Page 1

INSTALLATION AND

International Inc.

4140 WEST VICTORIA STREET • CHICAGO, ILLINOIS 60646 • (773) 604-8700 FAX: (773) 604-4070 • http://www.midco-intl.com

SERVICE INSTRUCTIONS

INCINOMITE MODELS

J81A-3 and J121A-3

Incinerator Gas Burners

The INCINOMITE Models J81A-3 and J121A-3 incinerator gas burners feature continuously monitored electronic flame safety and

spark ignited intermittent proven ignitor (pilot). They are adaptable to either primary or secondary chamber installation.

In the United States, installation must conform with local codes

or, in the absence of local codes, with National Fuel Gas Code

ANSI Z223.1-1992, or latest edition available fromAmerican

National Standard Institute. Further reference should be

made to the recommendation of your fuel supplier.

NOTE: Any additions, changes, or conversions required in order

for the gas utilization equipment to satisfactorily meet the

application needs must be made by a MIDCO distributor (or

other qualified agency) using factory specified and approved

parts.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

In Canada, installation must conform with local codes or, in the

absence of local codes, with Installation Codes for Gas

Burning Appliances and Equipment, CGA Standard

CAN/CGA 1-B-149.1 or 2. Further reference should be made

to the recommendation of your fuel supplier.

• Do not try to light any appliance.

• Do not touch any electrical switch;

INSTALLER: Inform and demonstrate to

the user the correct operation and

maintenance of this gas utilization

• Immediately call your gas supplier

equipment. Inform the user of the

hazards of storing flammable liquids and

vapors in the vicinity of this gas

• If you cannot reach your gas supplier,

utilization equipment and remove such

hazards. Affix this manual adjacent to

the incinerator burner. CODE

COMPLIANCE IS THE SOLE

RESPONSIBILITY OF THE INSTALLER.

USER: Retain this manual for future reference. If other than routine service or

maintenance as described in this manual is required, contact a qualified service agency.

DO NOT ATTEMPT REPAIRS. An inadvertent service error could result in a dangerous

condition.

SAFETY INFORMATION TERMS: The following terms are used to identify hazards, safety precautions or special notations and

have standard meanings throughout this manual. When you see the safety alert symbol and one of the safety information terms, as

shown below, be aware of the hazard potential.

DANGER: Identifies the most serious hazards which will result in severe personal injury or death.

WARNING: Signifies a hazard that could result in personal injury or death.

CAUTION: Identifies unsafe practices which would result in minor personal injury or product and property damage.

Installation and service must be

performed by a qualified installer, service

agency or the gas supplier.

WARNING: If the information in

these instructions is not followed

exactly, a fire or explosion may result

causing pro p e rty damage, personal

injury or death.

WHAT TO DO IF YOU SMELL GAS

do not use any phone in your

building.

from a neighbor's phone. Follow the

gas supplier's instructions.

call the fire department.

MIDCO

PRINTED IN U.S.A.

797

8470-70

Page 2

SPECIFICATIONS

1

BURNER AIR DELIVERY(Approximate Air Delivery at Zero Draft)

J81A-3………………………………………....90 SCFM

2

J121A-3………………………………………..180 SCFM

MINIMUM GAS PRESSURE LISTED FOR PURPOSE OF

INPUT ADJUSTMENT

( Take Pressure at Inlet Tap of Main Automatic Va l v e )

N ATURAL………………………………………………..5.5" W . C .

P R O PANE……………………………………………….8.0" W . C .

BURNER FIRING RATE (NAT U R A LOR PROP A N E )

All Ratings Based on 1000 BTU/cu. ft. NATURAL, 2500 BTU/cu. ft. PROPANE at Sea Level

3

M I N I M U M

J81A-3 or J121A-3………………………………… 100 MBH

MAXIMUM (With Combustion Air From Burner Only)

J81A-3

20% Excess Air……………………………450 MBH

0% Excess Air (stoichiometric)…………..540 MBH

J121A-3

20% Excess Air……………………………900 MBH

0% Excess Air……………………………1080 MBH

MAXIMUM (With Combustion Air From Burner Blower and

Additional Air Available in Combustion Chamber.)

NATURALGas 5.5" W.C. or PROPANE Gas

at 11.0" W.C. Gas Pressure at Main Automatic Valve

J81A-3…………………………………………800 MBH

J121A-3……………………………………..1,200 MBH

ELECTRICAL SUPPLY

J81A-3………………………………...120/1/60; 3 a m p s

J121A-3………………………………..120/1/60; 4.5 amps

BURNER ON-OFF CONTROL……………Toggle Switch.

Optional 0 to 6 Hr. Manual Timer

5

FLAME SAFETY…………………...Electronic Flame Safety

with spark ignited ignitor (pilot) and 100% shut-off.

OPTIONAL WEATHERHOOD

5

ADJUSTABLE FIRING ANGLE…………...Mounting Flange

adjustable for horizontal or 10° down firing.

NOTE: Burner components are ULrecognized, CGA listed, CSA

certified and/or AGA design certified, mounted and wired. The

complete burner is fire tested.

1. Standard burners are shipped as NATURAL gas models. A kit is

available for field conversion to PROPANE gas.

2. SCFM = Standard Cubic Feet/Minute.

3. NOTE: Firing rate with combustion air from burner blower only is

based on using standard air at sea level with zero draft over-fire.

Derate burner for altitudes over 2,000 feet by 4% for each 1000

feet above sea level.

4. 100 MBH = 100,000 BTU/Hr.

5. Kit is available for field installation.

PART 1 INSTALLATION

I PRIMARY CHAMBER FUEL INPUT

■ No. 1 Waste: Primarily dry material such as paper, rags

4

and wood. Burner normally required only for light-off.

■ No. 2 Waste:Consisting of approximately equal portions,

by weight of No. 1 and No. 3 waste; 70 lbs. per 100 MBH.

■ No. 3 Waste: Wet material such as garbage; 25lbs. per

100 MBH.

■ No. 4 Waste:Organic materials such as small carcasses

and waste from hospital operating rooms or pathological

laboratories; 13 lbs. per 100 MBH.

