicate of the first test bake. If you change any of the

conditions you will change the results.

If the test indicates an even bake, your adjustment

is complete.

If the test indicates that the bake is still uneven,

you will need to repeat the adjustment procedure

until an even bake is obtained. By keeping the

tests identical, you should be able to determine

how much more the shutter plates should be opened

or closed to achieve a balanced bake without removing the fingers for a third time.

VERY IMPORTANT: After attaining a proper adjustment of the fingers, each air finger should be marked

with a metal stamp showing its position inside the oven.

This will eliminate future problems of operators mixing

the adjusted fingers when cleaning the oven.

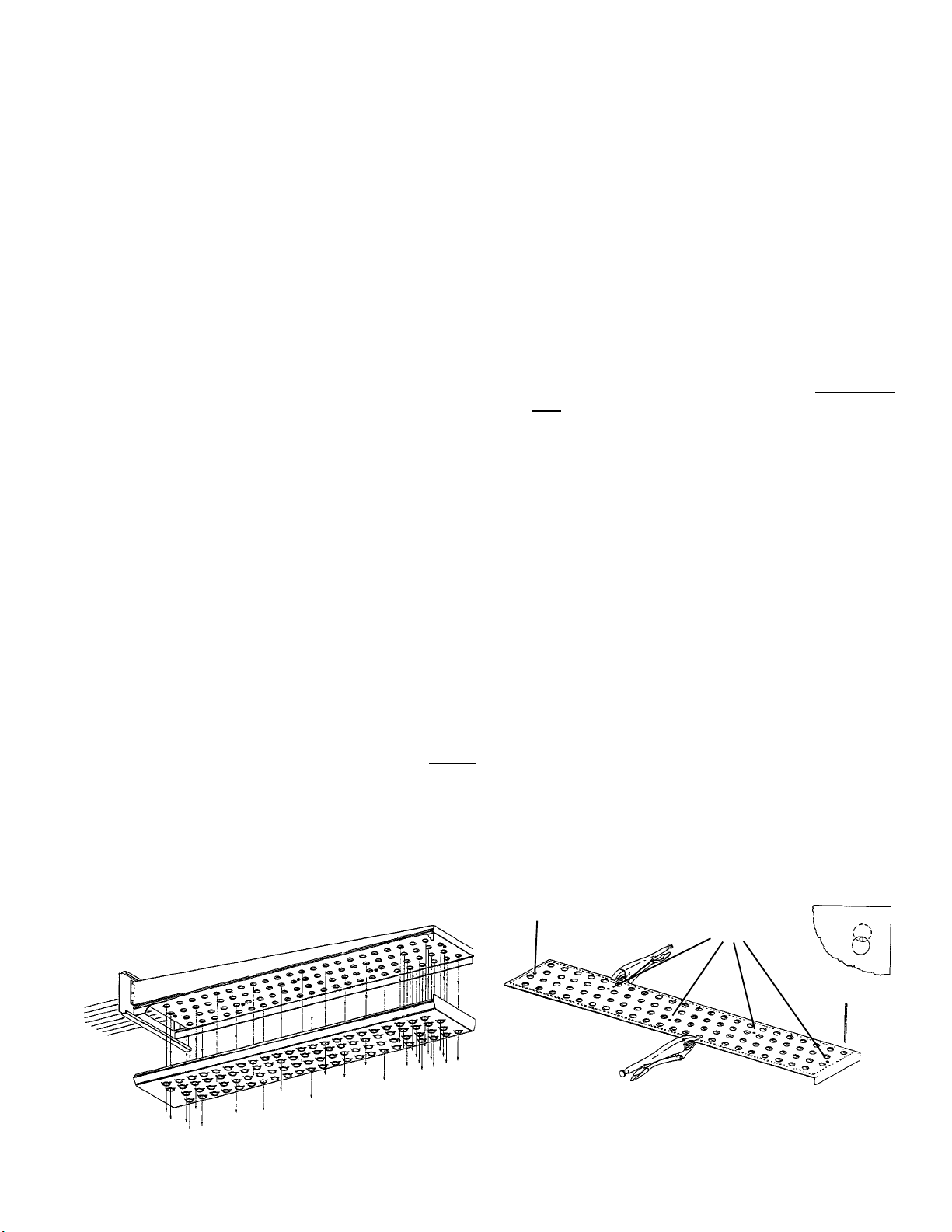

Figure 8

PS300/350-style air finger with adjustable shutter plate

Pivot

DO NOT

drill out

Vise grip

pliers

Higher pressure at the

front of the fingers is

regulated by the

shutter openings

Drill out

rivets

11

Insert drill bit

to check size

of opening

Page 13

SECTION 2 - AIR FLOW AND HEAT TRANSFER

IV. OVEN CAPACITY

Oven capacity is generally not a service issue. However,

when reporting a service problem, customers may use terms

relating to capacity, such as bake time, belt time, time of

delivery, etc. This information is provided as a reference for

understanding these terms.

A. Conveyor Speed and Bake Time

Middleby Marshall conveyor ovens display the Conveyor

Speed on the Thumbwheel (or on the display of the

Digital Speed Controller, as appropriate for the oven

model). Conveyor Speed is also called Bake Time.

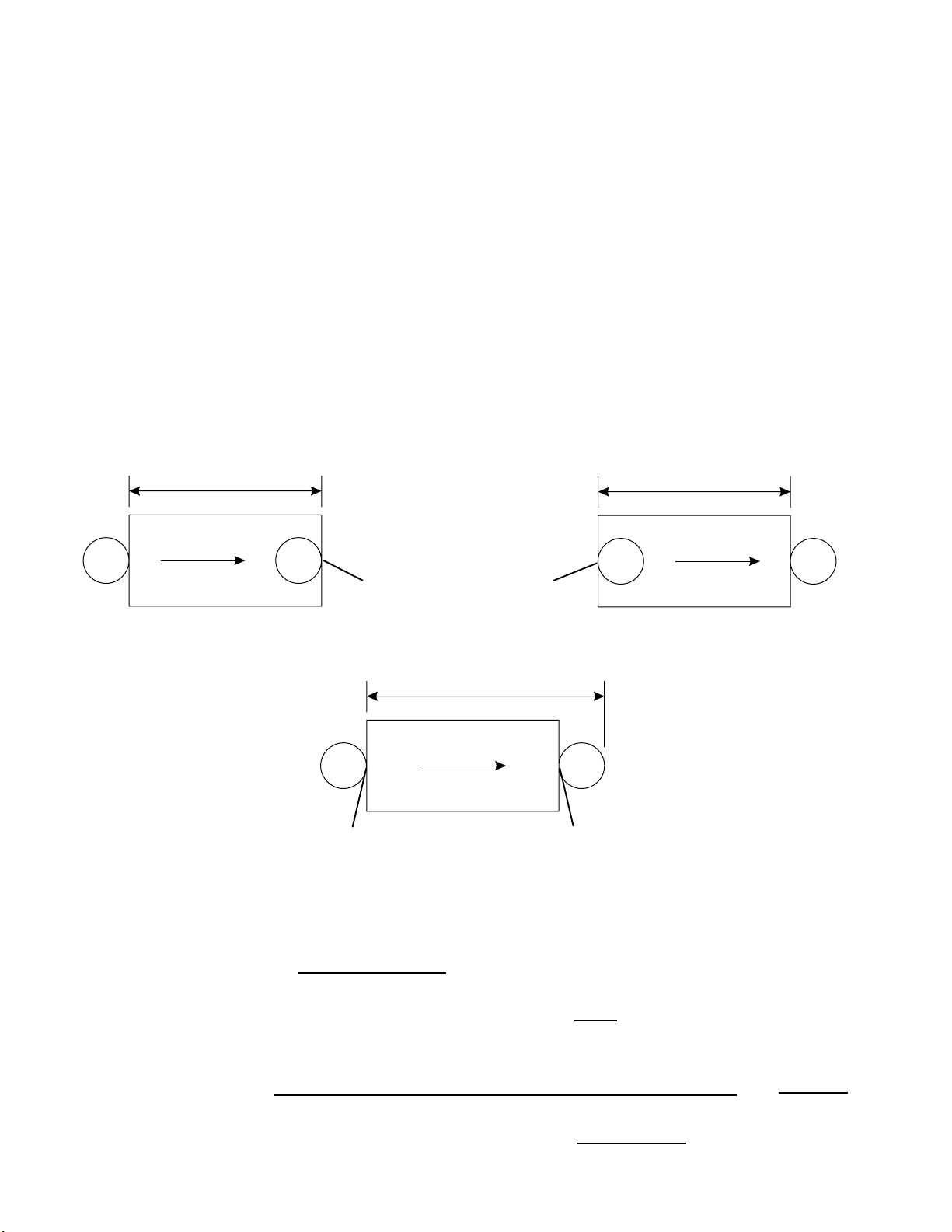

Conveyor Speed (Bake Time) is a leading edge to lead-

ing edge measurement. That is, it is the elapsed time

from the leading edge of the product entering the bake

chamber to the leading edge of the product leaving the

bake chamber. See Figure 9.

