Midco G56 Installation Manual

Installation for

Model G56

Flow Reversal Valve

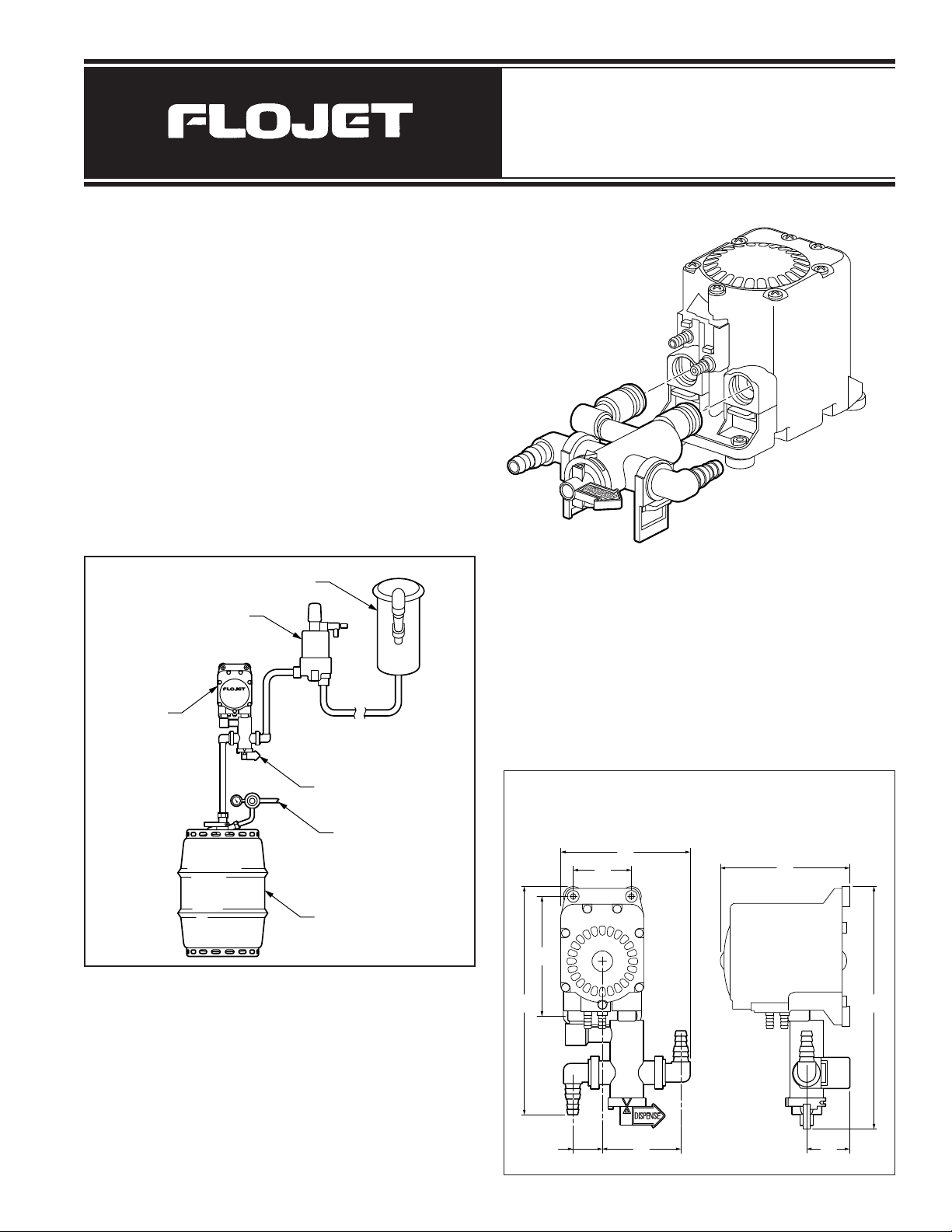

ASSEMBLY DIAGRAM

MOUNTING

• Pump must be located within 10 ft. (1.83 m) above or below

the keg or cask.

• Pump ports must be facing down to maximize pump

performance.

•Mounting grommets are part of pump assembly and add

stability.

• Fasten pump securely to wall or rack.

• If using a FOB device, mount it slightly above and directly

after the discharge of the pump. Caution: If a FOB is not

used, the pump will continue to cycle after the keg has run dry.

APPLICATION INFORMATION

Flojet’s G56 Flow Reversal Valve (FRV) is designed as an add-on

accessory for the G56 Beer Pump to allow beer line cleaners

to run cleaning solution through a Flojet G56 pump driven beer

system in both directions. Running cleaning solution through

draught beer systems in alternating directions from the faucet

to the tapping device (and vice versa) has been found

to enhance cleaning efficiency. Further, a multiple beer faucet

system utilizing G56 beer pumps with Flow Reversal Valves

allows for multiple lines to be cleaned at one time. This can

be done by connecting keg taps with double flushers

and connecting faucets with cleaning jumpers (see Line

Cleaning Diagram).

