Page 1

PS640/740/840 Series

Electric & Gas

Domestic & Std. Export

ENGLISH

P/N: 640

May, 2009 Rev. D

PS640 Series Ovens

Model

Combinations:

• Single Oven

• Double Oven (Two-Stack)

• Triple Oven (Three-Stack)

3$576 MANUAL

for domestic and standard export ovens

©2007 Middleby Marshall Inc.

is a registered trademark of Middleby Marshall, Inc. All rights reserved.

Middleby Cooking Systems Group • 1400 Toastmaster Drive • Elgin, IL 60120 • (847)741-3300 • FAX (847)429-7508

Page 2

NOTICE:

This parts manual should be kept in a prominent, easily reachable location.

Ovens are shipped from the factory configured for use with natural gas. If permitted by local, national and

international codes, at the time of installation the oven may be converted to propane gas operation. This conversion

requires the use of at Gas Conversion Kit that is supplied with the oven. For CE-approved ovens, the conversion is

described in the

included in the Gas Conversion Kit.

It is suggested to obtain a service contract with a Middleby Marshall Authorized Service Agent.

Installation

section of this Manual. For domestic and standard export ovens, instructions are

WARNING

POST, IN A PROMINENT LOCATION, THE EMERGENCY TELEPHONE NUMBER OF YOUR LOCAL GAS

SUPPLIER AND INSTRUCTIONS TO BE FOLLOWED IN THE EVENT YOU SMELL GAS.

Instructions to be followed in the event the user smells gas shall be obtained by consulting the local gas

supplier. If the smell of gas is detected, immediately call the emergency phone number of your local Gas

Company. They will have personnel and provisions available to correct the problem.

WARNING

FOR YOUR SAFETY, DO NO T STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

Improper installation, adjustment, alteration, service, or maintenance can cause

property damage, injury, or death. Read the installation, operation, and maintenance instructions

thoroughly before installing or servicing this equipment.

WARNING

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

IMPORTANT

An electrical wiring diagram for the oven is located inside the machinery compartment.

IMPORTANT

It is the customer’s responsibility to report any concealed or non-concealed damage to the

freight company. Retain all shipping materials until it is certain that the equipment has

not suffered concealed shipping damage.

NOTICE

CONTACT YOUR MIDDLEBY MARSHALL AUTHORIZED SERVICE AGENT TO INSTALL AND

PERFORM MAINENANCE AND REPAIRS AND IF NECESSARY TO CONVERT EQUIPMENT

FOR USE WITH OTHER GASES . AN AUTHORIZED SERVICE AGENCY DIRECTORY IS

SUPPLIED WITH YOUR OVEN.

NOTICE

Using any parts other than genuine Middleby Marshall factory manufactured parts relieves the manufacturer

of all warranty and liability.

NOTICE

Middleby Marshall (Manufacturer) reserves the right to change specifications at any time.

NOTICE

The equipment warranty is not valid unless the oven is installed, started and demonstrated under the

supervision of a factory certified installer.

NOTICE

THIS EQUIPMENT IS ONLY FOR PROFESSIONAL USE AND SHALL BE USED

BY QUALIFIED PERSONNEL.

RETAIN THIS MANU AL FOR FUTURE REFERENCE.

Middleby Cooking Systems Group • 1400 Toastmaster Drive • Elgin, IL 60120 USA • (847)741-3300 • FAX (847) 429-7508

www.Middleby-Marshall.com

ii

Page 3

Model No.

Modéle No.

Serial No.

Serié No.

Installation Date

Date d'installation

MIDDLEBY MARSHALL

NO QUIBBLE LIMITED WARRANTY

(U.S.A. ONLY)

MIDDLEBY MARSHALL, HEREINAFTER REFERRED TO

AS “THE SELLER”, WARRANTS EQUIPMENT MANUF A CTURED BY IT TO BE FREE FROM DEFECTS IN MATERIAL AND WORKMANSHIP FOR WHICH IT IS RESPONSIBLE. THE SELLER’S OBLIGATION UNDER THIS WARRANTY SHALL BE LIMITED TO REPLACING OR REPAIRING, AT SELLER’S OPTION, WITHOUT CHARGE, ANY

PART FOUND TO BE DEFECTIVE AND ANY LABOR AND

MA TERIAL EXPENSE INCURRED BY SELLER IN REP AIRING OR REPLACING SUCH PART. SUCH WARRANTY

SHALL BE LIMITED TO THE ORIGINAL PURCHASER

ONLY AND SHALL BE EFFECTIVE FOR A PERIOD OF

ONE YEAR FR OM DATE OF ORIGINAL INST ALLA TION, OR

18 MONTHS FROM DATE OF PURCHASE, WHICHEVER

IS EARLIER, PROVIDED THA T TERMS OF P AYMENT HAVE

BEEN FULLY MET.

This warranty is valid only if the equipment is installed, started,

and demonstrated under the supervision of a factory-authorized installer.

Normal maintenance functions, including lubrication, cleaning, or customer abuse, are not covered by this

warranty

Seller shall be responsible only for repairs or replacements

of defective parts performed by Seller’s authorized service

personnel. A uthorized service agencies are located in principal cities throughout the contiguous United States, Alaska,

and Hawaii. This warranty is valid in the 50 United States

and is void elsewhere unless the product is purchased

through Middleby International with warranty included.

.

The foregoing warranty is exclusive and in lieu of all other

warranties, expressed or implied. There are no implied

warranties of merchantability or of fitness for a particular purpose.

The foregoing shall be Seller’s sole and exclusive obligation

and Buyer’s sole and exclusive remedy for any action, including breach of contract or negligence. In no event shall

Seller be liable for a sum in excess of the purchase price of

the item. Seller shall not be liab le f or an y prospective or lost

profits of Buyer.

This warranty is effective on Middleby Marshall equipment sold on, or after, February 15, 1995.

no quibble

MIDDLEBY MARSHALL INC.

OVEN LIMITED WARRANTY

(Non U.S.A.)

The Seller warrants equipment manufactured by it to be free from

defects in material and workmanship for which it is responsible. The

Seller’s obligation under this warranty shall be limited to replacing or

repairing, at Seller’s option, without charge, F.O.B. Seller’s factory,

any part found to be defective and any labor and material expense

incurred by Seller in repairing or replacing such part. Such warranty

is limited to a period of one year from date of original installation or

15 months from date of shipment from Seller’s factory, whichever is

earlier, provided that terms of payment have been fully met. All labor

shall be performed during regular working hours. Overtime premium

will be charged to the Buyer.

This warranty is not valid unless equipment is installed, started,

and demonstrated under the supervision of a factory-authorized installer.

Normal maintenance functions, including lubrication, adjustment of

airflow, thermostats, door mechanisms, microswitches, burners and

pilot burners, and replacement of light bulbs, fuses and indicating

lights, are not covered by warranty.

Any repairs or replacements of defective parts shall be performed by

Seller’s authorized service personnel. Seller shall not be responsible for any costs incurred if the work is performed by other than

Seller’s authorized service personnel.

When returning any part under warranty, the part must be intact and

complete, without evidence of misuse or abuse, freight prepaid.

Seller shall not be liable for consequential damages of any kind

which occur during the course of installation of equipment, or which

result from the use or misuse by Buyer, its employees or others of

the equipment supplied hereunder, and Buyer’s sole and exclusive

remedy against Seller for any breach of the foregoing warranty or

otherwise shall be for the repair or replacement of the equipment or

parts thereof affected by such breach.

