Page 1

PS770 “WOW” SERIES GAS FIRED:

SPL030907-PF-BD

March 9, 2007

A MIDDLEBY COMPANY

Parts Manual

with Wiring Diagrams

for domestic ovens

Serial # Code (Nine Digit Code)

(for units produced prior to mid-July, 2006)

First 4 digits - order of production

Fifth digit - model specific

Sixth and Seventh digit - month of production

Eighth and Ninth digit - year of production

Serial # Code (Ten Digit Code)

(for units produced after to mid-July, 2006)

First 5 digits - order of production

Sixth digit - model specific

Seventh and Eighth digit- month of production

Ninth and Tenth digit - year of production

Replaces SPL053106-PF-BD

May 31, 2006

SPL120205-PF-BD

December 2, 2005

Starting Serial # 943650206

Table of Contents: Page 2

email: techsupport@middleby.com

1-847-741-3300 fax 1-847-741- 4406

© 2006 Middleby Marshall Inc.

www.middleby.com

1400 Toastmaster Drive

Elgin, IL 60120

Page 2

Table of Contents

Spec Sheet ...................................................................................................................... 3

Key Parts ........................................................................................................................ 6

Cross Reference of Wiring Diagram Symbols and Part Number(s) .............................. 7

View of Installation Kit(s) and Base Kit(s) ....................................................................8

Parts for Installation Kit(s) and Base Kit(s) ................................................................... 9

View of Oven Panels, End Plugs and Window ............................................................. 10

Parts for Oven Panels, End Plugs and Window ............................................................ 11

View of Gas Piping ....................................................................................................... 12

Parts for Gas Piping ...................................................................................................... 13

View(s) of Burner/Blower Motor Assembly ................................................................. 14

Parts for Burner/Blower Motor Assembly .................................................................... 15

View(s) of Front Control Area(s) .................................................................................. 16

Parts for Front Control Area(s) ..................................................................................... 17

View of Rear Compartment and Blowers (Conveyor Drive End Shown) .................... 18

Parts for Rear Compartment and Blowers (Conveyor Drive End Shown) ................... 19

View of “Single” Belt Conveyor ................................................................................... 20

Parts for “Single” Belt Conveyor .................................................................................. 21

View of “Split” Belt Conveyor .....................................................................................22

Parts for “Split” Belt Conveyor .................................................................................... 23

Standard Finger Conguration 58762E and Part Numbers .......................................... 24

3-D View Finger Arrangement w/Part Numbers 58762-1 Rev. E .................................. 25

Thermocouple Placements 59077 Rev. G ...................................................................... 26

Wiring Diagram, G208-240, 50/60Hz, 1 Phase 54745 Rev. I ....................................... 27

Start Up Form PS770 Initial Start-Up/Check Out Procedures - Form # P/N 59279 Rev. “B” Dated 7/20/06 .. 28

2

Page 3

!rill~

~

CONVEYORS

Middleby

..

Marshall

OF

EXCELLENCE

•

NA

File No.:

Item No.:

_____

-------

Dir

ect

_

Gas

•

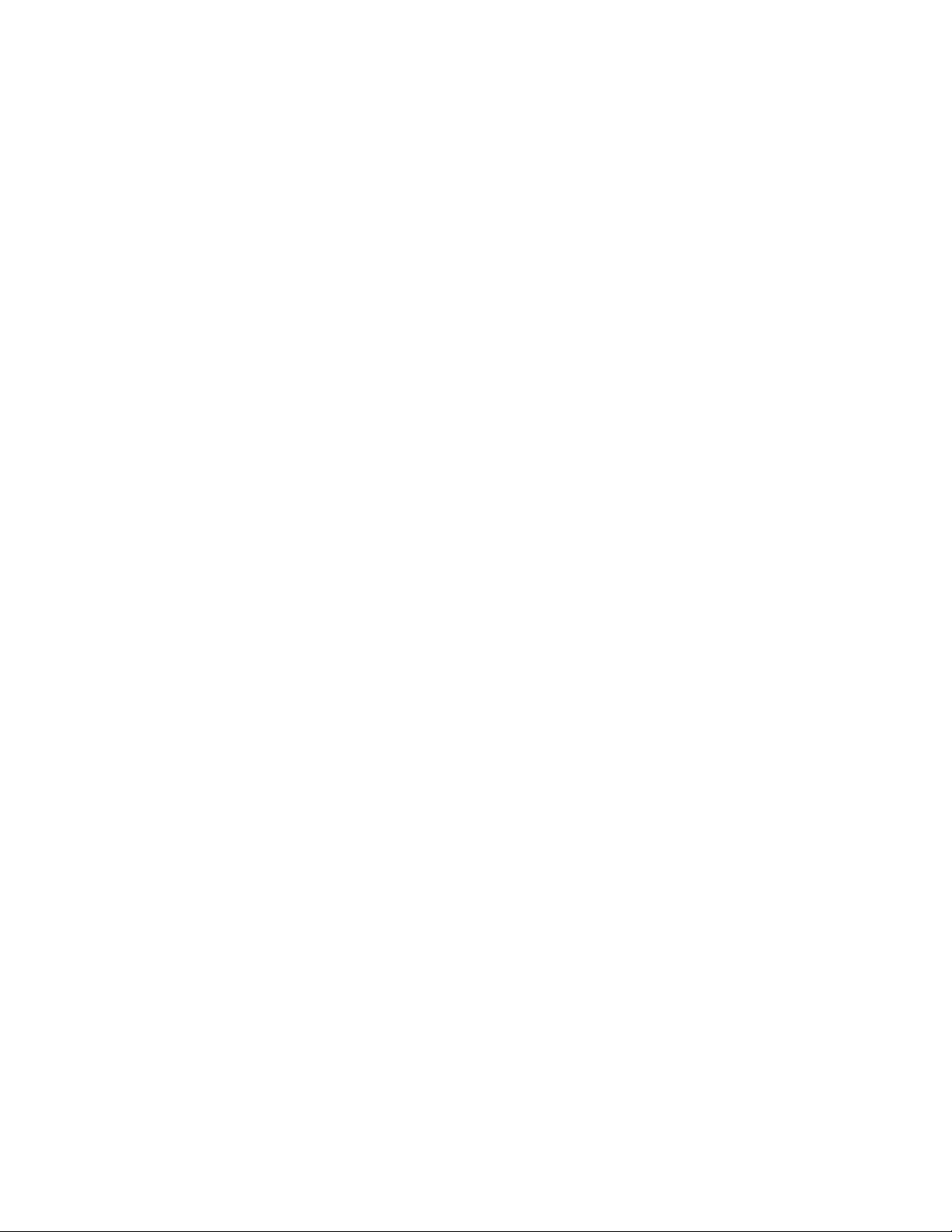

Principle

Middleby Marshall

faster and

ented vertical columns

cally instead

hot air remove the boundary layers

tend to insu

without burning.

cook Papa

at

late

John's

PS

Series Conveyor ovens bake both

a l

ower

temperature than other ovens.

of

hot

air

move

of

using high temperatures.

the

product. This gives very rapid baking

All

P$770

pizza at 4.5 minute

wow

standard Features

Impingeme

return

Patented

duces

ciency

70

..

/1778mm-long cooking chamber

32"/813mm-wide, 1

Optional

En

ergy Management System

The

(EMS)

Touch Screen Contr

ergy

ab

ility

ture.

Features

Unique

Jo

hn's menu items

PS770

that

saving modes.

to

automatically reduce air velocity and tempera-

nt

PLUS!

EMS

gas

consumption and increases cooki ng effi-

design

features an Energy Management System

automat

allows the PS770 to

ol

low

oven

Energy

ically reduces

Each mode

Management

06

..

/2692mm-long conveyor belt

at

4.5 minute Belt speed.

can

be

programmed

Pat

heat aerodynami-

The

streams

of

cool heavy air wh ich

ovens are designed to

Belt

speed .

profile and

System re-

bake

gas con

gives

sumpt

in

three en-

the

operator the

of

dual

air

all Papa

ion.