Figure 9 - Conveyor Speed (Bake Time)

Conveyor Speed

(Bake TIme)

B. Belt Time

Belt Time is a measurement used by several customers. It is a trailing edge to trailing edge measurement.

That is, it is the elapsed time from the trailing edge of

the product entering the bake chamber to the trailing

edge of the product leaving the bake chamber. See

Figure 10.

Note that belt time is equal in length to conveyor speed

(bake time), although the time is measured during a

different period of the baking process.

C. Time of Delivery (TOD)

Time of delivery (TOD) is a leading edge to trailing edge

measurement. That is, it is the elapsed time from when

the leading edge of the product enters the bake chamber to when the trailing edge of the product leaves the

bake chamber. See Figure 11.

Figure 10 - Belt Time

Belt Time

Direction of

Conveyor Travel

Leading edge

of product

Trailing edge

of product

Figure 11 - Time of Delivery

Time of Delivery

Direction of

Conveyor Travel

Leading edge

of product

D. Formulas for Determining Time of Delivery (TOD) and Oven Capacity per Hour

1. Time of Delivery (TOD)

Time of Delivery (TOD) = x (Bake Chamber Length + Product Diameter)

Conveyor Speed

Bake Chamber Length

Example: PS570S Oven, 7:00 Bake Time, 16 Product Diameter = x (70 + 16) = 8.6 mins. (8:36)

Trailing edge of

product

7 mins.

70

Direction of

Conveyor Travel

2. Oven Capacity/Hour

Oven Capacity/Hour = x

Example: PS570S Oven, 7:00 Bake Time, 16 Product Diameter = x 6.98 = 75 pizzas/hr.

(Bake Chamber Length + Product Diameter) x Bake Chamber Depth

Product Diameter²

(70 + 16) x 32

256 in.²

60 min./hr.

12

TOD

Page 14

SECTION 3 - SERVICING COMPONENTS

SECTION 3

SERVICING COMPONENTS

I. CONVEYOR SPEED CONTROLLER AND DRIVE

MOTOR

The Conveyor Speed Controller is used to set and monitor

the speed of the conveyor. The Controller consists of three

components:

Control Module

Early units used a module which featured a microcomputer that was unique to each oven model. Using this

control module required verifying that the correct microcomputer was installed.

Later units use DIP switches to set up the controller for

a particular oven model. This later model was initially

available with a thumbwheel unit (either 4 or 8 DIP

switches). Current models feature a digital display with

keypad (8 DIP switches).

Thumbwheel Unit (or Digital Display with Keypad)

This module displays the conveyor speed and allows it

to be adjusted by the operator. It is connected to the

control module by a ribbon cable.

Pickup Assembly

The pickup assembly consists of a magnetic wheel on

the end of the gear motor (conveyor drive motor) shaft,

and a Hall Device sensor that provides feedback to the

control module.

As the magnetic wheel turns, the revolutions of the

magnet are monitored by the Hall Device sensor. The

signals are sent to the control module, which compares

the motor speed with the speed shown on the

thumbwheel or digital display. The control module increases or decreases the voltage to the gear motor

(conveyor drive motor) depending on the signal.

A. Part Number Reference - Speed Controllers

1. Original-style speed controller with interchangeable microcomputer and thumbwheel. This unit is no longer

available and part numbers are provided for reference

only. Servicing this unit is beyond the scope of this

manual. If this controller is in need of service, we recommend simply installing a current unit (see below).

P/N Description

28174-0004 PS360 controller, yellow (12A) microcomputer

28074-0006 PS360 microcomputer, yellow (12A)

27170-0232 PS360 microcomputer w/emulator, yellow (12A)

28074-0007 PS314 controller, orange (13A) microcomputer

28074-0008 PS314 microcomputer, orange (13A)

27170-0233 PS314 microcomputer w/emulator, orange (13A)

28074-0013 PS200 microcomputer, pink (15A)

2. Current-style speed controller with either 4 or 8 DIP switch

settings and thumbwheel. This unit is no longer available

from the factory, but may still be stocked by service agencies.

P/N Description

42810-0133 Controller assembly with thumbwheel

42810-0118 Thumbwheel only

3. Current-style speed controller with 8 DIP switch settings and digital display/keypad. Note that the two types

of controllers ARE NOT compatible - the controller and

display unit MUST be of the same type.

P/N Description

37337 Controller assembly with digital display/keypad,

NCC (8/00-current)

37503 Digital display/keypad unit only, NCC

45133 Controller assembly with digital display/keypad,

Danaher (2/02-current)

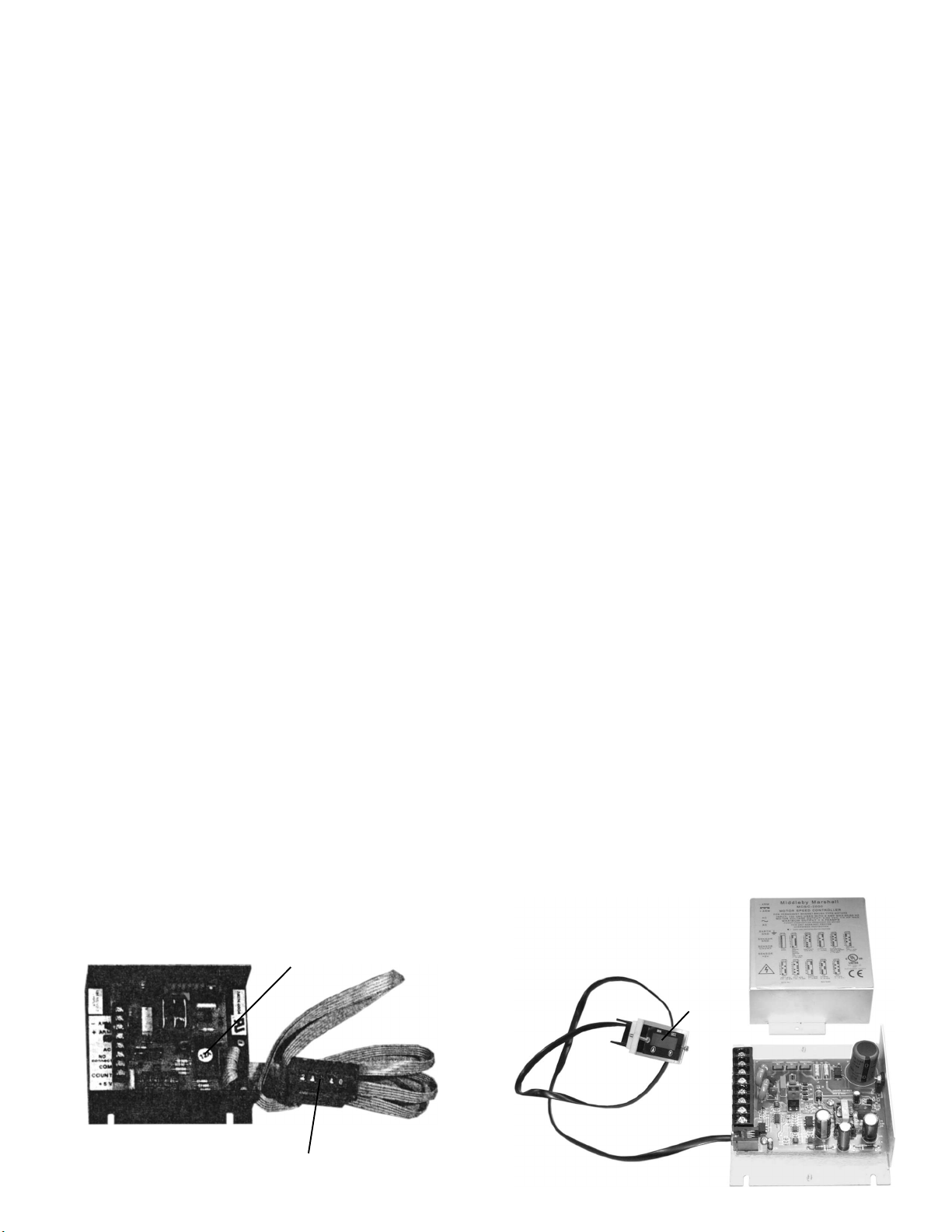

Figure 12

Original-style speed controller

Produced with thumbwheel only.

