Page 1

Installation and Service Instructions

Midco International Inc.

4140 West Victoria Street Chicago, Illinois 60646

tel 773.604.8700 fax 773.604.4070 web www.midco-intl.com

199

8449-11

Printed in U.S.A.

In the United States, installation must conform with local codes or

in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1-latest edition available from American

National Standard Institute. Further reference should be made to

the recommendation of your fuel supplier.

In Canada, installation must conform with local codes or in the

absence of local codes, with Installation Codes for Gas

Burning Appliances and Equipment, CGA Standard

CAN/CGA 1-B-149.1 or 2. When the conversion burner is used

on a Forced Air Central Furnace, the two yellow and black

warning labels in the literature envelope shall be attached in

accordance with Installation Code, CGA Standard CAN/CGA

1-B149, Clause 5.4.4.4. Further reference should be made to

the recommendation of your fuel supplier.

WARNING: Additions, changes, conversions and service

must be performed by an authorized Midco

representative, service agency or the fuel supplier. Use

only MIDCO specified and approved parts.

INSTALLER:

Inform and demonstrate to the user the

correct operation and maintenance of the gas

utilization equipment. Inform the user of the hazards

of storing flammable liquids and vapors in the

vicinity of this gas utilization equipment and remove

such hazards. Affix this manual and associated

literature to the conversion burner.

CODE COMPLIANCE IS THE SOLE RESPONSIBILITY OF THE

INSTALLER.

USER:

Retain this manual for future reference. If other

than routine service or maintenance as described in this

manual and associated literature is required, contact a

qualified service agency. DO NOT ATTEMPT REPAIRS.

An inadvertent service error could result in a

dangerous condition.

Unipower A-Series

Gas Burners

BURNER

MODEL

BILL OF MAT'L

NUMBER

DATE CODE

WIRING DIAGRAM

PIPING DIAGRAM

START-UP INSTRUCTIONS

FOR SERVICE CONTACT:

name

address

phone

SSAAFFEETTYY IINNFFOORRMMAATTIIOONN TTEERRMMSS:: The following terms are used to identify hazards, safety precautions or special notations

and have standard meanings throughout this manual. When you see the safety alert symbol and one of the safety

information terms as shown below, be aware of the hazard potential.

WARNING: Signifies a hazard that could result in personal injury or death.

CAUTION: Identifies unsafe practices which would result in minor personal injury or product and property damage.

Warning: If the information in these instructions

is not followed exactly, a fire or explosion may result,

causing property damage, personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in the building.

• Immediately call your gas supplier from

another building's phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier,

call the fire department.

Page 2

Part 1 Installation

I Specifications

Burner Style Power Type

Flame Safeguard Instantaneous electronic type

with flamerod detection (flame rectification).

• Provides pre-purge and intermittent pilot operation on UL listed models up to 2500 MBH

maximum input.

• Provides pre-purge and interrupted pilot operation on UL listed models over 2500 MBH

max.

Pilot Spark Ignited

Fuel Natural or Propane Gas to 14" W.C. Pressure

Controls 120 Volt, 60 Hz., 1-Phase

Burner Capacity Chart page 12

In U.S.A.: UL Listed, In Canada: ULC (A5 Series only)

Burner

Model

Minimum***

Maximum H.P. PhaseVolts

Burner Input Capacity*

Natural or Propane Gas MBH**

Motors

3450 RPM. 60 Hz.

A50G

A52G

A53G

A55G

A73G

A75G

A77G

1

1

1

1

3

3

3

1

/

3

1

/

2

3

/

4

3

/

4

11/

2

2

2

115

115

115/230

115/230

230/460

230/460

230/460

420

840

840

840

1,680

1,680

1,680

1,500

2,000

2,500

3,000

4,200

5,000

6,000

Table 1: Burner Specifications

* Values given based on -0.1" W.C. to +0.1" W.C. firebox pressure, altitudes to

2,000 feet. Derate burner for altitudes over 2,000 feet by 4% for each 1,000

feet over sea level. (One gallon fuel oil=140 MBH).

