Page 1

Installation and Service Instructions

LNB 1000

WARNING: If the information in these instructions

is not followed exactly, a fi re or explosion may result,

causing property damage, personal injury or death.

• In the United States, installation must conform with local codes

or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1-latest edition available from American

National Standard Institute. Further reference should be made

to the recommendation of your fuel supplier.

• WARNING: Additions, changes, conversions and service

must be performed by an authorized Midco representative,

service agency or the fuel supplier. Use only MIDCO specifi ed and approved parts.

• INSTALLER: Inform and demonstrate to the user the correct

operation and maintenance of the gas utilization equipment.

Inform the user of the hazards of storing fl ammable liquids

and vapors in the vicinity of this gas utilization equipment and

remove such hazards. Affi x this manual and associated

literature to the burner or equipment.

• CODE COMPLIANCE IS THE SOLE RESPONSIBILITY OF

THE INSTALLER.

• USER: Retain this manual for future reference. If other than

routine service or maintenance as described in this manual

and associated literature is required, contact a qualifi ed service

agency. DO NOT ATTEMPT REPAIRS. An inadvertent service

error could result in a dangerous condition.

AVOID ERROR IN PARTS SELECTION. When ordering use complete

MIDCO Part Number and Description. Furnish Burner Model Number,

Bill of Material Number and Date Code (if available) from the specifi cation plate found on the product

IMPORTANT: Availability of parts as well as specifi cations are subject

to change without notice. Please consult factory for item availability.

LNB 500 &

LNB 1000 Series

Low NOx Burners

Do not store or use gasoline or other fl ammable vapors and liquids in

the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately phone your gas supplier from another

building. Follow the gas supplier’s instructions. If

you cannot reach your gas supplier call the fi re

department.

Installation and service must be performed by a qualifi ed installer,

service agency or the gas supplier.

BURNER MODEL: _____________________________________

BILL OF MATERIAL

NUMBER: _____________________________________________

SERIAL NUMBER #: ____________________________________

WIRING DIAGRAM: ___________________________________

FOR SERVICE CONTACT

Name: ________________________________________________

Address: ________________________________________________

________________________________________________

Phone: ________________________________________________

Date of Installation: _______________________________________

Midco® International Inc.

4140 West Victoria Street

Chicago, Illinois 60646

tel 866.705.0514

fax 866.580.8700

web www.midcointernational.com

e-mail sales@midcointernational.com

SAFETY INFORMATION TERMS: The following terms are used to identify hazards, safety precaution of special

notations and have standard meanings throughout this manual. They are printed in all capital letters using a bold

type face as shown below, and preceded by the exclamation mark symbol. When you see the safety alert symbol

and one of the safety information terms as shown below, be aware of the hazard potential.

DANGER: Identifi es the most serious hazards which will result in severe personal injury or death.

WARNING: Signifi es a hazard that could result in personal injury or death.

CAUTION: Identifi es unsafe practices which would result in minor personal injury or product and

property damage.

Quality Designed for Proven Performance

8471 91

Printed in USA

914

Page 2

Part 1 - Installation

Specifi cations

1

The LNB Series burners are adaptable to most makeup air units, ovens and after burners. The

Midco LNB Series LOW NOx Series gas burner was developed to meet the changing emission

requirements required today.

With Chamber

LNB 500 LNB 1000

MIN VELOCITY 1000FPM 1000 FPM

MAX VELOCITY 3500 FPM 3500 FPM

* MIN INSERTION DEPTH 4.5″ 4.5″

* MAX INSERTION DEPTH 25.0″ 25.0″

2

FIRING RATE (NATURAL)

LNB 500 LNB 1000

Push Through Pull Through Push Through Pull Through

MIN MBH 3 100 125 150 225

MAX MBH 3 500 500 1000 1000

GAS SUPPLY PRESSURE REQUIRED

NATURAL ................................................. Min 5.0″ W.C. Max 14.0″ W.C.