-

c

leanabl

PS770 ovens are designed

parts include: crumb pans, end panel

folding conveyor belt assembly.

hty

Easily SeiViced

Control compartment is designed

cess. A

ll electrical controls

Warranty

All PS770 models have a

warranty. Oven start-

at

no

additional charge {USA only).

up

and demonstration are Included

Ventilation

For

Installation

under

a ventilation hood only.

PATEN

for

easy cleaning. Removable

are

door-mounted.

thr

ee

TS

PENDING

s,

air fingers, and a

for

quiCk

and easy ac-

year

parts and

labo

r

Fo-rm

3

•s10

WIII~Middlebr·

Mil_.

A

MIDDLE8Y

1400

E'OII ll. t'IOI$80-120USA

(tlof7)

WNN

Marshal

1.)"300 Fax:

COMPANY

(847.

T

Q<t51tn)$!~0nv•

74

m~com

741-001

S

Page 4

Will~

Middleby

·

~~Marshall

CONVEYORS

OF

EXCELLENCE

Direct

Gas

Fired

PS770

Conveyor

Series

Oven

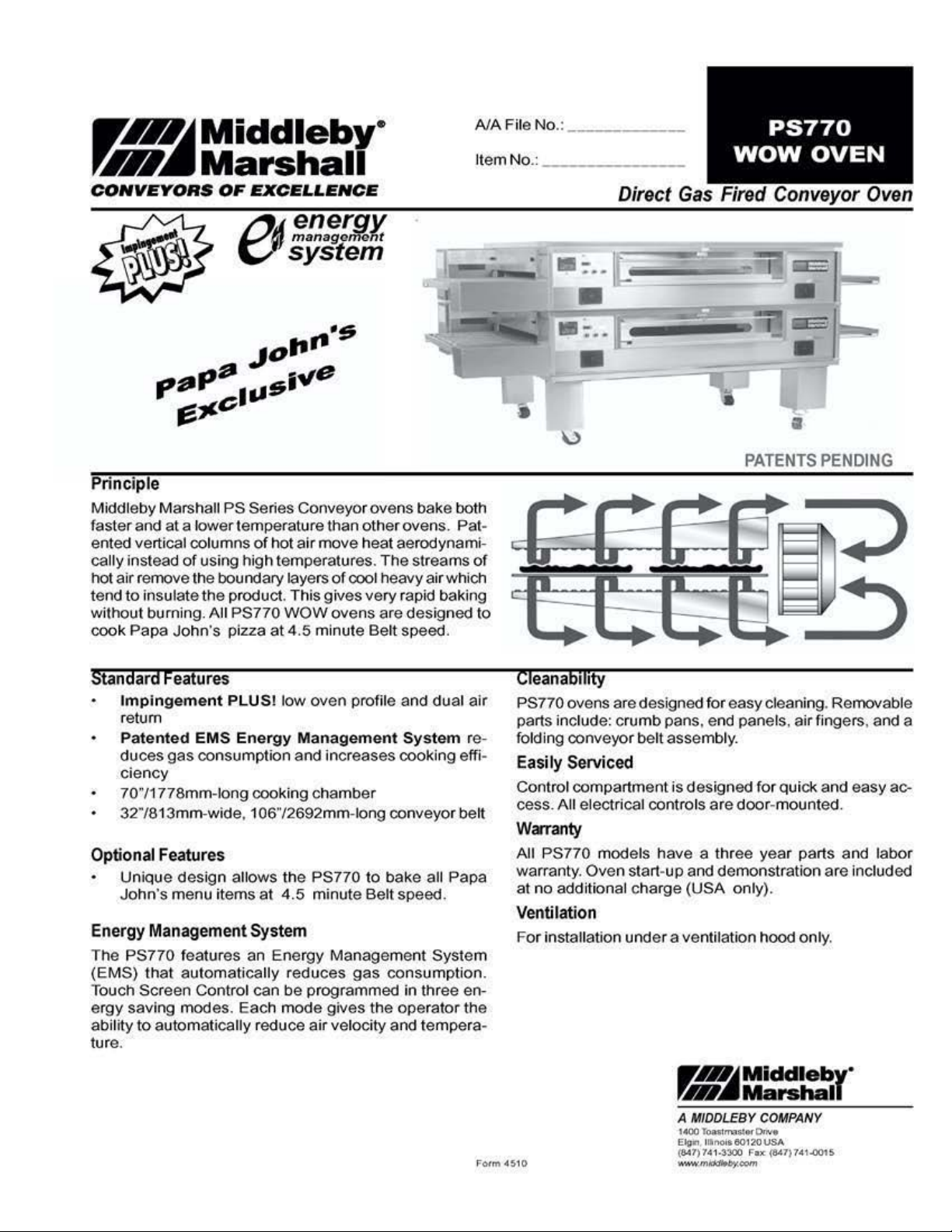

PS770·2

with

P

S770-3 Triple

ith

w

Doubl

15" (3

FRO

4 " (102m

81 mm) l

NT VIE

e oven

eg extens

W

Ove

m ) l

eg ext en sio n s

n

ion

s

.

I

~

@

J

l=

REAR

V

IE

WS

REAR

VIEWS

t

CE

CE

PNn

led

FRONT VIEW

tn

U.

SA

1400Toastmastcr Drive. Elgin,

tl60120

·9272.

