Page 1

INSTALLATION AND

SERVICE INSTRUCTIONS

UNIPOWER

G56B G57B

G58B G69B

Power Burners

In the United States, Installation must conform with local

codes or , in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1-latest edition available from

American National Standard Institute. Further reference

should be made to the recommendation of your fuel

supplier.

In Canada, Installation must conform with local codes or, in

the absence of local codes, with Installation Codes for Gas

Burning Appliances and Equipment, CGA Standard

CAN/CGA 1-B-149.1 or 2. When the conversion burner

burner is used on a Forced Air Central Furnace, the two

yellow and black warning labels in the literature envelope

shall be attached in accordance with Installation Code,

CGA Standard CAN/CGA 1-B149, Clause 5.4.4.4. Further

reference should be made to the recommendation of your

fuel supplier.

WARNING: Additions, changes, conversions, and

service must be performed by an authorized MIDCO

representative, service agency, or the fuel supplier. Use

only MIDCO specified and approved parts.

INSTALLER: Inform and demonstrate to

the user the correct operation and

maintenance of the gas utilization

equipment. Inform the user of the

hazards of storing flammable liquids

and vapors in the vicinity of this gas

utilization equipment and remove

such hazards. Affix this manual

and associated literature to the

WARNING: If the information in these

instructions is not followed exactly, a fire or

explosion may result, causing property

damage, personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

¥

Do not touch any electrical switch;

¥

do no use any phone in the building.

Immediately call your gas supplier from

¥

another buildingÕs phone. Follow the gas

supplierÕs instructions.

If you cannot reach your gas suppler, call

¥

the fire department.

Installation and service must be performed

by a qualifed installer, service agency or

the gas supplier.

BURNER

MODEL

BILL OF MATÕL

NUMBER

DATE CODE

WIRING

DIAGRAM

FOR SERVICE CONTACT:

name

address

conversion burner.

CODE COMPLIANCE IS THE SOLE

RESPONSIBILITY OF THE INSTALLER.

phone

USER: Retain this manual for future reference. If other than routine service or

maintenance as described in this manual and associated literature is required,

contact a qualified service agency. DO NOT ATTEMPT REPAIRS. An inadvertent

service error could result in a dangerous condition.

SAFETY INFORMATION TERMS: The following terms are used to identify hazards, safety precautions or special notations and

have standard meanings throughout this manual. When you see the safety alert symbol and one of the safety information terms,

as shown below, be aware of the hazard potential.

DANGER: Identifies the most serious hazards which will result in severe personal injury or death.

WARNING: Signifies a hazard that could result in personal injury or death.

CAUTION: Identifies unsafe practices which would result in minor personal injury or product and property damage.

MIDCO

International Inc.

4140 WEST VICTORIA STREET ¥ CHICAGO, ILLINOIS 60646 ¥ (773) 604-8700 FAX: (773) 604-4070 ¥ http://www.midco-intl.com

PRINTED IN U.S.A.

8470-86

598

Page 2

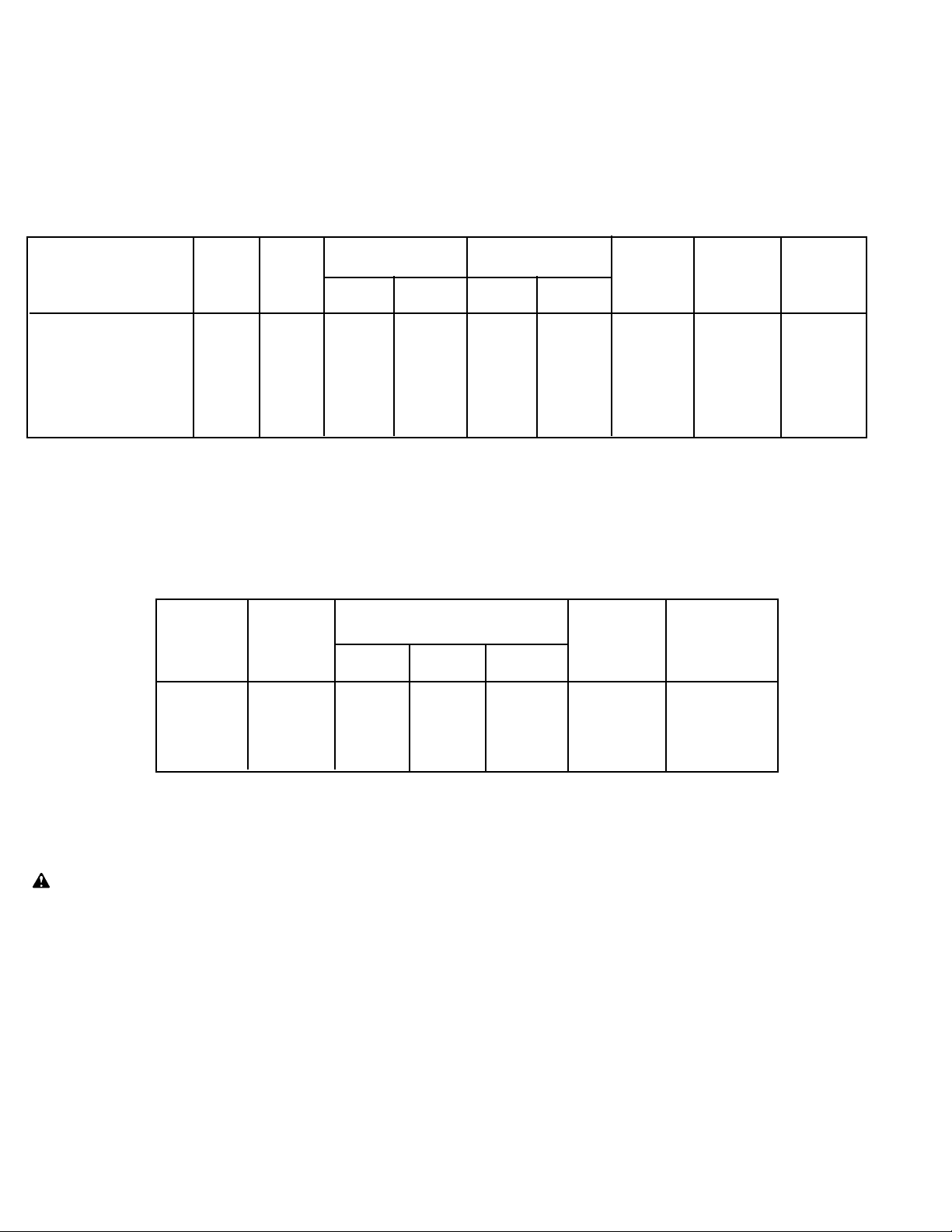

SPECIFICATIONS

BURNER STYLE...................................................................... Power Type

PILOT TYPE............................................................................. Intermittent, Spark Ignition

PILOT SAFETY........................................................................ Instantaneous Electronic Flame Safeguard

STANDARD VOLTAGE

CONTROLS (FIELD WIRING)...............................................120/1/60

MOTOR................................................................................. 115/1/60 (except G69B-115/230/1/60)

U.L. LISTED

NATURAL Gas

(1,000

BTU/cu. ft.)

