Page 1

Instruction Sheet

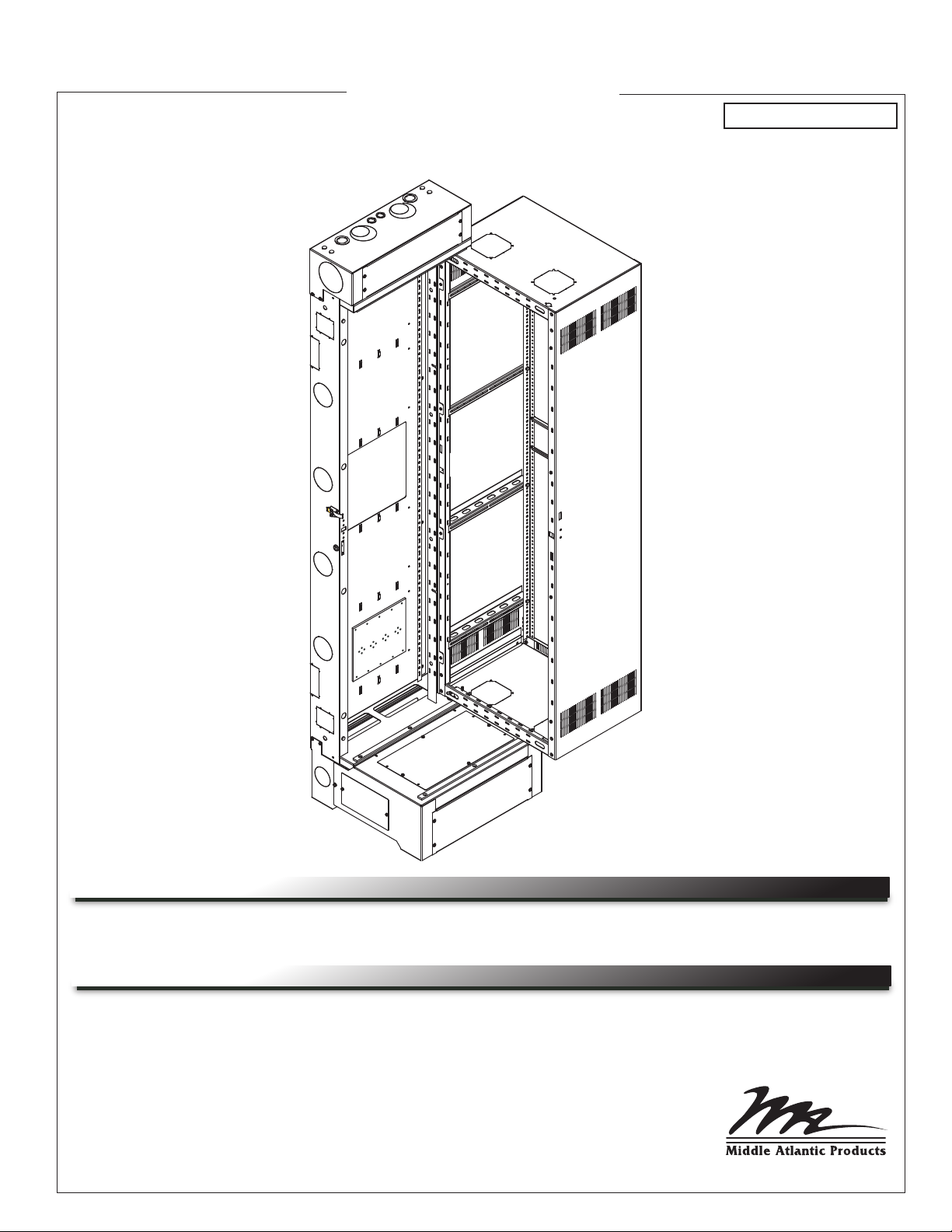

SR SERIES

PIVOTING RACK

U.S. PATENT 7,278,183

THANK YOU

Thank you for purchasing the SR Series Pivoting Rack. Please read these instructions thoroughly

before installing or assembling this product.

PRODUCT FEATURES

• Available in 23.5” and 29” widths.

• The 29” width includes front vertical cable management.

• Tool-Free Quick-Mount™ system for easy mounting of the center section to the backpan on the

job site.

• Pivots 90º on floor base for access to rear connections.

• Zero Clearance Latch option allows side-by-side or corner mounting.

I-00143 Rev P

Page 2

IMPORTANT SAFETY INSTRUCTIONS

• Read these instructions.

• Keep these instructions.

DANGER HAZARDOUS VOLTAGE: The lightning flash with the arrowhead symbol, within an equilateral triangle is intended to alert the user to the

presence of uninsulated dangerous voltage within the product’s enclosure that may be of sufficient magnitude to constitute a risk of electric shock to

persons.

WARNING: A warning alerts you to a situation that could result in serious personal injury or death.

CAUTION: A caution alerts you to a situation that may result in minor personal injury or damage to the product and/or property.

NOTE: A note is used to highlight procedures pertaining to the installation, operation, or maintenance of the product.

WARNING: Failure to read, understand and follow the following information can result in serious personal injury, damage to the

equipment or voiding of the warranty.

CAUTION: To avoid an unstable condition, place heavier components at the bottom of the enclosure. When more than one component

is placed in the enclosure, begin at the bottom of the enclosure and place equipment at the lowest available point, evenly distribute

weight (horizontally) within the enclosure.

Component weight should be distributed as follows:

• 1/2 of the total component weight (at a minimum) placed in the bottom third of the cabinet.

• 1/4 of the total component weight (at a maximum) placed in the middle third of the cabinet.

• 1/4 of the total component weight (at a maximum) placed in the top third of the cabinet.