The foregoing warranty shall be valid and binding upon Seller if and

only if Buyer loads, operates and maintains the equipment supplied

hereunder in accordance with the instruction manual provided to

Buyer. Seller does not guarantee the process of manufacture by

Buyer or the quality of product to be produced by the equipment

supplied hereunder and Seller shall not be liable for any prospective

or lost profits of Buyer.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF

ALL OTHER EXPRESS AND IMPLIED WARRANTIES WHATSOEVER. SPECIFICALLY THERE ARE NO IMPLIED WARRANTIES

OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR

PURPOSE.

The foregoing shall be Seller’s sole and exclusive obligation and

Buyer’s sole and exclusive remedy for any action, whether in breach

of contract or negligence. In no event shall seller be liable for a sum

in excess of the purchase price of the item.

© 2014 - Middleby Marshall, A Middleby Company.

The Middleby Marshall logo is a registered trademark of Middleby Marshall, A Middleby Company.

Middleby Marshall Inc. • 1400 Toastmaster Drive • Elgin, Illinois 60120-9272 U.S.A. • (847) 741-3300 • FAX: (847) 429-7508

iii

Page 4

Page

Installation items and kits ............................... 3 - 11

Key Spare Parts .................................................. 12

Cavity Assembly Components ............................ 13

Blower Assembly ......................................... 14 - 15

Blower Belt Alignment Tool ................................. 16

Right Hand Control Compartment ................ 17 - 18

Left Hand Gas Burner Compartment ............ 19 - 21

Left Hand Electric Heater Compartment ...... 22 - 23

PhotoEye Sensor Assembly ................................ 24

Conveyor Assembly, Single .......................... 25 - 26

Conveyor Assembly, Split Belt ...................... 27 - 28

Conveyor Assembly, Hearth Belt ......................... 29

Snorkel Kits ................................................... 30 - 32

Lifting Tool ............................................................ 33

Wiring Diagram .............................................. 34 - 35

Table of Contents

SECTION 1 – DESCRIPTION ............................................ 1

I. OVEN USES ............................................................ 1

II. OVEN COMPONENTS ............................................ 1

A. Conveyor Motor Drive ...................................1

B. Crumb Pans .................................................. 1

C. Conveyor....................................................... 1

D. End Plugs...................................................... 1

E. Eyebrows ...................................................... 1

F. Window ......................................................... 1

G. Machinery Compartment Access Panel ........ 1

H. Serial Plate.................................................... 1

I. Control Panel ................................................ 1

J. Photo Cell ..................................................... 1

K. Gas Burner.................................................... 1

L. Blowers ......................................................... 1

M. Air Fingers..................................................... 1

III. OVEN SPECIFICATIONS ........................................ 2

A. Dimensions ................................................... 2

B. General Specifications .................................. 2

C. Electrical Specifications for

PS640 Gas Ovens ........................................ 2

D. Gas Orifice and Pressure Specifications

for PS640 Gas Ovens ................................... 2

SECTION 2 – 3$576%5($.287................................... 3

Wiring Diagrams are in back of this Manual.

The diagram for each oven is also on the lower

inner surface of its Control Console.

iv

NOTE

Page 5

SECTION 1 – DESCRIPTION

I. OVEN USES

PS640 Series Ovens can be used to bake and/or cook a wide

variety of food products, such as pizza, pizza –type products,

cookies, sandwiches and others.

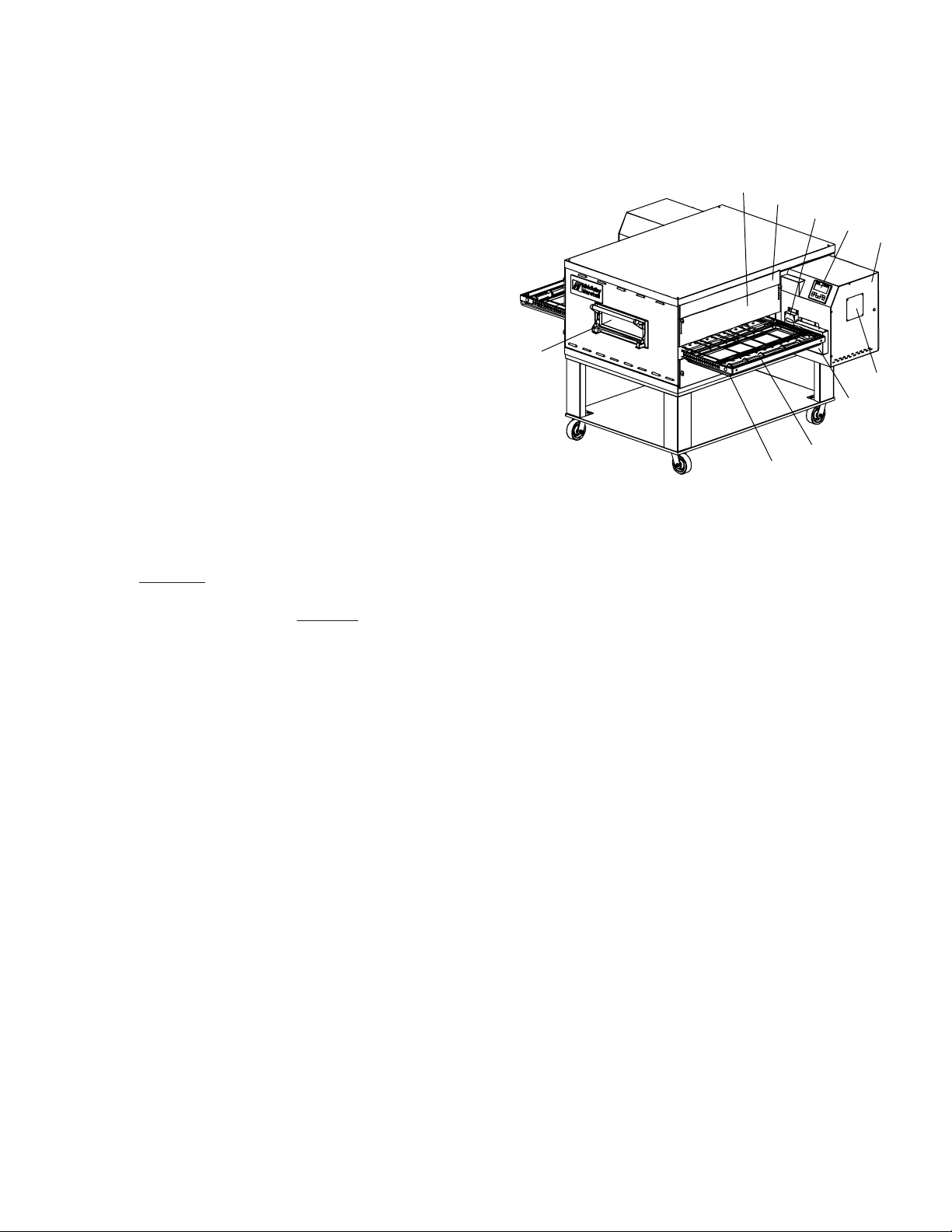

II. OVEN COMPONENTS – see Figure 1-1.

A. Conveyor Drive Motor: Moves the conveyor.

B. Crumb Pans: Catch crumbs and other materials that drop

through the conveyor belt. One crumb pan is located at

each end of the conveyor.

