Page 1

PS314SBI

Gas and Electric (AGA/UL)

ENGLISH/French/Spanish

P/N 42447

Rev. B V1 2/00

page 1page 21página 41

ENGLISHFRANÇAISESPAÑOL

Model PS314SBI Gas and Electric

Ovens

Models:

PS314SBI

Combinations:

Single Lower Oven

OWNER'S OPERATING

& INSTALLATION

MANUAL

© 2000 Middleby Marshall, Inc.

is a registered trademark of Middleby Marshall, Inc. All rights reserved.

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 (847)741-3300 FAX (847)741-4406

1

Page 2

NOTICE:

This Owner's Operating and Installation Manual should be given to the user. The operator of the oven should

be familiar with the functions and operation of the oven.

This manual must be kept in a prominent, easily reachable location near the oven.

ENGLISH

Gas ovens are designed for use with EITHER natural gas OR liquid propane gas, as specified on the serial plate.

Where permitted by local and national codes, the oven can be converted from natural gas to propane operation,

or from propane to natural gas operation. This conversion requires the installation of the appropriate Middleby

Marshall Gas Conversion Kit by an Authorized Service Agent.

It is suggested to obtain a service contract with a Middleby Marshall Authorized Service Agent.

WARNING

POST, IN A PROMINENT LOCATION, THE EMERGENCY TELEPHONE NUMBER OF YOUR LOCAL GAS

SUPPLIER AND INSTRUCTIONS TO BE FOLLOWED IN THE EVENT YOU SMELL GAS.

Instructions to be followed in the event the user smells gas shall be obtained by consulting the local gas

supplier. If the smell of gas is detected, immediately call the emergency phone number of your local Gas

Company. They will have personnel and provisions available to correct the problem.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of

this or any other appliance.

WARNING:

Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death. Read the installation,

operating and maintenance instructions thoroughly before installing

or servicing this equipment.

IMPORTANT

An electrical wiring diagram for the oven is located inside the machinery

compartment.

IMPORTANT

It is the customer's responsibility to report any concealed or non-concealed damage

to the freight company. Retain all shipping materials until it is certain that the

equipment has not suffered concealed shipping damage.

NOTICE: CONTACT YOUR MIDDLEBY MARSHALL AUTHORIZED SERVICE AGENT TO PERFORM MAINTENANCE

AND REPAIRS. AN AUTHORIZED SERVICE AGENCY DIRECTORY IS SUPPLIED WITH YOUR OVEN.

NOTICE: Using any parts other than genuine Middleby Marshall factory manufactured parts relieves the manufacturer of

all warranty and liability.

NOTICE: Middleby Marshall (Manufacturer) reserves the right to change specifications at any time.

NOTICE: The equipment warranty is not valid unless the oven is installed, started and demonstrated under the supervision

of a factory certified installer.

Retain This Manual For Future Reference

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 USA (847)741-3300 FAX (847)741-4406

24-Hour Service Hotline: 1-(800)-238-8444

www.middleby.com

2

Page 3

TABLE OF CONTENTS

page page

SECTION 1 - DESCRIPTION .................................................... 4

IV. THERMOCOUPLE INSTALLATION .......................... 8

I. OVEN USES ............................................................. 4

II. OVEN COMPONENTS ............................................. 4

A. Conveyor Drive Motor ........................................ 4

B. End Trays .......................................................... 4

C. Conveyor ........................................................... 4

D. End Plugs ......................................................... 4

E. Cool Rear Panels ............................................. 4

F. Cool Front Panel ............................................... 4

G. Machinery Compartment Access Panel ........... 4

H. Control Compartment Access Panel ............... 4

I. Control Panel .................................................... 4

J. Serial Plate ........................................................ 4

K. Crumb Pans ..................................................... 4

L. Gas Burner ........................................................ 4

M. Blowers ............................................................. 4

N. Air Fingers ......................................................... 4

III. OVEN SPECIFICATIONS ......................................... 4

V. CONVEYOR INSTALLATION .................................... 8

VI. FINAL ASSEMBLY ................................................... 1 0

VII. ELECTRICAL SUPPLY ........................................... 11

A. Electric Ovens ..................................................11

B. Gas Ovens .......................................................11

C. Ovens with External Transformers .................. 11

D. Connection.......................................................11

VIII. GAS SUPPLY .......................................................... 12

A. Connection ....................................................... 1 2

B. Gas Conversion ............................................... 12

SECTION 3 - OPERATION ...................................................... 1 3

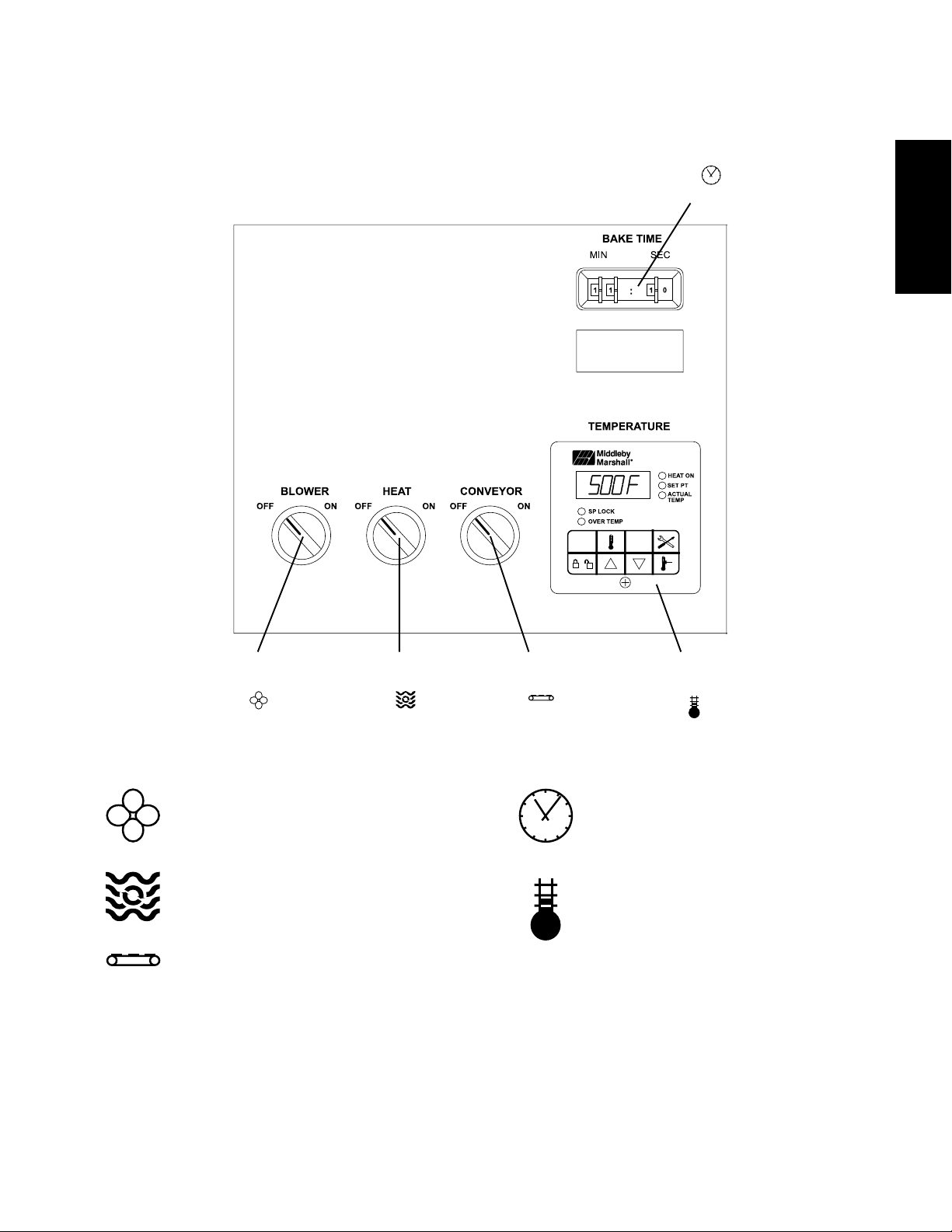

I. LOCATION AND DESCRIPTION OF CONTROLS .. 13

A. BLOWER ( ) Switch ...................................... 13

B. HEAT ( ) Switch ............................................ 13

C. CONVEYOR ( ) Switch ............................... 13

D. Conveyor Speed Controller ............................. 13

ENGLISH

A. Dimensions ...................................................... 4

B. General Specifications ..................................... 4

C. Gas Orifice and Pressure Specifications ......... 4

D. Electrical Specifications - Gas Ovens .............. 4

E. Electrical Specifications - Electric Ovens ......... 5

SECTION 2 - INSTALLATION .................................................. 5

I. INSTALLATION KIT .................................................. 6

A. Components ..................................................... 6

B. Additional Components - Gas Ovens .............. 6

II. VENTILATION SYSTEM ............................................ 6

A. Requirements ................................................... 6

B. Recommendations ........................................... 6

C. Other Ventilation Concerns .............................. 7

III. ASSEMBLY ............................................................... 7

A. Legs/Casters Installation ................................. 7

B. Restraint Cable Installation .............................. 7

E. Digital Temperature Controller ........................ 13

F. Machinery Cpt. Access Panel Safety Switch .... 13

II. NORMAL OPERATION, STEP-BY-STEP ................. 1 4

A. Daily Startup Procedures ................................. 14

B. Daily Shutdown Procedures ............................ 14

III. QUICK REFERENCE: DIGITAL TEMP CONTROL . 15

IV. QUICK REFERENCE: TROUBLESHOOTING ........ 16

SECTION 4 - MAINTENANCE .. ............................................... 17

I. MAINTENANCE - DAILY .......................................... 1 8

II. MAINTENANCE - MONTHLY ................................... 1 8

III. MAINTENANCE - EVERY 3 MONTHS ..................... 1 9

IV. MAINTENANCE - EVERY 6 MONTHS ..................... 19

V. MAINTENANCE - EVERY 12 MONTHS ................... 19

V. KEY SPARE PARTS KIT .......................................... 2 0

A. Components .................................................... 2 0

B. Additional Components - Gas Ovens ............. 20

3

Page 4

SECTION 1 - DESCRIPTION

I. OVEN USES

The PS314SBI oven is optimized to melt cheese for use on

ENGLISH

sandwiches and other food products.

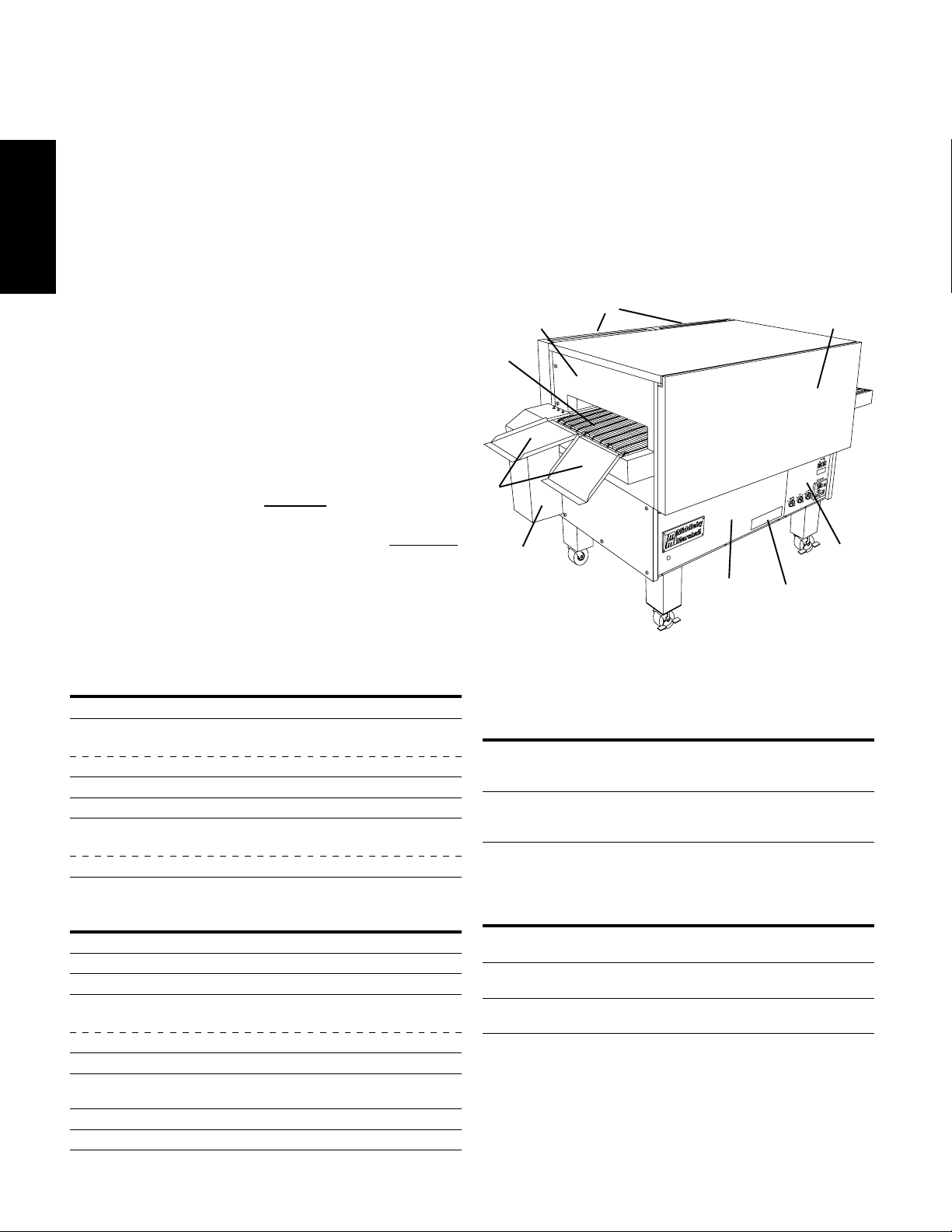

II. OVEN COMPONENTS - see Figure 1-1.

A. Conveyor Drive Motor: Moves the conveyor.

B. End Trays: Catch the food product as it exits the conveyor.

End trays are available in single and double versions for the

PS314SBI oven.

C. Conveyor: Moves the food product through the oven.

D. End Plugs: Allow access to the oven's interior.

E,F.

Cool Front and Rear Panels: Reduce direct user contact

with the body of the oven.

