Page 1

Middleby Cooking Systems Group • 1400 Toastmaster Drive • Elgin, IL 60120 • (847)741-3300 • FAX (847)741-4406

Oven Gas Conversion Kit p/n 36856

PS360EWB and PS360WB70

Natural Gas to Propane Installation Instructions

WARNING

This conversion kit is to be installed by a Middleby Marshall Authorized Service Organization in accordance with

the manufacturer’s instructions and all codes and requirements of the authority having jurisdiction. Failure to

follow instructions could result in serious injury or property damage. The authorized service organization

performing this work assumes responsibility for this conversion.

This kit consists of the following parts:

Qty. Units p/n Description

MiddlebyMiddleby

Middleby

MiddlebyMiddleby

MarshallMarshall

Marshall

MarshallMarshall

®®

®

®®

1 ea. 36857

1 ea. 31819

1 ea. 31822

1 ea. 22174-0009

1 ea. 22500-0065

1 ea. 22500-0123

Instructions for Conversion of Natural Gas Operation to Propane Operation, PS360EWB and

PS360WB70

Orifice, Pilot Assembly - Propane, 0.025” (0.64mm)

Orifice, Main - Propane, 0.185” (4.70mm)

Orifice, Low Flame - Propane, 0.034” (0.86mm, #62 drill)

Label, LPG, Red

Label, Conversion - Gas

- used for converting PS360WB70 only

IMPORTANT

When converting any oven that is installed at an altitude above 5000 ft. (1524m), consult Middleby before installing

this Kit.

1. PREPARATION

1.1 Turn off the electric power supply to the oven.

1.2 Turn off the gas supply at the service valve behind the oven.

WARNING

Before performing any service or conversion work, the electrical power supply AND the gas supply MUST be

turned off.

1.3 Open the machinery compartment access door.

2. PILOT ORIFICE REPLACEMENT

2.1 Unscrew the brass fittings at both ends of the aluminum pilot tubing that connects the pilot orifice to the combination gas control

valve. This allows the tubing to be removed. See Figure 1.