CAUTION: All installation and assembly steps must be performed by qualified personnel.

• Heed all warnings.

• Follow all instructions.

• Clean only with dry cloth.

• Only use attachments/accessories specified by the manufacturer.

CAUTION: Ensure that the wall has a structural load capacity that will support the weight of the cabinet fully loaded with

equipment.

CAUTION: The following parts are not effectively bonded to the protective earth terminal: Rack rails, lace bars, Lever Lock™, shelves,

baffle, blanking panels, fans, and cable management. If any part needs to be bonded to the protective earth terminal it shall be done in

accordance with Article 250 of the National Electrical Code.

CAUTION: To reduce the risk of personal injury and conform to the UL listing, the system must be grounded and bonded in accor-

dance with Article 250 of the National Electrical Code.

CAUTION: Power cord, for fans or other accessories, need to be secured to ensure that they are routed away from pinch points

and moving parts.

CAUTION: Do not attempt to unload or move the enclosures alone. Make sure to have sufficient amount of personnel and equipment to safely move this product.

CAUTION: Watch hands and fingers around pinch points.

CAUTION: Individual components mounted inside of the wall mount rack must have their own fire enclosure.

SEISMIC COMPLIANCE: An engineered system is vital to achieve seismic rating requirements. A licensed professional engineer must

approve the type of fasteners for the wall where the rack will be mounted. Braced according to speicifications set forth by licensed

architects and engineers, the Middle Atlantic Products rack you purchased is capable of sustaining a phenominal lateral load of high

importance equipment with the frontrails filled to a maximum capacity of 277 lbs. (125.65 kg).

Page 2

Page 3

INSTRUCTIONS IMPORTANTES SUR LA SÉCURITÉ

• Lire ces instructions.

• Conservez ces instructions.

DANGER TENSION DANGEREUSE: Le symbole de la pointe de flèche, dans un triangle équilatéral, est destiné à alerter l'utilisateur sur la

présence de tension dangereuse non isolée dans l'enceinte du produit qui peut être d'une ampleur suffisante pour constituer un risque

d'électrocution.

AVERTISSEMENT: Un avertissement vous avertit d'une situation pouvant entraîner des blessures graves ou la mort.

ATTENTION: Une attention vous avertit d'une situation pouvant entraîner des blessures mineures ou des dommages au produit et/ou à la

REMARQUE: Une remarque est utilisée pour mettre en évidence les procédures relatives à l'installation, au fonctionnement ou à l'entretien du

produit.

AVERTISSEMENT: Ne pas lire, comprendre et suivre les informations suivantes peut entraîner des blessures graves, des

dommages à l'équipement ou de la nullité de la garantie.

ATTENTION: Pour éviter un état instable, placez composants les plus lourds au fond de l'enceinte. Lorsque plus d'un composant est

placé dans la enceinte, commencer par le bas de l'enceinte et placer l'équipement à la point le plus bas disponible, de distribuer

uniformément le poids (horizontalement) dans le enceinte.

Le poids des composants devrait être réparti comme suit:

• 1/2 du poids total de la composante (au minimum) placé dans le tiers inférieur de l'armoire.

• 1/4 du poids total de la composante (au maximum) placé dans le tiers médian de l'armoire.

• 1/4 du poids total de la composante (au maximum) placé dans le tiers supérieur de l'armoire.

ATTENTION: Toutes installation et de montage étapes doivent être effectuées par du personnel qualifié.

• Respectez tous les avertissements.

• Suivez toutes les instructions.

• Nettoyer uniquement avec un chiffon sec.

• N'utilisez que des accessoires spécifiés par le fabricant.

ATTENTION: Veiller à ce que le mur a une capacité de charge structurelle qui supporter le poids de le cabinet entièrement

chargé avec l'équipement.

ATTENTION: Les pièces suivantes ne sont pas correctement liés à la borne de terre de protection: rails de rack, des bars de dentelle,

Lever Lock™, des étagères, des chicanes, des panneaux d'obturation, ventilateurs, et la gestion des câbles. Si une partie doit être lié

à la borne de terre de protection, il doit être fait conformément à l'article 250 du Code national de l'électricité.

ATTENTION: Pour réduire le risque de blessure et se conformer à la liste UL, le système doit être mis à la terre et collé

conformément à l'article 250 du Code national de l'électricité.

ATTENTION: Le cordon d'alimentation, pour les fans ou autres accessoires, doivent être fixé à veiller à ce que ils sont acheminés loin des points de pincement et des pièces mobiles.

ATTENTION: Ne essayez pas de décharger ou déplacer les enceintes seul. Assurez-vous d'avoir quantité suffisante de personnel

et de matériel pour déplacer ce produit en toute sécurité.

ATTENTION: Observez les mains et les doigts autour des points de pincement.

ATTENTION: Les composants individuels montés à l'intérieur de montage mural doivent avoir leur propre armoire à incendie.

CONFORMITÉ SISMIQUE: Un système d'ingénierie est essentiel pour atteindre les exigences d'évaluation sismique. Un ingénieur

professionnel agréé doit approuver le type de fixations pour le mur où le rack sera monté. Conçue selon les spécifications d'architectes

et d'ingénieurs agréés, l'enceinte Middle Atlantic Products que vous avez achetée est capable de supporter une charge latérale

phénoménale d'équipement de grande importance avec les chutes de charge remplies jusqu'à une capacité maximale de 277 lbs.

(125.65 kg).

Page 3

Page 4

WEIGHT RATINGS

Model Weight Rating

All 500 lbs. Maximum Total Rated Load

WARNING: This product is intended for use only with the products and maximum weights indicated. Use with other products or

products heavier than the maximum weights indicated may result in instability causing possible injury. Total equipment weight must

not exceed 500 lbs. (226.8 kg).

