Page 1

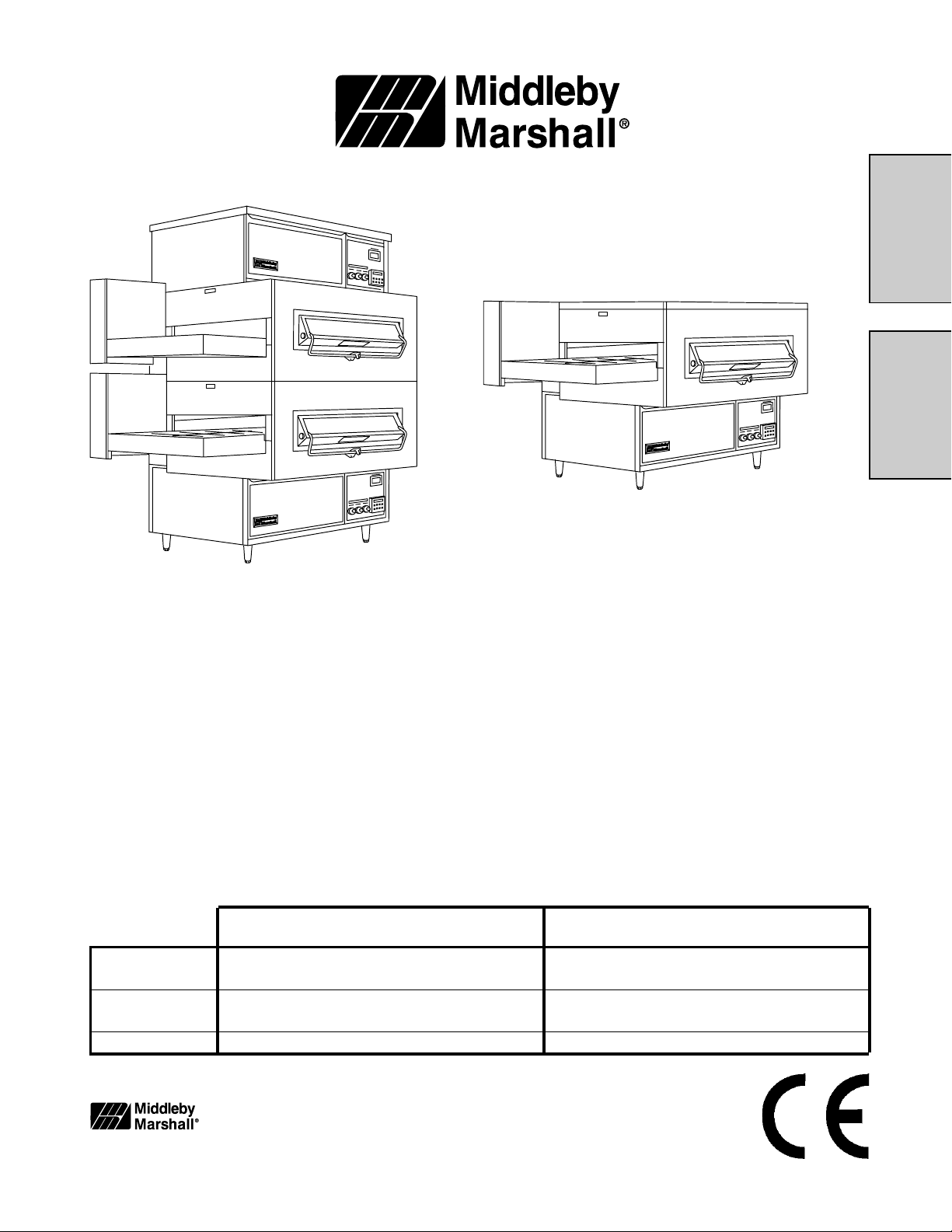

PS300 Series

Gas and Electric (Europe)

ENGLISH/Danish

P/N 46486

Rev. B V1 7/01

page 1

ENGLISH

side 25

DANSK

PS300 Series Gas and Electric Ovens

Models:

PS360-U, PS360-L Gas

PS360-U, PS360-L Electric

PS360WB-U, PS360WB-L Gas

OWNER'S OPERATING AND

INSTALLATION MANUAL

for European export ovens

Single Oven Double Oven

PS360 PS360WB PS360 PS360WB

Rated Heat Input 40kW 50kW 2x40kW 2x50kW

Gas Ovens

Rated Heat Input 26kW -- 2x26kW --

Electric Ovens

Heating Zones 1 controlled heat zone 2 controlled heat zones

© 2001 Middleby Marshall, Inc.

Combinations:

Single Oven

Double Oven (Two-Stack)

is a registered trademark of Middleby Marshall, Inc. All rights reserved.

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 USA (847)741-3300 FAX (847)741-4406

1

Page 2

NOTICE:

Owner's Operating and Installation Manual should be given to the user. The operator of the oven should

This

be familiar with the functions and operation of the oven.

This manual must be kept in a prominent, easily reachable location near the oven.

ENGLISH

Gas ovens are designed for use with EITHER natural gas OR liquid propane gas, as specified on the serial plate.

Where permitted by local and national codes, the oven can be converted from natural gas to propane operation,

or from propane to natural gas operation. This conversion is described in the Installation section of this Manual.

The conversion requires the installation of the appropriate Middleby Marshall Gas Conversion Kit.

It is suggested to obtain a service contract with a Middleby Marshall Authorized Service Agent.

WARNING

POST, IN A PROMINENT LOCATION, THE EMERGENCY TELEPHONE NUMBER OF YOUR LOCAL GAS

SUPPLIER AND INSTRUCTIONS TO BE FOLLOWED IN THE EVENT YOU SMELL GAS.

Instructions to be followed in the event the user smells gas shall be obtained by consulting the local gas

supplier. If the smell of gas is detected, immediately call the emergency phone number of your local Gas

Company. They will have personnel and provisions available to correct the problem.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of

this or any other appliance.

WARNING:

Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death. Read the installation,

operating and maintenance instructions thoroughly before installing

or servicing this equipment.

IMPORTANT

An electrical wiring diagram for the oven is located inside the machinery

compartment.

IMPORTANT

It is the customer's responsibility to report any concealed or non-concealed damage

to the freight company. Retain all shipping materials until it is certain that the

equipment has not suffered concealed shipping damage.

NOTICE: CONTACT YOUR MIDDLEBY MARSHALL AUTHORIZED SERVICE AGENT TO PERFORM MAINTENANCE

AND REPAIRS. AN AUTHORIZED SERVICE AGENCY DIRECTORY IS SUPPLIED WITH YOUR OVEN.

NOTICE: Using any parts other than genuine Middleby Marshall factory manufactured parts relieves the manufacturer of

all warranty and liability.

NOTICE: Middleby Marshall (Manufacturer) reserves the right to change specifications at any time.

NOTICE: The equipment warranty is not valid unless the oven is installed, started and demonstrated under the supervision

of a factory certified installer.

Retain This Manual For Future Reference

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 USA (847)741-3300 FAX (847)741-4406

24-Hour Service Hotline: 1-(800)-238-8444

www.middleby.com

2

Page 3

TABLE OF CONTENTS

page page

SECTION 1 - DESCRIPTION ................................................... 4

VII. ELECTRICAL SUPPLY ........................................... 11

I. OVEN USES............................................................. 4

II. OVEN COMPONENTS ............................................. 4

A. Crumb Pans ..................................................... 4

B. Conveyor Drive Motor ....................................... 4

C. Conveyor ........................................................... 4

D. End Plugs ......................................................... 4

E. Serial Plate ....................................................... 4

F. Window ............................................................. 4

G. Machinery Compartment Access Panel .......... 4

H. Control Compartment Access Panel .............. 4

I. Control Panel.................................................... 4

J. Eyebrows .......................................................... 4

K. Conveyor End Stop ........................................... 4

L. Gas Burner or Heating Elements .................... 4

M. Blowers ............................................................. 4

N. Air Fingers ........................................................ 4

III. OVEN SPECIFICATIONS ......................................... 4

A. Dimensions ...................................................... 4

B. General Specifications ..................................... 4

C. Electrical Specifications ................................... 5

D. Gas Orifice and Pressure Specifications........ 5

A. Additional Information - Gas Ovens ................ 11

B. Additional Information - Electric Ovens .......... 11

C. Connection ...................................................... 11

VIII. GAS SUPPLY .......................................................... 11

A. Gas Utility Rough-in Recommendations ....... 12

B. Connection ...................................................... 12

C. Preparation for Use with Various Gases ....... 13

D. Replacing the Gas Orifices .............................13

E. Checking the Gas Supply (Inlet) Pressure .... 14

F. Adjusting the Orifice (Manifold) Pressure

and Heat Input ................................................. 14

SECTION 3 - OPERATION ..................................................... 15

I. LOCATION AND DESCRIPTION OF CONTROLS . 15

A. "BLOWER" (

B. "HEAT" (

C. "CONVEYOR" (

D. "RESET" (

E. Conveyor Speed Controller .............................15

F. Digital Temperature Controller....................... 15

G. Machinery Cpt. Access Panel Safety Switch .. 15

II. NORMAL OPERATION, STEP-BY-STEP ................ 16

) Switch ................................... 15

) Switch ......................................... 15

) Switch .............................15

) Switch ....................................... 15

ENGLISH

SECTION 2 - INSTALLATION .................................................. 5

I. INSTALLATION KIT .................................................. 6

II. VENTILATION SYSTEM ........................................... 7

A. Requirements .................................................. 7

B. Recommendations .......................................... 7

C. Other Ventilation Concerns .............................. 7

III. ASSEMBLY ............................................................... 8

A. Caster Removal ............................................... 8

B. Stacking ............................................................ 8

C. Stands ............................................................... 8

D. Flue Vent(s) ...................................................... 8

IV. THERMOCOUPLE INSTALLATION ......................... 8

V. CONVEYOR INSTALLATION ................................... 9

VI. FINAL ASSEMBLY ................................................... 10

A. Daily Startup Procedures ................................ 16

B. Daily Shutdown Procedures ...........................16

III. QUICK REFERENCE: DIGITAL TEMP CONTROL. 17

IV. QUICK REFERENCE: TROUBLESHOOTING ....... 18

SECTION 4 - MAINTENANCE ................................................. 19

I. MAINTENANCE - DAILY ..........................................19

II. MAINTENANCE - MONTHLY .................................. 20

III. MAINTENANCE - EVERY 3 MONTHS .................... 21

IV. MAINTENANCE - EVERY 6 MONTHS .................... 22

V. KEY SPARE PARTS KIT ......................................... 22

SECTION 5 - ELECTRICAL WIRING DIAGRAMS ...................23

I. WIRING DIAGRAM, PS360-U/-L ELECTRIC OVEN,

380-400V, 50Hz, 1Ph .............................................. 23

II. WIRING DIAGRAM, PS360-U/-L OR PS360WB-U/-L

GAS OVEN, 220-230V, 50Hz, 1 Ph......................... 24

3

Page 4

SECTION 1 - DESCRIPTION

I. OVEN USES

PS300 Series Ovens can be used to bake and/or cook a

ENGLISH

wide variety of food products, such as pizza, pizza-type

products, cookies, sandwiches and others.

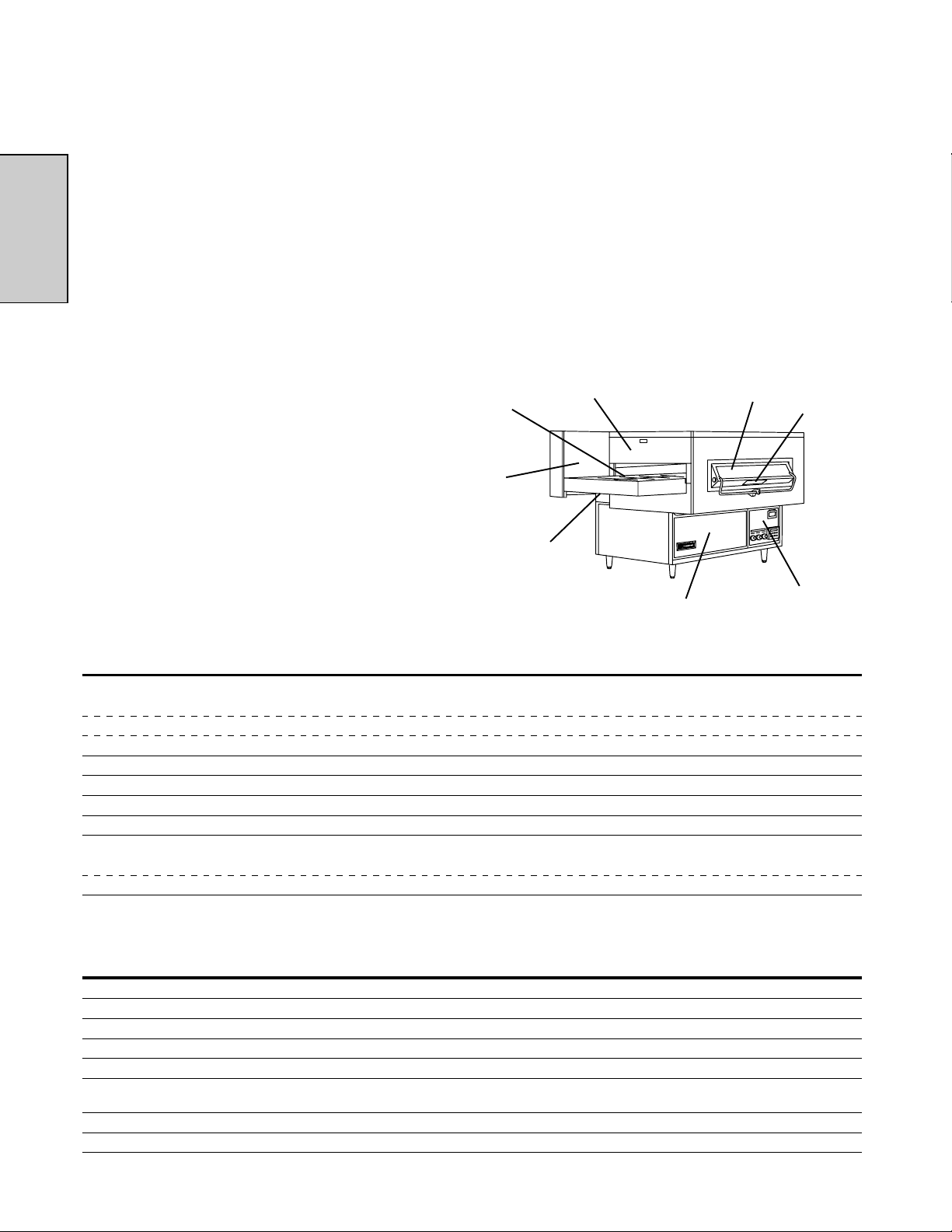

II. OVEN COMPONENTS - see Figure 1-1.

A. Crumb Pans: Catch crumbs and other material that drop

through the conveyor belt. One crumb pan is located

underneath each end of the conveyor.

