Midco Unipower V4, Unipower V1, Unipower V2, Unipower V3, Unipower V5 Oem Installation & Start Up Instructions

...Page 1

OEM Installation & Start Up Instructions

C

O

M

P

A

N

Y

R

E

G

I

S

T

E

R

E

D

E

D

• In the United States, installation must conform with local

codes or in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1-latest edition available from

American National Standard Institute. Further reference

should be made to the recommendation of your fuel supplier.

• In Canada, installation must conform with local codes or in

the absence of local codes, with Installation Codes for Gas

Burning Appliances and Equipment, Standard CAN/CGA

1-B-149.1 or 2.

• WARNING: Additions, changes, conversions and

service must be performed by an authorized Midco

representative, service agency or the fuel supplier. Use

only MIDCO specifi ed and approved parts.

• INSTALLER: Inform and demonstrate to the user the correct

operation and maintenance of the gas utilization equipment.

Inform the user of the hazards of storing fl ammable liquids

and vapors in the vicinity of this gas utilization equipment

and remove such hazards. Affi x this manual and associated

literature to the burner.

• CODE COMPLIANCE IS THE SOLE RESPONSIBILITY

OF THE INSTALLER.

Unipower VA Series

Variable Air Gas Burners

OEM Start Up

WARNING: If the information in these instructions

is not followed exactly, a fi re or explosion may result,

causing property damage, personal injury or death.

Do not store or use gasoline or other fl ammable vapors and

liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately phone your gas supplier from another

building. Follow the gas supplier’s instructions. If

you cannot reach your gas supplier call the fi re

department.

Installation and service must be performed by a qualifi ed installer, service agency or the gas supplier.

BURNER MODEL: _____________________________________

BILL OF MATERIAL

NUMBER: ____________________________________________

SERIAL NUMBER #: ___________________________________

WIRING DIAGRAM: ___________________________________

FOR SERVICE CONTACT

Name: ____________________________________________

Address: ____________________________________________

____________________________________________

Phone: ____________________________________________

• USER: Retain this manual for future reference. If other

Date of Installation: ___________________________________

than routine service or maintenance as described in this

manual and associated literature is required, contact a

qualifi ed service agency. DO NOT ATTEMPT REPAIRS.

An inadvertent service error could result in a dangerous

condition.

AVOID ERROR IN PARTS SELECTION. When ordering use

complete MIDCO Part Number and Description. Furnish Burner

Model Number, Bill of Material Number and Serial Number (if

available) from the specifi cation plate found on the product

IMPORTANT: Availability of parts as well as specifi cations are

subject to change without notice. Please consult factory for item

availability.

SAFETY INFORMATION TERMS: The following terms are used to identify hazards, safety precaution of special

notations and have standard meanings throughout this manual. They are printed in all capital letters using a

bold type face as shown below, and preceded by the exclamation mark symbol. When you see the safety alert

symbol and one of the safety information terms as shown below, be aware of the hazard potential.

Midco® International Inc.

4140 West Victoria Street

Chicago, Illinois 60646

toll free 866.705.0514

tel 773.604.8700

fax 773.604.4070

web www.midcointernational.com

e-mail sales@midcointernational.com

CAUTION: Identifi es unsafe practices which would result in minor personal injury or

product and property damage.

DANGER: Identifi es the most serious hazards which will result in severe personal injury or death.

WARNING: Signifi es a hazard that could result in personal injury or death.