Interchangeable microcomputer selects oven model.

THIS CONTROLLER IS OBSOLETE AND NO

LONGER AVAILABLE.

Control module

Microcomputer

Thumbwheel

Produced with Thumbwheel or digital display.

DIP switches may

be on control

module or digital

display, depending

on the controller

model.

13

Figure 13

Current-style speed controller

4 or 8 DIP switches select oven model.

Cover plate

shows DIP

switch settings

Thumbwheel

or digital

display

Control

module

Page 15

SECTION 3 - SERVICING COMPONENTS

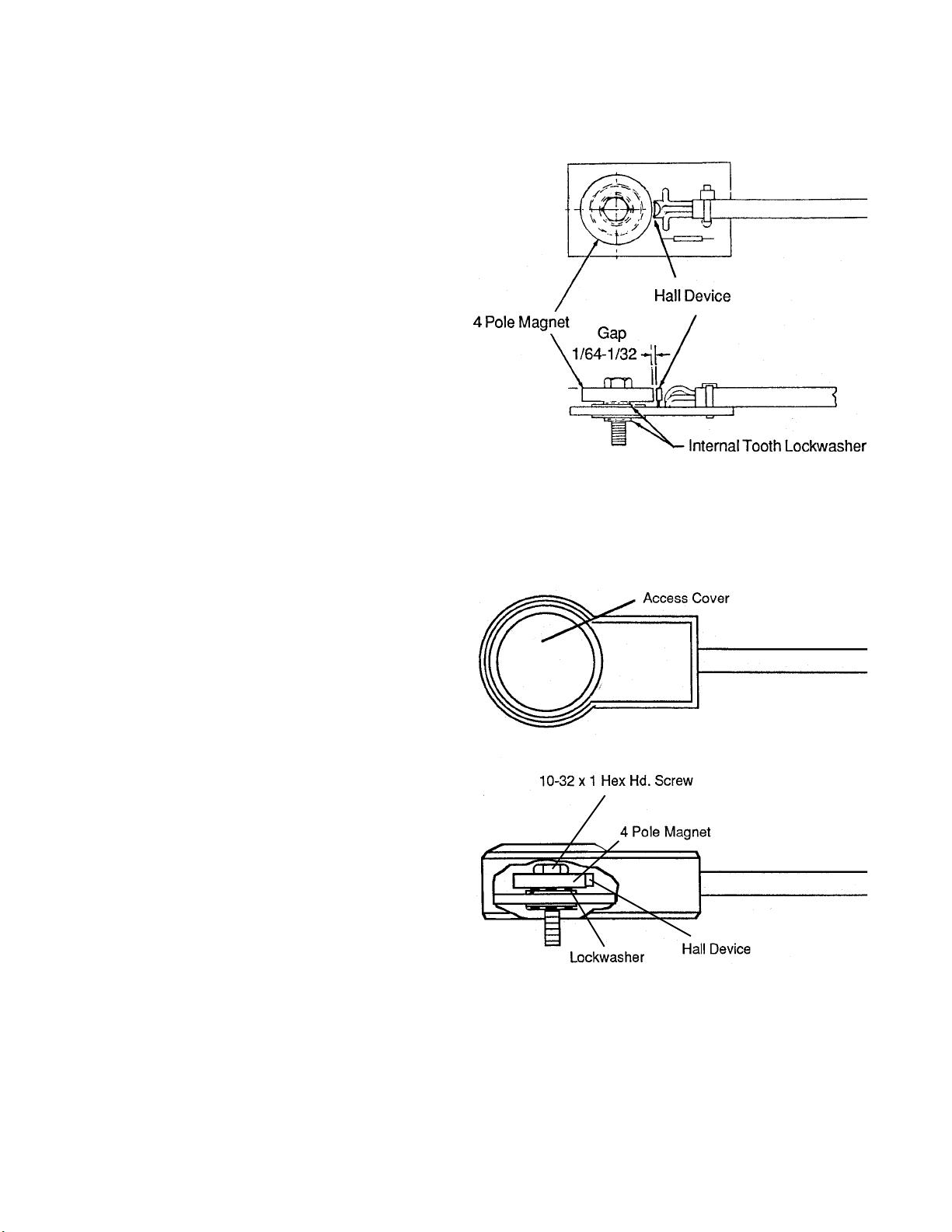

B. Part Number Reference - Pickup Assemblies

1. PS350-style pickup assembly or old-style pickup assembly (see Figures 14-15). These parts use the same

part number. They are no longer available from the

factory, but may still be stocked by some service agencies.

P/N Description

28074-0005 Pickup assembly, PS350-style or old-style

2. Current-style pickup assembly (see Figures 16-17)

P/N Description

27170-0263 Pickup assembly, current

C. Preparing to Service the Speed Controller

NOTE: To properly service this equipment, you must use a

digital meter. An analog meter will not work.

1. Before troubleshooting the conveyor speed controller,

check the following:

a. Conveyor belt is tight.

b. Drive chain is tight and aligned.

c. Set screws on drive sprockets are tight.

d. Axial fan(s) are running and clean of dust and de-

bris.

e. Motor and pickup wires are secure at the Conveyor

Terminal Block (location of the block varies by oven

model).

f. Wire connections on conveyor speed control mod-

ule (including the ribbon cable to the thumbwheel/

display unit) are secure.

2. Check the pickup for the following (see Figures 14-17):

a. Pickup is secure.

b. Magnet is not cracked or chipped.

c. Magnet is not rubbing on plastic housing.

d. Mounting bolt is not worn or bent.

e. Pickup bearing in good condition.

f. On PS350-style pickup (Fig. 14), gap between

magnet and Hall Device is spaced approximately

1/64-1/32 (0.4-0.8mm, or a business card thickness).

Figure 14

PS350-style pickup assembly

(used on early PS360)

Figure 15

Old-style pickup assembly

14

Page 16

SECTION 3 - SERVICING COMPONENTS

Figure 16

Current pickup assembly - side view

D. Controller/Motor Failure

When the conveyor speed controller fails, it is very possible that a shorted conveyor motor caused the problem.

Unless the motor is changed, the installation of another

conveyor speed controller will simply burn up the new controller.