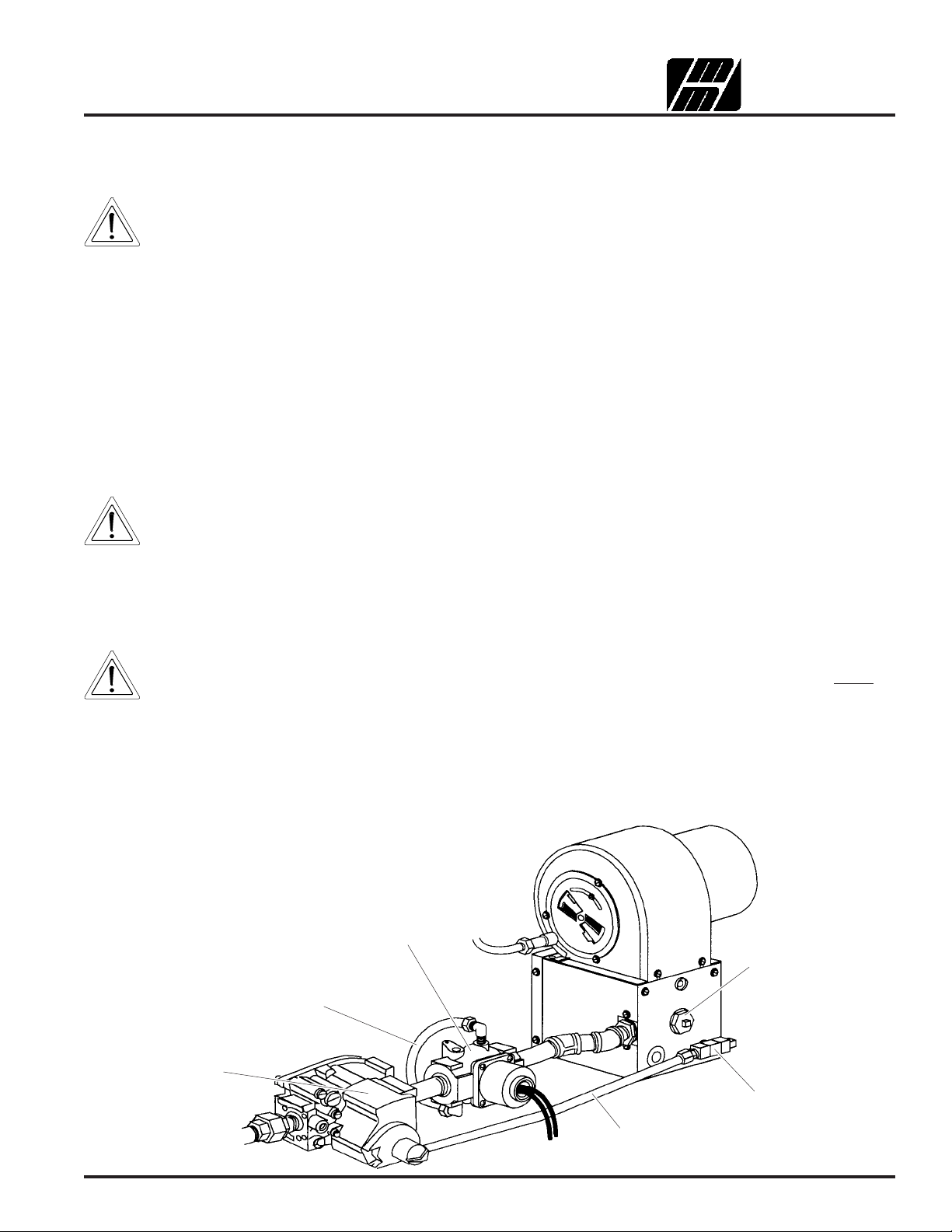

Figure 1

Conversion component locations

Solenoid valve

(PS360WB70 only)

Low flame bypass

(PS360WB70 only)

Combination gas

control valve

Aluminum

pilot tubing

p/n 36857 P. Jan 98 Rev. B Page 1 of 4

Main

orifice

holder

Pilot

orifice

Page 2

2.2 Remove and retain the aluminum pilot tubing from the burner

assembly. The end of the tubing that enters the combination gas

control valve should be removed first.

2.3 Remove and retain the pilot orifice by unscrewing it (counterclockwise)

from the burner plenum wall.