G56B

G57B

G58B

G69B

MODEL BURNER MANIFOLD

PROPANE Gas

(2,500

BTU/cu. ft.)

G56BP

G57BP

G58BP

G69BP

Maximum

1

Input

MBTU/Hr.*

1000

1450

1800

2500

Maximum

Air

SCFM

224

313

385

521

INLET GAS PRESSURE

REQUIRED

6

NATURAL

5.0" W.C.

7.0" W.C.

6.7" W.C.

7.5" W.C.

2

PROPANE

5.0" W.C.

5.0" W.C.

6.0" W.C.

8.0" W.C.

PRESSURE

NATURAL

2.2" W.C.

4.1" W.C.

4.6" W.C.

4.2" W.C.

1, 4, 5

PROPANE

1.2" W.C.

2.6" W.C.

3.8" W.C.

3.3" W.C.

Minimum Input

MBTU/Hr.*

300

300

500

800

3

Motor HP

(3450 RPM)

1/6

1/3

1/2

3/4

Recom-

mended

Combustion

Chamber Size

42" x 18"

48" x 21"

50" x 24"

60" x 27"

TABLE 1 Burner Specifications

1. Values given based on +0.000" W.C. firebox pressure, altitudes to 2000 feet. Derate burner for altitudes over 2000

feet by 4% for each 1000 feet over sea level.

2. Maximum inlet pressure both gases: 14" W.C. Refer to Section VI Piping for high pressure.

3. Modulating and two-step burners are limited to a 3 to 1 turndown ratio.

4. Manifold pressures are approximate and will vary slightly according to job condition. See Section VII para. 11.

5. Pressures are based on 25% excess combustion air.

6. SCFM = Standard Cubic Feet/Minute.

MAXIMUM CAPACITY IN MBH AT

* 1 MBH = 1,000 BTU/Hr.

MODEL

G56B

G57B

G58B

G69B

MINIMUM

FIRING RATE

MBH*

300

300

500

800

COMB. CH. - BACK PRESSURE

0" W.C.

1075

1500

1850

2500

.25" W.C.

950

1400

1750

2375

.5" W.C.

875

1325

1650

2275

TABLE 2 Maximum Capacity at Specified Back Pressures

MAXIMUM BACK

PRESSURE

IN " W.C.

0.7

0.8

1.0

1.0

MAXIMUM MBH* @

MAX. B.P.

700

1325

1400

2100

PART 1 INSTALLATION

CAUTION: Unipower GB -Series are not intended

for outdoor installation and must be protected from

excessive moisture. Provide adequate clearance for

service and proper operation.

I VENTILATION

Open basements will generally allow sufficient air

infiltration, so special provisions will seldom be required. If

the heating plant is located in a separate furnace room or

in an unusually tight basement, permanent means must be

provided to supply an ample volume of fresh air for

combustion and boiler room ventilation. A direct opening

to the outside air should be provided sized on the basis of

1/2 square foot of free opening for each 1,000,000 BTU of

burner rating when the vent connector is equipped with a

barometric draft control, 1 1/2 square feet when equipped

with a draft hood. If the ventilation opening is screened, it

should be of 1-1/4" mesh. The opening should be located

at least six feet over ground level to prevent accidental

obstruction. If a direct opening to the outside air is not

available, an ample sized air duct can be run to the

nearest outside air source; or, if practical, open stairwells

or building corridors connecting to an outside wall having a

ventilating opening can be used for this purpose, provided

that no possibility of accidental closure exists.

While the spark ignition pilot system performs successfully

under moderate or momentary back draft conditions, it is

not intended for operation under sustained reverse draft,

for example in a building with large ventilating fans but with

insufficient make-up air. Even if burner operation is

successful this condition must be corrected to prevent the

hazard of drawing flue gases into the building.

Consult your local gas company when doubt exists

concerning boiler room ventilation.

-2-

Page 3

II GAS UTILIZATION EQUIPMENT

The heating system, both the gas utilization equipment

and the distribution system, should be in good repair and

sufficient to properly heat the building. It should be

determined if any serious faults are present that would

cause excessive fuel consumption, unsafe operation or

improper heating, and measures taken to correct them.

After the grates and grate operating parts have been

removed from the firebox, the boiler interior should be

thoroughly cleaned, removing all adhering dirt, tars,

scale and soot. All joints should be cemented to prevent

excess air infiltration into the boiler. Clean out doors

should be checked for close fit, and sealed with furnace

cement if they fit poorly.

Firing door catches should be filed off or otherwise

arranged so that the door will open easily to relieve

pressure. No positive catches should be used. The use

of a spring type door holder is recommended.