** Refer to Burner Spec Plate for Inlet and Manifold gas pressure required.

*** Modulating and High-Low-Off burners are limited to a 3 to 1 turndown

ratio.

All models are capable of full input start. However, in some cases, (i.e. restricted draft or induced

draft) optional low fire start may be necessary. Specify On-Off, Hi-Lo-Off or Full Mod as required.

■■

■■ A permanent means must be provided to supply an ample volume of fresh air for combustion

and boiler room ventilation. A direct opening to the outside air for combustion and boiler room

ventilation. A direct opening to the outside air should be provided sized on the basis of

1

/2square

foot of free opening for each 1,000 MBH of burner input when the flue pipe is equipped with a

barometric draft control, as is commonly used on burners of this size. If the ventilation opening is

screened, it should be of 1

1

/4" mesh. The opening should be located at least six feet over ground

level to prevent accidental obstruction. If a direct opening to the outside air is not available, an

amply sized air duct can be run to the nearest outside air source.

■■

■■ While the Unipower A Series burner will perform successfully under moderate or momentary

back draft conditions, it is not intended for operation under sustained reverse draft, as might be

encountered in building with large ventilating fans but with insufficient make-up air. Even if

burner operation is successful under these conditions, they must be corrected to prevent the

hazard of drawing flue gases into the building.

■■

■■ The entire heating system should be inspected, cleaned and repaired as necessary to provide

proper heating.

■■

■■ Remove all grates and obstructions from the firebox, clean thoroughly, and seal all joints and

cracks. Complete sealing of the firebox is required where the combustion chamber pressure will

be positive during burner operation. It is also beneficial where the pressure is negative as it

promotes combustion efficiency.

■■

■■ Firing door catches should be filed off or otherwise arranged so that the door will open easily

to relieve excess pressure. No positive catches should be used. The use of a spring-type door

holder is recommended.

■■

■■ If the appliance has been designed for automatic firing and contains no firing doors, an

observation port should be provided that will allow inspection of the main flame and pilot.

II Ventilation

III Preparation of the

Heating Appliance

2

Page 3

III Preparation of the

Heating Appliance

Continued

IV Combustion Chamber

■■

■■ Make sure that the boiler gauge glass is clean so that water level can be easily ascertained. The

pop safety valve should be checked to see that it is in good operating condition. If an existing low

water cut-off is to be used, make sure it is clean and functioning properly.

■■

■■ The Unipower gas burner is designed for "in-shot" firing. It can be fired into the ashpit of a

boiler designed for solid fuels, or it can be fired into the primary heat exchanger of a boiler or

warm-air furnace designed for liquid or gaseous fuels. The ashpit installation requires a refractory

lining.