F01m

USA

415

www.middlob

4

• (847) 741·3300 • Fax: (847) 741·0015

y.com

10

Page 5

lrHI~

~Jill

CONVEYORS

Middleby

Marshall

OF

EXCEllENCE

•

Direct

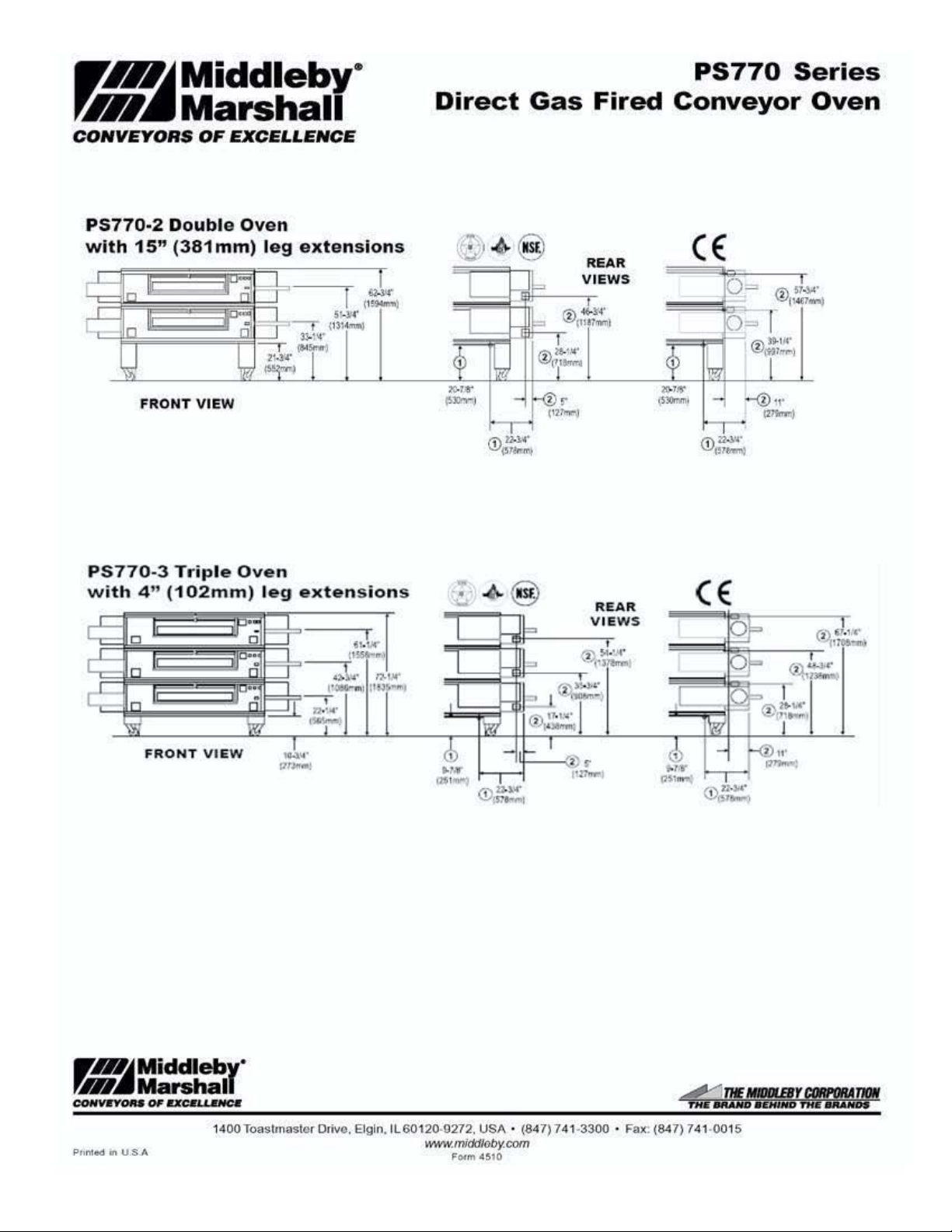

RECOMMENDED MINIMUM CLEARANCES

Gas

Fired

PS770

Conveyor

Series

Oven

M:lde

l

PS770.1

11111119'

(48311\m)

leg

e:t

len

s10

ns

PS770-2

~>~t

h

15'

(381mm)

l

eg

&l(

teosiOns

PS770.J

'Mlh4'(102mm

leg

ex

tens

ions

ELECTRICAL

Tha

avMag&

Heall•g

Zo

ne

7

0"

1778mm

l

«l'

-

2

)

oorrent draw during

10'

fm4mm

R<>3rorovoo

Io

wan

O"(O

mm) o·

GENERAL INFORMATION

Ba~on

g

'

7

A

'

2&!2mm

-

:1692mm

Bell Bell

eoolll

116"

81:lrnm

1116"

8

1116"

813ovn t5S&nm

AI

M l

!55sq 0 1

1.4~m

31

sq ll

2

88m

4S5sq

•

3".1m

SPECIFICATIONS

208-2«JV

OJXlrallon

Is

slgnificanlly

W>iil

~

~

13ovn

~

2

1l0i0

(2

ho

lower.

Control

en<!

oven to

wall

(Omm)

D

<!l

lh

•

-<>®

6

1-3

14"

156&nm 151<lllm

61

-314"

156&nm

61·314'

Max

.3w

,.

t,

I

gnd)

or

~

CE

6

3-3/8'

63-3/8

'

1&1

0mm 1594

63-318

t61

<lllm

Current

Non--control

ovootowa

O'(Omm)

hl

-114

'

-314

'

mm

••

~18bllg

at

Hela

~

122>nm

GZ

72-11

U!limm

Draw

20A'

enct

ot

ll

Ma

x

Bate

T•me

Teme

SWF 4-

288'C

SW"

288'C

Ranoe

2950

F

29

5WF

2

88'C

Startup

2950

~

-

50

4-

Sll!>

WI

17

5')

1ls

~g

35001>$.

1

5891;g

5?.i1J

ibs

2364l

Breaker

Aspe

r

loca

l

codes

;g

.

s

Ship

C

ube

1

1

50R

d5mJ

3

20ft

'

9

<l1l

'

480 ~'

135m'

GAS

Min. Gas Pipe Size

Na

luraiGas

Propa

ne

Gas

The gas supply ptes$ures $hown

pt

ossures

of

oth&r locations aro dopondonl on

ALL

SPECIFICATIONS

1400 Toasunaste<

2"

(50.8mm)

OM

1-114

bfanch to lower oven cavity

01

br

anch

w

' (12.7mm) N

with

mdiV

sh

utoff

2" (

50

.l!mm)

1a

1

- 1

/4~

10

r

ower

i1h

ind

lvkfual (u

shulolf valve

Oflvo. Elgin.

idual fuiHiow

{12.7

SUPPLY

maln

vdvc

main

•ru

n)

oven

ll·llow

are

SUBJECT

ll60

lor

SPECIFICATIONS

Supply

GAs

PtAS$ur'A

6-1

2"W

PT

NP r

cavity

ovens installed ;,, North America.

(14

(27

lha

focal gas type

.C.

.9·29.9 mbar)

1·14'

w.c.

1

.4-34.9 rnbar

and

TO CHANGE WITHOUT NOTICE.

120·9272. USA • (847) 741-3300 • Fax: (84

middleiJy.com

www.

F«m

•

sto

)

the

required g;,s supply

on

all

applicable local codes.

RAroo Haa11n

(42,840

50kW/hr

por

oven

(42

,$40

50

kW/hr)

per oven

7) 741·0015

put

kca

l,

.)

cavily

kcat

cavity

.

5

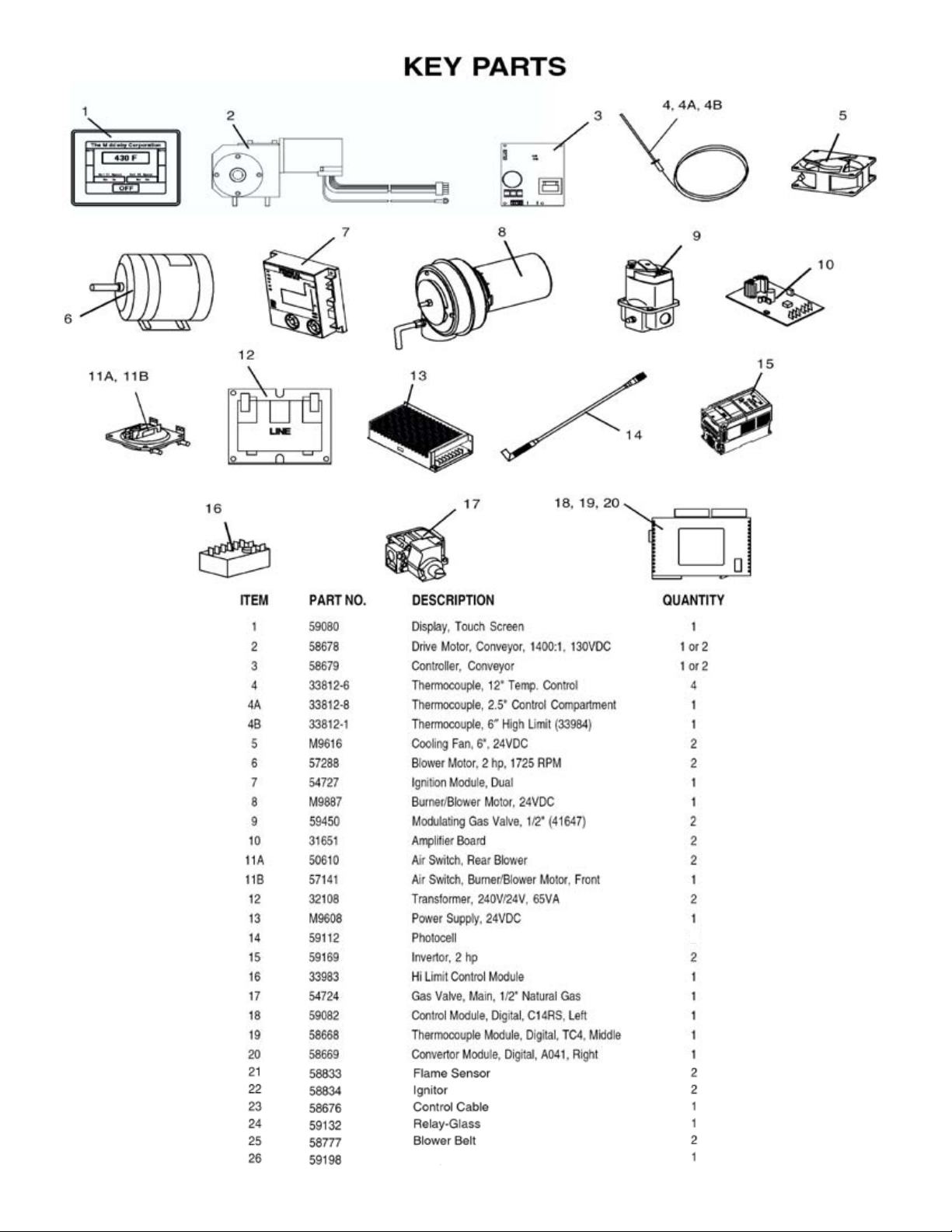

Page 6

-Touch Screen Display to PLC

Computer Cable Connects Main Oven Touch Screen

to Customers Point of Sale (POS) Computer System

6

1

Page 7

CROSS REFERENCE of WIRING DIAGRAM SYMBOLS and PART NUMBERS

• Air Switch 1 -Rear Right ................................................ 50610