PROPANE ................................................. Contact factory

LNB 500 LNB 1000

MOTOR HP - AMPS 0.32 HP 0.40 HP

CFM BLOWER 229 SCFM 361 SCFM

ELECTRICAL SUPPLY..................................................... 120 VAC/ 60 Hz / 5 AMPS

Standard 120V optional

IGNITION CONTROL MODULE VOLTAGE .................... 24 VAC - Standard 120V optional

IGNITION TRANSFORMER ............................................ 120 VAC

FLAME SAFETY ....

Electronic fl ame Safety with Spark Ignited Pilot and 100% Sut-Off 4

Table 1. Burner Specifi cations

* Consult factory for optional insertion depth

1

Standard burners are shipped as NATURAL gas models. Consult Midco for propane applications.

2

All Ratings Based on 1000 BTU/Cu. Ft. NATURAL gas, at sea level.

3

1 MBH = 1,000 BTU/hr. , Min MBH depends on system velocity.

4

See Section VI Burner Ignition Sequence.

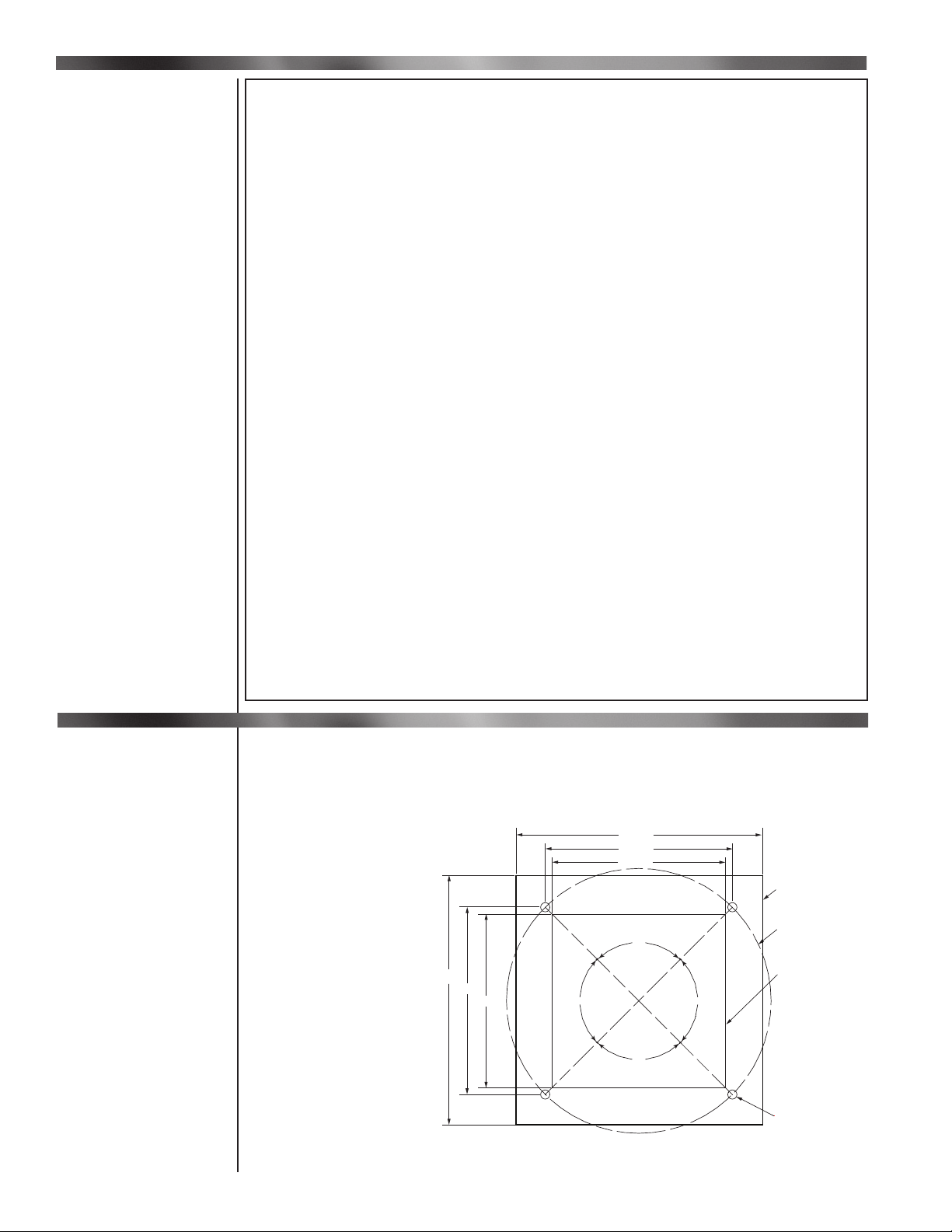

Part 1- Installation

2

When installing the Midco LNB burner the following instructions must be followed.

The Midco LNB Burner must be installed per the equipment manufacturer’s instructions. If not available

take the following steps. To install the burner an opening on the side or top of the heater must be

provided. See Figure 1

be centrally located on a

pull through make up air

unit to promote even heat

for opening size and mounting information. The Midco LNB burner should