G. Machinery Compartment Access Panel: Allows access

to the oven's interior components. No user-servicable

parts are located in the machinery compartment.

H. Control Compartment Access Panel: Allows access to

the control components. No user-servicable parts are

located in the control compartment.

I. Control Panel: Location of the operating controls for the

oven. Refer to Section 3, Operation, for details.

J. Serial Plate: Provides specifications for the oven that affect

installation and operation. Refer to Section 2, Installation.

Not Shown:

K. Crumb Pans: Catch crumbs and other material that drop

through the conveyor belt. One crumb pan is located

underneath each end of the conveyor.

L. Gas Burner: Gas ovens only. Heats air, which is then

projected to the air fingers by the blowers.

M. Blowers: Project hot air to the air fingers.

N. Air Fingers: Project streams of hot air onto the food product.

Fig. 1-1 - PS314SBI Oven Components

D

E

F

C

B

A

H,I

III. OVEN SPECIFICATIONS

A. Dimensions

Overall Height - inc. top and 9"/229mm legs 54" (1372mm)

Overall Depth - inc. front and rear shrouds

with single exit tray 38-1/2" (978mm)

with double exit trays 39-3/4" (1010mm)

Overall Length - inc. exit tray(s) 83-1/4" (2115mm)

Conveyor Width 24" (610mm)

Recommended Minimum Clearances

Rear of oven (inc. rear shrouds) to wall 1" (25mm)

Conveyor extension (right) or end tray(s) (left) to wall

B. General specifications

Weight 1080 lbs. (497kg)

Shipping Weight 1370 lbs. (630kg)

Shipping Carton Vol. 105 ft.3/2.98m

Rated Heat Input

Gas 135,000 BTU (34,020kcal,40kw/hr)

Electric 26kw/hr.

Max. Op. Temp. 550°F/288°C

Air Blowers

Air Jet Velocity (avg.) 2600 ft./min. (1320cm/sec.)

Warmup Time 15 minutes

2 blowers at 1550 ft.3 (43.9m3)/min. at 1700

RPM, 0.88" (2.2cm) water static pressure

0" (0mm)

3

G

J

C. Gas orifice and pressure specifications - for gas-fired

ovens

Main Pilot Bypass Supply (inlet) Manifold

orifice I.D. orifice I.D. orifice I.D. pressure pressure

Natural Gas

0.219 0.028 0.065/#53 drill 6-12" W.C. 3-1/2" W.C.

5.56mm 0.71mm 1.65mm 14.9-29.9mbar 8.7mbar

Propane

0.134" 0.018" 0.034"/#62 drill 11-14" W.C. 10" W.C.

3.40mm 0.46mm 0.86mm 27.4-34.9mbar 24.9mbar

D. Electrical specifications - for gas-fired ovens

Main Blower Control Circuit Current

Voltage Voltage Phase Freq. Draw Poles Wires

208-240V 120V 1 P h 60Hz 10A 3 Pole 4 Wire (2 hot,

208-240V 120V 1 P h 50/60Hz 10A 2 Pole 3 Wire

(export) (transformer) (2 hot, 1 gnd)

200-220V 120V 1 P h 50/60Hz 10A 2 Pole 3 Wire

(export) (transformer) (2 hot, 1 gnd)

1 neut, 1 gnd)

4

Page 5

SECTION 1 - DESCRIPTION

E. Electrical specifications - for electrically-heated ovens

Main Blower Control Current kW

Voltage Circuit Voltage Phase Freq. Draw Rating Poles Wires

208-240V 120V 3 P h 60 Hz 67.3A at 208V 26.0 kW at 208V 4 Pole 5 Wire (3 hot, 1 neut, 1 gnd)

(with 3 Ph blower motors) 58.4A at 240V 26.0 kW at 240V

208-240V 120V 3 P h 60 Hz 67.3A at 208V 26.0 kW at 208V 4 Pole 5 Wire (3 hot, 1 neut, 1 gnd)

(with 1 Ph blower motors) 58.4A at 240V 26.0 kW at 240V

200-220V (export) 120V (transfomer) 3 P h 50/60 Hz 67.3A at 208V 24.3 kW at 208V 3 Pole 4 Wire (3 hot, 1 gnd)

240V (export) 120V (transformer) 3 Ph 50/60 Hz 58.4A 26.0 kW 3 Pole 4 Wire (3 hot, 1 gnd)

380V (export) 120V (transformer) 3 Ph 50/60 Hz 36.8A 24.3 kW 3 Pole 4 Wire (3 hot, 1 gnd)

400-416V (export) 120V (transfomer) 3 P h 50/60 Hz 33.8A 24.3 kW 3 Pole 4 Wire (3 hot, 1 gnd)

480V 120V (transformer) 3 Ph 60 Hz 29.2A 26.0 kW 3 Pole 4 Wire (3 hot, 1 gnd)

IMPORTANT: Additional electrical information is provided on the oven's serial plate, and on the wiring diagram inside the

machinery compartment.

53.5A at 220V 20.4 kW at 220V

SECTION 2 - INSTALLATION

WARNING

Keep the appliance area free and clear of combustibles.

WARNING

Do not obstruct the flow of combustion and ventilation air to and from your oven. There must be no

obstructions around or underneath the oven.

ENGLISH

CAUTION

For additional installation information, refer to the following documents:

PS360 Pre-Installation Procedures Manual (Middleby Marshall P/N 88210-0024)

PS360 Installation Manual (Middleby Marshall P/N 88210-0025)

Or, contact your local Authorized Service Agent.

NOTE

There must be adequate clearance between the oven and combustible construction. Clearance

must also be provided for servicing and for proper operation.

NOTE

An electrical wiring diagram for the oven is located inside the machinery compartment.

NOTE

All aspects of the oven installation, including placement, utility connections, and ventilation requirements, must

conform with any applicable local and national codes. These codes supercede the requirements and guide-

lines provided in this manual.

NOTE

In U.S.A., the oven installation must conform with local codes, or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1. The oven, when installed, must be electrically grounded in accordance

with local codes, or in the absence of local codes, with the National Electrical Code (NEC), or ANSI/NFPA70.

NOTE

In Canada, the oven installation must conform with local codes, or in the absence of local codes, with the

Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Gas Installation Code, CAN/CGA-B149.2, as

applicable. The oven, when installed, must be electrically grounded in accordance with local codes, or in the

absence of local codes, with the Canadian Electrical Code CSA, C22.2, as applicable.

NOTE

For Australian installation, the oven installation must conform with AGA Code, AG601, and with any require-

ments of the appropriate statutory authority.

5

Page 6

SECTION 2 - INSTALLATION

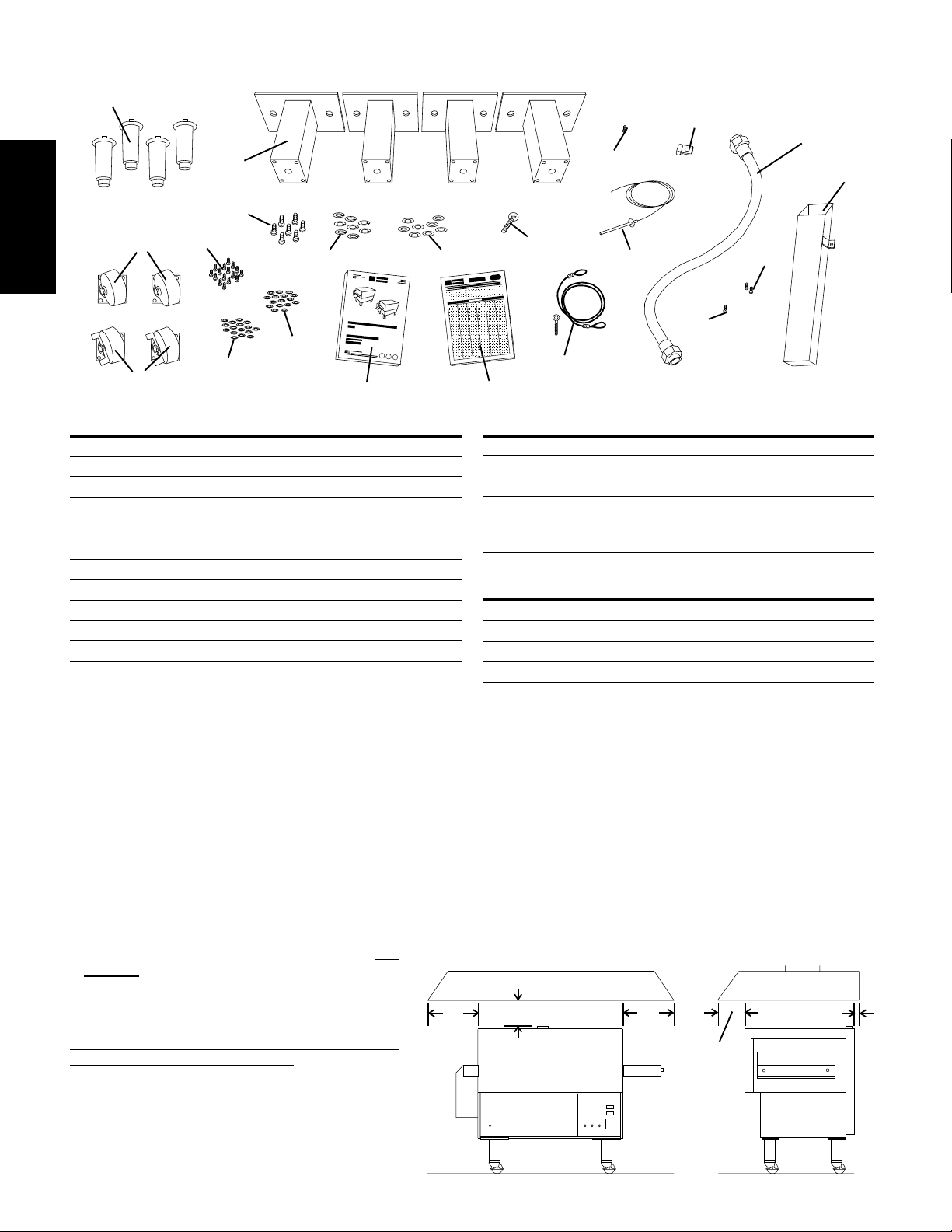

I. INSTALLATION KIT

1

ENGLISH

Fig. 2-1 - Installation Kit

14

18

7

15

19

8

2

4

9

10

6

3

5

16 17

A.Installation kit components

Item Description Part Number Qty.

1 Legs, adjustable 22450-0028 4

2 Caster (Rear), Swivel 22290-0010 2

3 Caster (Front), Swivel, with brake 22290-0009 2

4 Screw, hex, 3/8-16 x 1" 220373 16

5 Lockwasher, 3/8" 21422-0001 16

6 Flat washer, 3/8" 21416-0001 16

7 Leg, 9" (229mm) 34684 4

8 Screw, hex, 3/4-10 x 2" 21321-0016 7

9 Lockwasher, 3/4" 21421-0003 8

10 Flat washer, 3/4" 21411-0019 8

11 Shoulder eyebolt, 3/4"-10 x 2" 42440 1

12 Restraint Cable Assembly 22450-0228 1

11

13

20

21

12

Item Description Part Number Qty.

13 Thermocouple 33812-1 1

14 Cable Clamp 27276-0001 1

15 Screw, #10-32 x 3/8" 21256-0008 1

16 Model PS314SBI Owner's Operating 42447 1

and Installation Manual

17 Authorized Service Agency Listing 1002040 1

B. Additional installation kit components for gas ovens

18 Gas hose, flexible 22361-0001 1

19 Flue vent, 14" (356mm) 30773 1

20 Screw, hex, #2PT 10-16 x 3/4" HWH 21292-0001 2

21 Screw, #10-32 x 3/8" 21256-0008 1

II. VENTILATION SYSTEM

IMPORTANT

Where national or local codes require the installation of fire

suppression equipment or other supplementary equipment,

DO NOT mount the equipment directly to the oven.

MOUNTING SUCH EQUIPMENT ON THE OVEN MAY:

VOID AGENCY CERTIFICATIONS

RESTRICT SERVICE ACCESS

LEAD TO INCREASED SERVICE EXPENSES FOR THE

OWNER

A. Requirements

CAUTION

A mechanically driven ventilation system is RE-

QUIRED for gas oven installations.

A mechanically driven ventilation system is

STRONGLY RECOMMENDED for electric oven

installations.

PROPER VENTILATION OF THE OVEN IS THE RESPONSIBILITY OF THE OWNER.

B. Recommendations

NOTE THAT THE HOOD DIMENSIONS SHOWN IN

FIGURE 2-2 ARE RECOMMENDATIONS ONLY. LOCAL AND NATIONAL CODES MUST BE FOLLOWED

WHEN INSTALLING THE VENTILATION SYSTEM.

18"

458mm

ANY APPLICABLE LOCAL AND NATIONAL CODES SUPERSEDE THE RECOMMENDATIONS SHOWN IN THIS MANUAL.

The rate of air flow exhausted through the ventilation system

may vary depending on the oven configuration and hood design.

Consult the hood manufacturer or ventilation engineer for these

specifications.

To avoid a negative pressure condition in the kitchen area,

return air must be brought back to replenish the air that was

exhausted. A negative pressure in the kitchen can cause heatrelated problems to the oven components as if there were no

Fig. 2-2 - Ventilation System

2"/51mm minimum

6

18"

458mm

12"

305mm

3"

76mm

Page 7

ventilation at all. The best method of supplying return air is

through the heating, ventilation and air conditioning (HVAC)

system. Through the HVAC system, the air can be temperaturecontrolled for summer and winter. Return air can also be

brought in directly from outside the building, but detrimental

effects can result from extreme seasonal hot and cold temperatures from the outdoors.

NOTE: Return air from the mechanically driven system

must not

blow at the opening of the baking chamber. Poor oven baking

performance will result.

Fig. 2-3 - Leg Extensions

Rear of oven

SECTION 2 - INSTALLATION

Drive end

(left side of

oven)

C. Other ventilation concerns

Special locations, conditions, or problems may require the

services of a ventilation engineer or specialist.

Inadequate ventilation can inhibit oven performance.

It is recommended that the ventilation system and duct

work be checked at prevailing intervals as specified by the

hood manufacturer and/or HVAC engineer or specialist.