TYPICAL INSTALLATION

ASSEMBLY TO G56 PUMP

1. Slide port clips back against base of pump.

2. Insure that both O-rings of the FRV are adequately

lubricated.

3. Slide FRV ports into pump and secure with clips (see

Assembly Drawing).

4. Attach inlet tubing from keg to the left side port fitting and

secure with Oetiker Clamp (clamps not provided).

5. Attach discharge tubing to the right side port fitting and

secure with Oetiker Clamp.

6. Install air inlet and exhaust ports to pump.

DIMENSIONAL DRAWING

Inches (Millimeters) Consult factory if precise

Dimensional tolerances details are required.

± 0.06 inches

Model G56 Flow Reversal Valve

®

TECHNICAL SPECIFICATIONS

Materials of Construction (wetted parts): Polypropylene, EPDM

Temperature Limits:................................30°–120°F (-1.1° – 49°C)

Weight:..................................................................................3.3 oz.

Dimensions: ..............................5 3/16” H x 4 13/16” W x 2 3/8 D

Approvals: ......................................................................NSF listed

Beer

Faucet

FOB

Detector

Flojet G56

Beer Pump

Flow Reversal

Valve

CO2 Supply

Beer

Keg

4.92

8.63

(219)

4.52

(115)

1.11

(28)

2.20

(56)

(125)

TRIANGLES

MUST

LINE UP

2.96

(75)

4.84

(123)

1.59

(40)

9.13

(232)

PRODUCT WARRANTY

Flojet warrants this product to be free of defects in material and/or workmanship for

a period of one year after purchase by the customer from Flojet.During this one year

warranty period, Flojet will at its option, at no charge to the customer, repair or

replace this product,if found defective,with a new or reconditioned product,but not

to include costs of removal or installation. No product will be accepted for return

without a return material authorization number.All return goods must be shipped

with transportation charges prepaid. This is only a summary of our Limited

Warranty.For a copy of our complete warranty, please request Form No. 100-101.

RETURN PROCEDURE

Prior to returning any product to Flojet, call customer service for an authorization

number.This number must be written on the outside of the shipping package.Place

a note inside the package with an explanation for return as well as the authorization

number.Include your name, address and phone number.