AVERTISSEMENT: Cette produit est conçu pour être utilisé uniquement avec les produits et les poids maximum indiqué. unique-

ment avec les produits et les poids maximaux indiqués. En cas d'utilisation avec d'autres produits ou des produits plus lourds que

le poids maximal indiqué, le chariot peut devenir instable et causer des blessures. Le poids total de l'équipement ne doit pas

dépasser 226.8 kg (500 lbs).

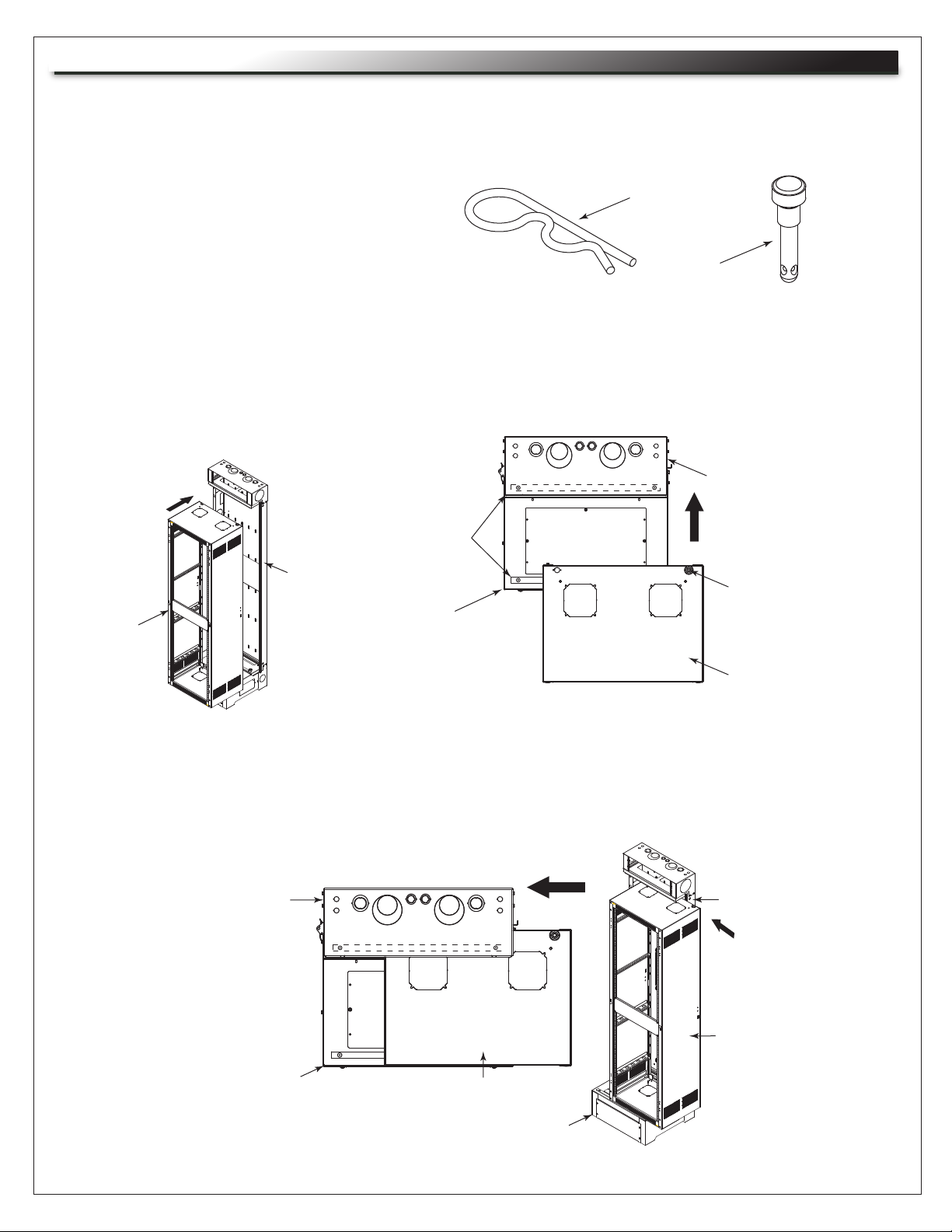

SUPPLIED COMPONENTS AND HARDWARE

Support Base

C

Backpan

A

REQUIRED TOOLS

• Power Driver

• 1/2” Socket

• 3/8” Socket

• 5/16” Deep Socket

(2x)

Center Section

B

Key

D

WARNING: Use tools with caution and follow all necessary safety

protocols.

AVERTISSEMENT: Utiliser des outils avec prudence et suivre

tous les protocoles de sécurité nécessaires.

Trim

E

• 3/16” Drill Bit

• Level

• 3’ Step Ladder (Optional)

• No. 2 Phillips Driver

INTRODUCTION

NOTE:

• Enclosures shown in this instruction sheet include show the zero clearance latch (DWRSR-ZL) and

sub plate (SR-SUB) options, which may or may not be a part of your configuration.

• Not all options available for the enclosure are included in these instructions and separate instruction

sheets are available for the individual options.

• Topics in this guide indicate that the zero clearance latch and sub plate options must be installed

prior to the enclosure assembly as do their separate instruction sheets.

