Page 1

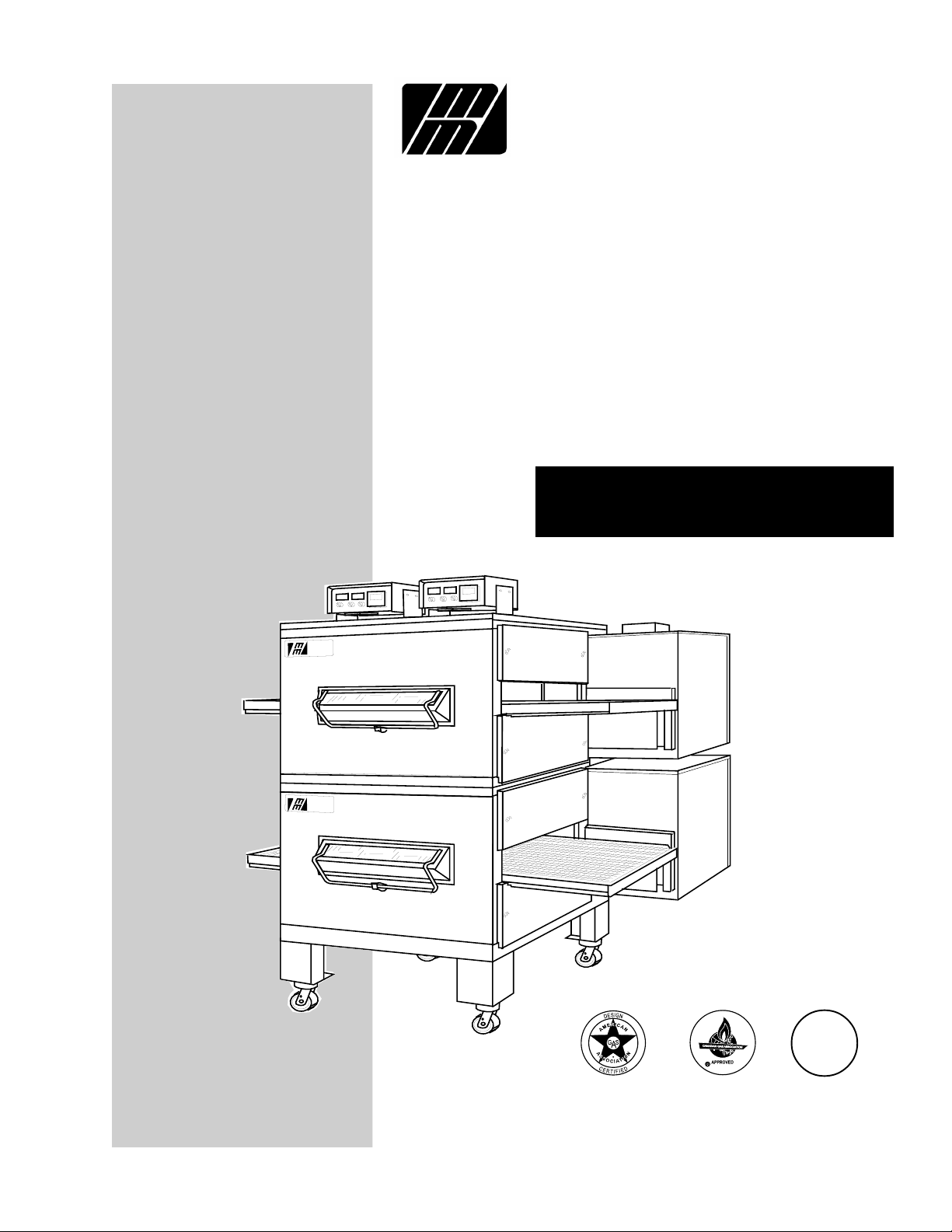

Middleby

A MIDDLEBY COMPANY

Marshall

Red Lobster

operating

& installation

manual

MIDDLEBY SERIES

PS200-R68 OVENS

Middleby

Marshall

Middleby

Marshall

NSF

®

©1995 Middleby Marshall Inc.

Part No. 31349

Price $15.00

P4/95

Page 2

Model No._________________Serial No.______________________________Installation Date_______________

MIDDLEBY MARSHALL INC.

NO QUIBBLE LIMITED WARRANTY

(U.S.A. ONLY)

MIDDLEBY MARSHALL, HEREINAFTER REFERRED TO AS THE SELLER, WARRANTS EQUIPMENT MANUFACTURED BY IT TO BE FREE FROM DEFECTS IN

MATERIAL AND WORKMANSHIP FOR WHICH IT IS RESPONSIBLE. THE SELLER’S

OBLIGATION UNDER THIS WARRANTY SHALL BE LIMITED TO REPLACING OR

REPAIRING AT SELLER’S OPTION, WITHOUT CHARGE, ANY PART FOUND TO BE

DEFECTIVE AND ANY LABOR AND MATERIAL EXPENSE INCURRED BY SELLER IN

REPAIRING OR REPLACING SUCH PART, SUCH WARRANTY SHALL BE LIMITED

TO THE ORIGINAL PURCHASER ONLY AND SHALL BE EFFECTIVE FOR A PERIOD

OF TWO YEARS FROM DATE OF ORIGINAL INSTALLATION, OR 30 MONTHS FROM

DATE OF SHIPMENT, WHICHEVER IS EARLIER; PROVIDED THAT TERMS OF

PAYMENT HAVE BEEN FULLY MET.

This warranty is valid only if the equipment is installed, started and demonstrated under

the supervision of a factory certified installer.

Normal maintenance functions, including lubrication, cleaning or customer abuse are not

covered by this no quibble warranty.

Seller shall be responsible only for repairs or replacements of defective parts performed

by Seller’s authorized service personnel. Authorized service agencies are located in

principal cities throughout the contiguous United States, Alaska and Hawaii. This

warranty is valid in the 50 United States and is void elsewhere unless the product is

purchased through Middleby International with warranty included.

The foregoing warranty is exclusive and in lieu of all other warranties, expressed

or implied. There are no implied warranties of merchantability or of fitness for a

particular purpose.

The foregoing warranty shall be Seller's sole and exclusive obligation and Buyer's sole

and exclusive remedy for any action including breach of contract or negligence. In no

event shall Seller be liable for a sum in excess of the purchase price of the item. Seller

shall not be liable for any prospective or lost profits of Buyer.

Middleby Marshall Inc. • 1400 Toastmaster Drive • Elgin, IL 60120 • (708) 741-3300 • FAX (708) 741-4406

National Service Cooperative 1-800-298-1862

Middleby Corporation Service Hotline 1-800-238-8444

Page 3

This Manual Must Be Kept

For Future Reference

WARNING

POST IN A PROMINENT LOCATION, THE EMERGENCY TELEPHONE NUMBER OF YOUR LOCAL GAS

SUPPLIER AND INSTRUCTIONS TO BE FOLLOWED IN THE EVENT YOU SMELL GAS.

Instructions to be followed in the event the user smells gas shall be obtained by consulting the local gas supplier.

If the smell of gas is detected, immediately call the emergency phone number of your local Gas Company. They

will have personnel and provisions available to correct the problem.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN

THE VICINITY OF THIS OR ANY OTHER APPLIANCE

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or

death. Read the installation, operating and maintenance

instructions thoroughly before installing

or servicing this equipment.

NOTICE

CONTACT YOUR LOCAL SERVICE COMPANY

TO PERFORM MAINTENANCE AND REPAIRS.

A SERVICE AGENT DIRECTORY IS SUPPLIED IN YOUR

INSTALLATION KIT.

NOTICE

Using any parts other than genuine

Middleby Marshall factory

manufactured parts relieves the manufacturer

of all warranty and liability.

NOTICE

Middleby Marshall (Manufacturer) reserves the right to

change specifications at any time.

WARNING

The equipment warranty is not valid unless the oven is installed, started and demonstrated under the supervision

of a factory certified installer.

Page 4

SECTION 1 - DESCRIPTION

I. MODEL IDENTIFICATION ................................................................................................. 1

OVEN SPECIFICATION CHART .......................................................................................... 2

ELECTRICAL SPECIFICATION CHART............................................................................... 3

II. PRINCIPLE OF AIR FLOW ............................................................................................... 4

A. Heat Transfer And How It Works ............................................................................... 4

B. Air Fingers ................................................................................................................. 5

III. COMPONENT FUNCTION............................................................................................... 7

A. Conveyor ................................................................................................................... 7

B. Fan .................................................................................................................... 7

C. Gas Burner(Gas Oven Only) ..................................................................................... 7

D. Electric Heaters (Electric Ovens Only) ...................................................................... 7

E. Front Window............................................................................................................. 7

F. Cooling Fan................................................................................................................ 7

G. Air Fingers ................................................................................................................. 8

SECTION 2 - INSTALLATION

I. UNLOADING ....................................................................................................................9

INSTALLATION KITS..................................................................................................... 10-12

DIMENSION DRAWING OF OVEN..................................................................................... 13

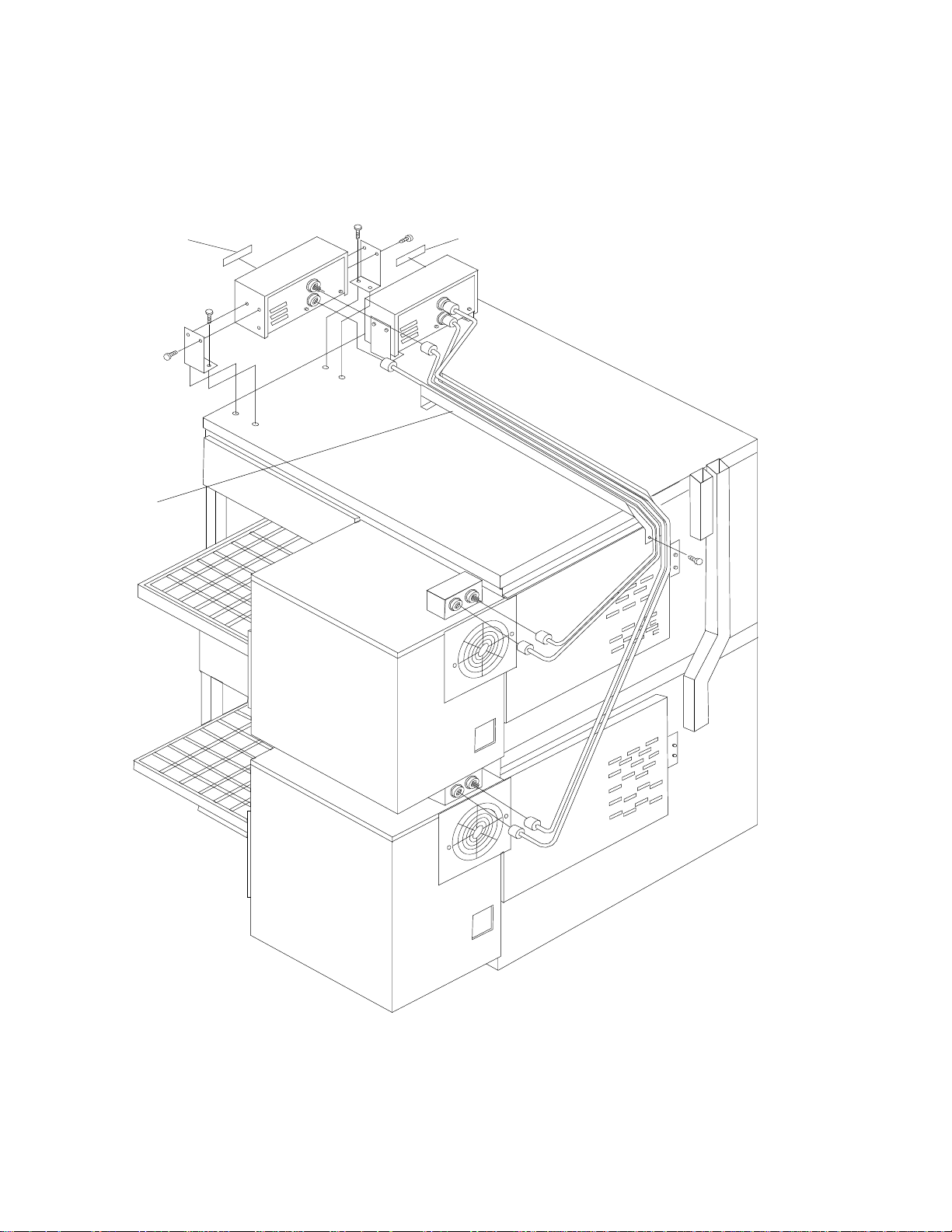

II. CONTROL BOX AND CABLE INSTALLATION............................................................... 14

III. FLUE VENT INSTALLATION ......................................................................................... 15

IV. RESTRAINT CABLE INSTALLATION............................................................................ 15

GAS OVEN ROUGH-IN....................................................................................................... 16

ELECTRIC OVEN ROUGH-IN ............................................................................................ 17

V. VENTILATION GUIDELINES.......................................................................................... 18

VI. ELECTRIC SUPPLY FOR GAS HEATED OVENS ........................................................ 19

VII. ELECTRICAL CONNECTION INFORMATION FOR ALL OVENS ............................... 19

VIII. ELECTRIC SUPPLY FOR ELECTRICALLY HEATED OVENS ................................... 20

IX. GAS SUPPLY FOR GAS HEATED OVENS .................................................................. 21

X. CONVEYOR BACKSTOP AND END STOP INSTALLATION......................................... 23

TABLE OF CONTENTS

Page

SECTION 3 - OPERATION

I. CONTROLS AND COMPONENTS .................................................................................. 25

II. COMPONENT INFORMATION AND LOCATION ........................................................... 26

A. Door Safety Switch .................................................................................................. 26

B. Blower Fan............................................................................................................... 26

C. Heat (Gas ovens only) ............................................................................................. 26

D. Temperature Controller............................................................................................ 26

E. Heat (Electrically heated ovens only)....................................................................... 26

F. Conveyor.................................................................................................................. 27

III. OPERATION ..................................................................................................................28

A. Start Up Procedures — Gas Heated Ovens ............................................................ 28

B. Temperature Controller Operation Instructions........................................................ 30

C. Start Up Procedures — Electric Ovens ................................................................... 32

D. Shut Down (Gas or Electric Ovens)......................................................................... 33

E. Conveyor Speed (Bake Time) And Time Of Delivery............................................... 33

Page 5

SECTION 4 - MAINTENANCE

I. MAINTENANCE - DAILY.................................................................................................. 35

A. Exterior .................................................................................................................. 35

B. Cooling Fan ............................................................................................................. 35

C. Crumb Pans............................................................................................................. 36

II. MAINTENANCE - WEEKLY ............................................................................................ 36

A. Removing Conveyor From Oven For Cleaning ........................................................ 36

B. Oven Interior Disassembly....................................................................................... 38

C. Window Disassembly For Cleaning ......................................................................... 39

D. Loading The Soak Bin ............................................................................................. 39

E. Cleaning Parts That Were Soaked Overnight .......................................................... 41

F. Cleaning Interior of Oven ......................................................................................... 43

G. Oven Reassembly ................................................................................................... 44

III. MAINTENANCE - EVERY 3 MONTHS........................................................................... 50

A. Cleaning Fan Motor ................................................................................................. 50

B. Electrical Terminals ................................................................................................. 50

C. Checking and/or Replacing Main Blower Fan Belt................................................... 51

D. Main Blower Fan Shaft Bearing Lubrication............................................................. 52

IV. MAINTENANCE - EVERY 6 MONTHS .......................................................................... 53

SECTION 5 - TROUBLESHOOTING

OWNERS TROUBLESHOOTING CHARTS........................................................................ 55

TABLE OF CONTENTS

Continued

SECTION 6 - PARTS LIST

Oven Panels, Window and Legs Exploded Drawing ........................................................... 60

Air Finger Exploded Drawing............................................................................................... 62

Control Panel Exploded Drawing......................................................................................... 64

Blower and Shroud Exploded Drawing................................................................................ 66

Conveyor Exploded Drawing ............................................................................................... 68

Gas Burner and Piping Assembly Exploded Drawing.......................................................... 70

Machinery Compartment Exploded Drawing ....................................................................... 72

Electric Oven Electrical Panel Drawing ............................................................................... 74

Junction Box and Export Transformer Exploded Drawing ................................................... 76