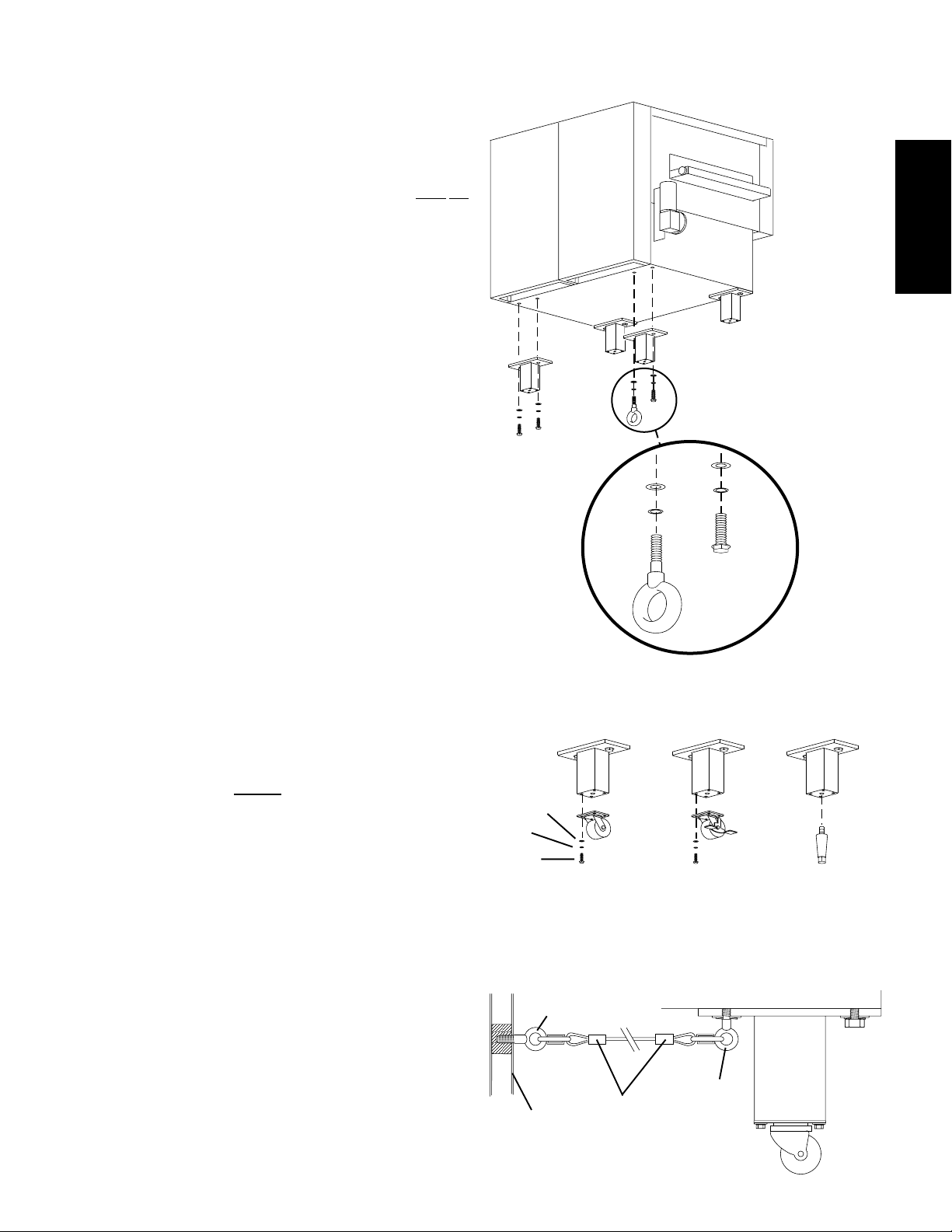

III. ASSEMBLY

A. Legs/Casters Installation

1. Move the oven to its final location using the casters that are

pre-attached to the bottom panel.

2. Elevate the oven until its bottom surface is at least 18"

(457mm) above the floor.

3. Remove the casters from the bottom of the oven. These

casters are attached for pre-installation movement ONLY,

and may not be left on the oven.

4. Attach one of the 9" (229mm) leg extensions to the REAR

DRIVE-END (rear left) corner of the oven, as shown in

Figure 2-3. On the OUTSIDE hole of the leg extension, use

one 3/4"-10 hex screw, one 3/4" lockwasher, and one 3/4"

flat washer. On the INSIDE hole of the leg extension, use

the 3/4"-10 shoulder eyebolt (supplied in the Installation

Kit) in place of the screw.

5. Attach the 3 remaining leg extensions using the remaining

screws, lockwashers, and flat washers.

6. Attach EITHER the 6" (152mm) adjustable legs OR the

casters to the bottom of the 9" leg extensions, as follows:

THE 6" (152mm) ADJUSTABLE LEGS may only be

used if there is at least 24" (610mm) service access

on ALL FOUR sides of the oven. To attach the adjustable

legs, screw the threaded stud into the center hole of the

leg extension. See Figure 2-4.

CASTERS may be used in all installations. To attach

the casters, use the 3/8"-16 hex screws, 3/8"

lockwashers, and 3/8" flat washers supplied in the

Installation Kit. See Figure 2-4. The two locking

casters should be installed at the front of the oven.

7. Lower the oven to the floor.

If the 6" (152mm) legs were used in the installation,

adjust the "foot" section of each leg to level the oven.

If the casters were used in the installation, lock the front

casters in place.

washer

Lock

washer

screw

Flat

washer

Lock

washer

Eyebolt (this

leg extension

only)

Fig. 2-4 - Adjustable Legs and Casters

Flat

Hex

Caster without

brake - rear legs

OR OR

Caster with brake -

front legs

Fig. 2-5 - Installing the Restraint Cable

3/4 (19mm)

eyebolt

Hex

screw

ENGLISH

Adjustable

leg

B. Restraint Cable Installation

Because the oven is equipped with casters, a restraint cable

assembly must be installed to limit the movement of the

appliance without depending on the connector and the quick

disconnect device or its associated piping. Anchor one end of

the cable to the eyebolt on the left rear leg extension. Anchor the

opposite end to the wall as shown in Figure 2-5, using the

eyebolt supplied with the restraint cable assembly.

Eyebolt on

Restraint cable

Wall of

structure

7

assembly

left rear leg

extension

Page 8

SECTION 2 - INSTALLATION

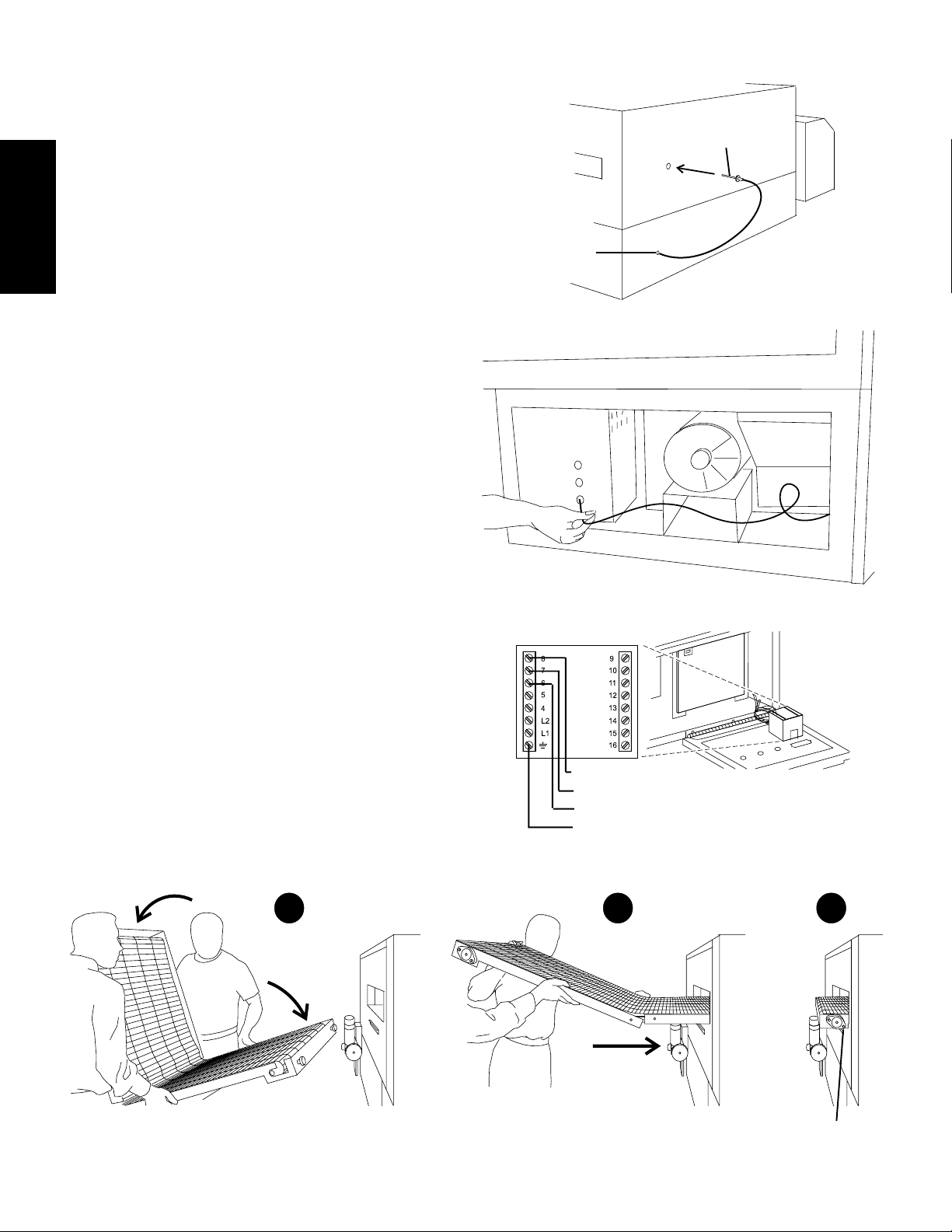

IV. THERMOCOUPLE INSTALLATION

1. Install the thermocouple sensing bulb into the hole in the

rear of the oven, as shown in Figure 2-6. Fasten the

thermocouple in place using the #10-32 x 3/8" screw

ENGLISH

supplied in the Installation Kit.

2. Thread the thermocouple lead(s) through the grommet

and into the machinery compartment, as shown in Figure

2-6.

Figure 2-6 - Thermocouple Installation Location

Thermocouple

3. Remove the right-side access panel of the machinery

compartment.

4. Thread the thermocouple lead(s) through the side of the

machinery compartment as shown in Figure 2-7, and into

the electrical box (at the right-front of the machinery compartment).

5. Connect the thermocouple leads to the temperature controller as shown in Figure 2-8.

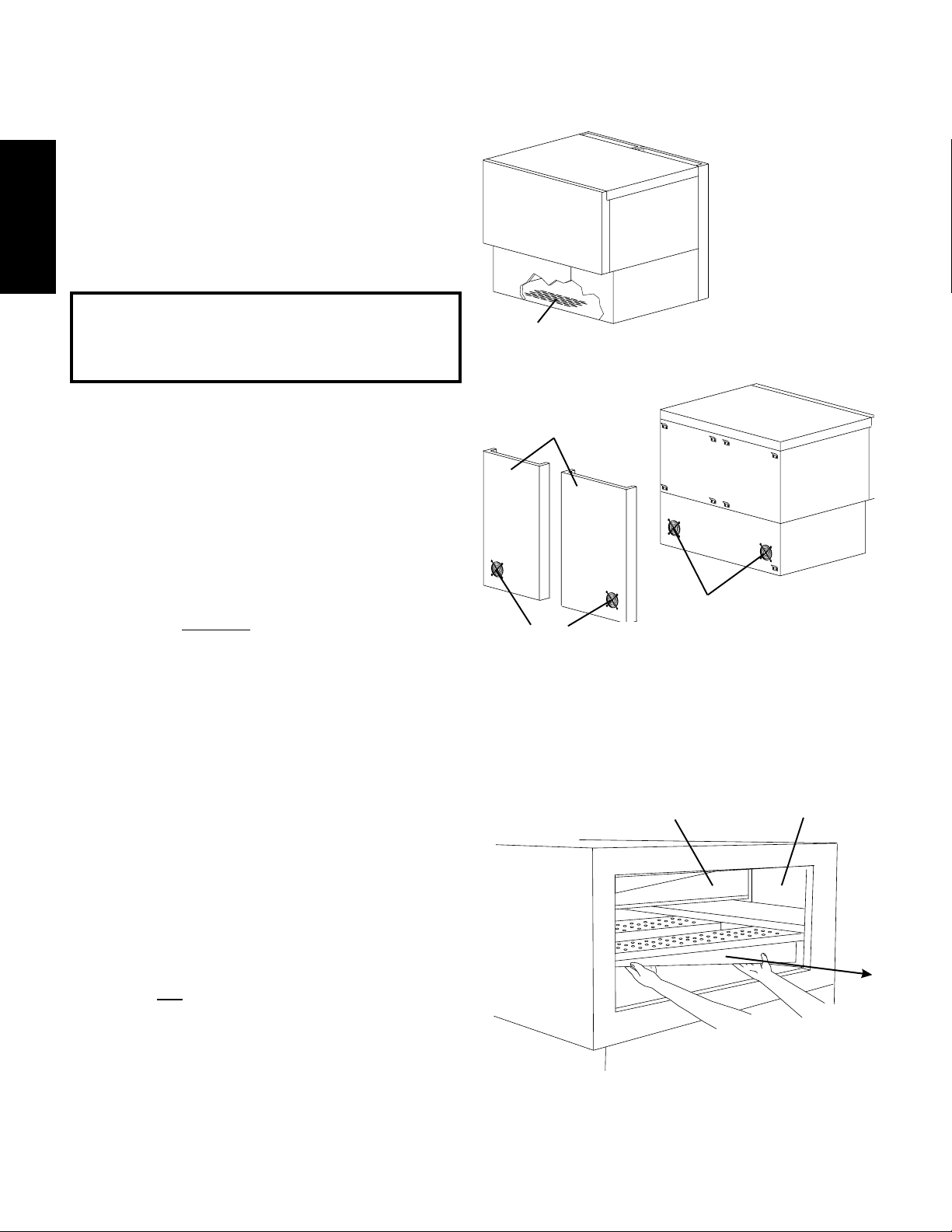

V. CONVEYOR INSTALLATION

NOTE

The conveyor assembly MUST be inserted from the drive end

of the oven.

1. Lift the conveyor and position it in the oven as shown in

Figure 2-9.

2. Continue moving the conveyor into the oven until the lip on

the bottom edge of the frame butts firmly against the end

plug.