B. Conveyor Drive Motor: Moves the conveyor.

C. Conveyor: Moves the food product through the oven.

D. End Plugs: Allow access to the oven's interior.

E. Serial Plate: Provides specifications for the oven that affect

installation and operation.

F. Window: Allows the user to see and access food products

inside the baking chamber.

G. Machinery Compartment Access Panel: Allows access

to the oven's interior components. No user-servicable

parts are located in the machinery compartment.

H. Control Compartment Access Panel: Allows access to

the control components. No user-servicable parts are

located in the control compartment.

I. Control Panel: Location of the operating controls for the

oven.

Not Shown:

J. Eyebrows (on ovens so equipped): Can be adjusted to

various heights to prevent heat loss into the environment.

K. Conveyor End Stop: Prevents food products from falling off

the end of the moving conveyor.

L. Gas Burner (gas ovens) or Heating Elements (electric

ovens): Heats air, which is then projected to the air fingers

by the blowers.

M. Blowers: Fans that project hot air from the burner to the air

fingers.

N. Air Fingers: Project streams of hot air onto the food product.

Figure 1-1 - Oven Components

D F

C

E

B

A

H,I

G

III. OVEN SPECIFICATIONS

Table 1-1: Dimensions PS360U, PS360L PS360WB-U, PS360WB-L

Overall Height

Lower oven, with top and legs 1143mm 1143mm

Upper oven, with stand and top 1638mm 1638mm

Double oven (two-stack) 2089mm 2089mm

Overall Depth (including rear shrouds and front window) 1194mm 1397mm

Overall Length 2299mm 2299mm

Conveyor Width, Single Belt Ovens 813mm 1016mm

Conveyor Width, Split Belt Ovens 2 x 381mm 2 x 483mm

Recommended Minimum Clearances

Rear of oven (inc. rear shrouds) to wall 25mm 25mm

Conveyor extension to wall (both ends) 0mm 0mm

Table 1-2: General specifications (per oven cavity)

PS360U, PS360L Gas PS360-U, PS360-L Electric PS360WB-U, PS360WB-L Gas

Weight 583kg 583kg 674kg

Shipping Weight 617kg 617kg 708kg

Shipping Carton Vol. 3.00m

Rated Heat Input 34,020kcal, 40kW 26kW 42,840kcal, 50kW

Max. Operating Temp. < - - - - - - - - - - - - - - - - - - 288°C - - - - - - - - - - - - - - - - - - >

Air Blowers < - - - - - - - 2 blowers at 43.9m

Air Jet Velocity (avg.) < - - - - - - - - - - - - - - - 1320cm/sec. - - - - - - - - - - - - - - - >

Warmup Time < - - - - - - - - - - - - - - - - 15 minutes - - - - - - - - - - - - - - - - >

3

2.2cm water static pressure

4

3

3.00m

3

/min. at 1700 RPM, - - - - - - - >

3.65m

3

Page 5

Table 1-3: Electrical specifications (per oven cavity)

Oven Model Voltage Circuit Voltage Phase Freq. Draw * Poles Wires

Gas Ovens 220-230V 120V (transformer) 1 Ph 50 Hz 8A 2 Pole 3 Wire (1 hot, 1 neut, 1 gnd)

Electric Ovens 380-400V 120V (transformer) 1 Ph 50 Hz 39A 2 Pole 5 Wire (3 hot, 1 neut, 1 gnd)

* CAUTION: The current draw shown in the chart above is an average value for normal operation. The initial amperage draw on oven startup

may exceed the listed value.

IMPORTANT: Additional electrical information is provided on the oven's serial plate, and on the wiring diagram inside the machinery compartment.

Table 1-4: Gas orifice and pressure specifications (per oven cavity)

Gas Type dia. dia. dia. II

PS360U, PS360L

Natural, G20 5.50mm 0.635mm 1.65mm 20 20 -- 20-25 20 6.8 40kw 4.2m3h 70.0 l/min

Natural, G25 5.50mm 0.635mm 1.65mm -- 20 25 -- -- 10.5 40kw 4.2m3h 81.7 l/min

Natural, G20, G25 4.50mm 0.635mm 1.50mm 20 20 25 20-25 20 6.8-10.5 40kw 4.2-4.9m3h 70.0-81.7 l/min

Liquid, G30 2.70mm 0.381mm 0.85mm 29-37 -- 28-30 29-37 50 * 40kw 3.1kg/h -Liquid, G30, G31 3.10mm 0.381mm 0.95mm -- 50 30 -- 50 * 40kw 3.1kg/h --

PS360WB-U, PS360WB-L

Natural, G20 6.30mm 0.635mm 2.30mm 20 20 -- 20-25 20 6.8 50kw 5.3m3h 88.0 l/min

Natural, G25 6.30mm 0.635mm 2.30mm -- 20 25 -- -- 10.5 50kw 6.1m3h 102.4 l/min

Natural, G20, G25 5.40mm 0.635mm 2.00mm 20 20 25 20-25 20 6.8-10.5 50kw 5.3-6.1m3h 88.0-102.4 l/min

Liquid, G30 3.10mm 0.381mm 1.40mm 29-37 -- 28-30 29-37 50 * 50kw 3.9kg/h -Liquid, G30, G31 3.50mm 0.381mm 1.40mm -- 50 30 -- 50 * 50kw 3.9kg/h --

* Pressure regulator (governor) not in operation, system at supply (inlet) pressure.

Orifice pressures apply to 15°C, 1.013mbar dry gas.

Main Blower Control Current

Supply (inlet) Pressure (mbar)

Main Pilot Bypass PT,ES, DK,FI, (manifold) Rated

Orifice Orifice Orifice GB DE NL BE,FR SE pressure Heat Supply Gas

IE,IT, AT,CH, Orifice

2H3+II2ELL3B/PII2L3B/PII2E+3+II2H3B/P

(mbar) Input Volume Flow

ENGLISH

SECTION 2 - INSTALLATION

WARNING - After any conversions, readjustments, or service work on the oven:

Perform a gas leak test.

Test for correct air supply, particularly to the burner blower.

Test for proper combustion and gas supply.

Check that the ventilation system is in operation.

WARNING

Keep the appliance area free and clear of combustibles.

WARNING

The oven must be installed on an even (level) non-flammable flooring and any adjacent walls must be non-

flammable. Recommended minimum clearances are specified in the Description section of this Manual.

WARNING

Do not obstruct the flow of combustion and ventilation air to and from your oven. There must be no

obstructions around or underneath the oven. Constructional changes to the area where the oven is

installed shall not affect the air supply to the oven.

NOTE

There must be adequate clearance between the oven and combustible construction. Clearance

must also be provided for servicing and for proper operation.

NOTE

An electrical wiring diagram for the oven is located inside the machinery compartment.

NOTE

All aspects of the oven installation, including placement, utility connections, and ventilation requirements,

must conform with any applicable local, national, or international codes. These codes supercede the require-

ments and guidelines provided in this manual.

