Page 1

installation

& operation

manual

PS520-Series OVENS

Model PS520E

PS520-Series Electric Ovens:English

PS520 Single

PS520 Double

©2006 Middleby Marshall Inc.

PS520 Triple

Part No., 52358

090/6

Page 2

WARNING

FOR YOUR SAFETY, DO NOT STORE OR

USE GASOLINE OR OTHER FLAMMABLE

VAPORS AND LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

WARNING

Improper installation, adjustment, alteration,

service, or maintenance can cause property

damage, injury, or death. Read the installa-

tion, operating, and maintenance instruc-

tions thoroughly before installing or servic-

ing this equipment.

NOTICE

The warranty is NOT VALID unless the oven is installed, started, and demon-

strated under the supervision of a factory-authorized installer

NOTICE

Contact your authorized Service Agency to perform maintenance and

repairs. A Service Agency Directory is supplied with your oven.

NOTICE

Using any parts other than genuine Middleby Marshall factory-manufactured

parts relieves the manufacturer of all warranty and liability.

NOTICE

Middleby Marshall (Manufacturer) reserves the right to change specifications

at any time.

KEEP THIS MANUAL IN A VISIBLE LOCATION NEAR THE

OVEN FOR FUTURE REFERENCE.

ii

Page 3

Model No.________________________ Serial No._______________ Installation Date __________

MIDDLEBY MARSHALL

No Quibble Limited Warranty

(U.S.A. Only)

Middelby Marshall, Hereinafter referred to as “The Seller”,

warrants equipment manufactures by it to be free from defects

in materials and workmanship for which it is responsible. The

seller’s obligation under thus warranty shall be limited to

replacing or repairing, at seller’s option, without charge, any

part found to be defective and any labor and material expense

incurred by seller in repairing or replacing such part. Such

warranty shall be limited to the original purchase of (1) one year

from date of original installation or 18 months from date of

purchase, whichever is earlier, provided that terms of payment

have been fully met.

This warranty is valid only if the equipment is installed, started,

and demonstrated under the supervision of a factory-authorized

installer.

Normal maintenance functions, including lubrication, cleaning,

or customer abuse, are not covered by this no quibble warranty.

Seller shall be responsible only for repairs or replacements of

defective parts performed by Seller’s authorized service

personnel. Authorized service agencies are located in principal

cities throughout the contiguous United States and Hawaii. The

warranty is valid in the 50 Unites States and is void elsewhere

unless the product is purchased through Middleby International

with warranty included.

The foregoing warranty is exclusive and in lieu of all other

warranties, expressed or implied. There are no implied

warranties of merchantability or fitness for a particular

purpose.

The foregoing shall be Seller’s sole and exclusive obligation

and Buyer’s sole and exclusive remedy for any action, including

breach of contract or negligence. In no event shall Seller be liable

for a sum in excess of the purchase price of the item. Seller shall

not be liable for any prospective or lost profits of Buyer.

This warranty is effective on Middleby Marshall equipment

sold on, or after February 15, 1995.

MIDDLEBY MARSHALL INC.

OVEN LIMITED WARRANTY (Non-U.S.A.)

The Seller warrants equipment manufactured by it to be free from defects

in material and workmanship for which it is responsible. The Seller’s obligation under this warranty shall be limited to replacing or repairing, at

Seller’s option, without charge, F.O.B. Seller’s factory, any part found to

be defective and any labor and material expense incurred by Seller in

repairing or replacing such part. Such warranty is limited to a period of

one year from date of original installation or 15 months from date of shipment from Seller’s factory, whichever is earlier, provided that terms of

payment have been fully met. All labor shall be performed during regular

working hours. Overtime premium will be charged to the Buyer.

This warranty is not valid unless equipment is installed, started and demonstrated under the supervision of a factory-authorized installer.

Normal maintenance functions, including lubrication, adjustment of airflow, thermostats, door mechanisms, microswitches, burners and pilot

burners, and replacement of light bulbs, fuses and indicating lights, are

not covered by warranty.

Any repairs or replacements of defective parts shall be performed by

Seller’s authorized service personnel. Seller shall not be responsible for

any costs incurred if the work is performed by other than Seller’s authorized service personnel.

When returning any part under warranty, the part must be intact and complete, without evidence of misuse or abuse, freight prepaid.

Seller shall not be liable for consequential damages of any kind which

occur during the course of installation of equipment, or which result from

the use or misuse by Buyer, its employees or others of the equipment

supplied hereunder, and Buyer’s sole and exclusive remedy against Seller

for any breach of the forgoing warranty or otherwise shall be for the repair

or replacement of the equipment or parts thereof affected by such breach.

The foregoing warranty shall be valid and binding upon Seller if and only

if Buyer loads, operates and maintains the equipment supplied hereunder

in accordance with the instruction manual provided to Buyer. Seller does

not guarantee the process of manufacture by Buyer or the quality of product to be produced by the equipment supplied hereunder and Seller shall

not be liable for any prospective or lost profits of Buyer.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF

ALL OTHER EXPRESS AND IMPLIED WARRANTIES WHATSOEVER. SPECIFICALLY THERE ARE NO IMPLIED WARRANTIES OF

MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE.

The foregoing shall be Seller’s sole and exclusive obligation and Buyer’s

sole and exclusive remedy for any action, whether in breach of contract or

negligence. In no event shall Seller be liable for a sum in excess of the

purchase price of the item

©2006 Middleby Marshall, A Middleby Company

The Middleby Marshall logo is a registered trademark of Middleby Marshall, A Middleby Company

Middleby Marshall Inc. - 1400 Toastmaster Drive - Elgin, Illinois 60120-9272 - (847) 741-3300 - Fax: (847) 741-4406

iii

Page 4

Table of Contents

SECTION 1 - DESCRIPTION

I. MODEL IDENTIFICATION ............................................ 1

Series PS520 Electrical Specifications ............................. 2

II. COMPONENT FUNCTION .......................................... 3

A. Conveyor Motor and Conveyor Belt ......................... 3

B. Blower Fan ............................................................... 3

C. Electric Heaters ........................................................ 3

D. Cooling Fan .............................................................. 3

E. Air Fingers and Blank Plates - Figure 4-8 & 4-14 ..... 3

SECTION 2 - INSTALLATION

I. UNLOADING ................................................................. 4

PS520 Oven Installation

Required Kits And Equipment ................................... 5

Oven Dimensions - Single, Double, Triple ................... 6

Utility Rough In Dimensions and Positioning

For PS520 Series Ovens .......................................... 7

Circuit Breaker .............................................................. 7

Electrical Specifications ................................................ 7

Electrical Rating ............................................................ 7

Supply Wire .................................................................. 7

Suggested ..................................................................... 7

II. VENTILATION GUIDELINES ....................................... 7

III. ELECTRICAL CONNECTION INFORMATION FOR

PS520-SERIES OVENS ........................................... 8

IV. ELECTRIC SUPPLY FOR ELECTRIC-HEATED

OVENS ...................................................................... 8

SECTION 3 - OPERATION

I. CONTROL FUNCTIONS ............................................... 9

II. COMPONENT FUNCTIONS ...................................... 10

A. Door Safety Switch ................................................. 10

B. Blower Switch ......................................................... 10

C. Heat Switch ............................................................ 10

D. Temperature Controller .......................................... 10

E. Conveyor ................................................................ 11

Measuring Conveyor Speed ....................................... 11

III. STEP-BY-STEP OPERATION .................................. 12

A. Start-up Procedures ............................................... 12

Daily Start-up .......................................................... 12

Power Failure .......................................................... 12

B. Shutdown Procedure .............................................. 12

IV. NORMAL OPERATION - STEP-BY-STEP ............... 13

A. Daily Start-up Procedure ........................................ 13

B. Daily Shutdown Procedure ..................................... 13

V. QUICK REFERENCE: TROUBLESHOOTING .......... 15

Table of Contents

(continued)