NOTE: The burner input required for the secondary

chamber must be determined from the heat required to

maintain the discharge temperature of the flue products as

specified by the EPA for the type of waste involved and the

location of the incinerator.

II INDOOR VENTILATION

Make sure that the incinerator room has suff i c i e n t

ventilation to provide the necessary combustion air for the

burner fuel, the waste material and any other appliance that

would draw its air from the same enclosed area.

WARNING: Under no condition should the access to

outside air be so restricted that the maximum possible

use of combustion air is inhibited. Pay particular

attention to exhaust fans that could draw air from the

area and create a negative pressure in the room.

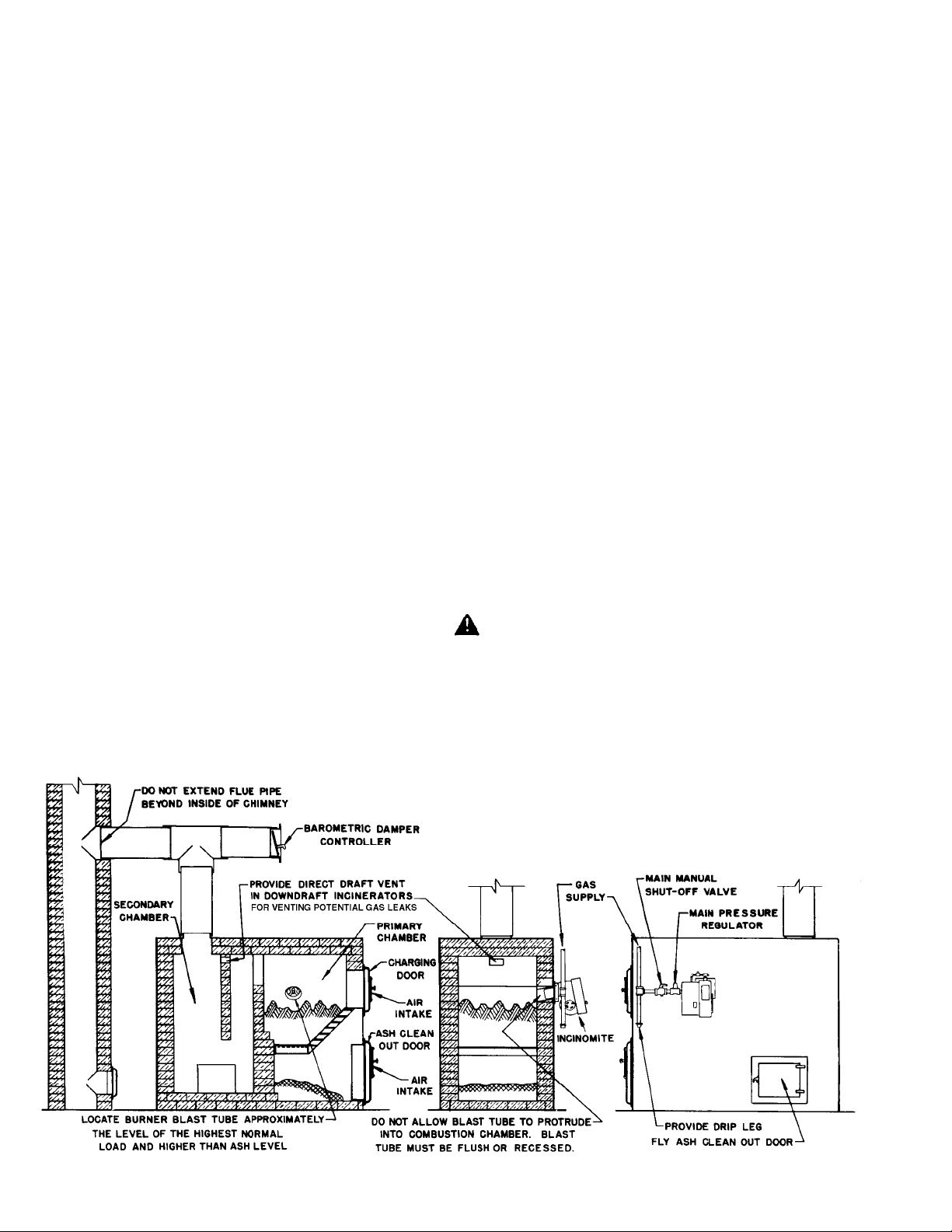

III INSTALLATION

Install the INCINOMITE burner(s) in location(s) specified by

the incinerator manufacturer. It should be positioned

approximately level with the top of the highest normal load

and fire with or across the draft flow.

FIGURE 1 Typical Installation

-2-

Page 3

■ If the incinerator is designed only for No. 4 waste, the

level can be lowered to bring the flame to play directly on

the smaller loads characteristic of this type of operation.

The opening through which the burner fires should be of a

diameter only large enough to accommodate the Blast T ube

(41⁄4" diameter x 3" minimum long.) Do not allow the Blast

Tube to protrude into the incineration chamber. If

necessary, build an extension outside of the incinerator wall

to increase wall depth.

■ To change the Mounting Flange to its alternate position,

horizontal or 10° down firing, remove the four (4) screws

that attach it to the burner, rotate the flange 180° and

reinstall the screws.

■ Before mounting the burner, check that the Blast Tube

and Blower Housing are clear of foreign material and that

the Main Gas Port and Nozzle Support is clean and

undamaged.

■ If the incinerator is located outdoors, the burner and all of

its components, except the Main Manual Shut-Off Valve,

must be protected from weather. The MIDCO Accessory

Weatherhood will provide such protection.

CAUTION: If the incinerator is of the down draft

design, make sure that a direct draft vent opening of

approximately 10 square inches has been put through

the top of the drop section(s) to provide for the venting

of any gas leakage. See Figure 1.

IV CHIMNEY, VENT CONNECTOR AND

DRAFT CONTROL

The size and type of material used for the vent connector

and chimney must conform to the recommendations of the

incinerator manufacturer, as well as local and national

codes. This is especially true where high flue gas

temperatures are encountered.

