Page 1

Installation and Service Instructions

MADE in the USA

HMA 2 &

HMA 2A

Direct-Fired Gas Burners

The Blue Flame Series

DIRECT FIRED MAKE-UP AIR BURNERS are used in

industrial and commercial applications to maintain the

desired environmental temperatures required by critical

processes i.e. health purposes, production systems,

quality control, comfort and loss prevention where it

is necessary or required to exhaust large amounts of

conditioned air.

Make-up Air Systems used as stand alone heating

systems or operating in combination with central heating

plants systems can be cost effective in three ways: 1)

reducing the initial expenditures, 2) tempering incoming

air which may extend the life of expensive central heating

plants and 3) reducing excessive equipment cycling or

premature component failures due to increased heating

demands.

Our innovative two stage combustion burner is not just a

modifi cation or improvement of the old, but a completely

new approach to direct-fi red combustion. The two-stage

combustion improves control of the fl ame process, meets

or exceeds the new ANSI Standards while outperforming

the competition. By incorporating two separate fl ames

within the burner combustion zone, the fl ame is more

stable, shorter and cleaner, permitting the reduction of

emissions levels and allowing for higher temperature rise

and higher tolerance to varying conditions when placed in

the profi le opening.

Features and Benefi ts

Reduced NO2 and CO Emissions: Lower emissions

levels that pass the ANSI Z83.4, Z83.18 and Z83.25 standards.

Higher Temperature Rise: The two stage combustion

process lowers NO

temperature rise.

Increased Capacity: Up to 750,000 BTU’S per foot. (Higher

BTU levels can be achieved if ANSI Z83 Standards for CO and

NO

emissions are not of a concern. Process heaters can fi re

2

up to 1,000,000 BTU’S a foot or more.)

Increased Differential Pressure Drop and Higher Velocities:

HMA 2 & 2A burners can operate as low as 0.05″ to 1.4″ W.C.

differential pressure range or in air velocity as low as 800 fpm to

4000 fpm.

Flame Stability: Two stage combustion provides better fl ame

stability and emission control, allowing for a shorter fl ame and

easier profi le confi guration.

Reduced Inventory Costs - HMA 2A: Single burner casting

can be fi red with natural, propane or butane gas

burner inventory.

Reduced Shipping Costs: A smaller, lighter casting than the

competition’s, can lower your freight costs.

Turndown: 30-1 turndown can be achieved with proper

modulating controls and valves. (Higher turndown possible

depending on equipment design.)

emissions which is the limiting factor in

2

1

, reducing

Midco® International Inc.

4140 West Victoria Street

Chicago, Illinois 60646

toll free 866.705.0514

tel 773.604.8700

fax 773.604.4070

web www.midcointernational.com

e-mail sales@midcointernational.com

Emission performance is application specifi c and may vary.

1

Consult Midco for applications using butane fuels.

Quality Designed for Proven Performance

1113

8471 34

Printed in USA

Page 2

Specifi cations

Specifi cations

*Firing Rate .............................................................. Up to 750,000 Btu/hr/ft

750,000+ Contact Midco

Burner Manifold Pressure

Natural Gas ................................................. 4.2 to 8 inch W.C.

Propane Gas .............................................. 1.6 to 3 inch W.C.

Pilot Capacity ............................................................ 12,000 Btu/hr

Pilot Manifold Gas Pressure

Natural Gas ................................................. 3.5 inch W.C.

Propane Gas .............................................. 2.0 inch W.C. **

Pressure Drop Across the Burner ............................ 0.05 to 1.4 inch W.C.

Air Velocity Across the Burner ................................... 800 to 4,000 FPM

Burner Turn-down Ratio ........................................... 30 to 1 (based on Btu / ft)

Flame Length ....................See page 5 for fl ame length Chart 5, and Tables 2 & 3

* Firing rate is dependent on the pressure across the burner. Please see the included

charts for recommended burner sizing.

** Using a natural gas pilot on propane.

Cast Iron (CI) Aluminum (AL)

*** Burner Confi gurations HMA 2 HMA 2A HMA 2 HMA 2A

2″ Straight Section (2A only) - - - 1020810

6″ Straight Section 1050700 1050710 1050800 1050810

6″ Straight Section with Back Inlet 1230700 1230710 1230800 1230810

12″ Straight Section 1010700 1010710 1010800 1010810

12″ Straight Section with Back Inlet 1060700 1060710 1060800 1060810

Elbow Section 1070700 1070710 1070800 1070810

Tee Section 1080700 1080710 1080800 1080810

**** Pilot Confi gurations Part # Natural # Propane #

Brute Pilot Spark Rod and Flame Rod 1190850 1190950

Brute Pilot Spark Rod and UV Mount 1200350 1200450

Brute Pilot Spark Rod 1342-03

Brute Pilot Flame Rod 1360-03

(Direct) Spark Rod and Flame Rod 1190800 1190900

(Direct) Spark Rod and UV Scanner Mount 1200300 1200400

Remote Flame Rod 1220800

Remote UV 1240800

Pilot with Spark Rod only 1210800 1210900

Flame Rod

Spark Rod (Direct Spark) 1342-06

*** See Page 14, Figure 6 for burner confi guration reference.

**** See Page 15, Figure 7 for pilot confi guration reference

(Direct Spark, Std + Brute)1360-03

Table 1 - Burner and Pilot Confi gurations

Midco International Inc. reserves the right to change the construction or confi guration of its products at any time.

All information is based on laboratory testing. Different unit size and/or confi gurations may affect data.

2

Midco International Inc.