• Air Switch 2 - Rear Left ..................................................50610

• Air Switch 3 - Front Right ...............................................57141

• Blower Motor–Left ..........................................................57288

• Blower Motor–Right ......................................................57288

• Burner Blower Motor ................................................... M9887

• Circuit Breakers

• CB1 - 15A ........................................................................45037

• CB2 - 15A ........................................................................45037

• CB3 - 15A ........................................................................45037

• CB4 - 15A ........................................................................45037

• CB5 - 3A ..........................................................................45036

• CB6 - 3A ..........................................................................45036

• CB7 - 1A ..........................................................................45644

• CB8 - 1A ..........................................................................45644

• Cooling Fan LH ............................................................. M9616

• Cooling Fan RH ............................................................. M9616

• Controller 1 DC ...............................................................58679

• Controller 1 DC (split belt) ..............................................58679

• Conveyor Motor ..............................................................58678

• Conveyor Motor (split Belt) ............................................58678

• Dual Burner .....................................................................54719

• Converter Module - Digital A041, Right .........................58669

• Control Module - Digital C14RS-A, Left ........................59082

• Thermocouple Module - Digital TC4, Middle ................58668

• Gas Valve .........................................................................54724

• Green Light (Reset Button) .............................................35145

• GT30 Display ..................................................................59080

• Ignition Module, Dual .....................................................54727

• Inverter - 1 Left, 2HP.......................................................59169

• Inverter - 2 right, 2 HP .....................................................59169

• Switch(es)

• LS1 (LH RR), Momentary .....................................28021-0061

• LS2 (RH RR), Momentary .....................................28021-0061

• LS3 (RH Front), Inter Lock ....................................28021-0047

• LS4 (LH Front), Inter Lock ....................................28021-0047

• Reset Button ....................................................................35145

• Mod Valve 1 (41647) .......................................................59450

• Mod Valve 2 (41647) .......................................................59450

• Photocell 1 Entrance ........................................................ 59112

• Photocell 2 Exit ...............................................................59112

• Power Supply ................................................................. M9608

• Relay ................................................................................59132

• Signal Amplier 1 ............................................................31651

• Signal Amplier 2 ............................................................31651

• TB1 RR LT (3 Pole) .........................................................44390

• TB2 RR LT (3 Pole) .........................................................44390

• TB3 RR RT (3 Pole) ........................................................44390

• TB4 RR LT (8 Pole) .........................................................31047

• TB5 Comp Brkt (4 Pole) ...............................................M0593

• TB6 Comp Brkt (4 Pole) ...............................................M0593

• TC1 - 6” High Limit (33984) .......................................33812-1

• TC2 - 12”, Oven Temp. ................................................33812-6

• TC3 - 12”, Oven Temp. ................................................33812-6

• TC4 - 2.5”, Control Compartment ................................33812-8

• XFMR1 - 240V/24V 65 VA .............................................32108

• XFMR2 - 240V/24V 65 VA .............................................32108

• High Limit .......................................................................33983

Wiring Diagram Drawing # 54745 Rev. I Shown on Page 27.

SET THE ENERGY MODES TO THE FOLLOWING SETTINGS AS OF 3/08/2007

OVEN WITH POS COMPUTER CABLE

OVEN WITHOUT POS CABLE

MODE 2--7:00 MINUTES MODE 2--7:00 MINUTES

MODE 3--14:00 MINUTES MODE 3--20:00 MINUTES

MODE 4--1 HOUR MODE 4--1 HOUR

(This is a “CONTROLLED” Screen-Password Required)

7

Page 8

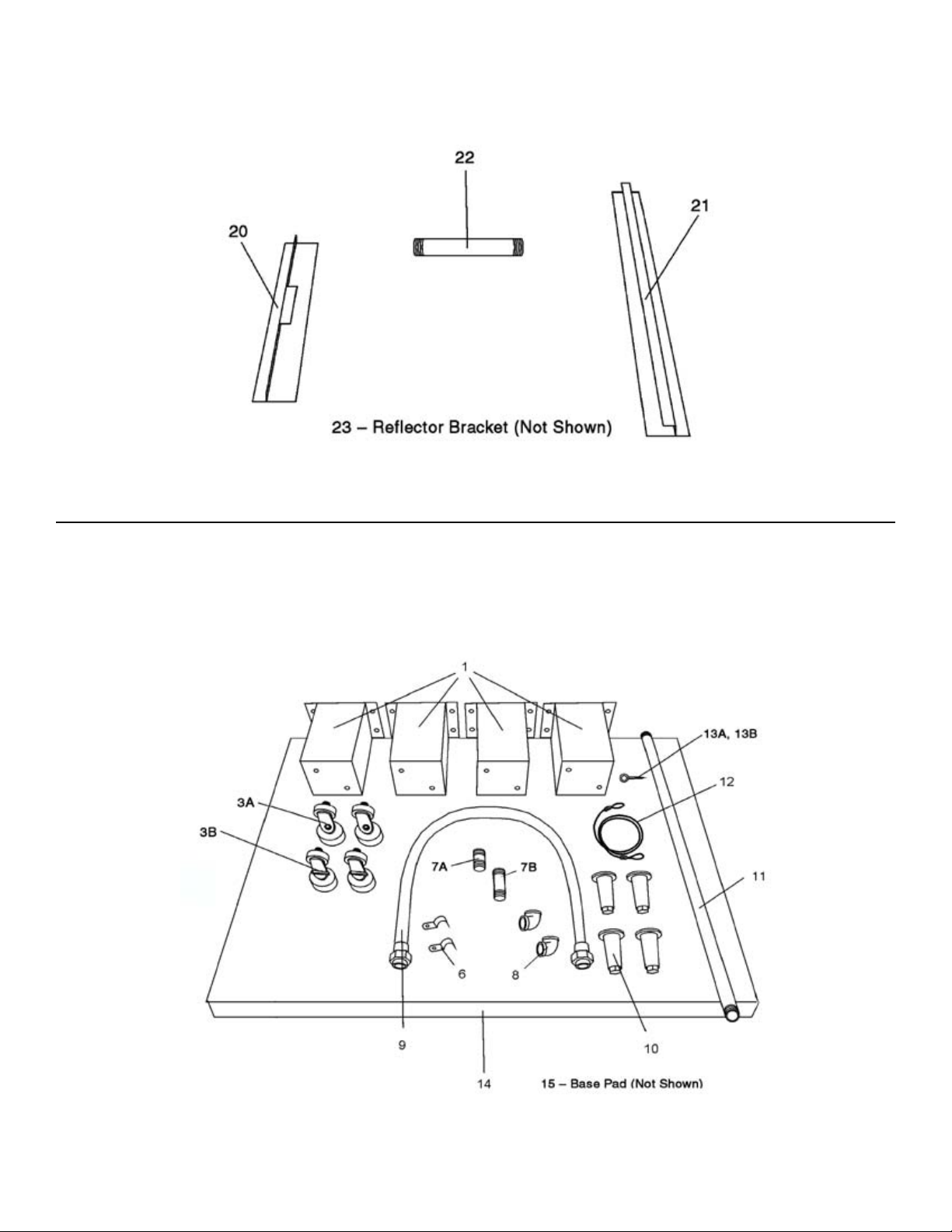

VIEW OF INSTALLATION KIT (PART NUMBER 59057)