Page 4

Page 5

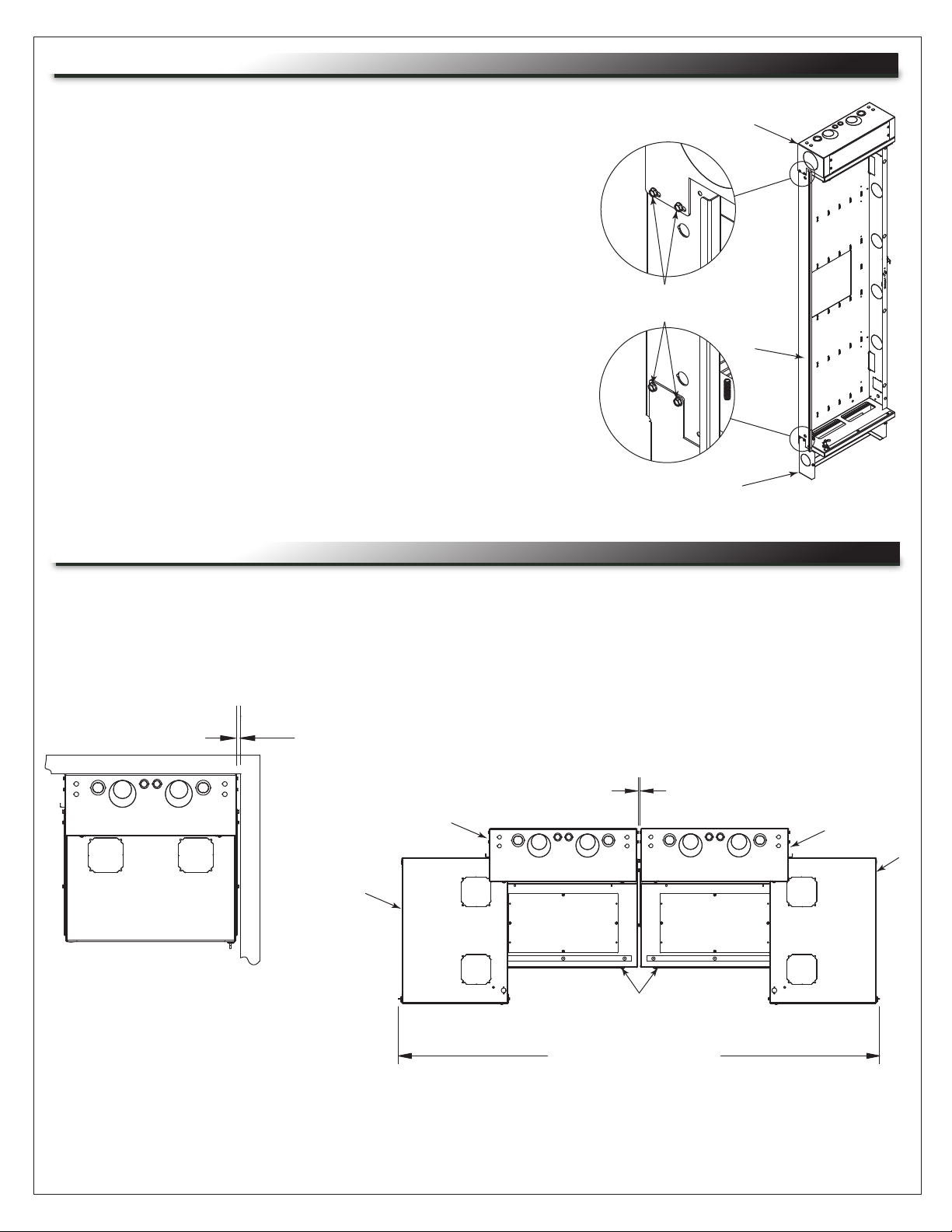

REVERSING THE PIVOT DIRECTION

This rack is factory configured for a right-hand pivot

and may be reversed using the following procedure:

1. If upper wire chamber is already installed, use a

5/16” socket to remove (4x) screws to remove it

from the backpan. (FIGURE A)

2. Use 5/16” socket to remove (4x) screws to remove

the backpan foot from the backpan.

3. Carefully rotate backpan (A) 180º.

4. Replace the upper wire chamber using previously

removed hardware.

5. Replace the backpan foot using previously

removed hardware.

NOTE: Holes are provided on both sides of center section

so bushing can be moved if rack is loaded and backpan

is mounted with pivot on wrong side. Top and bottom may

need to be removed for access to bushings.

ZERO CLEARANCE LATCH OPTION (DWRSR-ZL)

Upper Wire

Chamber

NOTE: Screws secure wire chamber

and foot on both sides of rack.

A

Backpan

Foot

FIGURE A

NOTE:

• Install the zero clearance latch option before mounting the backpan (A) to the wall and loading

equipment into the rack.

• For installation instructions, refer to the DWRSR-ZL Zero Clearance Latch instruction sheet (I-00142).

• The DWRSR-ZL must be installed for seismic compliance.

.57" min. distance required

between SR and wall or other

SR using Zero Clearance Latch.

.57" minimum distance

A

B

C

74.53" (SR-XX-22)

86.53" (SR-XX-28)

94.53" (SR-XX-32)

A

B

Page 5

Page 6

ZERO CLEARANCE LATCH OPTION (DWRSR-ZL, CONTINUED)

The zero clearance latch option saves

valuable wall space by allowing wall

B

racks to be placed side-by-side, in a

corner, or wherever side clearance is

an issue. This easy to install option

upgrades new SR Series racks to allow

the center section (B) to lock closed

without the need for side latches.

To open, simply pull the convenient

front-mounted handle. (FIGURE B)

Unlike time-consuming threaded rods,

the unique latch provides keylocked

security from the front (keyed

differently from optional front door).

FIGURE B

INSTALLING THE SUB PLATE MOUNTING OPTION (SR-SUB)

NOTE: Install the sub plate mounting option before mounting the backpan to the wall and loading

equipment into the rack.