8471 34

Page 3

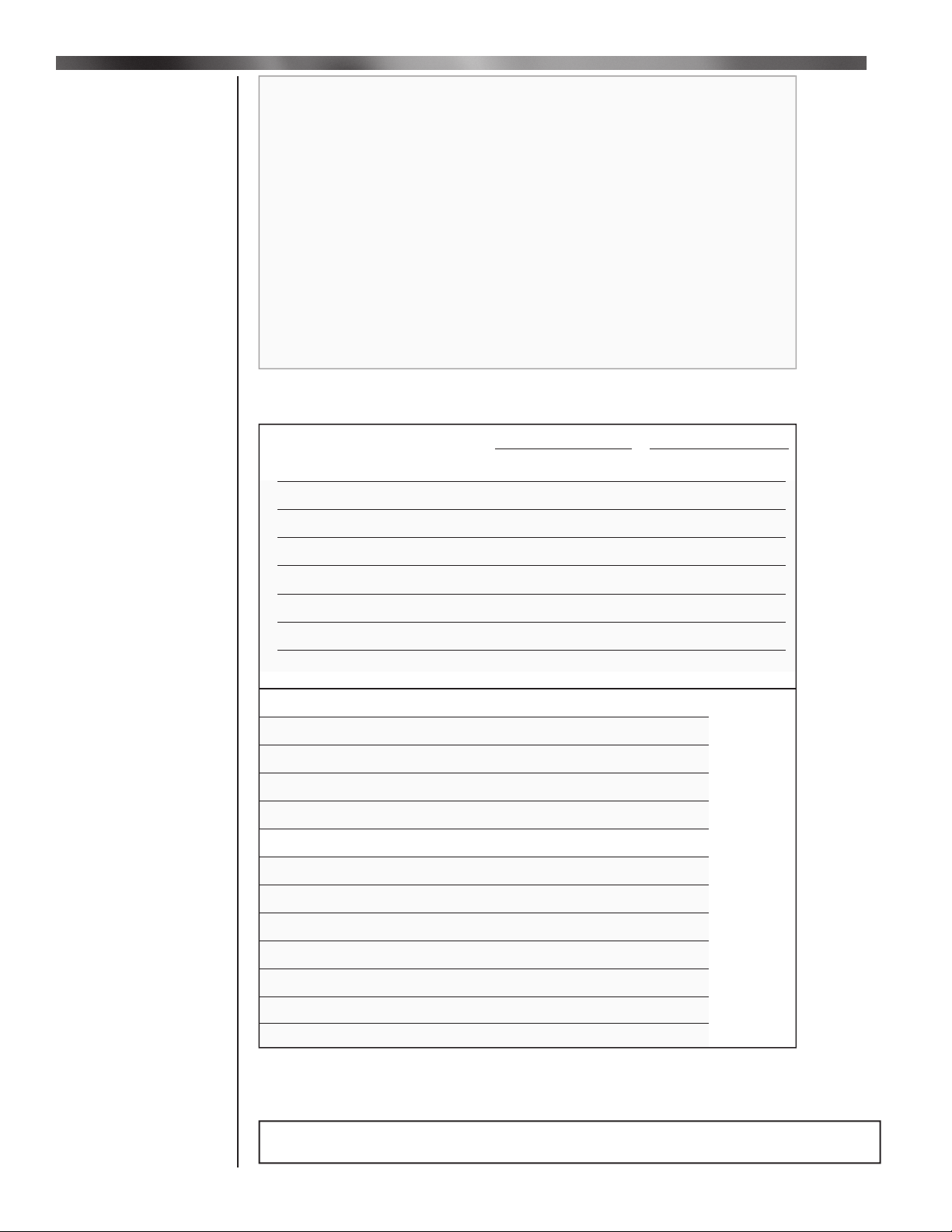

HMA 2 & HMA 2A Burner Performance

Burner Performance

5.0

4.0

CO Emission

3.0

2.0

CO (PPM)

1.0

0.0

0

20

40 60 80 100 120

Temperature Rise*

750,000 Btu/hr/ft at 1.1" W.C. pressure drop across the burner

5.0

4.0

CO Emission

3.0

2.0

CO (PPM)

1.0

0.0

0 20406080100

Temperature Rise*

550,000 Btu/hr/ft at 0.6" W.C. pressure drop across the burner

5.0

4.0

120

0.5

NO Emission

2

0 20406080100120

0.4

0.3

0.2

0.1

0.0

Temperature Rise*

750,000 Btu/hr/ft at 1.1" W.C. pressure drop across the burner

0.5

NO Emission

2

0 20406080100120

0.4

0.3

0.2

0.1

0.0

Temperature Rise*

550,000 Btu/hr/ft at 0.6" W.C. pressure drop across the burner

0.5

NO Emission

2

0.4

2

NO (PPM)

2

NO (PPM)

3.0

2.0

CO (PPM)

1.0

0.0

0 20406080100

CO Emission

120

Temperature Rise*

350,000 Btu/hr/ft at 0.35" W.C. pressure drop across the burner

100

90

80

2

70

60

50

40

30

x

20

NO (PPM at 3% O )

10

0.0

0

NO Emissions Profile

x

100000 200000 300000 400000 500000 600000

Heat Input (Btu/hr/ft)

0.3

0.2

0.1

0

20

40 60 80 100 120

0.0

Temperature Rise*

350,000 Btu/hr/ft at 0.35" W.C. pressure drop across the burner

.45 Delta P

.64 Delta P

.85 Delta P

* For higher temperature rise contact

Midco Engineering Department.

NOTE: Emission performance is

application specific and will vary

2

NO (PPM)

8471 34

Chart 1 - CO and NO2 Emissions Data

Midco International Inc.

