Page 1

SECTION 1

DESCRIPTION

SECTION 1

DESCRIPTION

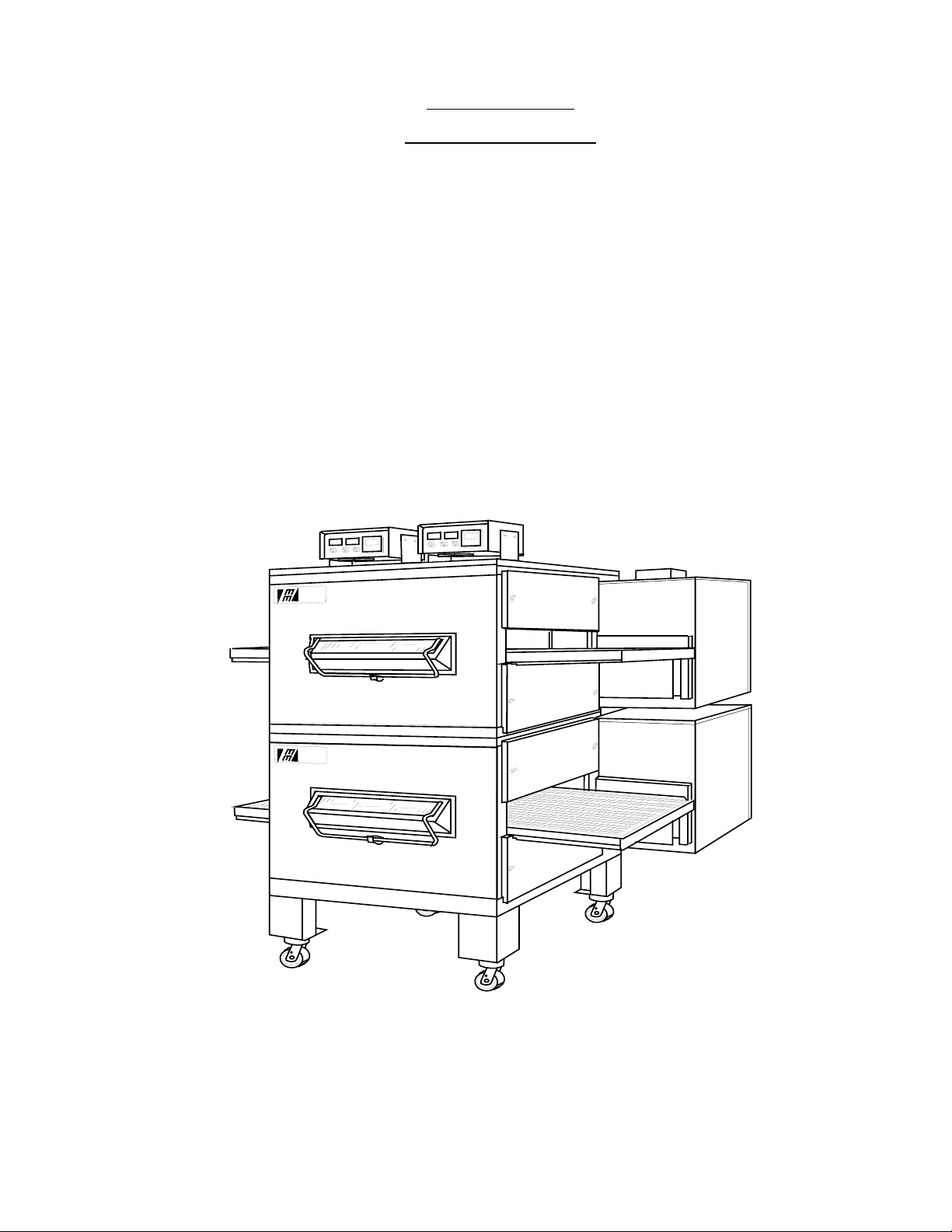

I. MODEL IDENTIFICATION

The Middleby™ Series PS200-R68 Ovens may be used

singly or stacked for use as double ovens.

The Series PS200-R68 single oven is mounted on a base

pad with 6" extension legs and casters. A double oven is

stacked and the lower oven is on a base pad with casters.

Middleby

Marshall

The ovens in a double oven operate completely independent of one another. Both ovens use identical controls

and components. One can be serviced while the other is

operating.

The Series PS200-R68 Ovens can be ordered with the

conveyor drive at either the right end or left end of the

oven. Each oven is equipped with a remote control box.