5

Page 6

SECTION 2 - INSTALLATION

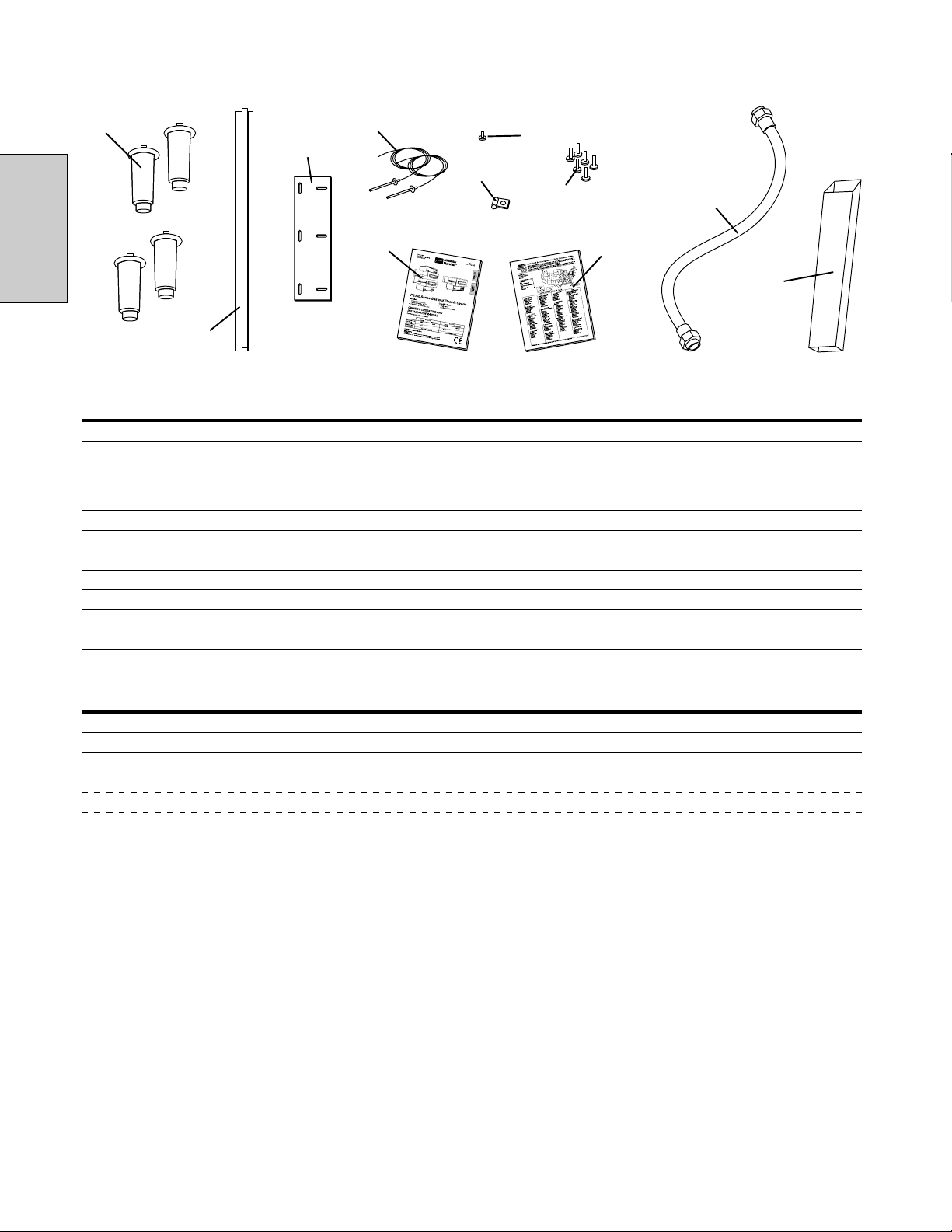

I. INSTALLATION KIT

1

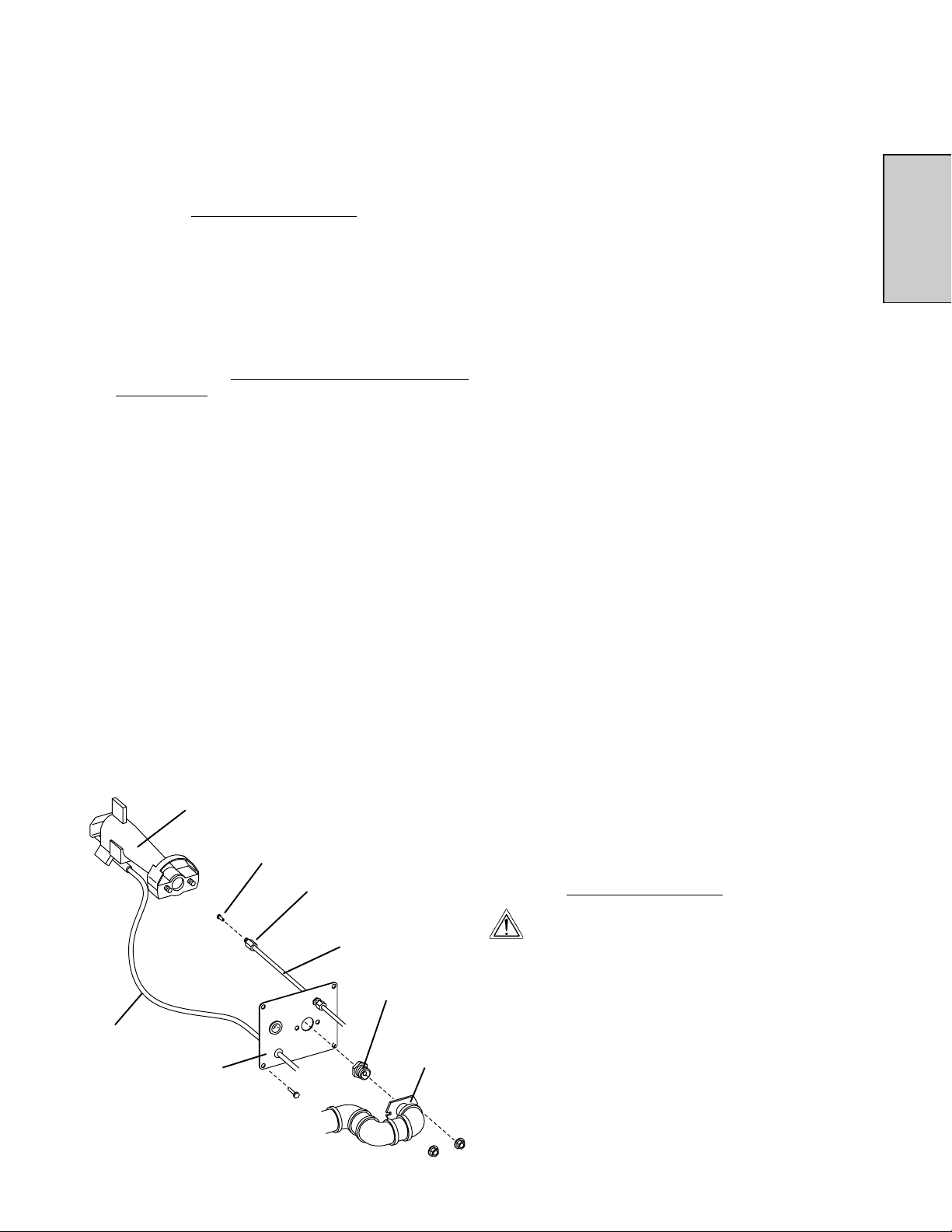

Fig. 2-1 - Installation Kit

4

3

5

ENGLISH

8

6

7

10

9

2

A. Installation kit components (one kit required per cavity)

Item Description Part Number Lower Oven w/o Top Lower Oven w/Top Upper Oven

1 Legs, adjustable 22450-0028 4 4 --

2a Conveyor End Stop - PS360/360S

2b Conveyor End Stop - PS360WB (Single or Split Belt) 36526 1 1 1

Single Belt 35000-1103 1 1 1

Split Belt 35509 2 2 2

3 Attachment Plate, upper oven 35122-0049 -- -- 2

4 Thermocouple 33812-1 2 2 2

5 Screw, #10-32 x 3/8" 21256-0008 2 2 2

6 Cable Clamp 27276-0001 1 1 1

7 Screw, #2PT 10-16 x 3/4" HWH 21292-0001 2 2 14

8 Owner's Operating and Installation Manual 46486 1 1 1

9 Authorized Service Agency Listing 1002040 1 1 1

11

B. Additional installation kit components for gas ovens

Item Description Part Number Lower Oven w/o Top Lower Oven w/Top Upper Oven

5 Screw, #10-32 x 3/8" 21256-0008 1 1 1

7 Screw, #2PT 10-16 x 3/4" HWH 21292-0001 2 2 2

10 Gas hose, flexible 22361-0001 1 1 1

11a Flue vent, 14" (356mm) 30773 -- 1 -11b Flue vent, 29-1/2" (749mm) 30759 -- -- 1

11c Flue vent, 50" (1270mm) 30758 1 -- --

6

Page 7

II. VENTILATION SYSTEM

IMPORTANT

Where national or local codes require the

installation of fire suppression equip-

ment or other supplementary equipment,

DO NOT mount the equipment directly to

the oven.

MOUNTING SUCH EQUIPMENT ON

THE OVEN MAY:

VOID AGENCY CERTIFICATIONS

RESTRICT SERVICE ACCESS

LEAD TO INCREASED SERVICE

EXPENSES FOR THE OWNER

A. Requirements

CAUTION

CAUTION

Gas oven installations

ventilation system with electrical exhaust air sensing control.

A mechanically driven ventilation system is

RECOMMENDED for electric oven installations.

PROPER VENTILATION OF THE OVEN IS THE

RESPONSIBILITY OF THE OWNER.

REQUIRE a mechanically driven

STRONGLY

SECTION 2 - INSTALLATION

B. Recommendations

NOTE THAT THE HOOD DIMENSIONS SHOWN IN FIGURE 2

RECOMMENDATIONS ONLY. LOCAL, NATIONAL, AND

ARE

INTERNATIONAL CODES MUST BE FOLLOWED WHEN

INSTALLING THE VENTILATION SYSTEM. ANY APPLICABLE

LOCAL AND NATIONAL CODES SUPERSEDE THE

RECOMMENDATIONS SHOWN IN THIS MANUAL.

The rate of air flow exhausted through the ventilation system

may vary depending on the oven configuration and hood design.

Consult the hood manufacturer or ventilation engineer for these

specifications.

To avoid a negative pressure condition in the kitchen area,

return air must be brought back to replenish the air that was

exhausted. A negative pressure in the kitchen can cause heatrelated problems to the oven components as if there were no

ventilation at all. The best method of supplying return air is

through the heating, ventilation and air conditioning (HVAC)

system. Through the HVAC system, the air can be temperaturecontrolled for summer and winter. Return air can also be

brought in directly from outside the building, but detrimental

effects can result from extreme seasonal hot and cold

temperatures from the outdoors.

NOTE: Return air from the mechanically driven system

blow at the opening of the baking chamber. Poor oven baking

performance will result.

C. Other ventilation concerns

Special locations, conditions, or problems may require the

services of a ventilation engineer or specialist.

Inadequate ventilation can inhibit oven performance.

It is recommended that the ventilation system and duct

work be checked at prevailing intervals as specified by the

hood manufacturer and/or HVAC engineer or specialist.

must not

ENGLISH

458mm

Fig. 2-2 - Ventilation System

458mm

7

51mm

minimum

76mm

305mm

Page 8

SECTION 2 - INSTALLATION

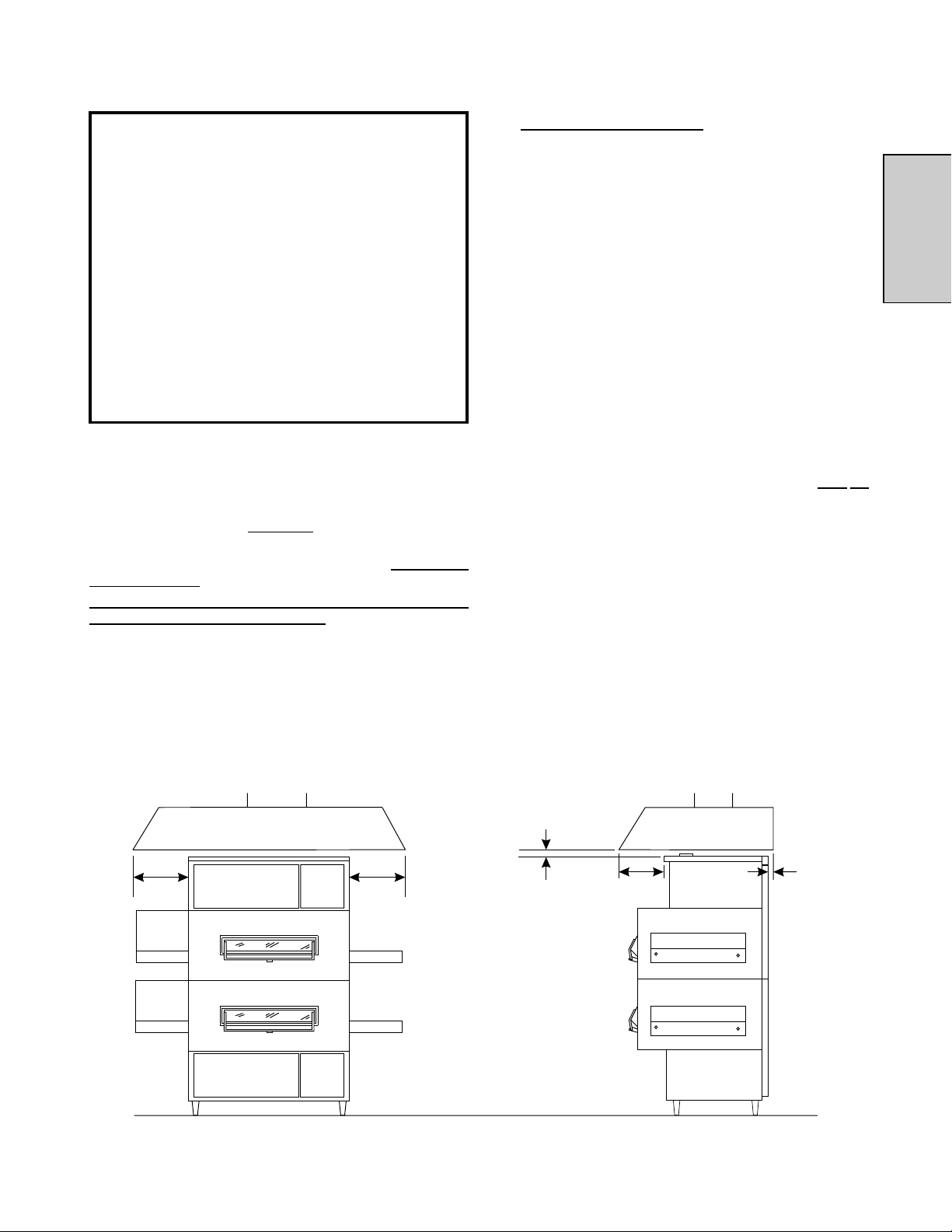

III. ASSEMBLY

A. Caster Removal

After moving the ovens in to the installation location, remove the

casters attached to each oven cavity. These casters are provided

for pre-installation movement ONLY.

ENGLISH

B. Stacking

If the installation will include upper ovens mounted atop lower

ovens, stack the oven cavities.

C. Stands

If the installation includes ovens that are to be mounted on

stands, assemble the ovens to the stands at this time. An

exploded view of the stand is shown in Figure 2-3.

D. Flue Vent(s)

For gas ovens, attach one flue vent to the rear wall of each oven

cavity. Use one #10-16 x 3/8" and two #10-32 x 3/4" screws for

each flue vent. These screws are provided in the Installation Kit.

Figure 2-3 - Exploded View, Oven Stand

Attachment

plates inc. w/

upper oven

installation kit

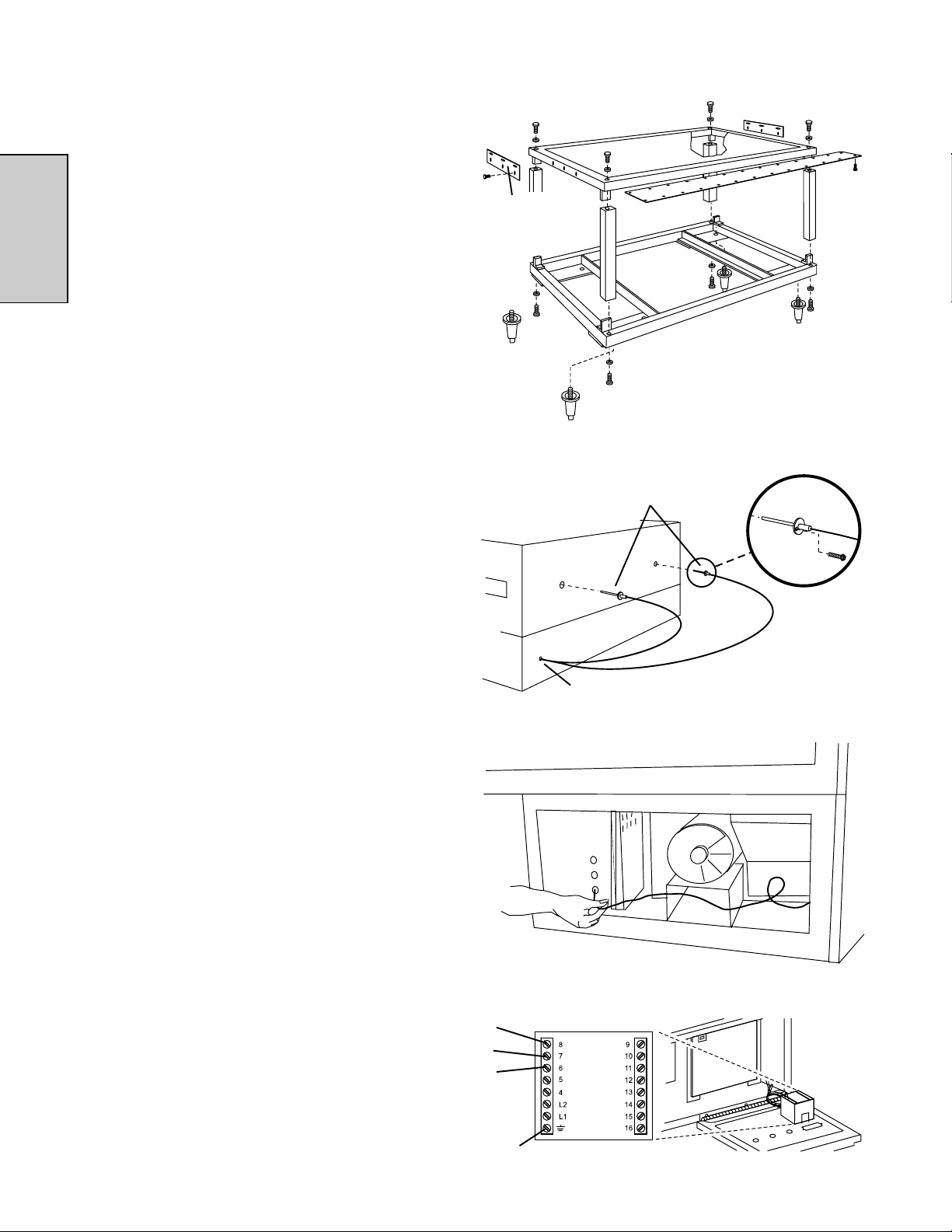

IV. THERMOCOUPLE INSTALLATION

1. Install one thermocouple sensing bulb into each of the two

holes in the rear panel of the oven, as shown in Figure 2-4.