VIEW OF BASE PAD KIT

8

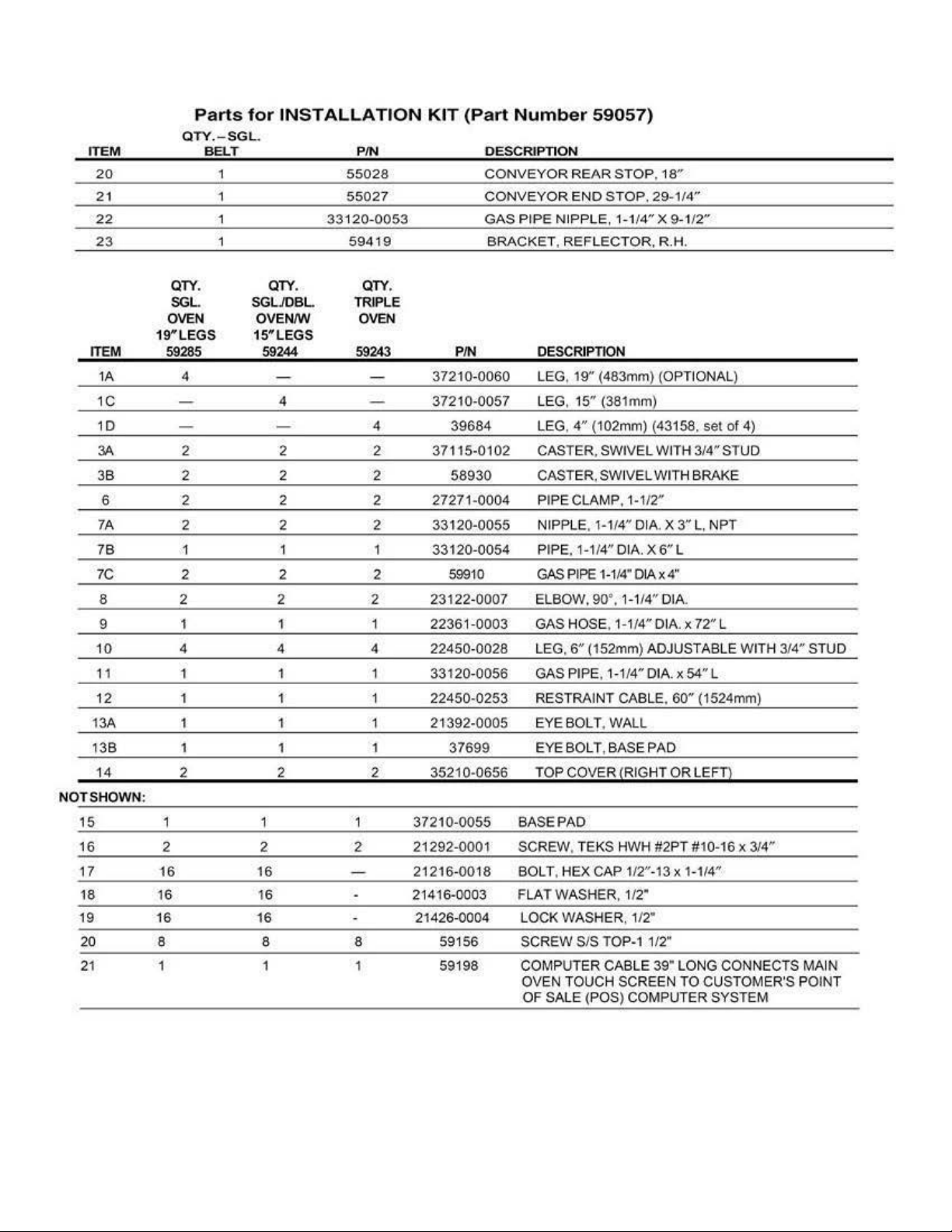

Page 9

ITEM

20

21

22

23

Parts for INSTALLATION

QTY.-SGL

BEl.T

.

1

1

PIN

55028

5502

7

33120-005

59419

KIT

(Part

3

Number

DESCRIPTION

CONVEYOR REAR

CONVEYOR END STOP, 29-1/

GAS

PIPE

BRA

CKE

59057)

NIPPLE, 1-1/

T, REFLEC

STOP

4"

TOR.

, 18"

X 9-

R.H

4"

112"

.

ITEM

1A

1C

1D

3A

3B

6

7A

76

7C

a

9

10

11

12

13A

13B

14

NOT SHOWN:

15

16

17

18

19

20

21

QTY.

SGL

OVEN OVENIW

19"LEGS 15"LEGS

59285 59244

4

2 2

2 2

QTY

.

SGLJDBL

4

2 2

2 2

2 2

2 2

1 1

4 4

1 1

1 1

1

1 1

2 2

2 2

16 16

16

16 16

8 8

1 1

16

QTY

.

TRIPLE

OVEN

59243

4

2

2

2

2

2

2

4

1

2

2

8

1

PIN DESCRIPTION

LE

37210-0060

37210-0057

39684

37115·0102

58930

0004

2727133120-0055

33120-0054 PIPE.

5991

0 GAS PIPE 1-1/

23122

-0007 ELBOW. 90',

22361-0003 GAS HOSE, 1

22450-0028

33

120-0056

22450-0253

21392-0005

37699

0656

35210·

37210-0055 BASEPAD

21292-0001

21216-00

21416-0003

21426-0004

91

56

5

59198

18

G, 19" (483mm) (OPTIONAL)

LE

G, 15" (381mm)

LE

G,

4"

CASTER, SWIVEL WITH 314" STUD

CASTER. SWIVEL WITH BRAKE

PIPE CLAMP, 1

NIPPLE, 1·114" DIA. X 3"

LE

G,

6"

GASPIPE,1-1/4"DIA.x54

RESTRAINT CABLE,

EYEBOLT

EYEBO

TOP COVER (RIGHT

SCREW

BOLT, HEX CAP 1/2"-13

FLAT

LOCK

SCREW SIS TOP-1

COMPUTER CABLE 39"

OVEN TOUCH SCREEN TO CUSTOMER'S

OF

, TEKS HWH #2PT #10-16 x 314"

WASHER, 1/2"

WASH

SA

LE (POS) COMPUTER SYSTEM

(102mm) (43158. set

-11

2"

1-1

14" DIA

.X6

" L

4"01Ax4"

1-1

/4" DIA.

-1

/4" DIA. x

(152mm) ADJUSTABLE WITH 314" STUD

60"

, WALL

LT, BASE PA D

OR

x 1

ER, 112•

1/2"

LO

of

4)

L, NPT

72"

L

" L

(1524mm)

LEFD

-1

14"

NG CONNECTS MAIN

PO

INT

9

Page 10

47

48 FILTER-ONLY

46

10

EARLIER MODELS REQUIRED A RIGHT TO LEFT KIT TO CONVERT TO RIGHT TO LEFT OPERATION PART #59340

NOT SHOWN ITEM 45

Page 11

Parts for PANELS , END PLUGS and WINDOW

ITEM

OTY. PIN

1 1

2 2 41

3 2

4

8

5 4 364

4 41

6

2

8

9 2

10 4

4 41

11

13 1 57501 ASSEMBLY, DRIVE MOTOR SHROUD

14A 1

11

14B 1

15 1

15A 1

16

17

18 2 31765

21 2 48522 SPACER

23

26

27

1

16A 1

2

2 35210-0656

1 42488 WIND

2 30927 BUMPER. WINDOW

39539

778

50834

220295

52

708

39569

41

779

364

52

708

59098

59099

57286

58758

57293

58758

54715

DESCRIPTION

ASSY, UPP

WELDME

EYEBROW

WI

PLATE , END PL

ASSY, LOWER E

WI

PLATE, END PL

BRACKET FOR REFLECTOR

REFLECTOR

ASSEMBLY. LEFT MOTOR SHROUD

ASSEMBLY. R

ASSEMBL

TOP

ER END PLUG

NT, UPPER END PLUG

SCREW. "AB" HEX WSHR HD #10 X 314"

NG

NUT

. 1/4"

·20

W/PLASTIC GRIP

UG

MOUNTING

ND PLUG

WELDMENT, LOWER END PLUG PS500

NG NUT. 1 14"·20 W/PLASTIC GRIP

UG

MOUNTING

GLASS, 2"x2" x 0.25"

IGH

T M

OTO

GLASS, 2"x2" x 0.