Middleby

Marshall

Figure 1-1. Middleby™ Series PS200-R68 Ovens

1

Page 2

PS200-R68 GAS PS200-R68 ELECTRIC PS224-R68 GAS PS224-R68 ELECTRIC PS220-R68 GAS PS220-R68 ELECTRIC

Conveyor Belt Width 32"(813mm) 32"(813mm) 24"(610mm) 24"(610mm) 20"(508mm) 20"(508mm)

Heating Zone Length 40-1/2"(1028mm) 40-1/2"(1028mm) 40-1/2"(1028mm) 40-1/2"(1028mm) 40-1/2"(1028mm) 40-1/2"(1028mm)

Baking Area Square Feet 9 sq.ft.(0.84sq.m.) 9 sq.ft.(0.84sq.m.) 6.4 sq.ft.(0.59sq.m.) 6.4 sq.ft.(0.59sq.m.) 5.5 sq.ft.(0.51sq.m.) 5.5 sq.ft.(0.51sq.m.)

Overall Dimension 68"(1727mm) L x 68"(1727mm) L x 68"(1727mm) L x 68"(1727mm) L x 68"(1727mm) L x 68"(1727mm) L x

Red Lobster Double Oven 57-3/4"(1467mm) W x 57-3/4"(1467mm) W x 49-3/4"(1264mm) W x 49-3/4"(1264mm) W x 45-3/4"(1162mm) W x 45-3/4"(1162mm) W x

Weight of Single Oven 925 lbs.(419kg) 925 lbs.(419kg) 825 lbs.(374kg) 825 lbs.(374kg) 750 lbs.(340kg) 750 lbs.(340kg)

Shipping Weight of Single Oven 1,100 lbs.(498.3kg) 1,100 lbs.(498.3kg) 1,000 lbs.(453kg) 1,000 lbs.(453kg) 925 lbs.(419kg) 925 lbs.(419kg)

Shipping Cube of Single Oven Approx.132 ft3(3.74 m3) Approx.132 ft3(3.74 m3) Approx.132 ft3(3.74 m3) Approx.132 ft3(3.74 m3) Approx.132 ft3(3.74 m3) Approx.132 ft3(3.74 m3)

Operating Range of Single Oven 120,000 BTU/HR 28kW/HR 100,000 BTU/HR 28kW/HR 100,000 BTU/HR 28kW/HR

Maximum Operating Temperature 550°F(287°C) 550°F(287°C) 550°F(287°C) 550°F(287°C) 550°F(287°C) 550°F(287°C)

Exhaust Vent Size 2" x 3"(50 x 75mm) -- 2" x 3"(50 x 75mm) -- 2" x 3"(50 x 75mm) -Exhaust Flow 80 C.F.M.(2.1m3m) -- 80 C.F.M.(2.1m3m) -- 80 C.F.M.(2.1m3m) -Warm Up Time 10 min. 15 min. 10 min. 15 min. 10 min. 15 min.

Gas Inlet Line Size 3/4"(19mm)ID for each cavity

Minimum Gas Meter Rating 450 cu.ft./hr.(12.74m3h) for 1 to 2 cavities

2

Minimum Gas Pipe Size: Natural 2" (51mm)ID for 1 or 2 ovens or

Propane 1.5" (38mm)ID for 1 to 2 ovens or

Gas Pressure: Natural 6"(152mm) to 14"(356mm) Water Column

Propane 11.5"(292mm) to 14"(356mm) Water Column

Gas Valves 0.75" (19mm)ID full flow gas shut-off valve.

Recirculating Air Blower One blower at 1700 RPM

Jet Air Velocity 3000 F.P.M.(1524cm/sec.)(Average)

Bake Time 2 min. 40 sec. Bake Time minimum

76-3/4"(1949mm) H 76-3/4"(1949mm) H 76-3/4"(1949mm) H 76-3/4"(1949mm) H 76-3/4"(1949mm) H 76-3/4"(1949mm) H

(30,240 kcal) (25,200 kcal) (25,200 kcal)

(35.1 kW/HR) (29.3 kW/HR) (29.3 kW/HR)

Add 180 cu.ft./hr.(5.1m3h)for each additional cavity

2.5" (64mm)ID for 3 or 4 ovens

2"(51mm)ID for 3 or 4 ovens -

(must be dedicated line)

A separate connection and valve must be provided for each cavity.