Fasten each thermocouple in place using one of the #1032 x 3/8" screws supplied in the Installation Kit.

2. Thread BOTH sets of thermocouple leads through the

grommet and into the machinery compartment, as shown

in Figure 2-4.

3. Remove the right-side access panel of the machinery

compartment.

4. Thread the thermocouple leads through the side of the

machinery compartment as shown in Figure 2-5, and into

the electrical box (at the right-front of the machinery compartment).

5. Connect BOTH sets of thermocouple leads to the temperature controller as shown in Figure 2-6. Note that the two

thermocouples are now tied together at the temperature

controller.

6. Replace the right-side panel of the machinery compartment.

7. Repeat Steps 1-6 for any other oven cavities in the installation.

Figure 2-4 - Thermocouple Installation Locations

Thermocouples

Grommet-protected hole

Figure 2-5 - Placing the Thermocouple Leads

8=White=Positive

7=Red=Negative

R=No Connection

Ground=Shielded cable

8

Figure 2-6 - Thermocouple Lead Connections

Page 9

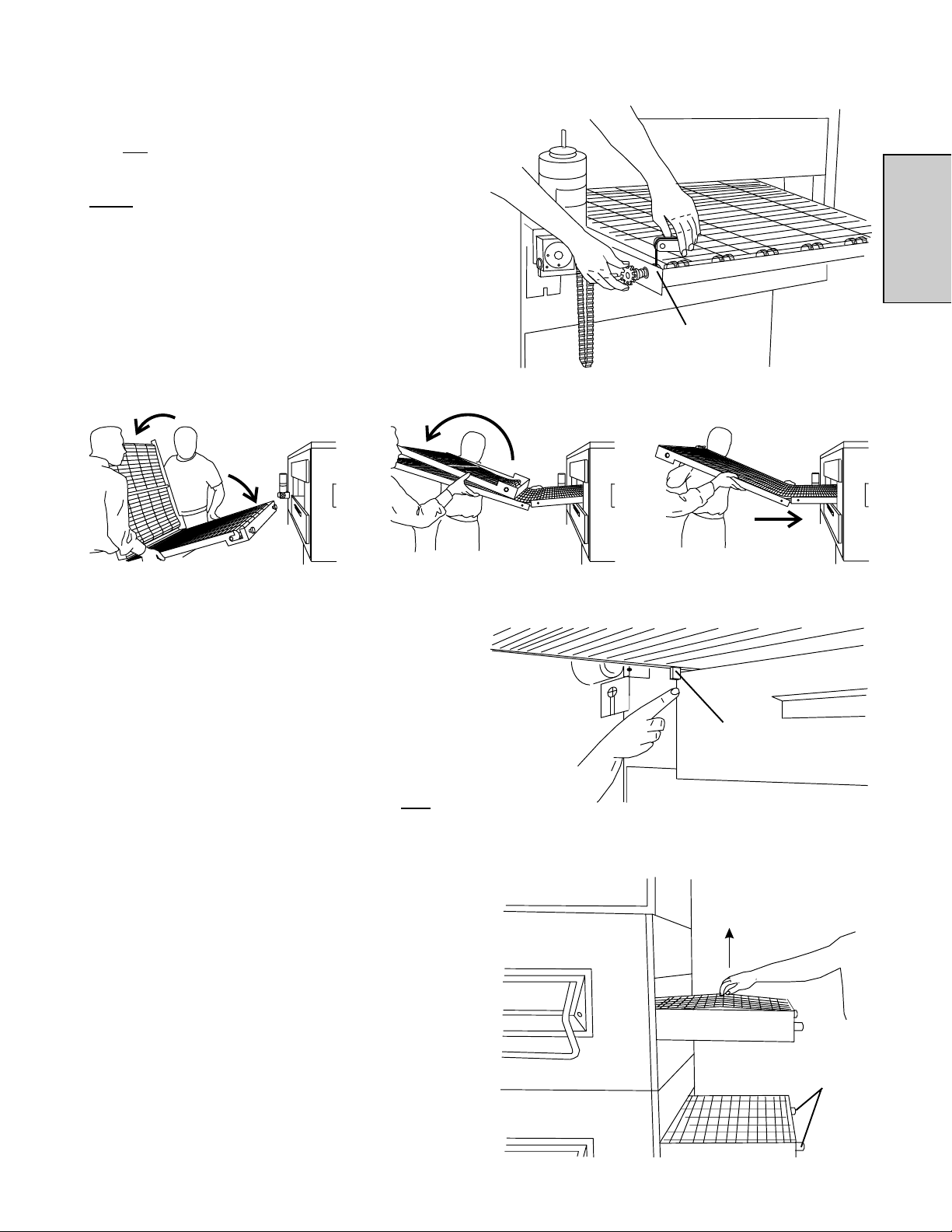

V. CONVEYOR INSTALLATION

NOTE

Split belt conveyors can only be installed from the end of the

with the drive motor.

oven

Single-belt conveyor assemblies may be inserted into either

end of the oven. If it is to be installed from the end of the oven

without the drive motor, the drive sprocket assembly must be

removed.

To remove the drive sprocket (if necessary), loosen the set

screw on the conveyor collar as shown in Figure 2-7. Then, pull

the sprocket assembly straight out.

1. Lift the conveyor and position it in the oven as shown in

Figure 2-8.

Figure 2-8 - Inserting the Conveyor

SECTION 2 - INSTALLATION

Figure 2-7 - Removing the Conveyor Drive Sprocket

ENGLISH

Loosen conveyor collar

set screw, then pull shaft

straight out

2. Continue moving the conveyor into the oven until the frame

protrudes equally from each end of the oven (about 457mm).

3. Check that the retainers located on the underside of the

conveyor frame rest firmly against the lower end plug, as

shown in Figure 2-9.

NOTE:

Each oven has retainer clips on the bottom of the conveyor

frame, as shown in Figure 2-9. The clips are only located

on the left (drive) side of the frame.

4. When the conveyor is positioned properly, check for freedom of movement of the conveyor belt by pulling it for about

60 to 90 cm with your fingers. The conveyor

must move

freely.

5. If the drive sprocket was removed when installing the

conveyor, replace it at this time.

6. Install the drive chain between the conveyor drive sprocket

and the motor sprocket. To install the chain, it will be

necessary to lift the drive end of the conveyor slightly. The

drive motor and sprocket are shown in Figure 2-7.

7. Install the conveyor drive motor cover and tighten its hanger

screw (on the rear wall of the oven).

8. Check the tension of the conveyor belt as shown in Figure

2-10. The belt should lift between 75-100mm. DO NOT

OVERTIGHTEN THE CONVEYOR BELT.

NOTE:

If necessary, the belt tension can be adjusted by turning the

conveyor adjustment screws, located at the idler (right) end

of the conveyor. See Figure 2-10.

Figure 2-9 - Conveyor retainers

Retainer clip

Figure 2-10 - Checking the conveyor tension

75-100mm

vertical

deflection

Conveyor

tension

adjustment

screws (idler

end only)

9

Page 10

SECTION 2 - INSTALLATION

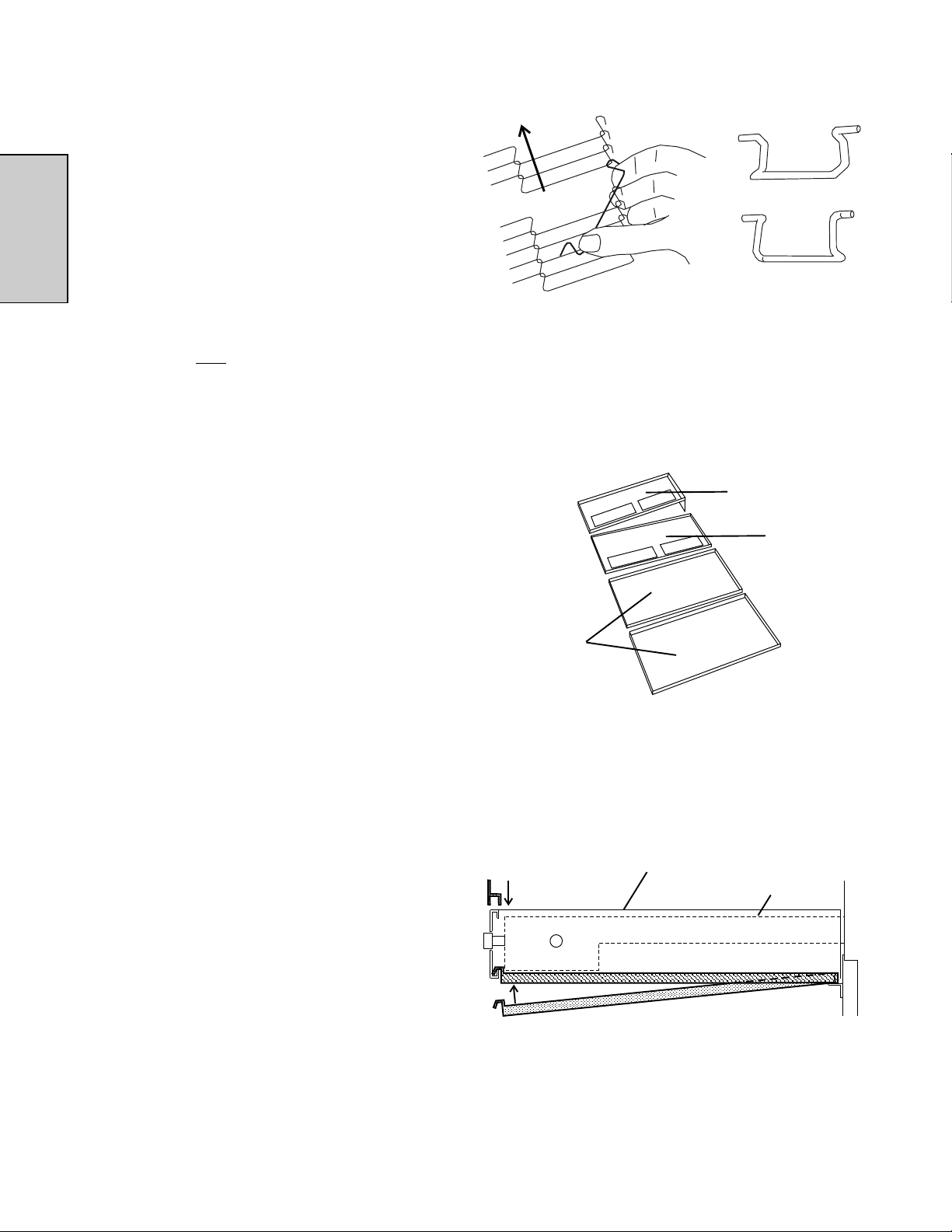

9. If necessary, links can be added to or removed from the

conveyor belt to achieve the correct deflection of 75-100mm.

If links must be removed from the belt, it can be reattached

to the conveyor as follows:

a. The conveyor belt links must be oriented as shown in

ENGLISH

Figure 2-11.

b. The smooth side of the conveyor belt must face UP.

c. Connect the inside master links. Check that the links

are oriented as shown in Figure 2-11.

d. Connect the outside master links. Note that the

outside master links have right and left sides. The

right-side master link has an open hook facing you, as

shown in Figure 2-11.

e. Check for freedom of movement of the conveyor belt by

pulling it for about 60 to 90 cm with your fingers. The

conveyor must move freely.

f. Return to Step 8, above, to re-check the belt tension.

Figure 2-11 - Conveyor and Master Link Orientation

Direction

of travel

Outside master link

orientation

CORRECT

master link

position

Incorrect

master link

position

Inside master link

orientation

VI. FINAL ASSEMBLY

1. Assemble the end plugs and motor housing onto the oven.

2. Slide the conveyor extensions over the ends of the conveyor

frame. Be sure that the extension with the drive sprocket

opening is placed on the drive end.

3. Refer to Figure 2-12 for the correct location of each crumb

tray. Then, install the crumb trays underneath the conveyor

as shown in Figure 2-13. First, place the inside edge of the

tray onto the bracket attached to the end plug. Then, swing

the outside edge of the tray up and into place.

4. Press the end stop down over the edge of the conveyor

extension at the exit end of the oven. See Figure 2-13.

5. Adjust the bottom section of the legs so that the oven is

level.