SECTION 7 - ELECTRICAL SCHEMATICS

Gas Oven Schematic, 208-240V,50/60Hz,1Ph,4W ............................................................. 80

Oven Control Box Cables .................................................................................................... 81

Page 6

NOTES

Page 7

SECTION 1

DESCRIPTION

SECTION 1

DESCRIPTION

I. MODEL IDENTIFICATION

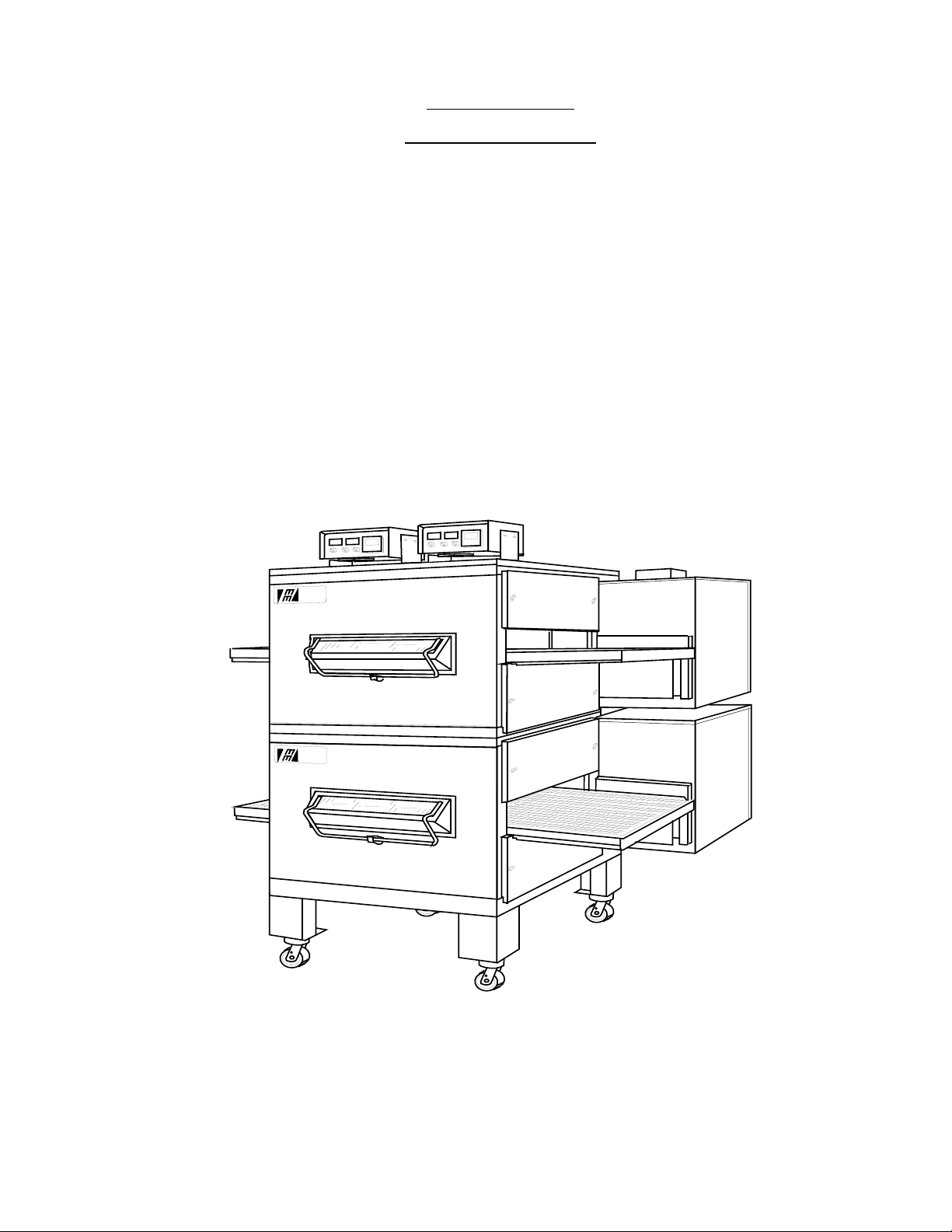

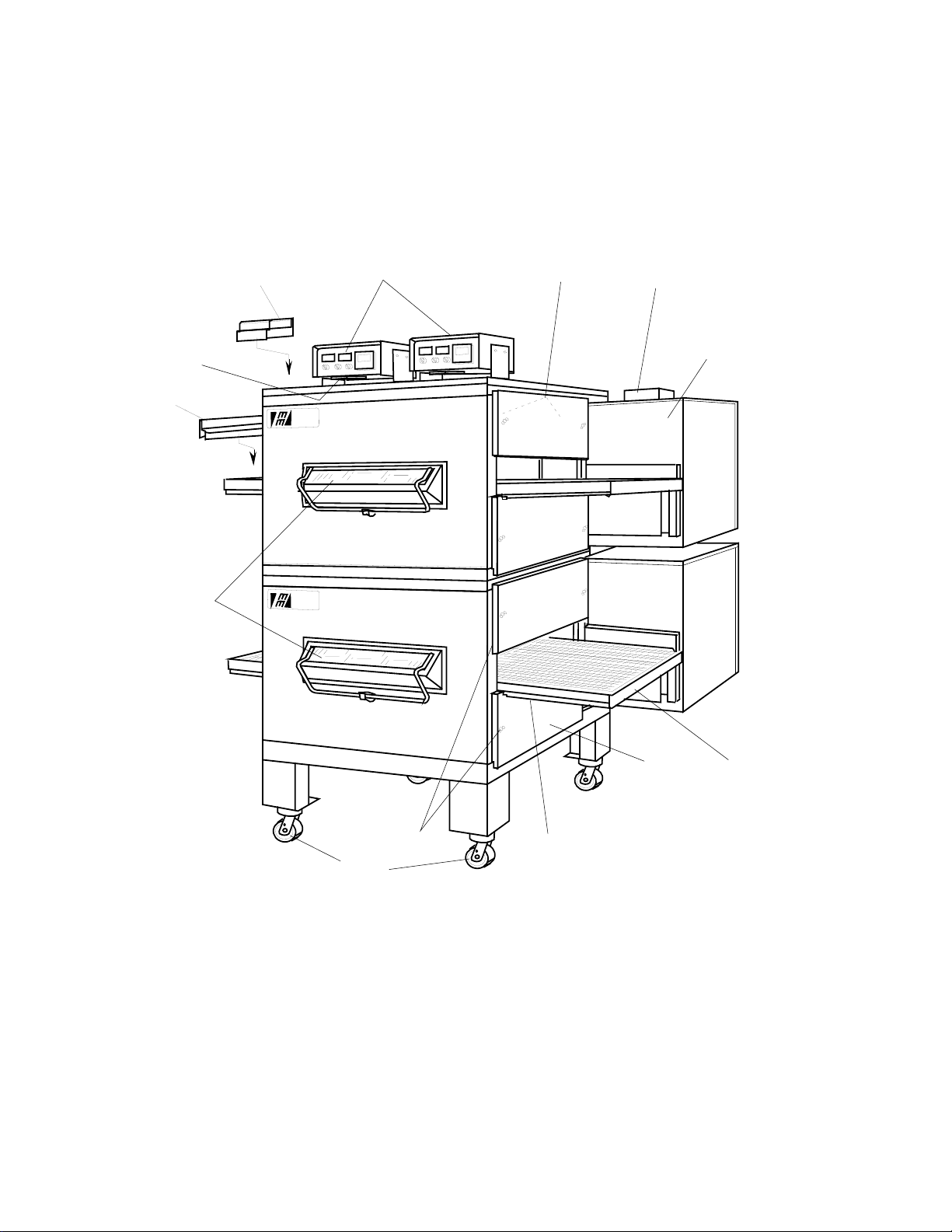

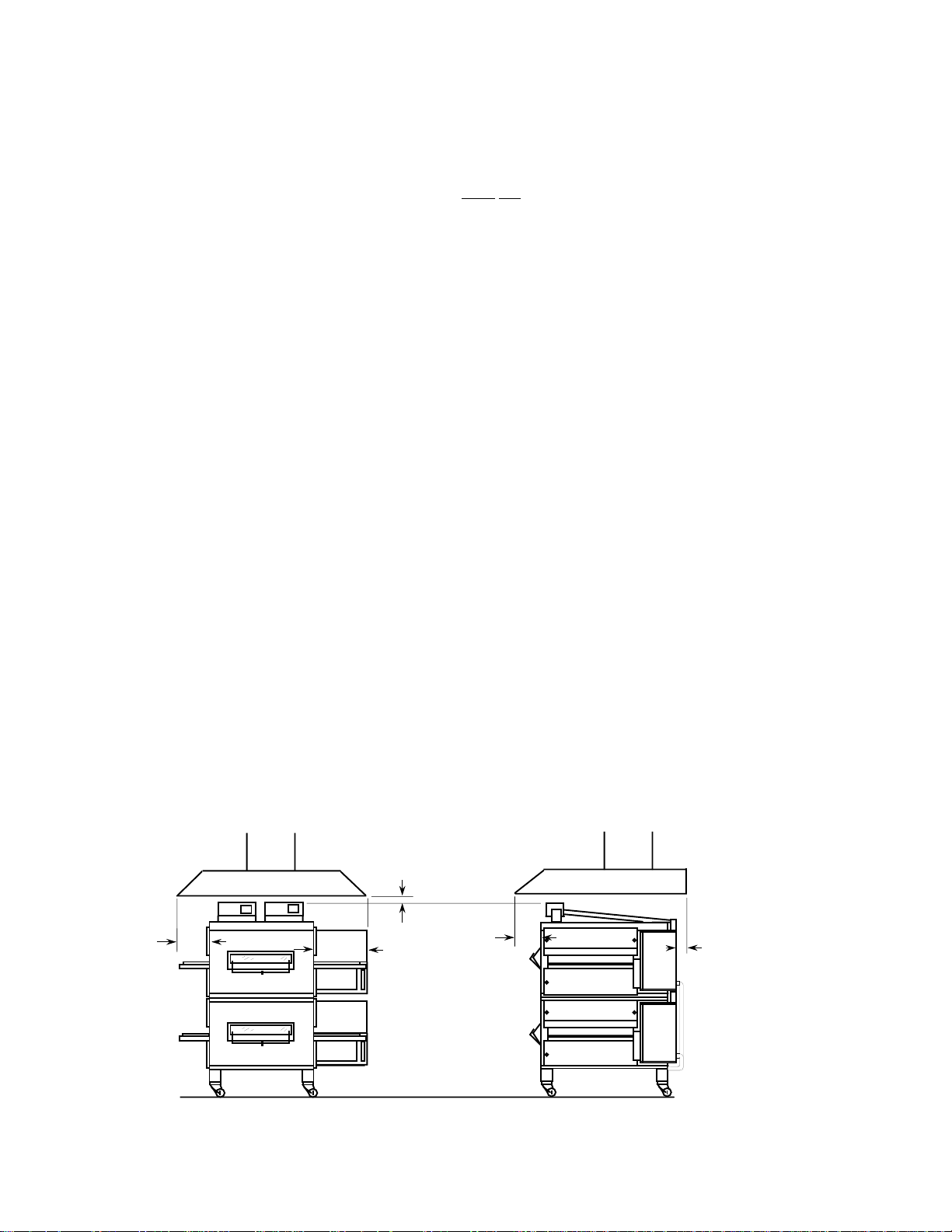

The Middleby™ Series PS200-R68 Ovens may be used

singly or stacked for use as double ovens.

The Series PS200-R68 single oven is mounted on a base

pad with 6" extension legs and casters. A double oven is

stacked and the lower oven is on a base pad with casters.

Middleby

Marshall

The ovens in a double oven operate completely independent of one another. Both ovens use identical controls

and components. One can be serviced while the other is

operating.

The Series PS200-R68 Ovens can be ordered with the

conveyor drive at either the right end or left end of the

oven. Each oven is equipped with a remote control box.

Middleby

Marshall

Figure 1-1. Middleby™ Series PS200-R68 Ovens

1

Page 8

PS200-R68 GAS PS200-R68 ELECTRIC PS224-R68 GAS PS224-R68 ELECTRIC PS220-R68 GAS PS220-R68 ELECTRIC

Conveyor Belt Width 32"(813mm) 32"(813mm) 24"(610mm) 24"(610mm) 20"(508mm) 20"(508mm)

Heating Zone Length 40-1/2"(1028mm) 40-1/2"(1028mm) 40-1/2"(1028mm) 40-1/2"(1028mm) 40-1/2"(1028mm) 40-1/2"(1028mm)

Baking Area Square Feet 9 sq.ft.(0.84sq.m.) 9 sq.ft.(0.84sq.m.) 6.4 sq.ft.(0.59sq.m.) 6.4 sq.ft.(0.59sq.m.) 5.5 sq.ft.(0.51sq.m.) 5.5 sq.ft.(0.51sq.m.)

Overall Dimension 68"(1727mm) L x 68"(1727mm) L x 68"(1727mm) L x 68"(1727mm) L x 68"(1727mm) L x 68"(1727mm) L x

Red Lobster Double Oven 57-3/4"(1467mm) W x 57-3/4"(1467mm) W x 49-3/4"(1264mm) W x 49-3/4"(1264mm) W x 45-3/4"(1162mm) W x 45-3/4"(1162mm) W x

Weight of Single Oven 925 lbs.(419kg) 925 lbs.(419kg) 825 lbs.(374kg) 825 lbs.(374kg) 750 lbs.(340kg) 750 lbs.(340kg)

Shipping Weight of Single Oven 1,100 lbs.(498.3kg) 1,100 lbs.(498.3kg) 1,000 lbs.(453kg) 1,000 lbs.(453kg) 925 lbs.(419kg) 925 lbs.(419kg)

Shipping Cube of Single Oven Approx.132 ft3(3.74 m3) Approx.132 ft3(3.74 m3) Approx.132 ft3(3.74 m3) Approx.132 ft3(3.74 m3) Approx.132 ft3(3.74 m3) Approx.132 ft3(3.74 m3)

Operating Range of Single Oven 120,000 BTU/HR 28kW/HR 100,000 BTU/HR 28kW/HR 100,000 BTU/HR 28kW/HR

Maximum Operating Temperature 550°F(287°C) 550°F(287°C) 550°F(287°C) 550°F(287°C) 550°F(287°C) 550°F(287°C)

Exhaust Vent Size 2" x 3"(50 x 75mm) -- 2" x 3"(50 x 75mm) -- 2" x 3"(50 x 75mm) -Exhaust Flow 80 C.F.M.(2.1m3m) -- 80 C.F.M.(2.1m3m) -- 80 C.F.M.(2.1m3m) -Warm Up Time 10 min. 15 min. 10 min. 15 min. 10 min. 15 min.

Gas Inlet Line Size 3/4"(19mm)ID for each cavity

Minimum Gas Meter Rating 450 cu.ft./hr.(12.74m3h) for 1 to 2 cavities

2

Minimum Gas Pipe Size: Natural 2" (51mm)ID for 1 or 2 ovens or

Propane 1.5" (38mm)ID for 1 to 2 ovens or

Gas Pressure: Natural 6"(152mm) to 14"(356mm) Water Column

Propane 11.5"(292mm) to 14"(356mm) Water Column

Gas Valves 0.75" (19mm)ID full flow gas shut-off valve.

Recirculating Air Blower One blower at 1700 RPM

Jet Air Velocity 3000 F.P.M.(1524cm/sec.)(Average)

Bake Time 2 min. 40 sec. Bake Time minimum

76-3/4"(1949mm) H 76-3/4"(1949mm) H 76-3/4"(1949mm) H 76-3/4"(1949mm) H 76-3/4"(1949mm) H 76-3/4"(1949mm) H

(30,240 kcal) (25,200 kcal) (25,200 kcal)

(35.1 kW/HR) (29.3 kW/HR) (29.3 kW/HR)

Add 180 cu.ft./hr.(5.1m3h)for each additional cavity

2.5" (64mm)ID for 3 or 4 ovens

2"(51mm)ID for 3 or 4 ovens -

(must be dedicated line)

A separate connection and valve must be provided for each cavity.