29 min. 50 sec. Bake Time maximum

SECTION 1

DESCRIPTION

PS200-R68 SERIES OVEN SPECIFICATIONS

Page 3

SERIES PS200-R68

ELECTRICAL SPECIFICATIONS

GAS HEATED OVENS

Main Blower Control Phase Frequency Amperage Poles Wires

& Elements Circuit Draw

Voltage Voltage

208-240V 120V 1 Ph 50/60 Hz 4.1 Amp 3 Pole 4 Wire

(2 hot,1 neut,1 grd)

208V 120V 1 Ph 50/60 Hz 4.1 Amp 2 Pole 3 Wire

Export Transformer (2 hot,1 grd)

200V 120V 1 Ph 50/60 Hz 4.1 Amp 2 Pole 3 Wire

Export Transformer (2 hot,1 grd)

220-240V 120V 1 Ph 50/60 Hz 4.1 Amp 2 Pole 3 Wire

Export Transformer (2 hot,1 grd)

ELECTRIC HEATED OVENS

Main Blower Control Phase Frequency Amperage Poles Wires

& Elements Circuit Draw

Voltage Voltage

208-240V 120V 3 Ph 50/60 Hz 75 Amp 4 Pole 5 Wire

(3 hot, 1 neut, 1 grd)

HEATER AMPERAGE

Voltage kW Amp Average Amps

208 27 70 37 37 37

220 23.5 67 30 30 30

230 25.7 63 31 31 31

240 27 61 33 33 33

220-240V 120V 3 Ph 50/60 Hz 75 Amp 3 Pole 4 Wire

Transformer (3 hot, 1 grd)

HEATER AMPERAGE

Voltage kW Amp Average Amps

220 23.5 67 30 30 30

240 27 61 33 33 33

380V 120V 3 Ph 50/60 Hz 50 Amp 4 Pole 5 Wire

Export Transformer (3 hot, 1 neut, 1 grd)

HEATER AMPERAGE

Voltage kW Amp Average Amps

380 27 38 22 22 22

400-416V 120V 3 Ph 50/60 Hz 50 Amp 4 Pole 5 Wire

Export Transformer (3 hot, 1 neut, 1 grd)

HEATER AMPERAGE

Voltage kW Amp Average Amps

415 27 35 28 28 28

SECTION 1

DESCRIPTION

NOTE

Wiring Diagram is contained at the back of this Manual

and is also located inside of the

machinery compartment.

.

3

Page 4

SECTION 1

DESCRIPTION

II. PRINCIPLE OF AIR FLOW

Air is heated and then pulled through the fan which

pushes the air into the oven plenum and delivers heated

air into the air fingers. The fingers contain an inner plate

and outer plate which columnate the air and evenly

distribute heated air across the conveyor belt on which

the product rides. Air is then pulled back into the blower

and the process continues.

A. Heat Transfer and How It Works

1. Heat constantly moves from a warm object to a cold

object. Heat moves using three different paths which are

conduction, radiation and convection.

Conduction:

tact. The pizza dough in contact with the pan is a good

example of conduction.

Radiation:

heat. Dark objects absorb heat whereas light or shiny

objects reflect more heat. This is the reason that the

This path utilizes surface to surface con-

This path has to do with objects radiating

inside of the Middleby Series PS200-R68 Oven is light in

color to reflect more heat back to the product.

Convection:

of air. It explains why hot air will rise and cooler air

replaces hot air. An industrial application of this principle

is to incorporate a fan to force the hot air movement which

in turn will increase the heat transfer to the product.

The Middleby Series PS200-R68 Oven has a large fan to

move the hot air through the air fingers and onto the

product so the most efficient bake is achieved.

2. Temperature is the intensity of heat at the point which

it is sensed. As discussed above, heat flows by conduction, radiation and convection. The speed at which the

heat flows is determined by the temperature difference

between the oven and the food product. The larger the

difference the faster the heat flows to the item that is

being baked.

This path has to do with moving amounts

Side View

Figure 1-2

Series PS200-R68 Air Flow

4

Page 5

II. PRINCIPLE OF AIR FLOW Continued

SECTION 1

DESCRIPTION

Air Flow From

Plenum Chamber

Outer Plate

High Velocity

Columns of Air to

Product

Air Flow From

Plenum Chamber

Manifold Baffle

Inner Plate

Manifold

Manifold Baffle

Inner Plate

Figure 1-3. Air Fingers Showing Air Passing Through Inner Plate And Outer Plate

Which Forms High Velocity Columns Of Air To The Product.