C. Conveyor: Moves the food product through the oven.

D. End Plugs: Allow access to the oven’s interior.

E. Eyebrows: Can be adjusted to various heights to prevent

heat loss into the environment.

F. Window: Allows the user to access food products inside

the baking chamber.

G. Machinery Compartment Access Panel: Allows access

to the oven’s interior and control components. No user

serviceable parts are located in the machinery compart-

ment.

H. Serial Plate: Provides specifications for the oven that

affect installation and operation. Refer to Section 2,

Installation for details.

I. Control Panel: Location of the operating controls for the

oven. Refer to Section 3, Operation, for details.

J. Photo Cell: Turns oven On when beam is interrupted.

Not Shown:

K. Gas Burner (gas ovens): Heat air, which is then projected

to the air fingers by the blowers.

L. Blowers: Project hot air from the burner or heating element

to the air fingers.

M. Air Fingers: Project streams of hot air onto the food

product.

Figure 1-1. Oven Components

E

D

J

I

G

F

H

A

C

B

1

Page 6

I. OVEN SPECIFICATIONS

Table 1-1 Dimensions

Overall Height 48-3/16″ (1219mm) 62-3/4″ (1575mm) 78-11/16″ (1981mm)

Overall Depth 60″ (1524mm) 60″ (1524mm) 60″ (1524mm)

Overall Length 76-1/2″ (1930mm) 76-1/2″ (1930mm) 76-1/2″ (1930mm)

Conveyor Width – belt width is 32″ 33-1/2″ (838mm) 33-1/2″ (838mm) 33-1/2″ (838mm)

Shortened Exit Conveyor - 24

Overall Depth 52.75″ (1340mm) 52.75″ (1340mm) 52.75″ (1340mm)

Overall Length 69″ (1753mm) 69″ (1753mm) 69″ (1753mm)

* All other dimension are the same

Recommended Minimum Clearances

Rear of Oven to Wall 3″ (76mm) 3″ (76mm) 3″ (76mm)

Control end of conveyor to Wall 1″ (25.4mm) 1″ (25.4mm) 1″ (25.4mm)

Non-control end of conveyor to Wall) 1″ (25.4mm) 1″ (25.4mm) 1″ (25.4mm)

″″

″

″″

Single Oven Double Oven Triple Ove

or 2 × 15″ (381mm) or 2 × 15″ (381mm) or 2 × 15″ (381mm)

Single Oven Double Oven Triple Ove

Table 1-2: General Specifications PS640 GAS 32

Weight 1150 lbs. (522kg) 1150 lbs. (522kg)

Rated Heat Input 99,000 BTU (25,000kcal, 29 kW/hr) 99,000 BTU (25,000kcal, 29 kW/hr)

Maximum Operation Temperature 600°F / 315°C 600°F / 315°C

Air Blowers Two Blowers at 1900 RPM Two Blowers at 1900 RPM

Warmup Time 15 min. 15 min.

Table 1-3: Electrical specifications for PS640G gas ovens

Main Blower Control Circuit Phase Freq Current Poles Wires

Voltage Voltage Draw

208-240VAC 208-240VAC 1Ph 50/60Hz 11-9.6 Amp 2 Pole 3 Wire (2 hot, 1 gd)

Table 1-4: Gas orifice and pressure specifications for PS640G gas ovens

Gas Main Orifice I.D. Supply (Inlet) Orifice (Manifold) Bypass

Type PS640G Pressure Pressure Pressure

Natural 0.1065″ (0.120mm) 6-8″ W.C. (14.9 - 19.9mbar) 3.5″ W.C. (8.7mbar) 0.25-0.3″ W.C. (0.6-0.8 mbar)

Propane 0.067″ (1.9mm) 11-14″ W.C. (27.4 - 34.9mbar) 10.0″ W.C. (24.9mbar) 0.9-1.0″ W.C. (2.2-2.5 mbar)

IMPORTANT –

Additional electrical information is provided on the oven’s serial plate, and on the wiring diagram inside the

machinery compartment.

″″

″ Belt 24

″″

″″

″ Belt

″″

GAS ORIFICE AND PRESSURE SPECIFICATIONS (PER OVEN CAVITY) - CE OVENS

Supply (Inlet) Pressure

Gas Orifice DK,FI NL DE BE,FR FI,DE,NL ES,UK (Manifold) Heat

Main UK,CH,IT,AT, SE,CH,AT,DK, BE,IE,IT,PT, Orifice Rated

Type dia.

G20 0.120″ 20 -- 20 20 -- -- 11.21 22.36

(3.05 mm) mbar mbar mbar mbar kW-hr.

G25 0.120″ -- 25 -- -- -- -- 16.19 22.36

(3.05 mm) mbar mbar kW-hr.

G30 0.075″ -- -- -- -- 29 or 50 28-30, 37 26.2 22.59

(1.9 mm) mbar or 50 mbar mbar kW-hr.

IT,PT,ES,SE,

I

2H

I

2L

I

2E

I

2E+

I

3B/P

I

3+

Pressure Input

NOTE

Wiring Diagrams are contained in Section 5 of this Manual

and are also located inside the oven at the

bottom of the Control Panel.

Additional electrical information is provided on the oven's serial plate.

This Manual Must Be Kept For Future Reference

2

Page 7

SECTION 2 – INSTALLATION

WARNING – After any conversions, readjustments, or service work on the oven:

• Perform a gas leak test. • Test for proper combustion and gas supply.

• Test for correct air supply, particularly to the • Check that the ventilation system is in operation.

burner blower.

WARNING - Keep the appliance area free and clear of combustibles.

WARNING – The oven must be installed on an even (level) non-flammable flooring and any adjacent walls

must be non-flammable. Recommended minimum clearances are specified in the Description section of

this manual.

WARNING – Do not obstruct the flow of combustion and ventilation air to and from your oven. There must

be no obstructions around or underneath the oven. Constructional changes to the area where the oven

is installed shall not affect the air supply to the oven.

CAUTION: To reduce the risk of fire, the appliance is to be mounted on floors of noncombustible construction with

noncombustible flooring and surface finish and with no combustible material against the underside thereof, or on

noncombustible slabs or arches having no combustible material against the underside thereof, such construction

shall in all cases extend not less than 12 inches (304mm) beyond the equipment on all sides.

CAUTION: For additional installation information, contact your local Authorized Service Agent.

NOTE – There must be adequate clearance between the oven and combustible construction. Clearance must also

be provided for servicing and for proper operation.

NOTE – An electrical wiring diagram for the oven is located inside the machinery compartment.

NOTE: All aspects of the oven installation, including placement, utility connections, and ventilation requirements,

must conform with any applicable local, national, or international codes. These codes supersede the requirements

and guidelines provided in this manual.

NOTE: In the USA, the oven installation must conform to local codes. In the absence of local codes, gas oven

installations must conform with the National Fuel Gas Code, ANSI Z223.1. Gas and electric ovens, when installed,

must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National

Electrical Code (NEC), or ANSI/NFPA70.

NOTE: In Canada, the oven installation must conform with local codes. In the absence of local codes, gas

oven installations must conform with the Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Gas

Installation Code, CAN/CGA-B149.2, as applicable. Gas and electric ovens, when installed, must be electrically

grounded in accordance with local codes, or in the absence of local codes, with the Canadian Electrical Code

CSA C22.2.