Grommet-

protected hole

Figure 2-7 - Placing the Thermocouple Leads

Figure 2-8 - Thermocouple Lead Connections

8=White=Positive

7=Red=Negative

R=No Connection

Ground=Shielded cable

Figure 2-9 - Conveyor Installation

1 2 3

Unfold

conveyor

Slide into drive

end of oven

Lip on bottom

edge of frame fits

against end plug

8

Page 9

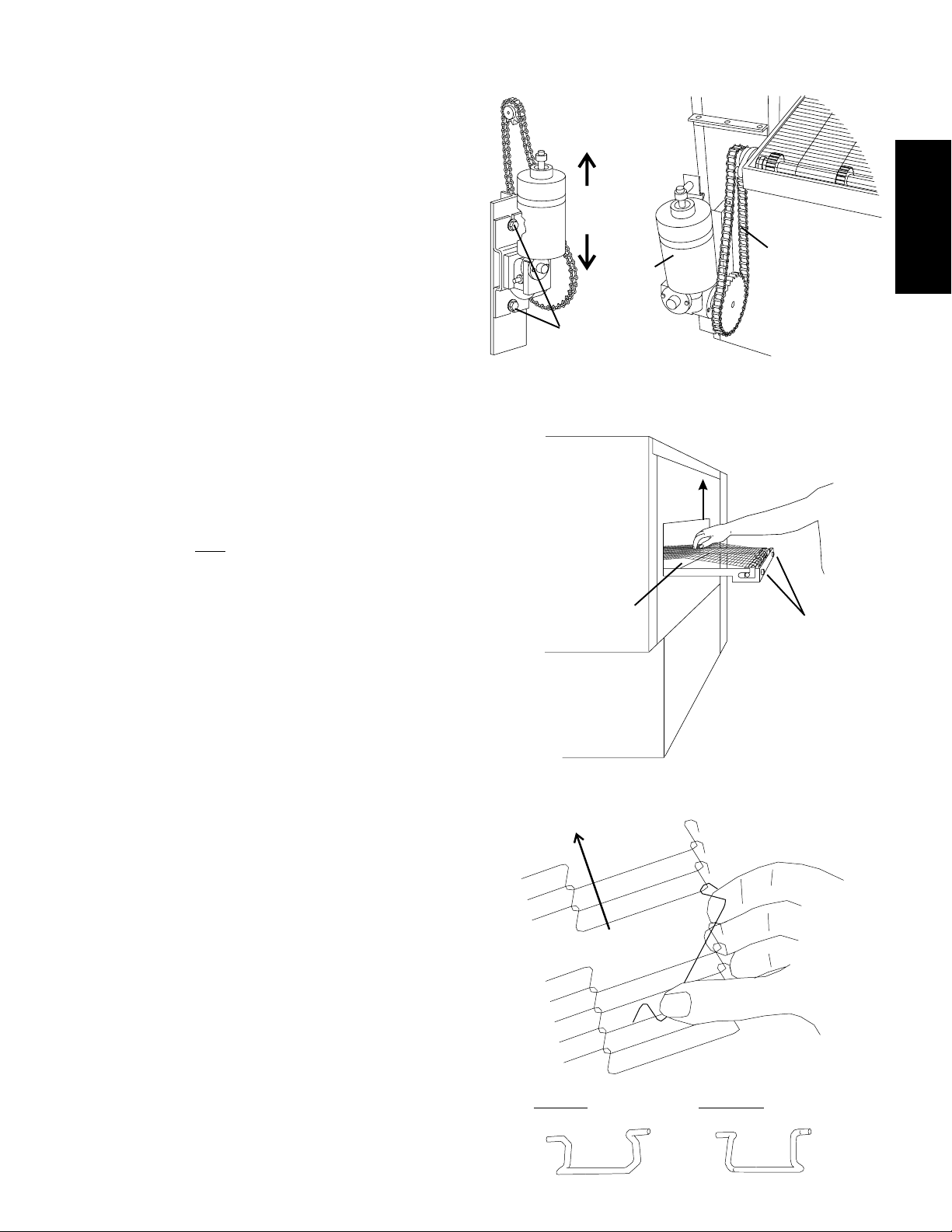

3. Install the drive chain between the conveyor drive sprocket

and the motor sprocket as shown in Figure 2-10. Then,

check the tension of the drive chain. The chain should have

a 1/2" (13mm) deflection.

If necessary, the motor can be repositioned to allow the

chain to be installed, or to correct the tension of the chain

after it is in place. To reposition the motor:

Loosen the two hex head screws that fasten the

conveyor motor's mounting bracket to the oven. The

screws are shown in Figure 2-10.

Raise or lower the motor slightly, as required. Tighten

the two hex screws, and check the chain tension.

Repeat these steps as necessary until the drive chain

has the correct 1/2" (13mm) deflection.

4. Check the tension of the conveyor belt at the IDLER (right)

end of the conveyor, by lifting the center of the belt straight

up with your fingers as shown in Figure 2-11. The belt

should lift between 2-3" (50-75mm). DO NOT OVERTIGHTEN THE CONVEYOR BELT.

NOTE:

If necessary, the belt tension can be adjusted by turning the

conveyor adjustment screws, located at the idler (right) end

of the conveyor. See Figure 2-11.

SECTION 2 - INSTALLATION

Figure 2-10 - Drive Motor and Drive Chain

Drive chain

Motor

Loosen hex screws and

slide motor up or down to

adjust belt tension

Figure 2-11 - Conveyor belt tension

Lift belt straight

up as shown

ENGLISH

5. Check for freedom of movement of the conveyor belt by

pulling it for about 2-3 feet (60 to 90 cm) with your fingers.

The conveyor must move freely.

6. If necessary, links can be added to or removed from the

conveyor belt to achieve the correct deflection of 2-3" (5075mm). If links must be removed from the belt, it can be

reattached to the conveyor as follows:

a. The conveyor belt links must be oriented as shown in

Figure 2-12.

b. The smooth side of the conveyor belt must face UP.

c. Connect the inside master links. Check that the links

are oriented as shown in Figure 2-12.

d. Connect the outside master links. Note that the

outside master links have right and left sides. The

right-side master link has an open hook facing you, as

shown in Figure 2-12.

e. Return to Step 4, above, to re-check the belt tension.

Belt deflection

should be 2-3

(50-75mm)

Adjust tension by

turning screws (2)

Figure 2-12 - Master link orientation

Direction of

travel

Correct outside

master link

orientation

CORRECT inside master

link orientation

9

INCORRECT inside master

link orientation

Page 10

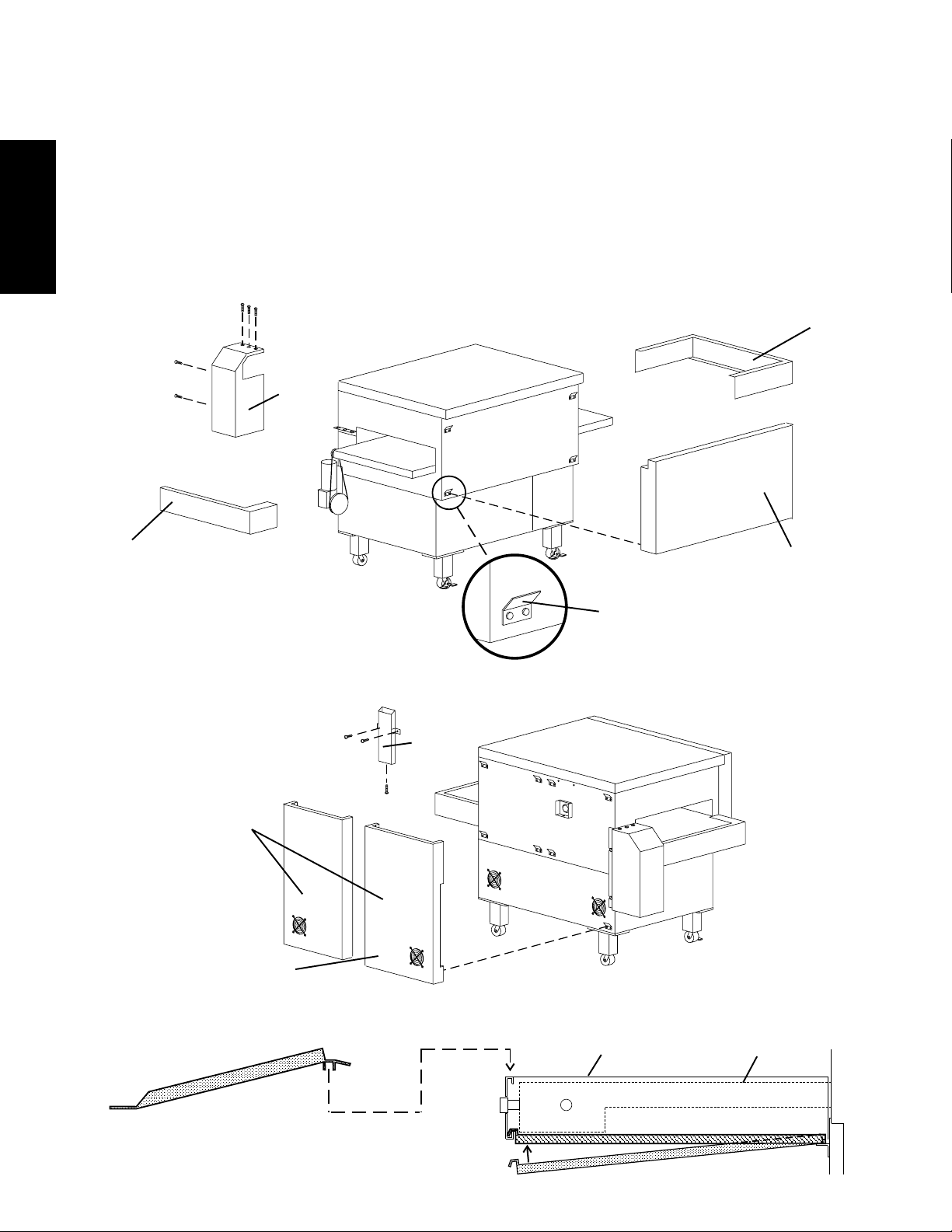

SECTION 2 - INSTALLATION

VI. FINAL ASSEMBLY

1. For gas ovens, attach the flue vent to the rear wall of the oven

as shown in Figure 2-13. Use one #10-16 x 3/8" screw and

two #10-32 x 3/4" screws. All three screws are provided in

ENGLISH

the Installation Kit.

2. Install the motor housing, and secure it in place with its five

mounting screws. Two screws are located on the back wall

of the oven, while three are located on the hanger bracket

on the left end panel. See Figure 2-13.

3. Install the conveyor extension covers over the ends of the

conveyor frame. See Figure 2-13.

4. Check that the cool panels are properly mounted, as shown

in Figures 2-13 and 2-14. Slots on the back of the panels

fit over the hangers on the walls of the oven. One cool panel

is attached to the front of the oven, while two are attached

to the rear.

5. Attach the exit tray(s) at the drive (left) end of the conveyor.

See Figure 2-15.

6. Install the crumb trays underneath the conveyor as shown

in Figure 2-15. First, place the inside edge of the tray onto

the bracket attached to the end plug. Then, swing the

outside edge of the tray up and into place.

2 rear

screws

Extension cover

(drive end)

3 upper

screws

Rear cool

panels

Motor

shroud

2 rear

#10-16 x 3/4"

screws

1 bottom

#10-32 x 3/8"

screw

Figure 2-13 - Final Assembly - Front

Figure 2-14 - Final Assembly - Rear

Flue vent

(gas ovens

only)

Extension cover

(idler end)

Front cool

panel

Hangers on oven

wall fit into slots on

cool panels

Exit tray(s)

Drive-end rear

panel notched for

motor shroud

Figure 2-15 - Final Assembly - Exit Tray(s) and Crumb Trays

Conveyor extension Conveyor frame

Crumb tray

10

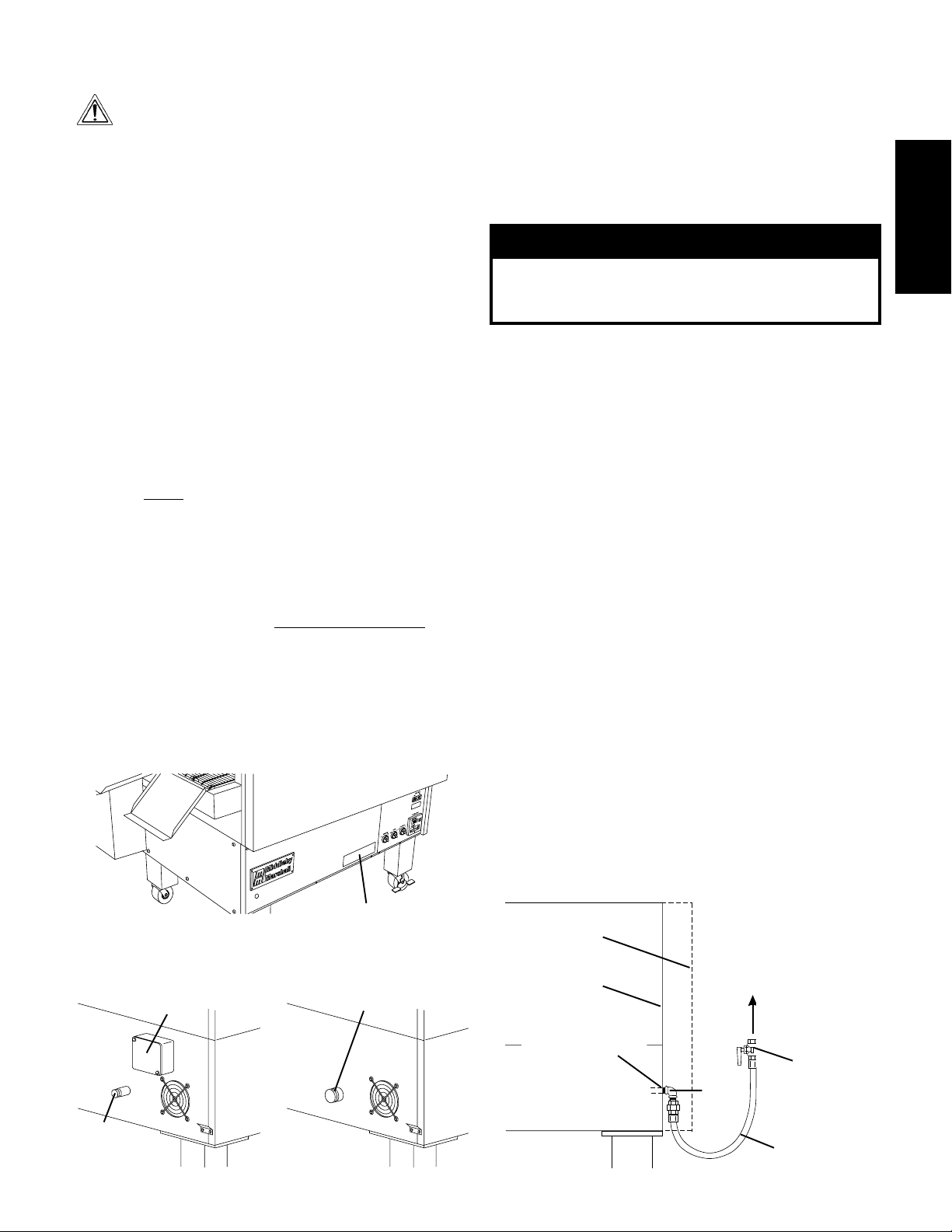

Page 11

VII. ELECTRICAL SUPPLY (all ovens)

WARNING

Authorized supplier personnel normally accomplish

the connections for the ventilation system, electric supply,

and gas supply, as arranged by the customer. Following

these connections, the factory-authorized installer can

perform the initial startup of the oven.