• Insert self-clinching stud through

A

mounting holes in backpan (A),

89-D Bracket

(Not Included)

through SR-SUB, and then tighten

flange nuts on self-clinching studs.

(FIGURE C)

Hardware included with option.

• Each SR-SUB

allows for the

mounting of up

to (4x) 89-D type

brackets, (4x) 1900

boxes or (1x) Raco

3 gang box.

Self-Clinching

Stud

FIGURE C

Flange

Nut

SR-SUB

FIGURE D

(FIGURE D)

Hardware included

with option.

NOTE: Install the sub plate nounting option before mounting the backpan

(A) to the wall and loading equipment into the rack.

FIGURE E

• Mount up to (4x) SR-SUB sub plates to each backpan (depending on

model) using mounting holes and included hardware. (FIGURE E)

NOTE: Shown with center section (B) of enclosure removed for clarity.

Page 6

Page 7

PRIOR TO MOUNTING BACKPAN TO WALL

NOTE:

• When installing next to another SR or wall using the zero clearance latch option, perform the support

base (C) installation for access to the base screws before mounting the backpan (A). For more

information, see “Installing the Base” on page 8.

• On 46 space SR enclosures, you may install either a dust cover or upper wire chamber option on top

of the rack. For more information, refer to the Dust Cover and Upper Wire Chamber Options instruction

sheet (I-00155).

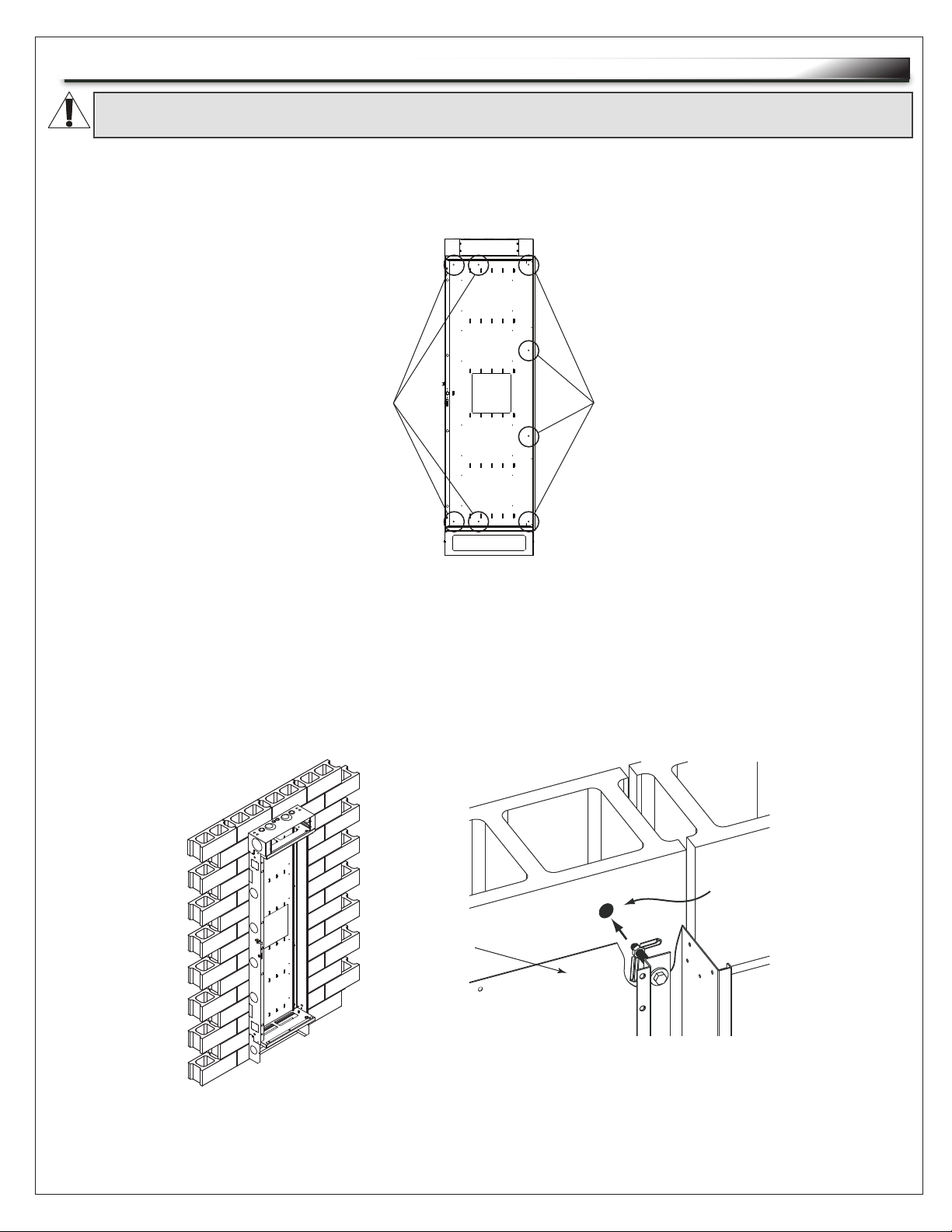

MOUNTING THE BACKPAN TO STUDS

CAUTION: The backpan must be installed plumb and level for proper operation.

ATTENTION: La plaque profilée doit etre aplomb et de niveau pour un fonctionnement.

NOTE:

• Ensure the backpan (A) is screwed to the

Wall Mounting Points

(Latch Side) for 16” Studs

studs. (FIGURE G)

• Use 5/16" diameter lag bolts with a

minimum length of 2" and standard flat

washers for hardware (not provided).

• The standard flat washers must be installed

under the lag bolt heads.