SECTION 4 - MAINTENANCE

I. MAINTENANCE - DAILY ............................................. 16

A. Exterior ................................................................... 17

B. Cooling Fan ............................................................ 17

C. Conveyor Belt ......................................................... 17

D. Crumb Pan ............................................................. 17

II. MAINTENANCE - MONTHLY .................................... 18

A. Removing Conveyor From Oven For Cleaning ...... 18

B. Air Fingers Disassembly For Cleaning ................... 20

C. Reassembly of Air Fingers ..................................... 21

D. Reinstall End Plugs ................................................ 23

E. Conveyor Reassembly Into Oven ........................... 24

F. Checking Conveyor Belt Tension ........................... 24

G. Conveyor Belt Link Removal .................................. 25

H. Attaching Drive Chain ............................................ 26

III. MAINTENANCE - EVERY 3 MONTHS ..................... 27

A. Electrical Terminals ................................................ 27

B. Ventilation ............................................................... 27

IV. MAINTENANCE - EVERY 6 MONTHS ..................... 27

Key Spare Parts Kits ................................................... 28

SECTION 5 - TROUBLESHOOTING CHARTS

Trouble Shooting Charts ............................................. 29

SECTION 6 - ELECTRICAL SCHEMATIC

Wiring Diagram, E208-240V 50/60 Hz 1Ph ................ 30

Wiring Diagram, E380-480V 50/60 Hz 1 Ph ............... 31

Wiring Diagram, E230-240V CE, 1Ph ......................... 32

Wiring Diagram, E380-400V CE, 1Ph ......................... 33

Wiring Diagram, E380-400V CE, 3Ph ......................... 34

iv

Page 5

SECTION 1

DESCRIPTION

I. MODEL IDENTIFICATION

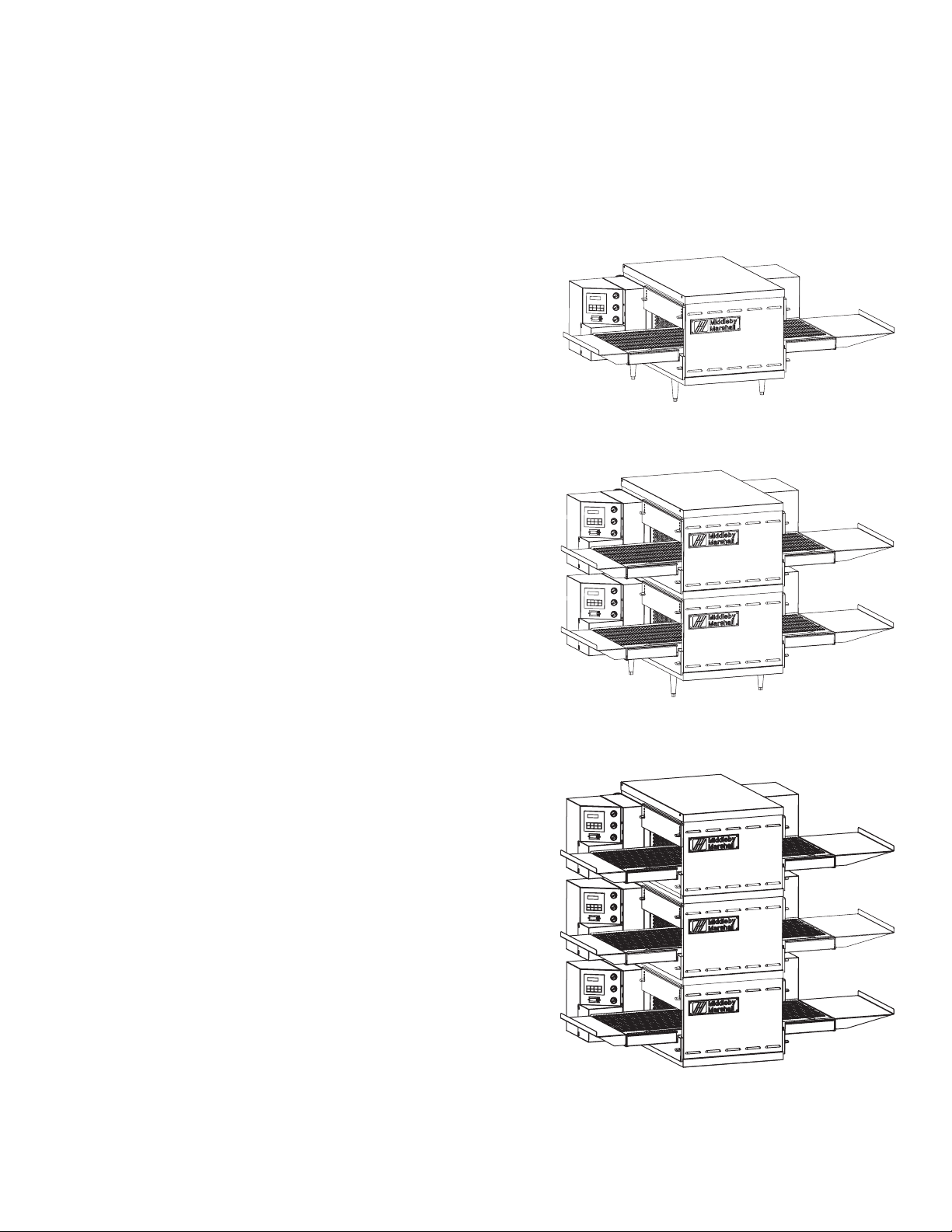

The Mideleby Marshall PS520-Series may be used

either as a single oven or stacked for use as a double

or triple ovens.

A single PS520-Series Oven (Figure 1-1) is mounted

on a base pad with legs. A double oven (Figure 1-2)

consists of two, stacked, single ovens. A triple oven

(Figure 1-3) consists of three stacked single ovens.

The lower oven is mounted on a base pad.

On a double or triple oven, the ovens operate independently. All ovens use identical controls and components. One oven can be cleaned or serviced, while the

others are operating.

SECTION 1

DESCRIPTION

Figure 1-1. Single PS520 Oven

Figure 1-2. Double PS520 Oven

Figure 1-3. Triple PS520 Oven

1

Page 6

SECTION 1

DESCRIPTION

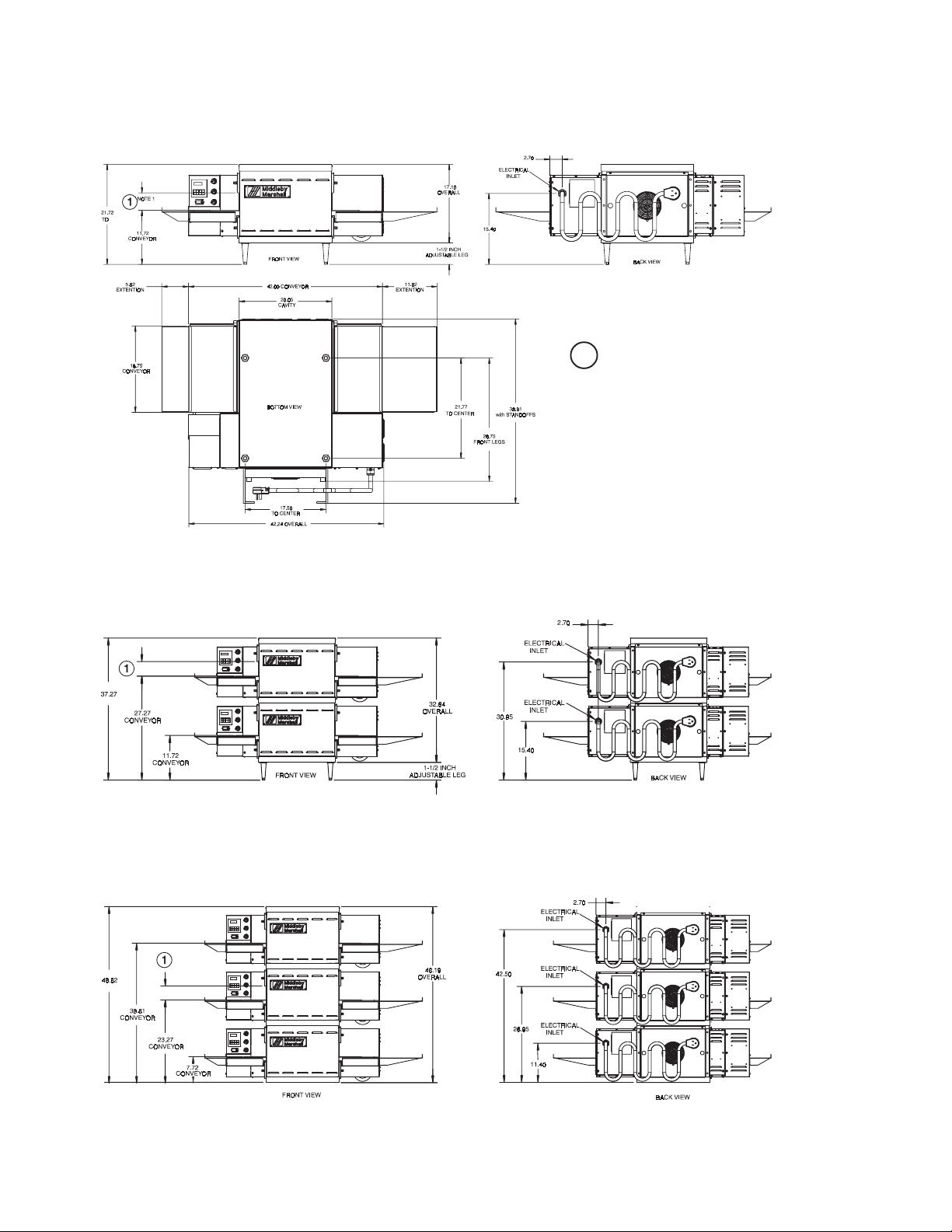

PS520 SERIES OVEN SPECIFICATIONS

Conveyor Belt Width 18.00” (457mm)

Heating Zone Length 20.00” (5098mm)

Baking Area Square Feet 2.5 sq ft (.023 sq. m.)