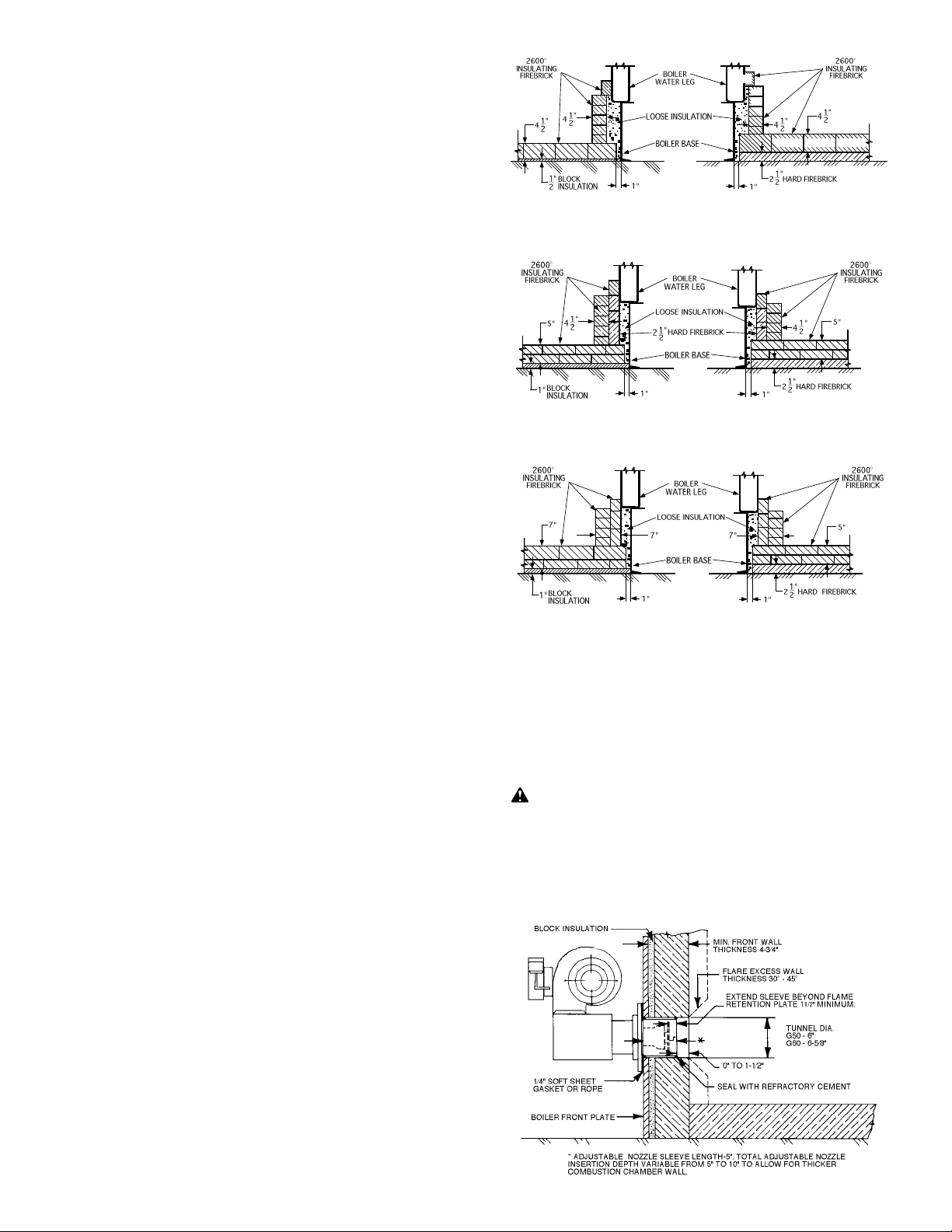

III COMBUSTION CHAMBER

The UNIPOWER gas burner is designed for "in-shot"

firing. It can be fired into the ashpit of a boiler designed

for solid fuels, or it can be fired into the primary heat

exchanger of a boiler designed for liquid or gaseous

fuels. The ashpit installation requires a refractory lining.

The combustion chamber serves to contain and promote

combustion and to protect non-heat exchange surfaces

from direct flame contact. Built-up combustion chambers

should be made of 2600

alternative, a monolithic floor can be cast in place, using

a high temperature (2400o), light weight insulating

refractory. Check with your supplier to determine the

thickness which will yield equivalent insulating qualities.

The top of the combustion chamber should be positioned

2 to 6" above the base of the heat exchanger. If the

combustion chamber is to be set directly on the floor,

provide a minimum of 1/2" insulating millboard or

magnesia block underlay for floor protection. Use high

temperature fill such as vermiculite in voids around the

combustion chamber. Any portion of the heat exchanger

not exposed to circulating air or water should be covered

with insulating firebrick.

The combustion chamber sizes given in Table 1 are

based on the maximum rated burner capacity. If the

input is to be permanently set at a reduced rate the

combustion chamber floor area can be reduced

proportionately to the proposed input, with the length as

closely proportioned to twice the width as possible.

Where recommended size combustion chambers

(225,000 BTU/sq. ft.) can be accommodated, the type of

construction shown in Figure 1 should be used. If lack of

space prohibits use of this construction, higher BTU

values per square foot can be allowed for by using the

constructions shown in Figure 2 and 3.

The back wall of the combustion chamber should be

carried 2 or 3 courses higher and overhung to deflect the

flames from direct impingement on the rear heat

exchanger surface. Hard firebrick should be used to

prevent erosion of the brick by high velocity gases.

o

insulting firebrick. As an

FIGURE 1 Typical Floor And Wall Construction For

225,000 BTU Per Square Foot. (Standard)

FIGURE 2 Typical Floor And Wall Construction For

275,000 BTU Per Square Foot.

FIGURE 3 Typical Floor And Wall Construction For

350,000 BTU Per Square Foot. (Maximum)

The burner is equipped with a mounting flange for direct

attachment to the boiler front, and mounting brackets for

legs. Use both if necessary for rigid installation. The

burner nozzle must not extend into the combustion

chamber. It should be sealed into the opening as shown

in Figure 4.

WARNING: BURNER CABINET MUST BE

MOUNTED IN ORIENTATION IN FIGURES 4 AND 7.

ANY OTHER MOUNTINGS MAY CAUSE A

DANGEROUS CONDITION, AND WILL VOID BURNER

WARRANTY AND AGENCY APPROVALS.

NON-STANDARD ARRANGEMENTS MAY BE

AVAILABLE FOR SOME MODELS-CONSULT

FACTORY FOR DETAILS IF REQUIRED.

-3-

FIGURE 4 Construction at Burner Entrance

Page 4

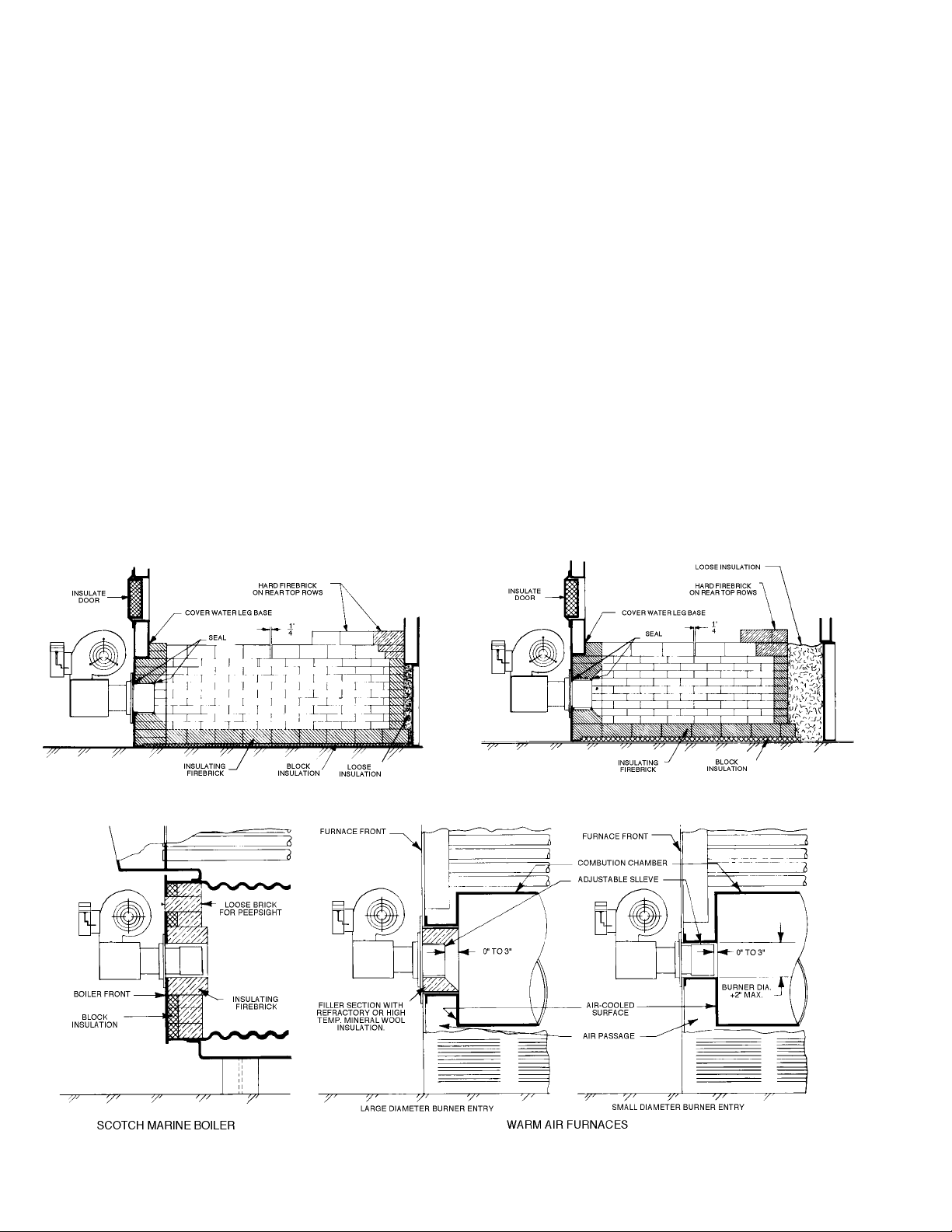

The refractory lined combustion chamber can be omitted in

"Scotch Marine" and "Steam Generator" boilers or warm

air furnaces that include no ashpits. The burner is fired

directly into the heat exchanger, requiring no refractory

unless the combustion chamber is so short that flame

would impinge excessively on the rear heat exchanger wall

(this particularly important in a warm air furnace).