Wall

1. Align backpan (A) to selected wall location

and mark pilot holes through wall

mounting points as shown. (FIGURE F)

Mounting

Points

(Latch Side)

for 24” Studs

Wall Mounting Points

(Pivot Side)

FIGURE F

2. User power driver and 3/16” bit to drill pilot holes on stud center markings. (FIGURE F)

3. Use 1/2” socket, 5/16" lag bolts and washers (not provided) in 6 places: (4x) on pivot side and (2x)

on latch side. (FIGURE F)

1/2” Drywall

A

Stud

Lag bolt must protrude 2"

into the stud.

Drill 3/16"

pilot hole on

stud center.

FIGURE G

Page 7

Page 8

MOUNTING THE BACKPAN TO CONCRETE BLOCK (INSTALL NOT EVALUATED BY UL)

CAUTION: The backpan must be installed plumb and level for proper operation.

ATTENTION: La plaque profilée doit etre aplomb et de niveau pour un fonctionnement.

1. Align backpan (A) to selected wall location and mark pilot holes through wall mounting points as

shown. (FIGURE H)

Wall Mounting Points

(Latch Side)

NOTE: Only 1 column

necessary on latch

side.

Wall Mounting Points

(Pivot Side)

FIGURE H

2. Drill at least 1” into concrete block for your selected hardware (not provided). (FIGURE J)

3. Use toggle bolts and washers (or other appropriate hardware, not provided) in 6 places: (4x) on pivot

side and (2x) on latch side. (FIGURE H)

A

Page 8

1” Hole

in Block

FIGURE J

Page 9

INSTALLING THE BASE

1. Use 3/8” socket to remove (2x) 3/8” screws pre-installed on the bottom foot of the backpan (A).

(FIGURE K)

2. Position the support base (C) to the outside of the

backpan foot (A).

A

3. Use hardware from

previous step to attach

Base mounts to

outside of foot.

the base (C) to the

backpan foot (A).

Pivoting support base

compensates for

variations in floor.

PREPARING TO MOUNT CENTER SECTION

1. Use No. 2 Phillips driver to remove (4x)

screws and remove top access panel

from the upper wire chamber. (FIGURE L)

2. FOR 46 SPACE SR ENCLOSURES

ONLY: Remove dust cover, if installed,

before proceeding. For more

information, refer to the Dust Cover and

Upper Wire Chamber Options instruction

sheet (I-00155).

Access

Panel

FIGURE K

C

Panel removes

for wire access.

Upper

Wire

Chamber

FIGURE L

3. Use 5/16” socket to remove (2x) screws and bottom access panel on the pivot side of the base (C)

only. (FIGURE M)

C

FIGURE M

A

Access

Panel

Page 9

Page 10

MOUNTING THE CENTER SECTION TO THE BACKPAN

NOTE: The pivot pins and security clips needed to mount the center section (B) to the backpan (A) are

pre-installed in the bushings on the backpan top and bottom. (FIGURE N)

1. Remove the clips and unscrew the pins.

Security Clip

FIGURE N

Pivot Pin

2. Remove wire-tied trim inside of center section and set aside for installation.

3. Place center section (B) up on support base (C) with pivot bushing hanging over side of support base

approximately 3” to 6". (FIGURE P)

4. Push center section (B) back. (FIGURE R)

Wear Strip

A

C

B

Top View

A

Pivot

Bushings

B

FIGURE P

FIGURE R

5. Once pivot has passed lower and upper wear strips located on backpan (A), slide center section (B)

over to engage the pivot bushing. (FIGURE S)

Top View

A

A

FIGURE S

B

C

B

C

Page 10

Page 11

MOUNTING THE CENTER SECTION TO THE BACKPAN (CONTINUED)

6. Keeping the center section (B) in the closed position,

insert a pivot pin through the bottom access hole into

bushing, hand tighten fully, and then back out one

turn. (FIGURE T)

Upper

Wire

Chamber

7. Open center section (B) slightly for top pin alignment.

8. Going through the upper wire chamber, drop the

pivot pin into the top bushing (use tip of pin to find

NOTE: Center section

(B) removed for clarity.

alignment) and insert, hand tighten fully, and then back

out one turn.

Bottom

Access

Hole

FIGURE T

Engagement

Area

9. As a final security measure, open the

center section (B) and install security

clips through hole in the pivot pin. (This

prevents removal of the pivot pins from

Handle

the exterior of the enclosure.) (FIGURE U)

FIGURE U

NOTE:

• Slide security clip into engagement area. Do not push pin in all the way. (FIGURE U)

• The center section (B) may be secured to the backpan (A) using the latch.

• The keys (D) may be used for additional security when securing your enclosure in the closed position.

10. Re-install access panels by reversing the steps in “Preparing to Mount Center Section” on page 9.

11. FOR 46 SPACE SR ENCLOSURES ONLY: Install dust cover or upper wire chamber option.

For more information, refer to the Dust Cover and Upper Wire Chamber Options instruction sheet

(I-00155).

