Page 1

Instruction Sheet

FlexView

FVS Series

THANK YOU

Thank you for purchasing the FlexView FVS Series. Please read these instructions thoroughly

before installing this product.

PRODUCT FEATURES

• Middle Atlantic PD-815SC (8) outlet, 15 amp power strip with surge and circuit breaker

• Simple display mounting with choice of monitor height

• Lever Lock™ for easy mounting of Codecs and smaller components

• Adjustable cable management included

I-00668 Rev -

Page 2

IMPORTANT SAFETY INSTRUCTIONS

WARNING/CAUTION! The exclamation point within an

!

equilateral triangle is intended to alert the user to the

presence of important operating and maintenance

(servicing) instructions in the literature accompanying the

appliance

!

AVERTISSEMENT/ATTENTION! Le point d'exclamation

dans un triangle équilatéral est destiné à alerter l'utilisateur

de la présence d'importants instructions d’opération et de

maintenance (entretien) dans la documentation

accompagnant l'appareil.

WARNING! Failure to read, understand and follow the

!

following information can result in serious personal injury,

damage to the equipment or voiding of the warranty. It is

the responsibility of the Installer/User to ensure

that this product is loaded according to specifications.

CAUTION! To avoid an unstable condition, place heavier

!

components at the bottom of the cabinet. When more than

one component is placed in the cabinet, begin at the

bottom of the cabinet and place equipment at the lowest

available point, evenly distribute weight (vertically) within

the cabinet.

ATTENTION! Pour éviter une condition instable, placer

!

des composants plus lourds dans le bas de l'armoire.

Lorsque plus d'un composant sera placé dans l'armoire,

commencez en bas de l'armoire, placent l'équipement sur

le point le plus bas disponible, distribuant uniformément le

poids (verticalement) dans l l'armoire.

WARNING! For use with televisions weighing 190lbs

!

(86 Kg) or less. Use with heavier televisions may

result in instability causing tip over resulting in death

or serious injury.

AVERTISSEMENT! Refus de lire, comprendre et suivre

!

la renseignements suivants peut traduire par de graves

blessures, des dommages à l'équipement ou invalider la

garantie. Il est la responsabilité de l'installateur / utilisateur

de s'assurer que ce produit est chargé conformément aux

spécifications.

WARNING! The weight ratings of this product can be

!

found on the product. Exceeding these weight ratings can

result in serious injury or damage to the equipment. It is the

responsibility of the Installer/User to ensure the components

installed do not surpass the weight ratings as an unstable

condition can occur which may cause possible injury or

damage.

AVERTISSEMENT! Les caractéristiques de poids de ce

!

produit peuvent être trouvées sur le produit. Le

dépassement de ces caractéristiques de poids peut

entraîner des blessures graves ou des dommages

à l'équipement. C'est l'responsabilité de l'installateur /

utilisateur de s'assurer que les composants installé ne

dépassent pas les notes de poids comme un instable

condition peut se produire qui peut causer des blessures

ou dommages.

WARNING! Relocating audio and/or video equipment to furniture

!

not specifically designed to support audio and/or

video equipment may result in death or serious injury due to

the furnishing collapsing or over turning onto a child.

AVERTISSEMENT - Pour utilisation avec des téléviseurs

!

pesant 190 lbs (86.2 kg) ou moins. Utilisation avec des

téléviseurs plus lourds peut provoquer une instabilité

entraînant l’unité a basculer, que peut causer la mort ou

des blessures graves.

WARNING! Death or serious injury may occur when children

!

climb on audio and/or video equipment furniture. A remote control

or toys placed on the furnishing may encourage a child to climb

on the furnishing and as a result the furnishing may tip over on to

the child.

AVERTISSEMENT - Mort ou blessures graves peuvent se

!

produire lorsque les enfants montent sur des meubles pour

l'audio et / ou vidéo. Une télécommande ou des jouets mis sur

le mobilier peuvent encourager un enfant à grimper sur le

meuble, provoquant une instabilité et entraînant l’unité a basculer

sur l'enfant.

AVERTISSEMENT - Déplacement de l’équipements audio et /

!

ou vidéo sur des meubles pas conçu spécifiquement à soutenir

l'équipement audio et / ou vidéo peuvent entraîner la mort ou

des blessures graves cause par l’effondrement du meuble ou

en basculant sur un enfant.