15.000

11.319

10.500

distribution. For a push

through unit the Midco

LNB burner should be

located in the center of

the blower discharge. For

other applications contact

our sales engineering

team. The opening of

the combustion chamber

15.000

11.319

10.500

90°

90°

90°

LNB

Mounting Flange

Ø16.000

10.50 x 10.50

Opening for

Combustion

Chamber

should be 90 degrees to

the blower. See Figure 2 for

proper chamber orientation.

90°

Clearance around heat

chamber must be a

minimum of 6″ on all sides.

Ø0.500 X 4

Figure 1 -

Midco International Inc.

LNB 1000 Mounting Flange

8471 91

Page 3

Part 1 - Installation

OFFSET INSIDE

HOT AIR

Ø10.000 Ø4.000

A A

1/2 A

Side Profile

LNB Combustion Chamber

Heater Box

Notes:

1. Above arrangement are for both push through and pull through units.

2. If the width or height of the combustion chamber is more than 28", a bottom profile plate may be required.

3. Any component, for example motor, blower, baffle, etc., should be 18" away from the chamber.

4. 3 o'clock arrangement is preferred.

5. For more information or special requirement please contact our Midco sales engineering team.

COLD AIR

24" or More

7" or More

Flame Exit

18"

or

More

18"

or

More

OFFSET OUTSIDE

Ø10.000 Ø4.000

1/2 B

LNB

COMBUSTION

CHAMBER

HEATER BOX

HOT AIR

COLD AIR

24" or More

B

7" or More

FLAME EXIT

18"

or

More

18"