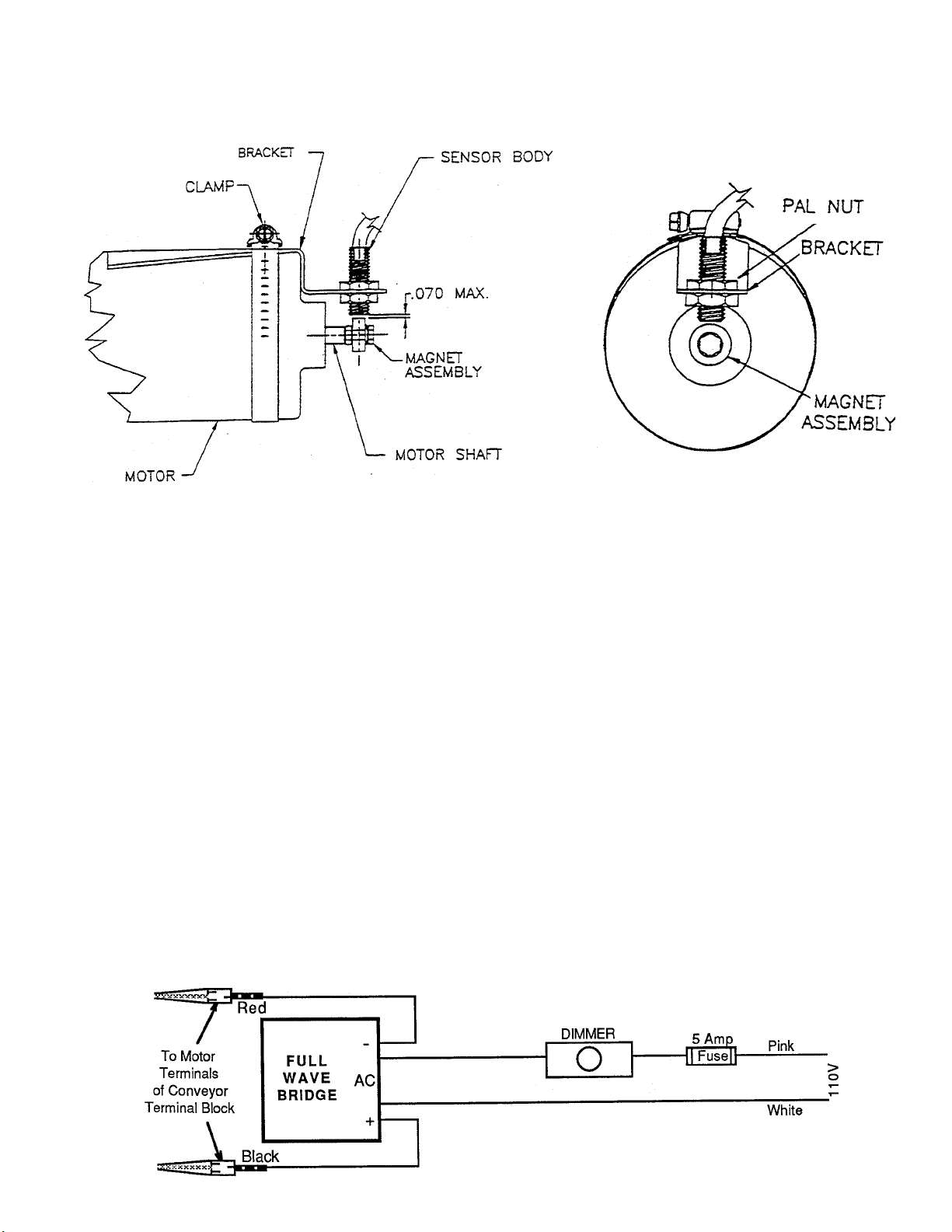

You are STRONGLY ADVISED to bypass the speed controller and install the tester unit shown in Figure 18 before

replacing any speed controller that has burned out. This

will identify the source of the problem - the speed controller

or the motor. It is much less expensive to burn out the

tester than another speed controller.

The components for this tester can be purchased at any

electrical supply store. The tester is not as accurate or

sensitive as the speed controller, and so should NOT be

left in place on the oven after servicing!

Figure 17

Current pickup assembly -

end view

Components needed for the field tester:

Full-wave AC-DC bridge, 400V, 4A

Light dimmer switch, 5A

In-line 5A AC fuse enclosed in plastic case

2 alligator clips

CAUTION: DO NOT turn the conveyor switch ON while

the field tester is connected!

1. Disconnect the motor lead wires and attach to the field

tester as shown in Figure 18. Depending on the oven

model, you can simply use the black and red gear motor

leads, or the remote leads at the terminal block connection.

To reverse the conveyor motor direction, simply interchange the black and red leads.

2. To start the test, the dimmer switch should be turned

until the motor begins to operate. The switch can then

be turned down to the desired motor speed.

Figure 18

Field Tester for Conveyor Drive Motor

15

or circuit breaker

Page 17

SECTION 3 - SERVICING COMPONENTS

E. Basic Troubleshooting Flowcharts

1. IF THE GEAR MOTOR RUNS AT FULL SPEED:

16

NOTE:

Middleby no longer stocks parts for the original

speed controller with interchangeable microcomputer. If it is necessary to replace this version of

the controller or the microcomputer, and the

service agent does not have the parts in stock, it

will be necessary to replace the entire speed

controller with a current model.

Page 18

2. IF THE GEAR MOTOR WILL NOT RUN AT ALL:

SECTION 3 - SERVICING COMPONENTS

17

NOTE:

Middleby no longer stocks parts for the

original speed controller with inter-

changeable microcomputer. If it is

necessary to replace this version of

the controller or the microcomputer,

and the service agent does not have

the parts in stock, it will be necessary

to replace the entire speed controller

with a current model.

Page 19

SECTION 3 - SERVICING COMPONENTS

F. Initial Troubleshooting

NOTE: When changing the conveyor speed on a controller

with a thumbwheel, it is advisable to turn the conveyor switch

OFF before adjusting the thumbwheel. Note that this cannot be done on a digital keypad, as switching the conveyor

switch OFF will also turn off the display.

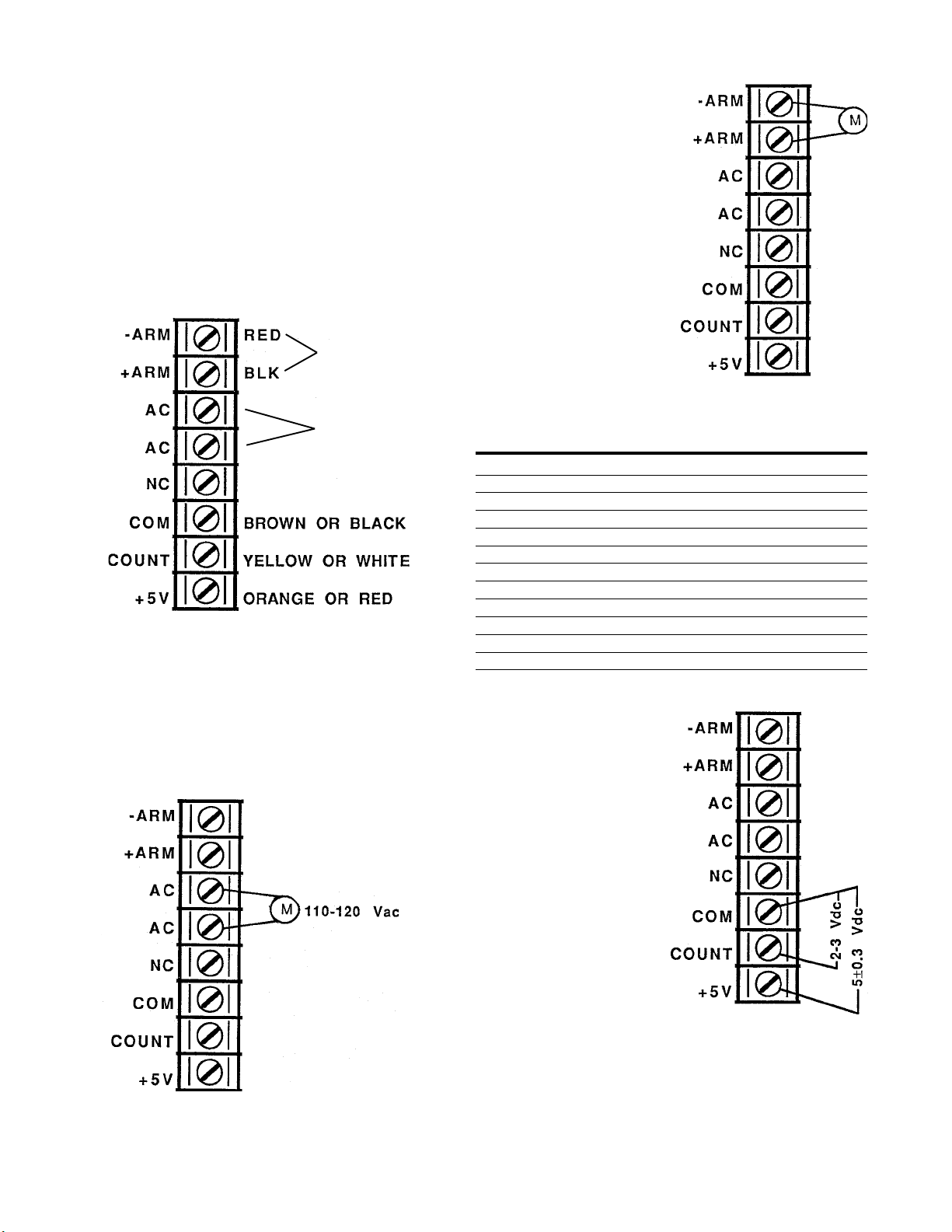

1. Check all connections at the terminals on the conveyor

speed control module to ensure that they are correct

and tight. Connections are shown in the drawing.

Correct the connections if necessary.

Connections are

reversed if

conveyor direc-

tion is reversed.

120VAC supply.

Wire colors vary

by oven model.

2. Ensure that there is power to the controller. Use a

digital multimeter to read the voltage between the terminals marked AC. The voltage should read between

110-120VAC.

If the power is not present or of an incorrect voltage,

check the power source.

3. With the AC power on,

check the DC voltage to

the conveyor motor.

Match the measured voltage with those shown on

the chart below. If the

voltage reading is more

than ±5VDC of that shown

on the chart, complete

the Motor Test on the next

page.

Thumbwheel/ DC Motor Voltage

Display PS200, PS310, 360,

Setting 570, 360WB70 360WB, 360EWB

3 mins. 84VDC 67VDC

4 mins. 63VDC 50VDC

5 mins. 51VDC 40VDC

6 mins. 43VDC 34VDC

7 mins. 37VDC 28VDC

8 mins. 32VDC 25VDC

9 mins. 29VDC 22VDC

10 mins. 27VDC 20VDC

11 mins. 24VDC 18VDC

12 mins. 22VDC 17VDC

13 mins. 19VDC 14VDC

15 mins. 18VDC 13VDC

4. Check the magnetic

pickup on the motor.