• Clean only with dry cloth

Nettoyer avec un chiffon sec seulemen

Page 2

Page 3

TABLE OF CONTENTS

Important Safety Instructions Page 2

Weight Ratings Page 4

Mobility Features Page 4

Tools Required Page 4

Hardware / Items Supplied Page 5

Flat Panel Installation Page 6

Flat Panel Installation (Continued) Page 7

Vesa 800 Extension Bracket Installation (If Required) Page 8

Flat Panel Installation (Continued) Page 8

Flat Panel Installation (Continued) Page 9

Door Reversal Procedure Page 10

Lever Lock

Cable Management / Equipment Mounting Page 12

™ Tool Free Internal Management System Page 11

Page 3

Page 4

WEIGHT RATINGS

ITEM

Screen

Screen (Including Camera Mount and Soundbar Mount)

Internal

Total Rated Load

DETAILS

175 lbs. (79.4 kg) Maximum

190 lbs. (86.2 kg)

50 lbs. (23 kg) Maximum

240 lbs. (109 kg) Maximum

Maximum

MOBILITY FEATURES

• (4) Directional locking casters are provided to allow easy “steering” of unit in locked direction.

NOTE: Push levers to lock, lift levers to unlock.

To prevent FlexView from moving, lock casters

perpendicular to each other as shown:

TOOLS REQUIRED

• #2 Phillips Screwdriver

• Protective Eyewear

• Adjustable Wrench

• 1/2” Socket

• 7/16” Socket

Page 4

Page 5

HARDWARE/ITEMS SUPPLIED

NOTE: Additional hardware is included

that may not be required for your installation.

#6 Washers For Mounting

Small-Screw Components

To Lever Lock™ (Qty 20)

Plastic Lever Lock™

Locking Rivets (Qty 3)

Cable Management

Clips (Qty 8)

Pan Head Screws 8-32 x 3/8”

(Qty 8)

FLAT PANEL MOUNTING HARDWARE

M4 x 16

M4 x 25

M5 x 12

M5 x 16

M5 x 20

M5 x 25

M5 x 50

M6 x 12

M6 x 20

M8 x 20

(Qty 8)

(Qty 4)

(Qty 8)

(Qty 6)

(Qty 6)

(Qty 4)

(Qty 8)

(Qty 8)

(Qty 6)

(Qty 6)

5/16” Flat Washers

(Qty 10)

5/16”-18 Hex Head

Monitor Mount Bolts

(1/2” Socket Req’d)

(Qty 4)

Thread Depth Indicator

(Qty 1)

Keys (Qty 2)

Vertical Monitor

Mounting Brackets

(Qty 2)

Flange Nuts 5/16” - 18

(Qty 8)

VESA 800 Monitor

Adapter Brackets

(Qty 2)

M8 x 25

M8 x 30

M8 x 35

M8 x 70

1/4” Small Nylon Spacers

(Qty 6)

1/2” Small Nylon Spacers

(Qty 6)

(Qty 6)

(Qty 6)

(Qty 4)

Universal Washers

(Qty 8)

(Qty 4)

1/4” Large Nylon Spacers

(Qty 6)

1/2” Large Nylon Spacers

(Qty 12)

Wire Ties (Qty 12)

Vertical Mounting

Bracket Locking Screws

10-32 x 3/4”

(Qty 2)

1” Nylon Spacers

Page 5

(Qty 6)

Nylon Spacers

(Qty 4)

Level

(Qty 1)

Page 6

FLAT PANEL INSTALLATION

NOTE: Horizontal mounting bracket

is pre-installed on FlexView at top

height. Perform the following steps

to adjust height of horizontal

mounting bracket.

Outer Screws

1/4-20 x 1”

(Qty 2)

1) Remove (2) 1/4”-20 x 1” outer screws and

(2) 1/4”-20 x 1/2” inner screws securing

horizontal mounting bracket to

FlexView. (FIGURE A)

2) Determine appropriate display height

and secure horizontal mounting bracket

to FlexView with (2) 1/4”-20 x 1” outer

screw and (2) 1/4”-20 x 1/2” inner

screws using the available holes for

mounting. (FIGURE A, B)

WARNING! Do not adjust height of

!

horizontal mounting bracket with

display attached.