NOTE: In Australia, the oven installation must conform with local codes. In the absence of local codes, gas

oven installations must conform with the requirements of AS5601/AG601, Gas, Electricity, and any other relevant

statutory regulations.

3

Page 8

PS640 24

″″

″ OVEN INSTALLATION

″″

REQUIRED KITS AND EQUIPMENT

PS640 PS640 PS640 PS640

Gas Oven Single Oven DoubleOven TripleOven

Installation Option Base w/ OptionBase w/ OptionBase w/

TYPE OF INSTALLATION Kit 15″ Legs, 6″ Legs, Casters& Top

Casters & Top Casters & Top Kit

Kit Kit

P/N61452 P/N61123 P/N61457 P/N61458

PS640 Single Gas Oven 1 1

PS640 Double Gas Oven 2 1

PS640 Triple Gas Oven 3 1

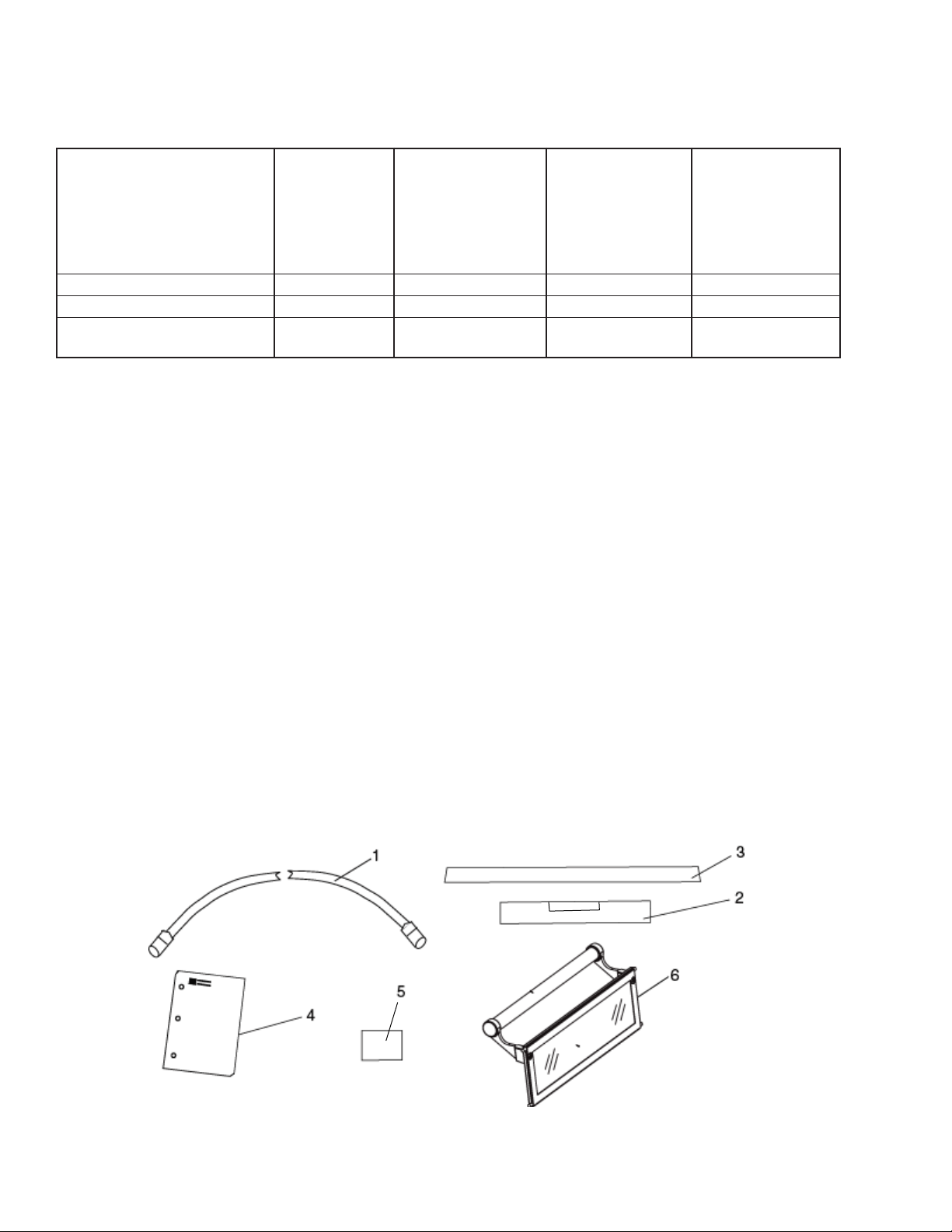

PARTS LIST FOR SERIES PS640 GAS OVEN

INSTALLATION KIT

P/N 61452

(Two required for double oven)

(Three required for triple oven)