If the pickup is in good

condition, check that

the conveyor is running

and then check the voltage between the COM

and ±5VDC terminals

on the controller. On

controllers with thumbwheels, the voltage

should read 5VDC,

±0.3VDC. Digital controllers should read

5VDC , ±1.0VDC.

Next, check the voltage

between the COM

and COUNT terminals. The reading should stay between 2 and 3VDC.

If EITHER of these two readings are incorrect, perform

the Conveyor Control Pickup Test on the next page.

18

Page 20

SECTION 3 - SERVICING COMPONENTS

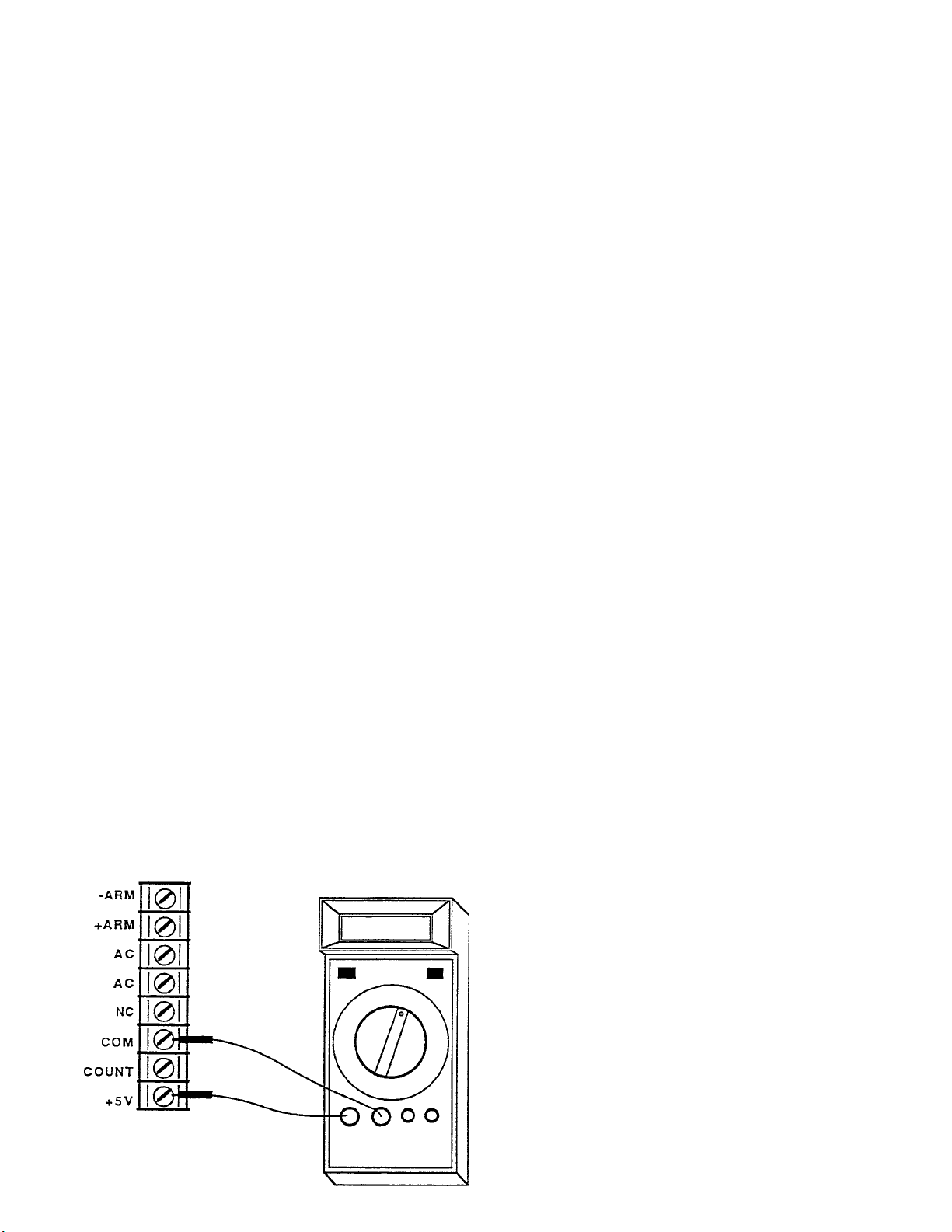

G. Conveyor Control Pickup Test

1. Visually check the pickup for the following:

The magnet is clean and the bearing is in good

condition.

There are no chips or cracks on the magnet.

If using a PS350-style pickup (see Figure 14), there

is a 1/64 to 1/32 (0-4-0.8mm, or a business card

thickness) gap between magnet and hall device.

2 Set the multimeter to the VDC scale, then connect the

meter probes as shown in Figure 19. The black (-common) probe should connect to the COM terminal on

the speed control board, while the red (+VW) probe

connects to the +5V terminal. +5VDC should be

present at all times when the conveyor is operating.

If +5VDC is present, proceed to Step 3.

If +5VDC is not present, disconnect the three pickup

wires (connected to the COM, SIGNAL, and +5V

terminals) and again check for +5VDC.

- If +5VDC is present with the pickup disconnected, replace the pickup assembly.

- If +5VDC is still not present, replace the conveyor speed controller.

3. Connect the multimeters red (+) lead to the SIGNAL

terminal; then, disconnect the motor wires from the ARM and +ARM terminals. Using a 5/16 open-end

wrench, very slowly rotate the motor pickup shaft while

observing the multimeter. Two (2) changes from +5VDC

to 0VDC should occur for each motor revolution.

lf the signal is always at 0VDC, go to Step 4.

lf the signal is always at 5VDC, OR if the signal

changes more than 2 times per revolution, replace

the pickup assembly.

4. Disconnect the pickup signal wire from the speed controller and check for +5VDC at the SIGNAL terminal of

the controller.

If +5VDC is present, replace the pickup assembly.

If 0VDC is present, replace speed control.

Figure 19

Connections for pickup test

H. Conveyor Motor Test

1. Disconnect the gear motor wires from the Speed Controller terminals (-ARM and +ARM).

2. Remove the brush retainer caps from the gear motor.

DO NOT remove the brushes.

3. Set the multimeter to the lowest Ohm scale. Then,

place one meter probe on each brush retaining plate.

BE SURE THAT NEITHER PROBE TOUCHES THE

MOTOR CASING.

4. Using a 5/16 open-end wrench, very slowly rotate the

motor pickup shaft while observing the multimeter. During a 1/2 rotation:

The Ohm reading should stay betweeen 3-5W.

There should NEVER be a complete short.

There should never be a high Ohm reading.

If the motor fails any of these tests, replace the motor.

I. Replacing the Magnetic Pickup

If you need to replace the magnetic pickup on a gear motor

shaft:

1. Apply Loctite Removable #242 (or equivalent) sparingly

to the threads.

2. Turn the mounting screw until it is finger tight, then turn

it an additional 1/4 turn with a wrench.

J. Unshielded Pickup Wires on Early PS360-series ovens

The conveyor speed controller can be affected by electrical

noise transmitted by other electrical components or wiring.

Early PS360-series ovens used an unshielded connection

between the pickup assembly and the control module. On

these ovens, the unshielded wiring can pick up the noise

and transmit it to the control module. The problem is most

easily seen when the conveyor fails during burner spark

ignition.

There are two remedies for this problem:

1. Turn the conveyor switch to the OFF position, and then

back to the ON position, after the burner has ignited.

The controller should reset and allow normal operation.

This should be used as a stop-gap measure ONLY to

allow the oven to continue operation.