Page 11

Page 12

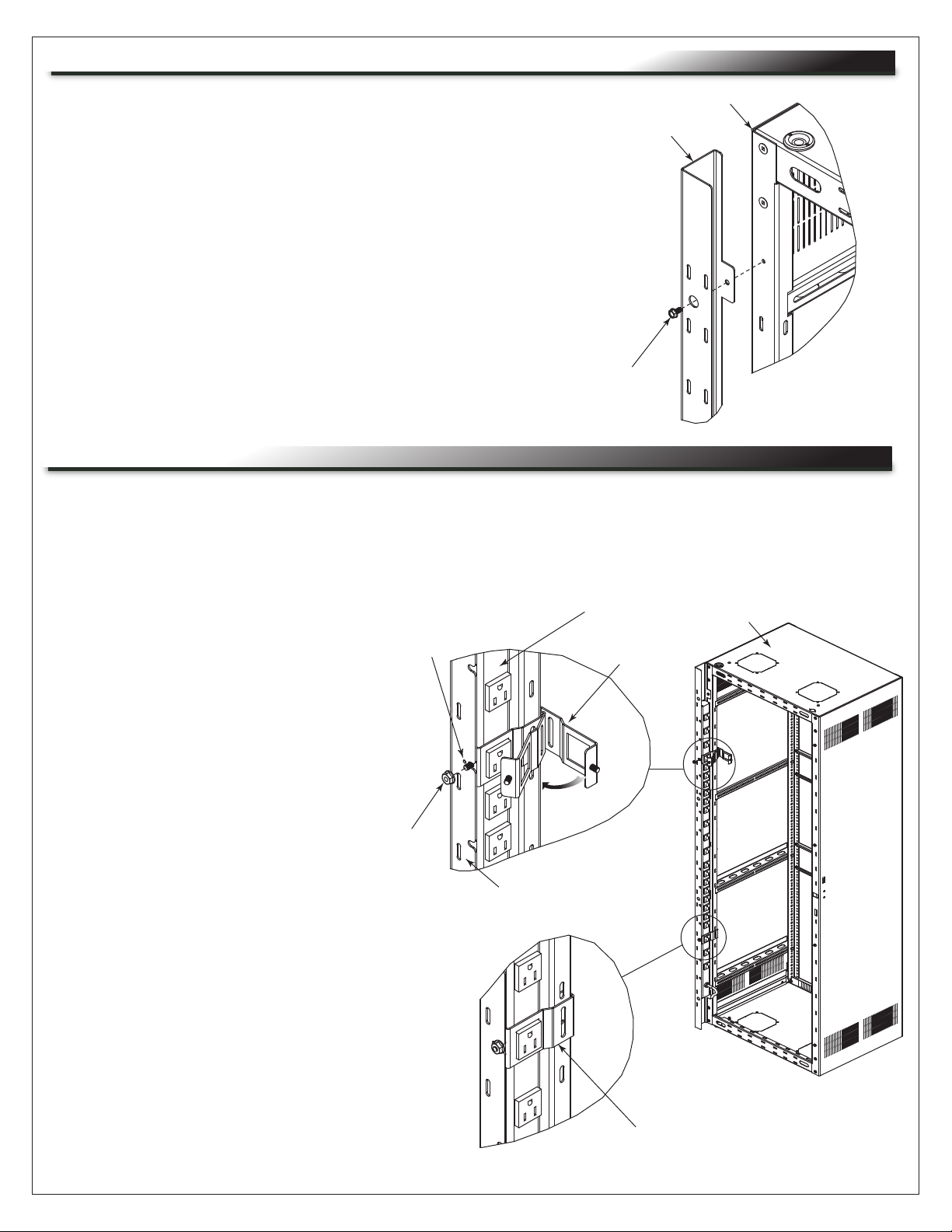

INSTALLING THE TRIM TO THE BACK, PIVOT SIDE OF THE CENTER SECTION

1. Pivot center section (B) into fully open position.

E

B

2. Use power driver and 5/16” deep socket to remove (4x)

pre-installed screws on the back, pivot side of the center

section (B).

3. Use hardware from previous step to attach trim (E) to the

center section’s (B) back, pivot side. (FIGURE W)

NOTE:

• Screws are supplied on both sides for your convenience.

• Leave unused screws in place on opposite side.

Pre-Installed

Thread Cutting

Screw

MOUNTING A POWER STRIP TO THE TRIM

Middle Atlantic Products power strips (PD-815SC, PD-815SC-NS, PD-2415SC,PD-2415SC-NS and

FIGURE W

PD-2420SC-NS only) can be mounted inside the center section trim (E) with the included hardware.

This simplifies cable management with no additional accessories required.

NOTE:

• PD-2415SC, PD-2415SC-NS,

and PD-2420SC-NS power

strips only fit in the 40 and 46

space wall racks and require

the use of 2 clips. Install clips

only to trim notches with a

hole.

• Power strips PD-815SC and

PD-815SC-NS fit in all SR

Series wall racks and require

only 1 clip. Clip can be

installed on any trim notch.

1. Place the power strip in the trim (E),

positioned so the clip mounts over an

outlet and aligns with the notch as

shown. (FIGURE X)

Notch With

Hole

Flange Nut

Power Strip

Clip

E

B

2. Install clip and tighten flange nut as

shown.

NOTE: Installation using a PD-24XX power

strip installed with 2 clips shown.