ITEM

NO. QTY PART NO. DESCRIPTION

1 1 22361-0001 FLEXIBLE GAS HOSE

2 1 61823 CONVEYOR END STOP, 18″

3 1 31461 CONVEYOR LEFT REAR STOP, 21.25″

4 1 42612 SERVICE AGENCY DIRECTORY

5 1 22500-0080 LABEL, MM

6 1 51054 ASSY, HANDLE & DOOR

Figure 2-1A. PS640-Series Gas Oven Installation Parts

1

5

4

4

3

2

6

Page 9

PS640 32

″″

″ OVEN INSTALLATION

″″

REQUIRED KITS AND EQUIPMENT

PS640 PS640 PS640 PS640

Gas Oven Single Oven DoubleOven TripleOven

Installation Option Base w/ OptionBase w/ OptionBase w/

TYPE OF INSTALLATION Kit 15″ Legs, 6″ Legs, Casters& Top

Casters & Top Casters & Top Kit

Kit Kit

P/N61033 P/N59720 P/N59725 P/N59726

PS640 Single Gas Oven 1 1

PS640 Double Gas Oven 2 1

PS640 Triple Gas Oven 3 1

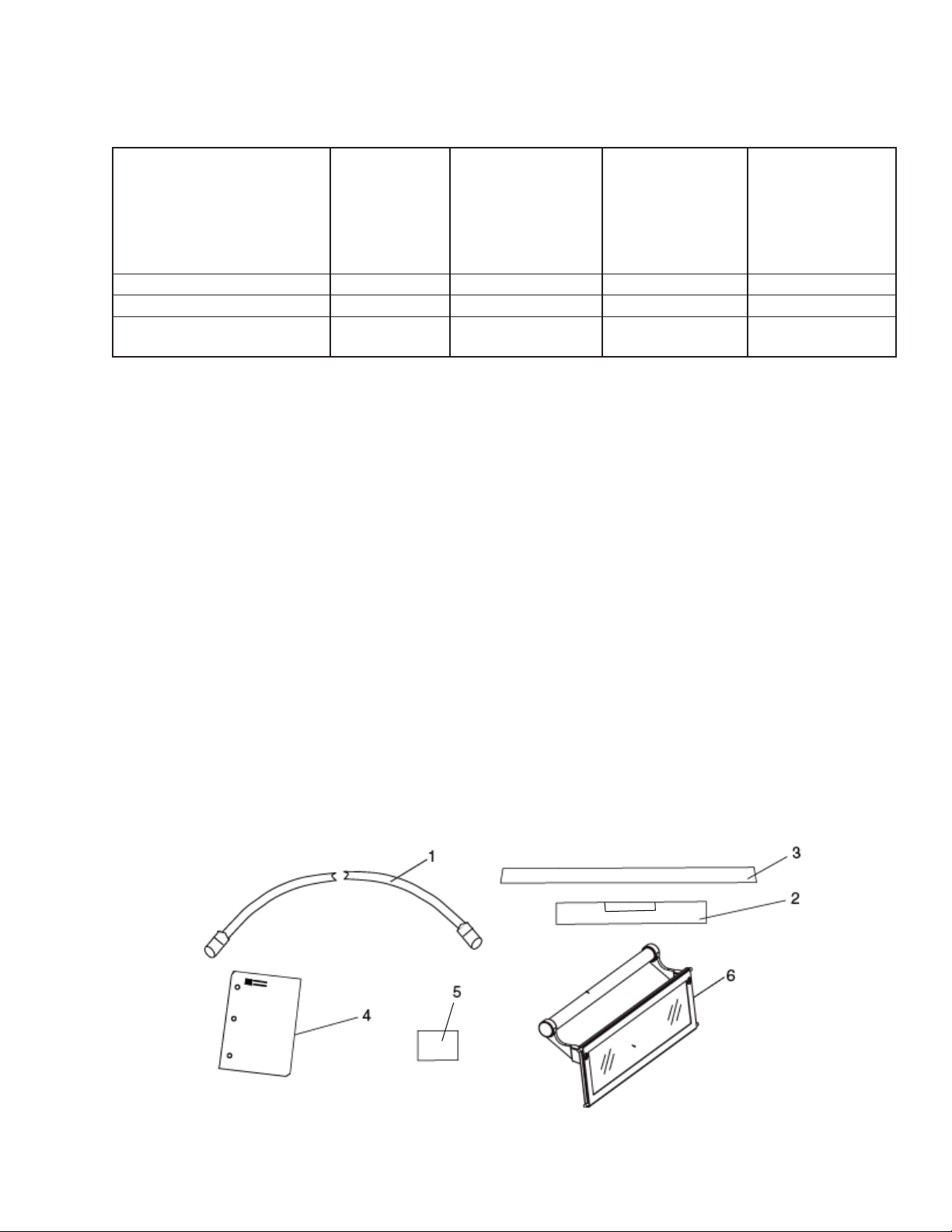

PARTS LIST FOR SERIES PS640 GAS OVEN

INSTALLATION KIT

P/N 61033

(Two required for double oven)

(Three required for triple oven)