Inner Screws

1/4”-20 x 1/2”

(Qty 2)

Vertical

Mounting

Brackets

Vertical Mounting

Bracket Locking Screws

10-32 x 3/4” (Qty 2)

Outer Screws (2) 1/4”-20 x 1”

Inner Screws (2)

1/4”-20 x 1/2”

Horizontal

FIGURE A

Mounting Bracket

Vertical Mounting Bracket

Locking Screws (2) 10-32 x 3/4”

Grommets (2)

(Reposition as needed)

FIGURE B

(REAR DOOR REMOVED)

Page 6

Page 7

FLAT PANEL INSTALLATION (CONTINUED)

Selecting The Mounting Hardware To Attach Brackets To Flat Panel

1) Identify the correct diameter screw for the flat

panel threaded inserts. The correct screws

should thread easily and not pull out when

tension is applied.

2) To determine proper screw length, insert thread

depth indicator into a threaded insert on the flat panel.

3) Mark the thread depth indicator 1/8” above the

depth of the threaded insert. (FIGURE C)

4) Select a screw that is shorter than the 1/8” mark

made on the thread depth indicator.

CAUTION! Do not use any screw longer than the 1/8”

!

mark or damage to the flat panel may occur.

Mark 1/8” Above Depth

Threaded Insert

Thread Depth Indicator

FIGURE C

Small Straw

or toothpick

Depth Plus 1/8”

Allowance Mark

Small Straw

or toothpick

Depth Plus 1/8”

Mark Allowance

Universal Washers

Universal washers are designed to accommodate the various M4, M5, M6 and M8 hole sizes found in

flat panels.