Quality Designed for Proven Performance

U

C

LISTED

IHEA

L

US

®

Member

8478 00

Printed in USA

619

Page 2

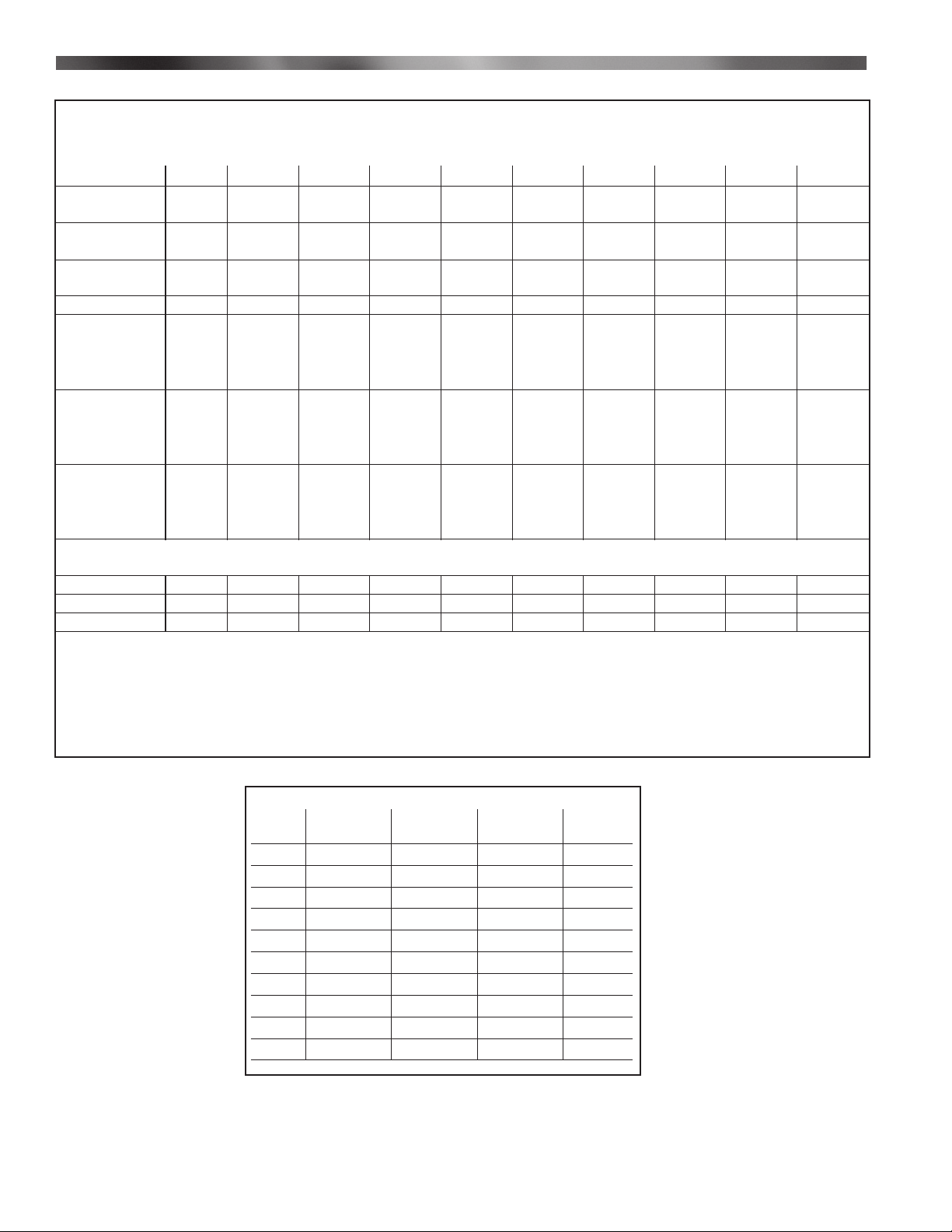

Installation - Speci cations

Specifi cations 1

The VA Series, Models V1 to V 6 burners with intermittent spark ignited pilots and V7 to V10 with interrupted pilots are adaptable

to most gas utilization equipment, including gravity and forced circulation furnaces, heat exchangers and process ovens. They are

particularly recommended for fi ring high effi ciency and high turndown applications.

Burner Model V1 V2 V3 V4 V5 V6 V7 V8 V9 V10

Maximum Input

at 10″

(MBH/hr)

Maximum Input

at 7″

(MBH/hr)

Minimum

Input

(MBH/hr)

Turndown 19-1 26-1 25-1 25-1 25-1 25-1 24-1 24-1 25-1 25-1

Inlet Gas

pressure for

maximum

fi ring rate

Manifold gas

pressure for

maximum

fi ring rate

Approximate

Air Delivery at

Zero Draft

2,3

670 1,260 2,000 2,000 2,500 2,500 3,000 3,000 3,800 3,800

2,3

550 1,150 1,890 1,890 2,500 2,500 3,000 3,000 3,300 3,330

2,3

36 48 80 80 100 100 120 120 150 150

4

(NG) 10.0″ 10.0″ 10.0″ 10.0″ 10.0″ 10.0″ 10.0″ 10.0″ 10.0″ 10.0″

(NG) 5.0″ 3.4″ 3.9″ 3.9″ 4.3″ 4.3″ 4.4″ 4.4″ 4.9″ 4.9″

(CFM) 115 210 360 360 440 440 620 620 720 720

Minimum Recommended Chamber Size

Width 18 24 34 28 42 30 48 36 54 36

Height 18 24 26 28 26 36 28 42 28 42

Depth 42 48 54 54 60 60 66 66 72 72

1

Standard burners are shipped as NATURAL gas models. Contact Midco for PROPANE gas burners.