ITEM

NO. QTY PART NO. DESCRIPTION

1 1 22361-0001 FLEXIBLE GAS HOSE

2 1 61823 CONVEYOR END STOP

3 1 55027 CONVEYOR LEFT REAR STOP

4 1 42612 SERVICE AGENCY DIRECTORY

5 1 22500-0080 LABEL, MM

6 1 51054 ASSY, HANDLE & DOOR

Figure 2-1B. PS640-Series Gas Oven Installation Parts

1

5

4

5

3

2

6

Page 10

HARDWARE BAG

5, 6, 7, 10 & 11

2

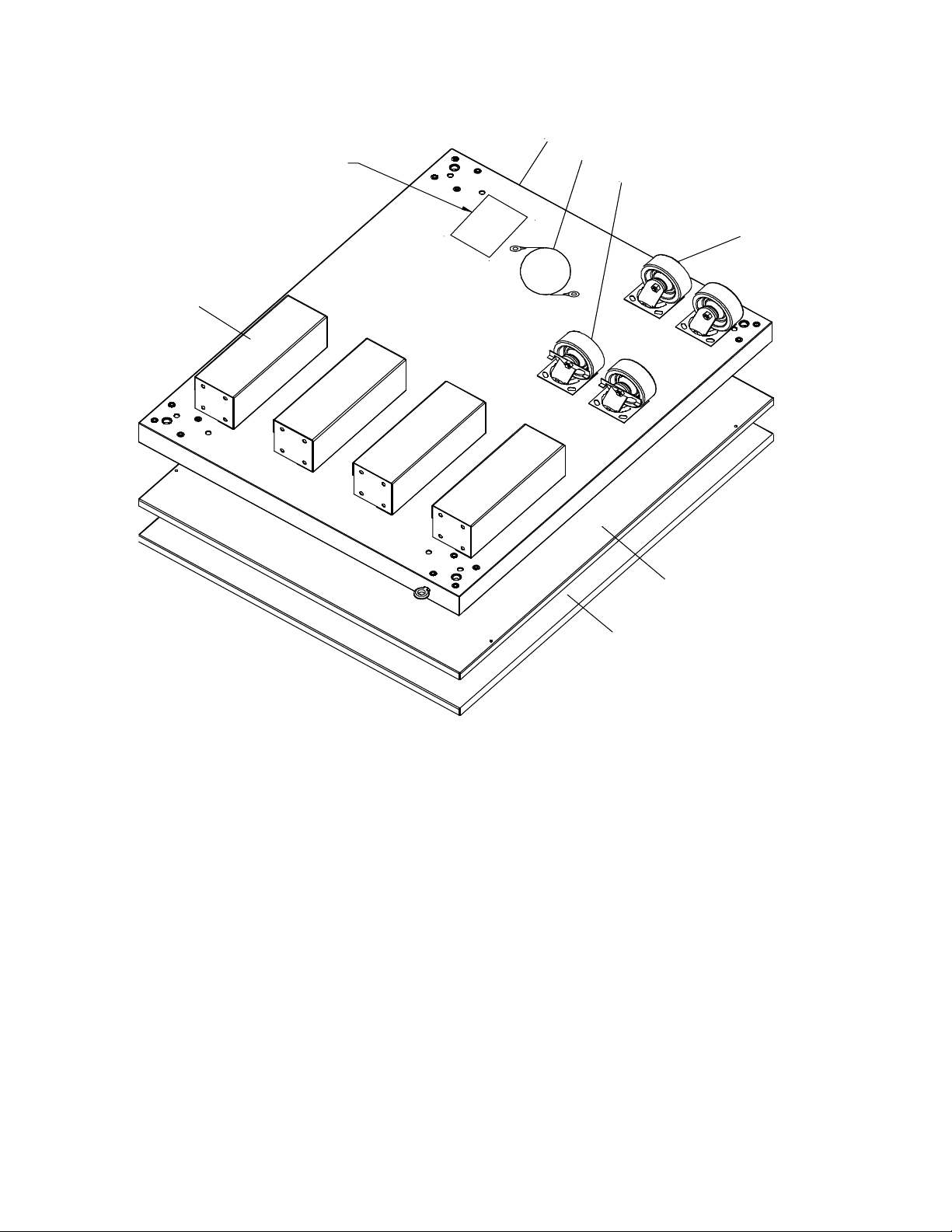

Figure 2-2A. Model PS640 24

Option Base with Legs and Top

″″

″ Single Oven

″″

1

8

3

4

PARTS LIST FOR PS640 SERIES 24

ITEM NO. QTY PART NO. DESCRIPTION

1 1 61126 COMPLETE BASE WELDMENT

2 4 37900-0024 TOP PLATE, LEG WELDMENT

3 2 22290-0009 SWIVEL CASTER W/BRAKE FLAT PLATE

4 2 22290-0010 SWIVEL CASTER FLAT PLATE

5 32 2000531 3/8″-16 × 1″ HEX SCREW, SST

6 32 21416-0001 3/8″ FLAT WASHER, SS

7 32 21422-0001 3/8″ SPLIT LOCK WASHER, ZP

8 1 22450-0228 RESTRAINT CABLE ASSEMBLY

9 1 61125 TOP COVER

10 2 59677 SCR, MS SL TR HD 10-32 × 2-1/2″

11 2 7A2S15 SCR, MS STR TRSHD 10-32 × 3/4″

12 1 61128 SUPPORT, SHELF

9

12

″″

″ SINGLE OVEN OPTION - BASE w/15

″″

P/N 61123

″″

″ LEGS & TOP

″″

6

Page 11

HARDWARE BAG

5, 6, 7, 10 & 11

2

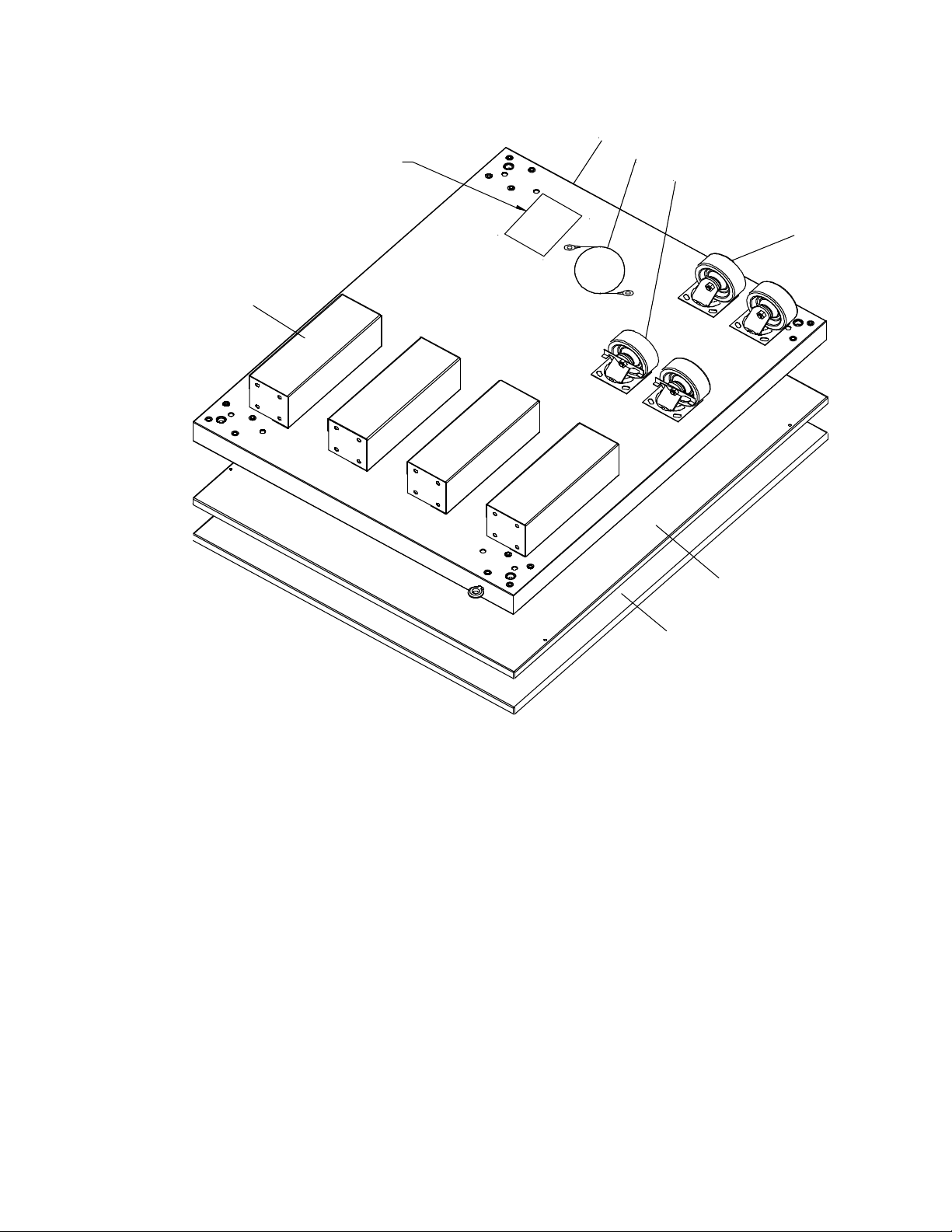

Figure 2-2B. Model PS640 32

Option Base with Legs and Top

″″

″ Single Oven

″″

1

8

3

4

PARTS LIST FOR PS640 32

ITEM NO. QTY PART NO. DESCRIPTION

1 1 60287 COMPLETE BASE WELDMENT

2 4 37900-0024 TOP PLATE, LEG WELDMENT

3 2 22290-0009 SWIVEL CASTER W/BRAKE FLAT PLATE

4 2 22290-0010 SWIVEL CASTER FLAT PLATE

5 32 2000531 3/8″-16 × 1″ HEX SCREW, SST

6 32 21416-0001 3/8″ FLAT WASHER, SS

7 32 21422-0001 3/8″ SPLIT LOCK WASHER, ZP

8 1 22450-0228 RESTRAINT CABLE ASSEMBLY

9 1 59560 TOP COVER

10 2 59677 SCR, MS SL TR HD 10-32 × 2-1/2″

11 2 7A2S15 SCR, MS STR TRSHD 10-32 × 3/4″

12 1 59724 SUPPORT, SHELF

9

12

″″

″ SERIES SINGLE OVEN OPTION - BASE w/15

″″

P/N 59720

″″

″ LEGS & TOP

″″

7

Page 12

5, 6, 7, 10 & 11

2

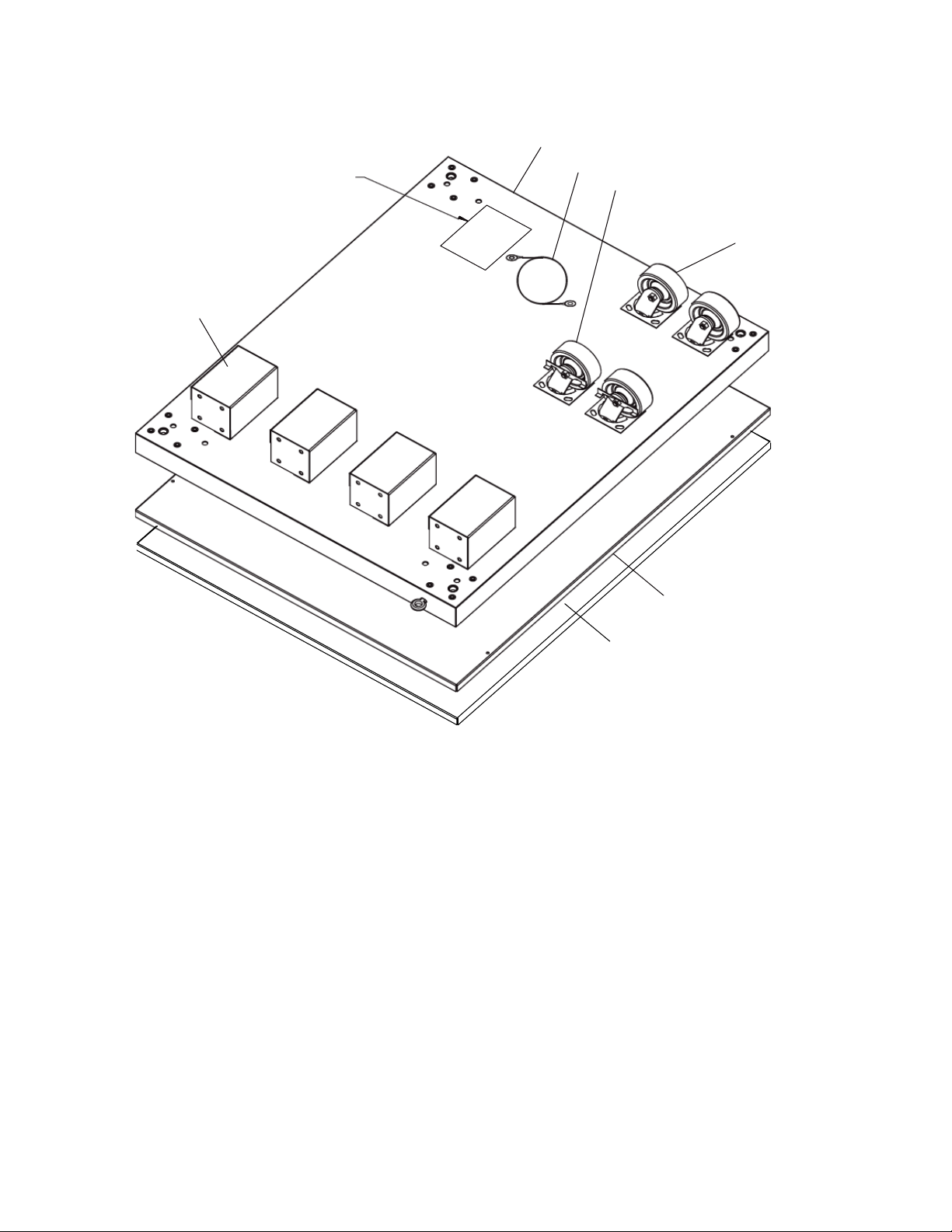

Figure 2-3A. Model PS640 24

Option Base with Legs and Top

HARDWARE BA G

″″

″ Double Oven

″″

1

8

3

4

PARTS LIST FOR PS640 SERIES 24

ITEM NO. QTY PART NO. DESCRIPTION

1 1 61126 COMPLETE BASE WELDMENT

2 4 37900-0102 TOP PLATE, LEG WELDMENT

3 2 22290-0009 SWIVEL CASTER W/BRAKE FLAT PLATE

4 2 22290-0010 SWIVEL CASTER FLAT PLATE

5 32 2000531 3/8″-16 × 1 HEX SCREW, SST

6 32 21416-0001 3/8″ FLAT WASHER, SS

7 32 21422-0001 3/8″ SPLIT LOCK WASHER, ZP

8 1 22450-0228 RESTRAINT CABLE ASSEMBLY

9 1 61125 TOP COVER

10 2 59677 SCR, MS SL TR HD 10-32 × 2-1/2″

11 2 7A2S15 SCR, MS STR TRSHD 10-32 × 3/4″

12 1 61128 SUPPORT, SHELF

9

12

″″

″ DOUBLE OVEN OPTION - BASE w/6