Refractory protection is recommended if the length of the

primary chamber is less than 20% larger than the length

given in Table 1. In any case, the burner entry wall must

be refractory lined if it is not a heat exchanger surface.

Firing Door Installations

It is advantageous, on occasion, to fire through the boiler

firing door. For example, pitting can be avoided on low

base boilers, damage to the burner can be avoided if

basement flooding is prevalent, or the combustion

chamber volume can be reduced in boilers with unusually

large ashpits.

Great care in planning will be required for firing door

applications since flame impingement on boiler surfaces is

more probable. Do not fire a boiler which contains a drop

section directly in the path of the flame, or do not fire over

a water grate in a smokeless type boiler. The firebox

length must be great enough to exceed the combustion

chamber lengths given in Table 1 by at least 20%.

When raising the floor, maintain sufficient firebox volume

to limit the heat release to 50,000 BTU per hour per cubic

foot or less. Use the entire floor as a combustion chamber

a and cover the water leg base to 6" from the bottom. Floor

construction should conform to Figures 1 to 3.

Firing door installations will usually entail removal of the

grates. Figure 8 shows a typical installation. A steel plate

floor can be supported from the grate lugs, if suitable. In

any case, the floor must be rigid enough to prevent

sagging, being supported by brick piers as necessary.

If firing over the grate, level it off with rubble of common

brick or firebrick if necessary; then cover over with

insulating block before laying the refractory floor.

The hearth of worm feed stokers can be used as a floor

base. Level off the hearth to a suitable height, remove the

worm feed mechanism and fill the tuyere with rubble.

Cover at least the tuyere area with block insulation; if using

castable refractory, pour a new floor over a leveling

surface of sand. The external stoker parts should be

removed to eliminate clutter under the burner.

The burner mounting in the door must be rigid and

refractory lined as shown in Figure 8. The burner nozzle

must not protrude directly into the combustion chamber.

The refractory liner must extend beyond or be flush with

the burner face as shown in Figure 4. A sheet metal rim

should encase the refractory up to the inside of the boiler

wall. It should be intermittently bent inward to retain the

refractory, or other means of anchoring should be

provided.

FIGURE 5 Conventional BoilerÑ Small Firebox

FIGURE 7 Tubular Combustion Chambers

FIGURE 6 Conventional BoilerÑLarge Firebox

-4-

Page 5

FIGURE 8 Firing Door Installation in Three Pass Boiler

As an alternate, the burner mounting plate can be

extended externally to locate the nozzle face and

refractory wholly within the door opening. Seal carefully to

prevent flue products from entering the boiler room.

In double door boilers it is recommended that the openings

be enlarged to a single opening by removing the center

post so that the burner can fire in the center. If a pressure

part of the boiler must be cut away, be sure to make

modifications in accordance with your local code covering

boiler repairs.

Since firing door installations will generally leave no

openings for flame observation, a peep sight must be

installed in the burner mounting plate.

IV CHIMNEY, VENT CONNECTOR, AND

DRAFT CONTROL

WARNING: The chimney shall be inspected for

unsafe conditions such as deteriorated masonry and

excessive soot or other blockage or potential

blockage. Installation must conform with local codes

or in the absence of local codes with NFPA, ANSI

Z223.1-latest edition.

WARNING: No movable vent connector damper is

permitted on any gas conversion installation. The

chimney should be inspected for unsafe conditions

such as deteriorated masonry and excessive soot or

other blockage or potential blockage. Check your local

authorities for regulations covering barometric draft

regulators on gas equipment.

WARNING: The vent connector shall not be

connected to a chimney already venting solid fuel

burning equipment, an incinerator or an open fire

place.

The UNIPOWER burner does not depend on chimney

draft. Combustion air is supplied by the forced air blower,

which is sufficient to supply adequate air for any normal

boiler. This reduces the function of the chimney to removal

of flue products from the boiler. A chimney height of 15'

above the boiler flue outlet will generally prove ample if the

recommended, or larger, vent connector and chimney

diameters are used. The chimney must of course extend

several feet over the roof of the building, or adjacent

buildings. Vent connector material should be 24 gauge or

heavier steel, galvanized to resist corrosion. The horizontal

run of vent connector should be pitched upward from the

appliance flue outlet at least 1/4" to the foot. Avoid excess

elbows or other constructional features that would create

excessive resistance to flow of flue products. Fasten joints

with sheet metal screws to prevent sagging. The vent

connector should be maintained at least 6" from

combustible building materials; more if it is uninsulated.

Where it passes through partitions constructed of

combustible materials a ventilated thimble should be used.

Refer to your local building codes. The vent connector

should be firmly cemented into the chimney but must not

extend beyond the inner face. Where two or more

appliances use the same chimney, be sure not to enter the

chimney with both flue pipes at the same level.

Do not arbitrarily reduce the vent connector size, since a

boiler back pressure can build up, leading to possible

leakage of flue products into the boiler room.

Chimney construction can be either of brick, preferably tile

lined, or of steel. Joints in the chimney should be smooth

and leak free to prevent uncontrollable air infiltration. They

should be made so that condensation, if any, will not

collect in the joints or leak to the outside.

If the vent connector must be extra long, the area of the

pipe and chimney should be increased, or the chimney

height must be increased, or both. Never allow the

horizontal length of the vent connector to exceed the

height of the chimney.

Two kinds of draft control are acceptable; an A.G.A. type

draft hood as illustrated in Figure 9, or a barometric

damper as shown in Figure 10. Use of a draft hood is

usually limited to burners with lower range capacities,

while a barometric draft control is suitable for all

capacities. Application should depend on the requirements

of the installation.

-5-

Page 6

FIGURE 9 Draft Hoods

FIGURE 10 Barometric Dampers

Figure 3 and 4 : Copyright by the American Gas Association.

Used by permission of the copyright holder.

If a draft hood is used, it should be of the same size as the

vent connector and should be located higher than the

highest part of the heating appliance flue passage.

If a barometric damper is used, it should be of the

double-swing type, which opens freely outward to afford

downdraft protection irrespective of settings made to the

balancing weights for updraft control. The damper should

be located so it is free to swing without interference from

surrounding objects so that the velocity pressure of the

flue gases does not interfere with its operation. See Figure

10 for proper installation.