29 min. 50 sec. Bake Time maximum

SECTION 1

DESCRIPTION

PS200-R68 SERIES OVEN SPECIFICATIONS

Page 9

SERIES PS200-R68

ELECTRICAL SPECIFICATIONS

GAS HEATED OVENS

Main Blower Control Phase Frequency Amperage Poles Wires

& Elements Circuit Draw

Voltage Voltage

208-240V 120V 1 Ph 50/60 Hz 4.1 Amp 3 Pole 4 Wire

(2 hot,1 neut,1 grd)

208V 120V 1 Ph 50/60 Hz 4.1 Amp 2 Pole 3 Wire

Export Transformer (2 hot,1 grd)

200V 120V 1 Ph 50/60 Hz 4.1 Amp 2 Pole 3 Wire

Export Transformer (2 hot,1 grd)

220-240V 120V 1 Ph 50/60 Hz 4.1 Amp 2 Pole 3 Wire

Export Transformer (2 hot,1 grd)

ELECTRIC HEATED OVENS

Main Blower Control Phase Frequency Amperage Poles Wires

& Elements Circuit Draw

Voltage Voltage

208-240V 120V 3 Ph 50/60 Hz 75 Amp 4 Pole 5 Wire

(3 hot, 1 neut, 1 grd)

HEATER AMPERAGE

Voltage kW Amp Average Amps

208 27 70 37 37 37

220 23.5 67 30 30 30

230 25.7 63 31 31 31

240 27 61 33 33 33

220-240V 120V 3 Ph 50/60 Hz 75 Amp 3 Pole 4 Wire

Transformer (3 hot, 1 grd)

HEATER AMPERAGE

Voltage kW Amp Average Amps

220 23.5 67 30 30 30

240 27 61 33 33 33

380V 120V 3 Ph 50/60 Hz 50 Amp 4 Pole 5 Wire

Export Transformer (3 hot, 1 neut, 1 grd)

HEATER AMPERAGE

Voltage kW Amp Average Amps

380 27 38 22 22 22

400-416V 120V 3 Ph 50/60 Hz 50 Amp 4 Pole 5 Wire

Export Transformer (3 hot, 1 neut, 1 grd)

HEATER AMPERAGE

Voltage kW Amp Average Amps

415 27 35 28 28 28

SECTION 1

DESCRIPTION

NOTE

Wiring Diagram is contained at the back of this Manual

and is also located inside of the

machinery compartment.

.

3

Page 10

SECTION 1

DESCRIPTION

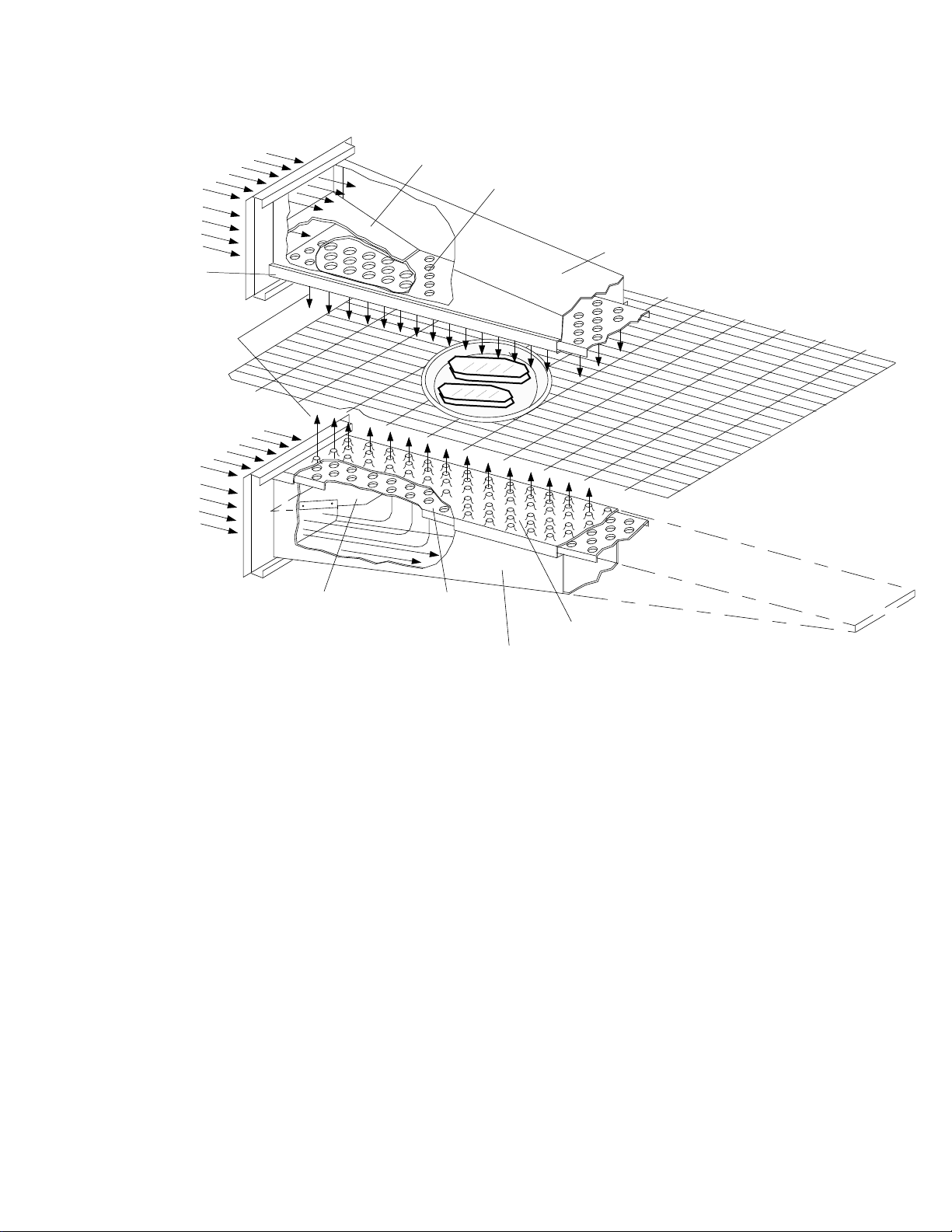

II. PRINCIPLE OF AIR FLOW

Air is heated and then pulled through the fan which

pushes the air into the oven plenum and delivers heated

air into the air fingers. The fingers contain an inner plate

and outer plate which columnate the air and evenly

distribute heated air across the conveyor belt on which

the product rides. Air is then pulled back into the blower

and the process continues.

A. Heat Transfer and How It Works

1. Heat constantly moves from a warm object to a cold

object. Heat moves using three different paths which are

conduction, radiation and convection.

Conduction:

tact. The pizza dough in contact with the pan is a good

example of conduction.

Radiation:

heat. Dark objects absorb heat whereas light or shiny

objects reflect more heat. This is the reason that the

This path utilizes surface to surface con-

This path has to do with objects radiating

inside of the Middleby Series PS200-R68 Oven is light in

color to reflect more heat back to the product.

Convection:

of air. It explains why hot air will rise and cooler air

replaces hot air. An industrial application of this principle

is to incorporate a fan to force the hot air movement which

in turn will increase the heat transfer to the product.

The Middleby Series PS200-R68 Oven has a large fan to

move the hot air through the air fingers and onto the

product so the most efficient bake is achieved.

2. Temperature is the intensity of heat at the point which

it is sensed. As discussed above, heat flows by conduction, radiation and convection. The speed at which the

heat flows is determined by the temperature difference

between the oven and the food product. The larger the

difference the faster the heat flows to the item that is

being baked.

This path has to do with moving amounts

Side View

Figure 1-2

Series PS200-R68 Air Flow

4

Page 11

II. PRINCIPLE OF AIR FLOW Continued

SECTION 1

DESCRIPTION

Air Flow From

Plenum Chamber

Outer Plate

High Velocity

Columns of Air to

Product

Air Flow From

Plenum Chamber

Manifold Baffle

Inner Plate

Manifold

Manifold Baffle

Inner Plate

Figure 1-3. Air Fingers Showing Air Passing Through Inner Plate And Outer Plate

Which Forms High Velocity Columns Of Air To The Product.

B. Air Fingers

The Middleby Series PS200-R68 Oven is a conveyorized

hot air oven employing vertical air streams (Figure1-3) to

give uniform and intensive heating. The columnated

vertical streams of hot air provide an exceptional heat

transfer rate and generally bake faster and at lower

temperatures than convection hot air or infrared heating

ovens.

Outer Plate

Manifold

This is accomplished with use of hot air fingers inside the

oven. The oven can accommodate up to 4 bottom air

fingers and 4 top air fingers. Standard PS200-R68 Series

ovens have 4 bottom fingers and 2 top fingers.

5

Page 12

SECTION 1

DESCRIPTION

Cooling

Fan

Conveyor

End Stop

Conveyor

Rear Stop

Middleby

Marshall

Control

Boxes

Removable

Jet Fingers

(Inside

Oven)

Machinery

Compartment

Conveyor

Motor

Front

Window

Middleby

Marshall

Removable End Plugs

Locking

Casters

(Rear Casters

are not locking

casters)

Figure 1-4. Component Location

Removable

Crumb Pans

Removable

Drip Pans

(Inside Oven)

Removable

Conveyor

6

Page 13

SECTION 1

DESCRIPTION

III. COMPONENT FUNCTION

A. Conveyor

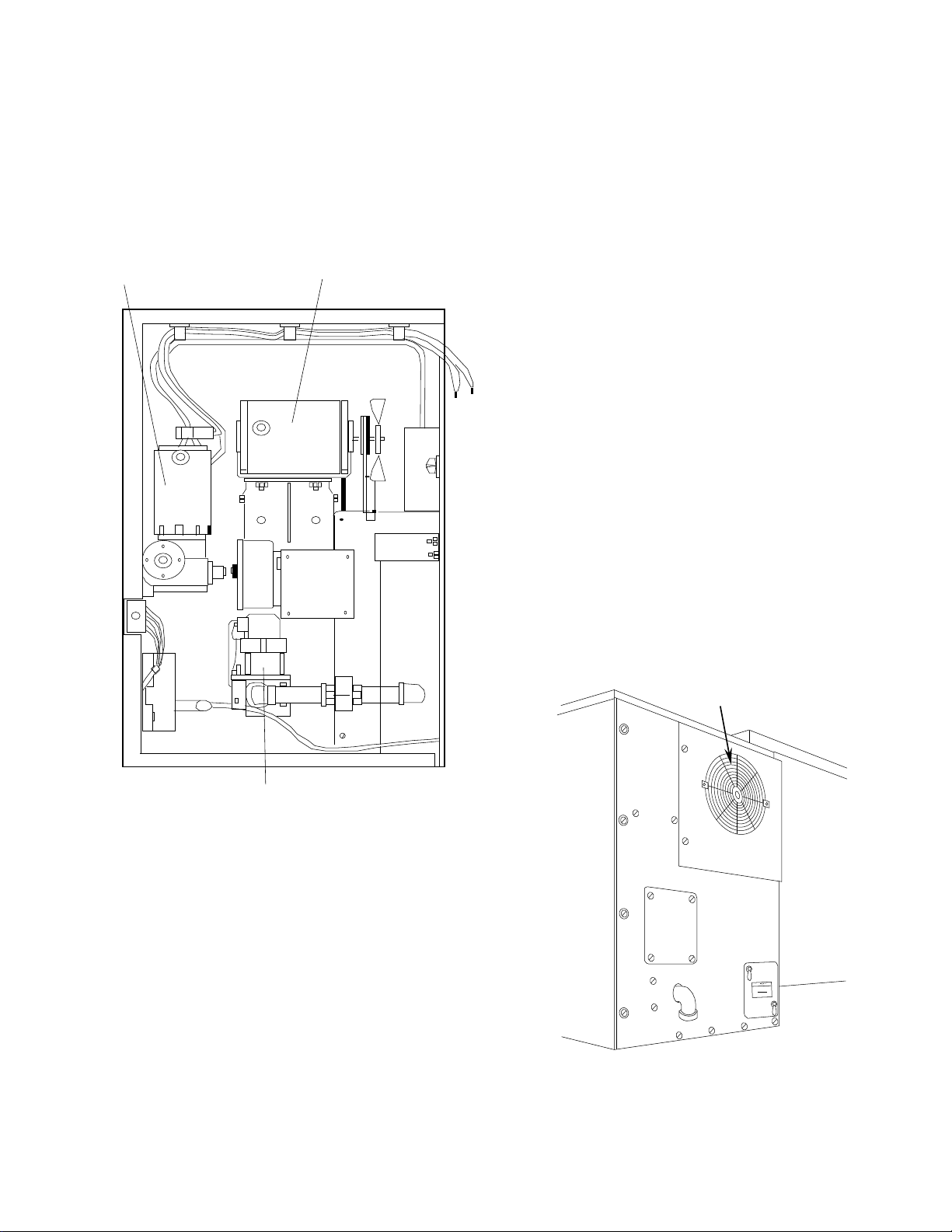

The conveyor is driven by a variable speed electric motor

operating through a gear reducer (See Figure 1-5). The

motor speed is controlled by a digital control. The stainless steel wire belt can travel in either direction and at

variable speeds from 3 minutes to 23 minutes.

Conveyor

Drive Motor

Fan

Motor

Should a flame outage occur the control will close the

main gas control valve within 0.8 seconds and attempt to

reignite the pilot.

D. Electric Heaters (Electric Oven Only)

There are six heater elements mounted on the inside of

the rear panel. Each element is connected to a separate

electrical contact which is energized by the temperature

controller.

E. Front Window

The front window is used for viewing items being baked

and provides access to the oven for items which do not

require full bake time, such as sandwiches, cookies,

small items or cheese melting processes.

F. Cooling Fan

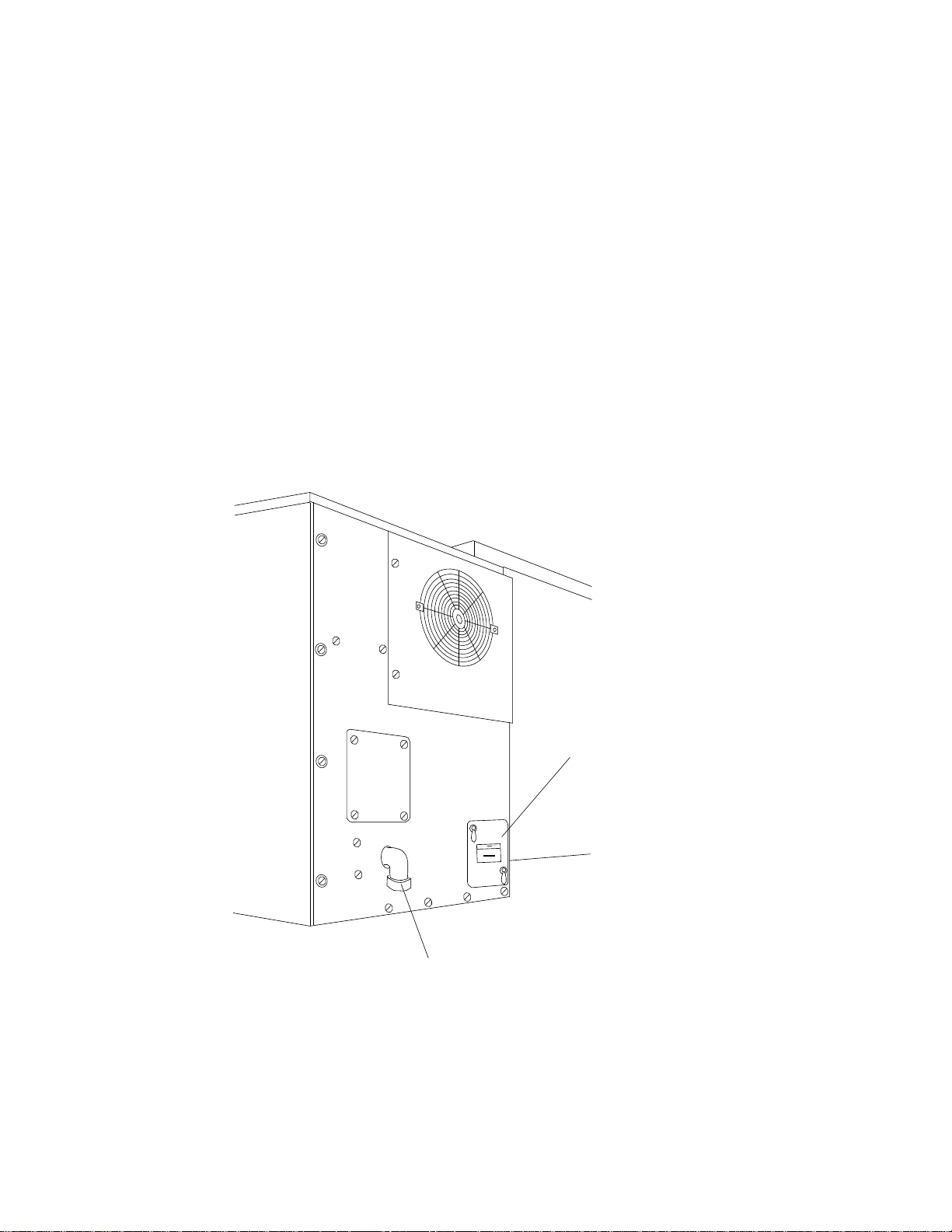

A cooling fan is located in the back of the oven. This

cooling fan blows cool air in through the machinery

compartment across the fan motor and conveyor motor

and control cabinet. The air is then exhausted through

the side of the cabinet and also out the back of the oven

compartment. Refer to Figure 1-6.