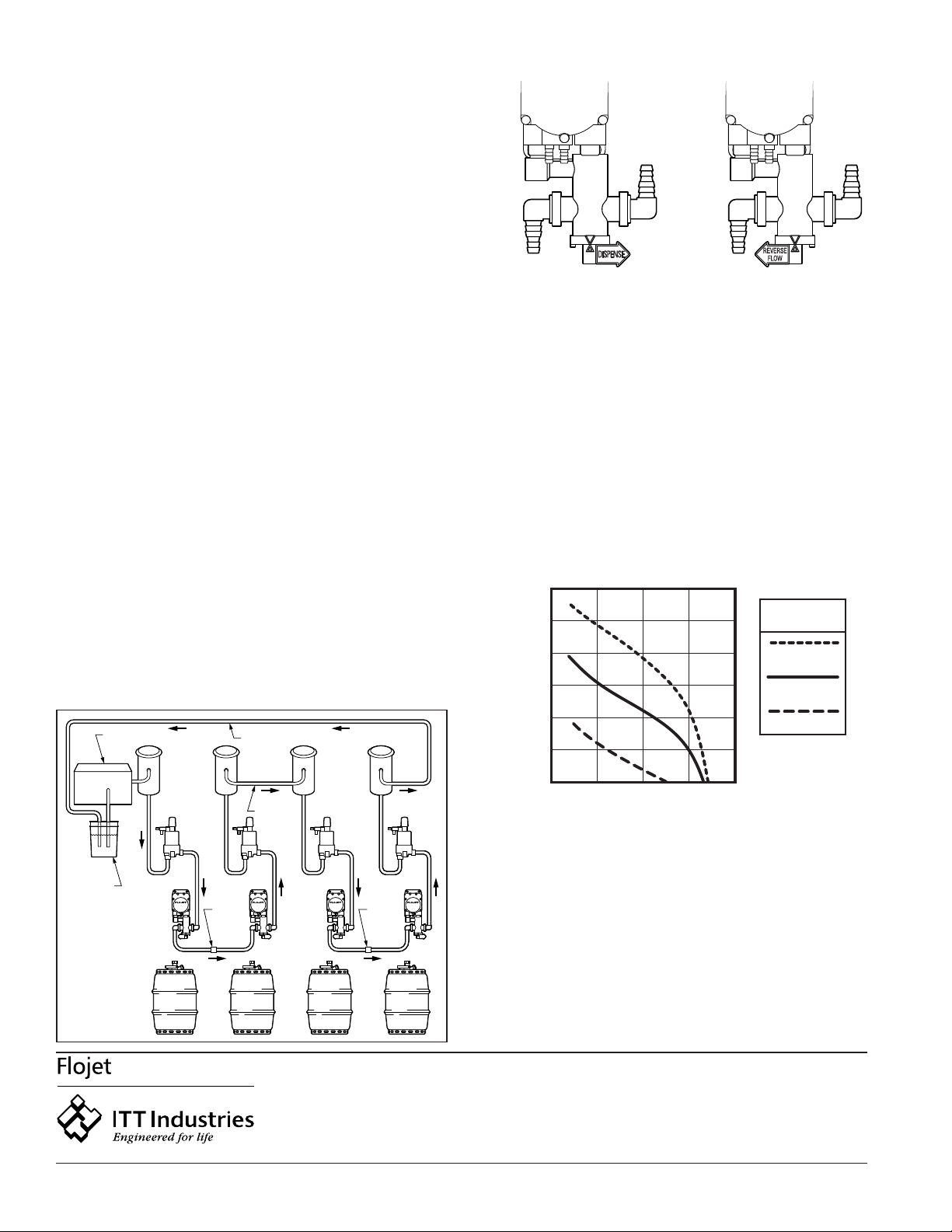

PUMP/LINE CLEANING OPERATION

For operation of the pump, please see G56 Beer Pump

Installation Instructions (form #81000-303). For normal

dispensing, if a Flow Reversal Valve is added to the pump, the

set-up would be as shown in the Typical Installation Drawing.

Note that the valve is in the “Dispense Position” (see Valve

Positions Drawing).

For cleaning one line from the faucet to the keg tap:

1. Turn the valve to the “Reverse Flow” position.

2. Attach a cleaning jumper to the faucet.

3. Set FOB to bypass mode.

4. Pump the cleaning solution from the faucet to the keg tap.

5. Be sure to rinse system with cold, clean rinse water.

6. After cleaning and rinsing system, return all valves to

normal operating (Dispense) positions.

For cleaning multiple lines:

1. Attach a cleaning jumper to the first faucet.

2. Turn the valve to the “Reverse Flow” position.

3. Connect the keg tap from the first line to the keg tap of

the second line with a double flusher.

4. Leave the valve on the second pump in the "Dispense

Position.”

5. Connect the second faucet to the third faucet with a

cleaning jumper.

6. Repeat steps 2 through 5.

7. Set all FOBs to bypass mode.

8. Circulate cleaning solution through system.

9. Be sure to rinse system with cold, clean rinse water.

10. After cleaning and rinsing system, return all valves to

normal operating (Dispense) positions.

CAUTION: Do not close the system while running the

cleaning pumps. Excessive pressure build-up could

damage pumps.

LINE CLEANING DIAGRAM

© Copyright 2004, ITT Industries Printed in U.S.A. All Rights Reserved P/N 81000-382 02/04

UNITED KINGDOM

Flojet, Unit 1, Avant Business Centre

Denbigh West Industrial Estate

Milton Keynes, Bucks, England MK1 1DL

Tel: 44 1908 370088

Fax: 44 1908 373731

U.S.A.

Flojet

20 Icon

Foothill Ranch, CA 92610-3000

Tel: (949) 859-4945

Fax: (949) 859-1153

VALVE POSITIONS

Dispense

Position

Reverse Flow

Position

FLOW CURVE

HOSE CONNECTIONS

• All fittings are quick change.

• Secure with appropriate Oetiker Clamp for specified tubing

size or worm gear clamp 360 degree uniform clamping band.

•

It is advisable to secure all hoses to prevent excessive movement.

AVAILABLE PORT FITTINGS

•Standard Fitting:

3/8”–1/2” (10mm–13mm) Barb, plastic, elbow

•Optional Fittings:

• 1/4” (6.35 mm) Barb, stainless steel, straight

• 3/8” (9.52 mm) Barb, stainless steel, straight

•3/8” – 1/2” (10 mm – 13 mm) Barb, plastic, straight

•1/2” (13 mm) Barb, plastic, straight

•1/2” (13 mm) Barb, plastic, elbow

Inlet From

Keg Tap

TRIANGLES

MUST

LINE UP

Outlet To

FOB/Faucet

Outlet

To Keg Tap

TRIANGLES

MUST

LINE UP

Inlet From

FOB/Faucet

30

(2.1)

20

(1.4)

Air Inlet

Pressure

30 PSI Air Inlet

Motor

Driven

Pump

Line

Cleaning

Solution

Double

Flusher

Recirculating

Line Back To

Cleaning

Solution

Cleaning

Jumper

Double

Flusher

20 PSI Air Inlet

10

(0.7)

Pressure in PSI (Bar)

0

0.5

(1.9)

Flow Rate in GPM (l/min)

1.0

(3.8)

1.5

(5.7)

(7.6)

10 PSI Air Inlet

2.0

Loading...

Loading...