2. Replace the pickup wiring between the control module

and the terminal block with a new shielded cable (P/N

42400-0334). When installing the shielded cable, follow the color code change shown here:

Old Wiring Shielded Cable

Br own Black

Orange Red

Yellow White

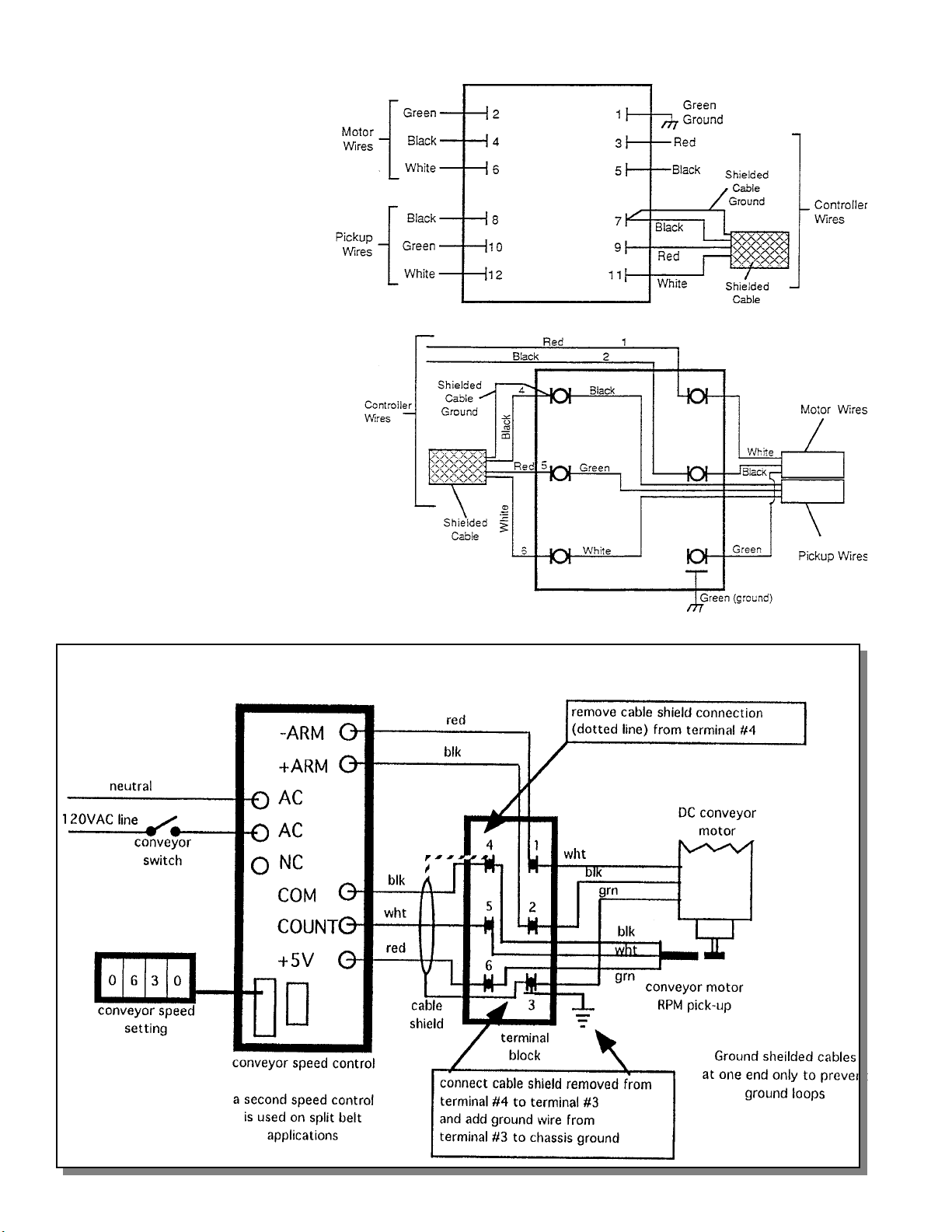

Wiring diagrams are also provided in Figures 20 and 21

on the next page.

There is a fourth lead on one end of the shielded cable.

This is a ground lead which is attached to the black

wire of the cable. The ground lead should be connected

to the terminal block inside the motor compartment.

Current PS360-series ovens have the shielded cable

installed at the factory and do not require this retrofit.