3

Page 4

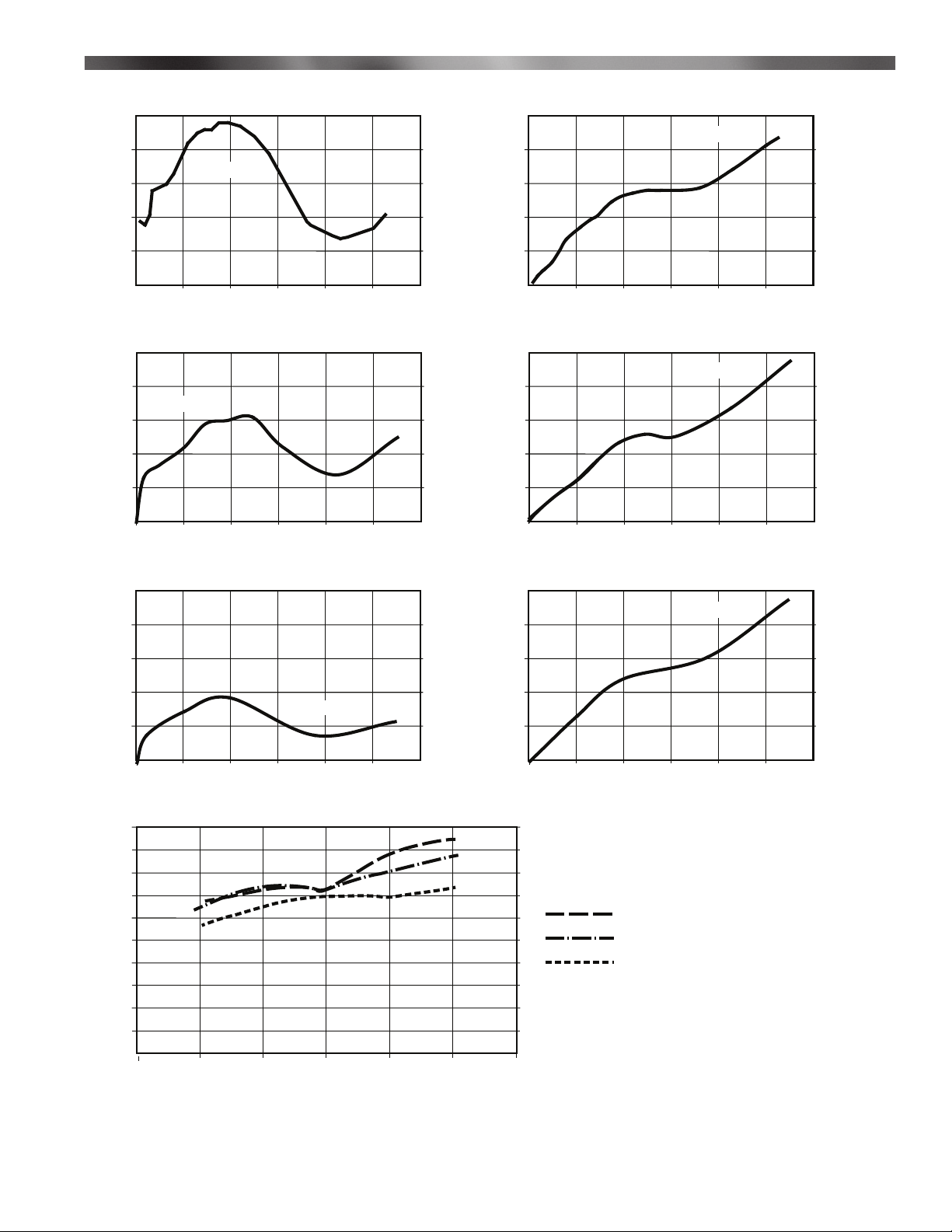

HMA 2 & HMA 2A Burner Performance

Burner Performance

Continued

800,000

700,000

600,000

BTU/hr/ft

500,000

400,000

300,000

9.0

8.0

7.0

6.0

5.0

4.0

(Manifold)

3.0

Natural Gas

Propane Gas

0.20 0.40 0.60 0.80 1.00 1.20

Pressure Drop across the Burner ("W.C.)

Chart 2- BTU’s verses Pressure Drop

Natural Gas

2.0

Fuel Gas Pressure ("W.C.)

1.0

0.0

100,000 200,000 300,000 400,000 500,000 600,000 700,000

Propane Gas

BTU/hr/ft

Chart 3- BTU’s verses Gas Pressure ( ″W.C.)

4,500

4,000

3,500

3,000

2,500

2,000

Profile Velocity (SFPM)

1,500

1,000

0.20 0.40 0.60 0.80 1.00 1.20

Pressure Across the Burner ("W.C.)

Chart 4 - Pressure Across the Burner verses Profi le Velocity

___________________________________

4

Midco International Inc.

8471 34

Page 5

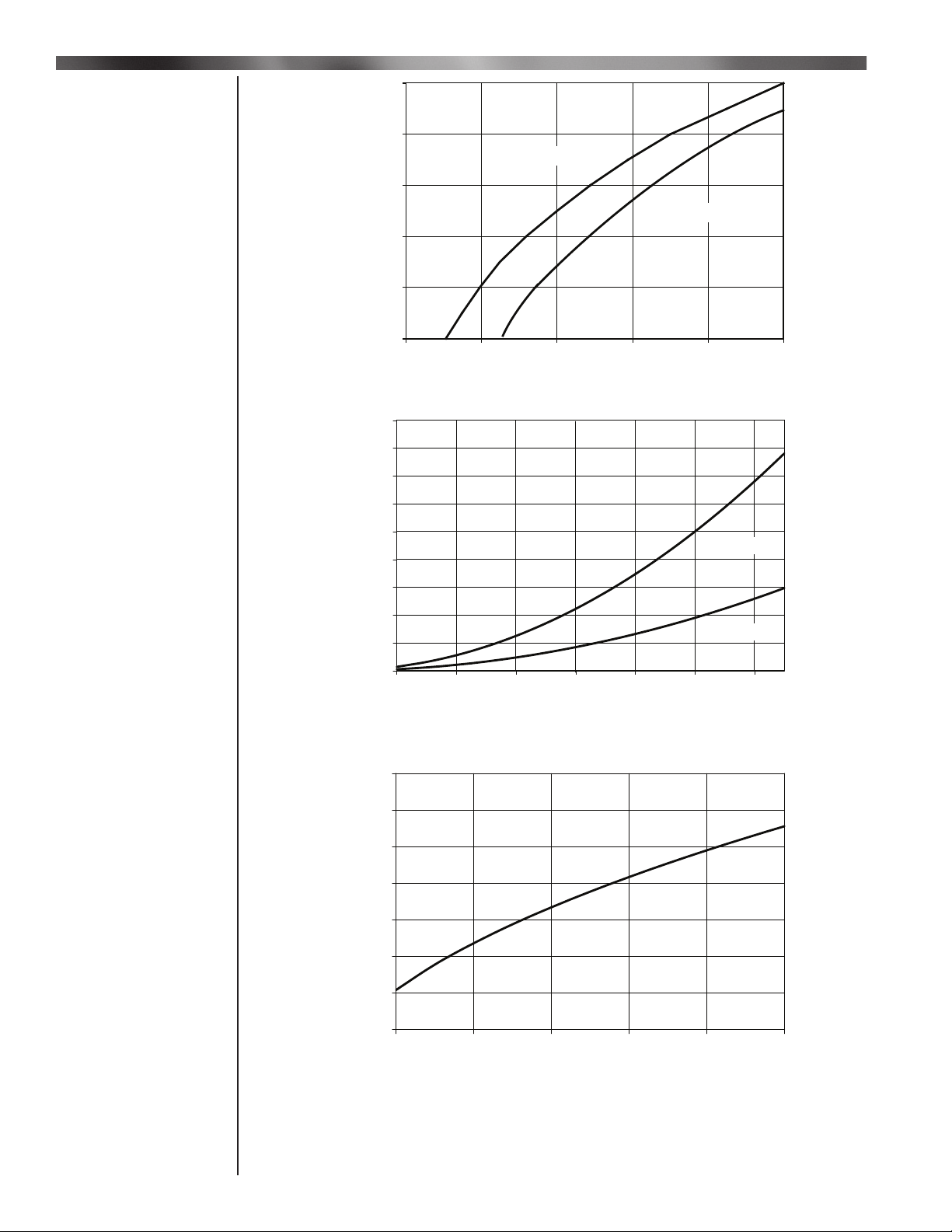

Installation

- Velocity and pressure drop fi gures shown in Table 2 apply to standard design conditions.

However, these conditions apply only when air enters the heater at 70° and requires little or no heat.

In practice with the burner operating, these fi gures will vary, especially with inlet air at the minimum

design temperature. This is because the blower handles a constant volume of air regardless

of its temperature. When the air is heated expansion takes place ahead of the blower and just

downstream of the burner. It follows therefore that when the air is being heated a lesser volume

enters the heater, causing a reduction, both in velocity and pressure drop at the burner. Table

2 shows the variation for minimum temperature air entry and with full input to the burner. Flame

lengths given in Table 2 and Chart 5 apply to conditions shown in Table 2.