2

1 MBH = 1,000 Btu/hr

3

All Ratings Based on 1000 BTU/Cu. Ft. NATURAL, 2500 BTU/Cu. Ft. PROPANE at sea level. Derate burner for altitude over 2,000 feet by 4%

for each 1,000 feet above sea level.

4

Lower gas inlet pressure may be used when maximum input is not required. Burner input based on 0.5″ W.C. back pressure.

Table 1. Burner Specifi cations

Burner Control Motor TOTAL Motor

Model amps amps amps HP

V1 1.3 3.5 4.8 .32

V2 1.6 4.0 6.8 .50

V3 1.5 10.5 12 1.10

V4 1.5 10.5 12 1.10

V5 2 10.5 12.5 1.10

V6 2 10.5 12.5 1.10

V7 2.1 13 15.1 1.75

V8 2.1 13 15.1 1.75

V9 2.1 13 15.1 1.75

V10 2.1 13 15.1 1.75

2

Midco International Inc.

8478 00

Page 3

Installation - Startup Adjustment

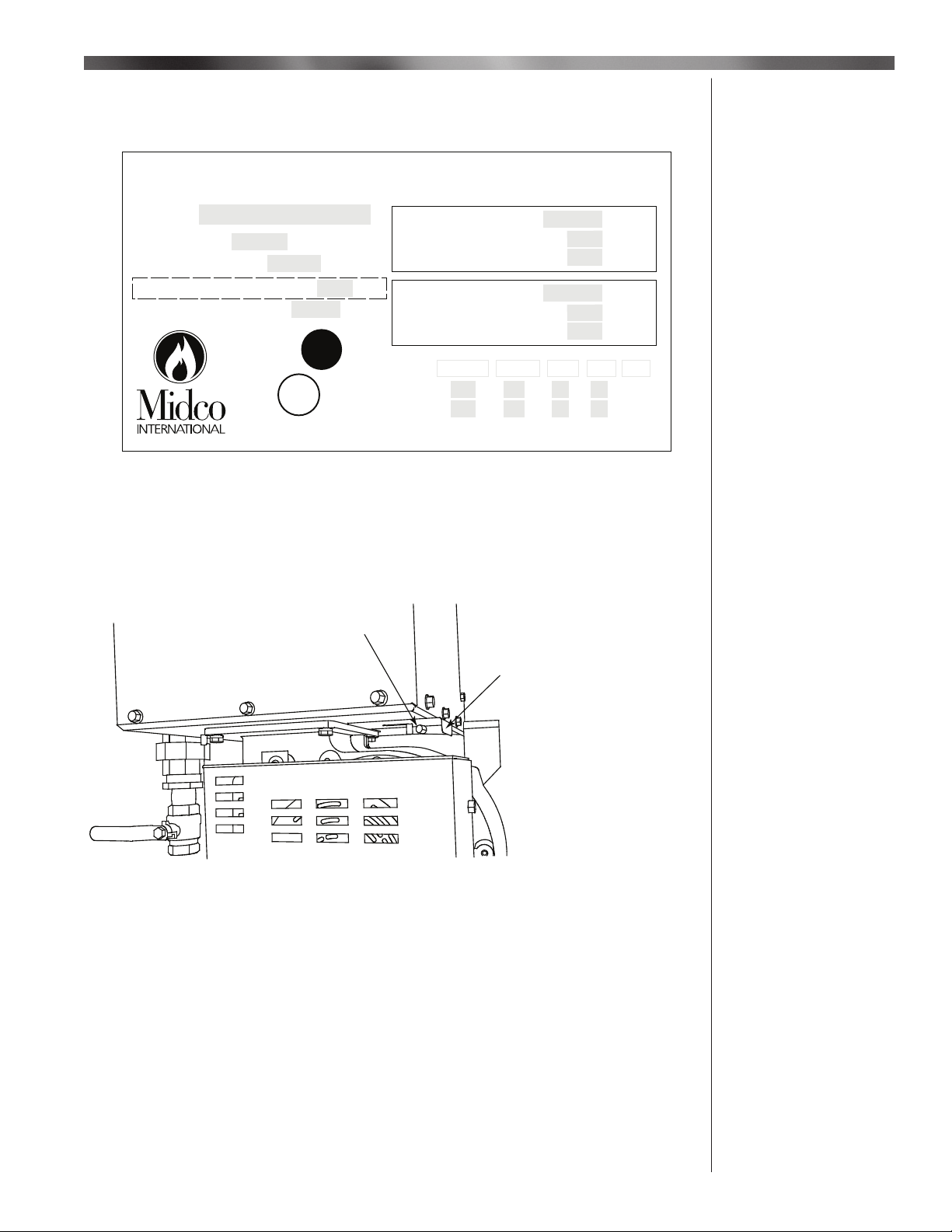

- Before opening the main supply gas valve, see Figure 3 - item # 9, verify that the inlet