Overall Dimensions

Standard Single Oven w/Legs 42.00” (1067mm) L x

35.21” (894mm) W x

21.72” (786mm) H x

Overall Dimensions

Double Oven 42.00” (1067mm) L x

35.21” (894mm) W x

37.27” (947mm) H x

Overall dimensions

Triple Oven 42.00” (1067mm) L x

35.21” (894mm) W x

52.82” (1342mm) H x

Weight of Single Oven 250 lbs (93.3kg)

Shipping Weight 325 lbs (121.3kg)

Operating Range 8.3 kW/hr

Maximum Operating temperature 5500F (2870C)

Warm-up Time 20 min.

Belt Speed Limits 1-10 minutes

SERIES PS520 ELECTRICAL SPECIFICATIONS

Main Blower & Control Circuit Phase Frequency Amperage Poles Wires

Elements Voltage Voltage Draw

All Models 208-240V 208-240V 1 Ph 50/60 Hz See Below 2 Pole 3 Wire

Heater Amperage

Voltage kW Amp

208 8.3 39.9

230 7.6 33.0

240 8.3 34.6

Non-CE 380V 230-240V 1 Ph 50/60 Hz See Below 3 Pole 4 Wire

Heater Amperage (2 hot, 1 neut, 1 grd)

Voltage kW Amp

380 8.3 21.8

Domestic/Non-CE 480V 208-240V 1 Ph 50/60 Hz See Below 3 Pole 4 Wire

Heater Amperage (2 hot, 1 neut, 1 grd)

Voltage kW Amp

480 8.3 17.3

CE Only 380-400V 230-240V 1 Ph 50/60 Hz See Below 2 Pole 3 Wire

Heater Amperage (2 hot, 1 grd)

Voltage kW Amp

380 8.3 21.8

400 8.3 23.0

3 Ph 50/60 Hz See Below 4 Pole 5 Wire

Heater Amperage (3 hot, 1 neut, 1 grd)

Voltage kW L1 L2 L3 N

380 8.3 21.8 21.8 1.2 1.2

400 9.2 23.0 23.0 1.2 1.2

(2 hot, 1 grd)

NOTE

Wiring Diagrams are contained in Section 6 of this manual and are also located inside the

oven at the bottom of the control panel.

This Manual Must Be Kept For Future Reference

2

Page 7

II. COMPONENT FUNCTION

SECTION 1

DESCRIPTION

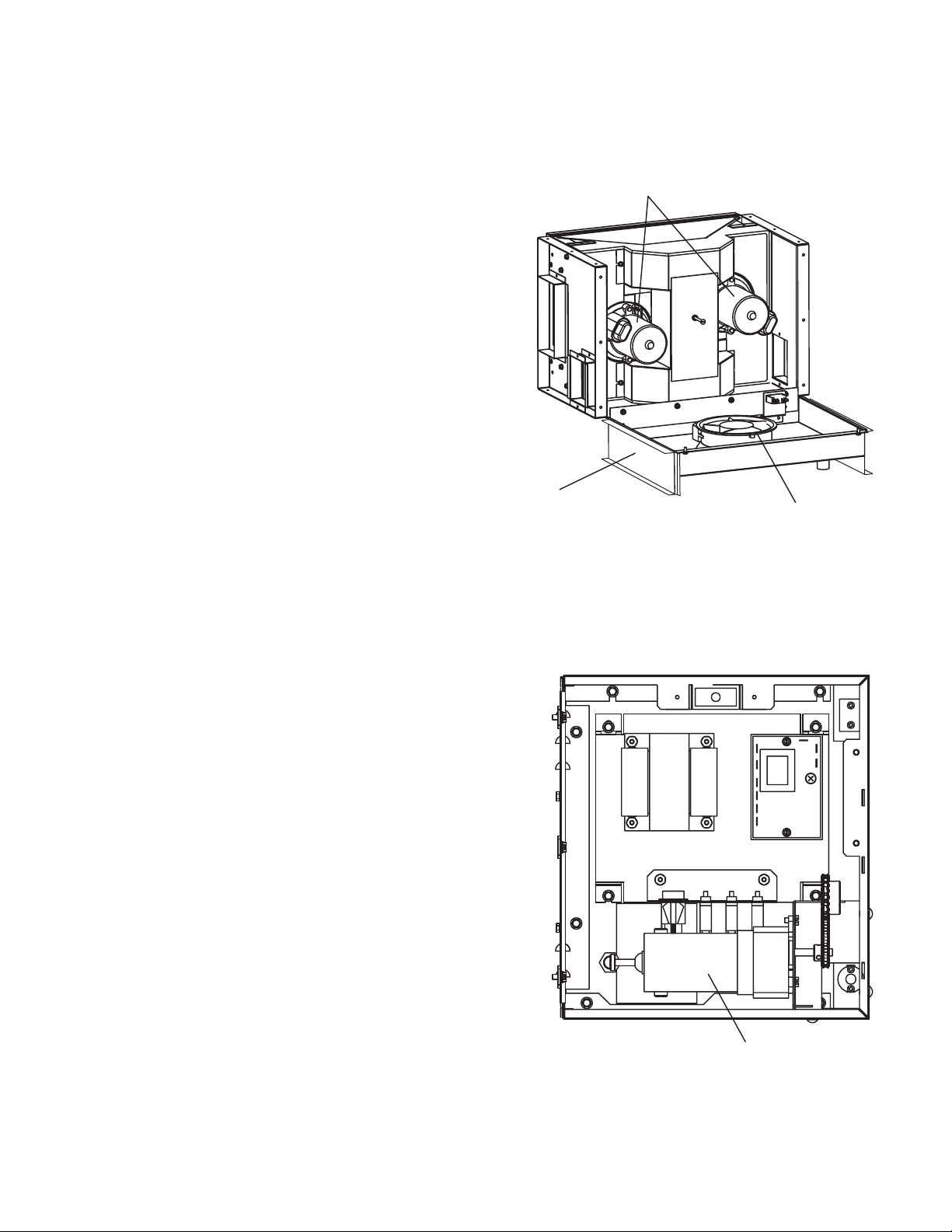

A. Conveyor Motor and Conveyor Belt

The conveyor belt is driven by a variable-speed electric

motor (figure 1-5) operating through a gear reducer. The

motor speed is controlled by a digital control. The

stainless-steel wire belt can travel in either direction at

variable rates ranging from 1 minute to 10 minutes; this

is the time that a product can take to pass trough the

oven.

B. Blower Fan

The blower fans are located at the rear of the oven. These

blowers force heated air through the air fingers. The

BLOWER switch must be set to “ON” or “I” for oven warmup and baking.

C. Electric Heaters

There is one heater element mounted on the inside of

the rear panel. The element is connected to an electrical

control which is energized by the temperature controller.

D. Cooling Fan - See Figure 1-4

Blower Motor

Stand off

Cooling Fan

Figure 1-4 Blower Assembly

The cooling fan is located in the back of the oven. The

cooling fan draws air through its grille, blowing it through

the blower motor compartment and the control

compartments into the oven top and exhausted out the

front louvers.

E. Air Fingers and Blank Plates - See Figure 4-8, 414

E1. Air fingers

An Air Finger Assembly is made up of three parts:

1. Outer Plate - The Outer Plate is the removable

covering with tapered holes, which direct the air stream

onto the product being baked.

2. Inner Plate - The perforated Inner Plate is vital in

forming the unique air jets. It must be assembled into

the manifold with it’s holes aligned with the holes of the

outer plate.

3. Manifold - the Manifold is the assembly which slides

on the tracks into the oven plenum.

Conveyor Drive Motor

Left Control Box

Figure 1-5 Machinery Compartment

Components

3

Page 8

SECTION 2

INSTALLATION

SECTION 2

INSTALLATION

NOTE: The oven, when installed, must be electrically

grounded in accordance with local codes, or in the

absence of local codes, with the National Electrical Code

(NEC), or ANSI/NFPA70

NOTE

There must be adequate clearance between

the oven and any adjacent combustible

construction. Clearance must also provide for

servicing and for operation.

CAUTION

It is recommended that the oven be placed

under a ventilation hood for adequate air

supply and ventilation.

CAUTION

Do not obstruct the flow of ventilation air to

and from your oven. Do not obstruct the fan

holes in the rear of the unit.

I. UNLOADING

Your Middleby Marshall PS520-Series Oven is

shipped partially assembled. It will arrive in a carton on

a crate.

Carton size for a PS520-Series Oven is:

44-1/4” (112mm) Long x

37-1/2” (953mm) Wide x

23” (584mm) High x

The crate and carton MUST be examined before

signing the Bill of Lading. Report any visible damage

to the transport company, and check for the proper

number of crates. If apparent damage is found, make

arrangements to file a claim against the carrier.

Surface Interstate Commerce Regulations (U.S.A.)

require that the claim must be initiated by the consignee within 10 days from the date that the shipment

is received.

CAUTION

On ovens with the Machinery Drive

Compartment located at the RIGHT end, a

minimum clearance of 0” to a left side wall,

18” to a right side wall and 6” from a back wall

to air openings at the rear of the oven must be

maintained.