When any vent connector passes through a partition the

draft control must be located in the same room as the

heating appliance. A device which will automatically shut

off gas to the burner in the event of sustained backdraft is

recommended if such backdraft might adversely affect

burner operation or if flue gas spillage might introduce a

hazard. If such a device is used, it shall be of the listed

type and installed and adjusted by a qualified service

technician in accordance with the manufacturerÕs

instructions.

V ELECTRICAL

The burner, when installed, must be wired and grounded in

accordance with local codes, or, in the absence of local

codes, with the National Electric Code ANSI/NFPA No.

70-latest edition. In Canada, refer to CSA Standard C22.1,

"Canadian Electrical Code Part 1."

CAUTION: REFER TO THE SEPARATE WIRING

DIAGRAM INCLUDED WITH EACH BURNER.

When wiring, be sure that the electric power take-off is

connected to a permanently live circuit and use multiple 14

gage copper wire conductors. Provide a fused disconnect

switch in the burner circuit. Each installation must include

a limit control to guard against excess temperature or

steam pressure. Steam or vapor systems will require a low

water cut-off.

VI PIPING

For the usual low pressure gas supply system, 5" to 14"

W.C. NATURAL (11" to 14" W.C. PROPANE) use Table 3

to find the recommended gas supply line size.

Piping follows normal practices and should be

connected to the burner in the manner shown in Figure 12.

If the piping must be rearranged because of space

limitations be sure to carry out the sequence of

components illustrated. While the pilot regulator can be

mounted in any position, the main regulator should be

mounted upright and in a horizontal run of pipe.

Run full size pipe or tubing from regulator vent openings

to outside of building. Provide no traps in the vent lines

and terminate away from all doors and windows; also

make provisions for keeping rain and foreign objects from

entering the vent piping.

When high supply gas pressure is encountered, as in

the case in many industrial plants, the gas line size can be

reduced to allow for a greater pressure drop; however, the

size must be sufficient to delivery burner rating pressure.

CAUTION: High gas pressure supply lines require

the proper pressure reducing regulators. Install two

separate high pressure regulators, of the Tight

Shut-Off type upstream of the low pressure regulators.

One sized for main gas input, and one suitable for the

minimum flow regulating capacity of the pilot.

The high pressure regulators may be substituted for the

low pressure regulators. If high pressure regulators are

used as substitutes, they must be adjustable down to a

minimum of 2"W.C. outlet pressure for the pilot and 5"

W.C. for the main gas. They must be adjustable down to

the maximum burner inlet pressure rating (14"W.C.).

DANGER: Explosion hazard.

Do not use oxygen for pressure testing. An

explosion could occur during initial start-up.

When the gas supply line is about to be put into service

it must be tested to insure that it is gas tight. Use air or

inert gas under pressure and test with soap and water or

other liquids to locate leaks.

CAUTION: Because it is difficult to accurately

control pressure, disconnect all low pressure (14"W.C.

max.) components (main and pilot) during supply pipe

leak testing. Exposing low pressure regulators and

valves to a pressure over 1Ú2 PSIG (14"W.C.) will

damage components and void their warranties.

-6-

Page 7

Gas Supply

Pipe Size

N.P.T.

1"

1-1Ú4"

1-1Ú2"

2"

2 -1Ú2"

3"

Type of

Gas

Natural

Propane

Natural

Propane

Natural

Propane

Natural

Propane

Natural

Propane

Natural

Propane

APPROXIMATE CAPACITY-MBH

Length of Pipe Ñ Feet

20

40

60

100

200

350

550

385

300

500

400

630

610

960

300

480

460

725

870

1370

1400

2200

2500

2500

330

320

500

610

960

980

1550

1700

2500

730

1150

1100

1730

2100

2500

2500

785

760

1200

1450

2280

2300

2500

2500

1150

1800

1850

2500

2500

CAUTION: Do not exceed maximum rated capacity

of burner model - See Tables 1 and 2.

Capacities shown are for total pressure drop of .3"W.C. For

higher permissible pressure drops consult your fuel

supplier.

Source: Gas Engineers HandbookÑ1974

TABLE 3 Schedule 40 Pipe Capacity Chart

Before gas is introduced to the system, a check must be

made to see that there are no open fittings and to make

sure the burner main and pilot manual valves are closed.

After checking above, purge the gas line up to the burner

inlet. Purging the air from the gas supply line at this step

will expedite the first light-off.

CAUTION: Purge outside the building. Do not

purge into the gas utilization equipment combustion

chamber.

VII INITIAL START-UP

WARNING: Repeated unsuccessful attempts to

light may result in accumulated gases in gas

utilization equipment and chimney. To prevent these

gases from reaching an explosive level, periodically

purge the gas utilization equipment.

CAUTION: All cover plates, guards, and

enclosures must be maintained in place at all times

except during maintenance and servicing.

CAUTION: Optional equipment and/or special

limit controls such as high/low gas pressure switches

can alter the start-up procedure. See Section XIVSPECIAL EQUIPMENT.

1. Check the piping for leaks. A quick way to do this is to

close the main manual shut-off valve and manual

pilot valve, then turn on the gas pressure to the gas

supply line and observe the meter test dial. There

should be no movement of the test dial hand for at

least twenty minutes. All other gas appliances must be

completely shut off during this test (including pilots). If

a leak is detected it should be located with a soap

suds test. Test the main automatic valve for tightness.

(see Section XII for instructions). The ball valve is

intended to be open at all times except when testing

for main valve leakage. The Main Manual Shut-Off

Valve must be used for manual gas shut-off.

2. Make sure that the burner main and pilot gas lines are

completely purged of air. Do not purge into the

combustion chamber. Purge outside the building.

3. Make sure the burner power switch is off, manual

valve is closed, pilot manual valve is closed,

motor is free to rotate, and flame safeguard reset

button is set.

4. Make the proper settings on all limit controls and set

controller to call for heat.

5. Set blower air shutter wide open.

PILOT MANUAL

VALVE

BALL

VALVE

MAIN REGULATOR

MAIN REGULATOR

VENT

DRIP LEG

INLET PRESSURE TAP

1/4 TEE

1/4 PLUG

PILOT

REGULATOR

BLOWER

MOTOR

MANUAL MOTOR RESET

BUTTON

(MAY HAVE AUTO RESET)

MANIFOLD PRESSURE

TAP

BALL VALVE

BF INPUT ADJUSTER

REDUNDANT MAIN

AUTOMATIC VALVES

(HIDDEN)

FIGURE 11 Piping Connections

PILOT SOLENOID

VALVE

FLAME SAFEGUARD

CONTROL

PILOT MIXING

TEE

RESET

BUTTON

PEEP SIGHT

PILOT

PRESSURE TAP

PILOT AIR

TUBE

BLOWER

AIR

SWITCH

-7-

Page 8

6. Turn on the line switch, and allow motor to run through

the pre-purge and ignition cycle. Check the blower

wheel for proper rotation. Viewing from the motor

shaft end (Blower Inlet side), rotation should be

counter clockwise. After a short run, the flame

safeguard will lock out, stopping the motor. Wait one

minute, then reset the flame safeguard.

7. Turn on pilot manual valve. With Main Manual

Shut-Off Valve still closed, turn on main line switch.