″″

P/N 61457

″″

″ LEGS & TOP

″″

8

Page 13

5, 6, 7, 10 & 11

2

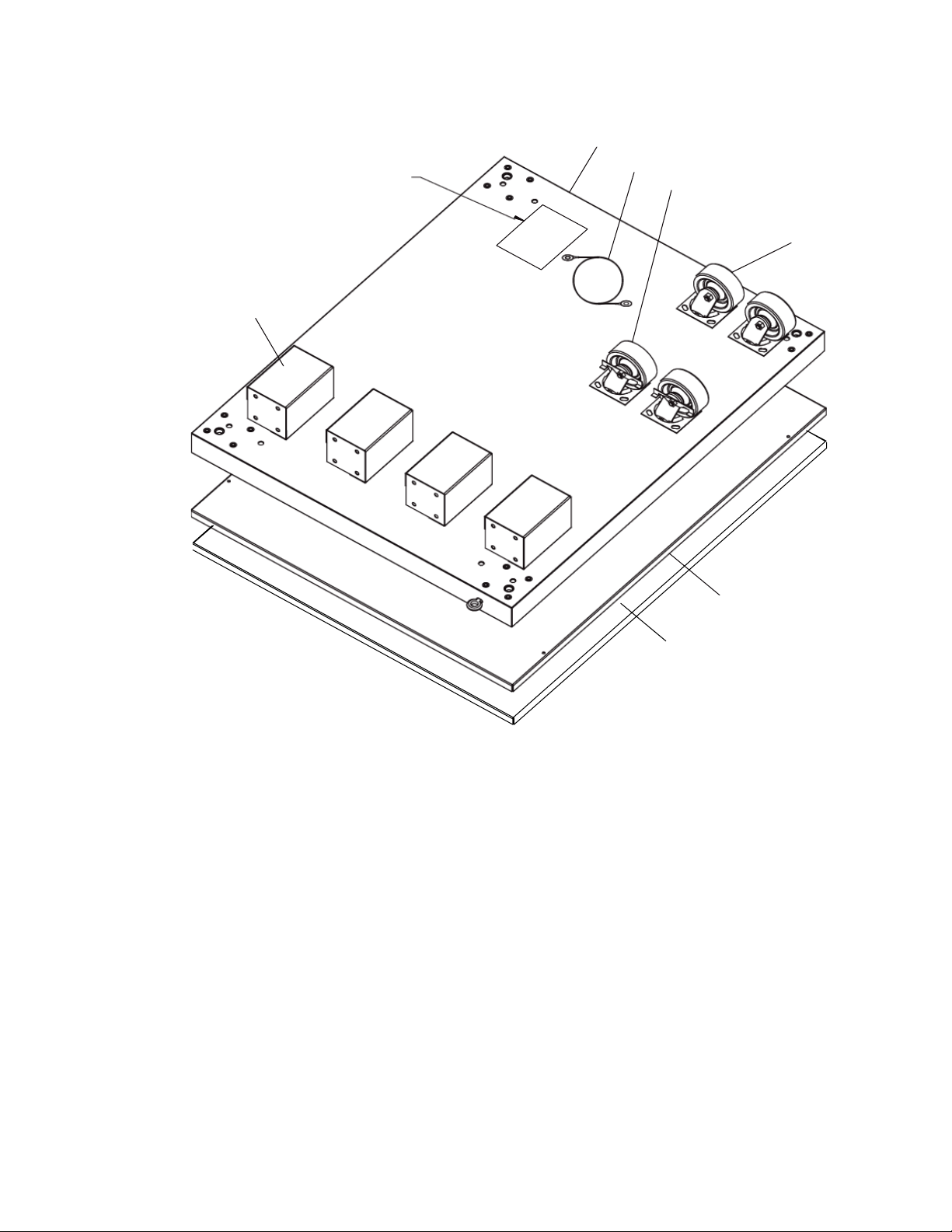

Figure 2-3B. Model PS640 32

Option Base with Legs and Top

HARDWARE BA G

″″

″ Double Oven

″″

1

8

3

4

PARTS LIST FOR PS640 SERIES 32

ITEM NO. QTY PART NO. DESCRIPTION

1 1 60287 COMPLETE BASE WELDMENT

2 4 37900-0102 TOP PLATE, LEG WELDMENT

3 2 22290-0009 SWIVEL CASTER W/BRAKE FLAT PLATE

4 2 22290-0010 SWIVEL CASTER FLAT PLATE

5 32 2000531 3/8″-16 × 1 HEX SCREW, SST

6 32 21416-0001 3/8″ FLAT WASHER, SS

7 32 21422-0001 3/8″ SPLIT LOCK WASHER, ZP

8 1 22450-0228 RESTRAINT CABLE ASSEMBLY

9 1 59560 TOP COVER

10 2 59677 SCR, MS SL TR HD 10-32 × 2-1/2″

11 2 7A2S15 SCR, MS STR TRSHD 10-32 × 3/4″

12 1 59724 SUPPORT, SHELF

9

12

″″

″ DOUBLE OVEN OPTION - BASE w/6

″″

P/N 59725

″″

″ LEGS & TOP

″″

9

Page 14

Figure 2-4A. Model PS640 24

″″

″ Triple Oven

″″

Option Base with Outriggers and Top

1

HARDWARE BAG

7, 8, 9, 10, 11, 12,

13, 14, & 17

5

6

2

15

3

4

PARTS LIST FOR PS640 SERIES 24

ITEM NO. QTY PART NO. DESCRIPTION

1 1 61126 COMPLETE BASE WELDMENT

2 4 45209 QUAD OUTRIGGER WELDMENT

3 2 22290-0009 SWIVEL CASTER, W/BRAKE FLAT PLATE

4 2 22290-0010 SWIVEL CASTER, FLAT PLATE

5 4 45206 INSERT,QUAD ADJUSTMENT FOOT

6 4 45205 SPACER,QUAD CASTER

7 32 A27727 3/83 -16x1-1/4 HEX BOLT

8 32 A21924 3/83 FLAT WASHER, SS

9 32 21422-0001 3/83 SPLIT LOCK WASHER, ZP

10 16 21172-0004 3/83 -16 NYLON INSULATED LOCKNUT, ZC

11 8 2001048 1/23 -13 x 1-3/8 18-8 HEX CAPSCREW

12 8 A27750 1/23 18-8 FLAT WASHER

13 8 21422-0016 1/23 18-8 LOCK WASHER

14

15 1 22450-0228 RESTRAINT CABLE ASSEMBLY

16 1 61125 TOP COVER

17 2 7A2S15 SCR, MS STR TRSHD 10-32X3/4″

2

16

″″

″ TRIPLE OVEN OPTION - BASE w/CASTERS & TOP

″″

P/N 61458

59677 SCR, MS SL TR HD 10-32X2-1/2

10

Page 15

Figure 2-4B. Model PS640 32

″″

″ Triple Oven

″″

Option Base with Outriggers and Top

1

HARDWARE BAG

7, 8, 9, 10, 11, 12,

13, 14, & 17

5

6

2

15

3

4

PARTS LIST FOR PS640 SERIES 32

ITEM NO. QTY PART NO. DESCRIPTION

1 1 60287 COMPLETE BASE WELDMENT

2 4 45209 QUAD OUTRIGGER WELDMENT

3 2 22290-0009 SWIVEL CASTER, W/BRAKE FLAT PLATE

4 2 22290-0010 SWIVEL CASTER, FLAT PLATE

5 4 45206 INSERT,QUAD ADJUSTMENT FOOT

6 4 45205 SPACER,QUAD CASTER

7 32 A27727 3/83 -16x1-1/4 HEX BOLT

8 32 A21924 3/83 FLAT WASHER, SS

9 32 21422-0001 3/83 SPLIT LOCK WASHER, ZP

10 16 21172-0004 3/83 -16 NYLON INSULATED LOCKNUT, ZC

11 8 2001048 1/23 -13 x 1-3/8 18-8 HEX CAPSCREW

12 8 A27750 1/23 18-8 FLAT WASHER

13 8 21422-0016 1/23 18-8 LOCK WASHER

14

15 1 22450-0228 RESTRAINT CABLE ASSEMBLY

16 1 59560 TOP COVER