For servicing and cleaning, a minimum of 18”

clearance from all walls is recommended.

4

Page 9

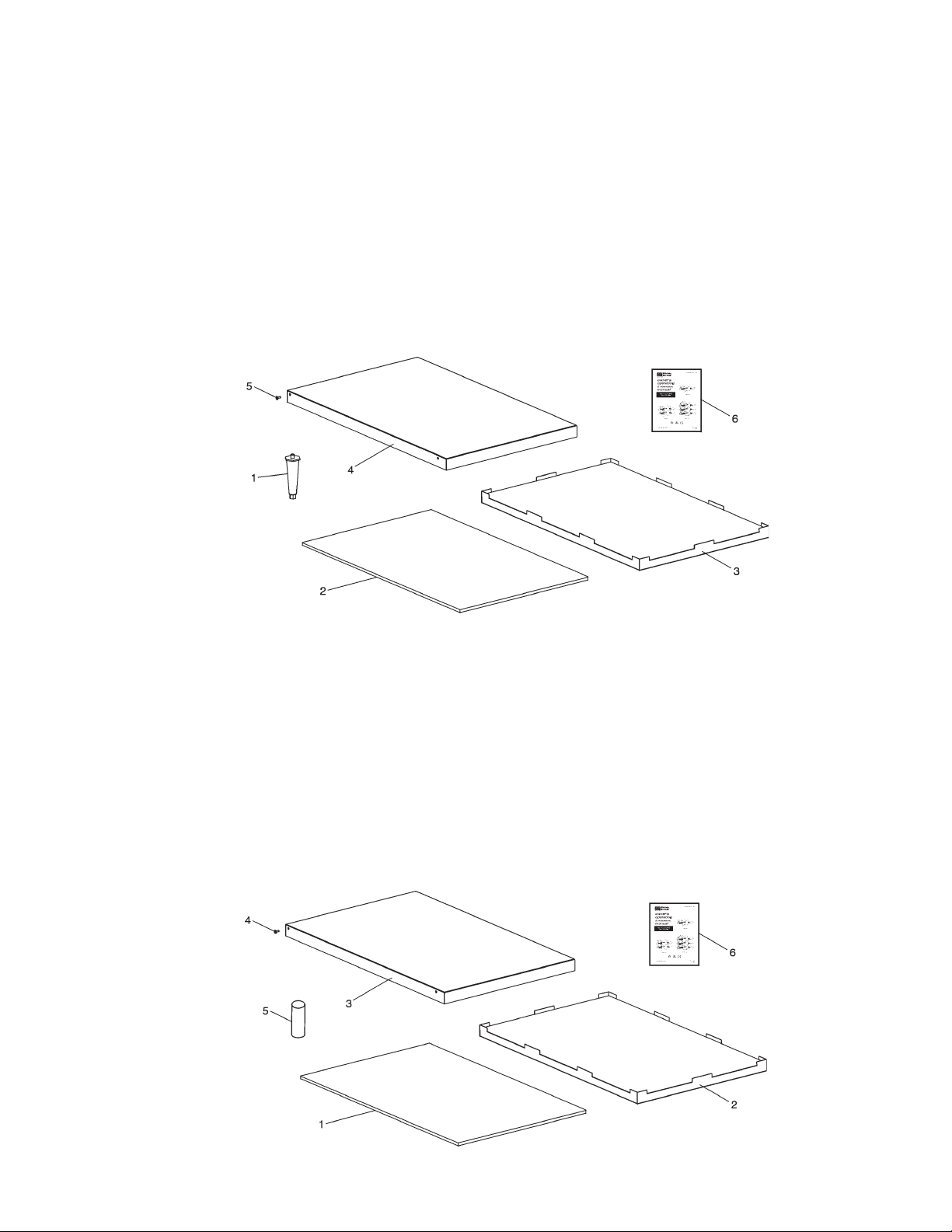

PARTS LIST FOR SERIES PS520 ELECTRIC OVEN

INSTALLATION KIT

Single and Double Stack Ovens

P/N 48397

Item

NO. QTY PART NO. DESCRIPTION

1 4 3101908 Leg 4” AD FT

2 2 48392 Insulation Bottom Tray

3 1 48394 Bottom Tray Weldment

4 1 48396 Top cover

5 4 51387 Screw MSSLT Thread 8-32 x 1/2, 18-8

6 1 52358 Installation & Operation Manual - English

6 1 59476 Installation & Operation Manual - French

SECTION 2

INSTALLATION

PARTS LIST FOR SERIES PS520 ELECTRIC OVEN

INSTALLATION KIT

Triple Stack Ovens

P/N 54593

Item

NO. QTY PART NO. DESCRIPTION

1 2 48392 Insulation Bottom Tray

2 1 48394 Bottom Tray Weldment

3 1 48396 Top cover

4 4 51387 Screw MSSLT Thread 8-32 x 1/2, 18-8

5 4 M3828 Pin, Alignment

6 1 52358 Installation & Operation Manual - English

6 1 59476 Installation & Operation Manual - French

5

Page 10

SECTION 2

INSTALLATION

Figure 2-5. MODEL PS520 SINGLE OVEN DIMENSIONS

1

The Opening Height is Adjustable

from 2-1/4 inch minimum to 3-3/4

inch maximum in 1/2 inch

increments.

Figure 2-6. MODEL PS520 DOUBLE OVEN DIMENSIONS

Figure 2-7. MODEL PS520 TRIPLE OVEN DIMENSIONS

6

Page 11

UTILITY ROUGH-IN DIMENSIONS AND POSITIONING

FOR PS520 SERIES OVENS

WARNING

DO NOT USE CONDUIT OR GAS LINE FOR

GROUNDING CONNECTION

CAUTION

IT IS RECOMMENDED THAT THE OVEN BE

PLACED UNDER A VENTILATION HOOD

FOR ADEQUATE AIR SUPPLY AND

VENTILATION

SECTION 2

INSTALLATION

To Oven

ELECTRIC SUPPLY TO BE

PROVIDED BY CUSTOMER

CIRCUIT BREAKER

Separate circuit breaker with lockout/tagout electrical

shutoff for each oven. Wire each oven separately.

50 amp circuit breaker for 208-240V, or 30 Amp circuit

breaker for 380-480V.

ELECTRICAL SPECIFICATIONS

ALL MODELS:

•208V main blower motors and elements, 1 Ph, 39.9

Amp draw, 50/60 Hz, 208V control circuit, 2 pole,

3 wire system per oven (2 hot, 1 grd).

•230V main blower motors and elements, 1 Ph, 33.0

Amp draw, 50/60 Hz, 230V control circuit, 2 pole,

3 wire system per oven (2 hot, 1 grd).

•240V main blower motors and elements, 1 Ph, 34.6

Amp draw, 50/60 Hz, 208-240V control circuit, 2 pole,

3 wire system per oven (2 hot, 1 grd).

Non-CE:

•380V elements, 1 Ph, 21.8 Amp draw, 50/60 Hz, 208-

240V control circuit and main blower motor, 3 pole,

4 wire system per oven (2 hot, 1 neut, 1 grd).

Domestic and Non-CE:

•480V elements, 1 Ph, 17.3 Amp draw, 50/60 Hz, 208-

240V control circuit and main blower motor, 3 pole,

4 wire system per oven (2 hot, 1 neut, 1 grd)

CE Only:

•380V elements, 1 Ph, 21.8 Amp draw, 50/60 Hz, 208-

240V control circuit and main blower motor, 2 pole,

3 wire system per oven (2 hot, 1 grd).

•400V elements, 1 Ph, 23.0 Amp draw, 50/60 Hz, 208240V control circuit and main blower motor, 2 pole,

3 wire system per oven (2 hot, 1 grd)

•380V elements, 3 Ph, 21.8/21.8/1.2 Amp draw, 50/60

Hz, 5 pole, 4 wire system per oven (3 hot, 1 neut, 1

grd).

•400V elements, 3 Ph, 23.0/23.0/1.2 Amp draw, 50/60

Hz, 5 pole, 4 wire system per oven (3 hot, 1 neut, 1

grd)

Do NOT use conduit for ground.

To Oven

Suggested dimensions are shown; utility code

requirements supercede any factors shown.

Figure 2-9. Typical PS520-Series Oven(s)

Installation

ELECTRICAL RATING

7.6 - 9.2 kW/hr

SUPPLY WIRING

Supply wire size must be in accordance with the National

Electrical Code (current edition) and must be in compliance

with local codes.

SUGGESTED

If space permits, service should be located near the control

console end of the oven(s) to allow convenient access to

safety switches.

CAUTION

UNIT MUST HAVE AIR VENT PLATES

INSTALLED OR WARRANTY WILL BE VOID.

II. VENTILATION

A mechanically driven ventilation system is required for

the PS520 Series Middleby Marshall conveyorized electric

ovens.