B. Air Fingers

The Middleby Series PS200-R68 Oven is a conveyorized

hot air oven employing vertical air streams (Figure1-3) to

give uniform and intensive heating. The columnated

vertical streams of hot air provide an exceptional heat

transfer rate and generally bake faster and at lower

temperatures than convection hot air or infrared heating

ovens.

Outer Plate

Manifold

This is accomplished with use of hot air fingers inside the

oven. The oven can accommodate up to 4 bottom air

fingers and 4 top air fingers. Standard PS200-R68 Series

ovens have 4 bottom fingers and 2 top fingers.

5

Page 6

SECTION 1

DESCRIPTION

Cooling

Fan

Conveyor

End Stop

Conveyor

Rear Stop

Middleby

Marshall

Control

Boxes

Removable

Jet Fingers

(Inside

Oven)

Machinery

Compartment

Conveyor

Motor

Front

Window

Middleby

Marshall

Removable End Plugs

Locking

Casters

(Rear Casters

are not locking

casters)

Figure 1-4. Component Location

Removable

Crumb Pans

Removable

Drip Pans

(Inside Oven)

Removable

Conveyor

6

Page 7

SECTION 1

DESCRIPTION

III. COMPONENT FUNCTION

A. Conveyor

The conveyor is driven by a variable speed electric motor

operating through a gear reducer (See Figure 1-5). The

motor speed is controlled by a digital control. The stainless steel wire belt can travel in either direction and at

variable speeds from 3 minutes to 23 minutes.

Conveyor

Drive Motor

Fan

Motor

Should a flame outage occur the control will close the

main gas control valve within 0.8 seconds and attempt to

reignite the pilot.

D. Electric Heaters (Electric Oven Only)

There are six heater elements mounted on the inside of

the rear panel. Each element is connected to a separate

electrical contact which is energized by the temperature

controller.

E. Front Window

The front window is used for viewing items being baked

and provides access to the oven for items which do not

require full bake time, such as sandwiches, cookies,

small items or cheese melting processes.

F. Cooling Fan

A cooling fan is located in the back of the oven. This

cooling fan blows cool air in through the machinery

compartment across the fan motor and conveyor motor

and control cabinet. The air is then exhausted through

the side of the cabinet and also out the back of the oven

compartment. Refer to Figure 1-6.

Main Gas

Control Valve

Figure 1-5. Conveyor Drive Motor

B. Fan

The fan is located at the rear of the oven. This fan forces

heated air through the fingers. The fan switch has two

positions and must be "on" for oven warm up and bake

and for the conveyor to run.

Another cooling fan is located in the bottom of each

control box. Air is drawn in through the louvers in the rear

of the control box and out through the fan. Refer to Figure

1-4.

C. Gas Burner (Gas Oven Only)

With the heat and blower switches ON the gas burner

heats the air as the air enters the main blowers to

maintain the set temperature. The burner flame is ignited

and monitored by a solid state burner control device.

Figure 1-6. Cooling Fan

7

Page 8

SECTION 1

DESCRIPTION

G. Air Fingers

The Air Finger Assemblies are made up of three parts as

follows (See Figure 1-7):

1. Outer Plate - The Outer Plate is the removable cover

with tapered holes, which directs the air stream onto the

product to be baked.

2. Inner Plate -The Inner Plate is vital to forming the

manifold with its holes lined up with outer plate holes.

The inner plate is also manufactured with no rows of

holes. This type of finger is a non-columnating air finger.

3. Manifold - The Manifold is the assembly which slides

on tracks into the oven plenum.

4. Blank Plates- The Blank Plates are installed on the

plenum where air fingers are not required.

columnated air jets. It must be assembled onto the

NOTE: On a PS200-R68 Series Red Lobster oven the 2 upper fingers (M3) have 3 rows of holes in the outer plate

and a non-columnating inner plate. The 4 bottom fingers (M6) have 6 rows of holes completely across the inner and

outer plates.

Manifold

4-1/32" Rear

Opening

No Large Holes,

Perforated Only

UPPER

Inner

Plate

M3RN

Finger

Outer Plate with

3 Rows of Holes

Stamped "UPPER"

UPPER

Full

Blank

RED LOBSTER FINGER CONFIGURATION IN OVEN

FB M3RNFBM3RN

Product Direction (Either Direction)

M6

M6

M6

M6

Finger

M6

5-5/32" Rear

Upper Fingers

Lower Fingers

Large Holes &

Perforated

Opening

Raised Front

(Stamped "UPPER")

Outer Plate

with 6 Rows

of Holes

Inner

Plate

Baffle

Manifold

Figure 1-7. Fingers

8

Loading...

Loading...