or

More

Figure 2 - LNB Burner Installation Guide - Typical Installation

__________________________________________

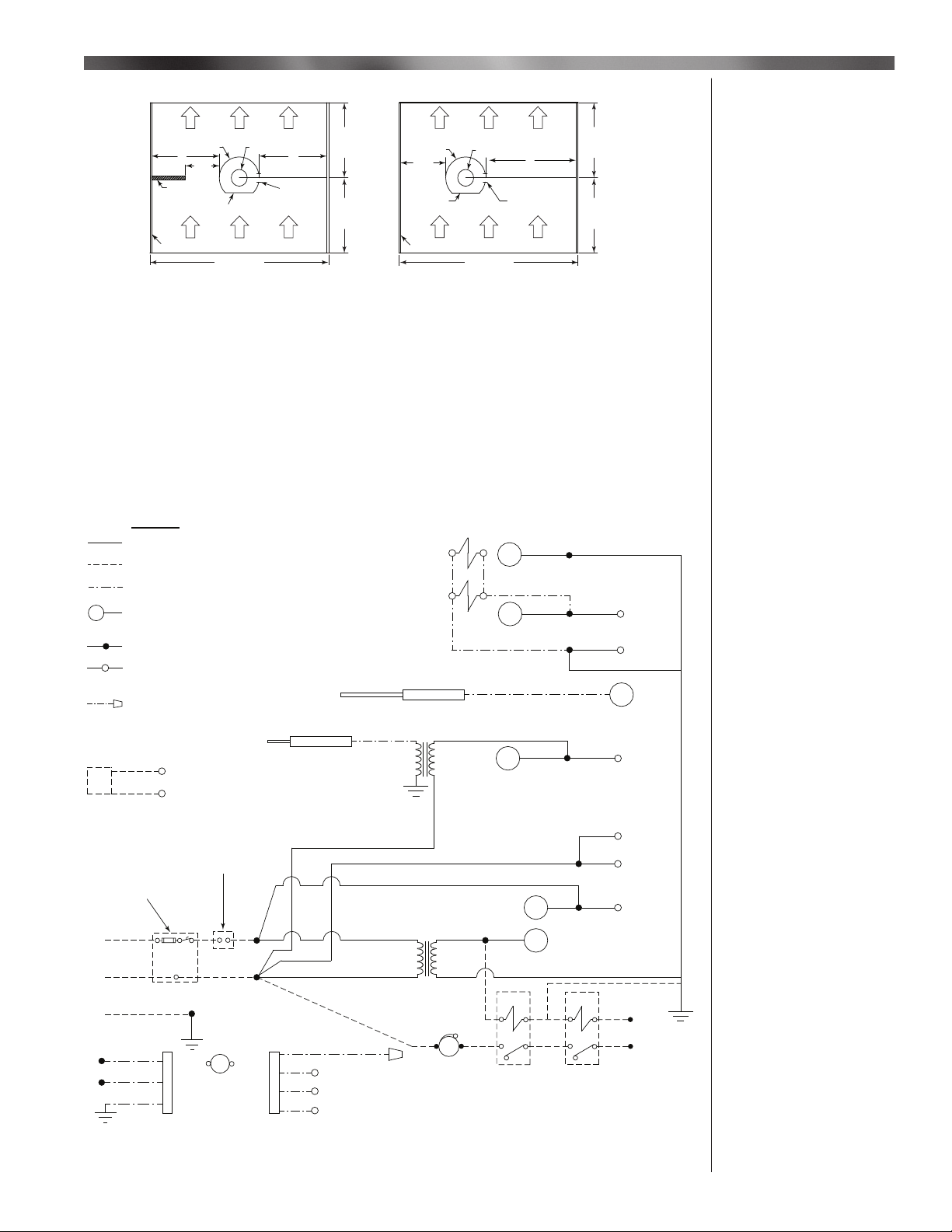

The Midco LNB wiring is included with the burner. Follow wiring diagram included with the burner for

proper wiring connections. When installing the Midco LNB burner all safety and operating controls

must be included and connected so if any safety fails the LNB burner will not operate. Do not bypass

any safety or operating control or equipment might be damaged.

LEGEND

SOLID WIRING AND COMPONENTS BY MIDCO

WIRING AND COMPONENTS BY OTHERS

SUPPLIED BY MIDCO INSTALLED BY OTHERS

MV

ENCIRCLED: SPARK IGNITION

CONTROLLER

5

SOLID ROUND: TERMINAL STRIP

OPEN ROUND: COMPONENT TERMINAL

P# TERMINAL ON RTC BOARD

P

WIRE NUT

2-10 VDC TEMPERATURE

CONTROLLER

+

-

(BY OTHERS)

P2

P4

SPARK ROD

SERIES CONNECT ALL SAFETY

AND / OR OPERATING CONTROLS IN

THE LINE (LINE

FUSE

VOLTAGE ONLY)

DISCONNECT

120/1/60

HOT

NEUTRAL

L1

L2

FLAME SENSE ROD

IGNITION

TRANSFORMER

BK

24V STEPDOWN

TRANSFORMER

BK

120V

W

RENDUNDANT

VALVE

MAIN

VALVE

BR

24V

4

3

BL

W

W

G

P7

(MAIN)