Main Gas

Control Valve

Figure 1-5. Conveyor Drive Motor

B. Fan

The fan is located at the rear of the oven. This fan forces

heated air through the fingers. The fan switch has two

positions and must be "on" for oven warm up and bake

and for the conveyor to run.

Another cooling fan is located in the bottom of each

control box. Air is drawn in through the louvers in the rear

of the control box and out through the fan. Refer to Figure

1-4.

C. Gas Burner (Gas Oven Only)

With the heat and blower switches ON the gas burner

heats the air as the air enters the main blowers to

maintain the set temperature. The burner flame is ignited

and monitored by a solid state burner control device.

Figure 1-6. Cooling Fan

7

Page 14

SECTION 1

DESCRIPTION

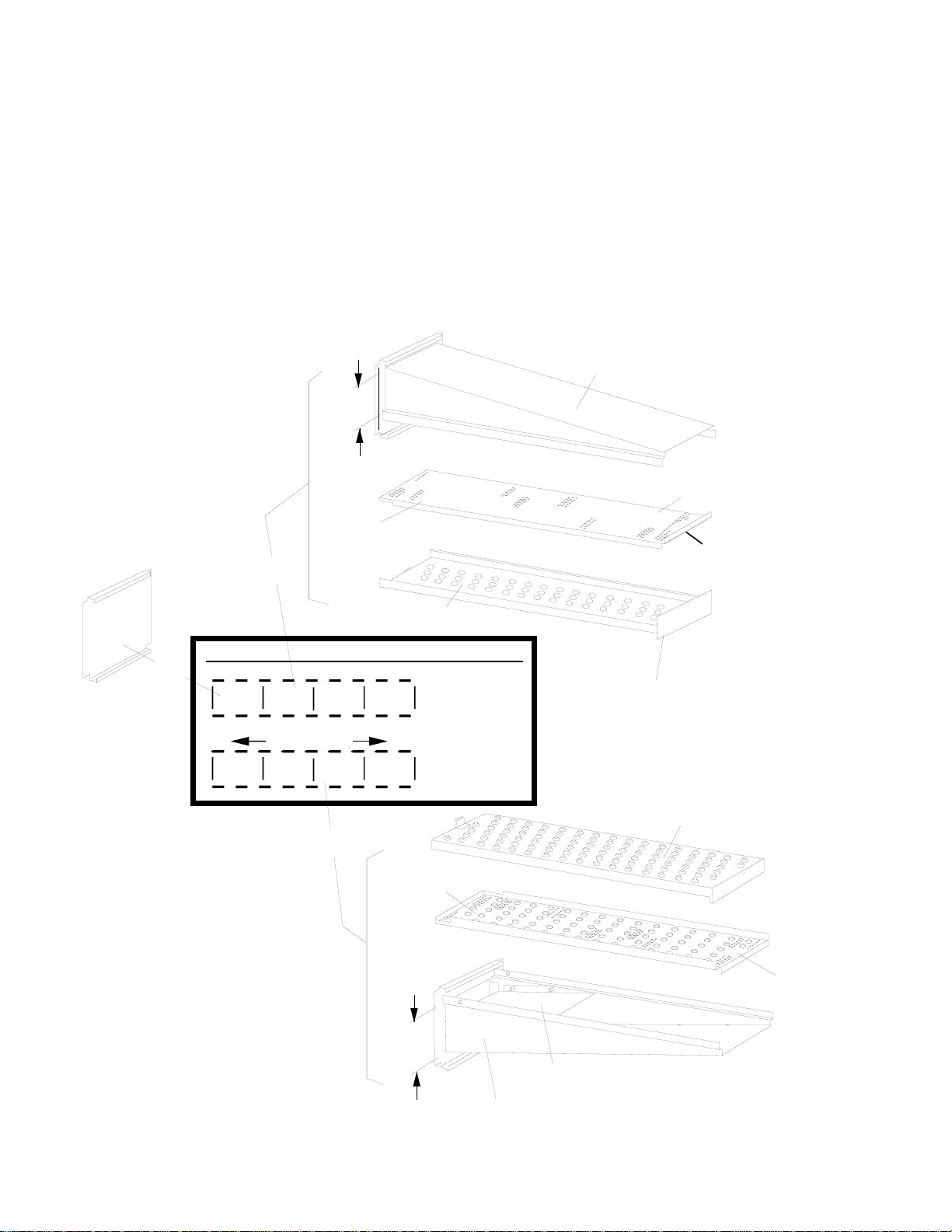

G. Air Fingers

The Air Finger Assemblies are made up of three parts as

follows (See Figure 1-7):

1. Outer Plate - The Outer Plate is the removable cover

with tapered holes, which directs the air stream onto the

product to be baked.

2. Inner Plate -The Inner Plate is vital to forming the

manifold with its holes lined up with outer plate holes.

The inner plate is also manufactured with no rows of

holes. This type of finger is a non-columnating air finger.

3. Manifold - The Manifold is the assembly which slides

on tracks into the oven plenum.

4. Blank Plates- The Blank Plates are installed on the

plenum where air fingers are not required.

columnated air jets. It must be assembled onto the

NOTE: On a PS200-R68 Series Red Lobster oven the 2 upper fingers (M3) have 3 rows of holes in the outer plate

and a non-columnating inner plate. The 4 bottom fingers (M6) have 6 rows of holes completely across the inner and

outer plates.

Manifold

4-1/32" Rear

Opening

No Large Holes,

Perforated Only

UPPER

Inner

Plate

M3RN

Finger

Outer Plate with

3 Rows of Holes

Stamped "UPPER"

UPPER

Full

Blank

RED LOBSTER FINGER CONFIGURATION IN OVEN

FB M3RNFBM3RN

Product Direction (Either Direction)

M6

M6

M6

M6

Finger

M6

5-5/32" Rear

Opening

Upper Fingers

Lower Fingers

Large Holes &

Perforated

Raised Front

(Stamped "UPPER")

Outer Plate

with 6 Rows

of Holes

Inner

Plate

Baffle

Manifold

Figure 1-7. Fingers

8

Page 15

SECTION 2

INSTALLATION

SECTION 2

INSTALLATION

NOTE: For U.S. installations the installation must conform with local codes or in absence of local codes, with

ANSI Z223.1-latest edition and electrical code ANSI/NFPA No. 70-latest edition.

NOTE: For Canadian Installations - The installation should be done in accordance with the CAN 1-B149.1 or .2

installation code and/or local code and the Canadian electrical code, Part 1, CGA C22.1 for the electrical features.

I. UNLOADING

Your Middleby Marshall Series PS200-R68 Oven(s)

is shipped partially assembled and it will arrive in a

carton.

Carton size for all Series 200-R68 Ovens is:

84"(2134mm) Long x

58" (1473mm) Wide x

44" (1118mm) High.

A Pre-installation Procedures Manual (MM P/N

88910-0009) is attached to the exterior wall of the

carton. This manual contains detailed instructions on

unpacking and moving the oven(s) into your facility.

When your common carrier or truck line notifies you

of delivery, you must have a forklift at the facility to

unload the carton(s).

Instructions for stacking the ovens are contained in

a separate manual issued to Middleby Marshall

Certified Installers.

If you have a door wider than the carton simply move

the carton into your facility and set up an appointment

with your Certified Middleby Marshall Installer.

If your door is narrower than the carton, then the oven

will have to be uncrated. Follow directions shown in

the Pre-Installation Procedures Manual.

Each crate must be examined before signing the Bill

of Lading. Report any visible damage caused by the

trucker in transit, and check for the proper number of

crates. If apparent damage is found, arrangements

should be made to file a claim against the carrier.

Interstate Commerce Regulations require that the

claim must be initiated by the consignee within 10

days from the date it is received.

NOTE

There Must Be Adequate Clearance Between

Oven And Combustible Construction.

Clearance Must Also Be Provided For

Servicing And For Operation.

CAUTION: It is required that the oven be placed under a ventila-

tion hood for adequate air supply and ventilation.

CAUTION: A minimum clearance of 0" from non-drive end of

oven to wall, 18" from drive end of oven to wall and 6" from

rear wall to air openings at rear of unit must be maintained.

For servicing and cleaning a minimum of 18" clearance from

all walls and combustible materials is recommended.

CAUTION: Do not obstruct the flow of combustion and ventila-

tion air to and from your oven. Do not obstruct the ventilation

holes in the control panel, as these provide the combustion

air for the burner.

9

Page 16

SECTION 2

INSTALLATION

PS200-R68 OVEN INSTALLATION

REQUIRED KITS AND EQUIPMENT

KITS AND EQUIPMENT

PS200-R68 PS200-R68 PS200-R68 PS200-R68

TYPE

OF

INSTALLATION

PS200-R68 Single Gas Oven 1 1

PS200-R68 Single Electric Oven 1 1

PS200-R68 Double Gas Oven 2 1

PS200-R68 Double Electric Oven 2 1

PS220-R68 Single Gas Oven 1 1

PS220-R68 Single Electric Oven 1 1

PS220-R68 Double Gas Oven 2 1

PS220-R68 Double Electric Oven 2 1

Gas Oven Electric Oven Single Oven Double Oven

Installation Installation Option Kit P/N Option Kit P/N

Kit P/N Kit P/N 49025-0007 31361

31350 31514

PS220-R68 OVEN INSTALLATION

REQUIRED KITS AND EQUIPMENT

KITS AND EQUIPMENT

PS220-R68 PS220-R68 PS220-R68 PS220-R68

Gas Oven Electric Oven Single Oven Double Oven

Installation Installation Option Kit P/N Option Kit P/N

Kit P/N Kit P/N 30752 31363

31352 31517

PS224-R68 OVEN INSTALLATION

REQUIRED KITS AND EQUIPMENT

KITS AND EQUIPMENT

PS224-R68 PS224-R68 PS224-R68 PS224-R68

Gas Oven Electric Oven Single Oven Double Oven

Installation Installation Option Kit P/N Option Kit P/N

Kit P/N Kit P/N 49025-0016 31362

31351 31516

PS224-R68 Single Gas Oven 1 1

PS224-R68 Single Electric Oven 1 1

PS224-R68 Double Gas Oven 2 1

PS224-R68 Double Electric Oven 2 1

10

Page 17

SECTION 2

INSTALLATION

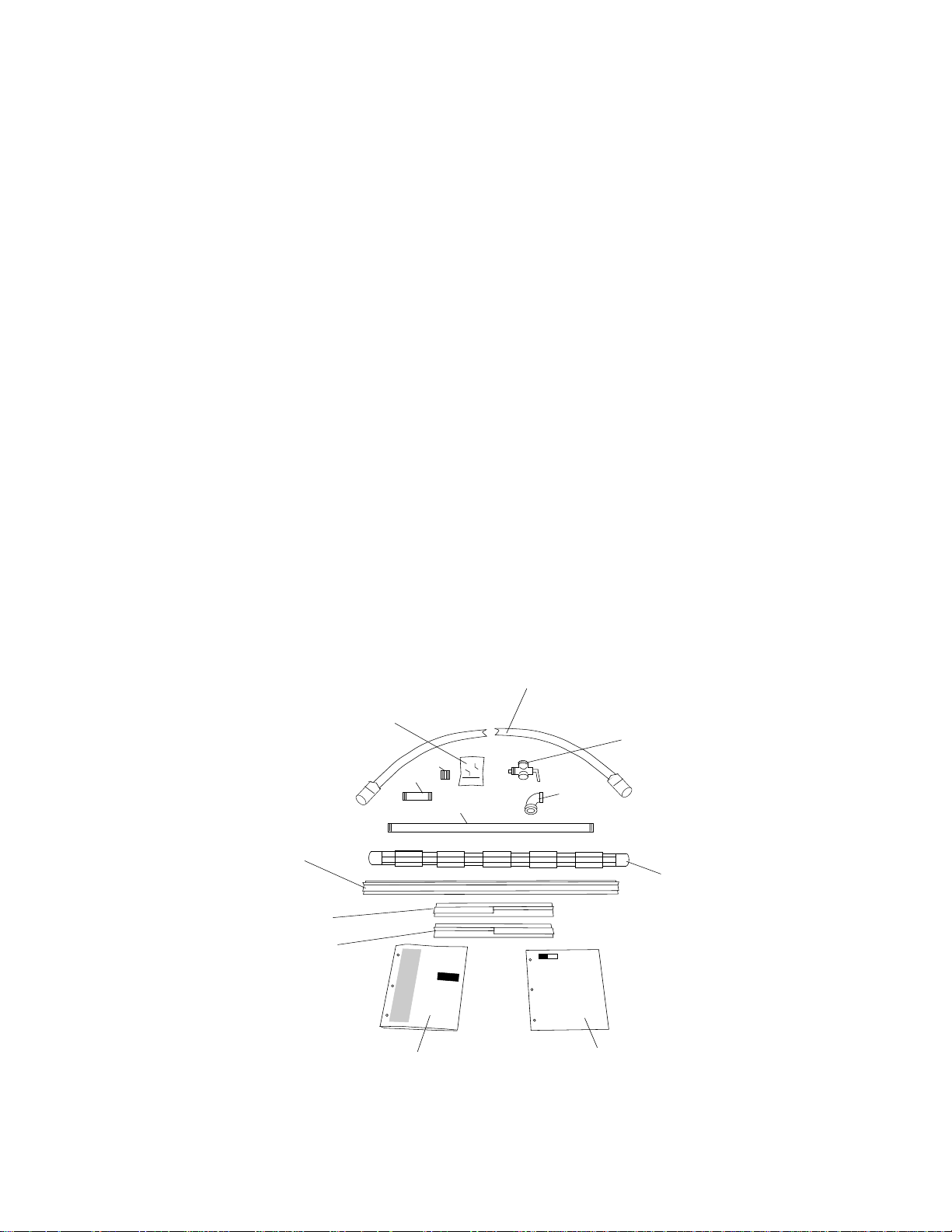

PARTS LIST FOR SERIES PS200-R68 GAS OVEN

INSTALLATION KIT

PS200-R68, P/N 31350

PS220-R68, P/N 31352

PS224-R68, P/N 31351

ITEM QTY PS200-R68 PS220-R68 PS224-R68 DESCRIPTION

NO. PART NO. PART NO. PART NO.

1 1 22361-0005 22361-0005 22361-0005 FLEXIBLE GAS HOSE, 72"

2 1 23115-0010 23115-0010 23115-0010 3/4" GAS SHUTOFF VALVE

3 1 31006 30849 30851 CONVEYOR END STOP

4 1 30830 30830 30830 CONVEYOR LEFT REAR STOP

5 1 30796 30796 30796 CONVEYOR RIGHT REAR STOP

6 1 88910-0008 88910-0008 88910-0008 SERIES PS200-R68 OWNER/OPERATOR MANUAL

7 1 1002040 1002040 1002040 SERVICE STATION DIRECTORY

8 1 33900-0032 33900-0081 33900-0035 CONVEYOR WIRE BELT

9 1 42400-0089 49400-0090 49400-0197 MASTER LINK KIT

10 1 23125-0002 23125-0002 23125-0002 ELBOW 90° BLK REDUCER 1/2" X 3/4"

11 1 23153-0005 23153-0005 23153-0005 NIPPLE BLK 3/4 CLOSE

12 1 31315 31315 31315 PIPE, 31", UPPER OVEN

13 1 31238 31238 31238 NIPPLE BLK 1/2" X 4"

PARTS LIST FOR SERIES PS200-R68 ELECTRIC OVEN

ITEM QTY PS200-R68 PS220-R68 PS224-R68 DESCRIPTION

NO. PART NO. PART NO. PART NO.