Air fl ow at burner Approximate length of fl ame

based on 70° (std) Burner Capacity (per foot) projecting beyond end of

blower rating Natural & Propane Gas burner and profi le plate *

Design

Design Pressure Max. Min.

velocity drop capacity capacity Turn 550,000 650,000 750,000

FPM ″ W.C Btu/Hr Btu/Hr Down per ft per ft per ft

3200 .7″ 550,000 19,000 29:1 13″ 16″ 20″

2850

(ideal)

2500 .45″ 550,000 17,000 32:1 17″ 20″ 24″

Reduce capacity 4% per each 1000 ft altitude over 2000 ft.

.55″ 550,000 18,000 30:1 15″ 19″ 22″

Table 2 - Design Data for Pull-Thru System

* Flame lengths are given to the end of the main mass of fl ame, excluding any isolated

wisps or fl ashes, and for normal operations ie. with cold inlet air (design minimum)

Air Flow Variations

Due to Heating in a

Pull-Thru System

Velocity Pressure Air Actual cold Actual cold

at burner drop at temp. air velocity air pressure

(from Table 1) burner rise at burner drop at burner

3200 fpm .7″ W.C.

100° 2600 fpm .46″ W.C.

2850 fpm .55″ W.C.

100° 2300 fpm .36″ W.C.

2500 fpm .45″ W.C.

100° 2000 fpm .29″ W.C.

75° 2750 fpm .52″ W.C.

75° 2450 fpm .41″ W.C.

75° 2150 fpm .33″ W.C.

Table 3 - Air Flow Variations for Pull-Thru System

EXAMPLE: A heater rated for 100° rise, 70° outlet temperature at a design velocity of 2850 fpm

and a design pressure drop of .55″ W.C., will in actual operation pass 2300 fpm over

the burner with a .36″ W.C. drop when air enters at -30°.

HMA 2 & HMA 2A Flame Length

35

30

750,000 Btu/ft

650,000 Btu/ft

25

550,000 Btu/ft

20

15

10

Flame Length ( inches )

5

0

1.20.2 0.4 0.6 0.8 10

Pressure Drop ( " W.C.)

Chart 5 - HMA 2 & 2A Flame Length

HMA 2 & HMA 2A fl ame length as a function of pressure drop and fi ring rate applies to push and pull

through systems using 100% fresh standard air.

8471 34

Midco International Inc.

5

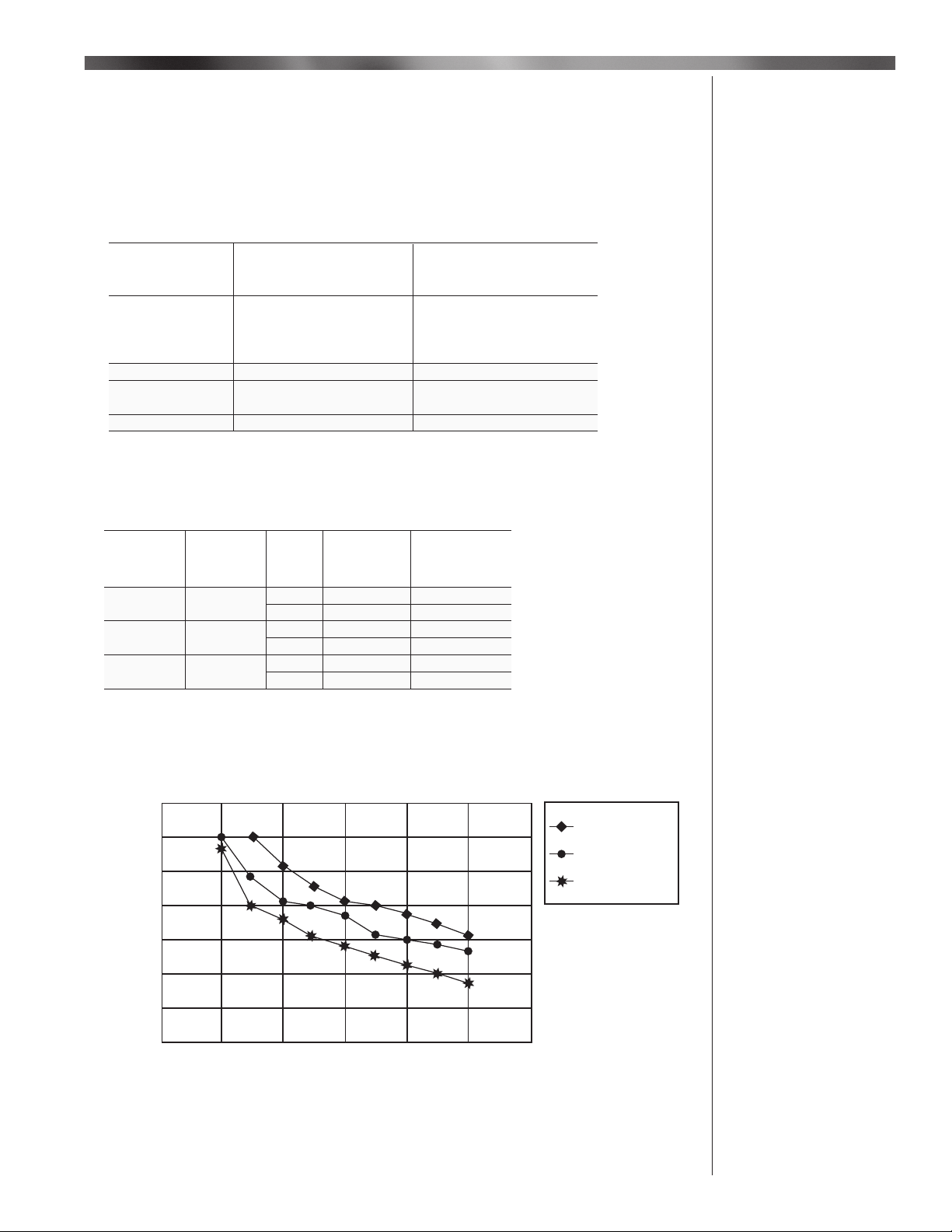

Page 6

Installation

Profi le Setup

1. Required BTU:

BTU/hr = Blower SCFM x Desired Temp. Rise x 1.08 / .92

2. Required Burner Length:

Feet of burner = [Required BTU/hr]÷[Burner Firing Rate (BTU/hr/ft)]

The Burner Firing Rate should correspond to the pressure drop across the burner

shown in Chart 2.

3. Required Profi le Area:

Total Burner Area = Number of burner sections x burner area

(Burner Section) Burner Area

2 inch 0.11 sq. ft.

6 inch 0.32 sq. ft.

12 inch 0.65 sq. ft.

T Section 0.77 sq. ft.