pressure is below the maximum inlet pressure specifi ed on the Burner Rating Label,

see Figure 1.

- Exposing components to pressure above the maximum inlet pressure can cause damage.

®

UNIPOWER VA Gas Burner

MODEL:

SERIAL NO.:

BILL OF MATERIAL:

MAXIMUM INLET PRESSURE: W.C.

Î

MINIMUM FIRING RATE: BTU/HR

NAT

®

CHICAGO, IL 60646

Figure 1. Burner Rating Label - Maximum Inlet Pressure

_____________________________________

U

®

L

C

LISTED

No. Pl-100, 058

US

FIRING RATE: BTU/HR

PRESSURE REQUIRED: W.C.

MANIFOLD PRESSURE: W.C.

MAX. CAPACITY: BTU/HR

PRESSURE REQUIRED: W.C.

MANIFOLD PRESSURE W.C.

VOLTS

CONTROLS

MOTOR

AMPS HZ PH HP

7”

10”

2121-07

I

Confi rm Inlet Pressure

- Confi rm that the air damper, see Figure 2, is completely open and has not been

inadvertently moved during packing, shipping, or installation.

- To open, loosen the nut that secures the damper and pull it outward. Then retighten

the nut.

Slide

Loosen the Nut

Outward

to Open

Figure 2. Air Damper

_____________________________________

II

Check Air Damper

8478 00

Midco International Inc.