NOTE: The electric supply installation must satisfy the

requirements of the appropriate statutory authority, such as the

National Electrical Code (NEC), ANSI/NFPA70, (U.S.A.); the

Canadian Electrical Code, CSA C22.2; the Australian Code

AG601; or other applicable regulations.

NOTE: The electric supply connection must meet all national

and local electrical code requirements.

NOTE: It may be necessary to temporarily remove the rear cool

panels to connect the electrical supply.

Check the oven serial plate before making any electric supply

connections. Electric supply connections must agree with data

on the oven serial plate. The location of the serial plate is shown

in Figure 2-16.

A fused disconnect switch or a main circuit breaker (customer

furnished) MUST be installed in the electric supply line for each

oven cavity. It is recommended that this switch/circuit breaker

have lockout/tagout capability.

The supply conductors must be of the size and material (copper) recommended. Refer to the wiring diagram inside the

machinery compartment or control compartment of the oven.

Electrical specifications are also listed on the oven's serial

plate (Figure 2-16) and in the

(on Pages 4-5).

The oven requires a ground connection to the oven ground

screw located in the electrical junction box. (The box is shown

in Figure 2-17.) If necessary, have the electrician supply the

ground wire. Do NOT use the wiring conduit or other piping for

ground connections!

Figure 2-16 - Oven Serial Plate

Electrical Specifications tables

SECTION 2 - INSTALLATION

CAUTION

Before connecting incoming power to the oven, measure the

voltage of each input leg to neutral. The expected voltage is

approximately 120V. ANY voltage reading exceeding 130V

indicates that the supply has a high leg. CONNECTING A

HIGH LEG TO THE OVEN VOIDS ALL OVEN WARRANTIES.

Connecting a high leg to the black lead of the oven can

severely damage the ovens electrical and electronic

components.

CAUTION

DO NOT CONNECT BLACK WIRE TO HIGH LEG.

VOLTAGE OF THE BLACK AND WHITE WIRES MUST

BE NO HIGHER THAN 130 VAC.

A. Additional Information - Electric Ovens

For electric ovens, a 1-1/4" (32mm) dia. cutout in the back

wall of the machinery compartment provides access for the

electrical supply connections. See Figure 2-17. Using

flexible cables for the electric power supply conductors

requires a 1-1/4" (32mm) strain-relief fitting (not furnished

with the oven) to enable safe access to the terminal block

from which power is distributed to the oven.

B. Additional Information - Gas Ovens

All gas oven electric supply connections are made via the

electrical junction box on the rear of the oven, shown in

Figure 2-17. The power lines then connect to the oven

circuits through the Machinery Compartment Access Panel

Safety Switch. This switch interrupts electric power to the

oven when the Machinery Compartment Access Panel is

opened.

C. Additional Information - Ovens with External Transform-

ers (export versions)

Position the transformer on the rear wall of the oven, on the

same side as the control compartment, as space permits.

Fasten it in place using the supplied mounting hardware.

D. Connection

Refer to the wiring diagram inside the machinery

compartment or control compartment of the oven to

determine the correct connections for the electrical supply

lines. Connect the supply as indicated on the wiring

diagram. Be sure to connect the electrical supply ground

wire to the oven ground screw located in the junction box on

the rear of the oven.

ENGLISH

3/4" (19mm)

pipe for

gas utility

connection

Serial plate location

Figure 2-17 - Utility Connection Locations

Gas oven Electric oven

Electrical

junction box

1-1/4" (32mm) conduit for

electric utility connection

11

Rear cool

panel

Rear wall

of oven

Appliance

Connection/Male

Nipple

Figure 2-18 -

Flexible Gas Hose

Installation

To Gas

Supply Pipe

90°

Elbow

Flexible

Gas Hose

Full-Flow Gas

Shutoff Valve

Page 12

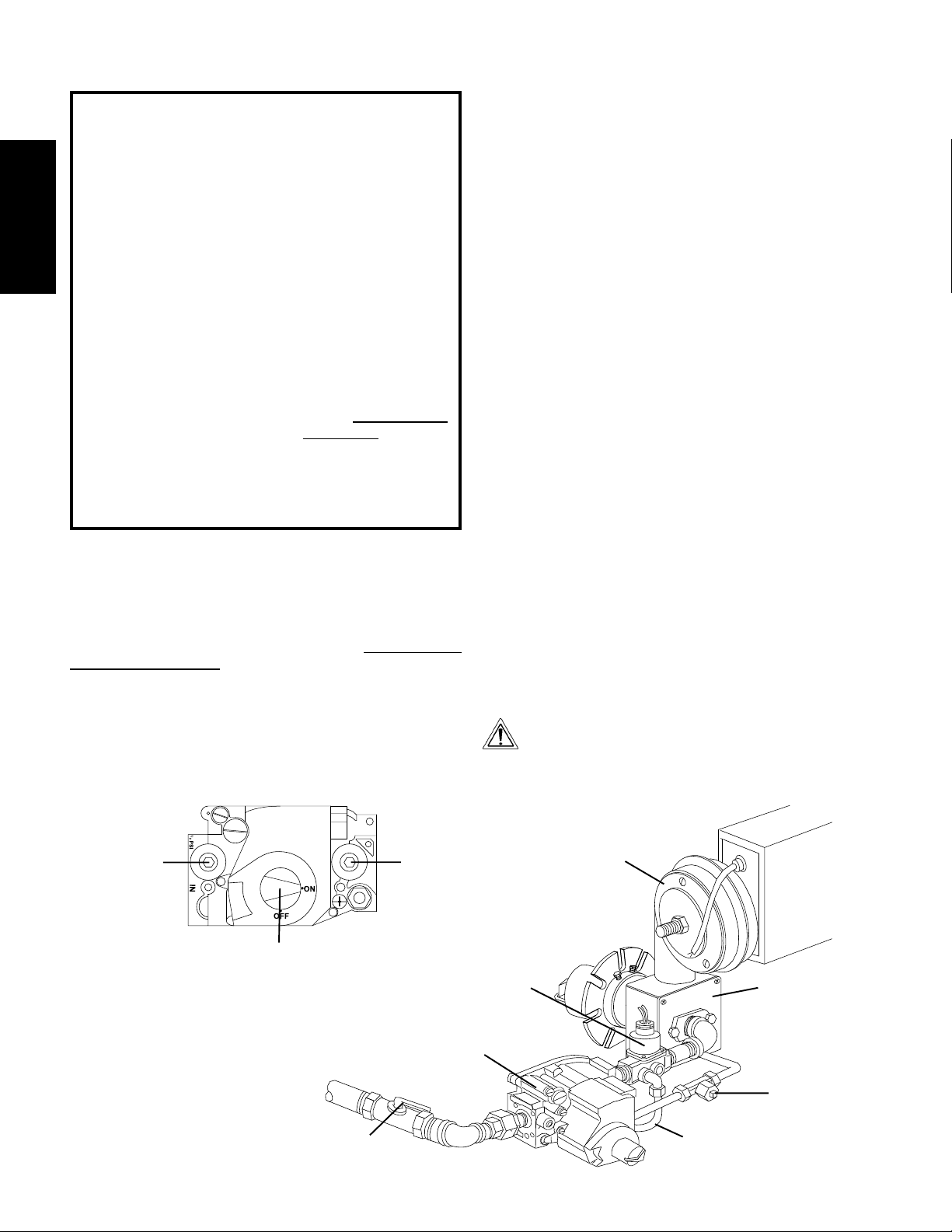

SECTION 2 - INSTALLATION

VIII. GAS SUPPLY (gas ovens only)

CAUTION

DURING PRESSURE TESTING NOTE ONE OF THE FOLLOW-

ENGLISH

ING:

1. The oven and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressure in

excess of 1/2 psi (3.45 kPa).

2. The oven must be isolated from the gas supply piping

system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressure equal to or less than 1/2 psi (3.45

kPa).

3. If incoming pressure is over 14 W.C. (35mbar), a

separate regulator MUST be installed in the line BEFORE

the individual shutoff valve for the oven.

WARNING: To prevent damage to the control valve

regulator during initial turn- on of gas, it is very important

to open the manual shutoff valve very slowly.

After the initial gas turn-on, the manual shutoff valve

must remain open except during pressure testing as

outlined in the above steps or when necessary during

service maintenance.

A. Connection

NOTE: It may be necessary to temporarily remove the rear cool

panels to connect the gas supply.

Check the ovens gas supply requirements before making the

gas utility connection. Gas supply requirements are listed on

the ovens serial plate (Figure 2-16) and in the Gas Orifice and

Pressure Specifications table (Page 4 of this manual).

Check the serial plate to determine the type of gas (Propane or

Natural) to be used with the oven.

Refer to the instructions in the gas hose package (included in

the Installation Kit) before connecting the gas line. One gas line

connection method is shown in Figure 2-18; however,

compliance with the applicable standards and regulations is

mandatory.

Inlet, regulated, and pilot gas pressure readings can be taken

using a U tube manometer at the tap locations shown in Figure

2-19.

One 90° elbow equals a 7 (2.13m) length of pipe. The

recommended pipe sizes are larger than usually required to

eliminate any operation problems. It is much less expensive

to make the initial installment large enough to do the job rather

than redoing the job later.

NOTE: The installation must conform with local codes or in the

absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1-latest edition.

In Australia, the installation must conform with AGA Code

AG601 and with any requirements of the appropriate statutory

authority.

CANADIAN:

CAN/CGA-B 149.1 Natural Gas Installation Code

CAN/CGA-B 149.2 Propane Installation Code

Certain safety code requirements exist for the installation of gas

ovens; refer to the beginning of Section 2 for a list of the

installation standards. In addition, because the oven is equipped

with casters, the gas line connection shall be made with a

connector that complies with the Standard for Connectors for

Movable Gas Appliances, ANSI Z21.69 (in U.S.A.), or, if applicable, Connectors for Movable Gas Appliances, CAN/CGA-6.16

(in Canada), as well as a quick-disconnect device that complies

with the Standard for Quick-Disconnect Devices for Use With

Gas Fuel, ANSI Z21.41 (in U.S.A.), or, if applicable, QuickDisconnect Devices for Use With Gas Fuel, CAN1-6.9 (in

Canada).

B. Gas Conversion

Where permitted by local and national codes, it is possible to

convert ovens from natural to propane gas, or from propane to

natural gas. Use the appropriate Middleby Marshall Gas

Conversion Kit for the specific oven model.

WARNING

All installations, conversions and service work must be

performed by an authorized service agent.

Inlet pressure tap

(where incoming

gas pressure is

measured)

On/Off Knob

Always leave in

ON position

Figure 2-19 - Gas Burner and Piping Assembly

Manifold pressure tap

(where manifold gas

pressure is measured)

High Flame

Solenoid Valve

Combination Gas

Control Valve

(Safety Regulator)

Manual

shutoff valve

12

Burner Blower

Gas Burner

Pilot pressure tap

(where pilot gas

pressure is measured)

Low Flame

Bypass Line

Page 13

SECTION 3 - OPERATION

I. LOCATION AND DESCRIPTION OF CONTROLS

Fig. 3-1 - Control Panel

D.

Conveyor Speed

(or "

")

controller

ENGLISH

A.

"BLOWER"

")

(or "

switch

A.

"BLOWER" Switch: Turns the blowers and

"HEAT"

(or "

switch

B.

")

cooling fans on and off. The HEAT Switch has no

C.

"CONVEYOR"

(or "

switch

D.

")

Conveyor Speed Controller: Adjusts and displays the bake time.

E.

Digital Temperature

(or "

")

controller

effect unless the BLOWER Switch is in the ON

position.

B.

"HEAT" Switch: Allows the gas burner to light.

Activation of the gas burner is determined by the

settings on the Digital Temperature Controller.

E.

Digital Temperature Controller: Continuously

monitors the oven temperature. Settings on the

Digital Temperture Controller control the activation of the gas burner.

C.

"CONVEYOR" Switch: Turns the conveyor drive

motor on and off.

NOT SHOWN:

F. Machinery Compartment Access Panel Safety Switch:

Disconnects electrical power to the controls and the blowers when the machinery compartment access panel is

opened. The panel should only be opened by authorized

service personnel.

13

Page 14

SECTION 3 - OPERATION

II. NORMAL OPERATION - STEP-BY-STEP

IMPORTANT

Bake time and temperature settings for the oven are preset

ENGLISH

at the factory to customer-approved settings. These settings should not be changed during normal operation.

A. DAILY STARTUP PROCEDURE

1. Check that the circuit breaker/fused disconnect is in the on

position. If the oven is equipped with a window, check that

the window is closed.

2. Turn the "BLOWER" (or

) switch to the ON (or

"I") position.

3. Turn the "CONVEYOR"

(or

ON (or "I") position.

4. If necessary, adjust the

conveyor speed setting

by turning the three

thumbwheels to change

the displayed bake time.

5. Adjust the temperature controller to a desired set temperature, if necessary.

Press the Set Point

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press the Up Arrow

6. Turn the "HEAT" (or

switch to the "ON" (or "I")

position, and wait for the

"HEAT ON" light to turn

on.