19

Page 21

SECTION 3 - SERVICING COMPONENTS

Figure 20

Wiring for PS360 Shielded

Pickup Cable - early terminal

block design

Figure 21

Wiring for PS360 Shielded

Pickup Cable - late terminal

block design

K. Appendices

Appendix - Conveyor sensor wiring changes for PS360-series and PS570S, 10/95

20

Page 22

SECTION 3 - SERVICING COMPONENTS

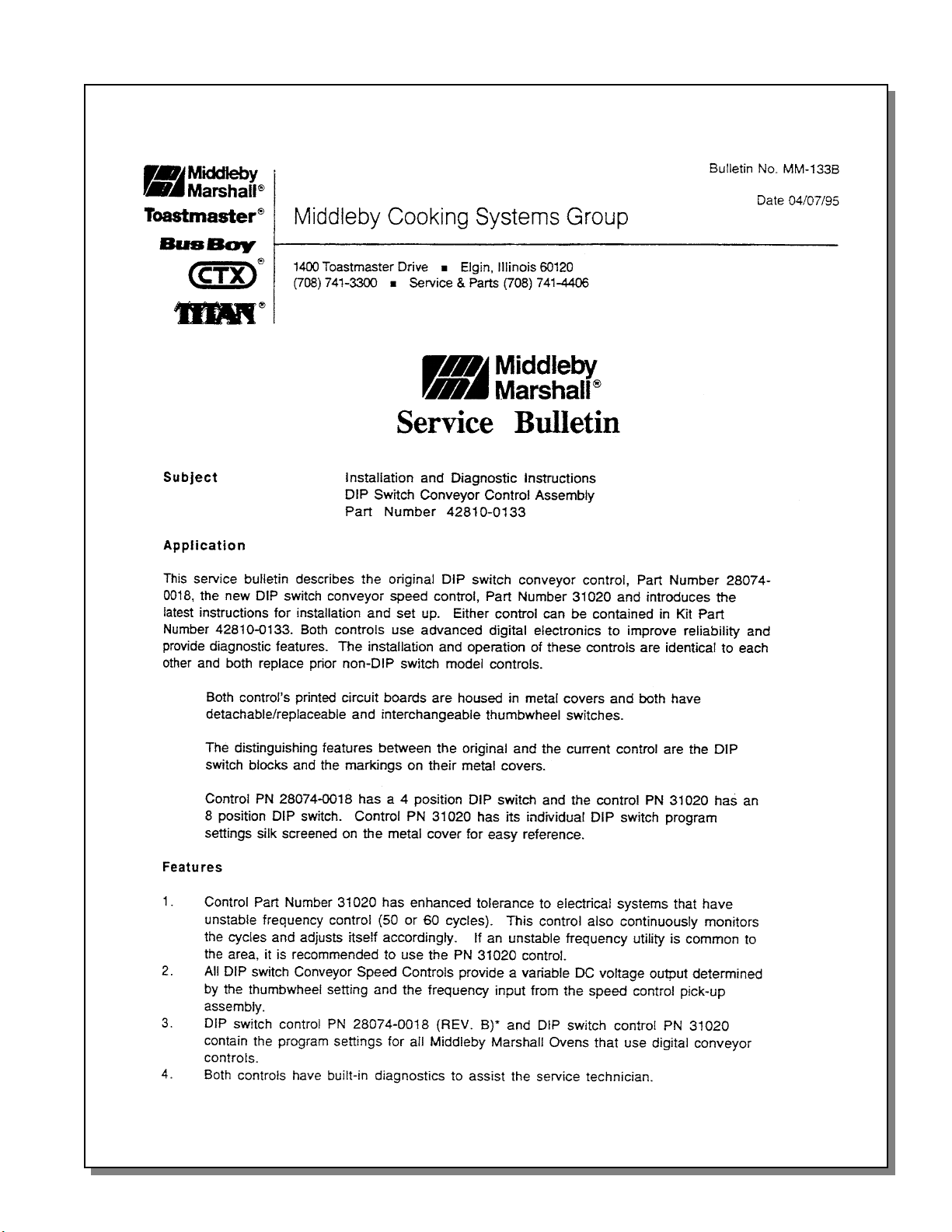

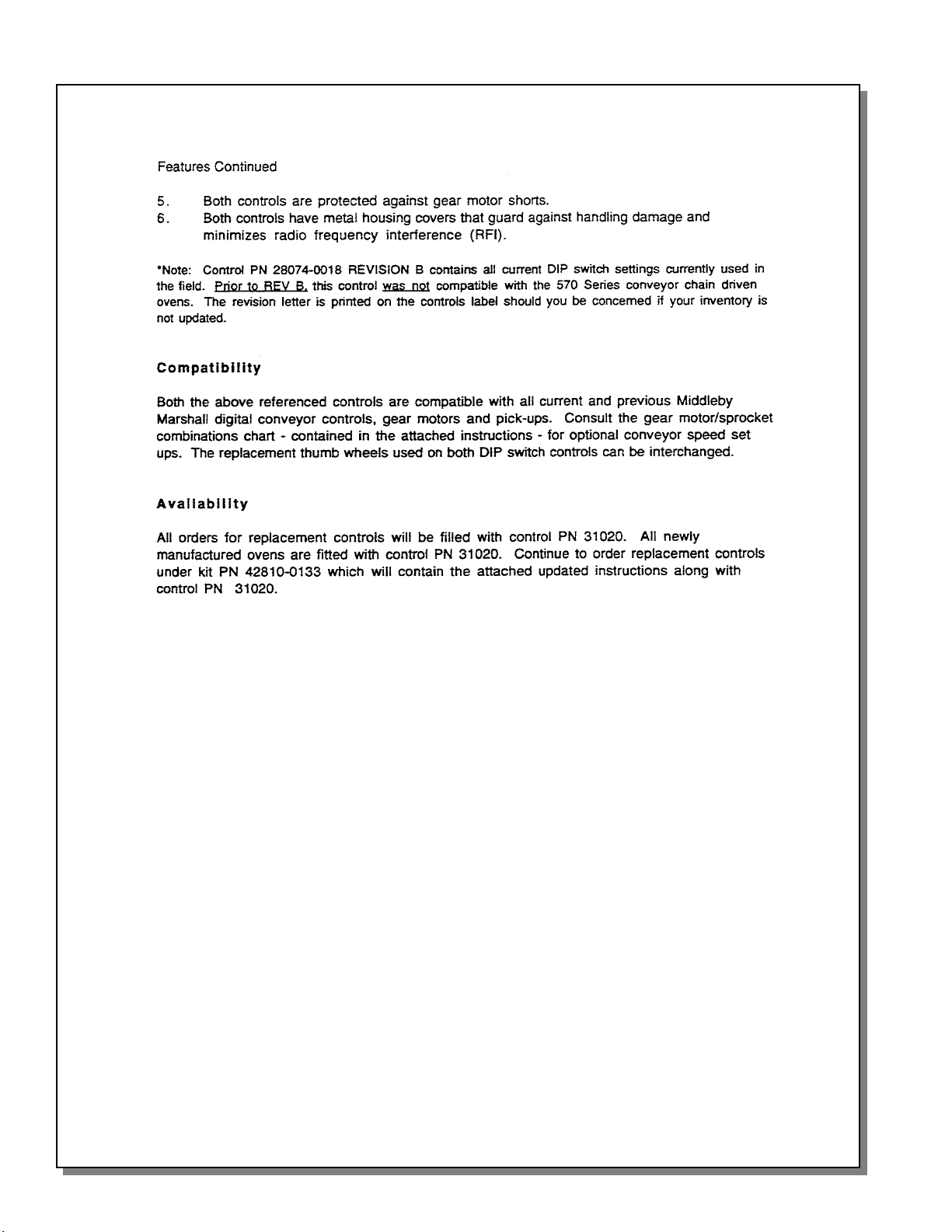

Appendix - Service Bulletin MM-133B - Installation Instructions for Conveyor

Speed Controller Kit with Thumbwheel, P/N 42810-0133, 4/95

21

Page 23

SECTION 3 - SERVICING COMPONENTS

Appendix - Service Bulletin MM-133B - Installation Instructions for Conveyor

Speed Controller Kit with Thumbwheel, P/N 42810-0133, 4/95

22

Page 24

SECTION 3 - SERVICING COMPONENTS

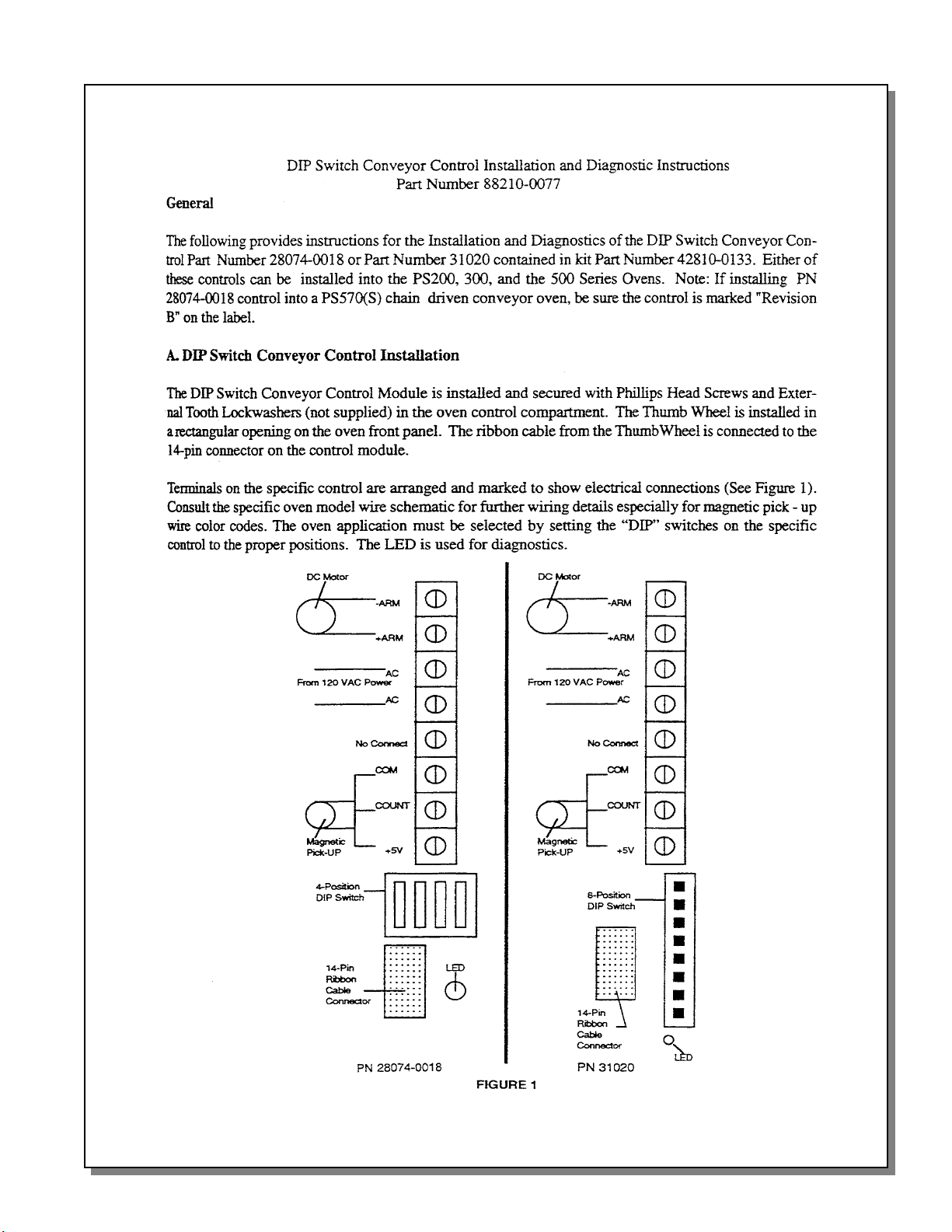

Appendix - Instructions for Service Kit 42810-0133-

Conveyor Speed Controller Kit with Thumbwheel, 4/95

23

Page 25

SECTION 3 - SERVICING COMPONENTS

Appendix - Instructions for Service Kit 42810-0133-

Conveyor Speed Controller Kit with Thumbwheel, 4/95

24

Page 26

SECTION 3 - SERVICING COMPONENTS

Appendix - Instructions for Service Kit 42810-0133-

Conveyor Speed Controller Kit with Thumbwheel, 4/95

25

Page 27

SECTION 3 - SERVICING COMPONENTS

Appendix - Instructions for Service Kit 42810-0133-

Conveyor Speed Controller Kit with Thumbwheel, 4/95

26

Page 28

SECTION 3 - SERVICING COMPONENTS

Appendix - Service Bulletin MM-177 - Introduction and Compatibility of

Conveyor Speed Controller with Digital Display, P/N 37337, 8/00

Bulletin No. MM-177

Date: 8/18/00

Middleby Cooking Systems Group

1400 Toastmaster Drive Elgin, IL 60120-9272 U. S. A. Telephone: (847)741-3300 Service and Parts Fax: (847)741-4406

Service Bulletin

SUBJECT

Availability of Conveyor Speed Controller Kits

GENERAL

Middleby Marshall is changing is standard Conveyor Speed Controller from the familiar thumbwheel

control to a unit that features a digital display with pushbutton speed selectors. The part numbers of

these components are summarized here:

Speed Controller with Thumbwheel

Kit (includes control module and thumbwheel): 42810-0133

Thumbwheel unit only: 42810-0118

Speed Controller with Digital Display

Kit (includes control module and digital display): 37337

Digital selector/display unit only: 37503

Because of this change, supplies of the previous speed controller are VERY LIMITED, and the separate thumbwheel is no longer available.

your remaining thumbwheel controls for use with the oven models that cannot use the new controller.