Motor will start. When pre-purge period has elapsed,

flame safeguard will energize pilot solenoid valve and

spark generator. When flamerod senses pilot

flame, the flame safeguard will energize the main

valves. No main flame will occur due to closed Main

Manual Shut-Off Valve. Quickly observe pilot flame . If

no flame, or if weak, screw in pilot regulator

adjustment. If the flame is rich and floating from the

pilot tip, back off the pilot regulator. Set to achieve the

largest stable blue flame with a base that burns firmly

within the pilot tip. The best operating pressure is

usually 3-1/2" to 4" W.C.. Test for ignition and stability

several times, cycling the burner with both open

and closed air shutter. Ignition and relay response

will be prompt with a good flame. Check flame signal

with a AC micrometer. Pilot should be set to yield

the highest steady reading, at least 2 microamps AC

and as high as 5 microamps.

8. Check operation of the electronic flame detection

circuit by turning off the pilot manual valve with pilot

burning and main manual shut-off valve still closed.

The circuit to the main automatic valve should be

broken when the pilot goes out.

*9. Turn off line switch to stop the burner. Reset flame

safeguard. Set blower air shutter about 1/4 open.

Loosen gland nut on Butterfly Valve and temporarily

lock air shutter wide open (slot in shaft parallel to

flow).

10. Turn on main line switch. After the main valve is

energized, slowly open main manual shut-off valve

until the main flame ignites. Then, opening the air

shutter as required to maintain a suitable flame, slowly

open the main manual shut-off valve to the wide open

position or until, with the air shutter wide open, the

main flame becomes excessively rich.

*11. The manifold pressures shown in tables 1 and 5

may be used to determine the approximate gas input

settings. The gas input for Natural gas models can be

determined by timing the gas meter. Accurately time

test dial for the number of seconds for one revolution

and use the following formula. All other gas utilization

equipment must be off.

3600 x test dial size x BTU value

no. of seconds for one rev. test dial

Then divide by 1,000 for MBH value.

Example 3600 x 1 x 1000

5

For Propane gas, consult your supplier for method of

determining firing rate.

CAUTION: The manifold pressures shown in

tables are both the blower air pressure and the

= 720,000 BTU/Hr. = 720 MBH

= BTU/Hr.

gas pressure. Air shutter adjustments will effect

manifold pressure and input. Clock the meter gas

rate and (if necessary) reset the main regulator to

control gas flow at about 10% over burner rating or

over desired input with Main Manual Shut-Off Valve

wide open. Turning the adjustment screw clockwise

on main regulator increases pressure and flow

rate, reverse decreases. Do not adjust the regulator

past the point where no further change in gas flow is

noted. ÒCloseÓ off Butterfly Valve to the desired

maximum input rate, secure gland nut, and replace

cap. Reset the blower air shutter to provide fairly long

flame, blue at the burner face, orange or red at the

tips. Flashes of yellow may be visible. Close firing

door for a few seconds; then open and quickly

observe fire. If a purple haze is noted at the rear of the

firebox, lack of air is indicated and air shutter should

be opened wider.

Refer to Table 4 pg. 9 if the manifold pressure is to

be used as a guide to gas input.

12. Check the flue gas temperature at the boiler flue

outlet. It should be above 325

550o. Excessive flue temperatures result in low

efficiencies. Low flue gas temperatures may cause

excessive condensation. Reset input if necessary to

adjust stack temperature; or if temperature is too

low, portions of the heat exchanger surface can be

blocked off with insulating firebrick.

13. Make the final setting of the air shutter by checking

the flue gases with an "Orsat" or similar combustion

testing instrument. There should be no carbon

monoxide and the carbon dioxide content should be

approximately 9.5% for NATURAL and 12.1% for

PROPANE, or within the limits prescribed by the local

fuel supplier.

14. Check the draft control to make sure there is no

spillage of flue products into the boiler room. This test

should be performed under the most severe possible

ventilating conditions. For example, perform this test

with all doors and windows tightly shut and any

ventilating fans in the building operating.

15. Start and stop the burner several times with the

controller and the limit controls to check their

operation.

16. Reset controller and limits controls to their desired

settings.

*Refer to Trouble Chart

After the initial start-up procedure the following steps can

be followed for routine start-up and shut-down on a

seasonal or extended basis.

o

but not exceeding

BURNER START-UP

1. Make sure line switch is off.

2. Set controller to call for heat.

3. Open firing door

4. Open Main and Pilot Manual Valves.

5. Reset flame safeguard.

6. Turn on line switch.

7. Close firing door after main flame ignites.

8. Reset controller to desired setting.

BURNER SHUT DOWN

1. Turn off main line switch.

2. Close Main Manual Valve

3. Close pilot manual Valve

-8-

Page 9

MODEL

G56B

G57B

G58B

G69B

CAPACITY

MBH*

1075

1000

900

800

700

600

500

300

1500

1300

1200

1000

900

700

600

300

1850

1700

1600

1500

1200

1000

800

500

2500

2200

2000

1800

1500

1200

1000

800

MANIFOLD PRESSURES ("W.C.)

2.10

1.82

1.47

1.16

0.89

0.65

0.45

0.16

4.10

3.08

2.62

1.82

1.48

0.89

0.66

0.16

4.60

3.88

3.44

3.02

1.94

1.34

0.86

0.34

4.15

3.21

2.66

2.15

1.49

0.96

0.66

0.42

GAS ON

PROPANE

1.45

1.25

1.01

0.80

0.61

0.45

0.31

0.11

2.79

2.10

1.79

1.24

1.01

0.61

0.45

0.11

3.75

3.17

2.80

2.47

1.58

1.10

0.70

0.27

3.65

2.83

2.34

1.89

1.31

0.84

0.58

0.37

AIR

ONLY

1.00

0.87

0.70

0.55

0.42

0.31

0.22

0.08

1.90

1.43

1.22

0.84

0.68

0.41

0.30

0.08

2.65

2.24

1.98

1.74

1.11

0.77

0.50

0.19

2.25

1.74

1.44

1.17

0.81

0.52

0.36

0.23

NATURAL

This table is provided as a guide to use the INPUT

ADJUSTING METHOD to approximate final settings.

The valve train MUST be tested for tightness and the pilot

adjusted for proper operation before proceeding. Refer to

Section VIII of the Installation and Service Instructions.

1. Install a Manometer (not a pressure gauge) in the

manifold pressure tap.

2. Close the Main Manual Gas Valve.

3. Close the Input Adjuster (butterfly valve).

4. Turn the burner on.

5. Adjust the air shutter to the ÒAir OnlyÓ pressure shown

for the desired MBH.

6. Open the Main Manual Gas Valve.

7. Slowly open the Input Adjuster until the observed

manifold pressure equals the Gas On pressure for the

desired MBH.

8. Take combustion readings and confirm the input rate by

clocking the gas meter.

9. Adjust the air shutter and/or the Input Adjuster as

needed.

10. Repeat steps 8 and 9 until you have the desired input

rate with clean combustion**.

11. Refer to section VIII of the Installation and Service

instructions for final Main Gas Regulator adjustment

procedures.

For capacities not shown:

MBH

P

= P

x (

2

1

*1 MBH=1000 BTU/Hr

2

MBH

**Approximately 25% excess air (4.5% O

2

)

1

)

2

ALL FIGURES ARE APPROXIMATE. Actual figures will vary depending upon application and ambient conditions.