) switch to the

and Unlock keys at

the same time. Wait

for the "SET PT" light

to turn on.

and Down Arrow

Keys as necessary

to adjust the setpoint.

+

or

)

or

or

mins secs

thumbwheels

or

wait

for

wait

for

7. Wait for the oven to heat to the setpoint temperature. Higher

setpoint temperatures will require a longer wait. The oven

can reach a temperature of 500°F (232°C) in approximately

5 minutes.

8. (Optional) Press the Temperature (

the Actual Temperature

in the display, and wait

for the "ACTUAL TEMP"

light to turn on. This allows you to monitor the

oven temperature as it

rises to the setpoint.

9. Allow the oven to preheat for 10 minutes after it has reached

the set point temperature.

B. DAILY SHUTDOWN PROCEDURE

1. Turn the "HEAT" (or )

and "BLOWER" (or

switches to the "OFF" (or

"O") position. Note that

the blowers will remain

in operation until the oven

has cooled to below

200°F (93°C).

) key to show

wait

for

)

+

- - - - - or - - - - -

+

2. Make certain that there

are no products left on

the conveyor inside the

oven. Turn the "CONVEYOR" (or

to the "OFF" (or "O") position.

3. If the oven is equipped with a window, open the window to

allow the oven to cool faster.

4. After the oven has cooled and the blowers have turned off,

switch the circuit breaker/fused disconnect to the off position.

) switch

IMPORTANT

On gas ovens, if the "HEAT ON" light will not illuminate, OR

if the oven does not heat, the gas burner may not have lit.

Turn the "HEAT" (

(

) switches to the "OFF" ("O") position. Wait for AT

LEAST FIVE MINUTES before restarting the oven. Then,

repeat the Daily Startup procedure.

), "BLOWER" ( ), and "CONVEYOR"

CAUTION

In case of power failure, turn all switches to the OFF (or

"O") position, open the oven window, and remove the

product. After the power has been restored, perform the

normal startup procedure.

The burner will not operate and gas will not flow through

the burner without electric power. No attempt should be

made to operate the oven during a power failure.

or

14

Page 15

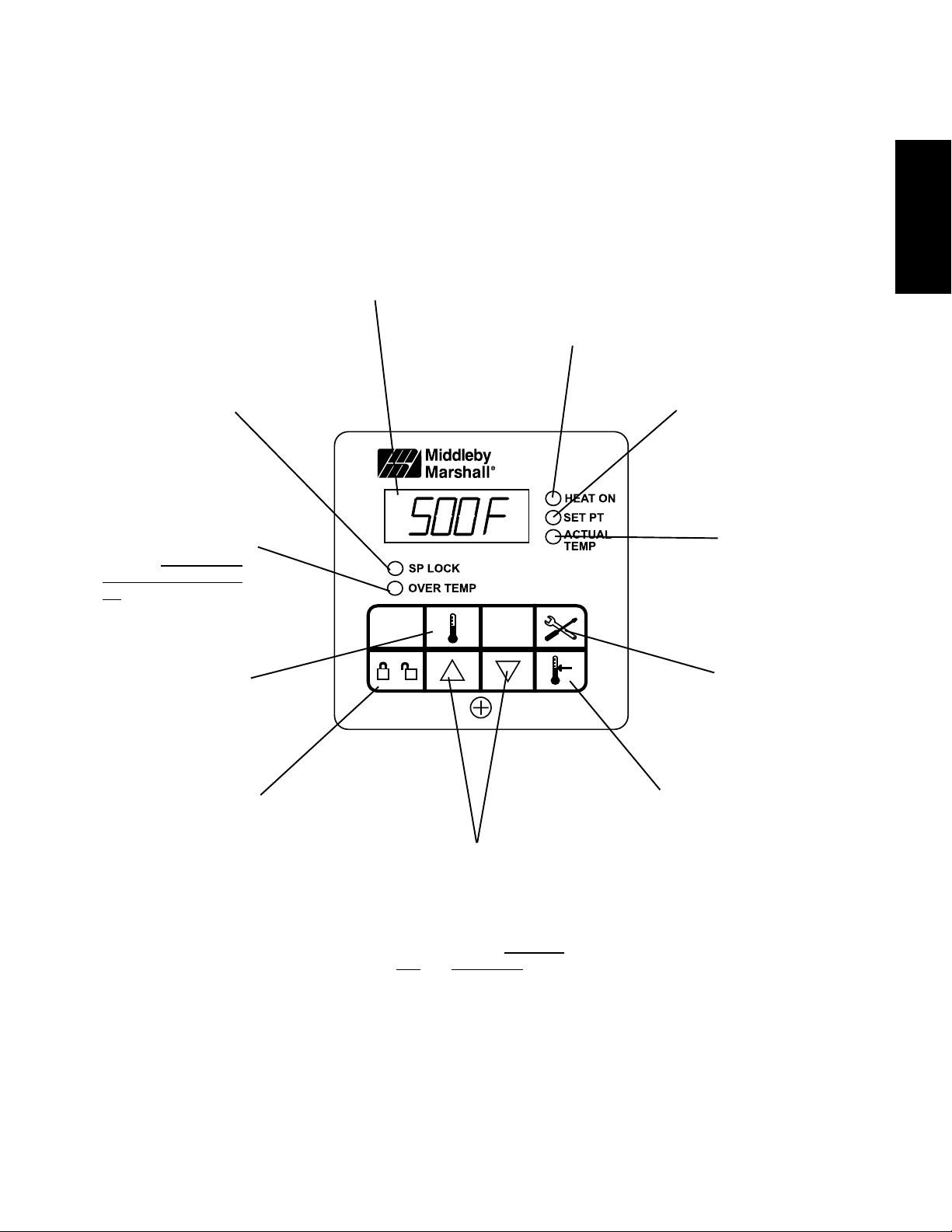

III. QUICK REFERENCE: DIGITAL TEMPERATURE CONTROLLER

SECTION 3 - OPERATION

"SP LOCK" Light

Lights when the set

point is locked out

from changes. This

setting can only be

changed by service

personnel.

OVERTEMP Light

Lights when the oven

temperature is greater

than 650°F (343°C).

Refer to

ence: Troubleshooting in this section.

Temperature Key

Press this key once to

view the Actual Temperature in the Display.

Quick Refer-

Display

Shows the Set Point or

the Actual Temperature in degrees Fahrenheit (F) or Celsius

(C).

"HEAT ON" Light

Lights when the

burner is in operation.

Note that on all ovens

EXCEPT the

PS360EWB, this light

cycles on and off during normal operation.

ENGLISH

"SET PT" (setpoint)

Light

Lights when the set

point is shown in the

display.

"ACTUAL TEMP"

Light

Lights when the

Actual Temperature is shown in

the display.

Service Key

For use by service personnel

only.

Unlock Key

Press this key together

with the Set Point Key

to allow the Set Point

to be changed.

Changes can only be

made for 60 seconds.

Up Arrow and Down Arrow

Keys

Press these keys to adjust

the Set Point up or down. If

the Set Point will not

change, refer to

Key and Unlock Key in this

section.

Set Point

15

Set Point Key

Press this key together

with the Unlock Key to

allow the Set Point to

be changed.

Changes can only be

made for 60 seconds.

Page 16

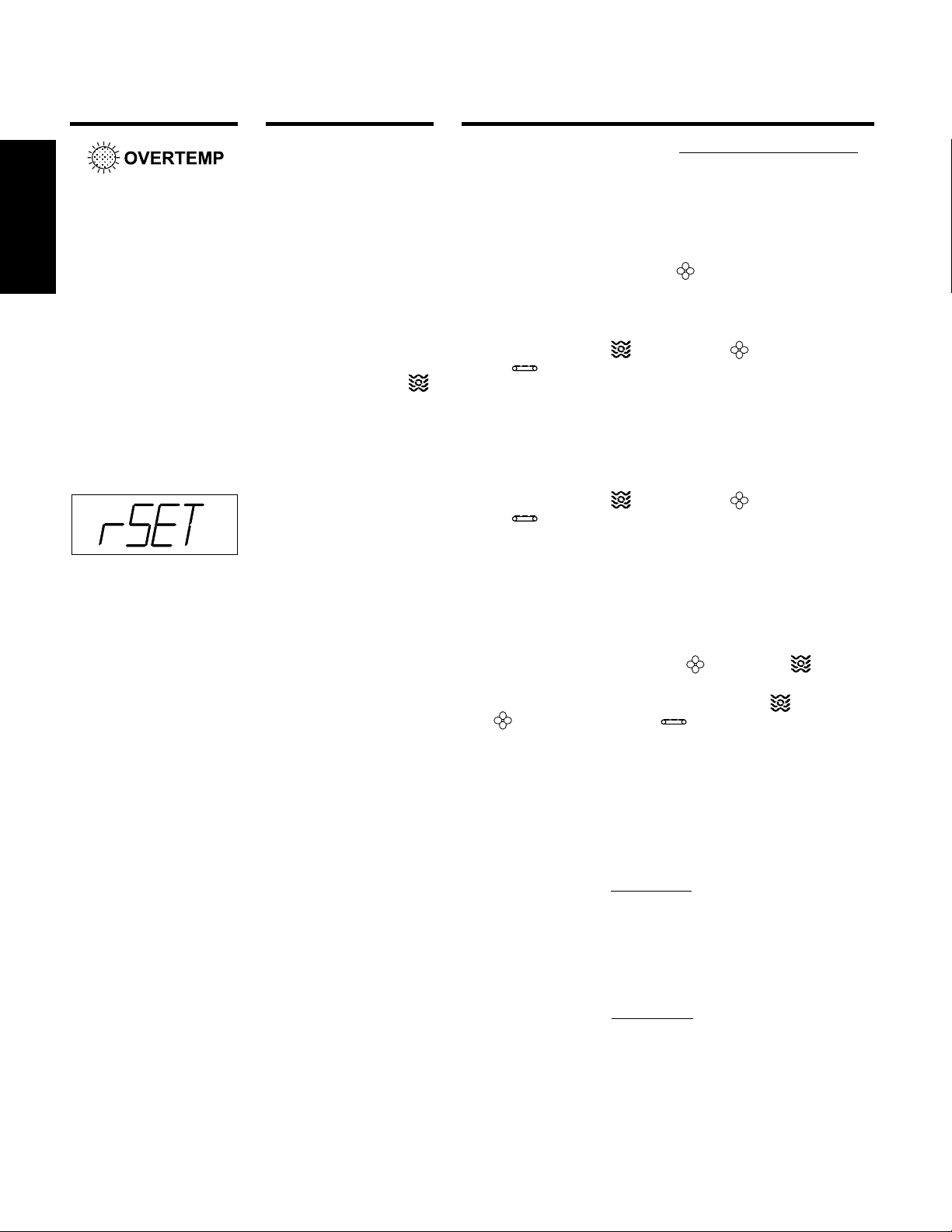

SECTION 3 - OPERATION

V. QUICK REFERENCE: TROUBLESHOOTING

SYMPTOM PROBLEM SOLUTION

ENGLISH

light is lit, food product is

undercooked

Oven will not

turn on at all

Oven shuts down shortly

after it is turned on

appears in display,

oven is not heating

The oven temperature exceeded 650°F (343°C), and

the burner was automatically shut down.

Electrical power may not be

reaching the oven, or the

controls may be set incorrectly.

The gas burner did not light

within 90 seconds of turning the "HEAT" (or

Switch to the ON (or "I")

position. This automatically engages a safety lockout mode.

The oven did not reach

200°F (93°C) within 15 minutes of startup, and the oven

has stopped heating.

Follow the procedures under Daily Shutdown Procedures in

this section to shut down the oven. Contact your Middleby

Marshall Authorized Service Agent to determine and correct the

cause of the condition to prevent damage to the oven.

Check that the circuit breaker/fused disconnect is turned on.

Check that the "BLOWER"

position. The burner cannot engage until the blowers are in

operation.

Turn the "HEAT" (or

(or )switches to the "OFF" (or "O") position.

)

Wait for AT LEAST FIVE MINUTES before restarting the oven.

Repeat the Daily Startup procedure.

Turn the "HEAT" (or

(or )switches to the "OFF" (or "O") position.

Wait for AT LEAST FIVE MINUTES before restarting the oven.

Repeat the Daily Startup procedure.

(or ) Switch is in the ON (or "I")

), "BLOWER" (or ), and "CONVEYOR"

), "BLOWER" (or ), and "CONVEYOR"

Oven will not heat

Oven is operating, but

little or no air is blowing

from air fingers

Conveyor moves with a

jerky motion, or will not

move at all

Food products are

overcooked or

undercooked.

Controls may be set incorrectly.

Air fingers may have been

reassembled incorrectly

after cleaning.

Conveyor may be jammed

on an object in the oven, or

conveyor belt or drive chain

tension may be incorrect.

Controls may be set incorrectly.

Check that the Set Point is correctly set.

Check that both the "BLOWER" ( ) and "HEAT" ( ) Switches

are in the ON ("I") position.

If the oven still will not heat,turn the "HEAT" ( ), "BLOWER"

( ), and "CONVEYOR" ( )switches to the "OFF" ("O")

position.

Wait for AT LEAST FIVE MINUTES before restarting the oven.

Repeat the Daily Startup procedure. Check that the Set Point

is above 200°F (93°C).

Turn the oven off, and allow it to cool. Disconnect electrical

power to the oven.

Refer to Section 4,

bling the air fingers.

Turn the oven off, and allow it to cool. Disconnect electrical

power to the oven.

Check if the conveyor is blocked by an object inside the oven.

Refer to Section 4,

the conveyor and drive chain tension.

Check that the set temperature and bake time settings are

correct.

Maintenance, for instructions on reassem-

Maintenance, for instructions on checking

IF THESE STEPS FAIL TO RESOLVE THE PROBLEM, CONTACT YOUR LOCAL MIDDLEBY MARSHALL

AUTHORIZED SERVICE AGENT. A SERVICE AGENCY DIRECTORY IS SUPPLIED WITH YOUR OVEN.

16

Page 17

SECTION 4 - MAINTENANCE

WARNING

Before ANY cleaning or servicing of the oven, perform the following procedure:

1. Switch off the oven and allow it to cool. Do NOT service the oven while it is warm.

2. Turn off the electric supply circuit breaker(s) and disconnect the electric supply to the oven.

3. If it is necessary to move the oven for cleaning or servicing, disconnect the gas supply connection before moving

the oven.