Figure 2-12 - Crumb tray positions

Upper Oven

(Drive End)

Upper Oven

(Idler End)

Lower Oven

Figure 2-13 - Crumb trays, extensions, and end stop

End

stop

Conveyor extension

Conveyor frame

10

Crumb tray

Page 11

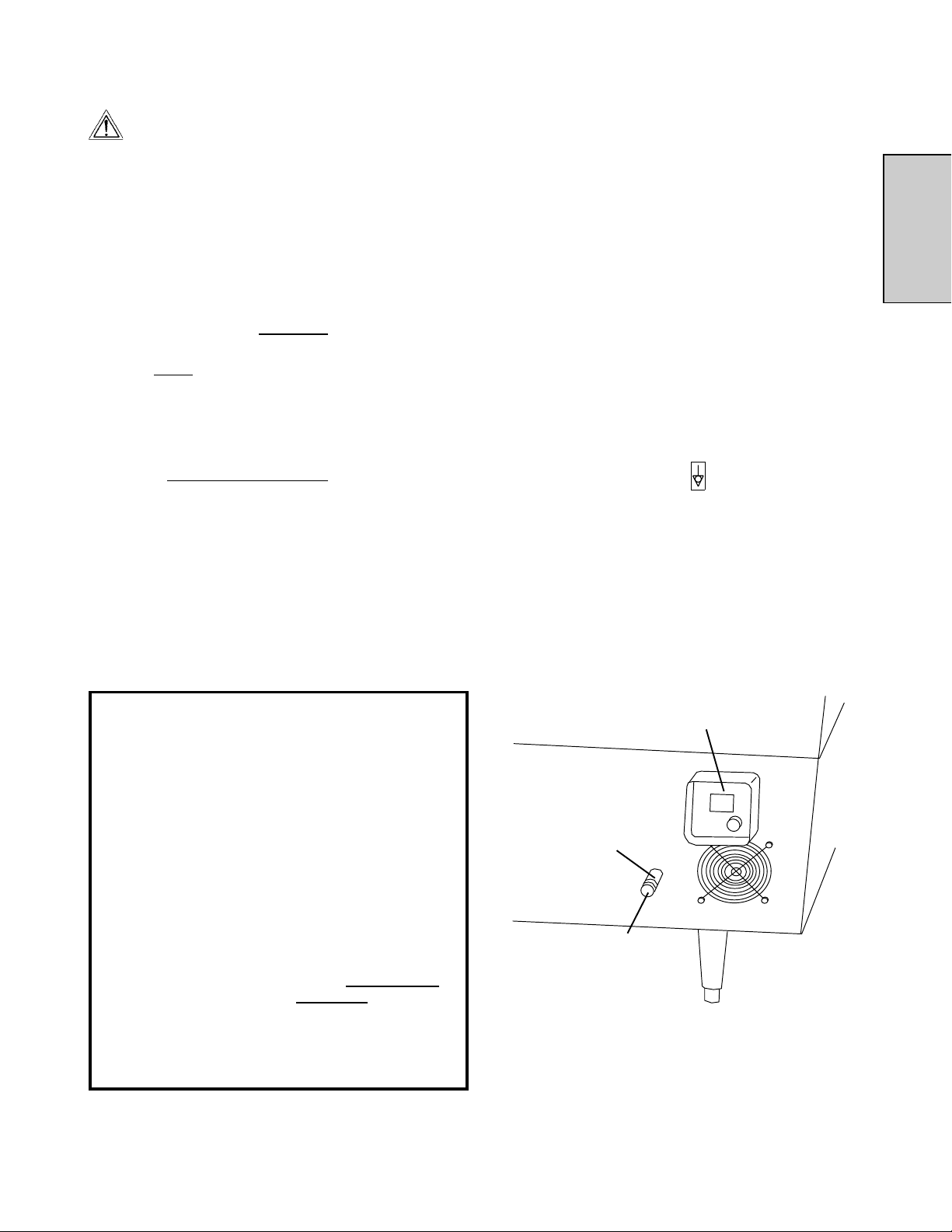

VII. ELECTRICAL SUPPLY

WARNING

Authorized supplier personnel normally accomplish

the connections for the ventilation system, electric supply,

and gas supply, as arranged by the customer. Following

these connections, the factory-authorized installer can

perform the initial startup of the oven.

NOTE: All aspects of the electrical supply connection must

comply with current IEC/CEE requirements and with all

applicable local, national, and international codes.

Check the oven serial plate before making any electric supply

connections. Electric supply connections must agree with data

on the oven serial plate. The location of the serial plate is shown

in Figure 1-1 (in Section 1,

A fused disconnect switch or a main circuit breaker (customer

furnished)

MUST be installed in the electric supply line for each

oven cavity. The circuit breaker/disconnect must have 3mm

contact gaps breaking all poles of the supply. It is recommended

that this circuit breaker/disconnect have lockout/tagout capability.

The supply conductors are to be 90°C-rated copper wiring.

Additional wiring information is shown on the wiring diagrams

in Section 5,

Electrical Wiring Diagrams and inside the machin-

ery compartment of the oven.

The oven requires a ground connection to the oven ground

screw located in the electrical junction box. (The box is shown

in Figure 2-14.) The ground connection must comply with

current IEC/CEE requirements and with all applicable local,

national, and international codes. If necessary, have the

electrician supply the ground wire. Do NOT use the wiring

conduit or other piping for ground connections!

Description).

SECTION 2 - INSTALLATION

A. Additional Information - Gas Ovens

All electric supply connections are made via the electrical

junction box on the rear of the oven, shown in Figure 2-14. The

power lines then connect to the oven circuits through safety

switches located inside the machinery compartment and each

blower motor compartment. These switches interrupt electric

power to the oven when the Machinery Compartment Access

Panel is opened, OR when either of the blower or rear shrouds

is removed.

B. Additional Information - Electric Ovens

A cutout in the back wall of the machinery compartment provides

access to the electrical supply connections. See Figure 2-14.

The actual wiring connections are made at the electrical junction

box.

C. Connection

Refer to the wiring diagram inside the machinery compartment,

or in Section 5 of this Manual, to determine the correct

connections for the electrical supply lines. Connect the supply

as indicated on the wiring diagram.

If required by national or local codes, connect an equipotential

ground wire to the lug next to the

symbol. The equipotential

ground connection must meet all applicable national and local code requirements.

ENGLISH

VIII. GAS SUPPLY

CAUTION

DURING PRESSURE TESTING NOTE ONE OF THE FOLLOWING:

1. The oven and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressure in

excess of 3.45 kPa.

2. The oven must be isolated from the gas supply piping

system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressure equal to or less than 3.45 kPa.

3. If incoming pressure is over 50mbar, a separate regulator MUST be installed in the line BEFORE the individual

shutoff valve for the oven.

WARNING: To prevent damage to the control valve regulator during initial turn- on of gas, it is

open the manual shutoff valve

very slowly.

After the initial gas turn-on, the manual shutoff valve must

remain open except during pressure testing as outlined

in the above steps or when necessary during service

maintenance.

very important to

Figure 2-14 - Utility Connection Locations

Electrical

Junction Box

Gas ovens:

19mm pipe for

gas utility connection

Electric ovens:

Cutout for electrical

connection

11

Page 12

SECTION 2 - INSTALLATION

A. Gas Utility Rough-In Recommendations

The following gas system specifications are STRONGLY

RECOMMENDED. Deviating from these recommendations

may affect the baking performance of the oven.

Gas Meter

ENGLISH

One or two oven cavities: 354

Three or four oven cavities: 566

l/sec

l/sec

meter

meter

Gas Line

DEDICATED LINE from the gas meter to the oven

50.8mm pipe for natural gas

38.1mm pipe for propane

Maximum length: 61m. Each 90° elbow equals 2.13m of

pipe.

B. Connection

WARNING

Some procedures in this section may require conversions, readjustments, or service on the oven's gas system.

Before performing these procedures, check that the main

gas supply valve and the circuit breaker/fused disconnect

are in the OFF ("O") position. After completing these procedures, perform a gas leak test before operating the oven.

CAUTION

The terms of the oven's warranty require all start-ups, conversions and service work to be performed by a Middleby Marshall

Authorized Service Agent. The installation, start-up and changes

required when changing from one gas type to another can be

performed ONLY by a certified professional.

NOTE: The gas supply connection should be according to

applicable ISO 228-1 or ISO 7-1 recommendations. All aspects

of the gas supply connection must comply with current IEC/CEE

requirements and with all applicable local, national, and international codes.

Check the ovens gas supply requirements before making the

gas utility connection. Gas supply requirements are listed on

the ovens serial plate.

Check the serial plate to determine the type of gas to be used

with the oven. Check that the gas type indicated matches the

local supply at the installation. If the gas type on the serial plate

does NOT match the local supply, directions for converting the

oven for use with other gases are described in

Preparation for

Use with Various Gases, in this section.

Refer to the instructions in the gas hose package (included in

the Installation Kit) before connecting the gas line. One gas line

connection method is shown in Figure 2-15; however,

compliance with the applicable standards and regulations is

mandatory.

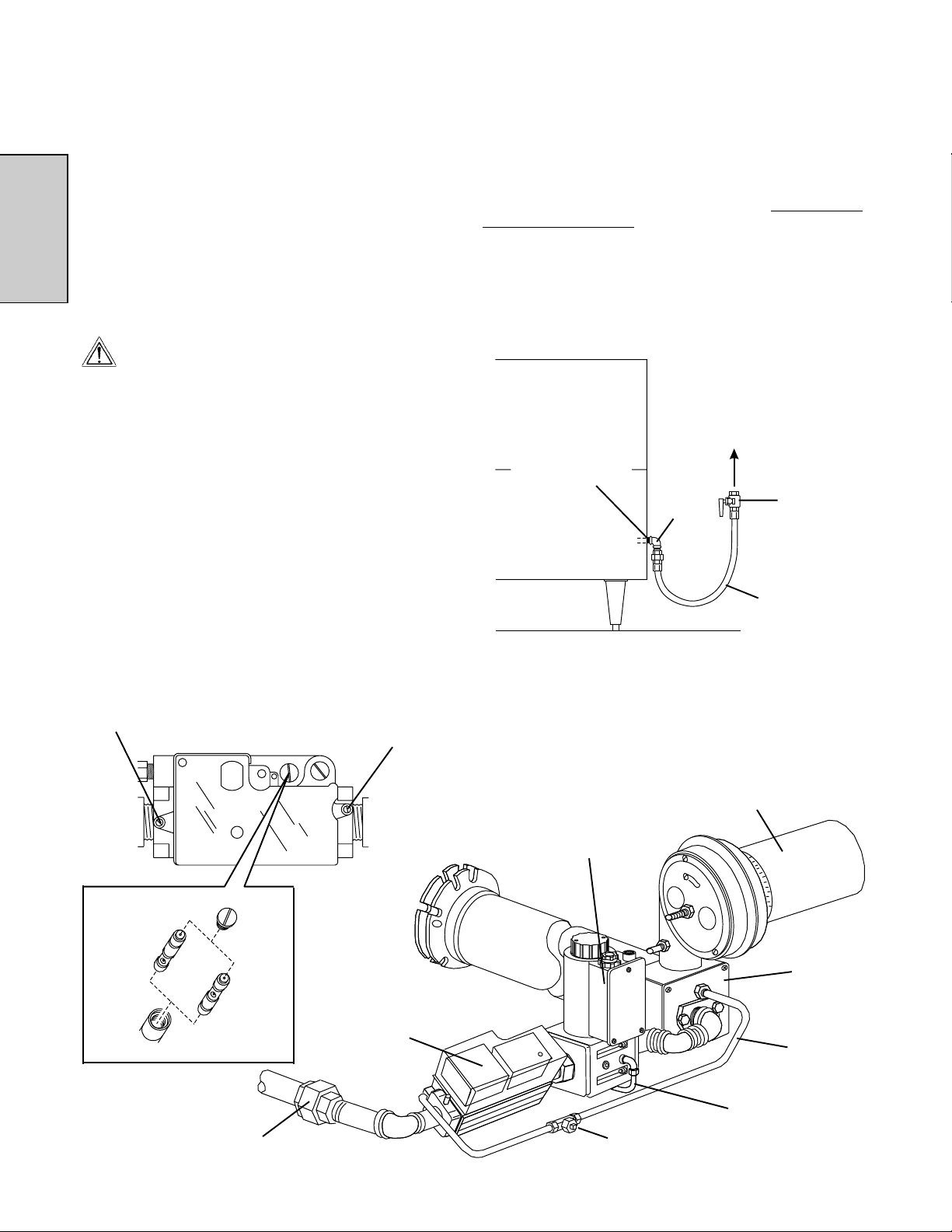

Figure 2-15 - Flexible Gas Hose Installation

To Gas

Supply Pipe

Appliance

Connection/Male

Nipple

90°

Elbow

Full-Flow Gas

Shutoff Valve

Flexible

Gas Hose

Supply (inlet)

pressure tap

Governor

disabled for

liquid

propane (LP)

operation

Multifunction Gas Valve

Governor

enabled for

natural gas

operation

Union

Figure 2-16 - Gas Burner and Piping Assembly

Orifice

(manifold)

pressure tap

Burner Blower

High Flame

Solenoid Valve

Gas Burner

Multifunction

Gas Valve

Pilot Line

Low Flame

Bypass Line

Pilot pressure tap

12

Page 13

C. Preparation for Use with Various Gases

Before proceeding to set up the oven for a specific gas, check

that the main gas supply valve and the circuit breaker/fused

disconnect are in the OFF ("O") position.

The main and pilot orifices must match the sizes shown in the

Gas Orifices and Pressure Specifications table, near the

beginning of this Section. If necessary, replace the orifices.

Refer to Part D,

Replacing the Gas Orifices.

The orifice (manifold) pressure should be adjusted to the value

shown in the Gas Orifices and Pressure Specifications table for

the specific gas type and location.

1. For Use with Natural Gas

The actual heat input to the oven must match the rated heat

input. The input to the burner can be determined using the

orifice (manifold) pressure data or by the volume supplied

using the gas meter. Both of these procedures are

described in Part F,

Adjusting the Orifice (Manifold) Pressure

and Heat Input.

If the measured input does not correspond with the rated

input (shown in the Gas Orifices and Pressure Specifications

table), check first that the correct orifices are installed. If the

orifices are correct, check and correct the supply and orifice

pressures to obtain the correct input based on the gas

meter reading.

2. For Use with Liquid Propane (LP) Gas

When using liquid gas, the converter in the multifunction

gas valve must be removed, and then replaced INVERTED

from its former position. See Figure 2-16. Inverting the

converter will disable the governor. This step is only

required if the supply pressure is below 50mbar.