■ When natural draft is used and the chimney height is over

25 feet, a barometric damper of the same size as the vent

connector should be installed. If the chimney is high

enough to make it difficult for the barometric to maintain a

maximum incineration chamber over-fire draft, (0 to minus

0.5” W.C. for Model J81A-3, 0 to minus 1.0” W.C. for Model

J121A-3), a fixed damper should be installed in the vent

connector between the barometric and chimney to restrict

the chimney draft to a point within the controlling capacity

of the barometric. After final setting, the damper should be

permanently fastened into position per ANSI Z223.1-1992

"National Fuel Gas Code", or latest edition available from

American National Standards Institute to prevent

tampering.

■ A suitable Main Gas Pressure Regulator should be

installed as shown in Figures 1 or 3. Choose a regulator(s)

to adjust the available gas pressure to the pressure shown

in SPECIFICATIONS, page 2.

CAUTION: The regulated gas pressures must not

exceed 14:" W.C. or Main Automatic Gas Valve and

Ignitor Regulator will be damaged. If excessive gas

pressure is prevalent, the regulator must be a tight

shut-off type to prevent high pressures from

developing during stand-by. The regulator must have a

minimum flow regulating capacity for the ignitor gas

rate (see Table 4). It is strongly recommended that a

separate smaller regulator be used for ignitor gas,

connecting to the gas line ahead of the Main Gas

Pressure Regulator and downstream of any

intermediate Regulator.

■ For full input, refer to SPECIFICATIONS, page 2, for

minimum gas pressure required. For reduced capacities,

refer to Firing Rate Curves, Table 2 or 3.

CAUTION: If gas supply pressure is below its

specified range during adjustment, an over-fire

condition could result when pressure returns to

normal, particularly if the regulator adjustment screw is

bottomed out. A LWAYS confirm that at least the

minimum rated pressure is being supplied during

regulator adjustments, and NEVER B O T TOM OUT

regulator screw.

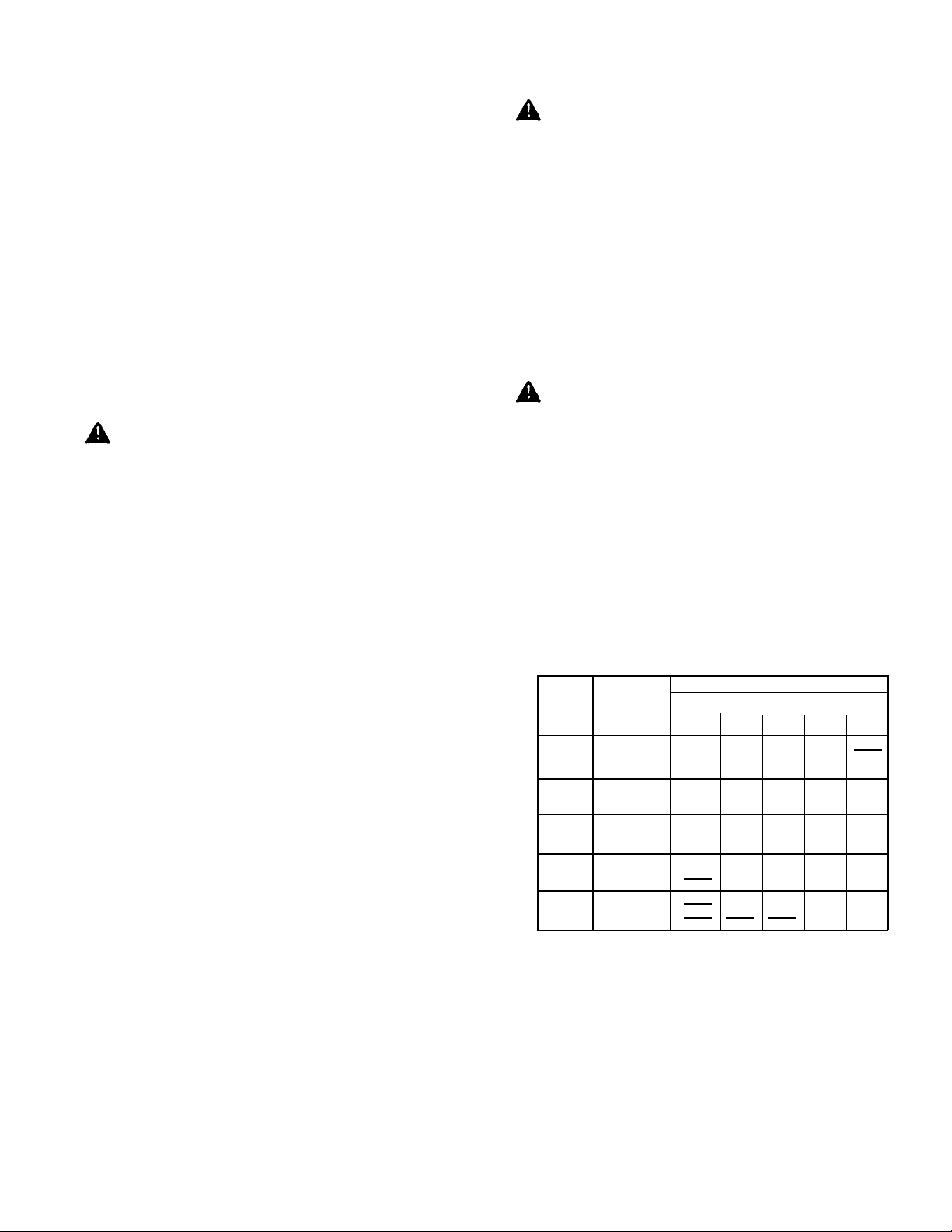

■ When selecting the burner supply piping size per Table 1,

the permissible pressure drop must be based on the

pressure available at the inlet to the supply pipe branch line

when all other gas equipment fed by the same source

(NATURALgas meter or PROPANE tank regulator) is firing

at full rate. Also take into account any other INCINOMITE

burners to be attached to the same branch line.