Based on 0 pressure over the fire at Standard Air and Specific Gravities of .64 for NATURAL GAS, and 1.52 for

PROPANE GAS. It is the responsibility of the installer to make final adjustments to insure proper and safe operating

conditions, and to comply with all codes and guidelines that may apply at the installation site. Contact the local Utility for

any requirements and recommendations they may have. In the absence of any local codes, guidelines or requirements,

refer to the latest edition of the National Fuel Gas Code, ANSI Z223.1-1992.

TABLE 4: Approximate ÒGÓ Series Capacities At Specified Manifold Pressures.

PART 2 SERVICE

CAUTION: BE SURE THAT THE MAIN MANUAL

SHUT-OFF, MANUAL PILOT VALVE, AND POWER

DISCONNECT BURNER SWITCH ARE TURNED OFF

BEFORE REMOVING ANY PARTS FOR SERVICE.

CAUTION: COVER PLATES, GUARDS, AND

ENCLOSURES MUST BE IN PLACE AT ALL TIMES

EXCEPT DURING MAINTENANCE AND SERVICE.

Maintenance of the burner box and firing head is minimal,

due to the simplicity of the parts and absence of small air

or gas passages. An occasional inspection of the parts in

contact with the flame will suffice. The flame retention

plate must show no loss of metal or severe warping. If the

heads of the retention plate mounting screws show loss of

metal they must be replaced. Use only stainless steel

screws.

Stainless nozzle sleeve must extend at least 1/2"

beyond flame retention plate.

VIII BURNER BOX AND FIRING HEAD

The UNIPOWER burner head is of the nozzle mixing

(non-premix), flame retention type. This design

accommodates a high capacity without flame lift off and a

low capacity without flash back.

The burner box serves as an air plenum chamber and a

If the burner mounting flange or adjacent furnace wall

show signs of overheating, check the tightness of the

burner mounting. The burner is intended to be sealed into

the boiler opening both at the face and at the mounting

flange as shown in Figure 4, to prevent blow-back of hot

flue products around the nozzle and flange.

frame to which all other parts are assembled. Blower air

enters the box and passes around the outside of the gas

manifold and through the retention plate. Gas passes

through ports in the manifold, then through the retention

plate where it is mixed with the blower air by turbulence

caused by the retention plate, and into the combustion

chamber for burning. The gas ports are not adjustable.

Variation in capacity is accomplished by a variation in gas

pressure.

IX PILOT AND FLAME SENSOR

The pilot is of the premix, blast type. Blower air is diverted

from the blower housing through an air orifice into the pilot

mixing tee mounted on the burner back plate, where the

proper amount of gas is added through the pilot orifice.

Both orifices are located at the end of their own respective

tubes in brass fittings leading into the mixing tee. The

-9-

Page 10

gas/air mixture is then discharged through the heat resistant

alloy flame retention pilot tip.

The spark rod is located on the center line of the pilot

and is arranged to arc to the inside of the central port.

Spark current is supplied by a spark generator to ignite

pilot gas.

The pilot regulator is factory set of an outlet pressure of

3 -1/2" W.C. for NATURAL gas and PROPANE, which will be

suitable for average conditions. Pressure can be varied to

suit particular job conditions. Do not increase orifice sizes

indiscriminately. Pilot troubles may be introduced by causing

the pilot to float and lose contact with the flamerod or flame

grounding area. Adjust the pilot per paragraph 7 of Section

VIII-Initial Start-Up.

Service of the pilot will generally consist only of inspection

and cleaning. Check that the pilot tip ports, air tube and

mixing tee are free of lint and dirt and that the pilot tip is free

of corrosion. Make sure that the air tube is re-inserted into

the blower housing pilot air tube hole. The spark insulator

and cable must be clean, dry and free from cracks and

abrasions. Make spark gap settings per Figure 15.

WIRE DRILL SIZES

MODEL

G56B(P)

G57B(P)

G58B(P)

G69B(P)

Proper operation of the flame safeguard depends on a

reliable current flow through the flamerod, pilot flame, and

flame grounding area. The flamerod must be free of any

contact with conductive burner parts. The insulator must be

clean, dry and free from cracks. While the rod is made of

heat resistant alloy, it may eventually deteriorate at the point

of flame contact and should be replaced if seriously

corroded. See Figure 15 for the proper alignment of the

flamerod. DO NOT BEND THE FLAMEROD TO REDUCE

THE DISTANCE FROM THE PILOT TIP.

AIR

ORIFICE

#26

(.147)

#30

(.128)

#26

(.147)

#26

(.147)

TABLE 5: Pilot Specifications

NATURAL

PILOT

ORIFICE

#60

(.040)

#60

(.040)

#55

(.052)

#55

(.052)

PROPANE

PILOT

ORIFICE

(.036)

(.036)

(.046)

(.046)

#64

#64

#56

#56

APPROX.

CAPACITY

BTU/HR

3500

3500

5000

5000

X BLOWER AND MOTOR

The blower functions to supply a constant and positive

supply of air for complete combustion. Air volume is

controlled by an adjustable shutter in the blower outlet. A

small supply of air is diverted ahead of the shutter for the

pilot and for operation of the blower air proving switch.

No routine service is necessary on the blower other than an

occasional cleaning of the blower wheel. If the blower wheel

must be replaced, be sure to check the replacement for

proper rotation. The concave sides of the blades must face

the blower outlet, and rotation of the wheel must be toward

the outlet. See Section VII pg. 8 para 6. The 3/4 HP single

phase motor used on the G69B burner uses a motor

switching relay to handle the motor load. All motors contain

integral motor overload protection, usually manual,

occasionally automatic reset.

Proof of blower operation is provided by a diaphragm air

switch, which must close its contacts and maintain them

closed when the blower is running. In case of

malfunction the air switch should be replaced.

XI GAS PRESSURE REGULATOR

The gas pressure regulator is used to automatically

reduce and maintain an constant gas pressure to the

burner. To vary the outlet pressure, remove the seal cap

for access to the adjusting screw. Turning the screw

clockwise will increase outlet pressure,

counter-clockwise will decrease outlet pressure.

Maximum and minimum allowable gas pressures are

shown in Table 1. Because these regulators are of the

low pressure type with metal seats, leakage through the

seat will cause outlet pressure to rise equal to inlet

pressure during burner shutdown. Therefore do not

subject the burner to inlet pressures above those listed

(14"W.C.). For higher inlet pressures, See Section VI PIPING for instruction on installing alternate regulators.

The vent in the upper diaphragm case normally breathes

air but should be vented to the outside for protection in

the event of a punctured diaphragm. See Section VI PIPING for proper venting procedures. Never connect

the regulator to the diaphragm valve vent.

When the regulator is to be installed or replaced, take

care not to distort the body casting. Apply wrench only to

the heavy body section adjacent to the pipe thread.

XII MAIN AUTOMATIC VALVES

NOTE: All burners are equipped with dual valves.

Select the type you have and reference. Burner

construction for special codes and/or insurance

requirements such as Factory Mutual or Industrial Risk

Insurers may require alternate construction. (Refer to

Section XIV SPECIAL EQUIPMENT).