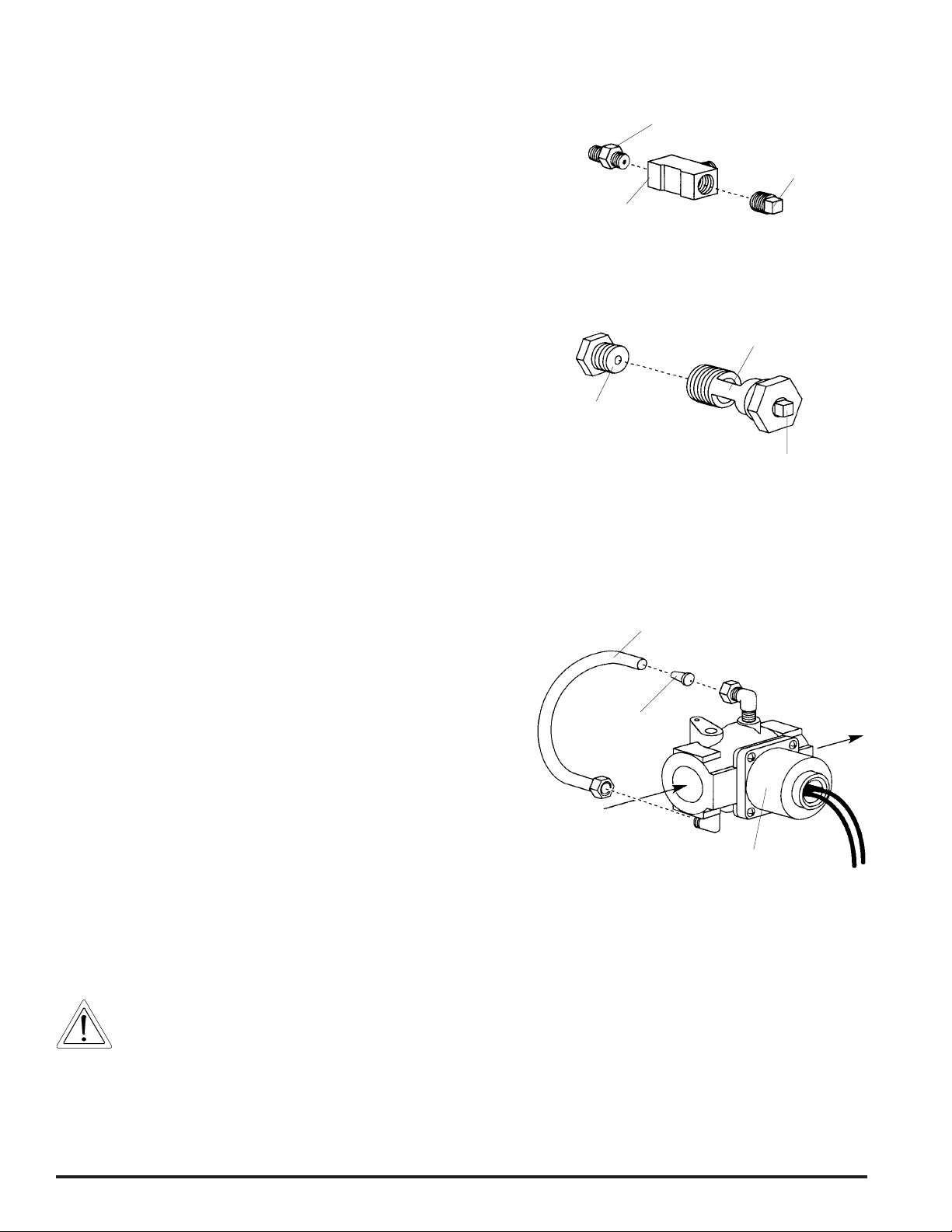

Figure 2

Pilot orifice assembly

Pilot tubing connector

2.4 Unscrew and retain the pilot tubing connector and the pilot tap plug

from the ends of the pilot orifice, as shown in Figure 2. When these

attachments have been removed, discard the pilot orifice.

2.5 Screw the pilot tubing connector and the pilot tap plug into place in

the new propane pilot orifice (p/n 31819). Tighten them to a snug fit.

2.6 Screw the new propane pilot orifice into its opening in the plenum

wall. Tighten it to a snug fit. Ensure that the end of the orifice holding

the pilot tubing mount points towards the piping assembly.

2.7

Replace the aluminum pilot tubing that was removed in Step 2.2, above.

2.8 Screw in the brass fittings at both ends of the aluminum pilot tubing.

Tighten them to a snug fit. DO NOT OVERTIGHTEN THE FITTINGS.

3. MAIN ORIFICE REPLACEMENT

3.1 Remove and retain the main orifice holder by unscrewing it

(counterclockwise) from the burner plenum wall.

3.2 Unscrew and discard the main orifice from the inner end of the holder,

as shown in Figure 3.

3.3 Screw the new propane main orifice (p/n 31822) into the orifice holder.

Tighten it to a snug fit.

3.4 Replace the main orifice holder into its opening in the burner plenum.

Tighten it to a snug fit.

4.

LOW FLAME ORIFICE REPLACEMENT

4.1 Unscrew the brass fittings at both ends of the aluminum low flame

tubing. This allows the tubing to be removed. See Figure 4.

(PS360WB70 only)

Pilot tap plug

Pilot orifice

Figure 3

Main orifice and holder

Main orifice

holder

Main orifice

Main manifold tap

plug (leave in place)

Figure 4

Low flame orifice replacement

Aluminum

tubing

4.2 Remove and retain the tubing from the solenoid valve.

4.3 Remove and discard the low flame orifice from the end of the low

flame tubing.

4.4 Insert the new propane low flame orifice (p/n 22174-0009) into the

discharge end of the low flame tubing, as shown in Figure 4.

4.5 Replace the low flame tubing into the fittings on the solenoid valve.

4.6 Screw in the brass fittings at both ends of the aluminum low flame

tubing. Tighten them to a snug fit.

Low flame

orifice

From combination

gas control valve

To burner

Solenoid valve

5. GAS LEAK TEST

5.1 Paint all pipe connections from the gas union to the burner plenum, and the aluminum pilot and low flame orifice tubing connections,

with a solution of soap and water (2/3 soap, 1/3 water is recommended). Any bubbles that are visible indicate a gas leak.

5.2 If a gas leak is detected, tighten the affected joints and connections. If tightening the connections fails to stop the leak, replace

the affected component and repeat the gas leak test.

WARNING - FIRE / EXPLOSION HAZARD

Hidden gas leaks can cause a flashback in the machinery compartment. THIS CAN CAUSE SEVERE INJURY OR

DEATH. Stand well clear when switching on the heating circuit.

5.3 If no leaks are detected by the test, switch on the oven. Switch on the heating circuit to ignite the main burner.

5.4 With the burner in operation, paint all gas pipe joints with the solution of soap and water.

5.5 If any further gas leaks are detected, shut down the oven. Reseal and tighten the affected joints and connections. If tightening

the connections fails to stop the leak, replace the affected component(s) and repeat the gas leak test.

Page 2 of 4 P. Jan 98 Rev. B p/n 36857

Page 3

6. INLET PRESSURE CHECK

6.1 Check the gas control inlet pressure at the inlet pressure tap. See Figure 6. An inlet pressure of 6-14” (14.9-34.9mbar) is

recommended for propane operation.

6.2 If the inlet pressure is:

• HIGHER THAN 14” W. C. (34.9mbar) - This pressure may damage the combination gas control valve. Decrease the supplied

gas pressure.

• LOWER THAN 3” W. C. (7.46mbar) - It may be necessary to increase the supplied gas pressure.

If it is necessary to adjust the gas line pressure, have the customer contact the gas utility supplier.

7. PILOT PRESSURE ADJUSTMENT

7.1 Ensure that the air supply is properly adjusted for propane operation.

• Units with a burner blower air shutter (see Figure 5) should have the shutter opening (at its outside edge) set to 5/16”

(7.94mm). A drill bit can be used to check the adjustment of this opening.