Local codes and conditions vary greatly from one area to

another and must be complied with. Following are the

suggested requirements for good ventilation. Please

remember these are recommendations or guidelines, you

may have a special condition or problem that will require

the services of a ventilation engineer or specialist. Proper

ventilation is the oven owner’s responsibility. Improper

ventilation can inhibit oven performance.

Please Note: There are now two “stand off” “C”

channels that must be installed in the field (See Section

1: Figure 1-4, page 3 for reference)

7

Page 12

SECTION 2

INSTALLATION

These “C” Channel brackets are installed in the vertical

plane using existing screws to support these ‘C”

Channels using the upper and lower Key Hole openings

in the ‘C’ Channels. The “C” Channels are identical and

once installed will allow ample amounts of air through

the cooling fan mounted on the rear side of the oven by

keeping the oven away from the rear wall.

III. ELECTRICAL CONNECTION INFORMATION

FOR PS520-SERIES OVENS.

WARNING

Authorized supplier personnel normally

accomplish the connection for the ventilation

system, electric supply, as arranged by the

customer. Following these connections, the

factory-authorized installer can perform the

initial start-up of the oven.

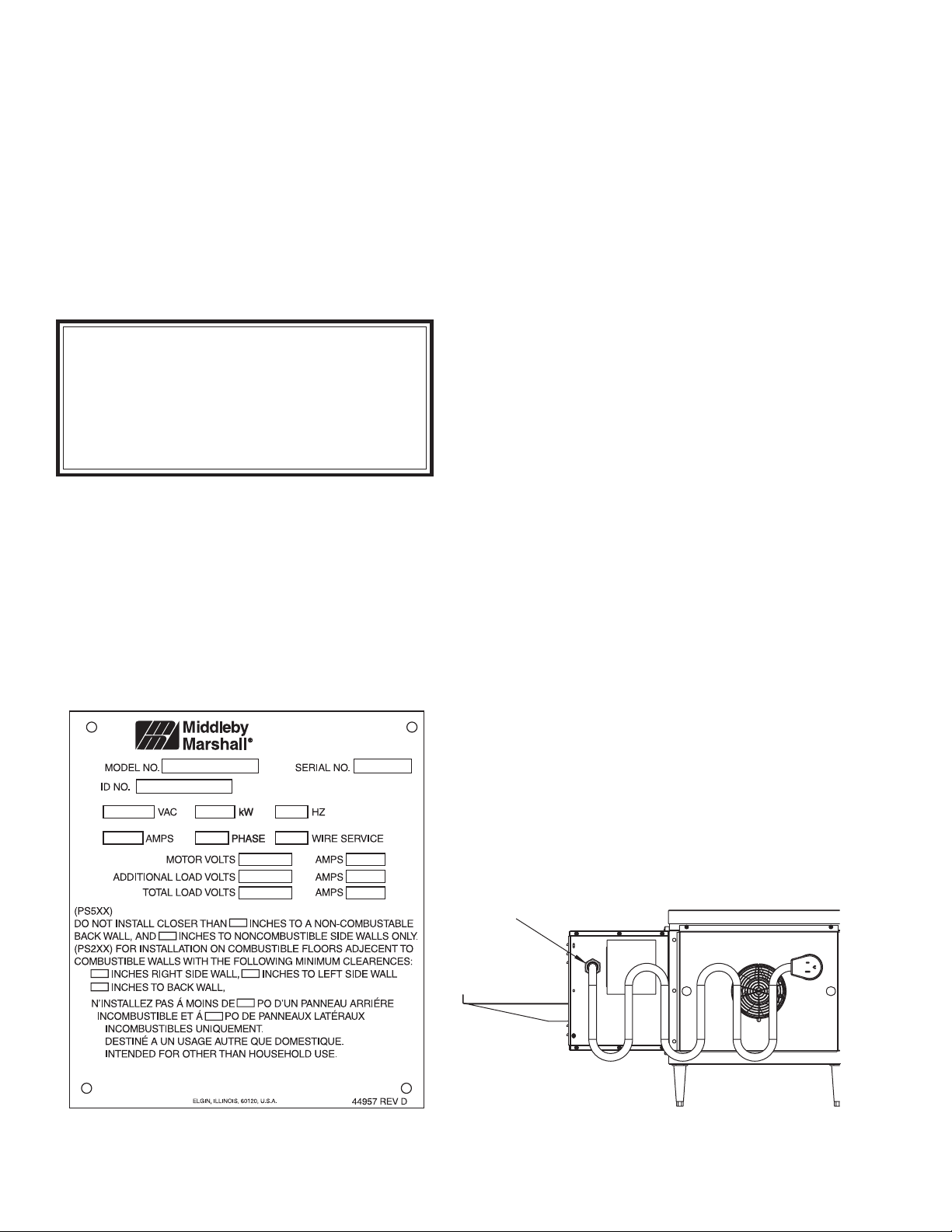

Check the oven data plate (Figure 2-10) before making

any electric supply connections. Electric supply

connections must agree with data on the oven data plate.

A fused disconnect switch or a main circuit breaker

(customer supplied) MUST be installed in the electric

supply line for each oven; it is recommended that this

switch/circuit breaker have lockout/tagout capability. The

electric supply connection must meet all national and

local electrical code requirements. Copper is the

recommended material for the electrical supply

conductors.

IV. ELECTRIC SUPPLY FOR ELECTRICALLY

HEATED OVENS

Power requirements for electrically heated ovens are

usually 208-240VAC, 1-phase, 3 wire (2 ‘hot’, 1 ground),

although ovens built for export can have power

requirements of 380VAC and 480VAC. (These ovens

have a 4-wire or 5-wire system.) A 1.5” (38mm) diameter

cutout/hole in the back of the machinery compartment

provides access for the electrical supply connections on

380V and 480V units. 208V and 240V units have a cord

and plug. Using flexible cable(s) for the electrical power

supply conductors requires a 2” (51mm) strain-relief fitting

(not furnished) to enable safe access to the terminal block

from which oven power is distributed.

NOTE: The electric supply installation must satisfy the

requirements of the appropriate statutory authority, such

as the National Electrical Code (NEC), ANSI/NFPA70,

(U.S.A); the Canadian Electrical Code, CSA C22:2; the

Australian Code AG601; or other applicable regulations.

The supply conductors must be of the size and material

(copper) recommended to provide the current require;

(refer to the data plate for the ampere specifications).

Typical specifications for each PS520-Series Oven are

208-240V, 1-phase, 3 wire, 8.3kW; this oven requires

50 ampere service. A PS520-Series Double Oven (Figure

1-2) installation would require two 50 ampere service

connections, one for each oven; the 8.3kW power

consumption also doubles for such an installation to

16.6kW.

The 208V, 230V or 240V AC electrically heated oven

uses two legs of the supplied power to provide 208V,

230V or 240V AC power for the oven control circuitry

ELECTRICAL

INLET

Figure 2-10. Typical Electric Oven Data Plate

Figure 2-11. Junction Connection Box

8

Page 13

I. CONTROL FUNCTIONS

SECTION 3

OPERATION

SECTION 3

OPERATION

Temperature

Controller

Conveyor

Speed

Control

Conveyor

Switch

Blower

Switch

Heat

Switch

Figure 3-1. PS520-Series Oven Control Functions

WARNING

A possibility of injury from rotating parts and electric

shock exists in the oven. Never disassemble or

clean the oven with the BLOWER switch or any

other oven control turned “ON” or “I”. Turn “OFF” or

“O” and lockout or tagout all electric power to the

oven before attempting to clean or service the oven.

9

Page 14

SECTION 3

OPERATION

II. COMPONENT INFORMATION AND

LOCATION (Figures 3-1 and 3-2)

A. Door Safety Switch

The Door Safety Switch is located at the lower right side

of the control panel opening. Opening the control panel

door permits this switch to open, disconnecting power

to all electrical controls.

CAUTION

Do NOT touch the wires going to this

safety switch. Current is always present.

B. Blower Switch

The blower switch has two positions. The switch must

be “ON” or “I” for the main blowers to come on and permit

the oven to run. The fan circulates the air throughout the

oven and must stay on during baking and during the

cool down cycle above 200

bearing damage. To protect the blower motor and

bearings a thermostatic override is built into the oven.

0

F (930C) to prevent blower

Temperature

Controller

If the temperature of the oven is over 2000F (930C) the

main blower will continue to run after the blower switch

is turned to the “OFF” or “O” position.

C. Heat Switch

Turning the HEAT switch to “ON” or “I” will energize the

electric heating system. This switch is in series with the

blower fan motor and high temperature override switch.

Both switches must be closed before the heating

elements can be energized.

D. Temperature Controller

The temperature controller is a solid-state, PID type to

maintain the operator-set temperature. The temperature

controller continuously monitors the oven temperature

and turns on the modulating solid state relay controller.

The heat is on for the time required to maintain a

consistent oven temperature.

The temperature controller contains a low-limit switch

which allows the oven to cool down to 200

0

F (930C)

before shutting off the blower. A high-limit indication

(ALM1) will appear on the display if the oven reaches

6500F (3430C).