Ell Section 0.65 sq. ft.

Net Profi le Area = Rated Fan (SCFM) ÷ Profi le Velocity (SFPM)

The Profi le Velocity can be determined from the following:

Profile Velocity

∆P is the pressure drop across the burner

Profi le Area = Net Profi le Area + Total Burner Area

___________________________________

=

945

PΔ

0750

.

Profi le Setup Example

Sizing the burner and the corresponding profi le for a 5,000 SCFM and a 115 degrees

temperature rise.

1. Required BTU:

BTU/hr = Blower SCFM x Desired Temp. Rise x 1.08 / .92

BTU/hr =5,000 (SCFM) x 115 (∆T) x1.08 / .92 = 675,000 BTU/hr

2. Required Burner Length:

Feet of burner = [Required BTU/hr]÷[Burner Firing Rate (BTU/hr/ft)]

To determine the optimum burner length we can choose from a combination of 12

inch or 6 inch burner sections referring to Table 1. We can either fi re the burner

at a rate of 675,000 BTU/hr per ft, or we can fi re the burner at 450,000 BTU/hr per ft

(1.5 feet of burner). Refer to Chart 3 for the fuel pressures requirements at different

fi ring rates.

3. Required Profi le Area:

Total Burner Area = Number of burner sections x burner area

(Burner Section) Burner Area

2 inch 0.11 sq. ft.

6 inch 0.32 sq. ft.

12 inch 0.65 sq. ft.

T Section 0.77 sq. ft.

Ell Section 0.65 sq. ft.

Total Burner Area = 1.0 (ft) x 0.65 = 0.650 ft

Or

Total Burner Area = 1.5 (ft) x 0.65 = 0.975 ft

6

Midco International Inc.

2

2

8471 34

Page 7

Installation

Net Profi le Area = Rated Fan (SCFM) ÷ Profi le Velocity (SFPM)

The Profi le Velocity should be determined based on the burner fi ring rates. If we choose to fi re the

burner at 675,000 BTU/hr/ft then the profi le opening should be sized for a pressure drop of 0.8 ″

W.C. across the burner. If the fi ring rate is 450,000 BTU/hr/ft then the profi le opening should be

sized for a pressure drop of 0.4 ″ W.C. across the burner. The corresponding profi le velocity across

the burner should be determined from Chart 4 or use the following equation.

0750

0750

PΔ

0750

.

3086(SFPM)

=

2

2182(SFPM)

=

2

Profile Velocity

For the 675,000 BTU/hr/ft

Profile Velocity

Net Profi le Area = 5000 (SCFM) ÷ 3086 (SFPM)=1.62ft

For the 450,000 BTU/hr/ft

Profile Velocity

Net Profi le Area = 5000 (SCFM) ÷ 2182 (SFPM)=2.29ft

To calculate the profi le area needed for both cases:

Profi le Area = Net Profi le Area + Total Burner Area

For the 675,000 BTU/hr/ft

Profi le Area = 1.62 + 0.650 = 2.27 ft

=

=

2

945

945

=

945

0.8

.

0.4

.

Profi le Setup Example

Continued

For the 450,000 BTU/hr/ft

Profi le Area = 2.29 + 0.975 = 3.265 ft

To calculate the length of the profi le opening add burner length to the desired clearance:

For the 675,000 BTU/hr/ft case

12 inch + 4 inch (2 inch on each side) = 16 inch (1.3ft)

For the 450,000 BTU/hr/ft case

18 inch + 4 inch (2 inch on each side) = 22 inch (1.83ft)

To calculate the height of the profi le opening divide the profi le area by the profi le length:

For the 675,000 BTU/hr/ft case

2.27 ft

For the 450,000 BTU/hr/ft case

3.265 ft

1. Conversion of SCFM to Actual CFM of air

SCFM = CFM x ρ

_____

0.075

2. Air density as a function of Temperature -- ρ = 1.35 x Barometric Pressure (in Hg)

T

3. Change in Standard Barometric Pressure as a function of Altitude

Barometric Pressure (in.Hg) = 29.921x (1-6.8753 x 0.000001x altitude (ft))^5.2559

4. Temperature difference -- Temperature Rise = T

5. Energy equation - - BTU/hr = SCFM x Temperature Rise x 1.08 / 0.92

Where: 1.08 is a sensible heat equation constant

1.08 = 0.2397

____ ___ ___

___________________________________

8471 34

2

÷ 1.3 ft = 1.75 ft (21 inch)

2

÷ 1.83 ft = 1.78ft (21.5 inch)

BTU

(

x 60 ( min) x 0.075 ( lb

)

lb H Ft

2

+ 460

(out)

- T

(out)

(in)

)

3

Midco International Inc.

7

Page 8

Installation

Burner Assembly

Burner Placement

in the Profi le

NOTE: If burner is over 4′, natural gas, or 5′, propane gas, a back inlet is required as shown

below. Gas Inlet Capacities

Maximum Feet of Burner

Inlet Size Natural Propane

1.5 ″ NPT End Inlet 4′ 5′

2″ NPT Back Inlet 6.5′ 8′

Centrally Located

___________________________________

Table 4 - Gas Inlet Capacities

The performance of the HMA-2 & 2A burner depends on the unit in which the burner is located. The

burner can perform differently in different units and can obtain different end results. Maintaining a

relative laminar fl ow around the burner and providing a suffi cient space between the burner and

the blower is a key factor in obtaining best burner performance. The unit should be free of any

obstructions that can create turbulent effect on the air.

Note: Any reinforcements around the profi le plates should be down stream of the profi le plate.

Static pressure probes are needed to sense the differential air pressure across the profi le plates.

The static pressure probes should be installed 12″ upstream from the burner and 12″ downstream

from the burner centrally located in the duct. See Figure 1a and 1b for typical location.

Adjustable

Profile Plate

Static

Pressure

Probe

Fixed

Profile Plate

Profile

Opening

should be

Centered to

the Burner

Static

Pressure

Probe

Air Flow

4"

Air Flow

Burner should

be Centered

to the Blower

12"

Figure 1a - Burner Placement in the Profi le

4"

1" to 4", typical 2"

Burner should

be Centered

to the Blower

12"

Figure 1b - Burner Placement in the Profi le

8

Midco International Inc.

8471 34

Page 9

The burner performance is highly dependent on its application and installation in the heater. Factors

such as airfl ow around the burner, positioning in the profi le , as well as, the profi le sizing have

infl uence on the fi nal emissions levels . Midco does not guarantee combustion results prior to

performing actual combustion tests.

The burner should be located in the center of the profi le. The profi le clearance from ends of the

burner should be kept at approximately 1 to 4-inches. Typically setting the profi le 2″ from the end

plates is recommended. Any reinforcements used on the edge of the profi le opening should be

on the downstream side of the profi le. The burner can be mounted either vertically or horizontally.