3 1 31006 30849 30851 CONVEYOR END STOP

4 1 30830 30830 30830 CONVEYOR LEFT REAR STOP

5 1 30796 30796 30796 CONVEYOR RIGHT REAR STOP

6 1 88910-0008 88910-0008 88910-0008 SERIES PS200-R68 OWNER/OPERATOR MANUAL

7 1 1002040 1002040 1002040 SERVICE STATION DIRECTORY

8 1 33900-0032 33900-0081 33900-0035 CONVEYOR WIRE BELT

9 1 42400-0089 49400-0090 49400-0197 MASTER LINK KIT

(Two required for double oven)

INSTALLATION KIT

PS200-R68, P/N 31514

PS220-R68, P/N 31517

PS224-R68, P/N 31516

(Two required for double oven)

1

9

2

11

13

10

12

3

8

4

5

Owners

Operating

Manual

6

7

Figure 2-1.

Series PS200-R68 Gas & Electric Oven

Installation Kits

11

Page 18

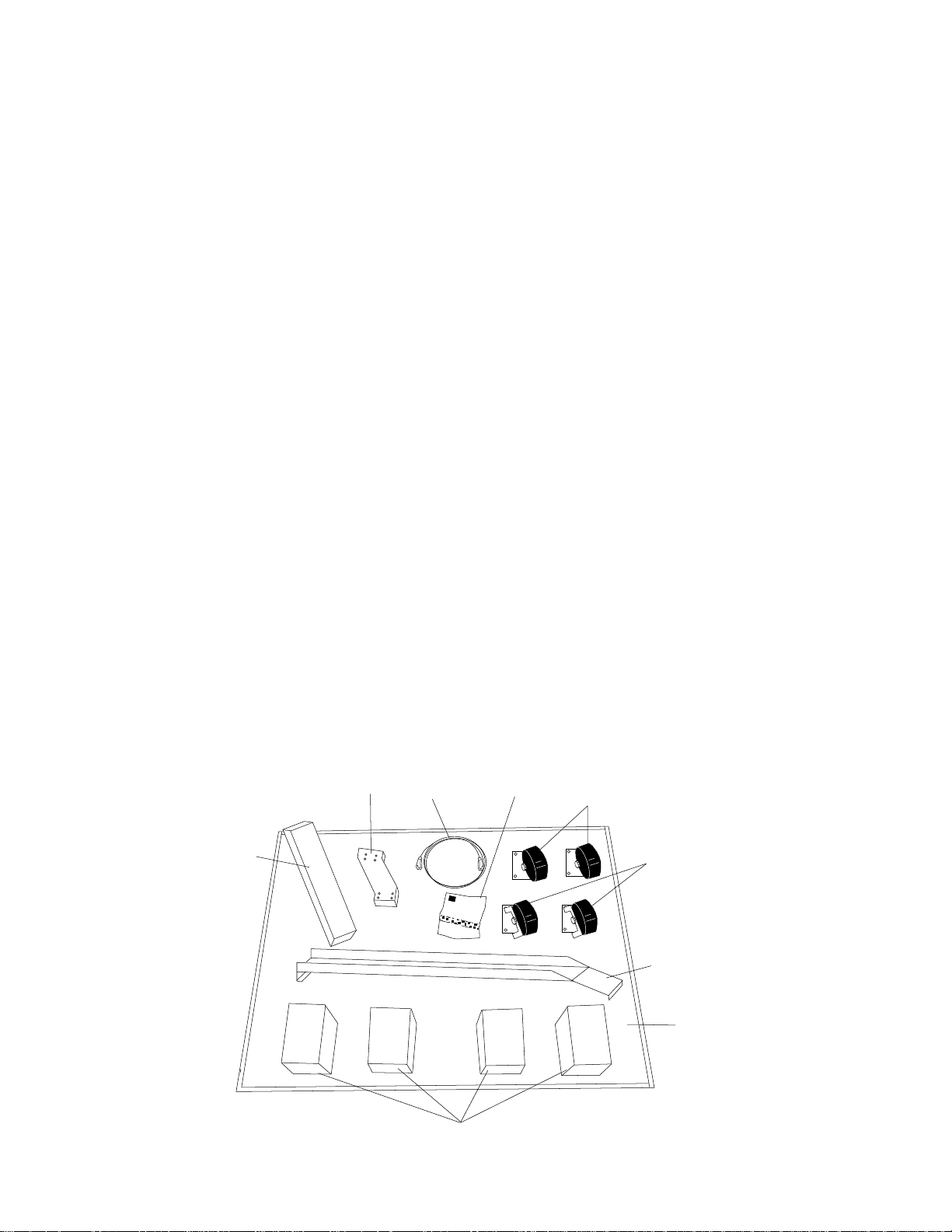

SECTION 2

INSTALLATION

ITEM QTY PS200-R68 PS220-R68 PS224-R68 DESCRIPTION

NO. PART NO. PART NO. PART NO.

1 1 35900-0055 37900-0184 35900-0411 BASE PAD

2 4 37900-0102 37900-0102 37900-0102 LEGS

3 2 22290-0009 22290-0009 22290-0009 SWIVEL CASTER W/LOCKING BRAKE

4 2 22290-0010 22290-0010 22290-0010 SWIVEL CASTER

5 32 A11039 A11039 A11039 3/8" LOCKWASHER

6 32 21416-0001 21416-0001 21416-0001 3/8" FLAT WASHER

7 32 220373 220373 220373 3/8 - 16 SCREW HEX HD SS

8 4 21256-0008 21256-0008 21256-0008 SCREWS FOR TOP 10-32 X 3/8" RH

9 32 21296-0005 21296-0005 21296-0005 10-32 X 3/4" SCREW HEX WASHER HD SS

10 1 22450-0228 22450-0228 22450-0228 RESTRAINT CABLE ASSEMBLY

13 1 31319 31319 31319 LABEL, UPPER

14 1 31320 31320 31320 LABEL, LOWER

15 1 32116 32116 32116 WIREWAY ASSEMBLY

16 2 21516-0001 21516-0001 21516-0001 POP RIVETS

17 1 32227 32227 32227 INSTRUCTION, CONTROL BOX INSTALLATION

Not shown 1 32023 31261 30878 OVEN TOP

ITEM QTY PS200-R68 PS220-R68 PS224-R68 DESCRIPTION

NO. PART NO. PART NO. PART NO.

1 1 35900-0055 37900-0184 35900-0411 BASE PAD

2 4 37900-0102 37900-0102 37900-0102 LEGS

3 2 22290-0009 22290-0009 22290-0009 SWIVEL CASTER W/LOCKING BRAKE

4 2 22290-0010 22290-0010 22290-0010 SWIVEL CASTER

5 32 A11039 A11039 A11039 3/8" LOCKWASHER

6 32 21416-0001 21416-0001 21416-0001 3/8" FLAT WASHER

7 32 220373 220373 220373 3/8 - 16 SCREW HEX HD SS

8 4 21256-0008 21256-0008 21256-0008 SCREWS FOR TOP 10-32 X 3/8" RH

9 32 21296-0005 21296-0005 21296-0005 10-32 X 3/4" SCREW HEX WASHER HD SS

10 1 22450-0228 22450-0228 22450-0228 RESTRAINT CABLE ASSEMBLY

11 1 30042 30042 30042 VENT EXTENSION

12 1 30039 30039 30039 OFFSET CROSSOVER VENT

13 1 31319 31319 31319 LABEL, UPPER

14 1 31320 31320 31320 LABEL, LOWER

15 1 32116 32116 32116 WIREWAY ASSEMBLY

16 2 21516-0001 21516-0001 21516-0001 POP RIVETS

17 1 32227 32227 32227 INSTRUCTION, CONTROL BOX INSTALLATION

Not Shown 1 32023 31261 30878 OVEN TOP

PARTS LIST FOR SERIES PS200-R68 SINGLE OVEN OPTION KIT

PS200-R68, P/N 31360

PS220-R68, P/N 30752

PS224-R68, P/N 49025-0016

PARTS LIST FOR SERIES PS200-R68 DOUBLE OVEN OPTION KIT

PS200-R68, P/N 31361

PS220-R68, P/N 31363

PS224-R68, P/N 31362

5,6,7,8,9,13,

12

10

14,16,17

4

11

Middleby

Marshall

3

15

2

Figure 2-2. Series PS200-R68 Single and Double Oven Option Kits

12

1

Page 19

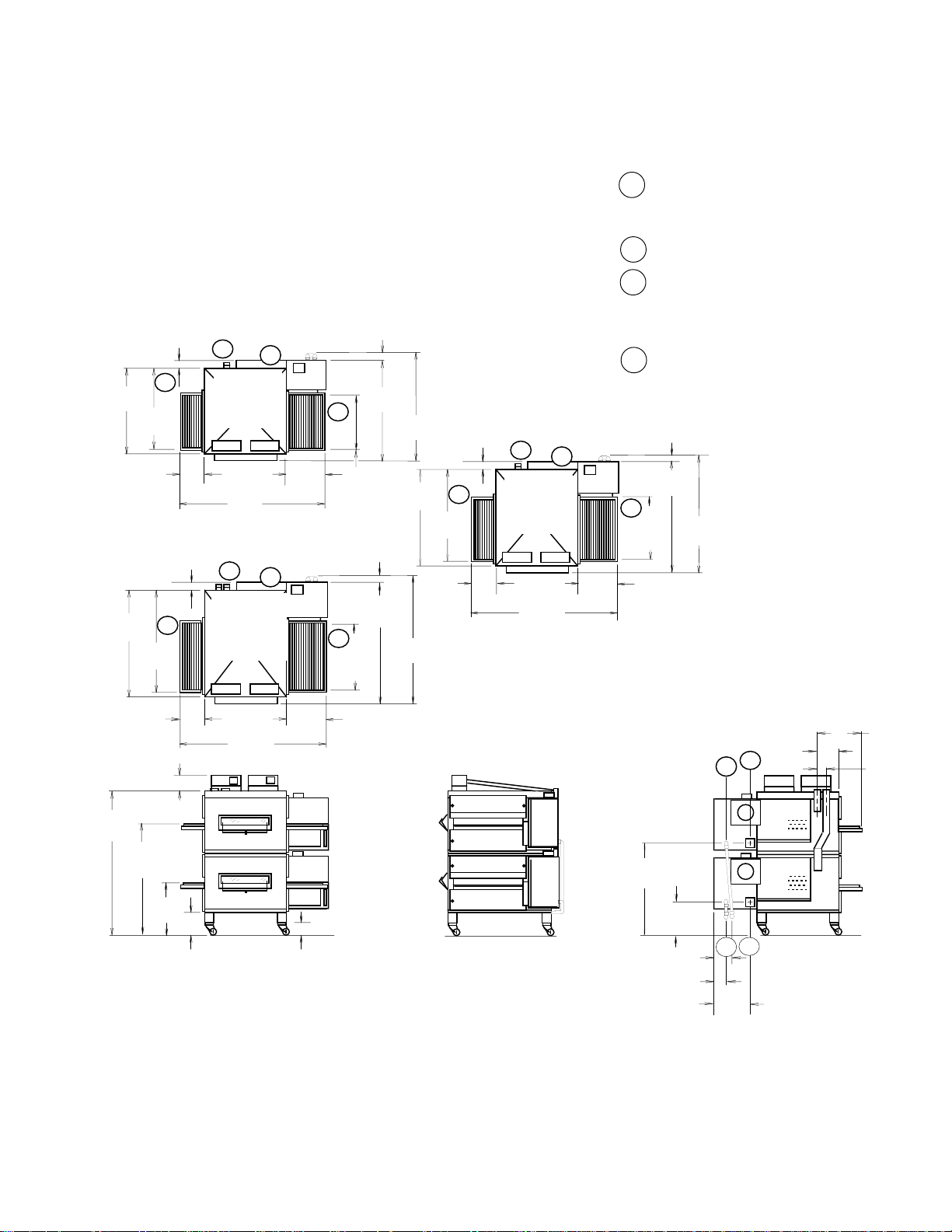

38-1/2"

978mm

50-1/2"

1283mm

NOTE: The Model PS200-R68 Series ovens are

manufactured with the conveyor drive at either the right or

left end of the oven.

3

20"

813mm

Cooking

Zone

3

32"

813mm

Cooking

Zone

1”

25mm

44-3/4”

1137mm

1”

25mm

56-3/4”

1441mm

3

36-1/2"

927mm

10"

254mm

48-1/2"

1232mm

3"

76mm

76mm

3

4

PS220-R68

Top View

3"

PS200-R68

Top View

Model

40-1/2"

1028mm

68"

1727mm

4

Model

3

3

17-1/2"

445mm

45-3/4”

1162mm

42-1/2"

1080mm

57-3/4”

1467mm

40-1/2"

1029mm

10"

254mm

3

3"

76mm

4

3

Model

PS224-R68

Top View

40-1/2"

1028mm

68"

1727mm

17-1/2"

445mm

INSTALLATION

GAS OVEN: Gas Inlet

1

ELECTRIC OVEN: Conduit for

GAS OVEN: Electrical Junction Box

2

RECOMMENDED MINIMUM

3

CLEARANCES:

Rear of Oven to Wall - 3" (76mm)

Non-Drive End of Oven to Wall - 0"

Drive End of Oven to Wall - 18" (457mm)

OVEN VENT - GAS OVEN ONLY

4

2" x 3" (50mm x 75mm)

25mm

48-3/4”

1238mm

3

24"

813mm

Cooking

Zone

Electrical Connection

1”

49-3/4”

1264mm

SECTION 2

69-1/2"

1765mm

11372mm

10"

254mm

54"

27-1/2"

699mm

7-1/4"

184mm

12-1/2"

318mm

40-1/2"

1028mm

68"

1727mm

Front

View

17-1/2"

445mm

End

6-1/2"

165mm

View

Figure 2-3. Series PS200-R68 Oven Dimensions

47"

1194mm

20"

508mm

178mm

127mm

19-3/4"

9-3/4"

248mm

2

1

2

View

14-1/2"

368mm

Rear

1

7”

5"

502mm

3-1/8"

79mm

13

Page 20

SECTION 2

INSTALLATION

II. CONTROL BOX AND CABLE INSTALLATION

CAUTION: When attaching cables turn the circuit breakers off.