P8

G

S2

P10

(PILOT)

P12

P3

(120VAC)

P1

GND

MV1

S1

W

BK

2

BL

Y

8

BL

BL

7

BL/W BL/W

5

ORANGE

BL

BR BR

6

BK BK

L1

W

I Equipment

Preparation

Continued

II Wiring

GROUND

BK

3

BK

4

G/Y

G

G

M

TO BLOWER

MOTOR

W

R

P9

P11

P13

(V+)

(PWM)

(GND)

Y

BL

ALARM

24 V COIL

NO

NC

TIME DELAY

RELAY 60 SEC

(OPTIONAL)

Figure 3 - Wiring Diagram

__________________________________________

8471 91

Midco International Inc.

24 V COIL

NO

NC

RELAY

7

L1

3

Page 4

Part 1 - Installation

III Piping

The Midco LNB is provided with all required components to install the gas train assembly. Refer to

piping diagram Figure 4a and 4b for a typical installation. Required modifi cations can be made to

the piping layout if required. The Dungs Ratio Regulator Zero Governor valve position CAN NOT be

changed as this is critical in burner performance. There is an orifi ce located downstream from the

Dungs Ratio Regulator Zero Governor valve and must not be modifi ed. When complete with gas train

assembly installation turn on gas to the unit and check for any gas leaks. Repair any that were found

at this time. The minimum required gas pressure at the inlet of the valve train is 5″ WC and maximum

gas pressure not above 14″ WC. The outlet gas pressure should be set at 6″ when burner is at high fi re

full input. Turn off main manual gas valve before starting the unit. Consult the Midco technical support

team if there are any piping questions. See Burner Startup, section IV, for operating instructions.

EBM G170 BLOWER

8435-23

1"x 4" NIPPLE WITH

PRESSURE TAP

5243-46

BLOWER INLET

8416-18

KIT

1"x 3"

NIPPLE

8488-61

1" UNION

8493-06

1" MANUAL

BALL VALVE

8404-38

1"x 3"

NIPPLE

w/ ORIFICE

5246 64

1" RATIO REGULATOR

ZERO

GOVERNOR

8416-04

1"x 2"

NIPPLE

8488-52

PRE ASSEMBLED SECTION

1"x 2"

NIPPLE

8488-52

1"x 2"

NIPPLE

8488-52

1" ELBOW

8495-24

1"x 2"

NIPPLE

8488-52

1"x 6"

NIPPLE

8488-63

EBM RG175 BLOWER

8435-30

FUEL

GAS

BLOWER INLET KIT

8416-22

8493-06

1/8" PIPE

PLUG

8496-00

1" T HAND

BALL VALVE

8404-29

1" X 3/4" HEX BUSHING

8492-52

1" REGULATOR

RV61

8416-33

1" SOLENOID

VALVE 24 V

8402-36

MANOMETER

Figure 4a - Piping - LNB 1000 - Standard

3/4" RATIO

REGULATOR

ZERO

3/4" x 3" NIPPLE WITH

GAS ORIFICE

5246-85

MANUAL BALL VALVE

3/4" NPT

8404-37

3/4" NPT X 2"

LONG NIPPLE

8488-02

PRE ASSEMBLED SECTION

GOVERNOR

8416-211" UNION

3/4" X 3" NIPPLE

WITH GAS ORIFICE

5246-72

1" SOLENOID

VALVE 24 V

8402-36

MANOMETER

1" ELBOW

8495-24

1/8 PIPE PLUG

8496-00

3 WAY RDNDNT 3/4"

COMB VALVE 24 V

8419-43

Figure 4b - Piping - LNB 500 - Standard

4

Midco International Inc.

8471 91

Page 5

Part 1 - Installation & Service

LNB 1000 FIRING RATE vs PRESSURE DIFFERENCE ACROSS

TWO SOLENOID VALVES

1000

950

900

850

800

750

700

650

600

550

500

450

400

350

300

250

200

FIRING RATE, MMBTU/HR

150

100

50

0

0.00 0.10 2.202.102.001.901.801.701.601.501.301.201.101.000.900.800.700.600.500.400.300.20 1.40

PRESSURE DIFFERENCE ACROSS TWO SOLENOID VALVES, “W.C.