3

Page 4

Installation

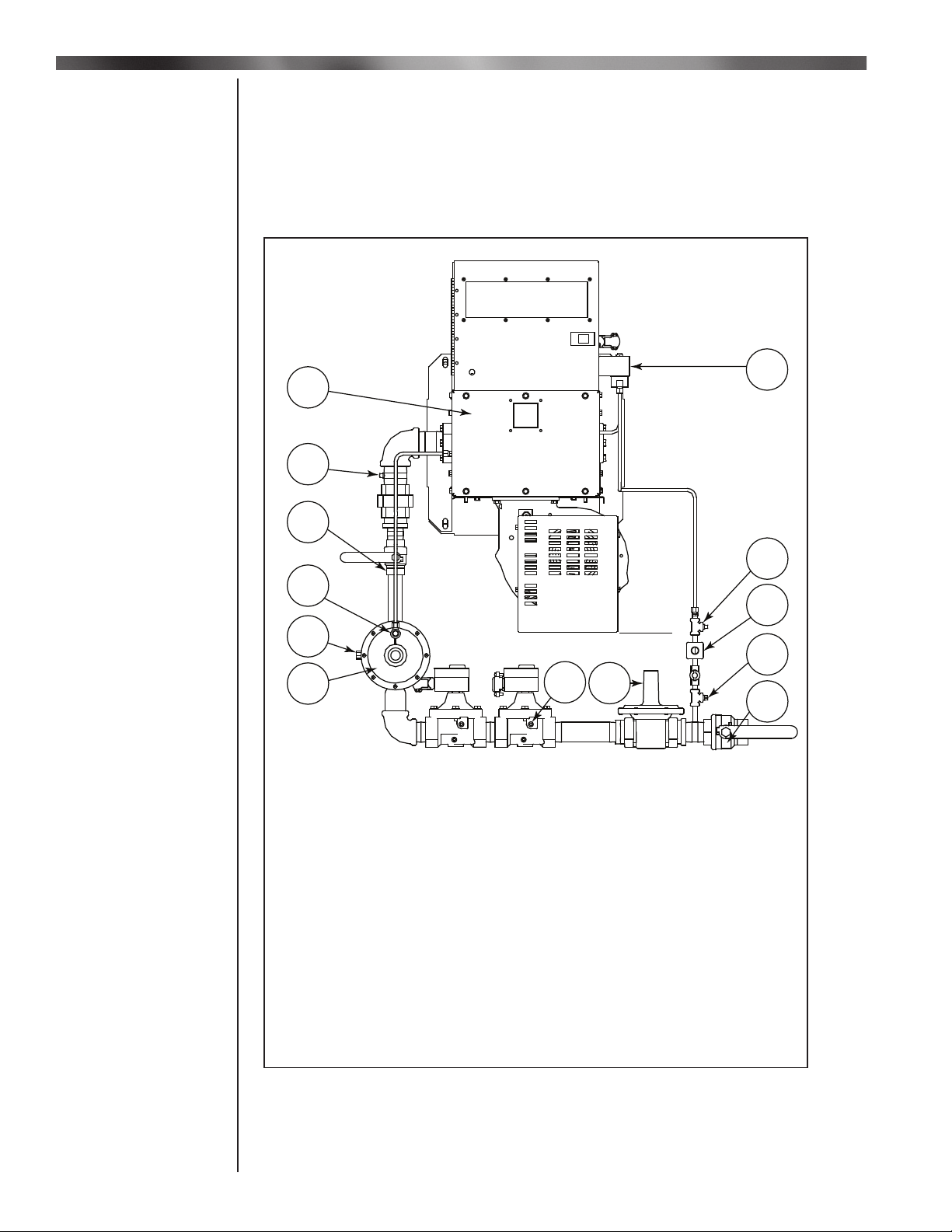

Install Shut-Off Type

Pressure Fittings

III

- Install the necessary fi ttings so that pressure can be measured at fi ve points

listed below ...

Refer to Figure 3:

a. Manifold pressure - item # 2

b. Load line pressure - item # 4

c. Main gas regulator outlet pressure - item # 7

d. Inlet pressure - item # 10

e. Pilot pressure - item # 12

1

2

13

3

4

5

6

7

8

Item # Description

1. Back Plate

2. Main Gas Manifold Pressure Tap

3. Manual Firing Valve

4. Load Line Pressure Tap

5. Low Fire Bypass

6. Ratio Regulator

7. Main Gas Regulator Outlet Pressure Tap

8. Main Gas Regulator

9. Main Supply Gas Valve

10. Inlet Gas Pressure Tap

11. Pilot Gas Regulator

12. Pilot Gas Manifold Pressure Tap

13. Pilot Solenoid Valve

12

11

10

9

Figure 3. Component and Pressure Tap Locations

_____________________________________

4

Midco International Inc.

8478 00

Page 5

Installation

- Close manual fi ring valve - see Figure 3, item # 3

- Open main Supply gas valve - see Figure 3, item # 9

- Initiate burner operation

a. The following are required to initiate burner operation:

1. 120V AC power supply

2. The on/off switch on the front of the burner needs to be in the on position

3. There needs to be at least a 2.0V DC signal from a temperature control or a

DC Volt generator.

b. The call for heat signal needs to be closed. With a call for heat the burner will

enter Purge Mode - see page 8, SCEBM-2 Module, paragraph a.

c. After the purge time specifi ed by the control the burner will attempt to ignite the

pilot

d. After the pilot is established, the burner will ignite the main fl ame

e. When the main fl ame ignites the burner will be in Run Mode

_____________________________________

- Use a manometer to check the pilot pressure on the tee downstream of the pilot

regulator, see Figure 4 - item # 2.

- For intermittent pilot systems

a. 3.2″ to 3.5″ W.C. pressure (internal pilot).

- For interrupted pilot systems

a. 1.5″ to 2.0″ W.C. pressure (external pilot ).

- Note: If adjustment is necessary the adjustment must be made while the pilot solenoid

valve is open and pilot gas is fl owing. Keep in mind that on interrupted pilot systems

the pilot solenoid valve closes after a set period of time after the main gas is turned on.

IV

Ignite Burner Pilot

V

Adjust Pilot Pressure

1

2

3

1. Pilot Pressure Regulator

2. Pilot Pressure Tap

3. Inlet Gas Pressure Tap

Figure 4. Pilot Gas Pressure Tap and Regulator

_____________________________________

- Open Manifold Gas Shut-off Valve, see Figure 3 - item # 3

- Adjust the input signal to 2.0V DC

- Use the sight glass on the back plate of the burner to look at the low fi re. If light

is visible through all of the holes in the burner plate, the low fi re is set within the range

of operation of the burner. If light is not visible coming through all of the holes, then the

low fi re is too low and the low fi re bypass located on the side of the ratio regulator, see

Figure 3 - item # 5, needs to be opened (counter-clockwise to open, clockwise to close).