When all cleaning and servicing is complete:

1. If the oven was moved for servicing, return the oven to its original location. For ovens with legs, adjust the legs so

that they are seated properly on the floor. For ovens with casters, lock the front casters.

2. Reconnect the gas supply.

3. Reconnect the electrical supply.

4. Turn on the full-flow gas safety valve. Test the gas line connections for leaks using approved leak test substances

or thick soap suds.

5. Turn on the electric supply circuit breaker(s).

6. Perform the normal startup procedure.

ENGLISH

WARNING

Possibility of injury from moving parts and electrical shock exists in this oven. Switch off and lockout/tagout the electric

supply BEFORE beginning to disassemble, clean, or service any oven. Never disassemble or clean an oven with the

BLOWER switch or any other circuit of the oven switched on.

CAUTION

NEVER use a water hose or pressurized steam-cleaning equipment when cleaning this oven. DO NOT use excessive

amounts of water, to avoid saturating the oven insulation. DO NOT use a caustic oven cleaner, which can damage the

aluminized bake chamber surfaces.

NOTE

ANY replacement parts that require access to the interior of the oven may ONLY be replaced by a Middleby Marshall

Authorized Service Agent.

NOTE

It is strongly recommended that the 3-Month, 6-Month, and 12-Month Maintenance procedures in this section be

performed ONLY by a Middleby Marshall Authorized Service Agent.

17

Page 18

SECTION 4 - MAINTENANCE

I. MAINTENANCE - DAILY

1. Check that the oven is cool and the power is disconnected,

as described in the warning on Page 17.

2. Clean the outside of the oven with a soft cloth and mild

ENGLISH

detergent.

3. Temporarily remove the rear cool panels.

4. Clean ALL of the cooling fan grills and vent openings with

a stiff nylon brush. Refer to Figure 4-1 for the locations of

the grills and vents.

5. Check that ALL cooling fans are operating properly.

CAUTION

If a cooling fan is not operating correctly, it must be replaced

IMMEDIATELY. Operating the oven without adequate cooling can seriously damage the oven's internal components.

Figure 4-1 - Cooling Fan/Vent Locations

FRONT

Vents in floor

of oven

6. Replace the rear cool panels.

7. Clean the conveyor belt with a stiff nylon brush. This is

more easily accomplished by allowing the conveyor to

run while you stand at the exit end of the conveyor. Then,

brush the crumbs off the conveyor as it moves.

8. Remove and clean the crumb trays. Be sure to replace

the trays in the same positions from which they were

removed, because they are NOT identical.

II. MAINTENANCE - MONTHLY

NOTE: When removing the conveyor, refer to the drawings on

Pages 8-9 in the Installation section.

1. Check that the oven is cool and the power is disconnected,

as described in the warning on Page 17.

2. Remove the drive motor shroud and conveyor extension

covers from the oven.

3. Disconnect the drive chain from the sprocket on the drive

shaft of the conveyor. If two people are available, one

person should lift the idler (right) end of the conveyor as the

second person presses down on the drive (left) end. This

will create enough slack in the chain to remove it.

If this procedure will not free the chain, or if only one person

is available, perform the following steps:

Loosen the two hex head screws that fasten the

conveyor motor's mounting bracket to the oven. See

Figure 2-10 (on Page 9).

Raise the motor to free the chain from the sprocket.

Disconnect the drive chain.

4. Slide the conveyor out of the oven.

NOTE: The conveyor can only be removed from the end of

the oven with the drive motor (left end).

5. Remove the end plugs from the oven. The end plugs are

shown in Figure 1-1, on Page 4 of this Manual.

6. Slide the air fingers and blank plates out of the oven, as

shown in Figure 4-2. AS EACH FINGER OR PLATE IS

REMOVED, WRITE A "LOCATION CODE" ON IT WITH A

MARKER to make sure that it can be reinstalled correctly.

Example of markings:

(Top Row) T1 T2 T3 T4 T5 T6

(Bottom Row) B1 B2 B3 B4 B5 B6

Rear cool panels

removed

REAR

2 rear fans

2 fan grilles in

rear cool panels

Figure 4-2 - Removing Air Fingers and Plates

Blank PlateAir Finger

18

Page 19

7. Disassemble the air fingers as shown in Figure 4-3. AS

EACH FINGER IS DISASSEMBLED, WRITE THE "LOCATION CODE" FOR THE FINGER ON ALL THREE OF ITS

PIECES. This will help you in correctly reassembling the

air fingers.

CAUTION

Incorrect reassembly of the air fingers will change the

baking properties of the oven.

8. Clean the air finger components and the interior of the

baking chamber using a vacuum cleaner and a damp cloth.

Refer to the boxed warnings on Page 17 for cleaning

precautions.

9. Reassemble the air fingers. Then, replace them in the

oven, using the "location code" as a guide.

10. Replace the end plugs on the oven.

11. Reassemble the conveyor into the oven.

12. Reattach the drive chain. If the motor was repositioned to

allow the chain to be removed, adjust the tension of the

chain to the proper 1/2" (13mm) deflection. Refer to Step

3 of the Conveyor Installation instructions (on Page 9).

13. Check that the conveyor belt has the proper 2-3" (50-75mm)

deflection. If it is necessary to adjust the tension of the belt,

refer to Steps 4-6 of the

(on Page 9).

14. Replace the drive motor shroud and the conveyor extensions.

Conveyor Installation instructions

III. MAINTENANCE - EVERY 3 MONTHS

1. Check that the oven is cool and the power is disconnected,

as described in the warning on Page 17.

2. Vacuum both of the blower motors, and their surrounding

compartments, using a shop vacuum.

3. Tighten all electrical control terminal screws.

IV. MAINTENANCE - EVERY 6 MONTHS

1. Check that the oven is cool and the power is disconnected,

as described in the warning on Page 17.

2. Check for excessive wear on the conveyor drive motor

brushes. The brushes should be replaced if they have worn

to less than 1/4" (6.4mm) in length.

3. Clean and inspect the burner nozzle and electrode assembly.

4. Check (and clean, if necessary) the oven venting system,

including the flue.

5. Check the conveyor drive shaft bushings and spacers.

Replace the components if they are worn.

SECTION 4 - MAINTENANCE

Figure 4-3 - Disassembling the Air Fingers

Manifold

Inner plate

Outer Plate

2

Pull outer plate

straight up

and off

Swing ends of inner plate and

manifold apart

4

Pull inner plate

upwards, and

then away from

manifold

1

Step on lip of manifold

Figure 4-4 - Lubricating the Bearings

ENGLISH

3

V. MAINTENANCE - EVERY 12 MONTHS

1. Remove the motor shroud and the drive-end conveyor

extension cover.

2. Disconnect the drive chain as described in Step 3 of the

Monthly Maintenance section (on Page 18).

3. Use a grease gun to lubricate the drive shaft bearings, as

shown in Figure 4-4. When lubricating the bearings:

Use a high-quality NLGI #2, lithium soap grease with

petroleum oil, such as Middleby P/N 17110-0015.

Add the grease slowly until a small bead of grease is

present at the seals. AVOID OVERGREASING.

Excessive greasing may cause harm to the bearing.

Grease fitting

(1 per bearing, 2 total)

4. Manually turn the drive shaft by pulling on the conveyor belt

to purge the grease.

5. Wipe off any excess grease on and around the bearings.

6. Reattach the drive chain. If the motor was repositioned to

allow the chain to be removed, adjust the tension of the

chain to the proper 1/2" (13mm) deflection. Refer to Step

3 of the Conveyor Installation instructions (on Page 9).

7. Replace the motor shroud and conveyor extension cover.

19

Page 20

ENGLISH FRANÇAIS ESPAÑOL

page 1 page 21 página 41

SECTION 4 - MAINTENANCE

VI. KEY SPARE PARTS KIT - Available separately. See Figure 4-5.

A. Key Spare Parts Kit components (all ovens) B. Additional Key Spare Parts Kit components for gas

ovens

Item Description Part Number

1 1 Kit, Digital Temperature Controller 36939

2 1 Conveyor Drive Motor 27384-0008

3 2 Brushes, Conveyor Drive Motor 22450-0052

4 1 Kit, Conveyor Speed Controller 42810-0133

5 1 Conveyor Control Pickup Assembly 27170-0263

6 1 Kit, Thermocouple 33984

7 1 Cooling Fan 27392-0002

8a 1 Blwr Mtr, 1 Ph, 1/3 HP 27381-0023

8b 1 Blower Motor, 3 Ph, 1/3 HP 27381-0024

Fig. 4-5 - Key Spare Parts Kit

12 34 5 6

9 1 Kit, Ignition Module 42810-0114

Item Description Part Number

10 1 Burner Blower/Motor Assembly 27170-0011

11 1 Solenoid Valve 28091-0017

10

7

89

IMPORTANT

An electrical wiring diagram for the oven is located inside the

machinery compartment or control compartment.

11

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 USA (847)741-3300 FAX (847)741-4406

24-Hour Service Hotline: 1-(800)-238-8444

www.middleby.com

20

Page 21

PS314SBI

Gaz et électrique (AGA/UL)

Anglais/FRANÇAIS/Espagnol

N/P 42447

Rev. B V1 2/00

page 1page 21página 41

ENGLISHFRANÇAISESPAÑOL

Fours électriques et à gaz, modèle

PS314SBI

Modèles :

PS314SBI

Combinaisons :

Four inférieur simple

MANUEL DINSTALLATION

ET DUTILISATION

© 2000 Middleby Marshall, Inc.

est une marque déposée de Middleby Marshall, Inc. Tous droits réservés.

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 (847)741-3300 Télécopieur (847)741-4406

21

Page 22

AVIS :

Ce manuel d'installation et d'utilisation doit être fourni à l'utilisateur. L'opérateur du four devrait être familier

avec les commandes du four et son fonctionnement.

Ce manuel doit être placé près du four, être bien visible et facilement accessible.

Les fours peuvent être alimentés SOIT en gaz naturel, SOIT en gaz propane, comme l'indique la plaque de série.

Si les normes locales et nationales le permettent, il est possible de convertir un four fonctionnant au naturel

gaz en un four fonctionnant au gaz propane, et vice versa. Cette conversion requiert l'installation de la trousse

de conversion au gaz Middleby Marshall appropriée par un technicien agréé.

Il est recommandé de se procurer un contrat d'entretien auprès d'un technicien agréé par Middleby Marshall.

AVERTISSEMENT

AFFICHEZ, DE MANIÈRE VISIBLE, LE NUMÉRO DE TÉLÉPHONE D'URGENCE DE VOTRE FOURNISSEUR

FRANÇAIS

DE GAZ LOCAL ET LES DIRECTIVES À SUIVRE DANS LE CAS OÙ IL Y AURAIT ODEUR DE GAZ.

Il est possible de se procurer les directives à suivre dans le cas où il y a odeur de gaz auprès d'un fournisseur

de gaz local. Si vous détectez une odeur de gaz, composez immédiatement le numéro d'urgence de votre

fournisseur de gaz local qui sera en mesure de corriger le problème.

DIRECTIVES IMPORTANTES DE SÉCURITÉ

N'entreposez pas ou n'utilisez pas d'essence, de substances produisant des

vapeurs inflammables ou de liquides inflammables à proximité de cet appareil ou de

tout autre appareil.

AVERTISSEMENT :

Une installation, un réglage, un entretien ou l'altération incorrects de

l'appareil peuvent causer des dommages matériels, des blessures, et

même la mort. Lisez les directives d'installation, de fonctionnement et

d'entretien dans leur intégralité avant d'installer ou de réparer ces

appareils.

IMPORTANT

Le schéma de câblage s'appliquant à ce four est situé à l'intérieur du compartiment

des composants.

IMPORTANT

Le consommateur est responsable de signaler toute avarie apparente ou non

apparente au transporteur. Conservez tout le matériel d'expédition jusqu'à ce que

vous soyez assuré que l'équipement n'a pas subi d'avarie.

AVIS : VEUILLEZ CONTACTER UN TECHNICIEN AGRÉÉ PAR MIDDLEBY MARSHALL POUR L'ENTRETIEN ET LES

RÉPARATIONS. UN RÉPERTOIRE DE CENTRES DE SERVICE AGRÉÉS EST FOURNI AVEC VOTRE FOUR.

AVIS : L'utilisation de pièces autres que les pièces fabriquées à l'usine de Middleby Marshall décharge le fabricant de

toute obligation et de toute responsabilité inhérente à la garantie.

AVIS : Middleby Marshall (fabricant) se réserve le droit de modifier les spécifications en tout temps.

AVIS : La garantie de l'équipement n'est valide que si l'installation, la mise en marche, et la démonstration du four sont

faites sous la surveillance d'un installateur qualifié de l'usine.