NPT

PIPE

SIZE

3⁄4"

1"

1-1⁄4"

1-1⁄2"

2

TYPE

OF GAS

NATURAL

PROPANE

NATURAL

PROPANE

NATURAL

PROPANE

NATURAL

PROPANE

NATURAL

PROPANE

APPROXIMATE CAPACITY-MBH

LENGTH OF PIPE/FEET

10

20

40

60

100

275

200

130

450

520

820

1050

1200

1200

300

350

550

730

1150

1100

1200

1200

200

245

385

500

790

760

1200

1200

100

165

195

300

400

630

610

960

1150

1200

125

150

235

300

480

460

725

870

1200

V PIPING

The supply piping to the burner should branch off from the

main line as close to the source as possible (NATURAL

gas meter or PROPANE tank regulator). When branching

off from an existing gas line, do not tap off the bottom of a

horizontal section. Use new black pipe and malleable

fittings free from cutting and threading burrs or defects.

■ Use pipe joint compound resistant to liquid petroleum

gases when using either NATURAL or PROPANE gas.

Piping must comply with the local and national codes. If the

burner piping must be rearranged because of space

limitations, be sure to carry out the general configuration

shown in Figure 3.

Capacities shown are for total pressure drop of 0.3"W.C. For

higher permissible pressure drops consult your fuel supplier.

Source: Gas Engineers Handbook-1974

Industrial Press Inc. NY, NY

TABLE 1 Schedule 40 Pipe Capacities in MBH

■ When pressure testing the supply piping, the burner

valve train must be protected. If the test pressure is 0.5

PSIG or less, closing the Main Manual Shut-Off Valve will

suffice.

-3-

Page 4

CAUTION: If the test pressure is over 0.5 PSIG, the

test must be made without any burner components

connected, including Main and Ignitor Manual Shut-Off

Valves.

WARNING: Explosion hazard.

Do not use oxygen for pressure testing. An explosion

could occur during initial start-up.

VI ELECTRICAL

Installation wiring to the burner must conform to local

codes, or, in their absence in the United States the National

Electric Code ANSI/NFPA No. 70-1990, or latest edition; in

Canada, to CSA standard C22.1, "Canadian Electrical

Code Part 1."

■ Use copper wires and provide disconnect and fuse

protection for each INCINOMITE installation. Refer to

SPECIFICATIONS, page 2, for ampacity. Confirm that the

polarity is correct—hot wire to strip terminal L1, neutral L2

and that the neutral line is not subject to induced low

voltage (check L2 to ground) from other equipment as that

can affect the flame safeguard, causing it to malfunction.

See Flame Safeguard Section X.

CAUTION: In order for the automatic cooling system to

function, power must be maintained to burner strip terminal

L1. Do not install any safety or on-off controls in the circuit

between the fused disconnect switch and strip terminal L1.

Optional remote control devices should be connected in

place of, or in addition to, the switch or timer as indicted in

Figure 2 Wiring Diagram.

NOTE: Optional 0-6 hour Timer may be substituted for the

burner On-Off Switch. Kit is available with full conversion

instructions.

VII INITIAL START UP/ADJUSTMENT

Burners are suitable for use with NATURAL or PROPANE

gas only.

■ If a standard NATURAL gas model is to be used with

P R O PANE gas, a conversion kit is available, which

contains a PROPANE Main Gas Port, a PROPANE Ignitor

Tee Orifice Fitting and a PROPANE label and conversion

instructions.

■ As shipped, the Air Shutter is in the full open position and

the Main Gas Input Adjuster 5 to 6 turns from full closed.

Ignitor regulator is factory set for recommended outlet

pressure of 3.5" W.C. suitable for most applications.

CAUTION: Ignition is automatic. Therefore, make ignitor

or spark observations into incineration chamber only with

Main Manual Shut-Off Valve closed.

1. Check the burner piping and valves for gas leaks by

applying a weak liquid soap solution to unions and

joints with the gas supply on. Leakage will be indicated

by the appearance of soap bubbles. Locate and correct

all gas leaks before proceeding.

WARNING: DO NOT USE OPEN FLAME.

2. Confirm that the main gas Input Adjuster is 5 to 6 turns

from full closed and that the Blower Air Shutter is fully

open.

3. Close the Main Manual Shut-Off Valve and Manual

Ignitor GAs Valve.

4. Purging the air from the gas supply line at this step will

expedite the first light-off.

CAUTION: Purge outside the building. Do not

purge into the incineration chamber.

5. Turn on the Fused Disconnect, Burner Switch or Timer

and press relay reset button. Let motor run long

enough to accomplish four air changes. Note that

motor will continue to run after Flame Safeguard

lockout occurs.

6. Open the incinerator charging door. making sure any

Door Open interlock is temporarily bypassed.

7. Turn on Manual Ignitor Gas Valve only, and press relay

reset button. Trial for Ignitor Ignition: Flame Safeguard

and motor are powered. There will be a delay until

blower reaches operating speed and trips blower

proving switch. When the blower proving switch is

made, the Ignitor Solenoid Valve and Spark Generator

are energized. Ignitor flame should light.

8. If ignitor fails to light during the trial prescribed for

ignition and goes into Flame Safeguard lockout, it is

probably due to air in ignitor gas line. Wait one minute

and press relay reset button for several relight attempts.

If the ignitor fails to light, turn off Manual Ignitor Gas

Valve and repeat from step 5 above. Then, if necessary,

refer to the Trouble Chart to isolate the problem. (Refer

to Section X for trial timings.)

WARNING: Repeated unsuccessful attempts to

light will result in accumulated gases in incineration chamber and chimney. To prevent these

gases from reaching an explosive level,periodically

purge the incineration chamber as described in

Step 5.

9. Observe the ignitor flame. If it is weak, screw in the

Ignitor regulator adjustment to increase the pressure. If

it is excessively rich and large or floating from the igni-

tor tip, back off the regulator adjustment to reduce the

pressure. Set the ignitor to a stable blue flame which

burns firmly within the ignitor tip. Check flame signal

with a DC voltmeter and adjust Ignitor Regulator

slowly for highest steady 2 or more volts DC.

CAUTION: When adjusting the regulator, take note

of the supply pressure. If gas supply pressure is

below its specified range during adjustment, an

over-fire condition could result when pressure

returns to normal, particularly if the regulator

adjustment screw is BOTTOMED OUT. ALWAYS confirm

that at least the minimum rated pressure is being

supplied to the ignitor during regulator adjustments,

and NEVER BOTTOM OUT regulator screw. Operate

air shutter throughout range to confirm Ignitor

stability. Try several relights. Refer to Table 4.