Door Safety

Switch

Conveyor Speed

Digital Control

Conveyor Speed

Control Module

Conveyor

Drive Motor

Figure 3-2. Interior View of Control Console

10

Page 15

E. Conveyor

The on-off switch for the conveyor motor is on the

digital control panel. Also on the control panel is the

digital conveyor speed control. The digital control can

be adjusted from 1-10 minutes bake time (conveyor

speed). Refer to Figure 3-3.

Conveyor speed is measured by the amount of time it

takes for an item to go through the bake chamber of

the oven.

SECTION 3

OPERATION

MEASURING CONVEYOR SPEED

See Figure 3-4 and 3-5.

To check conveyor speed, place a product item at the

entrance end of the baking chamber as shown. Time

how long it takes for the leading edge of the item to go

from the entrance end of the baking chamber to the

exit end. This should be the conveyor speed shown on

the conveyor speed digital control.

NOTE: In Figure 3-4 and 3-5, the oven shown is with

the conveyor running left to right.

WARNING

A possibility of injury from rotating parts and electric

shock exists in the oven. Never disassemble or

clean the oven with the BLOWER switch or any

other oven control turned “ON” or “I”. Turn “OFF” or

“O” and lockout or tagout all electric power to the

oven before attempting to clean or service the oven.

Minutes

Seconds

Figure 3-3. Conveyor Speed Digital Control

Figure 3-4. Product at entrance end of baking

chamber - BEGINNING OF TIMING

11

Figure 3-5. Product at exit end of baking

chamber - END OF TIMING

Page 16

SECTION 3

OPERATION

WARNING

OVEN MUST BE KEPT CLEAR OF

COMBUSTIBLES AT ALL TIMES

III. STEP-BY-STEP OPERATION

A. Start-up Procedure

Daily Start-up

1. Turn the BLOWER switch (Figure 3-6) to the “ON” or “I”

position. This starts the main blower fan and the cooling

fans. This blower circulates air through the air fingers and

must stay on during the cooking or baking process.

2. Check to see if the cooling fans (see Figure 4-1 page

13) are operating when the blower switch (see Figure 3-6)

is turned “ON” or “I”. The cooling fans cool the control

components and blower motor. The cooling fans, located

at the rear of the oven blows air into and through the

cabinet. Air is exhausted through the front of the cabinet

and also out the front of the oven. Refer to Daily

Maintenance Section for fan intake checking procedure.

IMPORTANT NOTICE

The cooling fan operates when the BLOWER

switch is turned “ON” or “I”. It must operate to

keep the control console below 1400F (600C)

4. Set the temperature controller to the desired baking

temperature.

NOTE: For complete temperature controller operation

instructions refer to Step C.

5. Turn the HEAT switch (see Figure 3-6) to the “ON” or “I”

position. This completes a circuit to supply electric power

to the electric heating system.

6. Oven will reach baking temperature of 500

approximately 20 minutes. Allow the oven to cycle for 30

minutes after it has reached desired baking temperature.

The oven is now ready for baking.

POWER FAILURE

In case of power failure, turn off all switches and remove

product. After power has been reestablished follow normal

start-up procedure.

B. Shutdown Procedure

1. Turn the BLOWER and HEAT switches to “OFF” or “O”.

NOTE: The blowers will remain on until the oven

temperature cools down to 2000F (930C) at which time they

will stop automatically.

0

F (2320C) in

3. Turn the CONVEYOR switch (see Figure 3-6) to the

“ON” or “I” position. This starts the conveyor belt moving

through the oven. Set the conveyer speed for the desired

baking time. Refer to the following Procedures E, F and G.

2. Make certain that there are no products left on the

conveyor inside the oven. Turn the CONVEYOR switch to

“OFF” or “O”

12

Figure 3-6. Control Panel

Page 17

SECTION 3

OPERATION

IV. NORMAL OPERATION - STEP-BY-STEP

A. Daily Start-up Procedure

1. Check that the circuit breaker/fused disconnect is in the on

position.

2. Turn the “BLOWER”

switch to the “ON”

or “I” position.

3. Turn the “CONVEYOR”

switch to the “ON” or

“I” position.

4. If necessary, adjust the

conveyor speed setting

by pressing the

pushbuttons on the con-

veyor speed controller to

change the displayed

bake time.

5. Adjust the temperature

controller to a desired set

temperature, if necessary.

• Press the Set Point

and Unlock keys at

the same time. Wait

for the “SET PT” light

to turn on.

• Press the Up Arrow

and Down Arrow

Keys as necessary

to adjust the setpoint.

or

7. Wait for the oven to heat to the setpoint temperature.

Higher setpoint temperatures will require a longer wait.

The oven cavity can reach a temperature of 500

in approximately 15 minutes.

8. (Optional) Press the

Temperature key to

show the Actual Temperature in the display,

and wait for the “ACTUAL TEMP” light to turn

on. This allows you to

monitor the oven temperature as it rises to the

setpoint.

9. Allow the oven to preheat for 10 minutes after it has

reached the set point temperature.

0

F (2320C)

B. DAILY SHUTDOWN PROCEDURE

1. Turn the “HEAT”

and “BLOWER”

switches to the “OFF” or

“O” position. Note the

blowers will remain in

operation until the oven

has cooled to below

2000F (930C).

2. Make certain that there

are no products left on the

conveyor inside the oven.

Turn the “CONVEYOR”

switch to the “OFF”

or “O” position.

3. After the oven has cooled and the blowers have turned

off, switch the circuit breakers/fused disconnect to the

“OFF” or “O” position.

6. Turn the “HEAT”

switch to the “ON” or “I”

position, and wait for the

“HEAT ON” light to turn

on.

CAUTION

In case of power failure, turn all switches to the “OFF” or

“O” position and remove the product. After the power has

been restored, perform the normal start-up procedure. IF

THE OVEN WAS SWITCHED OFF FOR LESS THAN (5)

FIVE MINUTES, WAIT FOR AT LEAST (5) FIVE

MINUTES BEFORE RESTARTING THE OVEN.

13

Page 18

SECTION 3

OPERATION

Light

Lights when the set point

is locked out from

changes. This setting can

only be changed by

service personnel.

OVERTEMP

Light

Lights when the oven

temperature is greater than

6500F (3430C). Refer to

Quick Reference;

Troubleshooting in this

section.

Temperature

Key

Press this key once to view

the Actual Temperature in

the Display

Display

Shows the Set Point or

the Actual Temperature

in degrees Fahrenheit (F)

or Celsius (C).

“HEAT ON”

Light

Lights when the burner is

in operation.“SP LOCK”

“SET

PT”(setpoint)

Light

Lights when the set

point is shown in the

display

“ACTUAL TEMP”

Light

Lights when the Actual

Temperature is shown in

the display.

Service Key

Service use only

Unlock Key

Press this key together

with the Set Point Key to

allow the Set Point to be

changed. Changes can

only be made for 60

seconds.

Up Arrow and Down

Arrow Keys

Press these keys to adjust

the Set Point up or down. If

the Set Point will not

change, refer to Set Point

Key and Unlock Key in this

section

14

Set Point Key

Press this key together

with the Unlock Key to

allow the Set Point to be

changed. Changes can

only be made for 60

seconds.

Page 19

V. QUICK REFERENCE: TROUBLESHOOTING

SYMPTOM PROBLEM SOLUTION

SECTION 3

OPERATION

light is lit,

food product is

undercooked

Oven will not turn on

at all

appears in display,

oven is not heating

Oven will not heat

The oven temperature exceeded 650

the burner was automatically shut down

Electrical power may not be

reaching the oven, or the

controls may be set incorrectly.

The oven did not reach

0

200

utes of start-up, and the

oven has stopped heating.

Controls may be set incorrectly

0

F (3430C), and

F (930F) within 15 min-

• Follow the procedures under Daily Shutdown Procedures

in this section to shut down the oven. Contact your

Middleby Marshall Authorized Service Agent to determine

and correct the cause of the condition to prevent damage

to the oven.

• Check that the circuit breaker/fused disconnect is turned

on.

• Check that the “BLOWER”

position.

• Turn the “HEAT” , “BLOWER” , and

“CONVEYOR” switches to the “OFF” or “O” position.

• Wait for AT LEAST FIVE MINUTES before restarting the

oven.

• Repeat the daily procedure.

• Check that the Set Point is correctly set.

• Check that both “BLOWER” and “HEAT”

switches are in the “ON” or “I” position.

• Wait for AT LEAST FIVE MINUTES before restarting the

oven.

• Repeat the Daily Start-up procedure. Check that the Set

Point is above 2000F (930C)

Switch is in the “ON” or “I”

Oven is operating, but

little or no air is

blowing from air

fingers

Conveyor moves with

a jerky motion, or will

not move at all

Food products are

overcooked or

undercooked

Air fingers may have been

reassembled incorrectly after cleaning.

Conveyor may be jammed

on an object in the oven, or

conveyor belt or drive chain

tension may be incorrect.