A. Install the control boxes, wireway and cables as shown in Figure 2-5.

B. Install the "UPPER" and "LOWER" labels as shown.

"UPPER" label

Wireway

"LOWER" label

Figure 2-4. Control Box, Wireway and Cable

Installation

14

Page 21

SECTION 2

INSTALLATION

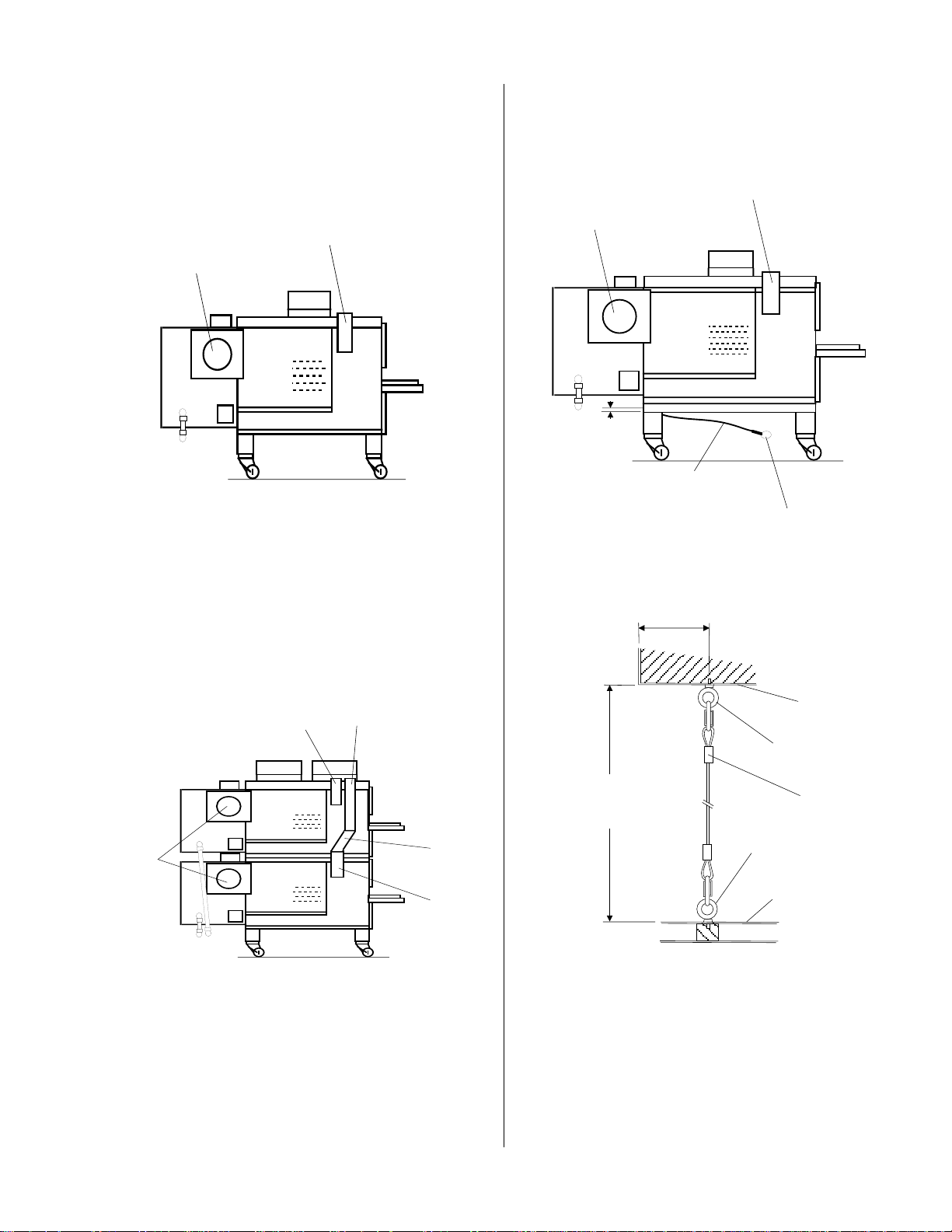

III. FLUE VENT INSTALLATION

A. Install the flue vent: (Gas oven only)

NOTE: On a single oven the flue is factory mounted.

Flue

Fan

Rear

View

Figure 2-5. Single Oven Flue Installation

IV. RESTRAINT CABLE INSTALLATION

Install the restraint cable assembly on the oven as

shown in Figure 2-7.

Flue

Fan

3/4"

(19mm)

Restraint

Cable

Assembly

Rear

View

To Eyebolt

On Wall

B. On a double oven install the flue extension and

flue offset by sliding it down over the lower flue. Then

attach both flues with the screws provided.

Flue

ExtensionUpper Oven

Flue

Flue

Fan

Rear View

Offset

Lower

Oven Flue

Figure 2-6. Double Oven Flue Installation

49-3/4"

(1264mm)

3-5/16"

(84mm)

Rear Surface

of Oven

3/4" (19mm) Eyebolt

in Base Pad

Restraint Cable

Assembly

3/4" (19mm) Eyebolt

Wall of Structure

Figure 2-7. Restraint Cable Assembly Installation

15

Page 22

SECTION 2

INSTALLATION

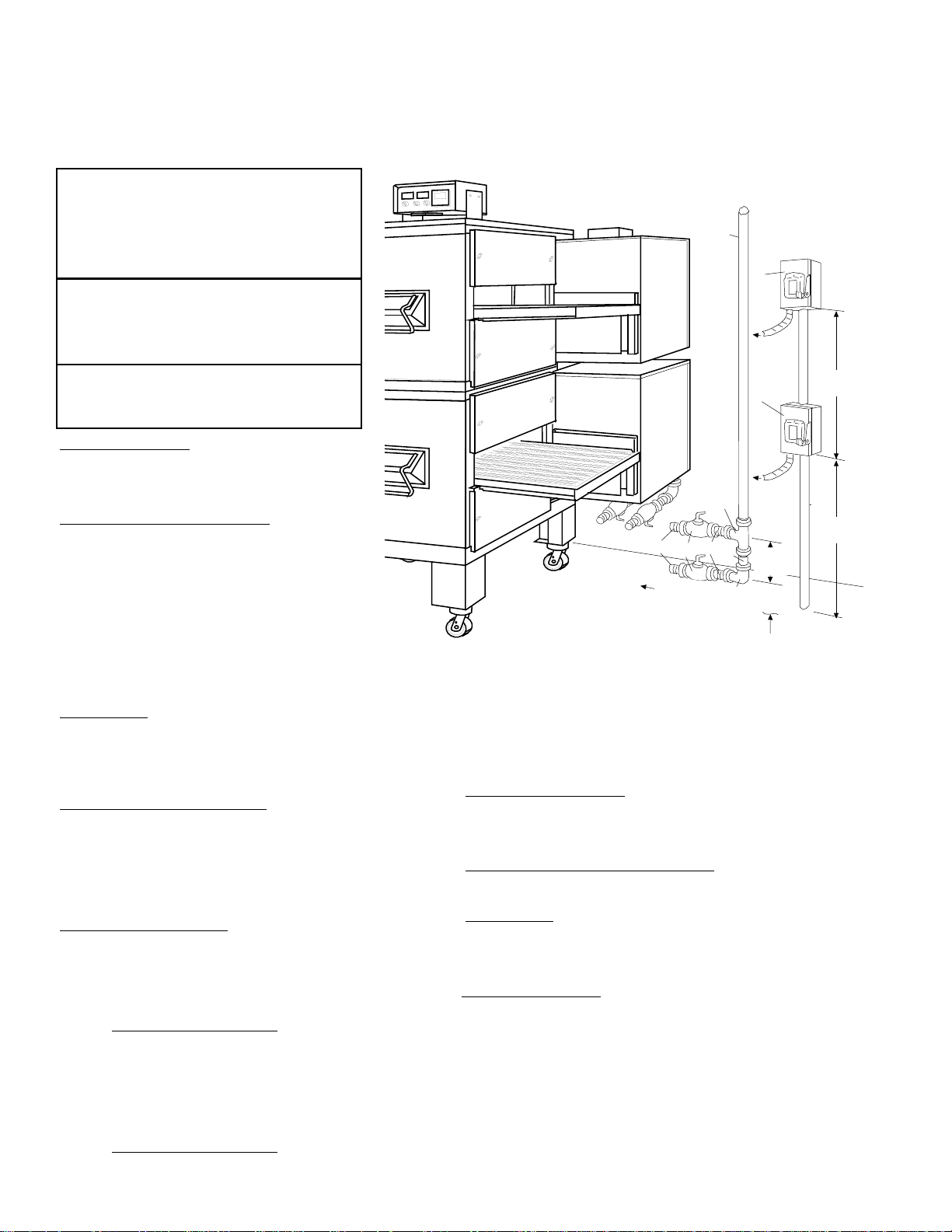

GAS OVEN ROUGH-IN

UTILITY ROUGH-IN DIMENSIONS AND POSITIONING

FOR PS200-R68 SERIES OVENS

CAUTION

IT IS REQUIRED THAT THE OVEN BE

PLACED UNDER A VENTILATION

HOOD FOR ADEQUATE AIR SUPPLY

AND VENTILATION.

GAS SUPPLY &

ELECTRICAL SUPPLY

PROVIDED BY CUSTOMER

DO NOT USE CONDUIT

FOR GROUND

5

ON

6

OFF

To

Oven

24"

6

610mm

ON

CIRCUIT BREAKER

15 Amp circuit breaker with lockout/tagout

electrical shutoff for each cavity. Wire each

cavity separately.

ELECTRICAL SPECIFICATIONS

DOMESTIC: 208-240V main blower motors, 1

Ph, 4.1 Amp draw, 50/60 Hz, 120V control

circuit, 3 pole, 4 wire system per cavity (2 hot,

1 neut, 1 grd). Do not use conduit for ground.

or

EXPORT: 200-208V or 220-240V main blower

motors, 1 Ph, 4.1 Amp draw, 50/60 Hz, 120V

transformer control circuit, 2 pole, 3 wire

system per cavity (2 hot, 1 grd). Do not use

conduit for ground.

GAS RATING

Model PS200-R68 is 120,000 BTU/Hour (30,240 kcal),

35.1 kW/HR

Models PS224-R68 & 220-R68 are 100,000 BTU/Hour

(25,200 kcal), 29.3 kW/HR

MINIMUM GAS METER RATING

450 Cu.Ft./Hour (12.74m3h) for 1 or 2 oven cavities.

Add 180 Cu.Ft./Hour (5.1m3h) for each additional cavity.

Minimum rating may not take other gas appliances into

consideration. Gas consumption varies at each site. Total BTU/

HR (kcal/hr) must be calculated on high flame off of each

appliance to determine if meter needs to be larger.

MINIMUM GAS PIPE SIZE

Natural: 2" (51mm) ID for 1 or 2 oven cavities with runs

up to 200 ft.(61m).

or

2-1/2" (64mm) ID for 3 or 4 oven cavities with runs up to

200 ft.(61m)

Must be a dedicated line.

Runs over 200 ft. consult factory

Propane: 1-1/2" (38mm) ID for 1 or 2 oven cavities with

runs up to 200 ft.(61m).

or

2" (51mm) ID for 3 or 4 oven cavities with runs up to 200

ft.(61m).

Must be a dedicated line.

Runs over 200 ft. consult factory

To

Oven

1

2

To Oven (Flexible Hose)

2

3

7

6”

152mm

3”

76mm

4

Figure 2-8

Typical Installation

GAS SHUTOFF VALVES

3/4" (19mm) ID full flow gas shut-off valve.

A separate connection and valve must be provided for

each oven.

REQUIRED SUPPLY GAS PRESSURE

Natural: 6 " to 14 " (152 to 356mm) water column

Propane: 11.5" to 14" (290 to 356mm) water column

SUGGESTED

If space permits service should be located at the drive

end of the ovens to allow access to switches and

valves.

User Supplied Items:

ITEM QTY DESCRIPTION

1 1 2"(51mm) X 2"(51mm) X 3/4"(19mm) TEE

2 3 3/4"(19mm) X 3"(76mm) NIPPLE

3 2 3/4" (19mm) FULL FLOW GAS SHUT-OFF VALVE

4 1 2"(51mm) X 2"(51mm) 90° ELBOW

5 1 2"(51mm) ID GAS SUPPLY PIPE LINE

-NATURAL GAS

6 2 15 AMP TOGGLE SWITCH - 2 POLE for GAS

16

OFF

24"

610mm

Page 23

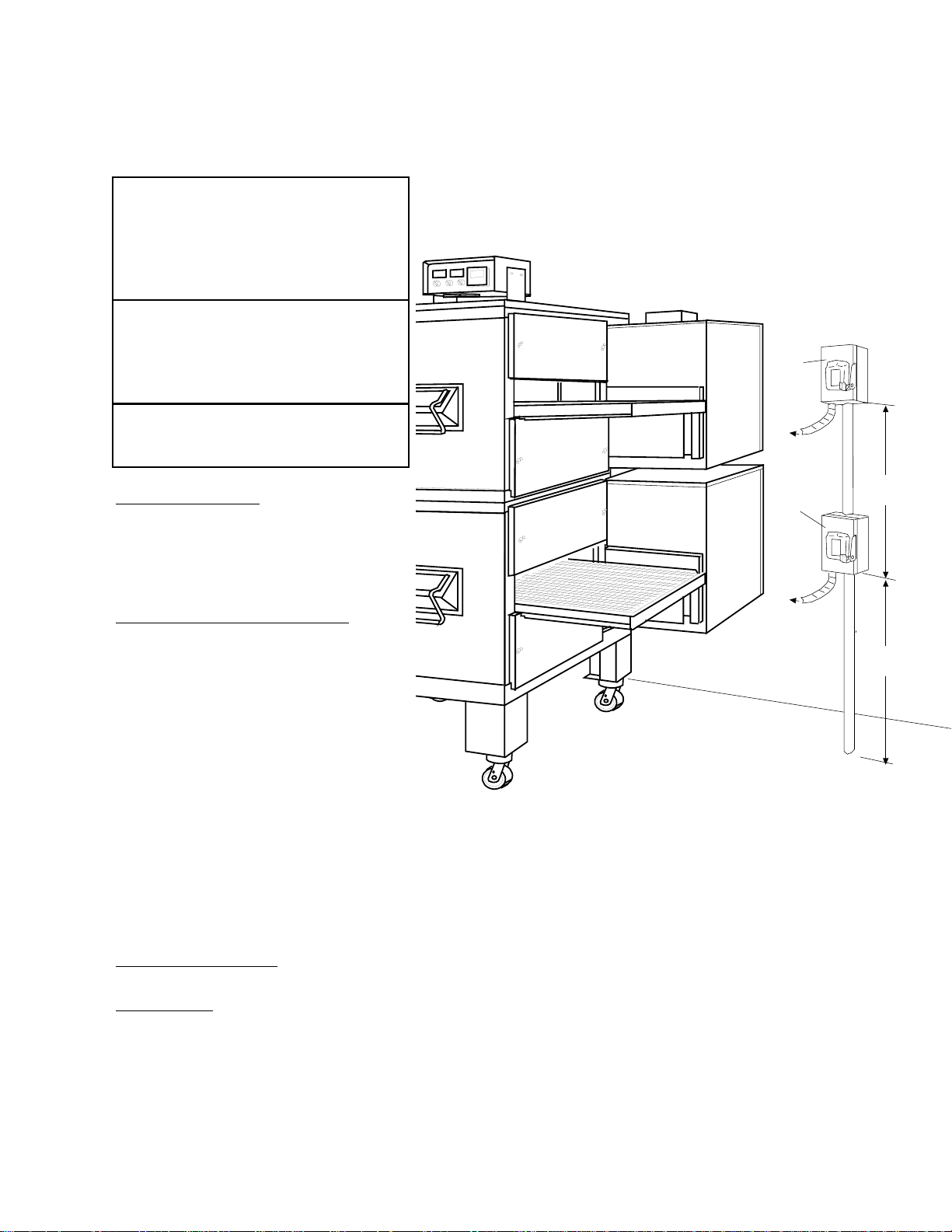

ELECTRIC OVEN ROUGH-IN

UTILITY ROUGH-IN DIMENSIONS AND POSITIONING

FOR PS200-R68 SERIES OVENS

CAUTION

IT IS REQUIRED THAT THE OVEN BE

PLACED UNDER A VENTILATION

HOOD FOR ADEQUATE AIR SUPPLY

AND VENTILATION.

SECTION 2

INSTALLATION

ELECTRICAL SUPPLY

PROVIDED BY CUSTOMER

DO NOT USE CONDUIT

FOR GROUND

CIRCUIT BREAKER

Separate circuit breaker with lockout/

tagout electrical shutoff for each

cavity. Wire each cavity separately.

100 Amp circuit breaker for 200-240V,

or 50 Amp circuit breaker for 380-480V.

ELECTRICAL SPECIFICATIONS

DOMESTIC: 208-240V main blower

motors and elements, 3 Ph, 75 Amp

draw, 50/60 Hz, 120V control circuit, 4

pole, 5 wire system per cavity (3 hot, 1

neut, 1 grd).

or

DOMESTIC: 220-240V main blower

motors and elements, 3 Ph, 75 Amp

draw, 50/60 Hz, 120V control circuit, 3

pole, 4 wire system per cavity (3 hot, 1

grd).

or

EXPORT: 380V or 400-416V main

blower motors and elements, 3 Ph, 50

Amp, 50/60 Hz, 120V transformer

control circuit, 4 pole, 5 wire system per

cavity (3 hot, 1 neut, 1 grd).

ELECTRICAL RATING

26 kW/HR

SUGGESTED

If space permits service should be

located at the drive end of the ovens to

allow access to switches and valves.

Figure 2-9

Typical Installation

6

To

Oven

6

To

Oven

ON

OFF

24"

610mm

ON

OFF

24"

610mm

17

Page 24

SECTION 2

INSTALLATION

V. VENTILATION GUIDELINES

A mechanically driven ventilation system is required for

the PS200-R68 Series Middleby Marshall conveyorized

gas ovens. The minimum hood canopy dimensions are

outlined below.

Local codes and conditions vary greatly from one area to

another and must be complied with. These are the

“Authority having jurisdiction” as stated by the National

Fire Protection Association, Inc. in NFPA 96-latest edition. Following are the suggested requirements for good

ventilation. Please remember these are general recommendations or guidelines, you may have a special condition or problem that will require the services of a

ventilation engineer or specialist. Proper ventilation is the

oven owner’s responsibility. Improper ventilation can

inhibit oven performance. It is recommended that the

ventilation and duct work be checked every three months.