Page 7

Page 8

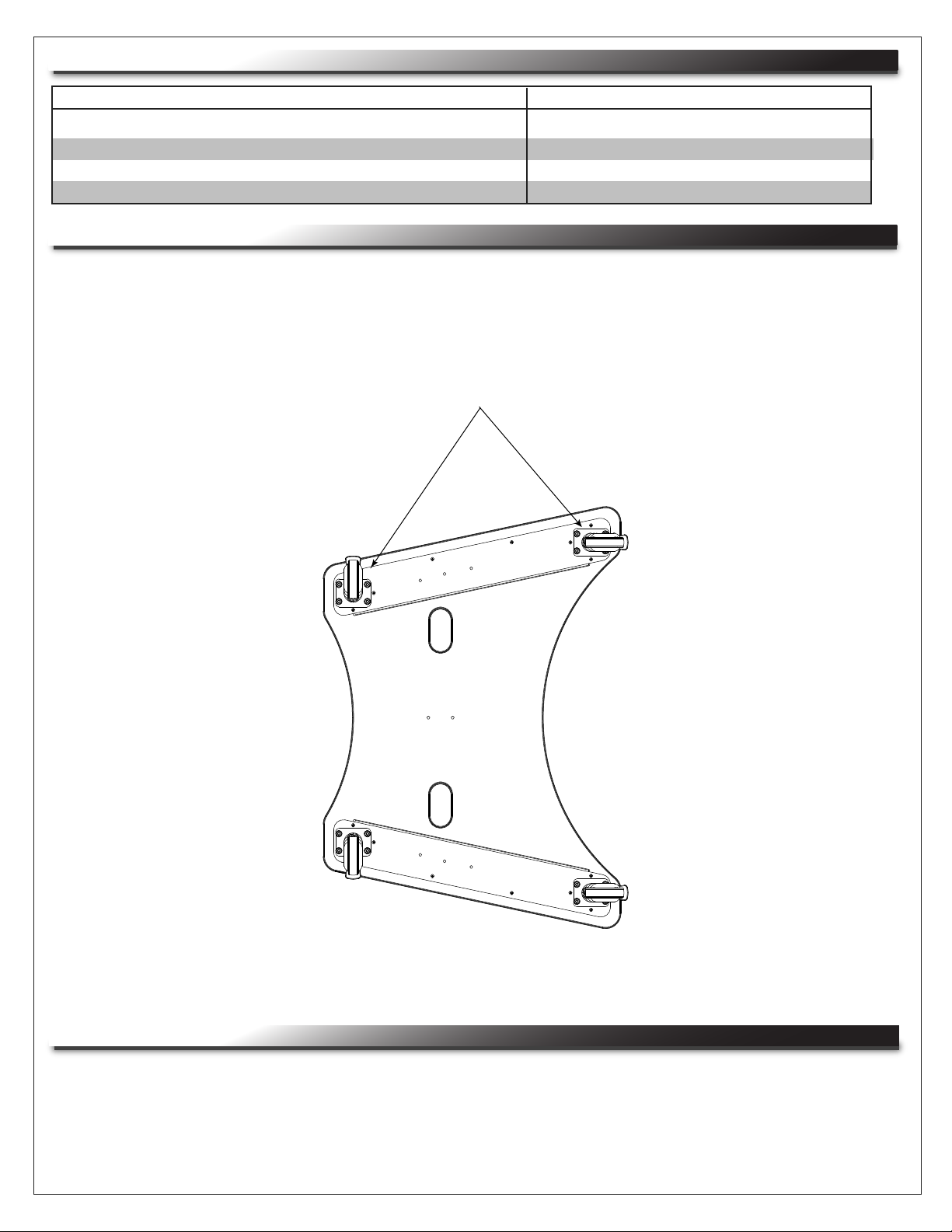

VESA 800 EXTENSION BRACKET INSTALLATION (IF REQUIRED)

1) For monitors that require VESA 800 spacing, the VESA 800 monitor adapter bracket must be

used (not required for VESA 600 or less spacing).

2) Place vertical monitor mounting brackets over VESA 800 adapter bracket studs and secure using

(4) 5/16” -18 flange nuts. (FIGURE D)

VESA 800 Monitor

Adapter Bracket (1)

Vertical Monitor

Mounting Bracket (1)

Flange Nuts

5/16”-18 (4)

FIGURE D

FLAT PANEL INSTALLATION (CONTINUED)

NOTES:

• Place flat panel on soft, flat surface while working.

• Do not place excessive pressure on back of the flat panel.

• Universal washers must be installed between the head of the

mounting screw and the vertical mounting bracket as shown.

(FIGURE E)

Nylon Spacers (FIGURE F, PAGE 9)

Nylon spacers add distance between vertical

mounting bracket and flat panel. They will fit

all supplied screw sizes. The spacers must be

used only when attaching flat panels which have:

• Recessed mount points

• Uneven mount points

Universal

Washers (4)

• Any obstruction near the mount points

• A curved back

Dimples (Face Up)

Universal

Washer

Mounting Screws (4)

M8

M6

M5

M4

NOTES:

• Nylon Spacers must be stacked and oriented as shown.

• Nylon Spacers must only be installed between the

vertical mounting bracket and the flat panel.

Page 8

Vertical Mounting Brackets (2)

FIGURE E

Page 9

FLAT PANEL INSTALLATION (CONTINUED)

Attaching Vertical Mounting Brackets to Flat Panel

NOTE: The brackets are indicated (L) Left and (R) Right.

1) Place the flat panel face down on a soft, flat surface and

identify the number and location of screws.

2) Align the holes on each vertical mounting bracket with the

Mounting Screw

Universal

Washer

Vertical

Mounting

Bracket

threaded inserts on the flat panel. (FIGURE F)

NOTE: To ensure a neat appearance, center vertical

mounting brackets on flat panel. Do not extend

Nylon Spacer

brackets past top or bottom of flat panel.

Flat Panel

3) Secure each vertical mounting bracket with the

FIGURE F

screws and hardware identified in previous

steps. Use a minimum of (2) mounting screws per

vertical mounting bracket.

WARNING! This operation requires two people. Do not release your flat panel until you are certain

!

that the top hook of each vertical mounting bracket is securely seated on the upper rail of the

horizontal mounting bracket.

Hanging the Flat Panel

Vertical Mounting

Bracket

1) Raise the flat panel slightly above the top and

bottom rails on the horizontal mounting bracket.

(FIGURE G)

FIGURE G

Horizontal

Mounting

Bracket

Flat Panel

2) Place the flat panel down slowly, ensuring that

the top and bottom hooks on the vertical

mounting brackets properly engage the horizontal

mounting bracket. (FIGURE G)

3) Check for proper height.

NOTE: Achieving desired height may require

repositioning of horizontal mounting bracket

and / or removal and re-installation of vertical

mounting brackets.

4) Secure vertical mounting bracket to cart using

(2) 10-32 x 3/4” locking screws.