Immediately stock the new Speed Controller units and save

APPLICATION

Service agents should immediately begin to stock P/Ns 37337 and 37503 to fulfill their normal

need for conveyor speed controllers. The new units can be used without modification on ALL

OVENS EXCEPT THE PS200R68-SERIES.

Your existing stock of P/Ns 42810-0133 and 42810-0118 should be used, whenever possible,

ONLY for PS200R68-series ovens.

The new speed controller and digital display are already in use on Middleby Marshall PS555 ovens;

so, your Agency may already have some of these components in stock. Please check your existing stock of these components before placing addtional orders.

COMPATIBILITY

The Speed Controller with Digital Display is compatible with all Middleby Marshall ovens EXCEPT the

PS200R68, PS220R68, and PS224R68.

AVAILABILITY

P/Ns 37337 and 37503 are available for immediate shipment.

P/N 42810-0133 is available in very limited quantities. Note that some future orders may not be

fulfilled.

P/N 42810-0118 is no longer available.

27

Page 29

SECTION 3 - SERVICING COMPONENTS

Appendix - Instructions for Service Kit 44756 - Conveyor Speed Controller Kit

for PS200R68-series Ovens, 2/02

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 USA (847) 741-3300 FAX (847) 741-4406

Instructions for Service Kit 44756

Conveyor Speed Controller Kit for PS200R68-series ovens

KIT COMPONENTS:

Qty. P/N Description

1 37337 Conveyor speed controller with digital display

1 44749 Cable assembly, PS200R68-series ovens

1 44757 Instructions, PS200R68-series oven conveyor speed controller kit

This Service Kit will update one Middleby Marshall PS200R68, PS220R68, or PS224R68 oven to operate using the current

digital conveyor speed controller with keypad display (P/N 37337), instead of the previous controller with thumbwheel

adjustment (P/N 42810-0133). If the oven is already equipped with controller P/N 37337, this Kit is not necessary; P/N 37337

may be used as a direct replacement for the existing controller.

WARNING

BEFORE PERFORMING ANY SERVICE WORK, THE ELECTRICAL POWER SUPPLY

SUPPLY

MUST BE TURNED OFF.

AND THE GAS

1. Disconnect the oven from its electrical power supply at

the circuit breaker/fused disconnect. For ga s o ve ns ,

shut off the gas supply to the oven.

2. Identify the 24-pin control cable (female at both ends) that

connects the rear of the remote box (on top of the oven) to

the rear of the machinery compartment (on the side of the

oven).

3. Remove and discard the cable.

4. Open the machinery compartment door and locate the

conveyor speed control module.

5. One at a time, disconnect the leads from the terminals on

the existing speed control module and connect them to

the corresponding terminals on the new control module.

6. Remove the ribbon cable plug from its socket on the old

speed control module, and attach it to the corresponding

socket on the new control module.

7. Remove and discard the old control module from the inside of the machinery compartment door.

8. Adjust the DIP switch settings on the new speed control

module to the correct settings for the PS200-series oven

with a 3-30 minute bake time range. These settings are

shown on the case of the controller and are also provided

in Figure 1.

9. Install the new module in place. Close and fasten the

machinery compartment door.

10. Temporarily remove the remote box from the top of the

oven. Open the remote box.

11. Disconnect the thumbwheel units ribbon cable plug from

its socket on the remote board. Then, remove and discard the thumbwheel unit.

12. Install the new digital display unit in place. Connect its

ribbon cable plug into its socket on the remote board.

13. Close the remote box and reinstall it atop the oven.

14. Install the new kit-supplied control cable between the back

of the remote box and the back of the machinery compartment.

15. Restore the electrical and gas utility supplies to the oven.

16. Test the operation of the new conveyor speed controller to

make certain that it is operating properly. The oven is now

ready for operation.

Figure 1

DIP Switch Settings

Middleby Cooking Systems Group

1400 Toastmaster Drive

Elgin, IL 60120

(847) 741-3300 FAX (847) 741-4406

Middleby Corporation Service

Hotline 1-800-238-8444

P/N 44757 Rev. C V1 2/02

28

Page 30

SECTION 3 - SERVICING COMPONENTS

Appendix - Service Bulletin MM-189 - New Conveyor Gear Motors,

Brushes, and Pickup Clamps, 8/01

Bulletin No. MM-189

Date: 8/24/01

Middleby Cooking Systems Group

1400 Toastmaster Drive Elgin, IL 60120-9272 U. S. A. Telephone: (847)741-3300 Service and Parts Fax: (847)741-4406

Service Bulletin

SUBJECT

New conveyor gear motors, brushes, and pickup clamps for Middleby Marshall ovens

GENERAL

The conveyor gear motors used on all Middleby Marshall ovens (except model PS536) have been redesigned by the

vendor. Changes to the motors include:

A smaller-diameter motor casing.

New motor brushes.

- Old-style motors continue to use brush P/Ns 22450-0052 or 22450-0230 as shown in the table below.

All of the new motors use brush P/N 46658.

-

A shorter clamp to attach the pickup assembly. This accommodates the smaller diameter of the motor.

- The pickup assembly with the original clamp is still available as P/N 27170-0263. This kit is only available in

limited quantities.

existing clamp to attach a new pickup assembly to an old-style motor.

- The pickup assembly with the new, shorter clamp is available as P/N 46451.

- All of the new motors will be shipped in a kit that also includes the new clamp. This allows you to attach an

existing pickup assembly to a new motor.

- In 7/01 and 8/01, some of the new motors were shipped under the part numbers of the old motors. These parts

shipped without the new clamp. In most of these cases, you can tighten the existing clamp to fit the new motor.

Some older clamps, however, cannot be tightened enough to fit.

in all ovens, you should add the new clamp, P/N 46602, to your required parts stocking list, and carry a few

spare clamps on each service vehicle.

Please be aware of these changes as you order your stocking parts. Some versions of the old motor, as well as the oldstyle pickup assembly, are still available in limited quantities. The brush for the old motor (P/N 22450-0052) will remain

available in order to maintain motors already in the field.

Ratio Used on Motor Brush Pickup Motor* Brush Pickup Clamp

1400:1 PS310 27384-0008 22450-0052 27170-0263 46603 46658 46451 46602

PS314

PS360/360S

PS360SS High Speed

PS360T Tandem

PS360WB

PS360WB70

PS360EWB

PS555

PS570/570S Single Belt

1350:1 PS200/220FS/224 27384-0011 22450-0230 27170-0263 46604 46658 46451 46602

PS200VL/220VL/224VL

PS200R68/220R68/224R68

PS200T Tandem

PS570/570S Split Belt (Standard)

600:1 PS314SBI 27384-0003 22450-0052 27170-0263 46605 46658 46451 46602

300:1 PS200/220FS/224 (High Speed) 27384-0014 22450-0230 27170-0263 46606 46658 46451 46602

PS570/570S Split Belt (High Speed)

* New Motor part numbers shown in this table are kits that include both the motor and the new pickup clamp.

After our stock of the old-style pickup assembly kit is exhausted, you will need to save the

To be sure that you can install the new motor

Old Old Old Ne w Ne w Ne w Ne w

29

Page 31

SECTION 3 - SERVICING COMPONENTS

Appendix - DIP switch settings for Conveyor Speed Controller

with Digital Display (P/N 37337), 4/02

II. TEMPERATURE CONTROLLER

The Temperature Controller is used to set and control the

oven temperature. Depending on the oven, model, the controller has several functions:

On gas ovens with On-Off gas valve operation, the tem-

perature controller opens and closes the high flame

solenoid. This allows 100% or 0% gas flow to the burner

in response for the need for heat to maintain the set

point temperature. The temperature controller has no

effect on the low flame bypass or oven ignition.

For this operating mode, the temperature controller is set

to the On-Off Mode as described in the Kit instructions.

On gas ovens with modulated gas valve (PID) opera-

tion, the temperature controller sends a signal to the

amplifier board which in turn controls the operation of

the modulating valve. This allows a modulated gas flow

of any necessary value from 0-100% in response for

the need for heat to maintain the set point. The temperature controller has no effect on oven ignition.

For this operating mode, the temperature controller is set

to the PID Mode as described in the Kit instructions.

On electric ovens with On-Off heater activation (includ-

ing most PS200-series and PS360-series electric ovens), the temperature controller permits or cuts power

to the heating elements as necessary to maintain the

set point temperature.

For this operating mode, the temperature controller is set

to the On-Off Mode as described in the Kit instructions.

On electric ovens with variable pulse heater activation

(including PS555 electric ovens), the temperature controller sends its signal to a controller module that contains an amplifier board and two solid state relays. The

relays activate the heating elements at 100% power on

a fixed cycle time, for a length of time proportional to