10. Remove the Input Adjuster Cap (see Figure 3) and turn

the Main Gas Input Adjusting Screw until the desired

input rating is reached (refer to Tables 2 or 3). Turning

of adjustment screw counterclockwise increases gas

flow; clockwise reduces gas flow. If Main Flame gas

pressure requires adjustment, refer to Section V Piping.

1 1. Reset the Blower Air Shutter to match the intended

input, i.e.; full open for maximum, closed for minimum

or partially open for midrange. The Blower Air Shutter is

factory set wide open. Adjust as necessary when, with

combustion air available in the incineration chamber, it

is desirable to increase the flame length, or to restrict

the amount of excess air discharged into the incineration chamber when the burner input is below 450 MBH.

-4-

Page 5

Page 6

NEUTRAL

120/1/60

HOT

FUSED DISCONNECT

Q7800 BASE FOR

RM7890 FLAME

SAFEGUARD

G

3

4

5

6

7

8

9

10

F

HOT

120/1/60

NEUTRAL

SWITCH OR TIMER

COMPONENT LAYOUT

12

3 2 1

13L2

14

THERMAL

SWITCH

15

16

17

18

19

20

21

22

L

L1

L2

L2

L1

BK

OPTIONAL HI-LO GAS PRESSURE

SWITCH. IF USED, REMOVE

JUMPER 3-4

R/BK

L2 3 4 5 6 7 8 9 10 11

SCHEMATIC

W

Y/BK

10

R/BK

3

SAFETY & OPERATING

CONTROLS

(LINE VOLTAGE)

IF NOT USED JUMPER

10 TO 3

TERMINAL STRIP

SAFETY & OPERATING

CONTROLS

(LINE VOLTAGE)

4 5

3

123

6

Y

J81A-3 MOTOR END SWITCH

J121A-3 BLOWER AIR SWITCH

6

Y/W

8

7

10

8

BL/W BK(W)

9

9

O

F

THERMAL SWITCH

R/W

4

Y/W

BL/W

FLAME ROD

1

2

BK

3

NO

C

5

R

NC

IGNITOR GAS VALVE

SPARK GENERATOR

BLOWER MOTOR

L2

6

W(BK)

SPARK ROD

BRBL BL

MAIN GAS VALVE

OPTIONAL

REDUNDANT VALVE

OPTIONAL VENT

VALVE

FIGURE 2 Wiring Diagram

CAUTION: If a remote switch or timer is installed, remove or turn off the burner switch when using the remote control

12. The actual NATURAL gas firing rate in BTU per hour

can be determined by timing the gas meter. Accurately

time the meter test dial for one revolution, convert to

hourly cubic feet and multiply by the BTU per cubic foot

value of your gas per formula:

3600 x Test Dial Size x BTU Value

No. of Seconds for One Rev. Test Dial

= BTU/Hr.

Then divide by 1,000 for MBH value.

Example: 3600 x 1 x 1000*

=180,000 BTU/ Hr. = 180 MBH

20

*Approximate BTU value.

13. Start and stop the burner several times to check its

operation with the charging door open, and then with

it closed. Remove any temporary Door Open bypasses

installed in Step 6.

14. Test operation of any auxiliary operating and/or limit

controls.

15. Load incinerator and make trial run. Confirm that the

incineration chamber pressure stays within the range of

0 to minus 0.5"W.C. for Model J81A-3 and 0 to minus

1.0” W.C. for Model J121A-3.

16. WARNING: When the incinerator is located

inside a building and a draft control is used, check

that there is no spillage of flue products from the draft

control.

17. To shut off: Turn Burner Switch or Timer off and close

Main Manual Shut -Off Valve

PART 1 SERVICE

WARNING: BE SURE THAT THE MANUAL VALVE AND

BURNER DISCONNECT SWITCH ARE TURNED OFF BEFORE

ANY PARTS ARE REMOVED FOR SERVICE.

VIII IGNITOR AND REGULATOR ASSEMBLY

The Ignitor and Regulator Assembly is removed as a unit.

■ When the ignitor gas pressure is in the proper range (see

Table 4) and the electrodes are adjusted to the dimensions

shown in Figure 5, any ignition problems are usually

caused by lint, dust, corrosion, cracked electrode

insulators, foreign matter in the blast tube or deterioration of

ignitor ports in Retention Plate.

■ Ignitor trouble will be evidenced by failure of main burner

ignition. It may also be indicated by poor or erratic relay

response which cannot be remedied by ignitor gas

adjustment, or it may cause frequent Flame Safeguard

lockout. Check for dirt in the ignitor air and mixture

passageways and check for obstructions in the ignitor

ports. Also check electrode adjustments (see Figure 5).

Replace any severely burned parts.

■ Proper operation of the flame sensor rod can be checked

by measuring the flame signal. With the Flame Safeguard

energized and only the ignitor burning, a good reading

should run steady 2 or more volts DC.

■ When servicing, clean the Ignitor Retention Plate ports

and blow out the internal air and gas passages. Clean the

Electrode Insulators and check them for hairline cracks.

Also check the electrode ends and the Ground Barrier for

serious corrosion or loss of metal. Replace any defective

parts.

■ Make sure that there is no debris in the Blast Tube that

could short out the Spark or Flame Electrode.

■ Clean the Ignitor Gas Orifice in Tee Orifice Fitting (see

Figure 5) and check that the orifice size is correct per Table

4.

MODEL

J81A-3

J121A-3

TYPE

OF

GAS

NATURAL

PROPANE

NATURAL

PROPANE

IGNITOR

ORIFICE

DIAMETER

.052 (#55 Dr.)

.042 (#58 Dr.)

.070 (# 50 Dr.)

.063 (#52 Dr.)

RECOMMENDED

IGNITOR GAS

PRESSURE

3.5 "W.C.

Disconnect the ignitor gas line and electrode wires, remove

the two mounting screws and pull out the assembly.