Controls may be set incorrectly

• Turn the oven to the “OFF” or “O” position, and allow to

cool. Disconnect electrical power to the oven.

• Refer to Section 4, Maintenance, for instructions on

reassembling the air fingers.

• Turn the oven to the “OFF” or “O” position, and allow to

cool. Disconnect electrical power to the oven.

• Check if the conveyor is blocked by an object inside the

oven.

• Refer to Section 4, Maintenance, for instructions on

checking the conveyor and drive chain tension.

• Check that the set temperature and bake time settings

are correct.

IF THESE STEPS FAIL TO RESOLVE THE PROBLEM, CONTACT YOUR LOCAL MIDDLEBY MARSHALL

AUTHORIZED SERVICE AGENT. A SERVICE AGENCY DIRECTORY IS SUPPLIED WITH YOUR OVEN.

15

Page 20

SECTION 4

MAINTENANCE

SECTION 4

MAINTENANCE

WARNING

Possibility of injury from rotating parts and electrical

shock exist in this oven. Turn off and lockout or tagout

electrical supply to oven(s) before attempting to

disassemble, clean or service oven(s). Never

disassemble or clean the oven with the blower switch or

any other part of the oven turned on.

WARNING

Before performing any maintenance work or cleaning,

turn main power switch off.

CAUTION

When cleaning do not use any abrasive cleaning

materials or water spray, wipe clean only. Never use a

water hose or pressurized steam cleaning equipment

when cleaning this oven.

NOTICE

If the oven is to be removed from it’s installed location

for servicing, perform the following procedure:

1. Switch off the oven and allow it to cool, DO NOT

service the oven while it is warm.

2. Turn off main circuit breakers and disconnect

connector from oven.

3. Move oven to desired location for servicing.

4. When servicing is complete, move oven to original

location.

5. Adjust legs to level oven.

6. Connect electrical connectors to oven.

7. Turn on main circuit breaker.

8. Follow normal start-up instructions.

16

Page 21

SECTION 4

MAINTENANCE

I. MAINTENANCE - DAILY

A. Exterior

Everyday you should clean the outside of the oven with

a soft cloth and mild detergent.

WARNING

Never use a water hose or pressurized steam

cleaning equipment when cleaning the oven.

B. Cooling Fan

1. ONE COOLING FAN GRILLE AT THE REAR OF THE

OVEN MUST CLEANED DAILY - Clean grille with a stiff

nylon type brush.

2. Check the air intake of the cooling fan daily. The best

time to check is right after starting the oven.

IMPORTANT NOTE

The cooling fan operates when the blower switch

is turned to “ON” or “I”. It must operate to keep

the electrical control cabinet below 140

0

F (600C).

D. Crumb Pans (Figure 4-2)

WARNING

Crumb pan is extremely hot while oven is operating.

Allow oven to cool before removing crumb pan.

When oven is cool remove and clean the crumb pan at

each end of the oven. Each crumb pan can be removed

by sliding it out, as shown in Figure 4-2. Reinstall the

crumb pans after cleaning.

Cooling Fan Grille

WARNING

IF FAN BLADE IS NOT ROTATING, BROKEN,

OR FAN ASSEMBLY IS MISSING FROM MAIN

BLOWER MOTOR SHAFT, DO NOT OPERATE

OVEN. REPLACE COOLING FAN BLADE

BEFORE OPERATING OVEN. Serious damage

could be done to the burner blower motor and/or

solid-state electrical components if oven is

operated while cooling fan is not running or vent

grille is plugged.

3. Using a stiff nylon brush clean control compartment

vent grille.

C. Conveyor Belt (Figure 4-2)

Everyday, just after starting the oven, stand at the

unloading end of the conveyor, and with a brush, remove

food particles (crumbs etc.) clinging to the conveyor belt,

brushing them into the crumb pan.

Figure 4-1. Oven Cooling Fans

Figure 4-2. Conveyor Belt and

Crumb Pan Cleaning

17

Page 22

SECTION 4

MAINTENANCE

II. MAINTENANCE - MONTHLY

NOTE: The oven interior may require cleaning more than once a

month depending on the volume of baking. To clean the interior , you

have to disassemble some parts of the oven.

When cleaning your PS520-Series Oven note the following:

PRECAUTIONS-

1. Do not use excessive water or saturation of oven

insulation will occur.

2. Do not use caustic oven cleaner or the aluminized

finger manifold surfaces will be severely damaged.

When cleaning your oven, first remove all heavy debris

with a vacuum cleaner. Use a damp cloth for light

cleaning. For heavier cleaning of baked on grease and

carbon deposits use a non-caustic cleaner that will not

Console

Controls

Temperature

Controller

Removable Air Fingers

(inside baking chamber)

react with the aluminized finger manifold surfaces.

You can order non-caustic cleaner from your local

authorized Middleby Marshall Parts Distributor in the

quantities listed below

Part# Quantity

27170-0244 Case of Quarts (6)

27170-0246 Case of Gallons (4)

A. Removing Conveyor From Oven For Cleaning

1. Remove entry and exit trays

2. Loosen (do not remove) two screws on housing guard.

3. Remove motor housing guard.

4. Lift conveyor and remove chain.

Blower and Cooling

Fan Motor

Conveyor

Speed

Control

Conveyor

Motor

(inside)

Motor

Housing

Guard

Removable

Crumb Pan

Removable

Conveyor

Assembly

Adjustable

Eyebrow

Legs

Figure 4-3

18

Page 23

SECTION 4

MAINTENANCE

5. Lift other side of conveyor and push toward other

side.

6. Remove conveyor as shown.

Figure 4-4

Figure 4-5

Figure 4-6

Figure 4-7

CAUTION

19

Be careful no to bump the drive sprocket while

handling the conveyor, to avoid damaging the

drive shaft.

Page 24

SECTION 4

MAINTENANCE

B. Air Fingers Disassembly For cleaning

1. As the air fingers are removed use a felt pen to mark

all parts of the fingers. This includes the finger manifold,

inner plate and the outer plate (see Figure 1-9). If a blank

or choke plate is used, mark that plate also, Fingers are

marked in the order shown; as viewed from the front of

the oven. (The marks for an upper oven should be

preceded with a “U”, example UB1, UT2, etc.)

Standard Fingers

2. Slide blank plates straight out.

Figure 4-8

Figure 4-9

3. Remove air fingers.

NOTE: Some oven users require a custom finger

arrangement where the quantity of air fingers may vary.

You can remove the top and bottom fingers and blank

plates from each or either end. It is highly recommended

that each finger be marked before removing so it is placed

in exactly the same position when reassembled (refer to

step 1).

4. With air fingers out, place them in an upright position

to remove the outer plate.

5. Gently step on the lip of the finger and pull the outer

plate off.

Remove the air fingers, pull the finger at the back sidepull straight out.

Figure 4-10

20

Page 25

SECTION 4

MAINTENANCE

6. To remove the inner plate, pull the plate out and

then up.

Figure 4-11

7. The outer finger plate is stainless steel and may be

cleaned by either soaking in a hot, strong detergent

solution or using a caustic cleaner. The conveyor belt

can also be cleaned in the same way.

C. Reassembly of Air Fingers

1. Air fingers are made up of one inner plate, one

outer plate and the finger housing manifold. Be sure to

match up the markings (T1, T2, T3, etc.) on all parts of

the air fingers as you are reassembling.

Figure 4-14

Figure 4-12. Standard Lower Finger

2. Reassemble the inner plate. Keep your fingers clear

so you won’t pinch them. The inner plate of a finger

will only go in one way because of its design.

3. Replace the outer plate by placing your hands flat

on the top of the plate and pushing down. Keep your

fingers clear so you won’t pinch them.

Figure 4-13. Standard Upper Finger

Figure 4-15

21

Page 26

SECTION 4

MAINTENANCE

4 . Replace the air fingers by pushing in at the back

side. Remember to replace them according to the

numbers marked on them when they were removed.

They must go back in the same way they came out.

IMPORTANT: When inserting fingers the tab

on the outer plate must be in the groove as

shown in Figure 4-18. There is a blocking tab

on the outside of the groove which will prevent

inserting the finger in the groove if the outer

plate is moved away from the flange of the

finger.

Figure 4-16

Extended Lip

Flange of

Finger Manifold

Tab on

Outer Plate

Tab on

Outer Plate

Figure 4-17

22

Page 27

MAINTENANCE

5. Install fingers and blank plates correctly with edges interlocked and no space between edges.

SECTION 4

Top Finger

Tab on Outer Plate of

Finger Located in Groove

Correct -

Edges Overlap

Completely

Figure 4-18

D. Reinstall End Plugs

1. Reinstall lower end plug. Be sure to tighten the wing screw on the end plug.

2. Reinstall conveyor.

Blank Plate

3. Reinstall upper end plug. Be sure to tighten two wing screws on the end plug..

Figure 4-19

23

Page 28

SECTION 4

MAINTENANCE

E. Conveyor Reassembly Into Oven

1. Lift conveyor and position it in the oven as shown.

NOTE: Conveyor may be inserted into either end of

the oven. If it is ti be installed from the non-drive end of

the oven the drive sprocket assembly must be

removed as shown in conveyor disassembly section.