_____________________________________

- Use a manometer to check the inlet pressure on the tee on the upstream side of the pilot

regulator, see Figure 4 - item # 3.

- Use another manometer to check the main gas regulator outlet pressure on the upstream

side of the most upstream solenoid valve, see Figure 3 - item # 7.

- Turn the burner up to its actual fi ring rate applying an input signal of 10V DC for maximum

fi ring rate

- Confi rm that the inlet pressure remains between the maximum and minimum values

specifi ed on the Burner Rating Label, see Figure 5.

8478 00

Midco International Inc.

VI

Adjust Low Fire

VII

Adjust the Main Gas

Regulator

5

Page 6

Installation

Adjust the Main Gas

Regulator

Continued

- The main gas regulator outlet pressure should be 1″ W.C. lower than the minimum

VII

pressure required fi gure on the Burner Rating Label.

a. When “Pressure Required” is 7.0″ set the main gas regulator outlet pressure at 6.0″

b. When “Pressure Required” is 10.0″, set the main gas regulator outlet pressure at 9.0″

UNIPOWER VA Gas Burner

®

VIII

Verify the Ratio

Regulator Adjustment

MODEL:

SERIAL NO.:

BILL OF MATERIAL:

MAXIMUM INLET PRESSURE: W.C.

Î

MINIMUM FIRING RATE: BTU/HR

FIRING RATE: BTU/HR

PRESSURE REQUIRED: W.C.

MANIFOLD PRESSURE: W.C.

MAX. CAPACITY: BTU/HR

PRESSURE REQUIRED: W.C.

MANIFOLD PRESSURE W.C.

Î

NAT

CHICAGO, IL 60646

®

U

®

L

C

LISTED

No. Pl-100, 058

US

VOLTS

CONTROLS

MOTOR

AMPS HZ PH HP

2121-07

Figure 5. Burner Rating Label - Maximum and Minimum Pressure Required

_____________________________________

- Use a manometer to check the manifold pressure near where the valve train attaches to

the burner, see Figure 3 - item # 2.

- Use another manometer to check the load pressure on the ratio regulator, see

Figure 3 - item # 4.

- Modulate the burner until the load line pressure is 2.0″ W.C. by adjusting the input voltage

to the burner. See page 9, Figure 8 for manual adjustments.

- Verify that the manifold pressure is within the values given in Table 2.

- If necessary turn the screw on the ratio regulator, see Figure 4, in order to adjust

the manifold pressure.

Model Pressure

V1-V4 0.8-0.9″ W.C.

V5-V6 0.2-0.3″ W.C.

V7-V10 0.5-0.6″ W.C.

Table 2.

Figure 4. Ratio Regulator

_____________________________________

6

Midco International Inc.

8478 00

Page 7

Installation

Note: Burners are not always set up to maximum capacity. Refer to the “Firing Rate” portion of

the Burner Rating Label or the Label of the heating equipment for the actual fi ring rate.

- Modulate the burner to high fi re by applying a 10V DC input signal. See page 9, Figure 8

for manual adjustments.

- Verify that the manifold pressure is the same as marked on the Burner Rating Label(s) for

the actual fi ring rate.

- If necessary adjust the fHi (fan high) setting on the SCEBM-2 module until the desired

manifold pressure is achieved. Use Figure 7 to determine desired manifold pressure.

a. For information on how to adjust the fHi setting refer to page 9, the SCEBM-2 Module

section of this manual.

Manifold Pressure vs. Firing Rate - VA Burners

5

V1

4.5

V5 - V6

V3 - V4

Manifold

Pressure

(Inches W.C.)

3.5

2.5

4

V2

3

2

IX

Verify High Fire Input

Adjustment

V9 - V10V7 - V8

1.5

1

0.5

0

0 350030002500200015001000500

_____________________________________

- Use a combustion analyzer to confi rm that the high fi re oxygen (O

3.0 to 5.0% and the carbon dioxide (CO2) level is between 8.5 to 10.0%. The carbon

Firing Rate (mbtu/hr)

Figure 7.

) level is between

2

monoxide (CO) should be less than 100 ppm while the fl ue gas temperature should be

below 550° F.

- Confi rm that at low fi re the oxygen level is between 16.0 to 18.5% and the carbon

monoxide (CO) level is less than 400 ppm corrected to 3% O

_____________________________________

.

2

- Remove call for heat (open heat enable contact).