Figure 2-17 - Replacing the Main and Pilot Orifices

Venturi

assembly

Pilot

orifice

Compression

nut

Pilot tube

Main

orifice

SECTION 2 - INSTALLATION

D. Replacing the Gas Orifices (if so required)

1. Replacing the Main Orifice

a. Check that the main gas supply valve and the circuit

breaker/fused disconnect are in the OFF ("O") position.

b. Open the union in the gas supply line. The union is

shown in Figure 2-16, on the previous page.

c. Refer to Figure 2-17. Unscrew the four hex screws that

hold the venturi mounting plate to the front of the

burner. Remove the gas train/venturi assembly from

the oven.

d. Remove the two 1/2" nuts that secure the gas train to

the venturi mounting plate.

e. Remove the main orifice using an 11/16" wrench.

f. Install the new orifice.

2. Replacing the Pilot Orifice

NOTE: All natural gases use the same size pilot orifice

(0,635mm), as do all liquid propane (LP) gases (0,381mm).

Because of this, it is not normally necessary to replace the

pilot orifice unless converting the oven from natural to

propane, or from propane to natural, operation.

a. Refer to Figure 2-17. Unscrew the pilot tube

compression nut and slide it out of the way. Pull the

tube from the fitting to expose the pilot orifice.

b. Remove the pilot orifice.

c. Slip the new pilot orifice into the pilot tube.

d. Push the pilot tube back into place until it bottoms, and

hold it in place. Slide the compression nut back into

place and engage the threads. Tighten the nut to a

snug fit with your fingers.

e. Gently tighten the nut one complete turn with a wrench.

DO NOT OVERTIGHTEN THE COMPRESSION NUT.

3. Replacing the Bypass (Low Flame) Orifice

a. Refer to Figure 2-16. Note the locations of the 1/2" hex

compression nuts that hold the bypass line in place.

Loosen the compression nuts using a 1/2" wrench.

b. Remove the bypass tube. Then, remove the bypass

orifice from the tube.

c. Slip the new orifice into the bypass tube.

d. Replace the tube onto its fittings on the solenoid valve.

While holding the tube in place, slide the compression

nuts back into place and engage the threads. Tighten

the nut to a snug fit with your fingers.

e. Gently tighten the nuts one complete turn with a wrench.

DO NOT OVERTIGHTEN THE COMPRESSION NUTS.

f. Replace the gas train and venturi by following Steps a-

Replacing the Main Orifice, above, in reverse order.

d in

WARNING

After completing these procedures, perform a gas

leak test before operating the oven.

ENGLISH

Ignition

sensor

wire

Venturi

mounting

plate

Main orifice

holder (attached

to gas train)

13

Page 14

SECTION 2 - INSTALLATION

E. Checking the Gas Supply (Inlet) Pressure

1. Remove the supply (inlet) pressure cap screw from the

multifunction gas valve. Attach a manometer to the stud.

2. Depress the machinery compartment safety switch to

ENGLISH

allow the oven to operate.

3. Open the main gas supply valve. Switch the circuit breaker/

fused disconnect to the ON ("I") position.

4. Start the oven and adjust the temperature controller to the

maximum setting (288°C).

5. Measure the supply (inlet) pressure.

6. Switch the oven off. Close the main gas supply valve, and

switch the circuit breaker/fused disconnect to the OFF ("O")

position. Remove the manometer, and replace the cap

screw onto the multifunction gas valve.

7. Compare the measured supply (inlet) pressure to the

nominal pressures shown in the Gas Orifices and Pressure

Specifications table.

If the supply pressure is lower or higher than the nominal

pressure, the reason should be investigated and the gas

supplier contacted.

For natural gas ovens, if the measured supply pressure is lower

than 17mbar, or higher than 25mbar, contact the gas supplier.

DO NOT OPERATE THE OVEN or adjust the oven controls.

F. Adjusting the Orifice (Manifold) Pressure and Heat Input

To use the orifice pressure method, you must know the specific

gas type and quality used. If using the orifice pressure method,

you should double-check the input using the volumetric method.

To use the volumetric method, you must know the heat value

(HuB) of the gas used. This information is available from your

gas supplier.

During these measurements, do not operate any other

appliances that use the same gas meter as the oven.

1. Orifice (Manifold) Pressure Method

a. Check that the main gas supply valve and the circuit

breaker/fused disconnect are in the OFF ("O") position.

b. Remove the regulated (manifold) pressure cap screw

from the multifunction gas valve. Attach a manometer

to the stud.

c. Remove the cap screw from the pressure adjustment

screw (governor) on the multifunction gas valve.

d. Depress the machinery compartment safety switch to

allow the oven to operate.

e. Open the main gas supply valve. Switch the circuit

breaker/fused disconnect to the ON ("I") position.

f. Start the oven and adjust the temperature controller to

the maximum setting (288°C).

g. Adjust the pressure adjustment screw as necessary

to match the correct pressure for the oven's specific

gas type. Refer to the Gas Orifices and Pressure

Specifications table. Turning the adjustment screw

clockwise increases the flow, while turning it

counterclockwise reduces the flow.

h. Switch the oven off. Close the main gas supply valve,

and switch the circuit breaker/fused disconnect to the

OFF ("O") position. Remove the manometer, and

replace the cap screws onto the multifunction gas

valve.

2. Volumetric Method

a. Determine the time of 0.1m

3

(100 liters) of gas usage

as follows.

Consumption (m

3

/hr.) =

NB (Rated input in kW)

HuB (Heat [Calorific] value

of gas in kW/m3)

Time (in minutes) of

0.1m3 of gas usage

=

6

Consumption

b. Check that the main gas supply valve and the circuit

breaker/fused disconnect are in the OFF ("O") position.

c. Remove the cap screw from the pressure adjustment

screw (governor) on the multifunction gas valve.

d. Depress the machinery compartment safety switch to

allow the oven to operate.

e. Open the main gas supply valve. Switch the circuit

breaker/fused disconnect to the ON ("I") position.

f. Start the oven and adjust the temperature controller to

the maximum setting (288°C).

g. Adjust the pressure adjustment screw as necessary

to match the calculated volume using the time (in

minutes) of 0.1m

3

of gas usage. Turning the

adjustment screw clockwise increases the flow, while

turning it counterclockwise reduces the flow.

h. Record the reading obtained from the gas meter and

calculate the obtained gas flow. Compare this value

to the information in the Gas Orifices and Pressure

Specifications table.

i. Switch the oven off. Close the main gas supply valve,

and switch the circuit breaker/fused disconnect to the

OFF ("O") position. Replace the cap screw onto the

multifunction gas valve.

14

Page 15

SECTION 3 - OPERATION

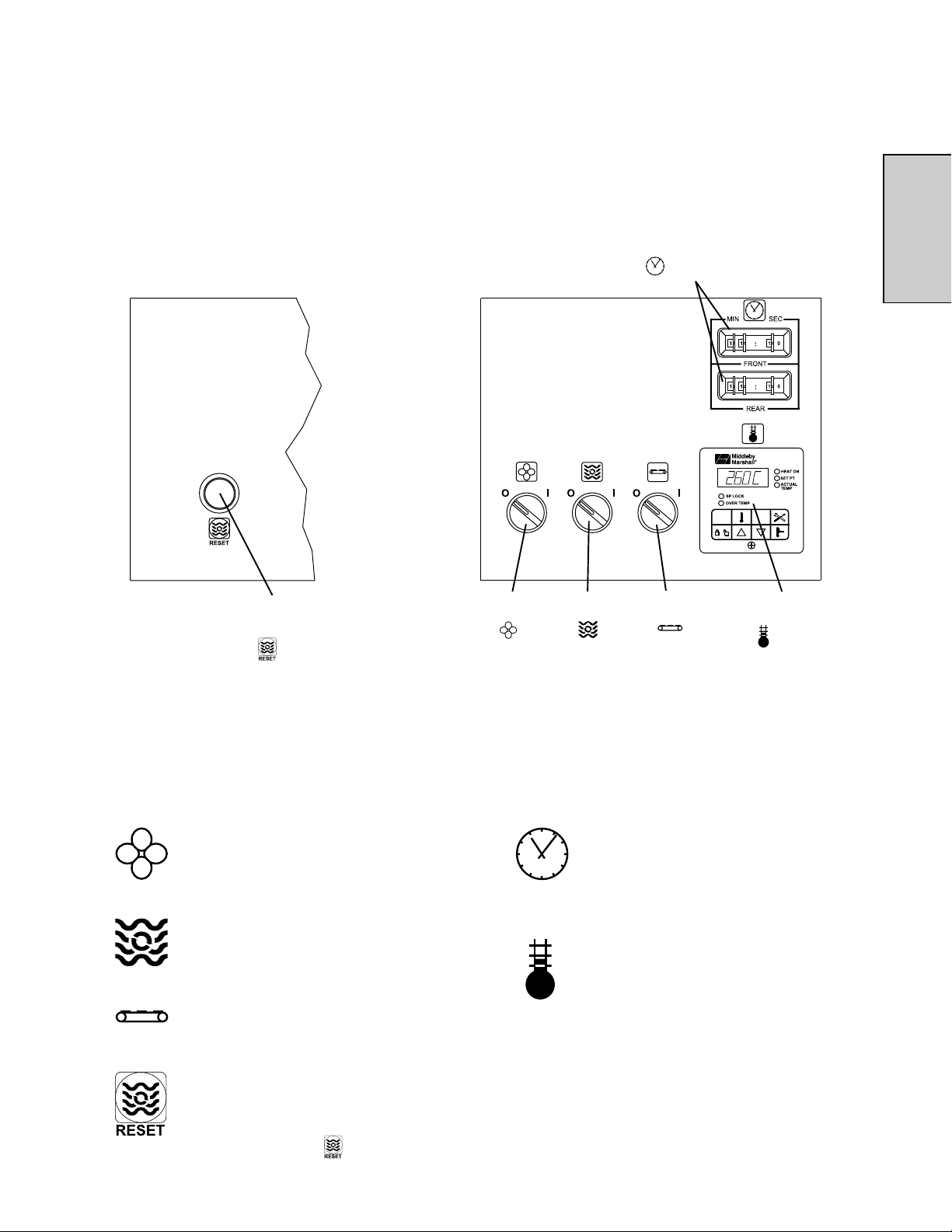

I. LOCATION AND DESCRIPTION OF CONTROLS

Fig. 3-1 - Control Panel

E.

Conveyor Speed

") controller(s)

("

ENGLISH

D.

"RESET"

) switch

(

GAS OVENS ONLY

A.

"BLOWER" Switch: Turns the blowers and

A.

"BLOWER"

")

("

switch

E.

cooling fans on and off. The HEAT Switch has

no effect unless the BLOWER Switch is in the

ON position.

B.

"HEAT"

("

switch

")

C.

"CONVEYOR"

("

switch

")

Conveyor Speed Controller: Adjusts and displays the bake time. Single-belt ovens have one

controller. Split belt ovens have one controller

for each conveyor belt, labeled "FRONT" and

F.

Digital Temperature

") controller

("

"BACK."

B.

"HEAT" Switch: Allows the burner or heating

elements, as appropriate for the oven model, to

activate. Activation is determined by the settings on the Digital Temperature Controller.

F.

Digital Temperature Controller: Continuously

monitors the oven temperature. Settings on the

Digital Temperture Controller control the activation of the burner or heating elements.

C.

"CONVEYOR" Switch: Turns the conveyor drive

motor on and off.

NOT SHOWN:

D.

"RESET" Switch: Gas ovens only. Illuminates

if the gas burner does not light. The switch can

be pressed repeatedly to attempt to light the

burner. If the burner does not light within 15

minutes, the "RESET" (

) switch is locked out.

G. Machinery Compartment Access Panel Safety Switch:

Disconnects electrical power to the controls and the blowers when the machinery compartment access panel is

opened. The panel should only be opened by authorized

service personnel.

15

Page 16

SECTION 3 - OPERATION

II. NORMAL OPERATION - STEP-BY-STEP

A. DAILY STARTUP PROCEDURE

1. Check that the circuit breaker/fused disconnect is in the on

ENGLISH

position. Check that the window is closed.

2. Turn the "BLOWER" ( )

switch to the ON ("I")

position.

3. Turn the "CONVEYOR"

) switch to the ON

(

("I") position.

4. If necessary, adjust the

conveyor speed setting

by pressing the

pushbuttons on the conveyor speed controller to

change the displayed

bake time.

Some ovens may be

equipped with a

thumbwheel speed controller. For these ovens,

turn the three

thumbwheels to change

the displayed bake time.

5. Adjust the temperature

controller to a desired set

temperature, if necessary.

Press the Set Point

and Unlock keys at

the same time. Wait

for the "SET PT" light

to turn on.

Press the Up Arrow

and Down Arrow

Keys as necessary

to adjust the setpoint.

or

+

or

mins secs

thumbwheels

or

wait

for

7. (Gas ovens only) If the "RESET" (

nates, the gas burner did

not light. Press the "RESET" (

edly if necessary) to attempt to light the burner.

NOTE: If the burner does not light within 15 minutes, the

oven enters a safety lockout mode that disables the "RESET" (

"BLOWER" (

"OFF" ("O") position.

Then, repeat the Daily Startup procedure.

7. Wait for the oven to heat to the setpoint temperature. Higher

setpoint temperatures will require a longer wait. The oven

can reach a temperature of 232°C in approximately 5

minutes.

8. (Optional) Press the Temperature ( ) key to show

the Actual Temperature

in the display, and wait

for the "ACTUAL TEMP"

light to turn on. This allows you to monitor the

oven temperature as it

rises to the setpoint.

9. Allow the oven to preheat for 10 minutes after it has reached

the set point temperature.

B. DAILY SHUTDOWN PROCEDURE

1. Turn the "HEAT" (

"BLOWER" (

ches to the "OFF" ("O")

position. Note that the

blowers will remain in operation until the oven has

cooled to below 93°C.