(FIGURE A, PAGE 6)

Page 9

Page 10

DOOR REVERSAL PROCEDURE

1) Lift and twist door hinges to remove door. (FIGURE H)

FIGURE H

2) Remove and reinstall hinge on opposite side. (FIGURE I)

FIGURE I

Page 10

Page 11

Page 11

LEVER LOCK™ TOOL FREE INTERNAL MANAGEMENT SYSTEM

The FlexView comes equipped with the following Lever Lock™ items: (6) LL receptacle brackets,

(2) LL-HC21 horizontal channels, and (1) LL-VP2110 vertical 10” deep plate. Additionally, a “Knobs up

or ”Knobs down” 2-space rail is provided.

Use Receptacle

Brackets To Lace

Cable Bundles

From Top To Bottom

2-Space Rail

Lever Lock™ Plate Installation / Configuration

Use Vertical

Plate To Mount

Small Devices

Use Horizontal

Channels To

Manage Cables

1) Insert the Lever Lock™ plate into the

mating slots in the upper horizontal channel.

(FIGURE J)

2) Secure lock mechanism into the mating slots

in the lower horizontal channel. (FIGURE J)

NOTE: Position the flanges to the outside of

the rack to maximize usability.

Horizontal Channel Installation / Configuration

1) Insert horizontal channels into the mating slots in

the side receptacle brackets. Ensure the lock

mechanism is facing the bottom of the rack.

(FIGURE K)

2) Push horizontal channels into place until

locking mechanism ‘clicks’.

Locking Rivet Installation

FIGURE J

Locking Rivet

1) Install plastic locking rivet into the inner

holes as shown to prevent locking

mechanism from disengaging. (FIGURE L)

Lock Mechanism

FIGURE K

FIGURE L

Page 12

CABLE MANAGEMENT / EQUIPMENT MOUNTING

Cables can be secured to movable clips (provided) using wire ties. Position and secure clips in

channels as necessary using screws. (FIGURE M)

Clip

Cable

Screw

(Knobs Up) 2 Space Rackrail

Middle Atlantic PD-815SC

(8) outlet, 15 amp power strip

Accessory / Storage Trough

with surge and circuit breaker

FIGURE M

WARRANTY

Middle Atlantic Products (the "Company") warrants the FlexView FVS Series for a period of (7) seven years from date of shipment by the

Company.

The Company's entire liability to the purchaser, and the purchaser's (or any other party's) sole and exclusive remedy, under this warranty

shall be limited, at the Company's option, to either (a) return of and refund of the price paid for, or (b) repair or replacement at the

Company's factory of the products purchased, or any part or parts thereof, which the Company has determined to be defective after

inspection thereof at the Company's factory.

This warranty does not cover damage due to acts of God, accident, misuse, abuse or negligence by parties other than the Company, or

any modification or alteration of the products. In addition, this warranty does not cover damage due to improper handling, assembly,

installation or maintenance.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES OF ANY KIND, EITHER EXPRESSED OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, IN NO EVENT SHALL THE COMPANY BE LIABLE FOR ANY

SPECIAL, INCIDENTAL, INDIRECT, OR CONSEQUENTIAL DAMAGES WHATSOEVER (INCLUDING, WITHOUT LIMITATION,

DAMAGES FOR LOSS OF BUSINESS PROFITS, BUSINESS INTERRUPTION OR ANY OTHER PECUNIARY LOSS) ARISING OUT OF

THE USE OF THE PRODUCTS PURCHASED, EVEN IF THE COMPANY HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES. THE COMPANY'S LIABILITY TO THE PURCHASER (OR ANY OTHER PARTY) HEREUNDER, IF ANY, SHALL IN NO

EVENT EXCEED THE PURCHASE PRICE OF THE PRODUCTS PAID TO THE COMPANY.

Corporate Headquarters

Corporate Voice 973-839-1011 - Fax 973-839-1976 / International Voice +1 973-839-8821 - Fax +1 973-839-4982

middleatlantic.com - info@middleatlantic.com

Middle Atlantic Canada

Voice 613-836-2501 - Fax 613-836-2690 / middleatlantic.ca - customerservicecanada@middleatlantic.ca

Factory Distribution

USA: NJ - CA - IL Canada: ON - BC

At Middle Atlantic Products we are always listening. Your comments are welcome.

Middle Atlantic Products is an ISO 9001 and ISO 14001 Registered Company.

Page 12

Loading...

Loading...