Conservez ce manuel pour référence ultérieure

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 USA (847) 741-3300 Télécopieur (847) 741-4406

Service dassistance téléphonique 24 heures : 1-(800)-238-8444

22

Page 23

TABLE DES MATIÈRES

page page

SECTION 1 - DESCRIPTION ................................................... 2 4

IV. INSTALLATION DU THERMOCOUPLE .................. 28

I. UTILISATIONS DU FOUR ....................................... 24

II. COMPOSANTS DU FOUR ...................................... 24

A. Moteur d'entraînement du transporteur ........... 24

B. Plateaux latéraux .............................................. 24

C. Transporteur ....................................................24

D. Panneaux latéraux ........................................... 24

E. Panneaux arrière froids ................................... 24

F. Panneau avant froid ......................................... 24

G. Panneau de service du compartiment des

composants ..................................................... 24

H. Panneau de service du compartiment de

commande....................................................... 24

I. Tableau de commande ................................... 24

J. Plaque de série ............................................... 24

K. Plateaux à miettes ...........................................24

L. Brûleur à gaz ....................................................24

M. Souffleries ........................................................ 24

N. Conduits d'air ................................................... 24

III. SPÉCIFICATIONS DU FOUR .................................. 24

A. Dimensions ..................................................... 24

B. Spécifications générales ................................. 24

C. Spécifications des orifices de gaz et de

pression ........................................................... 24

D. Spécifications électriques - Fours à gaz ......... 24

E. Spécifications électriques - Fours électriques 25

V. INSTALLATION DU TRANSPORTEUR ................... 28

VI. ASSEMBLAGE FINAL .............................................. 3 0

VII. ALIMENTATION EN ÉLECTRICITÉ ......................... 3 1

A. Fours électriques ............................................. 31

B. Fours à gaz ...................................................... 31

C. Fours avec transformateurs extérieurs ........... 31

D. Raccordement .................................................31

VIII. ALIMENTATION EN GAZ ......................................... 3 2

A. Raccordement ................................................. 32

B. Conversion du gaz ........................................... 32

SECTION 3 - OPÉRATION ...................................................... 3 3

I. EMPLACEMENT ET DESCRIPTION DES

COMMANDES .......................................................... 33

A. Bouton de commande BLOWER

(ventilation) ( ) .............................................. 33

B. Bouton de commande HEAT (chaleur) ( ) ... 33

C. Bouton de commande CONVEYOR

(transporteur) ( ) ......................................... 33

D. Régulateur de vitesse de transporteur ........... 33

E. Régulateur de température électronique ........ 33

F. Interrupteur de sécurité du panneau de service du

compartiment des composants ...................... 33

II. OPÉRATION NORMALE, PAS-À-PAS ...................... 3 4

A. Procédures quotidiennes de mise en marche34

B. Procédures quotidiennes de mise en arrêt .... 34

FRANÇAIS

SECTION 2 - INSTALLATION ................................................. 2 5

I. TROUSSE D'INSTALLATION .................................. 2 6

A. Composants .................................................... 2 6

B. Composants additionnels- Fours à gaz ......... 26

II. SYSTÈME DE VENTILATION .................................. 2 6

A. Exigences ........................................................ 2 6

B. Recommandations .......................................... 2 6

C. Autres considérations pour la ventilation ........ 27

III. ASSEMBLAGE ......................................................... 27

A. Installation des pieds/roulettes ....................... 27

B. Installation du câble de retenue ...................... 27

III. CONSULTATION RAPIDE : RÉGULATEUR DE

TEMPÉRATURE ÉLECTRONIQUE ......................... 35

IV. CONSULTATION RAPIDE : DÉPANNAGE .............. 36

SECTION 4 - ENTRETIEN .. ..................................................... 3 7

I. ENTRETIEN - QUOTIDIEN ..................................... 38

II. ENTRETIEN - MENSUEL ........................................38

III. ENTRETIEN - TRIMESTRIEL .................................. 39

IV. ENTRETIEN - SEMESTRIEL ................................... 39

V. ENTRETIEN - ANNUEL........................................... 39

V. TROUSSE DE PIÈCES DE RECHANGE

ESSENTIELLES ...................................................... 40

A. Composants .................................................... 40

23

B. Autres composants - Fours à gaz ...................40

Page 24

SECTION 1 - DESCRIPTION

I. UTILISATIONS DU FOUR

Le four PS314SBI est optimisé pour faire fondre le fromage

utilisé pour les sandwichs et autres aliments.

II. COMPOSANTS DU FOUR - Figure 1-1.

A. Moteur d'entraînement du transporteur : Met le

transporteur en mouvement.

B. Plateaux latéraux : Reçoivent les aliments lorsqu'ils

sortent du transporteur. Les plateaux latéraux existent en

modèle simple ou double pour le four PS314SBI.

C. Transporteur : Fait passer les aliments dans le four.

D. Panneaux latéraux : Permettent d'avoir accès à l'intérieur

FRANÇAIS

du four.

E,F.

Panneaux avant et arrière froids : Réduisent le contact

direct de l'utilisateur avec le corps du four.

G. Panneau de service du compartiment des

composants : Permet d'avoir accès aux composants

situés à l'intérieur du four. Ce compartiment ne contient

pas de pièce pouvant être entretenue ou réparée par

l'utilisateur.

H. Panneau de service du compartiment de commande :

Permet d'avoir accès aux composants de commande. Le

compartiment de commande ne contient pas de pièce

pouvant être entretenue ou réparée par l'utilisateur.

I. Tableau de commande : Emplacement des commandes

de fonctionnement du four. Reportez-vous à la rubrique,

Fonctionnement de la section 3 pour obtenir plus de

détails.

J. Plaque de série : Fournit les spécifications du four rela-

tives à l'installation et au fonctionnement. Reportez-vous

à la rubrique,

Installation de la section 2.

Non illustrés :

K. Plateaux à miettes : Reçoivent les miettes et les autres

aliments qui passent à travers la bande transporteuse du

transporteur. On trouve un plateau à miettes en dessous

de chaque transporteur.

L. Brûleur à gaz : Fourneaux à gaz uniquement. Chauffe l'air

qui est ensuite projeté vers les conduits d'air par les

souffleries.

M. Souffleries : Projettent de l'air chaud vers les conduits

d'air.

N. Conduits d'air : Projettent de l'air chaud sur les aliments.

Fig. 1-1 - PS314SBI Composants du four

D

E

F

C

B

A

G

J

H,I

III. SPÉCIFICATIONS DU FOUR

A. Dimensions

Hauteur hors-tout - inc. dessu et pieds de 54" (1372mm)

9"/229 mm

Profondeur hors-tout - inc. protecteurs avant et arrière

avec un seul plateau de sortie 38-1/2" (978mm)

avec plateaux de sortie doubles 39-3/4" (1010 mm)

Longueur hors-tout - inc. plateau(x) de sortie 83-1/4" (2115mm)

Largeur du transporteur 24" (610 mm)

Dégagements minimums recommandés

De l'arrière du four 1" (25mm)

(inc. les protecteurs arrière) au mur

De l'allonge du transporteur (à droite) ou 0" (0mm)

plateau(x) latéral/aux(à gauche) au mur

B. Spécifications générales

Poids 1080 lbs. (497kg)

Poids à l'expédition 1370 lbs. (630kg)

Vol. emballage d'expédition 105 pi3/2,98m

Débit calorifique nominal

Gaz 135 000 BTU (34 020 kcal, 40 kw/hre)

Électricité 26kw/hr.

Temp. de fonc. max. 550 °F/288 °C

Souffleries à air 2 souffleries à 1550 pi3 (43,9m3)/min à 1700

tr/min, 0,88"/2,2 cm pression statique d'eau

Vitesse d'injection d'air (moy.) 2600 pi/min (1320 cm/sec)

Temps de préchauffage 15 minutes

3

C. Spécifications des orifices de gaz et de pression - pour

les fours alimentés au gaz

D.I. de l'orifice D.I. orifice D.I. orifice Pression de Pression

principal du pilote de dérivation canalisation d'admission

Gaz naturel

0,219" 0,028" 0,065"/mèche no 53 6-12" C.E. 3-1/2" C.E.

5,56mm 0,71mm 1,65mm 14,9-29,9 mb 8,7 mb

Propane

0,134" 0,018" 0,034"/mèche no 62 11-14" C.E. 10" C.E.

3,40mm 0,46mm 0,86mm 27,4-34,9 mb 24,9 mb

D. Spécifications électriques - Fours alimentés au gaz

Tension soufflerie Tension circuit Débit

principale de commande Phase Fréq. courant Pôles Câblage

208-240V 120V 1 P h 60Hz 10A 3 pôles 4 fils (2 chauds,

208-240V 120V 1 P h 50/60Hz 10A 2 pôles 3 fils

(export) (transformateur) (2 chauds,

200-220V 120V 1 P h 50/60Hz 10A 2 pôles 3 fils

(export) (transformateur) (2 chauds,

24

1 neut.,

1 masse)

1 masse)

1 masse)

Page 25

SECTION 1 - DESCRIPTION

E. Spécifications électriques - pour tous les fours chauffés à lélectricité

Tension soufflerie Tension circuit Débit V. nominale

principale de commande Phase Fréq. courant kW Pôles Câblage

(avec moteurs de soufflerie 3 Ph) 58,4A à 240V 26 kW à 240V 1 masse)

(avec moteurs de soufflerie 1 Ph) 58,4A à 240V 26 kW à 240V 1 masse)

IMPORTANT: Des renseignements supplémentaires sur l'électricité se trouvent sur la plaque de série du four et sur le schéma

de câblage situé à l'intérieur du compartiment des composants.

208-240V 120V 3 P h 60 Hz 67,3A à 208V 26 kW à 208V 4 pôles 5 fils (3 chauds, 1 neut.,

208-240V 120V 3 P h 60 Hz 67,3A à 208V 26 kW à 208V 4 pôles 5 fils (3 chauds, 1 neut.,

200-220V (export) 120V (transformateur) 3 Ph 50/60 Hz 67,3A à 208V 24 kW à 208V 3 pôles 4 fils (3 chauds, 1 masse)

53,5A à 220V 20 kW à 220V

240V (export) 120V (transformateur) 3 Ph 50/60 Hz 58,4A 26 kW 3 pôles 4 fils (3 chauds, 1 masse)

380V (export) 120V (transformateur) 3 Ph 50/60 Hz 36,8A 24,3 kW 3 pôles 4 fils (3 chauds, 1 masse)

400-416V (export) 120V (transformateur) 3 Ph 50/60 Hz 33,8A 24,3 kW 3 pôles 4 fils (3 chauds, 1 masse)

480V 120V (transformateur) 3 Ph 60 Hz 29,2A 26 kW 3 pôles 4 fils (3 chauds, 1 masse)

SECTION 2 - INSTALLATION

AVERTISSEMENT

Dégagez le site d'exploitation de l'appareil de tout produit combustible.

AVERTISSEMENT

N'obstruez pas le débit de l'air de combustion ou de ventilation en provenance du four ou en direction

du four. Il ne doit pas y avoir d'obstructions autour ou en dessous du four.

FRANÇAIS

MISE EN GARDE

Pour obtenir des renseignements supplémentaires sur l'installation, reportez-vous aux documents suivants :

Manuel de procédures de préinstallation du modèle PS360 (N/P Middleby Marshall 88210-0024)

Manuel d'installation du modèle PS360 (N/P Middleby Marshall 88210-0025)

Ou contactez votre technicien local agréé.

REMARQUE

Le dégagement doit être suffisant entre le four et les structures combustibles. Il doit également

permettre l'entretien et le fonctionnement.

REMARQUE

Le schéma de câblage s'appliquant à ce four est situé à l'intérieur du compartiment des composants.

REMARQUE

Tous les aspects touchant à l'installation du four, notamment l'emplacement, les connexions électriques et les

exigences de ventilation doivent être conformes aux normes locales et nationales qui s'appliquent. Ces

normes remplacent les exigences et les directives fournies dans ce manuel.

REMARQUE

Aux États-Unis, l'installation du four doit se conformer aux normes locales ou, en l'absence de telles normes,

au National Fuel Gas Code, ANSI Z223.1. Lors de l'installation, le four doit être mis à la terre selon les normes

locales ou, en l'absence de telles normes, selon le National Electrical Code (NEC) ou ANSI/NFPA70.

REMARQUE

Au Canada, l'installation du four doit se conformer aux normes locales ou, en l'absence de telles normes, au

Natural Gas Installation Code, CAN/CGA-B149.1 ou au Propane Gas Installation Code, CAN/CGA-B149.2,

selon le cas. Lors de l'installation, le four doit être mis à la terre selon les normes locales ou, en l'absence de

telles normes, selon le Canadian Electrical Code CSA, C22.2, selon le cas.

REMARQUE

Pour l'Australie, l'installation du four doit se conformer au AGA Code, AG601, et à toutes les exigences de

l'autorité statutaire appropriée.

25

Page 26

SECTION 2 - INSTALLATION

I. TROUSSE D'INSTALLATION

1

Fig. 2-1 - Trousse d'installation

14

18

7

8

2

4

9

FRANÇAIS

6

3

A.Composants de la trousse d'installation

Article Description Numéro de pièce Qté.

1 Pieds, réglables 22450-0028 4

2 Roulette (arrière), pivot 22290-0010 2

3 Roulette (avant), pivot, avec frein 22290-0009 2

4 Vis, hex, 3/8-16 x 1" 220373 16

5 Rondelle d'arrêt, 3/8" 21422-0001 16

6 Rondelle plate, 3/8" 21416-0001 16

7 Pied, 9 po (229 mm) 34684 4

8 Vis, hex, 3/4-10 x 2" 21321-0016 7

9 Rondelle d'arrêt, 3/4" 21421-0003 8

10 Rondelle plate, 3/4" 21411-0019 8

11 Piton à il à épaulement, 3/4"-10 x 2 " 42440 1

12 Assemblage du câble de retenue 22450-0228 1

5

16 17

15

10

11

13

20

21

12

Article Description Numéro de pièce Qté.

13 Thermocouple 33812-1 1

14 Attache pour câble 27276-0001 1

15 Vis, no10-32 x 3/8" 21256-0008 1

16 Modèle PS314SBI Manuel d'installation 42447 1

et d'utilisation

17 Répertoire de centres de service agréés 1002040 1

B. Composants additionnels de la trousse d'installation des

fours à gaz

18 Conduite à gaz, flexible 22361-0001 1

19 Conduit de fumées, 14" (356mm) 30773 1

20 Vis, hex, n° 2PT 10-16 x 3/4" HWH 21292-0001 2

21 Vis, no10-32 x 3/8" 21256-0008 1

19

II. SYSTÈME DE VENTILATION

IMPORTANT

Lorsque les normes nationales ou locales exigent l'installation

d'équipement d'extinction des incendies ou d'équipement

supplémentaire, n'installez PAS l'équipement directement sur

le four.

L'INSTALLATION DE TEL ÉQUIPEMENT SUR LE FOUR

PEUT :

ANNULER LES HOMOLOGATIONS DES ORGANISMES

RESTREINDRE L'ACCÈS AUX SERVICES

MENER À UNE AUGMENTATION DES DÉPENSES

D'ENTRETIEN POUR L'USAGER

A. Exigences

MISE EN GARDE

Un système de ventilation à commande mécanique

REQUIS pour l'installation d'un four à gaz.

est

L'utilisation d'un système de ventilation à

commande mécanique est

RECOMMANDÉE dans le cas de l'installation d'un

four électrique.

LE PROPRIÉTAIRE DU FOUR EST RESPONSABLE

DE L'INSTALLATION APPROPRIÉE DU FOUR.

B. Recommandations

VEUILLEZ PRENDRE NOTE QUE LES DIMENSIONS

DE LA HOTTE INDIQUÉES À LA FIGURE 2-2 NE

SONT QUE DES RECOMMANDATIONS. LORS DE

L'INSTALLATION D'UN SYSTÈME DE VENTILATION,

FORTEMENT

18"

458mm

LES NORMES LOCALES ET NATIONALES DOIVENT ÊTRE