• Units without the air shutter (see Figure 5) should have the burner air supply adjustment screw turned 11-17 full revolutions

clockwise from the fully closed (counterclockwise) position. The screw is located on the front wall of the burner plenum, and

is surrounded by a “MORE AIR” label.

Figure 5

Insert a 5/16”

(7.94mm) drill

bit to measure

opening

(remove before

operation)

Burner blower configurations

External

air

shutter

Blowers without

external air shutter

OR

7.2 Before proceeding:

• For a PS360EWB oven, the set point should be reduced

below the room temperature.

• For a PS360WB70 oven, set the oven to low flame.

Figure 6

Gas pressure measurement/adjustment locations

7.3 Measure the pilot pressure at the pilot pressure tap, as shown

in Figure 6. The gas pressure should be 5-6” W. C. (12.5-

14.9mbar) for proper operation.

7.4 If necessary, adjust the pilot pressure as follows:

• Remove the pilot adjustment cap screw.

• Using a screwdriver, turn the inner adjustment screw

counterclockwise to increase, or clockwise to decrease,

the pilot gas pressure.

• Replace the cap screw and tighten it firmly.

7.5 Measure the current across the pilot flame sensor. The

current must measure at least 2.0

is too low, recheck the pilot pressure as per Step 7.3. If the

pressure reading is correct, consult the factory; otherwise,

repeat Steps 7.4 and 7.5.

µA. If the current reading

Pressure

regulator cap

screw

Inlet pressure

tap

adjustment

cap screw

Main orifice

pressure tap

8. MAIN MANIFOLD PRESSURE ADJUSTMENT

8.1 With the oven set to high flame, measure the regulated gas

pressure to the burner. The outlet pressure should be

checked at the main orifice pressure tap. See Figure 6.

The gas pressure should be 3” W. C. (7.46mbar) for proper

operation.

8.2 If necessary, adjust the pressure regulator as follows:

• Remove the pressure regulator cap screw.

• Using a screwdriver, turn the inner adjustment screw clockwise to increase, or counterclockwise to decrease, the main

burner gas pressure.

• Replace the cap screw and tighten it firmly.

Pilot pressure

tap

Pilot tube

connects

here

Pilot

8.3 Record the final measured regulated gas pressure on the silver conversion information label (included in the kit).

p/n 36857 P. Jan 98 Rev. B Page 3 of 4

Page 4

9. CONVERSION LABELING

9.1 Remove and discard the round, green “NAT.” label from the

front face of the burner plenum.

9.2 Apply the round, red “LPG.” label (p/n 22500-0065) to the front

face of the burner housing as shown in Figure 7.

9.3 Close the machinery compartment access door.

9.4 Record the information requested on the silver conversion

information label. Figure 8 shows a representation of this label.

9.5 Apply the conversion information label to the front of the

machinery compartment access door, next to the control panel.

See Figure 9.

Figure 8

Conversion information label

Signature of technician

performing conversion

Red “LPG.” label placement

Upper oven

label location

Date of conversion

Figure 7

(on burner housing)

Lower oven

label location

THIS APPLIANCE HAS BEEN CONVERTED ON _______________ TO ______________ GAS WITH KIT

NO. ________________ BY _______________ , WHO ACCEPTS THE RESPONSIBILITY FOR

36856

PROPANE

THE CORRECTNESS OF THIS CONVERSION.

MODEL NO. MAIN BURNER ORIFICE SIZE MANIFOLD PRESSURE

INPUT RATING MAXIMUM INLET PRESSURES

Stated on the

oven’s data plate

175,000 BTU

.185”/4.70mm

14” W.C./34.9mbar

Measured value

recorded in Step 8.3

Figure 9

Conversion information label placement

THIS APPLIANCE HAS BEEN CONVERTED ON _______________ TO ______________ GAS WITH KIT

NO. ________________ BY _______________ , WHO ACCEPTS THE RESPONSIBILITY FOR

THE CORRECTNESS OF THIS CONVERSION.

MODEL NO. MAIN BURNER ORIFICE SIZE MANIFOLD PRESSURE

INPUT RATING MAXIMUM INLET PRESSURES

PS360EWB placement

THIS APPLIANCE HAS BEEN CONVERTED ON _______________ TO ______________ GAS WITH KIT

NO. ________________ BY _______________ , WHO ACCEPTS THE RESPONSIBILITY FOR

THE CORRECTNESS OF THIS CONVERSION.

MODEL NO. MAIN BURNER ORIFICE SIZE MANIFOLD PRESSURE

INPUT RATING MAXIMUM INLET PRESSURES

PS360WB70 placement

Page 4 of 4 P. Jan 98 Rev. B p/n 36857

Loading...

Loading...