Grease filters in the intake of the hood may be required

by local codes.

VENTILATION HOOD

The rate of air flow exhausted through the ventilation

system is generally between 1400 and 2500 CFM, but

may vary depending on the oven configuration and hood

design. To avoid a negative pressure condition in the

kitchen area, return air must be brought back to replenish

the air that was exhausted. A negative pressure in the

kitchen can cause heat related problems to the oven

components as if there were no ventilation at all. The best

method of supplying return air is through the heating,

ventilation and air conditioning system (HVAC). Through

the HVAC system, the air can be temperature controlled

for summer and winter. Return air can be brought in

directly from outside the building, but detrimental affects

can result from either extreme seasonal hot and cold

temperature from the outdoors.

NOTE: Return air from fan driven system within the hood

must not blow at opening of bake chamber or poor oven

baking performance will result.

VENTILATION CAPTURE TEST

It is recommended that a 30 second smoke candle test be

performed on your ventilation hood system. Follow the

steps below to complete the ventilation smoke test.

All tests are to be done on single ovens or lower units of

a double oven. We recommend you wear protective

gloves when performing this test. At no time should food

be present when the smoke test is being conducted. Also

check that no fire suppression system will be activated by

the smoke.

1. Turn ventilation system on.

2. Turn oven(s) on and allow to heat up to customers

normal operating temperature, or a minimum of 480°F

(248°C).

3. Turn conveyor off. Place a 30 second smoke candle

in a pie or cake pan which is no higher than 3" (76mm).

4. Open the front oven window. Next, light the smoke

candle in the pan and then slide the pan into the center

of the bake chamber on the conveyor belt and close the

window.

5. The ventilation hood should capture 90% to 100% of

the smoke produced by the candle.

10”

254mm

2”

51mm

minimum to

allow stacking

of ovens

17-1/2”

445mm

Figure 2-10

Vent Hood

8”

203mm

18

3”

76mm

Page 25

SECTION 2

INSTALLATION

VI. ELECTRIC SUPPLY FOR GAS HEATED OVENS

Electric supply for all gas heated ovens is 208-240 volts

AC single phase. Each oven requires a separate 15 amp

service. Connection is made as shown in Figures 2-8 &

2-12. A separate ground wire must also be supplied.

CAUTION: Before connecting incoming power to oven,

a voltage reading of each leg to neutral must be made.

These readings should not normally exceed 120 volts

each.

If one of the incoming legs reads over 130 volts, this

indicates the supply voltage has a high leg.

Export ovens are supplied with a stepdown transformer

for the 110V control circuit.

Call your local electrician or electrical power supply

company and have them remove the high leg from the

electrical supply line for the oven.

Connecting a high leg to the black lead of the oven will

severely damage many of the electrical components in

the oven.

CONNECTING A HIGH LEG TO THE BLACK WIRE

VOIDS ALL OVEN WARRANTIES.

Connect one 208-240V supply leg to the black wire and

the other 208-240V supply leg to the red wire. The supply

neutral should connect to the white oven wire and supply

ground should connect to the oven ground screw located

in the main junction box.

VII. ELECTRICAL CONNECTION

INFORMATION FOR ALL OVENS.

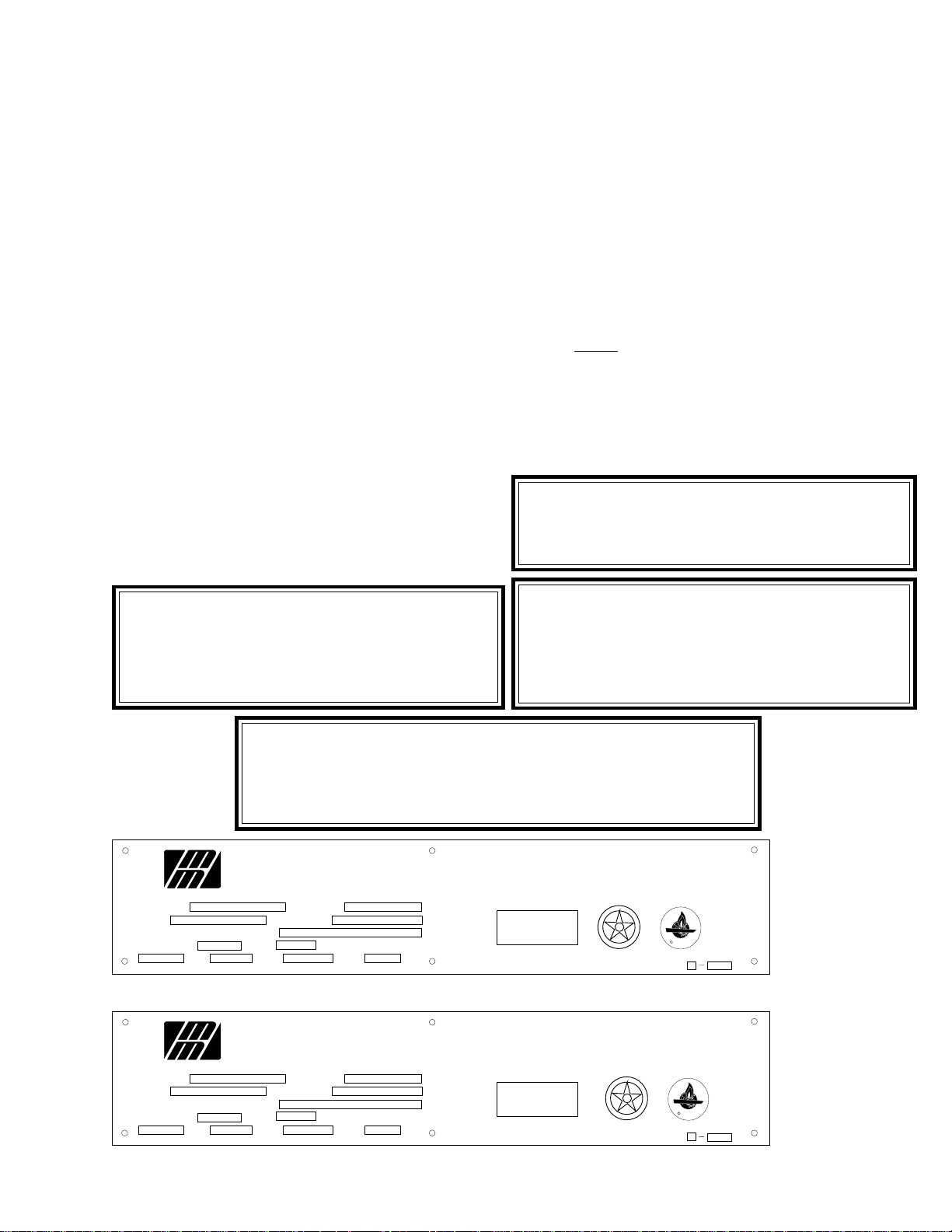

Check the oven data plate before making any electrical

connections. Connections must agree with data on oven

data plate (Refer below to Figure 2-11).

NOTE: In Canada with C22.1,Part 1 and/or local code.

A fused disconnect switch or circuit breaker (not furnished) MUST be installed in the electrical supply line

FOR EACH OVEN. A lockout/tagout electrical shutoff

must be installed for each oven, refer to Figure 2-9. The

service connection must meet all national and local

electrical code requirements. All connections are made

at one common connection at the back of each control

box.

NOTE:

When the oven is installed it must be electrically

grounded in accordance with local codes, or in the

absence of local codes. ANSI/NFPA - Latest edition.

WARNING

CAUTION

IT IS REQUIRED THAT THE OVEN BE

OVEN MUST BE KEPT CLEAR

OF COMBUSTIBLES

AT ALL TIMES.

CAUTION:

The power burner will not operate and gas will not flow through the burner

without electric power. No attempt should be made to operate the oven during

power failure.This oven is to be operated only on the type of gas as shown on

the specification data plate.

SUITABLE FOR INSTALLATION ON COMBUSTIBLE FLOORS ADJACENT

TO COMBUSTIBLE AND NONCOMBUSTIBLE WALLS WITH THE FOLLOW-

Middleby

A MIDDLEBY COMPANY

MODEL NO.

ID NO.

INPUT BTU PER HOUR MAXIMUM

MAN. PRESS.

DATA PLATE FOR OVENS WITH THE MACHINERY/DRIVE COMPARTMENT LOCATED AT THE RIGHT END OF OVEN

Marshall

SERIAL NO.

TYPE OF GAS

VAC AMPS AMPS HZ

IN.W.C.

WIRE WITH GROUND

Middleby

A MIDDLEBY COMPANY

MODEL NO.

ID NO.

INPUT BTU PER HOUR MAXIMUM

MAN. PRESS.

DATA PLATE FOR OVENS WITH THE MACHINERY/DRIVE COMPARTMENT LOCATED AT THE LEFT END OF OVEN

Marshall

SERIAL NO.

TYPE OF GAS

VAC AMPS AMPS HZ

IN.W.C.

WIRE WITH GROUND

ING MINIMUM CLEARANCES: ZERO INCHES TO LEFT SIDE WALL,

EIGHTEEN INCHES TO RIGHT SIDE WALL, SIX INCHES TO BACK WALL.

FOR INSTALLATION UNDER VENTILATING HOOD ONLY

MANUFACTURED UNDER U.S. PATENT NUMBERS 3,844,213 AND 4,154,861

ELGIN, ILLINOIS, 60120, U.S.A. COMMERCIAL OVEN ANS Z 83.12

SUITABLE FOR INSTALLATION ON COMBUSTIBLE FLOORS ADJACENT

TO COMBUSTIBLE AND NONCOMBUSTIBLE WALLS WITH THE FOLLOWING MINIMUM CLEARANCES: ZERO INCHES TO RIGHT SIDE WALL,

EIGHTEEN INCHES TO LEFT SIDE WALL, SIX INCHES TO BACK WALL.

FOR INSTALLATION UNDER VENTILATING HOOD ONLY

MANUFACTURED UNDER U.S. PATENT NUMBERS 3,844,213 AND 4,154,861

ELGIN, ILLINOIS, 60120, U.S.A. COMMERCIAL OVEN ANS Z 83.12

PLACED UNDER A VENTILATION HOOD

FOR ADEQUATE AIR SUPPLY

AND VENTILATION

"INTENDED FOR OTHER THAN HOUSEHOLD USE"

I

G

S

E

N

D

I

ACCEPTED FOR USE

CITY OF NEW YORK

DEPARTMENT OF BUILDINGS

MEA 309-83-E

"INTENDED FOR OTHER THAN HOUSEHOLD USE"

ACCEPTED FOR USE

CITY OF NEW YORK

DEPARTMENT OF BUILDINGS

MEA 309-83-E

C

R

E

A

M

N

A

G

S

A

A

S

S

O

C

I

C

E

R

T

I

A

A

S

S

C

E

CANADIAN GAS ASSOCIATION

N

O

I

T

A

D

E

I

F

S

E

D

R

E

M

G

A

O

C

I

R

T

I

APPROVED

R

I

G

N

I

C

A

N

S

N

O

I

T

A

D

E

I

F

19

CANADIAN GAS ASSOCIATION

APPROVED

R

Figure 2-11.

Oven Specifi-

cation Data

Plate Refer-

ence

Page 26

SECTION 2

INSTALLATION

VIII. ELECTRIC SUPPLY FOR ELECTRICALLY

HEATED OVENS

Electrically heated ovens are available in 208 or 240

volts, 5 wire, 3 phase only. They are pre-wired at the

factory and only one common connection is necessary.

A standard oven is a 5 wire system (3 hot, 1 neut, 1 grd),

it will not have a stepdown transformer. The neutral wire

is combined with one 208-240 VAC, 3 phase leg to

provide a 110V control circuit.

If the oven was special ordered for a 4 wire system, it will

use a stepdown transformer for the 110V control circuit.

A 1-1/4" cutout is supplied on the rear of oven control box

for the electrical connection. A 1-1/4" strain relief fitting

must be used if flexible cable is used to run electrical

supply.

Be sure wire size is adequate to handle amperage draw

listed on data tag. Use Copper Wire Only.

Minimum Supply Conductor

ampacity -- 95 Amps Per Unit.

Maximum Supply Circuit protective

device -- 100 Amps Per Unit

Normal electrical requirements are as follows:

PS200 Series Single - 208-240V, 3 phase, 5 wire, 27kw,

100 amp service.

PS200 Series Double Oven - 208-240, 3 phase, 5 wire,

54 kw, 2 separate 100 amp services, one for each oven.

FOR OTHER SERVICES CONSULT FACTORY.

Electrical

Junction

Cover Plate

3/4" pipe for gas oven gas connection

or

1-1/4" hole for electrically heated oven

connection

Figure 2-12

Junction Connection Box

20

Page 27

CAUTION

DO NOT CONNECT BLACK

LEAD TO HIGH LEG

BLACK AND WHITE MUST

BE 120 VAC

High Leg Warning tag located on cover of electrical

connection box of gas heated ovens.

IX. GAS SUPPLY FOR GAS HEATED OVENS

Check identification plate located on machinery compartment (see Figure 2-11) to determine type of gas (Propane or Natural) to be used with the oven.

NOTE: If identification plate (Figure 2-11) is missing,

natural or propane ovens can usually be determined by

checking the manifold pressure rating on the gas combination valve. The rating for natural gas is 3-1/2" w.c. The

rating for Propane gas is 10.5" w.c.

Install the manual shutoff valve(s) enclosed with the oven

on the 3/4" gas connection pipe extending through the

control compartment at rear of oven control box.

If the rear of the oven is installed close to the wall, install

the 3/4" elbow on the 3/4" gas connection pipe coming

out the rear of the oven and then install the manual

shutoff valve(s). This will prevent kinking the connection

hose.

The minimum and maximum incoming line flow pressures (when oven(s) and all other gas appliances are on

high flame cycle) should be the following:

Natural Gas: 6.0"w.c. Minimum, 14"w.c. Maximum

Propane Gas: 11.5"w.c. Minimum, 14"w.c. Maximum

This incoming pressure reading can be taken by installing a gas pressure gauge in the inlet pressure tap of the

main gas valve. See Figure 2-13. Outgoing pressure can

be measured at the outlet pressure tap of the main gas

valve.

Remember, the longer the pipe runs, the more pressure

drops. One 90° elbow equals a 4 foot length of pipe.

NOTE

The installation must conform with local codes or in

the absence of local codes, with the National Fuel

Gas Code, ANSI Z223, 1-latest edition

In Australia the installation must conform with AGA

Code AG601 and with any requirements of the

appropriate statutory authority.

CANADIAN:

CAN/CGA-B 149.1 Natural Gas

Installation Code

CAN/CGA-B 149.2 Propane

Installation Code

SECTION 2

INSTALLATION

On ovens equipped with casters, the installation shall be

made with a gas connector that complies with the standard for gas connectors for Moveable Gas Appliances,

ANSI Z21.69-1987/CANI 6.10-88(or latest edition), and

Addenda, Z21.69a-1989(or latest edition), and a quick

disconnect device that complies with the standard for

Quick-Disconnect Devices for Use With Gas Fuel, ANSI

Z21.41-1989/CANI 6.9M79(or latest edition), and cable

restraint assembly (refer to Figure 2-7) must be provided

to limit the movement of the oven without depending on

the connector and the quick-disconnect device or its

associated piping to limit oven movement.

When an oven is required to be removed from its installation for service, shut off the gas valve upstream of the

gas connector. Disconnect gas connector, disconnect

the restraining device, move oven for servicing.

When service is complete, place oven in original location,

connect restraining cable device, connect gas connector, turn gas valve on. Follow standard start up procedure.

Refer below to determine what size gas pipe to run to the

oven (NOTE: each oven requires maximum BTU usage

of 120,000 BTU per hour for a PS200-R68 or 100,000

BTU per hour for a PS220-R68 and PS224-R68.) The

maximum total for a Double Oven would be 240,000 BTU

per hour for a PS200-R68 or 200,000 BTU per hour for a

PS220-R68 and PS224-R68.

RECOMMENDED SUPPLY PIPE SIZE:

Natural-

2" (51mm) ID for 1 or 2 oven cavities with runs up to 200

ft.(61m).

or

2-1/2" (64mm) ID for 3 or 4 oven cavities with runs up to 200

ft.(61m)

Must be a dedicated line. Runs over 200 ft. consult

factory.