-6-

TABLE 4 Ignitor Firing Rate

IGNITOR

GAS

RATE

6 MBH

7 MBH

13 MBH

15 MBH

Page 7

■ Check that the electrode ends are positioned and that the

gap between the end of each electrode and the ground

barrier is spaced per Figure 5.

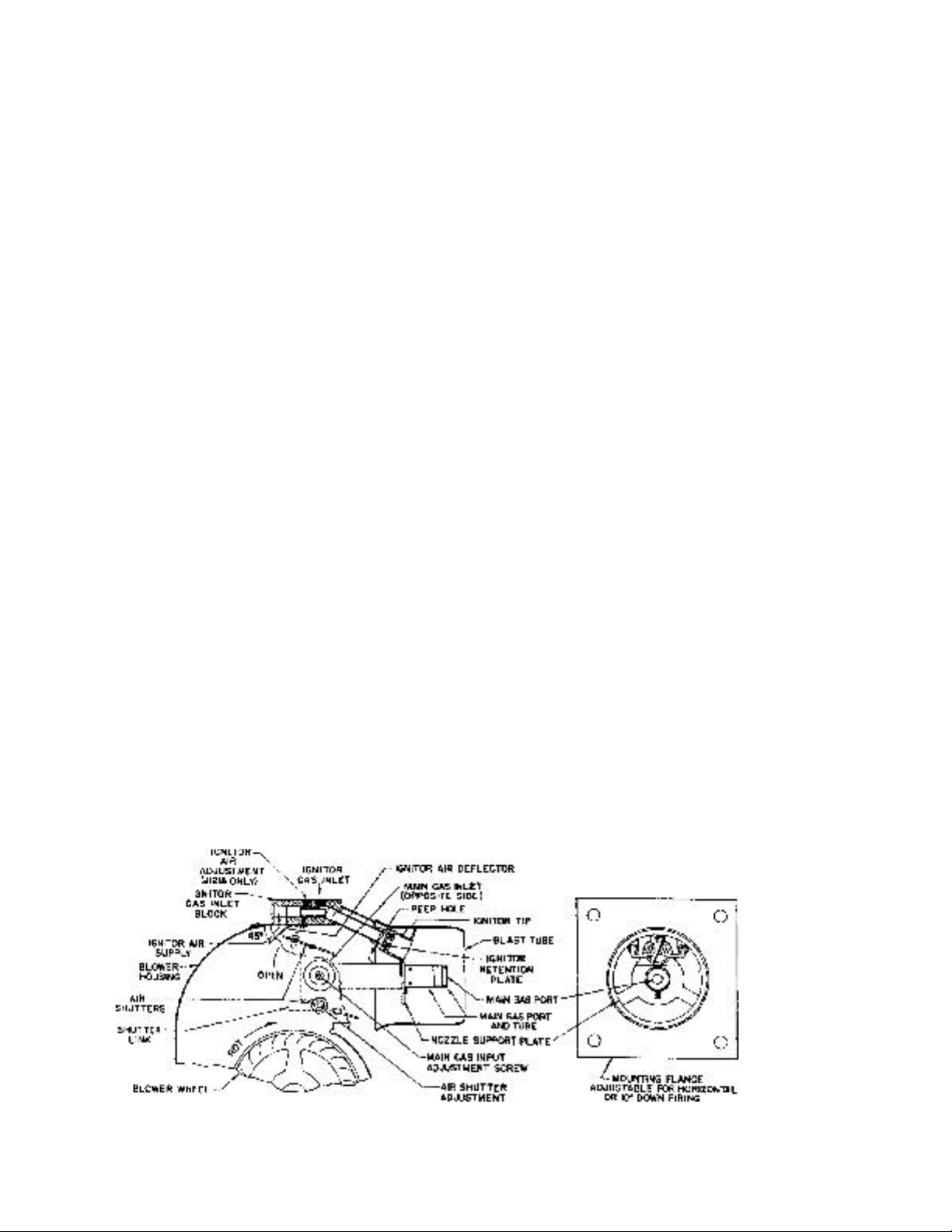

■ Check that the Ignitor Air Deflector is at the correct angle

(45°). See Figure 4.

■ Inspect the electrode wire insulation for cracks or worn

areas, or any contact with the burner frame. Dampness will

facilitate electrical leakage to ground, which will cause

ignition or flame signal failure.

SPARK TEST—Main Manual Shut-Off Valve must be off.

Place the Ignitor Assembly on top of the burner with the

electrode ends visible and good metal to metal contact

between the Ignitor Mounting Plate and the burner chassis.

■ Connect the high voltage wire to the spark electrode.

Spark should be visible during trial for ignition period and

arc from the electrode end to the Ground Barrier. It should

be audible and visible, though it is rather thin and difficult to

see in bright light.

■ If the spark is not audible or visible it is leaking directly to

ground. Before removing electrodes, check to make sure

voltage is available by positioning the spark wire 1/8" from

the end of the electrode. If necessary, press relay reset

button to recycle ignition sequence.

■ Disconnect Flame Electrode wire and switch the high

voltage wire to the flame electrode and repeat test for

insulator leakage.

CAUTION: Do not indiscriminately change the

ignitor gas orifice size as ignition troubles are rarely

cured in this manner. The ignitor utilizes a premixed

gas/air mixture and, as the air input is relatively fixed,

any adjustment to the gas/air ratio that might be

required for a specific application should be made by

careful adjustment of the ignitor regulator to vary its

outlet gas pressure. Pressure adjustments must be

made when the gas is flowing. If cleaning and electrode

adjustment does not eliminate an ignition problem,

further checks are required. Refer to Trouble Chart.

IX IGNITOR GAS/AIR ADJUSTMENT (J121A-

3 ONLY)

The ignitor assembly as shipped is pre-set during factory

fire-testing and normally needs no adjustment except in

installations where the air shutter is full open. The ignitor

should not be adjusted until it is confirmed that good lightoffs are not possible with ignitor gas pressure adjustments

only as described in Section VIII.

■The Air adjustment screw is located under a plug button

in the Ignitor Block about 1⁄2 inch behind the Ignitor Orifice

(refer to Figure 4). A 5⁄64 (.078) inch hexagon wrench is

required for adjustment. Pry up the plug button to expose

air adjustment screw. Adjust the screw up or down to find

the best Flame Signal or until repeatable and stable lightoffs are achieved. Ignitor airflow is decreased as the screw

is turned clockwise, and increased as it is turned counterclockwise. Generally 3 to 5 turns up from full closed (screw

bottomed out) works best.