Since the airfl ow varies from unit to unit best results should be determined by actual testing.

___________________________________

Installation

Burner Placement

in the Profi le

Continued

The HMA-2 & 2A Burners are designed to operate in an air heater and in an air stream taken directly

from outdoors for most applications. To avoid stratifi cation of the heated air, the burners should be

located on the intake side center to the blower. Such positioning will take advantage of the blower

mixing effect and ensure minimum temperature stratifi cation. It will also allow for a relatively uniform

airfl ow across the burner resulting in a clean combustion.

Weatherhood

Air Inlet

Screen

and

Filter

Adjustable

Profile Plate

HMA-2 &

HMA 2A

Burner

Installation in a Heater

2x

x

Blower Inlet

Outlet

Center Burner

to the Blower

Figure 2 - Pull-Thru System

The total pressure of the blower must include allowance for the resistance of the heater and

pressure drop across the burner, together with pressure losses at the inlet screen, inlet louvers,

fi lters, plus the external pressure rating of the heater, if any. Contact equipment manufacturer for

proper information.

___________________________________

Push-Thru System

Center Burner

to the Opening

Pull Thru System

Push-Thru Systems

Air Inlet

Blower Inlet

Outlet

Figure 3 - Push Thru System

The HMA-2 & 2A Burner will operate satisfactorily when located downstream of the blower. A

mixing plenum may be required at the heater discharge opening to insure minimum temperature

stratifi cation. Blower and motor selection must be made on the basis of corrections for the coldest

anticipated inlet temperature. In the push-thru system the heater outlet CFM will vary due to the

expansion of air.

8471 34

Midco International Inc.

9

Page 10

Installation

Push-Thru Systems

Continued

Profile Plate

Duct Height "A"

Profile Plate

Duct Width "B"

Typical Gas Train Assembly

Air Flow

Minimum Straight

Run 2 x "B"

Air Flow

Minimum Straight

Run 1-1/2 x "A"

3 Ft. Minimum

Elbow Duct Limits

Figure 4 - Installation in a Duct

___________________________________

Typical

Gas Train

Assembly

400,000 BTU/Hr

and Under

Main Manual

Gas Valve

Typical Gas

Train Assembly

400,000 BTU/Hr

and Above

Main

Regulator

Main Manual

Gas Valve

Manual Pilot

Valve

Flame Rod

Spark Rod

Combination Gas Valve with

Main & Pilot Regulator

Main

Operating

Valves

Pilot

Val ve

Pilot

Modulating Valve

Manual Pilot Valve

Safety Shut-off

Valve

Pilot

Regulator

Pilot Gas Pressure Tap

Union

Pilot Tube

Burner

*

Spark Rod

Pilot Tube

A heater having an input over

400,000 BTU/Hr shall have

provisions for measuring gas

pressure between the valves,

except for heater incorporating

a single safety shut-off valve

with valve seal over travel

interlock. (ANSI Z83.4)

Pilot

Flame Rod

Modulating

Valve

* A manifold pressure tap

needs to be provided

at the burner to check

manifold pressure

3 Ft. Minimum

Union

Manual

Firing Valve

Burner

*

10

Figure 5a - Gas Train Assemblies

Midco International Inc.

8471 34

Page 11

Direct Spark Ignition

Typical

Gas Train Assembly

400,000 BTU/Hr

and Under

Installation

Typical Gas Train Assembly

Continued

Pilot

Flame Rod

Spark Rod

Burner

Main

Regulator

Main

Manual Gas

Valve

Main

Operating

Valves

Combination Gas Valve

with Main & Pilot Regulator

Main Manual

Gas Valve

Direct Spark Ignition

Typical

Gas Train Assembly

Safety Shut-off

Valve

Pilot

Regulator

Manual

Pilot Valve

Main Gas

Pressure

Ta p

Modulating

Valve

Flame Rod

Spark Rod

Modulating

Valve

Pilot Gas

Pressure Tap

Union

Manual Firing

Valve

Pilot

Union

Manual Firing

Valve

Pilot Tube

* A manifold pressure tap

needs to be provided

at the burner to check

manifold pressure

*

Burner

*

Figure 5b - Direct Spark Gas Train Assemblies

___________________________________

Burner operation depends on the unit control setup in which the HMA-2 & 2A burner is used. A

typical setup should consist of a Flame Safety Control with appropriate air fl ow proving system and

a Modulating Gas Control System.

1. Verify the pressure across the burner. The pressure across the burner can be measured by

placing two static pressure probes, one downstream and one upstream of the profi le opening

and measure the differential pressure. The pressure should be within burner operating

specifi cations and within the expected calculated pressure. See Chart 2

2. With the burner off check the Flame Safety Air Proving System

a. Check the operation of the air proving system for low and high airfl ow setting. Refer to

the Specifi cations of the Flame Safety Control for setup instructions and air switch

operational characteristics.

8471 34

Midco International Inc.

Burner Setup

11

Page 12

Installation

Burner Setup Continued

3. For intermittent, or interrupted ignition systems. See Figure 5a for typical piping.

a. Pipe the pilot gas supply line up stream of the main gas valve.

b. With the unit running adjust the pilot pressure regulator to 3.5 inch W.C. for natural gas

or 2.0 inch W.C. for propane gas. Using a natural gas pilot or 5″ to 7″, using a propane

pilot with orifi ce # 4957-07 (#58 Drill .042)

4. For direct spark ignition system when using a pilot for ignition. See Figure 5b.

a. Pipe the pilot gas supplied line to the main gas line downstream of the main gas valve.

5. Pilot ignition

a. Make sure the main gas valve to the burner is closed for intermittent or interrupted

ignition.

b. Observe the pilot fl ame, the fl ame should be blue and should extend approximately to

half of the burner end plate.

c. Check the fl ame signal.

d. Flame signal should be between 2-5 UA or 2-5 VDC

6. Depending on the pilot confi guration make following adjustments, if required.

a. For Spark rod and fl ame rod confi gurations

Make sure the fl ame rod is pointing towards burner manifold.

Make sure the fl ame rod is not touching baffl es or burner manifold.

Make sure the spark rod is positioned above the pilot gas tube and that it will spark to

the end of the gas tube. See Pilot Detail Drawings for this setting on page 15.

b. Spark rod and UV

Make sure the spark rod is positioned above the pilot gas tube and that it will spark to

the end of the gas tube.

7. Main burner ignition

Close the manual gas valve.

a. Set the Modulating Gas Control System to low fi re position.

· Slowly open the manual gas valve.

· The fl ame should be evenly extending in the burner.

· The fl ame should be located in the casting of the burner.

· Check the fl ame signal.

Close the manual gas valve.

b. Set the Modulating Gas Control System to high fi re position.

· Slowly open the manual gas valve.