Y.

REAR SHROUD

GR

ILL. COOLING FAN

COVER

OW

GUARD

25'

(INC. ITEMS 2·6)

(INC. ITEMS 9-11)

R SHROUD

(INC.

ITEM 18 &

19)

ITEM

QTY.

28

29

31

32

33

34A 4

34B 4

34C

35

36

37

38A 2

-----------------------------------------

38B 2

39

40

4

41

42

43

44

45

1 3721 0·

2

1

4

16

16 21426·0004

16

4

0A

2

2

1 59340 RIGHT TO LEFT DIRE

46 2

47 58764 MIDDLEBY LOGO

PIN

0055

34121·0003

45012

4

1597

45087

37210·0060

37210·00

21

216-00

21416·

37115·0102

224

57

39684

18

0003

5893

0

50·

0028

5909

8 BRACKET, REFLECTOR. RIGHT HAND

59099

49975 CORD & PLUG. L6-20P

59048

59049

59226

59562 COOL HANDLE INSULATOR

DESCRIPTION

BASE P

SCREW, WIND

ASSEMBL

(INC. ITEM 32 &

BOLT, HEX

DOUBLE

LOCKWASHER, 112" • SGL

FLAT WASHER. 1/

CASTER. SWIVEL WITH 31

D

CASTER. SWIVEL WITH

LEG. 6" (152mm) ADJUSTABLE WITH

STU

REFLECTOR

HEAT SHIELD. TOP.

HEAT SHIELD, BOTTOM

ASSEMBLY. SHROUD. RIGHT HAND

MODELS PRODUCED BEFORE 09/06

AD

OW

PIVOT

Y,

WINDOW/LATCH

33)

GLASS. WINDOW. PRE-CUT. 3· 112"

LA

TCH

LEG

. 19"

LEG, 15"

LEG.

4"

CAP

112"·13

OVENS

2"

• SGL & DBL OVENS

OUB

LE, & TRIPLE OVENS

D·

SINGLE, DOUBLE . & TRIPLE OVENS

X 1·114" ·SINGLE &

& DBL OVENS

4" STUD· SINGLE.

BRAKE

CT

ION K

IT-EARLY

X20

3/4"

"

48

2

310-2468 FILTER ONLY

Page 12

12

View

of

GAS

PIPING

CONTROLS RIGHT HAND BURNER

4

4

CONTflOLS LEFT HAND BURNER

BURNER ASSEMBLY

DUAL

FI

TS HERE

1

Page 13

Parts

for

GAS

PIPIN

G

13

ITEM

QTY

.

1 4

2

3

4 2 59450

5

SA

1 23051-0012 UNION,

1 23115-0009

1 54724

1 28092-0018 SPRING FOR

23051-0003

PIN

DESCRIPTIO

UNION,

MANUALONIOFFGASVALVE.112".BALL

MODULATINGGASVALVE, 1/£(41647)

VALVE.COMBINATION,

--------------------

6

1 42410-0016 BRACKETICLAMP

N

112~

1-1W

112

• · NATURAL GAS

LP

CONVERSION

---------------------

Page 14

(1/8” GAP)

14

Page 15

Parts for BURNER/BLOWER MOTOR ASSEMBLY

15

ITEM QTY.

1 2

PIN

22450-0259 CLAMP, DUCT

2 1 22450-0255

3

1 35210-0053 TUBE EXTENSION (Not Shown )

DESCRIPTI

DUCT

ON

4 1 58754 CLAMP

5 1 54719

(AS

OF

6 1

7 2 Contact Factory ORIFICE. NATURAL GAS, .173, #17

M9887 BURNER/BLOWER MOTOR, 24V DC

DUAL ASSEMBLY BURNER

411/07- TARGETS

AREA

POS

ffi

ONED INSIDE BURNER TUBES)

8 1 Contact Factory GASKET, AIR INTAKE

9 1

10 2 58833 ELECTRODE, FLAME SENSOR

11

2 58836 WIRE, IGNITION, 27" LONG, 5mm

Contact Factory GASKET. DUAL VERTURE

12 2

_ _

2

~

13

_1~

14A 2 59074 ORIFICE,

-----------------

14B

15

1

1

58835 WIRE, FLAME SENSOR, 36" LONG

58834 IGNITOR, ELECTRODE - 1/8" GAP

_

__

C_o~t~c~

F_a~t~rt

____

K~T_T9

---------------

28092-0018 SPRINGFOR GAS VALVE

TO

Contact Factory KIT

CONVERT TO NAT GAS

~9~~

LP,.118

E~!

!<2_

L

_P ________

---------

_

Page 16

26

1, 1A, 9

1, 1A, 9

View of FRONT CONTROL AREA(S)

27

16

Page 17

Parts

for F

RONT

CONTROL

ARES(

s)

17

ITEM

OlY.

1 2 310·2458

lA

2

2 2

2

3

4 59080

5

6

1012

8 2

9 2

10

1

11

1

12

13

14

1

15

16

PI

310.2468

31&51

32108

54727

58679

M0593

1119616

33983

57141

59082

58668

58669

M9608

35145

N

OESCRJPllO

FILTER/GUARD, FAN

FILTER

M1PLIFIER80ARD

TRANSFORMER.240/24V.65VA

TOUCH

DUAL

CONTROLLER. CONVEYOR

TERMINAL

COOLING

HI-liMIT

AIR

CONTROL,

THERMOCOUPLE (MIDDLE

CONVERTER. (RI

POWER

RESET

N

ONLY

SCREEN

IGNITION

BLOCK.

FAN, 24VDC

CONTROL

SWITCH.

(LEFT

SUPF'L

SWITCH

DISPLAY

MODULE

2.POLE

FRON

T.

BURNER/BlOWER

-HAND

),

DIGITAL CI4RS

),

GHT-HAND). A041

Y, 24

VDC

W/GRE

EN

CONTROL,

LIGHT. HI-LIMIT

TC4

17

18

19 2

20

21 2

22

23

24

25

26

27

2

2

4

4

59169

45644

28021·0047

45037

45036

33812·8

33812·6

33812

·1

59132

58764

58980

INVERTOR

CIRCUIT

SWITCH. INTERLOCK

CIRCUIT

CIRCUIT

THERMOCOUPLE,

THERMOCOUPLE,

THERMOCOUPLE

RELAY

MIODLEBY

lABEL-WOW

-PROGRAMMED

BREAKER. 1 AMP

BREAKER, 15

BREAKER, 3 AMP

2.5· x

12" x

6"

DPDT. 24VDC

LOGO

OVEN

-P$770

AMP

so

·.

120", REAR

(HIGH

LIMIT)

COIL

CONTROL

Of

REAR

COMPARTMENT

OVEN

OF

OVEN

(33984)

Page 18

·/

<

1'

t

',

I

I ' I

1 -

I

1

I

I

''/l,

18

...

11

',,J

'

',

...

Vlew(

11

t1A

1

1

I

1

I

s)

of

REAR

COMPARTME

«1

I

I

I

I

!,_

14

..

\

....

---

---

-1

I

I

I

I

I

I

I

I

..:-

a-:i__..

NT

\

AND

BLOWER

---

.

,

(CONVEYOR

~--

...