2. Make certain that there

are no products left on

the conveyor inside the

oven. Turn the "CONVEYOR" (

the "OFF" ("O") position.

) switch illumi-

) switch (repeat-

) switch. If this occurs, turn the "HEAT" ( ),

), and "CONVEYOR" ( ) switches to the

Wait for AT LEAST FIVE MINUTES.

wait

for

) and

) swit-

+

) switch to

6. Turn the "HEAT" ( )

switch to the "ON" ("I")

position, and wait for the

"HEAT ON" light to turn

on.

wait

for

3. Open the window to allow the oven to cool faster.

4. After the oven has cooled and the blowers have turned off,

switch the circuit breaker/fused disconnect to the off position.

CAUTION

In case of power failure, turn all switches to the OFF ("O")

position, open the oven window, and remove the product.

After the power has been restored, perform the normal

startup procedure.

On gas ovens, the burner will not operate and gas will not

flow through the burner without electric power. No

attempt should be made to operate the oven during a

power failure.

16

Page 17

III. QUICK REFERENCE: DIGITAL TEMPERATURE CONTROLLER

SECTION 3 - OPERATION

"SP LOCK" Light

Lights when the set

point is locked out

from changes. This

setting can only be

changed by service

personnel.

OVERTEMP Light

Lights when the oven

temperature is greater

than 343°C. Refer to

Quick Reference:

Troubleshooting in

this section.

Temperature Key

Press this key once to

view the Actual Temperature in the Display.

Display

Shows the Set Point or

the Actual Temperature in degrees Fahrenheit (F) or Celsius

(C).

"HEAT ON" Light

Lights when the

burner or heating elements, as appropriate

for the oven model,

are in operation.

ENGLISH

"SET PT" (setpoint)

Light

Lights when the set

point is shown in the

display.

"ACTUAL TEMP"

Light

Lights when the

Actual Temperature is shown in

the display.

Service Key

For use by service personnel

only.

Unlock Key

Press this key together

with the Set Point Key

to allow the Set Point

to be changed.

Changes can only be

made for 60 seconds.

Up Arrow and Down Arrow

Keys

Press these keys to adjust

the Set Point up or down. If

the Set Point will not

change, refer to

Key and Unlock Key in this

section.

Set Point

17

Set Point Key

Press this key together

with the Unlock Key to

allow the Set Point to

be changed.

Changes can only be

made for 60 seconds.

Page 18

SECTION 3 - OPERATION

IV. QUICK REFERENCE: TROUBLESHOOTING

SYMPTOM PROBLEM SOLUTION

ENGLISH

light is lit, food product is

undercooked

Oven will not

turn on at all

"RESET" (

illuminated, oven will not

(gas ovens only)

appears in display,

oven is not heating

heat

) switch is

The oven temperature exceeded 343°C, and the

burner or heating elements

were automatically shut

down.

Electrical power may not be

reaching the oven, or the

controls may be set incorrectly.

The gas burner did not light

within 90 seconds of turning the "HEAT" (

to the ON ("I") position.

The oven did not reach

93°C within 15 minutes of

startup, and the oven has

stopped heating.

) Switch

Follow the procedures under

this section to shut down the oven. Contact your Middleby

Marshall Authorized Service Agent to determine and correct the

cause of the condition to prevent damage to the oven.

Check that the circuit breaker/fused disconnect is turned on.

Check that the "BLOWER"

position. The burner cannot engage until the blowers are in

operation.

Press the "RESET" (

attempt to light the burner.

If the burner does not light within 15 minutes, the oven will enter

a safety lockout mode that disables the "RESET" (

If this occurs, turn the "HEAT" (

"CONVEYOR" (

for AT LEAST FIVE MINUTES before restarting the oven. Then,

repeat the Daily Startup procedure.

Turn the "HEAT" (

)switches to the "OFF" ("O") position.

(

Wait for AT LEAST FIVE MINUTES before restarting the oven.

Repeat the Daily Startup procedure.

)switches to the "OFF" ("O") position. Wait

), "BLOWER" ( ), and "CONVEYOR"

Daily Shutdown Procedures in

( ) Switch is in the ON ("I")

) switch (repeatedly if necessary) to

) switch.

), "BLOWER" ( ), and

Oven will not heat

Oven is operating, but

little or no air is blowing

from air fingers

Conveyor moves with a

jerky motion, or will not

move at all

Food products are

overcooked or

undercooked.

Controls may be set incorrectly.

Air fingers may have been

reassembled incorrectly

after cleaning.

Conveyor may be jammed

on an object in the oven, or

conveyor belt or drive chain

tension may be incorrect.

Controls may be set incorrectly.

Check that the Set Point is correctly set.

Check that both the "BLOWER"

are in the ON ("I") position.

If the oven still will not heat,turn the "HEAT" (

( ), and "CONVEYOR" ( )switches to the "OFF" ("O")

position.

Wait for AT LEAST FIVE MINUTES before restarting the oven.

Repeat the Daily Startup procedure. Check that the Set Point

is above 93°C.

Turn the oven off, and allow it to cool. Disconnect electrical

power to the oven.

Refer to Section 4,

bling the air fingers.

Turn the oven off, and allow it to cool. Disconnect electrical

power to the oven.

Check if the conveyor is blocked by an object inside the oven.

Refer to Section 4,

the conveyor and drive chain tension.

Check that the set temperature and bake time settings are

correct.

Maintenance, for instructions on reassem-

Maintenance, for instructions on checking

( ) and "HEAT" ( ) Switches

), "BLOWER"

IF THESE STEPS FAIL TO RESOLVE THE PROBLEM, CONTACT YOUR LOCAL MIDDLEBY MARSHALL

AUTHORIZED SERVICE AGENT. A SERVICE AGENCY DIRECTORY IS SUPPLIED WITH YOUR OVEN.

18

Page 19

SECTION 4 - MAINTENANCE

WARNING

Before ANY cleaning or servicing of the oven, perform the following procedure:

1. Switch off the oven and allow it to cool. Do NOT service the oven while it is warm.

2. Turn off the electric supply circuit breaker(s)

3. If it is necessary to move a gas oven for cleaning or servicing, disconnect the gas supply connection before moving the oven.

and disconnect the electric supply to the oven.

When all cleaning and servicing is complete:

1. If the oven was moved for servicing, return the oven to its

original location. Adjust the legs so that they are seated

properly on the floor.

2. For gas ovens, reconnect the gas supply.

3. Reconnect the electrical supply.

4. For gas ovens, turn on the full-flow gas safety valve. Test

the gas line connections for leaks using approved leak

test substances or thick soap suds.

5. Turn on the electric supply circuit breaker(s).

6. Perform the normal startup procedure.

WARNING

Possibility of injury from moving parts and electrical shock exists in this oven. Switch off and lockout/tagout the electric supply

BEFORE beginning to disassemble, clean, or service any oven. Never disassemble or clean an oven with the BLOWER (

switch or any other circuit of the oven switched on.

CAUTION

NEVER use a water hose, water jet, or pressurized steam-cleaning equipment when cleaning this oven. DO NOT use

excessive amounts of water, to avoid saturating the oven insulation. DO NOT use a caustic oven cleaner, which can damage

the aluminized bake chamber surfaces.

NOTE

ANY replacement parts that require access to the interior of the oven may ONLY be replaced by a Middleby Marshall Authorized

Service Agent. It is also strongly recommended that the 3-Month Maintenance and 6-Month Maintenance procedures in this

section be performed ONLY by a Middleby Marshall Authorized Service Agent.

I. MAINTENANCE - DAILY

A. Check that the oven is cool and the power is disconnected,

as described in the warning at the beginning of this Section.

B. Clean the outside of the oven with a soft cloth and mild

detergent.

C. Clean ALL of the cooling fan grills and vent openings with a

stiff nylon brush.

D. Check that ALL cooling fans are operating properly.

CAUTION

If a cooling fan is not operating correctly, it must be replaced

IMMEDIATELY. Operating the oven without adequate

cooling can seriously damage the oven's internal components.

E. Clean the conveyor belts with a stiff nylon brush. This is

more easily accomplished by allowing the conveyor to run

while you stand at the exit end of the conveyor. Then, brush

the crumbs off the conveyor as it moves.

F. Remove and clean the crumb trays. Be sure to replace the

trays in the same positions from which they were removed,

because they are NOT identical. Refer to Figure 4-1.

G. Clean the window in place.

Lower oven

Figure 4-1 - Crumb trays

Upper oven

(drive end)

Upper oven

(idler end)

ENGLISH

)

19

Page 20

SECTION 4 - MAINTENANCE

II. MAINTENANCE - MONTHLY

A. Check that the oven is cool and the power is disconnected,

as described in the warning at the beginning of this Section.

B. Remove the crumb trays, drive motor shroud, and conveyor

ENGLISH

extension covers from the oven.

C. Lift the drive end of the conveyor slightly, and push it forward

into the oven. This removes the tension from the drive

chain. Then, remove the drive chain from the conveyor

sprocket.

NOTE

Split belt conveyors can only be removed from the end of

the oven

with the drive motor.

Single-belt conveyor assemblies may be removed from

either end of the oven. If it is to be removed from the end

of the oven

without the drive motor, the drive sprocket

assembly must be removed.

To remove the drive sprocket (if necessary), loosen the set

screw on the conveyor collar as shown in Figure 4-2. Then,

pull the sprocket assembly straight out.

D. Slide the conveyor out of the oven, folding it as it is removed.

See Figure 4-3.

E. Remove the end plugs from the oven.

F. Slide the air fingers and blank plates out of the oven, as

shown in Figure 4-4. AS EACH FINGER OR PLATE IS

REMOVED, WRITE A "LOCATION CODE" ON IT WITH A

MARKER to make sure that it can be reinstalled correctly.

Example of markings:

(Top Row) T1 T2 T3 T4 T5 T6

(Bottom Row) B1 B2 B3 B4 B5 B6

G. Disassemble the air fingers as shown in Figure 4-4. AS

EACH FINGER IS DISASSEMBLED, WRITE THE "LOCATION CODE" FOR THE FINGER ON ALL THREE OF ITS

PIECES. This will help you in correctly reassembling the

air fingers.

CAUTION

Incorrect reassembly of the air fingers will change the

baking properties of the oven.

H. Clean the air finger components and the interior of the

baking chamber using a vacuum cleaner and a damp cloth.

Refer to the boxed warnings at the beginning of this Section

for cleaning precautions.

I. Reassemble the air fingers. Then, replace them in the

oven, using the "location code" as a guide.

J. Replace the end plugs on the oven.

K. Reassemble the conveyor into the oven. If the drive sprocket

was removed when installing the conveyor, replace it at this

time.

L. Reattach the drive chain.

M. Check the tension of the conveyor belt as shown in Figure

4-5. The belt should lift between 75-100mm. DO NOT

OVERTIGHTEN THE CONVEYOR BELT. If necessary, the

belt tension can be adjusted by turning the conveyor adjustment screws, located at the idler (right) end of the conveyor.

N. Replace the conveyor extension covers, drive motor shroud,

and crumb trays.

Figure 4-2 - Removing the Conveyor Drive Sprocket

Loosen conveyor collar

set screw, then pull

sprocket straight out

Figure 4-3 - Removing the Conveyor

Figure 4-4 - Removing Air Fingers and Plates

Manifold

Inner plate

Outer plate

Figure 4-5 - Checking the conveyor tension

75-100mm

vertical

deflection

Conveyor

tension

adjustment

screws (idler

end only)

20

Page 21

III. MAINTENANCE - EVERY 3 MONTHS

A. Check that the oven is cool and the power is disconnected,

as described in the warning at the beginning of this Section.

B. Vacuum both of the blower motors, and their surrounding

compartments, using a shop vacuum.

C. Tighten all electrical control terminal screws.

D. Split Belt Disassembly and Cleaning

For split belt ovens ONLY, disassemble, clean and lubricate the

conveyor shaft components as described below.

1. Remove the motor shroud, conveyor extensions, and conveyor as described in Part II,

2. Remove the master links from each conveyor belt. Then,

roll the belts up along the length of the conveyor to remove

them from the frame.

3. Remove the two conveyor adjustment screws from the idler

end of the conveyor frame, as shown in Figure 4-6.

4. Remove the idler shaft assembly from the conveyor.

5. Pull apart the two sections of the idler shaft. Clean the

shafts thoroughly using a rag. Then, lubricate both the

extended shaft and the interior of the hollow shaft using an

FDA-approved light food-grade lubricant.

CAUTION

DO NOT lubricate the shafts using WD40 or a similar

product. This can cause the shafts to wear rapidly.

6. Before reassembling the shafts into the conveyor frame,

check that they are oriented properly. Remember that

unequal-width split belt ovens should ALWAYS have the

narrower belt at the front of the oven.

7. Reassemble the idler shaft into the conveyor.

that the bronze washer is in place between the two sections

of the shaft. See Figure 4-8.

8. Replace the conveyor adjustment screws as shown in

Figure 4-6. To allow the conveyor belt to be reinstalled later,

do not tighten the screws at this time.

9. Loosen the set screw on both of the conveyor drive sprockets. Then, remove the sprockets from the shaft.

10. Loosen the locking collar set screw, as shown in Figure 4-7.

11. Push the drive shaft to the right, then lift it free of the conveyor

frame. Then, disassemble and lubricate the two sections

of the drive shaft as described in Step 5.

12. Before reassembling the shafts into the conveyor frame,

check that they are oriented properly. Remember that

unequal-width split belt ovens should ALWAYS have the

narrower belt at the front of the oven.

13. Reassemble the drive shaft into the conveyor.

the nylon spacer is in place, as shown in Figure 4-8. Also,

check that the bronze washer is in place between the two

sections of the shaft.