Figure 4-21

2. Reinstall the conveyor extension.

F. Checking Conveyor Belt Tension

WARNING

Oven conveyor belt must be cool when adjusting belt.

Do not adjust belt if HOT.

1. With the conveyor assembly in the oven, stand at

one end of the conveyor and check tension by lifting

the conveyor belt at the center of the oven chamber

opening (see Figure 4-23). The belt should not lift

higher then 1” to 2” (75mm to 102mm).

2. If conveyor belt is still not under proper tension, an

entire link must be removed. Use the following

procedure “H. Conveyor Belt Link Removal” to

remove a link. If conveyor belt is under proper tension

proceed directly to “J. Attaching Drive Chain”.

3. Newer model PS520-Series ovens have adjustment

screws at the end to tighten the conveyor belt. If these

adjustment screws are at their limit and belt tension is

still not correct, loosen the adjustment screws,

proceed to “H. Conveyor Belt Link Removal” to

shorten the belt and then return to “F. Checking

Conveyor Belt Tension” for proper adjustment. If belt

is tensioned properly proceed directly to “J. Attaching

Drive Chain”.

Conveyor Extension

Figure 4-22

Figure 4-23

24

Page 29

SECTION 4

MAINTENANCE

G. Conveyor Belt Link Removal

1. Using long nose pliers, an entire link can be

removed with the conveyor assembly either in or out of

the oven. Position master links at the end of the

conveyor as shown in Figure 4-24.

Master

Links

Figure 4-24

2. Using long nose pliers, unhook master links at left

end of conveyor as shown in Figure 4-25.

4. Unhook the link to be removed.

5. Pull up on the link section and remove. Do not

discard the link removed as it may be used for making

spare master links.

NOT: If a section of the conveyor is being replaced it

should be done now. Remove the links that need

replacing and use the section of conveyor belt

furnished in the installation kit to replace them.

Figure 4-25

3. Remove the outside master links on the right and

left sides of the conveyor belt as shown in Figure 4-26.

Figure 4-27

NOTE: Before connecting the inside master links,

notice that these links have a correct position (Figure

4-28). The link at the right is in the correct (horns up)

position for inserting into the conveyor belt. The horns

facing down are in the incorrect position.

Correct

Position

Incorrect

Position

Figure 4-28

Figure 4-26

25

Page 30

SECTION 4

MAINTENANCE

6. Reconnecting the inside master links (Figure 4-29)

Figure 4-29

NOTE: The outside master links have right and left

sides to them. The right edge master link has an open

hook facing you as shown in Figure 4-30. This will

match up with the outer edges of the conveyor belt.

Remember this hook travels backwards on the

conveyor.

H. Attaching Drive Chain

1. If drive sprocket assembly was removed,

reassemble it onto the conveyor drive shaft. Be sure

flat on end of drive shaft aligns with set screw in

conveyor shaft collar. Once in place tighten 3/32” set

screw.

2. Lift conveyor and install drive chain to conveyor

drive sprocket and motor sprocket.

Figure 4-30

7. Reconnect the outside master links.

8. Replace all parts removed from the oven.

Figure 4-32

3. The angle plate located on the underside of the

conveyor must be against the lower end plug. This is

true on both sides of the oven.

Crumb Pan

Mounting Bracket

Lower End Plug

Figure 4-33

Figure 4-31

26

Page 31

SECTION 4

MAINTENANCE

4. Reattach conveyor guard to control panel and

secure two screws.

Install both upper end plugs.

Figure 4-34

III. MAINTENANCE - EVERY 3 MONTHS

A. Electrical Terminals

Open the control cabinet door by removing the three

screws from the control cabinet door. Tighten all

electrical control terminal screws as shown in Figure 4-

35.

Figure 4-35

B. Ventilation

WARNING

Shut OFF all electrical power and lockout/tagout

the switch before attempting maintenance work.

NOTE: It is recommended that the 3-month

maintenance be performed by an authorized Middleby

Marshall technician.

Check that the air circulation throughout the oven is

not blocked and is working properly.

IV. MAINTENANCE - EVERY 6 MONTHS

A. Check brushes on D.C. conveyor motor. When

worn to less then 1/10” (2.4mm), replace the brushes.

B. Check your venting system.

IMPORTANT NOTICES:

• Installation of replacement parts requiring

access to the interior of the oven is permitted

only by an authorized service technician.

• If there are any problems with the operation of

the oven, the authorized service technician

must be called.

• It is suggested to obtain a service contract with

a manufacturer’s authorized service technician.

27

Page 32

SECTION 4

MAINTENANCE

PS520-SERIES ELECTRIC OVEN KEY SPARE PARTS KIT

ITEM PART NO. DESCRIPTION QUANTITY

1 58504 Kit, Temperature Control On/Off PID 1

2 51402 Relay, 100A 1

3 58390 Conveyor Drive Motor with 2 pole magnet 1

4 58323 Conveyor Speed control 1

5 33812-5 Thermocouple 3

6 50715 Heater Element, 208V 1

6 51017 Heater Element, 240V 1

6 51958 Heater Element, 380V 1

6 51961 Heater Element, 480V 1

7 57408 Contactor 65 amp 3-pole 1

28

Page 33

SECTION 5

TROUBLESHOOTING

SECTION 5

TROUBLESHOOTING

PROBLEM:

PRODUCTS ARE OVERCOOKED

OR UNDERCOOKED

Check for correct Check for correct

setting of conveyor setting on temperature

speed control. controller

Set the conveyor Turn temperature

speed control at control to correct

correct setting. setting.

Verify the food

preparation process.

If products still cook incorrectly,

call your Middleby Marshall

Service Agency.

PROBLEM:

OVEN BLOWER AND CONVEYOR OPERATE,

YET THE OVEN IS NOT HEATING

Reset the temperature controller

to a new setting (above 2000F),

after turning the BLOWER switch

to off for 30 seconds.

Start the oven again. If the oven still does not

heat, call your Middleby Marshall Service Agency.

PROBLEM:

CONVEYOR WILL NOT HOLD PROPER

SPEED OR WILL NOT RUN AT ALL

Check whether the conveyor is

jammed on something in the oven.

PROBLEM:

OVEN DOES NOT HEAT

Check to see if both BLOWER

switch and HEAT switch are in

the “ON” or “I” position.

If oven does not heat, call your

Middleby Marshall Service Agency

PROBLEM:

BLOWER MOTOR IS RUNNING, YET LITTLE

OR NO AIR BLOWS FROM AIR FINGERS

Air fingers reassembled incorrectly,

after cleaning

Assemble air fingers correctly, after cleaning.

Refer to Section 4 procedure, or call your

Middleby Marshall Service Agency

Check for proper tension of conveyor drive chain and

conveyor belt. Refer to Section 4 for

correct procedure.

Check that the conveyor

drive sprocket is tight.

If conveyor still does not run correctly, contact

your Middleby Marshall Service Agency.

PROBLEM:

OVEN DOES NOT TURN ON WHEN ITS

SWITCHES ARE TURNED ON

Check that all electric supply switches are set to

the “ON” or “I” position. Then, start the oven.

If oven still will not start, contact your Middleby

Marshall Service Agency.

29

Page 34

SECTION 6

ELECTRICAL SCHEMATICS

30

Drawing 48713 Rev J: Wiring Diagram, E208-240V 50/60/1

Page 35

SECTION 6

ELECTRICAL SCHEMATICS

31

Drawing 52445 Rev J: Wiring Diagram, E380-480V 50/60/1

Page 36

SECTION 6

ELECTRICAL SCHEMATICS

32

Drawing 52446 Rev K: Wiring Diagram, E230-240V CE, 1Ph

Page 37

SECTION 6

ELECTRICAL SCHEMATICS

33

Drawing 54661 Rev J: Wiring Diagram, E380-400V CE, 1Ph

Page 38

SECTION 6

ELECTRICAL SCHEMATICS

34

Drawing 58158 Rev F: Wiring Diagram, E380-400V CE, 3Ph

Page 39

NOTES

35

Page 40

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death. Read

the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

NOTICE

During the warranty period. ALL parts replacement and servicing should be

performed by your Middleby Marshall Authorized Service Agent. Service that is

performed by parties other than your Middleby Marshall Authorized Service Agent

may void your warranty.

NOTICE

Using any parts other than genuine Middleby Marshall factory manufactured parts

relieves the manufacturer of all warranty and liabilities.

NOTICE

Middleby Marshall reserves the right to change specifications at any time.

Middleby is proud to support the Commercial Food

Equipment Service Association (CFESA). We

recognize and applaud CFESA’s ongoing efforts to

improve the quality of technical service in the industry.

Middleby Cooking Systems Group • 1400 Toastmaster Drive • Elgin, IL 60120 • USA • (847) 741-3300 • FAX (847) 741-4406

www.middleby.com

Loading...

Loading...