Chart 1 - Gas Pressure - LNB 1000

LNB 500 FIRING RATE vs PRESSURE DIFFERENCE

ACROSS 0.5” GAS ORIFICE

500

450

400

350

300

250

200

150

100

FIRING RATE, MMBTU/HR

0.00 2.202.001.801.601.201.000.800.600.400.20 1.40

PRESSURE DIFFERENCE ACROSS GAS ORIFICE, “ W.C.

III Piping

Continued

Chart 2 - Gas Pressure - LNB 500

__________________________________________

Power up unit and the starting sequence begins. The EBM blower motor is energized and will run up

to high blower speed for 20 seconds. After initial prepurge the EBM blower motor will modulate down

to low speed. Once EBM blower motor reaches low speed the main gas valve and ignition control

will be energized. If the burner lights and the temperature control is calling for heat the burner will be

modulated depending on the DC Volt signal being generated from temperature control.

__________________________________________

The Midco LNB burner comes with a limiting gas orifi ce which is required to maintain the Low NOx

readings and fi ring rate. The orifi ce is located between the dungs valve and EBM blower inlet. Do not

attempt to modify the location or orifi ce size. Attach a differential gas pressure manometer to check

gas fl ow. The locations for attaching the gas pressure manometer are located on the main gas valves.

See page 4. The taps that should be used is one on the upstream tap on fi rst main gas valve and the

other on the downstream BTM tap on the 2nd MGV for LNB 1000. Refer to piping diagram, Figure #

4a, for proper location. For LNB 500 attach a differential gas pressure manometer to check for gas

fl ow to outlet pressure tap on main gas valve, and the other on the 1/8″ tap on gas pipe downstream of

main gas valve. Remove the plug on both fi ttings. Attach a barb fi tting in order to hook up the required

8471 91

Midco International Inc.

IV Burner Startup

V Burner Setup

5

Page 6

Part 1 - Installation, Service & Maintenance

V Burner

Setup Continued

VI Burner

Ignition Sequence

tubing to the differential gas pressure manometer. Set temperature control below booth temperature

so burner will light and stay at low fi re (or remove DCV wiring from RTC board). Energize burner

power switch.

The burner blower will be energized and start sequence will begin. Once main fl ame established

the burner will start at low fi re. The gas pressure at the two gas pressure taps will be approximately.

1″ WC to .25″ WC. This is the minimum fi ring rate for the Midco LNB burner.

Adjusting low fi re: If the fl ame stays on and low fi re settings is too high, adjust low fi re on the Ratio

Regulator Zero Governor. The LNB burner is shipped with the adjustment screw located on the top of

the Ratio Regulator Zero Governor at 4-5 turns counterclockwise. To decrease low fi re turn the screw

counterclockwise. To increase the low fi re turn the screw clockwise. If the low fi re is adjusted properly

the fl ame will be mostly blue with a slight orange glow, visually inspect the fl ame through burner

peep sight. Check the differential gas pressure and fl ame signal and adjust the Ratio Regulator Zero

Governor valve as required.

Adjusting high fi re: Turn temperature control above set point to provide 10 DCV to RTC board to set

high fi re. Minimal adjustments can be made. Check inlet pressure to fi rst gas valve and it should be

5″ W.C. maximum. Adjust main gas pressure regulator if required. Flame signal should be steady and

above 2 DCuA. For gas pressure settings see Charts 1 & 2 on page 5.