-

--

--

DRIVE

END

SHOW

N)

',

'

ITEM

30

MOMENTARY SWITCH, NOT SHOWN

ITEM

40

AIR SWITCH NOT SHOWN

41

ITEM

ITEM

ITEM

ITEM

ITEM

ITEM

ALUMINUM

42

TUBING SIUCONE. NOT

43

TH£RMOCOUPL£

44

THER~~E

47

PHOTO

48

MOUNl1NG BRACKET

TUOINO. NOT SHOWN

SHOWN

NOT

SHOWN

NOT SHOY/N-6.

CCU

PHOTO

·

I:!"

CEU

NOTE: IDENTIFY THE DEFECTIVE INNER FROM THE DEFECTIVE OUTER BEARING ITEM 14 PER ENGINEERING’S REQUEST

(THESE PARTS ARE TO BE RETURNED FOR OUR INSPECTION)

Page 19

28 4 A3682 LOCKWASHER, SPLIT 5/16″

ITEM QTY. P/N DESCRIPTION

Parts for EACH REAR COMPARTMENT AND BLOWER

31 1 57296 PULLEY, 5.6″

32 1 57297 INSERT, 5/8″

33 1 43024 EXTENDER, FAN

34A 1 27399-0008 FAN BLADE, CW, 8″ , CONVEYOR DRIVE END

34B 1 27399-0009 FAN BLADE, CCW, 8″, IDLER END

35 1 57316 BRACKET, MOTOR SUPPORT

SHAFT SEAL, PTFE

36 1 57298 INSERT, 1-7/16″

37 1 Contact Factory KEY, 5/8 x 1

38 2 57325 RING

39 1 28021-0061 SWITCH, MOMENTARY

40 1 50610 AIR SWITCH

41 A/R 15125-0002 ALUMINUM TUBING

42 A/R 22450-0297 TUBING, SILICONE

43 4 33812-6 THERMOCOUPLE, 12″ x 1 2 0 ″, REAR OF OVEN

44 1 33812-1 THERMOCOUPLE 6″ (HIGH LIMIT) (33984)

45 1 41575 MOUNTING BRACKET

46 1 44550 SUPPORT BRACKET

47 1 59112 PHOTO CELL, 24V DC

48 1 59108 MOUNTING BRACKET, PHOTO CELL

2 1 37210-0124 PLATE, INLET RING

1A 1 22521-0005 BLOWER WHEEL, IDLER END

1B 1 22521-0006 BLOWER WHEEL, CONVEYOR DRIVE END

ITEM QTY. P/N DESCRIPTION

3 4 21211-0001 SCREW, CAP HEX HD 3/8″-16 x 3″

5 10 21422-0001 LOCKWASHER, SPLIT 3/8″

6 4 35210-0576 SPACER

7 1 35210-0541

8 1 37210-0101 PLATE, SHAFT SEAL INNER

12 1 57323 SHAFT BLOWER

13 1 35210-0286 KEY, BLOWER WHEEL

14 2 57321 BEARING

15 4 57320 SPACER, BEARING

16 4 2000535 SCREW, CAP HEX HD

17 4 A6235 FLATWASHER, 7/17″

18 4 21121-0013 HEX NUT, 1/2″-13

19 1 57295 PULLEY, 5″

17A 4 21422-0016 LOCKWASHER

21 1 58777 BELT

25 1 57288 MOTOR, BLOWER 2HP

26 1 59133 BRACKET, MOTOR MOUNTING

27 4 6673 SCREW, CAP HEX HD 5/16″-18 x 1″

19

Page 20

·-

20

~r-----7

0

..

' / I

/

'

' 0

,

/

'

"'

- I

::::

\

e'

'\

.'\

I

I

I

I

I

I

)

-~-

~

-·

~

I"'

........._

:;:

tit

....

~

%--·

~

- -

~---

t;1

--

•

...

-

~

0

"'

..

....

,

. ,

. \

I

•

•

. . '

• .

·:

' . , ;

·.

..

/'

I

I

I

/

~

,.

)'\

....

,

..

~

ti

·.-

·.

'I

•

. ,

·

~

tt. - - • I , l

/

\1

, ,

\

I '

I ' / "

.

"

~

jj

~\

'):.

--

' I I

I I )

I / ( •

/

~./ \ ~

II!

,--~)

\ ~ \

"1

I

I

I

I

I

I

_..)

/

'I

I 1

I I

,/

-

~

:,.

--

t-4

~

I r .

II

' !

//

\

---

II

I - \

1/

'

;;

/ ,

I

ll

_,

..

' - ;

L

----

1-·

--·--·

,r-----?

I -

I w

/

,''

I

I

/ I

' I

I I

/ I

' I

,' - \

I • I

\ / .

..

'

:;,

;;;

~')')

>;I~

'

r·

~--

~

~

~

-

'J)--.- -

-

~

~

/~

,o

\

...

\

I

~)

--

·

:1! --·

'

--

-

View of Single-Belt Conveyor

~

;;

1\

~

w

a

Page 21

Parts

for

Single-Belt

Conveyor

ITEM OTY

1

2 1 3721o-D046

3

4

5

6 8

1

8

8 8

9A

------------------------------------------

9S

10

12

13

15

21

17 2 22034·0003

19 2 35000·1008

20 2

21

1

11

•

14

6 22229-0003

18

2

PARTNs;!

3721(1.0117

37210.0116

3521o-D029

l521o-D091

F716A8805

21

176-0001

224~

3390o-0032

51380

3500Q.101

37000·0

3S000·10t2

41

549<17

.

WEI.OMENT.CONVEYORORIVEFRAME

WEUlMENT. CONIIEYORCENTEIU'RMIE

WEUJMENT

PIVOT

PlATE

BUSHING.CONIIEYORADJUSTMENT

WASHER.EXTERHAL

LOCI<NVT

CONVEYOR

CONVE

MASTERLINI<SKIT. 32"'(0.81m)8El T

HEX 11•"·20

YOR

MASTER.N<.lEFT

MASTERJNI<.

MASTERIJNK.RIGHT

1 SHAFT.IClER

SPROCKET.CONVEYORBEL

BUSHING, BRONZE

3

BRACKET.IOI.ER

SC

REW1 CONVEYOR

BRACKET. SHAFT

SHAFT, DRIVE

DE

§S:R

IPT

!S!N

, ()()t.M;YQRIClERFRAME

TOOTH

1.4"

BELT

COMPlETE.

BELT

3TWx1ZL(081

3TWx206"l

CENTER

T

31

4" 0 .0. x

SHAFT

TENSION

SUPPORT

518"

1 0.

ADJUSTMENT

ADJUSTMENT

x 0.30m)

IINC.ITEMS

1 1-13)

ITEM

OTY

22

24 22011.0013

26

25

27

28

29

30

31

32

6

2

2

2

33

l5

40

41

42 2 30004

43

44 1

P~RTNO

2222~

22Q34..0003

~1080

549C7

~1013

22152.0017

•2&00-0

22273.0001

22152.0018

3521(J.0610

58678

55027

55028

M10098

450

35

,

161

DESCRlP'TlO

SPROCKET

COllAR.

BUSHING

SPAa:R.

IIRAOIET. SHAF'TSU'PORT

AON"TER. CRIVE

SPROCKET

St:l'tf:N

ASSEt.a.

MASTERLN<.ROU.ERCHAIN

SPROCK£T.DRIII£UOTOR.SI8"BORE. 15T wrTWSET

St:l'tf:N

ACW>TER.DRIIIE

ORIVEMOTOR

END

REAR STOP, CO

CRUMB

HARNES

MOUNTINOB

CONVEYOR

SHAFT

.

wrTW

SET

BRONZE

NYlON

Y.ROU.ERCHAIN(II2UNKS)wrTWMASTERI.H<

STOP

CONVEYOR

PAN

S, WI

314

• 0 D x

1·1

4" 0 0 x 3/4"1 0

SHAFT

ORIVESHAFT,54'90RE..9T

MOTORWITHSETSCREW

,flRUSHlESS 14001

NVEYOR, 18.LONG

RE

RACKET.ORIVE MOTOR

N

BELT

SCREW

SIS"

1 0

29·114"LONG

WTTHSET

1301/DC

Page 22

I

--"

"""'

I

I

I

I

I

I

I

I

/

I

I

I

/

I

/

/

I

I

I

I

~

/

...