Page 12

Clip Shown Installed

FIGURE X

Page 13

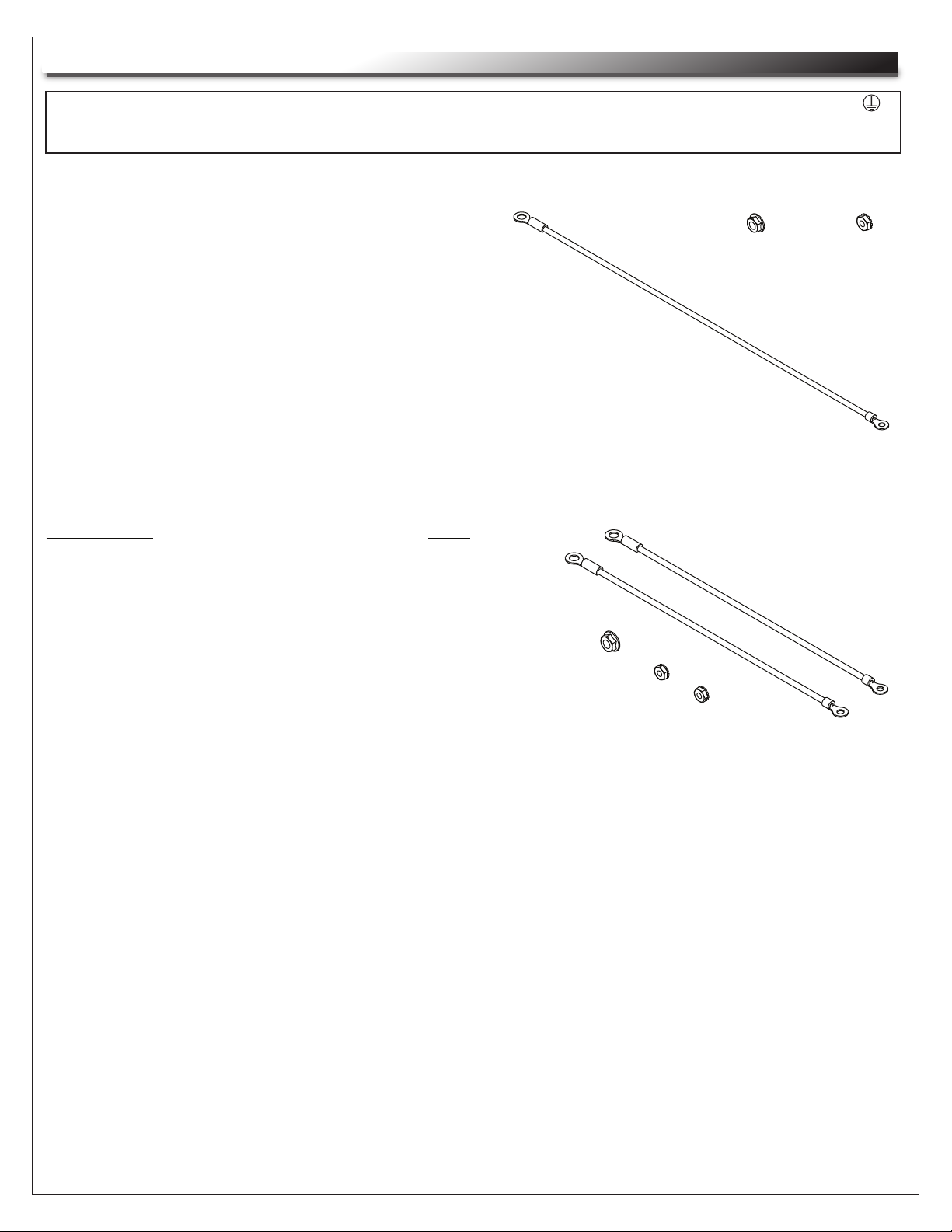

GROUNDING AND BONDING

Protective Earth Terminals (PET) are located in backpan of the wall rack. These terminals are marked with the symbol

Wall rack parts, center section and door, contain or are provided with bonding points for connection to the backpan / PET.

Protective earth and bonding connections shall be in accordance with Article 250 of the National Electric Code.

OPTIONAL PROTECTIVE EARTH TERMINAL KIT: #PET-K-D/EWR

PARTS LIST

• Backpan bonding wire [12 Gauge Wire

QTY

(1)

(#10 ring terminal to 1/4” ring terminal) 14”]

• Flange Nut 1/4-20

• Locking Nut 10-32

(1)

(1)

OPTIONAL PROTECTIVE EARTH TERMINAL KIT: #PET-K-SR

PARTS LIST

• Door bonding wire [12 Gauge Wire

QTY

(2)

(#10 ring terminal to 1/4” ring terminal) 9”]

• Flange Nut 1/4-20

• Locking Nut 10-32

(1)

(2)

(1)

(1)

(1)

Page 13

Page 14

GROUNDING AND BONDING (CONTINUED)

1. Attach backpan bonding wire from 1/4”-20 backpan protective earth terminal (PET) to nearest

center section (B) bonding stud (10-32) using hardware provided. (FIGURE Y)

NOTE: The main protective earth ground needs to be the first terminal placed on the PET and this

terminal needs to be secured on its own with a nut. The bonding wire for the center section (B) can

be added to the PET after securing the nut for the main ground.

2. Attach cable entry bonding wire from upper wire chamber to nearest 10-32

center section (B) bonding stud using hardware provided.

3. Attach base bonding wire from support base (C) to nearest

center section (B) bonding stud (10-32) using hardware provided.

B

(2x) 10-32 Upper Wire Chamber

(4x Upper, 4x Lower) 10-32

Center Section Bonding Studs

Upper Wire Chamber

Bonding Studs

(2x) 10-32 Base

Bonding Studs

(2x Upper, 2x Lower)

Backpan PET Studs

A

Top View

C

(2x Upper, 2x Lower)

Backpan PET Studs

FIGURE Y

Page 14

Page 15

WARRANTY

For warranty information, refer to http://www.middleatlantic.com/company/about-us.aspx#warranty

Corporate Headquarters

Corporate Voice: 973-839-1011 - Fax: 973-839-1976 / International Voice: +1 973-839-8821 Fax: +1 973-839-4982

www.middleatlantic.com - info@middleatlantic.com

Middle Atlantic Canada

Voice: 613-836-2501 - Fax: 613-836-2690 / ca.middleatlantic.com customerservicecanada@middleatlantic.ca

Factory Distribution

USA: NJ - CA - IL Canada: ON - BC

At Middle Atlantic Products we are always listening. Your comments are welcome.

Middle Atlantic Products is an ISO 9001 and ISO 14001 Registered Company.

Page 15

Page 16

Loading...

Loading...