__________________________________________

Burner Ignition Sequence:

1. Call for heat

a. LNB Burner blower will go to maximum speed

b. SCEBM-1 control LED will fl ash red

2. After 20 seconds delay

a. LNB burner will go to minimum speed

b. Ignition control will be energized

c. Ignition control will send 120V to the spark generator

d. SCEBM-1 control LED will remain solid red

e. Main gas valves will be energized

f. SCEBM-1 control LED will fl ash red or green, depending on DCV signal

VII Maintenance

If Burner ignites

A. Ignitor will be de-energized

B. Check DC micro amps signal at ignition control sense terminal which needs to be

above 1.5 micro amps

C. LNB Burner will modulate based on 2-10 VDC signal from the temperature control

D. SCEBM-1 control LED will remain solid green

If Burner does not ignite

A. Igniter will be de-energized

B. LNB burner blower will go to maximum speed

C. SCEBM-1 control LED will slowly fl ash red.

D. Red light on ignition control will be fl ashing.

E. Power will need to be de-energized and reset.

For additional trouble shooting information contact Midco International as shown on front page.

__________________________________________

The LNB burner will require maintenance every 12-18 months depending on usage. There are four

components that should be inspected. The EBM blower, pilot assembly, burner chamber and burner

head should be inspected. Turn off the main gas manual valve and main panel disconnect to insure

unit will not start. Remove the fl ame sensor wire, spark cable and wiring harness attached to the EMB

blower. To inspect the blower inlet loosen the union between the Dungs valve and blower. Loosen the

4 ½″ bolts attaching the burner to the heater. This will allow removal of the Midco LNB burner. Inspect

the heat chamber. To inspect the burner head you can look into the heat chamber and if any issue

contact Midco for replacement. The fl ame sensor and spark rod can be removed by loosening two

nuts holding the pilot assembly. To clean the sensor and spark rod if required you can use steel wool

6

Midco International Inc.

8471 91

Page 7

Part 1 - Maintenance

5246

or sand paper. If any crack on the porcelain then the sensor or igniter needs replacing. Reinstall the

LNB burner and make sure gas union and wiring were reinstalled. Open manual gas valve and

reenergize heater and cycle as shown in section IV - Burner Startup.

7

1

8

2

9

10

Item Part # Description Qty

1 Hardware #8-32 X 5/16 Socket Head Cap

2 5246-45 Ignition Assembly Weldment Spk 1

3 8432-21 O-Ring 1/2" X 11/16" X 3/32" 1

4 5246-22 Ignition & Flame Assembly Plate 1

5 5246-48 Igniter Flange Gasket Spk 1

6 5246-17 Flame Rod LNB Assembly 1

7 Hardware 1/4-20 Hex Nut 2

8 Hardware 1/4" Split Lock Washer 2

9 Hardware 1/4" Star Lock Washer 2

10 8432-20 O-Ring 5/32" X 11/32" X 3/32" 1

11 8432-22 O-Ring 7/16" X 5/8" X 3/32" 1

12 5246-43 Spark Rod Assembly LNB 1

3

11

4

12

Screw

5

6

NOTE: Flame rod

tip angled to

the side

FROM TIP TO TIP

5/32" +/- 0.01 GAP

FRONT VIEW

-42R

1-1/2"

1-15/32"

SIDE VIEW

4

VII Maintenance

Continued

(Note: Kit # 5246-42R includes Items #s - 1,2,3,5 and 6)

__________________________________________

The Midco LNB burner uses a direct spark pilot. The LNB direct spark pilot is factory set. The spark

gap should be set at 5/32″ from center ground rod. Inspect porcelain on the fl ame rod and spark

rod. Any signs of a crack the rods should be replaced. For proper parts selection contact Midco

International as shown on the front page. When re-installing a direct spark pilot the fl ame rod should

be installed on the right side of the unit.

__________________________________________

8471 91

Figure 5 - Direct Spark Pilot Assembly

Midco International Inc.

VIII Pilot

Assembly

7

Page 8

8

tel: 866.705.0514 - fax: 866.580.8700 - web: www.midcointernational.com - e-mail: sales@midcointernational.com

Midco® International Inc. - 4140 West Victoria Street - Chicago, Illinois 60646

914

8471 91

Printed in USA

Loading...

Loading...