0

>-

<1>

>

s:

0

0

-

<I>

co

1-

.J

CL

(/)

.

.·

:'.

~

. . .

·

..

· ·

•

______

_,~

..

. · · .

. .

.

·\

:

'it .••

. . .

. . . .

.

..

.

~

·

...

.

./

..

~

I

/

/

I

/

I

I

N

·.

/.

--

1

I

I

I

I

I

I

I

I

I

/

I

/

..

•

.

...

.

.

. .

..

.

22

Page 23

Parts for"SPLIT" Belt

Conveyor

ITEM OTY

2 37210·0046

3

4

5

6 8

7 8

8 21

8

9A 2 22450-0271

----------------

98

10 2 51382

14

15

16

23

17

19

8

2 22034-0003

20 2 37000-0

21

22 2

23 42400·0355 SHAFT. DRIVE, REAR, 35·1/3"

24

25 35000-1536 SHAFT,DRIVE,

2

PAR T NO.

37210·0117 WELO

37210-0116

35210·0429

35210-0491

F716A8805

176

-00

01

MENT.CO

WELDMENT.CONVEYORCENTERFRAME

WELDMENT,CONVEYORIDLERFRAME

PI

VOTPLATE

BUSHING. CONVEYOR

WASHER.

L

OCKNU

CONVEYORBELT.COMPLETE.

J~~~2~y~~~~

33900-0037

42400-0354 SHAFT, ID

21415-0001

35000-1535

22229-0003

413

35000-1

21415·00

008

54947

01

CONVEYOR

MASTIERLINKS

FLAT

WASHER.

SHAFT.

SPROCKET. CONVEYORBE

BUSHING

BRACKET, IDLER

SCREW. CONVEYOR

BRACKET.SHAFTSUPPORT

FLAT

IDLER. FRONT. 16-318

WASHER.

EXTERNAL

T,

HEX

BELT

LER

. BRONZE

DES

CRIPTION

NVEYORDRJVEFRAME

ADJUSTMENT

TOOTH

114'

114"-20 32 35900·0023

IT

EM

OTY PART

26 8 22229·0003

27 35000·

28 1

29

30 2 35000·1080

31

33

2 22034·0003

2

2 22152-0017

22011·0014

54947

L-------------

, 15"W x

KIT. 15' (0.81m) BELT (INC./TEMS 11-13) 35

, REAR, 32-3/4"

BRONZE

SHAFT

BRONZE

FRON

12"l

, 1"0 .D. X 112"

LT

314" O.D. x

ADJUSTMENT

TENSION

, 1"0.

T,17-

3/4

(0.38 x 0.30m) 34

1.D

.

"

518"1

.D.

ADJUSTMENT

D.X

112"1.D.

*

424

00·

0164

424

10·0128

36

37

38

40 2 58678

45 1 55027 ENDSTOP.CONVEYOR.29·1/4"

46

47

48 2

49

2 22273-00

2 22152-0018

1 35

2

1 45035

21

0-0640

55028

30004

M10098

NO.

1531

01

DESCRIPTION

SPROCKET.

SPACER.NYLON.FITSBETWEENSPROCKET

COllAR

BUSHING.

SPACER. NYLON

BRACKET.

BUSH

SPROCKET.

SCREW

ASSEMBLY.

ASSEMBLY.

MASTERLIN

SPROCKET. DRIVE MOT

SCREW

ADAPTER, DRIVE

DR

IVEMOTOR,BR

REARSTOP.CONVEYOR,18"

CRUMB

H

ARNESS. WIRE

MOUNTING

CONVEYOR BELT

. SPLIT

LOCK

ING

BRONZE

SHAFT

ING,

SPLITBELTDRIVESPROCKET

DRI

PAN

BRACKET, DRIVE

3/4" O.D. x 518" 1.D.

1·114' O.D. x 3/4"

SUPPORT

VE

SHAFT.518"BORE

ROLLER

ROL

CHAIN

LER

CHAIN

K, ROL

MOTOR

USHLESS.

LER

OR.

COMPLETIE

COMPLETIE

CHAIN

518"BORE

WITH

1/8HP,1

MOTOR

I.

SET

D.

. 9T.

. 15T.

SCREW

400

WITH SET

(62

(48

:1

LINKS)

LIN

WITH

KS)

SET

Page 24

B

C

D

E

1/9/2006

2/15/2006

9/19/2006

2/23/2007

CHG’D DESC FROM 770M TO 770G ECN006363A

CHANGED DESC FROM PS670M TO PS770M ECN006034

RELEASE TO PROD RPM WAS 2000, Hz WAS 60 ECN 004386

AJ

AJ

AJ

AJ

CHANGED BAKE TEMP WAS 480-490 F ECN 006285

E

E

SYMMETRICAL FINGER CONFIG.

AVG CONTROL T/CS: 4 USED

ENT: TOP INNER & OUTER LOCATIONS: 12” PROBES

EXIT: TOP INNER & OUTER LOCATIONS: 12” PROBES

RPM=2100RPM, INVERTERS SET @ 63Hz AND ENERGY SAVING LOW SPEED 40

BAKE TIME & TEMP: 4’30” @ 480-490°F

BOTH SIDES END PLUGS HAVE DIVERTERS

OVEN DERATED TO 175,000 BTU/HR

24

°

Page 25

Right to Left or Left to Right - No Change to Finger Configuration

RPM: 2100 (Inverters Set @ 63Hz)

25

Page 26

THERMOCOUPLE PLACEMENTS 59077 REV G

G_ T/C Positions Shown for Either Conveyor Direction

G

26

Page 27

-

DAH

toM

•••

IIIIW..

G_

z

H_

I

-

.,,_

..

.,..

~

17

II

ttGHl.IIIT

17

LH

L.S1

RR

toM

NO

11

1 I I

•

, 1

I

IN02

•

•••

-

t1IIIE1al

~

llfVT a

___

-I'GSITIIIII

~

DII'D

~

-

HVISION

camvr

CIIIEYIII

tiLCia

.....

,

DHORIPTION

Ill

'R:I I

Mft-1~1111

CLINI

I'GSITICIN

Ill

IY

OHK

--

1'1:-

·-

-

DAH

_,_

.,.,,..

_,_

27

.

LOAD

kJ

=

~

L1

L.I\E

l1

lCFMR1

PRI1ARY

50/~Hz

~A~UY

L2

(fjVA

t.EFTl

2~V

117

~~

RT

f

FRT

Ill<

'

1ii

..

ctWTAOU.ER

IJ!L-2302

IU

-

-0~

..!!

0~

-o~

~

llJJ

OP

OVI

J!..!!._

1

0[

n

Ll

11-

1.2

WD

LABEL

PIN

58813

IMTERIM.

1-

~-IN-ISH---------1

1111111\1

•

®©

-·

DEDCBJ

-·-

-

WD,G208-240J50J60J1

-·-

~,::

Mlil.E!II

DI!C

.11:

.XX

.lXX

.NIIImWED

-

llltl,..

...

a t.o•

•.DJO

•.1'11

•.DDS

THIS IIIWIING

THE

MIDDLEBY

1400

Toa•tllll

Elgin,

1£7-7U-33DO

15

CCIFIDENTIAL

PROPERTY

DF

CORPORA

t1r

Dr

In

llllnolo

60IZO

PS870J770

Alll

T10N

Page 28

OVEN WITH POS CABLE

MODE 2--7:00 MINUTES

MODE 3--14:00 MINUTES

MODE 4--1 HOUR

OVEN WITHOUT POS CABLE

MODE 2--7:00 MINUTES

MODE 3--20:00 MINUTES

MODE 4--1 HOUR

NOTE: ATTACH This PS770 Initial Start-Up/Check Out Procedures Completely Filled Out Along With

The Completely Filled Out Startup Checklist Pages 1 And 2 (Form #P/N 37201 • Rev. F • V1• 7/05)

28

P/N 59279

REV. “B”

7/20/06

Page 29

Loading...

Loading...