1. Diaphragm Main Automatic Valve

(Employed with Redundant Solenoid Valve.)

The Honeywell V88 diaphragm valve supplied on a

UNIPOWER burners is of the slow opening, fast closing

type and requires venting to the bleed connection on the

burner box. Closing force combines a gas pressure

differential, diaphragm weight and spring.

When the controller is not calling for heat, the coil is

de-energized. The plunger of the three way actuator is in

the down position, so that the bleed is closed and the

supply port is open. Gas flows to the top diaphragm,

causing the gas pressure and spring to hold the valve

closed.

With a call for heat, the flame safeguard energizes the

coil. This pulls the plunger to the up position, opening

the bleed valve and closing the supply port. The gas

then bleeds off the top of the diaphragm, allowing the

gas pressure below to lift the diaphragm and open the

valve. When all the gas has bled off the top of the

diaphragm, the valve is fully opened. In the event of a

power failure during operation, the valve will close.

Normal operation will resume upon restoration of power.

For general service, tests for gas tightness and proper

operation will suffice. If leakage is observed, replace

valve.

-10-

Page 11

FIGURE 12 Drawer Assembly

If the valve will not open, make sure that normal gas

pressure is available at the valve, the bleed line is

unobstructed, and power is available at the terminals.

If the valve fails to close, make sure power is off at the

terminals and gas flow is in the direction of the arrow on the

valve body. When a malfunction is found to be caused by

the valve operator head, the entire valve must be replaced.

2. Redundant Solenoid Gas Safety Valve

(Required Construction)

Unipower burners feature a redundant solenoid gas safety

valve. This valve is a On-Off (2 position) valve.

When the valve operator is electrically energized, a

plunger lifts the valve disk off the valve seat, allowing gas to

flow. When the current is broken the valve closes. It will

normally require no service. If the operator malfunctions or

the valve leaks replace the entire valve. After replacement

check for leakage.

XIII FLAME SAFEGUARD

WARNING: Explosion hazard. Do not use this

device if it gets wet. It can malfunction and cause

serious injury or death. Replace any device that has

been wet.

Unipower burners are equipped with a flame safeguard

control employing a flame rectification system of flame

detection. The flame safeguard controls function sequence

operation.

For operation characteristics refer to flame safeguard

control literature provided with the burner.

XIV SPECIAL EQUIPMENT (OEM

VERSIONS)

Special equipment, either factory or field installed, can

cause variations in the procedures and descriptions given

in this manual. Generally, any burner ordered with special

factory installed equipment will be supplied with the

appropriate wiring diagram and related instruction manuals

from the special equipment manufacturer. Consult these

manuals to identify any differences in construction,

operation, and testing. Field installed special equipment is

the responsibility of the installing contractor.

For example, when a high/low gas pressure switch is

used, the high gas pressure setting must be higher than

the maximum manifold pressure during initial start-up and

the low pressure setting must be set below the normal

minimum inlet pressure to prevent nuisance shutdowns

during the start-up procedure.

After the burner is started, the low pressure setting

should be raised until the burner shuts off. Reduce the

setting and set the low pressure switch to restart the

burner. Reduce the high pressure setting until the burner

shuts off. Then raise the setting slightly and reset the high

pressure switch to restart the burner. Do not make the

adjustments too close to trip points or nuisance shut

downs may occur. Any time the burner gas supply is shut

off with the main manual valve, the low pressure switch will

require resetting.

If any doubt exists concerning burner operation when

special equipment is involved, contact the installing

contractor or MIDCO INTERNATIONAL INC. (front cover).

-11-

Page 12

XV TROUBLE CHART

Make sure the thermostat and operating controls are calling for heat. Defective wiring or loose connecting can simulate the

component defects outlined below. Check associated wiring before replacing a component. ELECTRICAL AND FLAME

CHECKS MUST BE MADE IN THE ORDER LISTED

I. MOTOR FAILS.

A. No power to flame safeguard.

B. Flame safeguard locked out.

C. Defective flame safeguard.

D. Defective motor relay.

E. Motor overload "out".

II. MOTOR FAILS TO START, FLAME SAFEGUARD

ENERGIZED.

A. Motor overload "out."

B. Defective motor.

C. Defective flame safeguard.

III. MOTOR RUNS CONTINUOUSLY, NO LIGHTING

ATTEMPT.

A. Defective air switch.

B. No air pressure at air switch.

C. Defective purge timer.

D. Defective flame safeguard.

IV. PILOT DOES NOT LIGHT, FLAME SAFEGUARD

LOCKS OUT.

A. No pilot gas.

B. Low pilot gas pressure.

C. Defective pilot gas regulator.

D. Misadjusted pilot regulator.

E. Blocked pilot regulator vent.

F. Defective pilot solenoid valve.

G. Defective spark electrode.

H. Misadjusted spark electrode.

I. Defective spark cable.

J. Defective spark generator.

K. Clogged or incorrect pilot orifice.

L. Defective pilot tip.

M. Excess pilot air.

N. Air orifice missing.

O. Clogged pilot air tube.

P. Defective flame safeguard.

V. PILOT LIGHTS, FLAME SAFEGUARD LOCKS OUT.

A. Poor flame signal.

B. Poor pilot flame.

C. Misadjusted pilot regulator.

D. Low gas pressure.

E. No pilot air (see above).

F. Excess pilot air (see above).

G. Defective pilot tip.

H. Defective flamerod wire.

I. Defective or misadjusted flamerod.

J. Defective amplifier.

K. Defective flame safeguard.

VI. PILOT LIGHTS, NO LOCKOUT ON FLAME

SAFEGUARD, NO MAIN GAS.

A. Low gas pressure.

B. Misadjusted main regulator.

C. Blocked regulator vent.

D. Defective main regulator.

E. No power at main valve(s).

F. Blocked main valve bleed line (If equipped).

G. Defective main valve(s).

H. Closed test cock.

I. Input adjuster closed.

J. Defective flame safeguard.

VII. MAIN FLAME LIGHTS, BUT GOES OUT, PILOT

RELIGHTS.

A. Poor pilot.

B. Pilot gas pressure drops severely when main gas

valve opens.

VIII. SHORT MAIN FLAME.

A. Too little gas.

B. Low gas pressure.

C. Defective main regulator.

D. Misadjusted main regulator.

E. Too much air.

F. Partially closed test cock.

IX. LONG, HAZY FLAME.

A. Too much gas.

B. High gas pressure.

C. Defective main regulator.

D. Misadjusted main regulator.

E. Misadjusted input adjuster.

F. Too little air.

G. Dirty blower wheel.

X. MAIN VALVE(S) FAILS TO SHUT OFF OR LEAKS.

A. Defective valve(s).

B. Defective valve actuator.

C. Dirty valve seat.

XI. MOTOR OVERLOAD FREQUENTLY TRIPS OUT.

A. Low voltage.

B. Spasmodic start.

C. Defective motor.

D. High ambient temperature.

XII. FLAME SAFEGUARD NEEDS FREQUENT

RESETTING.

A. See IV above.

B. See V above.

C. See VI above.

NOTE: Some of the probable causes listed above apply only to certain models as indicated, therefore some may not

apply to your particular case.

-12-

Loading...

Loading...