· Observe the fl ame at high fi re; the fl ame should be blue approximately 10

to 12 inches long. If the fl ame is long, lazy and orange the air to fuel ratio

is not correctly adjusted . The pressure across the burner should be

increased, refer to Chart 2.

· Check the fl ame signal.

· Check the manifold pressure to the corresponding fi ring rate. If the manifold

pressure does not correspond to the pressures shown in Chart 3. Re-adjust if

necessary.

12

For a high fi re start system the fi rst gas port next to the pilot might require to be blocked using

furnace cement to prevent potential pilot blow outs and fl ame failures. See Figure 7 - Pilot

Confi guration.

Slight redness and warpage of the baffl e plates may occur at the high and intermediate fi re inputs.

This will not harm the burner. Once an initial discoloration and warp has taken (“set”) no further

permanent change will take place.

If the end plates redness occurs during high and intermediate fi re inputs, the distance between the

end plates and the profi le opening might not be suffi cient for the air to cool the end plates. Profi le

readjustments might be necessary.

___________________________________

Midco International Inc.

8471 34

Page 13

Burner Trouble Shooting

The Midco Burner is only a component of the complete system. For trouble shooting of the

equipment contact the OEM (Original Equipment Manufacturer) or the component manufacturer.

If the pilot fails to light: install a manometer on the pilot pressure tap. Check for 3.5″ W.C. for

natural gas or 2″ W.C. for propane, using a natural gas pilot or 5″ to 7″ using a propane pilot with

orifi ce # 4957-07 (#58 Drill .042). If no gas check for voltage to pilot solenoid valve. If no voltage

check operating controls or primary fl ame safeguard. If voltage to pilot solenoid valve is present

and if there is 3.5″ W.C. gas pressure at pilot pressure tap then check for spark or fl ame rod

settings. See Figure 7. If there is no voltage to pilot solenoid valve, refer to Flame Safety control

specifi cations or contact the original equipment manufacturer.

If Main Burner fails: If no main fl ame check manifold pressure. If no manifold pressure check for

voltage to the gas solenoid valve and check if main manual fi ring valve is open. If no voltage to gas

valve refer to Flame Safety control specifi cations or contact the original equipment manufacturer.

If the pilot fails as main gas valves open, the fi rst adjacent gas port hole (next to the pilot) might

need to be plugged with furnace cement. For high fi re start units see Figure 7 - Pilot Confi guration.

___________________________________

Burner Maintenance

Annual maintenance of HMA 2 & HMA 2A burner is recommended to ensure trouble free operation.

Direct Gas-Fired Heater Burner Maintenance

1. Clean the burner plates

2. Clear the burner gas and air ports

3. Change the spark rod igniter

4. Insure the fl ame sensor is in good condition

Use a stiff wire brush to clean the burner plates. Scrub both sides of the stainless steel burner plates

to remove any soot or other crud, which may be on the burner. All of the burner plate holes must

be clear so air can pass through them unrestricted. The holes in the burner plate allow air to mix

with the gas in increasing amounts, as the fl ame gets longer. Scrub the rust, soot and other foreign

material from the burner orifi ce area. After the burner plates are cleaned inspect them for cracking.

Cracks occurring between one or two holes are normal and should be of no concern. If the cracking

is more extensive, the affected plates should be replaced. Clean the burner gas and air ports using a

drill or piece of wire of the appropriate size. See the Table 5 for drill size. After the orifi ces are drilled

to the correct size and using compressed air or a vacuum, remove any debris from the manifold.

Debris left in the manifold will prematurely clog the orifi ces in the future.

Gas Port Air Port

Burner Section and Gas Type Drill Size Decimal Drill Size Decimal

Wire Gauge Wire Gauge

HMA 2 Natural / Propane 1/8″ .125 43 .089

HMA 2A Natural / Propane 1/8″ .125 42 .093

Table 5 - Drill Sizes for HMA 2 / 2A

After the burner plates and orifi ces are cleaned inspect the spark rod. The tip should be clean and

free of dirt and carbon. The porcelain must be intact. If it is cracked, replace it. Pull the fl ame rod or

ultraviolet scanner as well. If the fl ame sensor is a scanner, clean the lens with a clean damp soft

rag. The fl ame rod’s metal rod should be clean and free of dirt and carbon. Like the spark rod igniter,

the porcelain on the fl ame rod must be intact as well. Replace it if it is cracked.

___________________________________

8471 34

Midco International Inc.

13

Page 14

Burner Confi guration

2" Straight

Aluminum

HMA 2A - 1050810

2.0"

8.63"

10.47"

Cast Iron

HMA 2 -1050700

HMA 2A - 1050710

Aluminum

HMA 2 - 1050800

HMA 2A - 1050810

6" Straight with

2" NPT Back Inlet

Cast Iron

HMA 2 -1230700

HMA 2A - 1230710

Aluminum

HMA 2 - 1230800

HMA 2A - 1230810

6.00"

8.63"

10.47"

12" Straight6" Straight

Cast Iron

HMA 2 -1010700

HMA 2A - 1010710

Aluminum

HMA 2 - 1010800

HMA 2A - 1010810

12" Straight with

2" NPT Back Inlet

Cast Iron

HMA 2 -1060700

HMA 2A - 1060710

Aluminum

HMA 2 - 1060800

HMA 2A - 1060810

12.00"

Te e

Cast Iron

HMA 2 -1080700

HMA 2A - 1080710

Aluminum

HMA 2 - 1080800

HMA 2A - 1080810

Ell

Cast Iron

HMA 2 -1070700

HMA 2A - 1070710

Aluminum

HMA 2 - 1070800

HMA 2A - 1070810

8.63"

10.47"

Caution:

Under no

circumstances are

the HMA-2 baffl es

and the HMA-2A

baffl es or castings

to be mixed. For

further details see

service bulletin

# 8449-83.

Caution:

Under no

circumstances

should grade

hardware or

Aluminum rivets

be used.

12.00"

6.00"

8.63"

10.47"

14

2" Straight

8.22"

6" Straight

4.11"

6" Straight with

2" NPT Back Inlet

6.00"

12" Straight

12.00"

8.63"

11.38"

2" NPT

Inlet

12" Straight with

2" NPT Back Inlet

Figure 6 - Burner Sections - Assembly

Midco International Inc.

2" NPT

Inlet

6.00"

8.63"

11.38"

Tee Section

10.11"

Elbow

Section

6.00"

8.63"

10.47"

8471 34

Page 15

Parts - Pilot Confi guration & Mounting

1190800

Spark Rod &

Flame Rod

Direct Spark

1220800

Remote

Flame Rod

1200300

Spark Rod

and UV

1200350

Spark Rod

and UV

Brute Pilot

1240800

Remote UV

2.96"

1210800

Pilot with Spark

Rod Only

1190850

Spark Rod &

Flame Rod

Brute Pilot

5.57"

3.72"

Brute Pilot - w/ Spark Rod

1190850

1/8"

5.57"

3.72"

Brute Pilot - UV Scanner Mount

1200350

Location of First Burner Port Plug - See Installation,

Burner Setup Section or Trouble Shooting Section

(Used on high fire start systems ONLY)

5.57"

3.72"

0.65"

2.96"

8471 34

Pilot Detail - Spark Gap Measurement

Brute Pilot

1190850

Figure 7 - Pilot Confi guration

Midco International Inc.