17 2 7A2S15 SCR, MS STR TRSHD 10-32X3/4″

2

16

″″

″ TRIPLE OVEN OPTION - BASE w/CASTERS & TOP

″″

P/N 59726

59677 SCR, MS SL TR HD 10-32X2-1/2

11

Page 16

V. KEY SPARE PARTS KIT # 60904 – Available separately. See Figure 4-8. This Page Updated 8-20-2015

12 345

10

15

16, 17, 18

19

20

21

Figure 4-8. Key Spare Parts

KEY SPARE PARTS PS640 GAS

ITEM QTY. P/N DESCRIPTION

1 1 67050 Digital Display, Programmed

2 1 58920 Motor, Conveyor Drive

3 1 66759 Conveyor Control Board

4 1 70884 Inverter, Programmed

5 1 69533 Power Supply

6 1 33984 Kit, Thermocouple

7 1 65061 Fan Cooling Control (97525 until 7/2011)

8 1 51399 Fan Cooling Rear

9 1 60598 Air Switch

10 1 57288 Motor, Blower

11 1 62285 Ignition Module

12 1 60679 Assy, Valve Gas Modulating

13 1 60671 Board, Signal Cond. 0-15VDC

14 1 33983 High Limit Control Module,240V

15 2 32108 Transformer,240Vp:24Vs

16 1 67052 PLC ModuIe, Programmed

17 1 58668 Thermocouple Module

18 1 58669 Current Module

19 1 60185 PhotoCell

20 2 59132 Relay, DPDT 24V Coil

21 1 59668 Belt, Blower

22 1 71037 Ignitor, Single Rod

23 1 50240 Ignition Cable, 25″

24 1 68371 Bearing, PB 5/8 Bore

22

23

24

12

Page 17

13

Page 18

14

Page 19

15

Page 20

16

Page 21

Page 22

18

Page 23

19

Page 24

20

Page 25

2122232425

Page 26

Page 27

Page 28

Page 29

Page 30

26

Page 31

27

Page 32

28

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

SECTION 5 - WIRING DIAGRAM

59324 Rev. E

35

Middleby-Marshall Model Number G208-240 Volt 50/60 Hz, 1 Phase

Page 40

NOTES

36

Page 41

NOTES

37

Page 42

WARNING

Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death. Read the installation,

operating and maintenance instructions thoroughly before

installing or servicing this equipment.

NOTICE

During the warranty period, ALL parts replacement and servicing should be performed

by your Middleby Marshall Authorized Service Agent. Service that is performed by

parties other than your Middleby Marshall Authorized Service Agent may void your

warranty.

NOTICE

Using any parts other than genuine Middleby Marshall factory manufactured parts

relieves the manufacturer of all warranty and liability.

NOTICE

Middleby Marshall reserves the right to change specifications at any time.

Middleby is proud to support the Commercial Food Equipment

Service Association (CFESA). We recognize and applaud

CFESA's ongoing efforts to improve the quality of technical

service in the industry.

Middleby Cooking Systems Group • 1400 Toastmaster Drive • Elgin, IL 60120 • USA • (847)741-3300 • FAX (847) 429-7508

www.middleby-marshall.com

www .mid dleby.com

Loading...

Loading...