■When adjustments are completed, replace plug button to

protect adjustment screw

X FLAME SAFEGUARD

WARNING: Explosion hazard. Do not use this device

if it gets wet. It can malfunction and cause serious

injury or death. Replace any device that has been wet.

Standard Incinomite J Series burners are equipped with a

Honeywell RM7890 microprocessor based burner control

employing a flame rectification system of flame detection.

Burner construction for special codes and/or insurance

requirements such as Factory Mutual or Industrial Risk

Insurers (IRI) may require alternate controls. (Refer to

Section XI SPECIAL EQUIPMENT). A safe start and run

control sequence is provided with instantaneous response

to presence or loss of flame signal. Flame failure response

time is .8 seconds. Pilot Flame Establishing Period (PFEP)

is field selectable from 4 or 10 seconds. The RM7890

features a plug in amplifier. Five LED’s (light emitting

diodes) are provided to display sequence information.

Refer to the Honeywell RM7890 literature for detailed

operating information, configuration requirements, testing,

and service.

FIGURE 3 Control Components -7-

Page 8

INITIATE (“POWER” LED is lit).

■ The RM7890 enters the INITIATE sequence when it is

powered. The INITIATE sequence lasts for ten seconds

unless the voltage or frequency tolerances are not met

(refer to Honeywell RM7890 literature for criteria). When

tolerances are met, the INITIATE sequence will restart. If

the condition is not corrected and the hold condition exists

for four minutes, the RM7890 will lock-out. causes for hold

conditions in the INITIATE sequence are in the Honeywell

RM7890 literature.

STANDBY (“POWER” LED is lit).

■ The RM7890 is idle in this state of sequencing. When the

burner switch, limits, operating limit controls, and all

microprocessor monitored circuits are in the correct state

for RM7890 to continue, sequencing will advance to

IGNITION TRIAL.

IGNITION TRIAL

1. PILOT FLAME ESTABLISHING PERIOD (PFEP)

A. The pilot valve (“PILOT” LED will be lit) and spark

generator are energized.

B. Flame must be proven by end of the 4 or 10-

second PFEP to allow the sequence to continue. If

flame is not proven by the end of PFEP, a safety

shutdown occurs.

2. MAIN FLAME ESTABLISHING

■ After the ignition trials, and with the presence of flame,

the main valve is energized. (“MAIN” LED will be lit.) If a

flame-out occurs, the RM7890 will lock-out or recycle within

.8 seconds. Refer to Honeywell literature for proper

configuration.

RUN

■ The RM7890 is now in RUN mode and will remain in run

mode until the controller input opens, indicating that the call

for heat has been satisfied or a limit has opened. Once this

occurs the RM7890 will sequence back to the STANDBY

mode.

Notes: 1. During STANDBY and during RM7890

sequencing the “POWER” LED will blink every

four seconds. This is normal.

2. The “ALARM” LED will be lit in the event of

any flame failure.

3. To maintain proper operation of this device it

MUST be electrically grounded. Refer to

Honeywell RM7890 literature for criteria.

XI SPECIAL EQUIPMENT (OEM VERSIONS)

Special equipment, either factory or field installed, can

cause variations in the procedures and descriptions given

in this manual. Generally, any burner ordered with special

factory installed equipment will be supplied with the

appropriate wiring diagram and related instruction manuals

from the special equipment manufacturer. Consult these

manual to identify any differences in construction,

operation, and testing. Field installed special equipment is

the responsibility of the installing contractor. For example,

when a high/low gas pressure switch is used, the high gas

pressure setting must be higher than the maximum

manifold pressure during initial start-up and the low

pressure setting must be set below the normal minimum

inlet pressure to prevent nuisance shutdowns during the

start-up procedure.

■After the burner in started, the low pressure setting should

be raised until the burner shuts off. Reduce the setting and

set the low pressure switch to restart the burner. Reduce

the high pressure setting until the burner shuts off. Then

raise the setting slightly and reset the high pressure switch

to restart the burner. Do not make the adjustments too

close to trip points or nuisance shut downs may occur. Any

time the burner gas supply is shut off with the main manual

valve, the low pressure switch will require resetting.

■IIf any doubt exists concerning burner operation when

special equipment is involved, contact the installing

contractor or MIDCO INTERNATIONAL INC. (front cover).

FIGURE 4 General Burner Head Assembly

-8-

Page 9

XII MAIN AUTOMATIC AND IGNITOR GAS

VALVES

Both valves are single function on-off type with automatic

closing on current failure. Replace entire valve if valve

fails to open when power is applied or if leakage is

detected on standby.

XIII BLOWER ASSEMBLY

Model J81A-3 uses a 1550 RPM shaded pole motor with

auto-reset overload protection. It contains a centrifugal

Interlock Switch which is connected in the control circuit to

prevent burner operation if the motor fails. Model J121A-3

is equipped with 1⁄6 HP split phase 3450 RPM motor. It may

contain either a manual or auto-reset overload protector. It

has no interlock, this function being performed by an Air

Pressure Switch on the burner.

Both motors feature permanently lubricated ball bearings

that require no routine oiling maintenance.

■ Cleaning of the blower wheel is usually the only service

required. Need for cleaning is required if the inlet screen or

blower wheel shows an accumulation of dust and lint. The

motor air cooling vents should also be cleaned at this time.

■ If the motor must be replaced, disconnect the motor wires

from the burner terminal strip and thermal switch. Remove

the blower inlet screen and blower wheel and remove the

motor case bolt nuts and lockwashers.

■ When remounting the blower wheel, the distance from

the wheel and the outside of the blower housing air inlet

side plate should be 5⁄16".

■ The switch mechanism is a bi-metallic disc that snaps

over when it is heated to the set temperature. The switch is

mounted so that the disc bears against the side plate of the

blower housing.