15

Page 16

Parts - Isometric View - HMA 2 & HMA 2A

2” Straight

1

15

2

14

13

6

3

5

7

6

4

11

12

6

8

10

11

9

Ell Section

17

8

Tee Section

1

11

10

14

24

16

6” Straight

6

3

1

18

19

20

16

25

23

12” Straight

4

Figure 8 - Typical Burner Assembly Parts - Isometric View

Midco International Inc.

22

21

1 11

8471 34

Page 17

Parts List for Isometric View

Item Number in Isometric View * #12 #15 #16 #23 #22 #6 #28

2″ 6″ 6″ 12″ 12″ Elbow Tee

Burner Castings

Part #s for Cast Iron HMA 2 N/A 1359-25 1398-25 1364-25 1361-25 1362-25 1365-25

Part #s for Cast Iron HMA 2A N/A 1359-30 1398-30 1364-30 1361-30 1362-30 1365-30

Part #s for Aluminum HMA 2 N/A 1359-75 1398-75 1364-75 1361-75 1362-75 1365-75

Part #s for Aluminum HMA 2A 1370-18 1359-80 1398-80 1364-80 1361-80 1362-80 1365 -80

Item

No. Part Description Part No Quantity Quantity Quantity Quantity Quantity Quantity Quantity

1 S62 Steel Rivet Body Hardware 12 12 12 22 22 22 26

2 HMA-2A 2″ Baffl e 1355-55 2

3 HMA Pilot End Plate 1354-60 Select the correct required end plates

4 Blank End Flange 1372-02 Select the correct required end plates

5 Mounting Bracket 1130100 2 2 2 2 2 2 3

6 HMA-2A 6″ Baffl e 1395-23 2 2 4 4 2 2

7 HMA-2A Outside

Corner Baffl e 1395-35 1

8 HMA-2/2A Tee Baffl e 1395-11 1 2

9 Elbow Casting Section * See above listing for proper selection

10 Inside Baffl e Clamp 1356-10 2 4

11 10-24x9/16 Phillips Rd

Hd S.S. Mach Screw Hardware 2 4 4 8 8 8 12

12 Baffl e Clamp - 2″ 1356-20 2

13 2″ Casting (2A only) * See above listing for proper selection

14 HMA Blank End Plate 1354-50 Select the correct required end plates

15 1/2″ NPT Inlet Flange 1372-05 Select the correct required end plates

16 6″ Straight Casting * See above listing for proper selection

17 6″ Back Inlet Casting * See above listing for proper selection

18 Pilot See pilot listing on Page 15 - Pilot Confi guration (For selection)

19 5/16-18 x 2″ Hex

Head Cap Screw Hardware 3 3 3 3 3 3 6

20 Inlet Flange (Tapered) 1352-02 (Select the correct required end plates

21 Baffl e Clamp 1356-00 2 2 4 4 2 2

22 12″ Back Inlet Casting * See above listing for proper selection

23 12″ Straight Casting * See above listing for proper selection

24 Tee Section Casting * See above listing for proper selection

25 5/16-18x 1-3/4″ Hex

Head Cap Screw Hardware 3 3 3 3 3 3 3

Not Shown

5/16 Lock Washer Hardware 6 6 6 6 6 6 9

5/16-18 Hex Nut Hardware 6 6 6 6 6 6 9

Straight Straight Back Inlet Straight Back Inlet Section Section

Burner Confi gurations: see page 14 for complete burner sections

Table 5 - Burner Assembly Parts

8471 34

Midco International Inc.

17

Page 18

Burner Assembly

Instructions

Burner Assembly Instructions

A

Figure 9 - Typical HMA 2 & HMA 2A 6″ Direct Fire Burner Assembly

Figure 9 shows the assembly of a typical HMA 2 and HMA 2A direct fi red burner assembly for both

“in fi eld” and factory assembly line.

A) 1-1/2″ Inlet Flange With Pilot Mount or Blank Plate Hardware Required:

Furnace Cement

8 Stainless Steel Pcs of 10-24 X 3/8″ Slotted Round Head Screw,

10-24 Hex Nut, 10-24 Lock Washer or S62 Stainless Steel Rivet Body (Rivet Gun Required)

3 Pcs 5/16″ X 2″ Hex Cap Screws

3 Pcs 5/16″ Lock Washers

3 Pcs 5/16″-18 Nuts

B) Blank Flange With Blank Plate or Pilot Mount Plate Hardware Required:

Furnace Cement

8 Stainless Steel Pcs of 10-24 X 3/8″ Slotted Round Head Screw,

10-24 Hex Nut, 10-24 Lock Washer or S62 Stainless Steel Rivet Body (Rivet Gun Required)

3 Pcs 5/16″ X 1-3/4″ Hex Cap Screws

3 Pcs 5/16″ Lock Washers

3 Pcs 5/16″-18 Nuts

(See Notes # 1)

(See Notes # 1)

B

18

Notes:

1) Furnace cement is to be applied between the casting and either blank plate, pilot plate and

end fl anges only, not between baffl es and end plates.

2) The hardware listed on instructions A and B applies to each end of any size burner with such

confi guration.

3) For defi nition and views of burner section, plates, fl anges, or hardware refer to page 16 and

17 of the Installation and Service Instructions manual.

4) Burner drawing symbols represent a view of the burner from side opposite the fl ame exit.

5) In the absent of a rivet gun, use the hardware specifi ed on these instructions, stainless steel

hardware is highly recommended.

UNDER NO CIRCUMSTANCES SHOULD STANDARD GRADE

OR ALUMINUM RIVETS BE USED.

6) Hardware used between burner sections is the same as the hardware used on Instructions B.

7) Pilot hardware Is Included with the pilot assembly.

8) If Installing mounting brackets, they must be Installed on the exterior side of the Inlet or blank

fl ange.

UNDER NO CIRCUMSTANCES SHOULD THEY BE INSTALLED

BETWEEN THE FLANGE AND THE BURNER CASTING.

___________________________________

Midco® International Inc. - 4140 West Victoria Street - Chicago, Illinois 60646 - toll free: 866 705 0514

tel: 773.604.8700 - fax: 773.604.4070 - web: www.midcointernational.com - e-mail: sales@midcointernational.com

1113

8471 34

Printed in USA

Loading...

Loading...