Propane-

1-1/2" (38mm) ID for 1 or 2 oven cavities with runs up to 200

ft.(61m).

or

2" (51mm) ID for 3 or 4 oven cavities with runs up to 200

ft.(61m).

Must be a dedicated line. Runs over 200 ft. consult

factory.

NOTE: The recommended pipe sizes are larger than

usually required to eliminate any operation problems. It is

much less expensive to make the initial installment large

enough to do the job rather than redoing the job later.

GAS METER SIZE:

Minimum Gas Meter Size:

450 cu.ft./hour (3.2 liters/sec.) for single or double

oven.

Add 180 cu.ft./hour (1.3 liters/sec.) for each

additional cavity.

21

Page 28

SECTION 2

INSTALLATION

CAUTION

DURING PRESSURE TESTING NOTE

THE FOLLOWING:

1. The oven and its individual manual shutoff valve

(located at the left rear of the oven) must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressure in

excess of 1/2 psig (3.45 kPA). Turn OFF main gas

shutoff valve or main gas supply line.

2. The oven must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve located at the rear of the oven during

any pressure testing of the gas supply piping system

at test pressure equal to or less than 1/2 psig (3.45

kPA).

3. If incoming w.c. pressure is over 14" w.c. a

separate regulator must be installed before the

3/4"manual gas shutoff valve located at the rear

outside of the oven.

WARNING

TROL VALVE REGULATOR DURING INITIAL TURN

VERY IMPORTANT TO OPEN MANUAL SHUTOFF

After the initial gas turn on, the manual shutoff valve

must remain open except during pressure testing as

outlined in the above steps or when necessary during service maintenance.

:

TO PREVENT DAMAGE TO CON-

ON OF GAS, IT IS

VALVE VERY SLOWLY.

22

Page 29

It is possible to convert ovens from natural gas to propane

and back. Call your local authorized factory service agent

to perform the conversion.

NOTE: In Canada to conform with CAN/CGA-B149.2

Propane Installation Code the oven must be ordered

Propane, it may not be converted in the field.

SECTION 2

INSTALLATION

Outlet

Pressure

Tap

Burner Blower

Air Adjustment

Plate

Figure 2-13. Gas Train

X. CONVEYOR BACKSTOP AND END STOP INSTALLATION

Locate the conveyor backstop and end stop in the

installation kit. Install the backstop and end stop at the

exit end of the oven. Refer to Figure 2-14.

Pilot Line

Low

Flame

Bypass

Line

Conveyor

End Stop

High

Flame

Solenoid

Valve

Conveyor

Rear Stop

On/Off KnobAlways Leave

In On Position

Combination

Gas Control

Valve

Manual

Shutoff Valve

Gas Cock

located below

machinery

compartment

Incoming

Pressure Tap

(Where

incoming gas

pressure is

measured)

Figure 2-14.

Installing Backstop and End Stop

23

Middleby

Marshall

Page 30

SECTION 2

INSTALLATION

NOTES:

24

Page 31

I. CONTROLS AND COMPONENTS

Upper Oven

Control Box

SECTION 3

OPERATION

SECTION 3

OPERATION

Temperature

Controller

Conveyor

Speed Control

Lower Oven

Control Box

Blower

Switch

Conveyor

Switch

Heat

Switch

Figure 3-1.

PS200-R68 Series

Control Functions

25

Page 32

SECTION 3

OPERATION

II. COMPONENT INFORMATION AND LOCATION

Blower

Fan Motor

Door Safety

Switch

Figure 3-2

A. Door Safety Switch

The Door Safety Switch is located at upper left hand side

of control cabinet. Opening the control cabinet door will

permit the switch to open, disconnecting power to all

electrical controls.

CAUTION: DO NOT TOUCH WIRES GOING TO THIS

SWITCH AS CURRENT IS ALWAYS PRESENT.

B. Blower Fan

The blower switch located on the control box has

two positions. The switch must be on (I) for the burner and

conveyor to come on and permit the oven to warm up.

The fan circulates the air throughout the oven and must

stay on during baking and during the cool down cycle

above 200° F. (93°C.) to prevent blower bearing damage. To protect the blower motor and bearings a thermostatic override is built into the oven. If the temperature

inside the oven is over 180° F. (82° C.) the main blower

and conveyor will continue to run even when the blower

switch is turned to the off position.

An air pressure switch monitors the air flow from the main

blower, this acts as a safety interlock for the burner. The

heat will not come on if the air switch does not sense air

flow off the main blower fan.

C. Heat (Gas ovens only)

Turning the heat switch to on (I) will initially set up the

Conveyor

Speed

Control

oven purge circuit after approximately 30 seconds the

pilot will light. After the pilot is lit the main control valve will

open permitting gas to go to the burner and heat the oven.

This switch is in series with the burner blower motor

centrifugal switch, high temperature safety switch and

blower fan air pressure switch. All three safety switches

must be closed for gas to flow and the burner to light.

D. Temperature Controller

The temperature controller located on the control box

is a solid state on/off type which is used to maintain the

desired set temperature. The temperature controller

continuously monitors the oven temperature and turns

high flame solenoid valve on in gas heated ovens. The

heat is on for the time required to maintain a constant

temperature.

The temperature controller contains a Hi-Limit switch

which will shut down the oven when the oven reaches

650°F. (343° C.) and a low-limit switch which allows the

oven to cool down to 180°F. (82° C.) before shutting off

the blowers.

E. Heat (Electrically heated ovens only)

Turning the heat switch located on the control box

to on (I) will energize the electric heating system. This

switch is in series with the blower fan motor centrifugal

switch and high temperature override switch. Both

switches must be closed before the elements may be

energized.

26

Page 33

1 1 1

:

SECTION 3

OPERATION

F. Conveyor

The conveyor switch is on

0

the control box. Also on the control box is the digital control for the

conveyor speed. The digital control can be adjusted from 2 minutes 40 seconds to 29 minutes 50

Figure 3-3. Conveyor Speed Digital Control

Figure 3-4. Product at entrance end of bake chamber- BEGIN TIMING.

seconds bake time (conveyor

speed). Refer to Figure 3-3.

Conveyor speed is measured by

the amount of time it takes for an

item to go through the bake chamber of the oven.

MEASURING CONVEYOR SPEED.

Refer to Figure 3-4 & 3-5.

To check conveyor speed place

an item at the product entrance

end of oven bake chamber as

shown. Time how long it takes for

the leading edge of the item to go

from the entrance end of the bake

chamber to the exit end and this

will be your conveyor speed.

NOTE: In Figures 3-4 & 3-5 the

oven shown has the conveyor running right to left.

Figure 3-5. Product at exit end of bake chamber-END OF TIMING

27

CAUTION

Possibility of injury from

rotating parts and electri-

cal shock exist in this

oven.

Never disassemble or

clean the oven with the

blower switch or any other

part of the oven turned

"on". Turn OFF and

lockout or tagout all

electrical power to the

oven before attempting to

clean or service this oven.

Page 34

SECTION 3

OPERATION

II. OPERATION

A. Start Up Procedures -- Gas Heated Ovens

Initial Start Up

1. Check that manual gas shutoff valve is on. Valve is

located below machinery compartment. See Figure 2-12.

Daily Start Up

1. Turn blower switch to the on (I) position. This

starts the main blower fan and the cooling fan. The blower

circulates air through the air fingers and must stay on

during the cooking or baking process.

2. Check to see if the cooling fans (see Figures 1-4 and

1-6) are operating when the blower switch is turned on (I).

The cooling fans cool the electrical components and

burner blower motor. The cooling fan, located at the rear

of the machinery cabinet blows air into and through the

cabinet. Air is exhausted out the back of the oven. A

cooling fan is also located in the bottom of the control box

to draw air through the rear louvers and out the bottom.

Clean the cooling fan grills and louvers daily.

IMPORTANT NOTE: The cooling fan will operate when

the blower switch is turned on (I). It must operate to keep

the machinery cabinet below 140°F. (60° C.).

WARNING: IF FAN BLADE IS NOT ROTATING, BROKEN OR IF FAN ASSEMBLY IS MISSING FROM MAIN

BLOWER MOTOR SHAFT, DO NOT OPERATE OVEN.

REPLACE COOLING FAN BLADE BEFORE OPERATING OVEN. Serious damage could be done to the burner

blower motor and/or the solid state electrical components if oven is operated while cooling fan is not running

or vent grill is plugged.

3. Turn the conveyor switch to the on (I) position.

This now starts the conveyor belt moving through the

oven. Set conveyor speed digital control for desired bake

4. The temperature controller should be set at your

desired baking temperature. See section on bake times

to determine desired temperature.

NOTE: For complete temperature controller operation

instructions refer to Step B.

5. Turn the heat switch to the on (I) position. This will

complete a circuit which supplies power to the burner.

When an oven that has not been in operation for approximately 1/2 hour is turned on it goes through a 15 second

purge cycle. The burner blower motor will not operate

during the time the main fan is purging the oven. After 15

seconds the burner blower motor starts, which can be

detected by feeling a slight vibration when touched. This

should permit the burner to light.

When in operation, the burner is either on low or high

flame. A flame sensing electrode must be satisfied to

keep the pilot and gas valve open. If for some reason the

pilot flame is extinguished, the pilot will try to relight for 90

seconds. If the pilot does not relight in 90 seconds the

oven will go into automatic safety lockout.

To relight the oven the heat switch must be turned off

for 5 minutes and then repeat the oven start-up proce-

dure.

6. Close front window.

7. Oven will reach a baking temperature of 500° F (260°

C) in approximately 10 minutes. Allow the oven to cycle

for 30 minutes after it has reached desired bake temperature and the oven is now ready for baking.

Power Failure

In case of power failure, turn off all switches, open oven

window and remove product. After power has been

reestablished follow normal start-up procedure.

time .

CAUTION

The burner will not operate and gas will not

flow through the burner without electric

power. No attempt should be made to

operate the oven during power failure.

28

Page 35

Middleby Marshall

SECTION 3

OPERATION

MIN

Conveyor Speed

SEC

Control

ALM

HEAT

1

351

F

S E T P T

FUNCTION DISPLAY RESET SET UP

Temperature

Controller

Lower

Left Blank

˚C

SEC

MIN

MIN

SEC

0

0

0

0

I

O

I

O

I

RESET

O

SETUP

DISPLAY

FUNCTION

Lower Right

Blank

Blower Switch

Conveyor Switch

Heat Switch

Figure 3-6. Control Panel

29

Page 36

SECTION 3

OPERATION

B. Temperature Controller Operation Instructions

1. UNLOCKING SET POINT. The temperature controller set point must be 450°F (232.2°C) for the upper oven and

350°F (176.7°C) for the lower oven. To raise or lower the set point on a Red Lobster oven the set point must first

be unlocked by pressing the Lower Left Blank and the Lower Right Blank keys simultaneously. The set point will

remain unlocked for 60 seconds or until the DISPLAY key is pressed.

a. Raising the temperature set point. Refer to Figure 3-7.

AA. Slow Method: 1 Degree increments.

Press the UP Arrow Button (▲). The temperature set point will

increase one degree. If this button is kept depressed, the temperature set point will continue to increase in one degree increments.

BB.Fast Method: 10 Degree increments.

Press and hold the UP Arrow Button (▲). The temperature set point

will begin to increase one degree at a time. With your other hand,

press the DOWN Arrow Button (▼) and release. The temperature

set point will begin increasing in 10 degree increments.

CC.Fast Method: 100 Degree increments.

Press and Hold the UP Arrow Button (▲). The temperature set point

will begin to increase by one degree at a time. With your other hand,

press the DOWN Arrow Button (▼) once and release. The temperature set point will begin increasing in 10 degree increments. Press

the DOWN Arrow Button (▼) again and release. The temperature

set point will begin increasing in 100 degree increments. See Figure

3-7.

b. Lowering the temperature set point.

AA.Follow the previous steps AA through CC for raising the temperature set point but use the opposite UP/DOWN

Arrow Buttons.

ALM

HEAT

FUNCTION DISPLAY RESET SET UP

Lower Left

Blank

Middleby Marshall

1

351

S E T P T

Figure 3-7

F

Lower Right

Blank

2. Displaying the actual oven temperature. Refer to Figure 3-8.

a. To check the oven temperature press the DISPLAY Button once

and the actual oven temperature and the word “TEMP” will be displayed.

See Figure 3-8.

b. Press the DISPLAY Button again and the display will return to the

temperature set point. If the DISP key is not pressed, then the display

will automatically return to the temperature set point after 60 seconds.

30

Middleby Marshall

ALM

HEAT

1

F

351

TEMP

FUNCTION DISPLAY RESET SET UP

Figure 3-8

Page 37

SECTION 3

OPERATION

3. Display Messages

a. ALM - The ALM window will display either a “1” or “2” or will be

blank.

AA.Refer to Figure 3-9. The “1” signals that the oven tempera-

ture is above 650°F (343°C) and therefore the high limit feature

has been activated. The burner will then shut off and the oven

will not function until the temperature cools down below 650°F

(343°C).

BB.Refer to Figure 3-10. The “2” signals that the oven temperature is below 180°F (82°C). The “2” will appear only when the

oven is initially heating up and has not yet reached 180°F

(82°C) or the heat switch is turned off and the oven has cooled

down below 180°F (82°C).

CC.The ALM window is blank during normal operation when

the oven temperature is 180°F to 650°F (82°C to 343°C).

Middleby Marshall

ALM

1

HEAT

F

651

S E T P T

FUNCTION DISPLAY RESET SET UP

Figure 3-9

Middleby Marshall

ALM

2

HEAT

F

199

S E T P T

b. HEAT - The HEAT window will display either a “1” or will be

blank. Refer to Figure 3-11.

AA.The “1” signals that the temperature controller is calling for

heat and the burner is turned full on.

BB.When the HEAT window is blank the temperature set point

has been reached and the burner is turned down to low flame.

CC.The “1” will continue to blink on and off every few seconds

during normal operation. This indicates that the temperature

controller is maintaining the correct temperature.

FUNCTION DISPLAY RESET SET UP

Figure 3-10

Middleby Marshall

ALM

HEAT

1

F

500

S E T P T

FUNCTION DISPLAY RESET SET UP

Figure 3-11

31

Page 38

SECTION 3

OPERATION

c. FAILSF (Failsafe)

AA.Refer to Figure 3-12. If the oven does not reach 200°F (93°C)

in 15 minutes the temperature controller will shut off the high flame

valve and begin flashing “FAILSF” and “SET PT” alternately. You

will also note that the “2” in the ALM window stays on but the “1” in

the HEAT window turns off. This condition signals a problem in

oven heating or heat sensing.

BB.To reset the temperature controller, turn off the oven blower

switch. Wait 10 seconds and turn the oven blower switch back on.

The “2” in the ALM window, the “1” in the HEAT window, the current

temperature set point, and the words “SET PT” will be displayed

again. The temperature controller will now cycle through its normal

procedures.

d. F/C - The F/C window will display either an “F” or a “C”.

AA.The “F” indicates that the temperature displayed is in degrees

Fahrenheit.

BB.The “C” indicates that the temperature displayed is in degrees Celsius.

C. Start Up Procedures -- Electric Ovens

1. Turn blower switch to the"ON" position. This starts the main blower fan and cooling fan. The blower circulates

air through the air fingers and must stay on during the cooking or baking process. The cooling fan cools the electrical

components and blower fan motor of the oven.

2. Check to see if the cooling fans (see Figures 1-4 and 1-6) are operating when the blower switch is turned "ON". The

cooling fans cool the electrical components and burner blower motor. The cooling fan, located at the rear of the

machinery cabinet blows air into and through the cabinet. Air is exhausted out the back of the oven. A cooling fan is

also located in the bottom of the control box to draw air through the rear louvers and out the bottom.

Clean the cooling fan grills and louvers daily.

IMPORTANT NOTE: The cooling fan will operate when the blower switch is turned "ON". It must operate to keep the

machinery cabinet below 140°F. (60° C.).

WARNING: IF FAN BLADE IS NOT ROTATING, BROKEN OR IF FAN ASSEMBLY IS MISSING FROM MAIN

BLOWER MOTOR SHAFT, DO NOT OPERATE OVEN. REPLACE COOLING FAN BLADE BEFORE OPERATING