- Close main supply gas valve, see Figure 3 - item # 9.

- Turn off main power disconnect and burner control panel switch.

- Remove pressure tap fi ttings and gauges for pressure measurements. Replace pipe plugs.

- Reinstall the caps to the pilot regulator, main regulator, low-fi re bypass and ratio regulator.

_____________________________________

4000

X

Check Emissions

XI

Shut Down

- Open all manual gas valves

- Turn on power at disconnect switch

- Turn on power switch on burner control panel door

- Set heat enable and temperature controller to desired operating condition and temperature

- Burner will start and operate based on 2 to 10V DC analog input provided

_____________________________________

8478 00

Midco International Inc.

XII

Normal Operation

7

Page 8

Installation - SCEBM-2 Module

SCEBM-2 Module is designed to control the speed of the combustion blower based on three input

I

SCEBM-2 Module

signals and several programmable parameters.

- The inputs

a. 2-10V DC control signal

i. Controls the speed of the combustion blower whenever the burner is in run mode.

ii. Also, there needs to be at least 2.0 V DC signal to this input in order for the burner to

turn on.

b. Main valve input

i. When power is supplied to the main valves it is also supplied to the SCEBM-2 control.

Along with the pilot valve input, this determines what mode the burner is in.

c. Pilot valve input

i. When power is supplied to the pilot valve(s) it is also supplied to the SCEBM-2 control.

Along with the main valve input, this determines what mode the burner is in.

Inputs

Application Pilot Main Display Relay PWM Output

Intermittent Off Off PRGE Open 100%

Pilot On Off PIL Closed Min

VA-A On On RUN Open Modulate

Off On ERR Open Min

Interrupted Off Off PRGE Open 100%

Pilot On Off PIL Open Min

VA-B On On IGN Open Min

Off On RUN Open Modulate

Accessing the

Program Menu

PRGE=Purge mode. Before the burner starts or after the burner

stops the combustion blower is modulated to high speed to purge the

combustion chamber with air.

PIL=Pilot mode. The period where the pilot valve is on but the main

valve is not on yet during which the pilot fl ame is established. In this

mode the combustion blower is modulated to low speed.

IGN=Ignition mode. On interrupted pilot systems, the time where both

valves are open is the period where the main fl ame is ignited by the

pilot fl ame. During this time the combustion blower will remain at low

speed.

RUN=Run mode. After the ignition sequence is complete, the burner will

be in run mode. Only in this mode will the combustion blower modulate

based on the 2-10V DC temperature control signal.

Table 3.

_____________________________________

II

- Refer to the Figure 8, page 9, for an overview of the program menu. To enter the program

menu, hold the enter key down for 3 seconds until “APP” is displayed. Use the up and

down arrow keys to navigate to the desired parameter as shown in column 1. To

edit a menu parameter, press the right arrow key once on the desired parameter. The

current value of the parameter will be displayed. Use the up and down arrow keys again to

edit the parameter. Press the enter key to save changes made or press the left arrow key

to cancel without saving and return to column 1. If a key is not pressed for 20 seconds or

the enter key is held for 3 seconds while in program mode, the control will return to normal

mode.

8

Midco International Inc.

8478 00

Page 9

Installation - SCEMB-2 Module

p

(

play

SCEBM-2 Menu Map

What you want to do What you see What it means

Column 1 Column 2

Control applications for Variable Air or NOX

Set the lowest the user can adjust the

temperature to in normal mode for setpoint.

Set the highest the user can adjust the

temperature to in normal mode for setpoint.

Set the minimum percentage the user can adjust

the Fan to in normal mode

Set the maximum percentage the user can adjust

the Fan to in normal mode

Control input modes

Override allows the user to manually control the

ercentage

Fan

Select the desired aggression/speed of the PID

curve for the valve

Set a temperature offset. For examples, to correct

for duct losses or sensor calibration errors.

Set the control to convert the temperature to

either °F or °C.

dis

The password may either be enabled or disabled.

View the software version number.

Standard, Low, or High).

DN

PASS

DN

APP

tLo

thi

FLo

Fhi

inPt

ovEr

Pid

oFS

ForC

vEr

P

P

LT RT

ENT

vA-A

vA-b

noX

40

90

10

100

dC

rE

tS

dAbL

EnAb

Lo

Std

° F

° C

dAbL

EnAb

1.0

Column 1 shows the menu parameters

Column 2 shows the factory set defaults for each

parameter. Temperature defaults are shown in °F.