■ Testing the switch to prove that it is functional can be

done by removing the ignitor assembly and blowing hot air

through the opening toward the blower inlet. If hot air is not

available, remove the switch and check for continuity. With

the switch cool, there should be continuity between

terminals 1 (black wire) and 3 (red/white). To simulate the

“hot” condition, place the switch on a firm surface and apply

finger pressure to the switch disc. When the disc “snaps”,

there should be continuity between terminals 1 and 2

(yellow/black wire).

XIV THERMAL SWITCH

The Thermal Switch is a heat sensitive single pole double

throw snap switch that energizes the blower motor to

provide cooling air if, because of a heat back up through the

burner when the motor is off, the temperature of the blower

housing reaches 160° F. The thermal switch is not wired

into the gas valve circuit and does not turn valve off when

activated by heat back up.

FLAME

SENSOR

ELECTRODE

FIGURE 5 Type “3” Ignitor and Regulator Assembly

-9-

Page 10

TROUBLE CHART

Make sure the switch or timer is calling for heat. Defective wiring or loose connections can simulate the component

defects outlined below. Check associated wiring before replacing a component.

ELECTRICAL AND FLAME CHECKS MUST BE MADE IN THE ORDER LISTED.

I. MOTOR WILL NOT RUN.

A . Confirm 120 volts between strip terminals.

1. L2 and L1: No voltage, Fused Disconnect off or

Fuse open.

2. L2 and 3: No voltage, Safety Controls open.

3. L2 and 10: No voltage, Burner Switch or

Timer open and/or Remote Switch or Timer

open.

4. L2 and 4: No voltage, optional high or low gas

pressure switch is tripped.

5. L2 and Thermal Switch Terminal 1 (black wire):

a.No voltage, Thermal Switch is defective.

b.Voltage present, defective Motor.

II. MOTOR RUNS CONTINUOUSLY, BUT NO FLAME

AND BURNER HOUSING COOL.

A. Make certain Flame Safeguard lockout switch is

not tripped.

CAUTION: Tests are valid only during the 4 or

10 second trial for ignition. Main Manual Shut-Off

Valve must be closed and Manual Ignitor Valve

open.

1. Confirm 120 volts on strip terminals L2 and 5.

a.Voltage present: Continue to Step 2.

b.No voltage:

J81A - Motor Interlock Switch defective.

J121A - Blower Air Switch defective.

2. Confirm 120 volts between strip terminal L2 and

terminal 6.

a.Voltage present, continue to Step 3.

b.No voltage, Flame Safeguard defective.

3. Confirm 120 volts on strip terminal L2 and 7.

a.Voltage present, continue to Step 4.

b.No voltage, Flame Safeguard defective.

4. Check for ignition spark (spark length

approximately 1/8").

a.Between spark generator hi-voltage terminal

and ground: No spark, defective Spark

Generator.

b.Between spark electrode wire and chassis

ground: No spark, Spark Generator defective.

c.For checking spark gap between Spark

Electrode and Ground Barrier, refer to PART

2 SERVICE VIII IGNITOR AND

REGULATOR ASSEMBLY, SPARK TEST.

5. Connect manometer to ignitor gas pressure

test tap, and check pressure during trial for

ignition period.

a.No pressure, confirm that pressure of at least

5.5" W.C. is available at the inlet of the Ignitor

Gas Valve, and repeat Step 5. If still no

ignitor gas pressure, ignitor gas valve defective.

b.Ignitor gas pressure 3.0" to 4.0" W.C.,

continue with Step 6.

c.Adjust the ignitor regulator to 3.5" W.C. while

gas is flowing.

6. Open the charging door, make sure any door

open interlock is temporarily by-passed and

repeat trial for ignition.

a.Open Main Manual Shut-Off Valve. With main flame

present, close charging door, remove temporary door

open interlock and check incineration chamber

pressure. Burner peep hole can be used for access

to obtain approximate reading (See Figure 3). Make

sure sensing tube extends into the incineration

chamber at least 6". Pressure should be between

0" to minus 0.5" W.C. for J81A, 0" to minus 1.0" W.C.

for J121A. If pressure is on the high negative side of

the range, increase the ignitor flame gas pressure to

4.0" to 5.0" W.C.

b.No flame present, clean and reset electrode

assembly per Figure 5 and repeat Step 6a.

III. IGNITOR FLAME ON ONLY DURING THE 4 or 10

SECOND TRIAL FOR IGNITION.

A. With motor running, confirm 120 volts as follows:

1. Between strip terminals L1 and L2: 120 volts

present, voltage OK.

2. Between strip terminals L1 and Ground: 120

volts present, ground OK.

3. Between strip terminals L2 and Ground: No

voltage, neutral OK.

B. Follow test procedure as specified in Step II.A.

1. Disconnect Flame Electrode Wire and check

for continuity.

2. Connect DC voltmeter in test jack in amplifier.

With ignitor flame on, reading should be at 2 or

more volts DC and steady. Adjust ignitor gas

pressure to obtain acceptable signal and note

gas pressure and signal strength for future

reference.

C. If all checks listed above were satisfactory and

the ignitor will not stay lit, Flame Safeguard defective.

IV. IGNITOR LIGHTS BUT NO MAIN FLAME.

A. Confirm 120 volts between strip terminal L2 and 8.

1.120 volts present, continue with Step B.

2.No voltage, Flame Safeguard defective.

B. Connect manometer to Main Automatic Valve

downstream pressure tap.

1. No gas pressure when valve is energized.

a.Confirm that pressure of at least 5.5" W.C.

NATURAL, 8.0" W.C. PROPANE, is available

at the inlet of the Main Automatic Valve.

b.Pressure at inlet side OK, Main Automatic

Valve defective.

V. SHORT MAIN FLAME.

A. Low gas pressure.

B. Air shutter open too far.

C. Input adjuster not set properly.

VI. LONG HAZY MAIN FLAME.

A. High gas pressure.

B. Air shutter closed too far.

C. Insufficient free air in incineration chamber.

D. Dirty blower wheel.

E. Input adjustor open too far for air shutter setting.

VII. GAS FAILS TO SHUT OFF.

A. Main Automatic and/or Ignitor Gas Valve defective.

-10-

B. High gas pressure.

Loading...

Loading...