14. Replace the drive sprockets. Reassemble the belts and

master links onto the conveyor. Check that the smooth side

of the conveyor belt faces UP, and that the belt and master

links are oriented as shown in Figure 4-9.

15. Reassemble the conveyor, motor shroud and conveyor

extensions onto the oven.

16. Check the tension of the conveyor belt as shown in Figure 4-5. The

belt should lift between 75-100mm. If necessary, adjust the belt

tension by turning the conveyor adjustment screws.

Monthly Maintenance.

Make sure

Check that

21

SECTION 4 - MAINTENANCE

Figure 4-6 - Split Belt Idler Shaft

Conveyor

adjustment

screw

Figure 4-7 - Split Belt Drive Shaft

Locking collar

Figure 4-8 - Washer and Spacer

Bronze washer on

BOTH idler and

drive shafts

Nylon spacer

on drive shaft

ONLY

Figure 4-9 - Conveyor and Master Link Orientation

Direction

of travel

CORRECT

master link

position

Incorrect

master link

position

ENGLISH

Page 22

SECTION 4 - MAINTENANCE

IV. MAINTENANCE - EVERY 6 MONTHS

A. Check that the oven is cool and the power is disconnected,

as described in the warning at the beginning of this Section.

B. Check for excessive wear on the conveyor drive motor

ENGLISH

brushes. The brushes should be replaced if they have worn

to less than 1/4" (6.4mm) in length. Be sure to replace the

brushes in exactly the same position.

C. For gas ovens, clean and inspect the burner nozzle and

electrode assembly.

D. Check (and clean, if necessary) the oven venting system.

E. Check the conveyor drive shaft bushings and spacers.

Replace the components if they are worn.

V. KEY SPARE PARTS KIT - Available separately. See Figure 4-10.

Item Part No. Description

1 36939 Kit, Digital Temperature Controller

2 27384-0008 Motor, Conveyor Drive

3 22450-0052 Brushes, Drive Motor

4 27170-0263 Assembly, Pickup, Conveyor Drive

5 37337 Kit, Conveyor Speed Controller

6 33984 Kit, Thermocouple

7 27392-0002 Fan, Cooling

8 35625 Kit, Air Switch

9a 27381-0023 Motor, Blower, PS360U and PS360L Gas and

Electric Ovens, 1/3 HP

9b 31432 Motor, Blower, PS360WB-U and PS360WB-L

Gas Ovens, 1 HP

GAS OVENS ONLY:

10 27170-0287 Assembly, Burner Blower and Motor

11 35825 Kit, Ignition Module

12a 37770 Kit, High Flame Solenoid Valve, 220V

12b 37851 Kit, High Flame Solenoid Valve, 120V (for

ovens with external transformers)

ELECTRIC OVENS ONLY:

13 27374-0003 Heating Element, 380-400V / 1.35-1.5 kW

14 33983 Module, High Limit Control, 240V

15 31463 Relay, Solid State

Fig. 4-10 - Key Spare Parts Kit

1

2

3

6

7

45

8

9

10

11

12

22

13

14

15

Page 23

23

CIRCUIT

BREAKER

BLOCKS 20A

SOLID

STATE

RELAYS

Black

#12 AWG

Brown

#12 AWG

Black

#12 AWG

TERMINAL

BLOCK

RFI FILTER

Black

Black

#12 AWG

Brown

Brown

#12 AWG

Black

Black

#12 AWG

Black

#12 AWG

Brown

#12 AWG

Black

#12 AWG

Blue

Brown

SAFETY

SWITCH

Brown

Black

Black

#16 AWG

#16 AWG

#16 AWG

Black

Black

Black

BLOWER

MOTOR

CENTRIFUGAL SWITCHES

CIRCUIT

BREAKERS

6A

CONTACTOR

Brown

Brown

Black

Black

BREAKERS

#16 AWG

#16 AWG

#16 AWG

CONTACTOR

Black

Black

Black

BLOWER

MOTOR

Brown Brown

Brown

CIRCUIT

6A

HEAT

SWITCH

CIRCUIT

BREAKERS

6A

TRANSFORMER

240-480V PRI.

120V SEC.

CIRCUIT

BREAKER

6A

Brown

PRESSURE SWITCH

Blue

Brown

CONTROL MODULE

CIRCUIT

BREAKER

2A

BLOWER SWITCH

Brown

COOLDOWN RELAY

HIGH LIMIT

FOR USE IN SPLIT BELT

APPLICATIONS ONLY

CONVEYOR

DRIVE MOTOR

CONVEYOR

DRIVE MOTOR

CONVEYOR SWITCH

Brown

Brown

HIGH LIMIT CONTROL MODULE

Brown

TEMPERATURE

CONTROLLER

Black

Red

Black

Red

COOLING FAN

COOLING FAN

CONVEYOR SPEED CONTROLLER

Pink

COIL

COIL

RESET SWITCH

PICKUP

Red

White

Black

CONVEYOR SPEED CONTROLLER

White

Blue

Black

White

PICKUP

Red

SECTION 5 - ELECTRICAL WIRING DIAGRAMS

Wiring Diagram, PS360-U/-L Electric Oven, 380-400V, 50 Hz, 1 Ph

Fig. 5-1

diagram for the oven is

also located inside the

An electrical wiring

compartment.

machinery

IMPORTANT

HEATING

ELEMENTS

TC

SOLID

STATE

RELAYS

ENGLISH

Page 24

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 USA (847)741-3300 FAX (847)741-4406

An electrical wiring diagram for the oven is also located inside the machinery compartment.

GND

GROUND

Grn/Yellow

LINE

CIRCUIT BREAKER (IN INSTALLATION LOCATION)

PH

N

CHECK FOR PROPER POLARITY.

Brown

NEUTRAL

INSTALLATION LOCATION

Blue

FOR USE IN SPLIT BELT

APPLICATIONS ONLY

side 25

DANSK

CONVEYOR SPEED CONTROLLER

page 1

ENGLISH

SECTION 5 - ELECTRICAL WIRING DIAGRAMS

PICKUP

24-Hour Service Hotline: 1-(800)-238-8444

www.middleby.com

24

IMPORTANT

TERMINAL

BLOCK

Orange

TEMPERATURE

CONTROLLER

CIRCUIT

BREAKERS

8A

BLOWER

MOTOR

Red

Orange

PRESSURE SWITCH

PRESSURE SWITCH

HIGH LIMIT SWITCH

RFI FILTER

SAFETY

SWITCH

Orange

CENTRIFUGAL

SWITCHES

Red

TRANSFORMER

220-240V PRI.

110-120V SEC.

CIRCUIT

BREAKER

6A

CONTACTOR

BLOWER

MOTOR

Orange

Black

CIRCUIT

BREAKER

HEAT

SWITCH

6A

Purple

Black

Pink

CIRCUIT

BREAKER

2A

Pink

Blue

HIGH LIMIT

CONTROL MODULE

Brown

CONVEYOR

DRIVE MOTOR

220V NEUTRAL

CONVEYOR

DRIVE MOTOR

CONVEYOR SWITCH

Yellow

Blue

BLOWER

SWITCH

Black

Black

Red

120V NEUTRAL

Black

Red

COOLDOWN

RELAY

COMBINATION GAS

CONTROL VALVE

White

Pink White

Brown

PRESSURE SWITCH

BURNER

BLOWER

CONVEYOR SPEED CONTROLLER

BURNER BLOWER

RESET SWITCH

AND LAMP

Red

White

Black

Red

White

Black

COOLING FAN

COIL

220V NEUTRAL

PICKUP

COOLING FAN

Blue

IGNITOR

Wiring Diagram, PS360-U/-L or PS360WB-U/-L Gas Oven, 220-230V, 50 Hz, 1 Ph

Fig. 5-2

RESET

LAMP

Black

TC

HIGH LIMIT

CONTROL

MODULE

White

SOLENOID

VALVE

White

Red

SWITCH

RESET

Red

TC

White

Black

IGNITION MODULE

Yellow

Red

Brown

2A

Yellow

Red

Pink

Orange

Red

Page 25

PS300 serien

Gas og elektrisk (Europa)

Engelsk/DANSK

P/N 46486

Rev. B V1 7/01

page 1

ENGLISH

side 25

DANSK

PS300 serien gas- og elektriske ovne

Modeller:

PS360-U, PS360-L gas

PS360-U, PS360-L elektrisk

PS360WB-U, PS360WB-L gas

BRUGER- OG INSTALLATIONSHÅNDBOG

for europæiske eksportovne

Enkelt ovn Dobbeltovn

PS360 PS360WB PS360 PS360WB

Nominel varmeeffekt 40kW 50kW 2x40kW 2x50kW

Gasovne

Nominel varmeeffekt 26kW -- 2x26kW --

Elektriske ovne

Opvarmningszoner 1 reguleret opvarmningszone 2 regulerede opvarmningszoner

© 2001 Middleby Marshall, Inc.

Kombinationer:

Enkelt ovn

Dobbeltovn (to-stabel)

er et registreret varemærke tilhørende Middleby Marshall, Inc. Alle rettigheder forbeholdes.

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 USA +1 (847)741-3300 FAX +1 (847)741-4406

25

Page 26

MEDDELELSE:

Denne

ovnens funktioner og betjening.

Håndbogen skal opbevares på et iøjnefaldende og let tilgængeligt sted i nærheden af ovnen.

Gasovne er designet til brug sammen med ENTEN naturgas ELLER flydende propangas (bygas) som angivet på

fabrikationspladen. Hvor det er tilladt i henhold til lokale og nationale love, kan ovnen konverteres fra naturgastil bygasdrift eller omvendt. Denne konvertering er beskrevet i håndbogens afsnit om Installation. Konverteringen

kræver installation af det hensigtsmæssige Middleby Marshall gaskonverteringssæt.

Det foreslås, at der indhentes en servicekontrakt med en autoriseret Middleby Marshall serviceagent.

Bruger- og installationshåndbog skal gives til brugeren. Brugeren af ovnen skal være fortrolig med

ADVARSEL

PÅ ET IØJNEFALDENDE STED SKAL DE ANBRINGE NØDTELEFONNUMMERET TIL DERES LOKALE

GASFORSYNING SAMT VEJLEDNING, DER SKAL FØLGES, HVIS DE KAN LUGTE GAS.

DANSK

Vejledning, der skal følges, hvis brugeren kan lugte gas, skal indhentes ved rådføring med den lokale

gasforsyning. Hvis der spores gaslugt, skal De straks ringe til Deres lokale gasforsyning på

nødtelefonnummeret. Der findes personale og foranstaltninger, der kan korrigere problemet.

AF HENSYN TIL DERES SIKKERHED

Må De ikke opbevare eller anvende benzin eller andre brændbare dampe eller

væsker i nærheden af dette eller andre apparater.

ADVARSEL:

Forkert installation, indstilling, ændring, service eller vedligeholdelse

kan forårsage tingskade, personskade eller dødsfald. Læs

vejledningen for installation, betjening og vedligeholdelse grundigt

før De installerer eller vedligeholder udstyret.

VIGTIGT

Der findes et ledningsdiagram for ovnen inden i maskinkassen.

VIGTIGT

Det er kundens ansvar at oplyse om eventuel skjult eller ikke skjult skade til

fragtfirmaet. De skal opbevare alt forsendelsesmateriale, indtil det er sikkert, at

udstyret ikke har lidt skjult forsendelsesskade.

MEDDELELSE: KONTAKT DERES AUTORISEREDE MIDDLEBY MARSHALL SERVICEAGENT FOR AT UDFØRE

VEDLIGEHOLDELSE OG REPARATIONER. DER MEDFØLGER EN ADRESSELISTE OVER AUTORISEREDE

SERVICEAGENTER MED DERES OVN.

MEDDELELSE: Anvendelse af andre dele end ægte Middleby Marshall fabriksfremstillede dele fritager producenten for alle

garantier og erstatningspligt.

MEDDELELSE: Middleby Marshall (producent) forbeholder sig ret til på ethvert tidspunkt at ændre specifikationer.

MEDDELELSE: Apparaturgarantien er ikke gyldig med mindre ovnen er installeret, startet og demonstreret under

overvågning af en fabriksgodkendt installatør.

Denne håndbog skal opbevares til fremtidig brug

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 USA +1 (847)741-3300 FAX +1(847)741-4406

24-timers servicehotline: 1-(800)-238-8444

www.middleby.com

26

Page 27

INDHOLDSFORTEGNELSE

side side

AFSNIT 1 - BESKRIVELSE .....................................................28

I. OVNENS ANVENDELSESMULIGHEDER ............. 28

II. OVNKOMPONENTER ............................................. 28

A. Krummepander ...............................................28

B. Transportbåndets drivmotor ........................... 28

C. Transportbånd ................................................. 28

D. Slutmuffer ........................................................ 28

E. Fabrikationsplade ........................................... 28

H. Rude ................................................................ 28

G. Maskinkassens adgangslem ......................... 28

H. Kontrolkassens adgangslem ......................... 28

I. Kontrolpanel .................................................... 28

J. Afviserlister ...................................................... 28

K. Transportbåndets afslutningsstop .................28

L. Gasbrænder eller varmeelementer ................28

M. Blæsere ...........................................................28

N. Luftfingre ..........................................................28

III. OVNSPECIFIKATIONER .........................................28

A. Mål .................................................................... 28

B. Generelle specifikationer ................................ 28

C. Elektriske specifikationer ................................ 29

D. Gasåbning og trykspecifikationer ...................29

AFSNIT 2 - INSTALLATION .................................................... 29

I. INSTALLATIONSSÆT ............................................. 30

II. VENTILATIONSSYSTEM .........................................31

A. Krav ..................................................................31

B. Anbefalinger .................................................... 31

C. Andre ventilationsanliggender ........................ 31

III. MONTERING ...........................................................32