Arrow Keys:

Up and Down: to navigate or adjust a menu parameter

Right: to access column 2 for editing a parameter

Left: to return to column 1 without saving a parameter

Enter: to return to column 1 with saving a parameter

Low (tLo) can be set from 40°F - 240 °F and must be at

least 10°F less than the High. High (thi) can set be from

50°F - 250°F and must be at least 10°F greater than the

Low. These will limit how far the user can change the

temperature outside of programming mode.

Setpoint may be adjusted on the main screen with the

up and down arrows, then pressing enter to save the

selected setpoint.

hi

Applications (APP):

VA-A is the intermittent piloted burners

VA-B is burners with an interrupted pilot

0

NOX is for low nox burners

Input (inPt) modes:

dC: Allows the user to directly control the fan speed

with a 2-10V input

rE: Allows the user to use an external remote 2-10V

input

tS: Allows the user to use the built-in onboard setpoint

and ignores the 2-10V input

UP

LT

ENT

RT

DN

Figure 8.

_____________________________________

- There are several parameters that can be adjusted for the specifi c application. The

adjustable parameters are as follows.

- APP

a. Determine the functionality of the inputs by specifying which type of burner the control

is being used on.

b. VA-A is for VA series burners that use an intermittent pilot

c. VA-b is for VA series burners that use an interrupted pilot

d. NOx is for Midco Low-NOx series burners

8478 00

Midco International Inc.

III

Setting the Parameters

9

Page 10

Installation - SCEMB-2 Module

III

Setting the Parameters

Continued

- tLo and thi

a. Use these parameters to adjust the minimum and maximum temperature set point that

a user can set while outside of programming mode.

b. NOTE: These parameters only have an eff ect on the operation of the burner when the

burner is operated by temperature control. See section inPt below.

- FLo and Fhi

a. Use these parameters to adjust the minimum and maximum speed that the

combustion blower can achieve (displayed as a percentage of the maximum capacity

of the blower).

b. Adjusting FLo will change the speed of the combustion air blower during ignition and

when in run mode at 2.0V DC. This eff ectively changes the minimum fi ring rate. The

default setting is 10% of maximum fan speed.

c. Adjusting Fhi will change the speed of the combustion air blower while in run mode

with a 10.0V DC input signal. This eff ectively changes the maximum fi ring rate of the

burner. The default setting is 100% of maximum fan speed.

- inPt

a. The inPt (input) parameter is used to specify which type of input is used to control the

modulation of the burner.

b. DC is for using a 2-10V DC input signal sent from an external temperature controller.

c. tS is the setting used when one connects a discharge temperature sensor directly

to the SCEBM-2 module. The SCEBM-2 then modulates the burner based on the

discharge temperature and the temperature set point.

d. rE is used when one connects a discharge temperature sensor as well as an external

thermostat. The SCEBM-2 still modulates the burner based on the discharge

temperature and the temperature set point, but in this mode the temperature set point

is set from an external device.

- ovEr

a. Enables or disables the manual override function. When enabled, the user can adjust

the combustion fan speed manually using the up and down arrows. The input signal

from the external temperature controller or the discharge temperature sensor will be

overridden.

- Pid

a. The Pid parameter is used to adjust how aggressively the SCEBM-2 module tracks

the discharge temperature. NOTE: This parameter only has an eff ect on the operation

of the burner when the burner is operated by temperature control.

- oFS

a. The oFS (off set) parameter is used to adjust the discharge air sensor. NOTE: This

parameter only has an eff ect on the operation of the burner when the burner is

operated as a temperature control.

- ForC

a. This parameter is used to choose whether the SCEBM-2 module displays the

temperature in degrees Fahrenheit or degrees Celsius. NOTE: This parameter only

has an eff ect if there is a temperature discharge sensor hooked up to the SCEBM-2

- PASS

a. The user can use this parameter to enable or disable the password. If the password is

enabled, one must enter it in order to access the program menu.

- vEr

a. The installed version of the software.

10

Midco International Inc.

8478 00

Page 11

8478 00

Midco International Inc.

11

Page 12

12

Midco® International Inc. - 4140 West Victoria Street - Chicago, Illinois 60646 - toll free 866.705.0514

tel: 773.604.8700 - fax: 773.604.4070 - web: www.midcointernational.com - e-mail: sales@midcointernational.com

G

E

R

ISO

9001

C

O

T

S

E

I

R

N

M

A

P

E

D

Y

Printed in USA

619

8478 00

Loading...

Loading...