■■

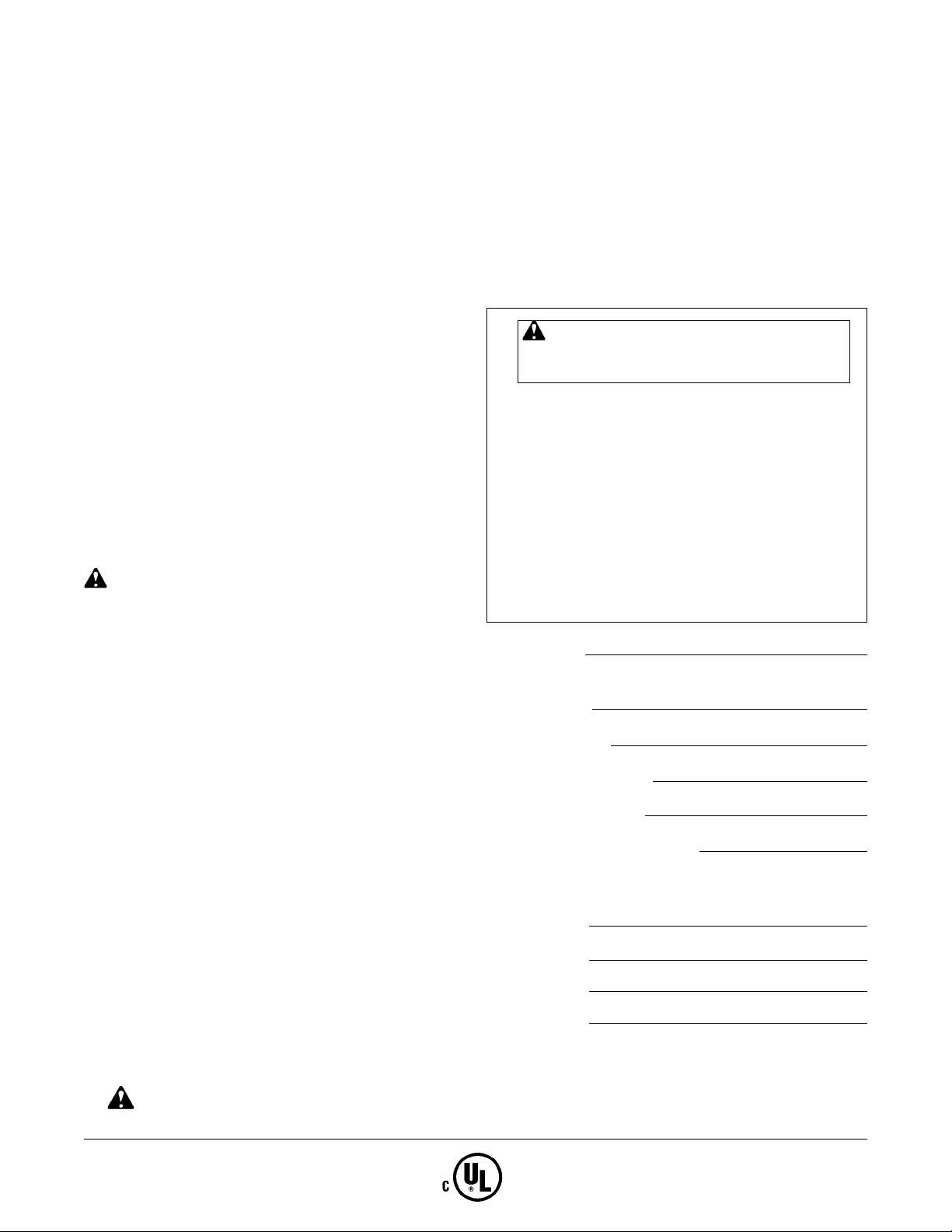

■■ For conventional firebox boilers refer to Table 2 and Figure 1 for recommended combustion

chamber dimension and typical floor and wall construction. If the recommended dimensions

cannot be provided, make length as long as possible and increase the width to maintain the floor

area. Where the floor are must be reduced, use the optional construction shown in Figures 2 or 3.

Figure 1: Typical Floor and Wall Construction

Standard Size Combustion Chamber up to 225 MBH per square foot

Figure 2: Typical Floor and Wall Construction

Alternate Size Combustion Chamber up to 275 MBH per square foot

Figure 3: Typical Floor and Wall Construction

Alternate Size Combustion Chamber up to 350 MBH per square foot (Maximum)

3

Page 4

■■

■■ For warm-air furnaces or Scotch Marine boilers with tubular combustion chambers, the

combustion chamber length must be great enough to exceed the lengths given in Table 2 by at

least 20%.

■■

■■ Combustion chamber proportions may be changed if necessary to avoid flame impingement on

critical parts such as drop sections in cast iron boilers or the heat exchanger surfaces of a warmair furnace. If sustained flame contact cannot be avoided, protect the surfaces with 2

1

/2" or

firebrick.

■■

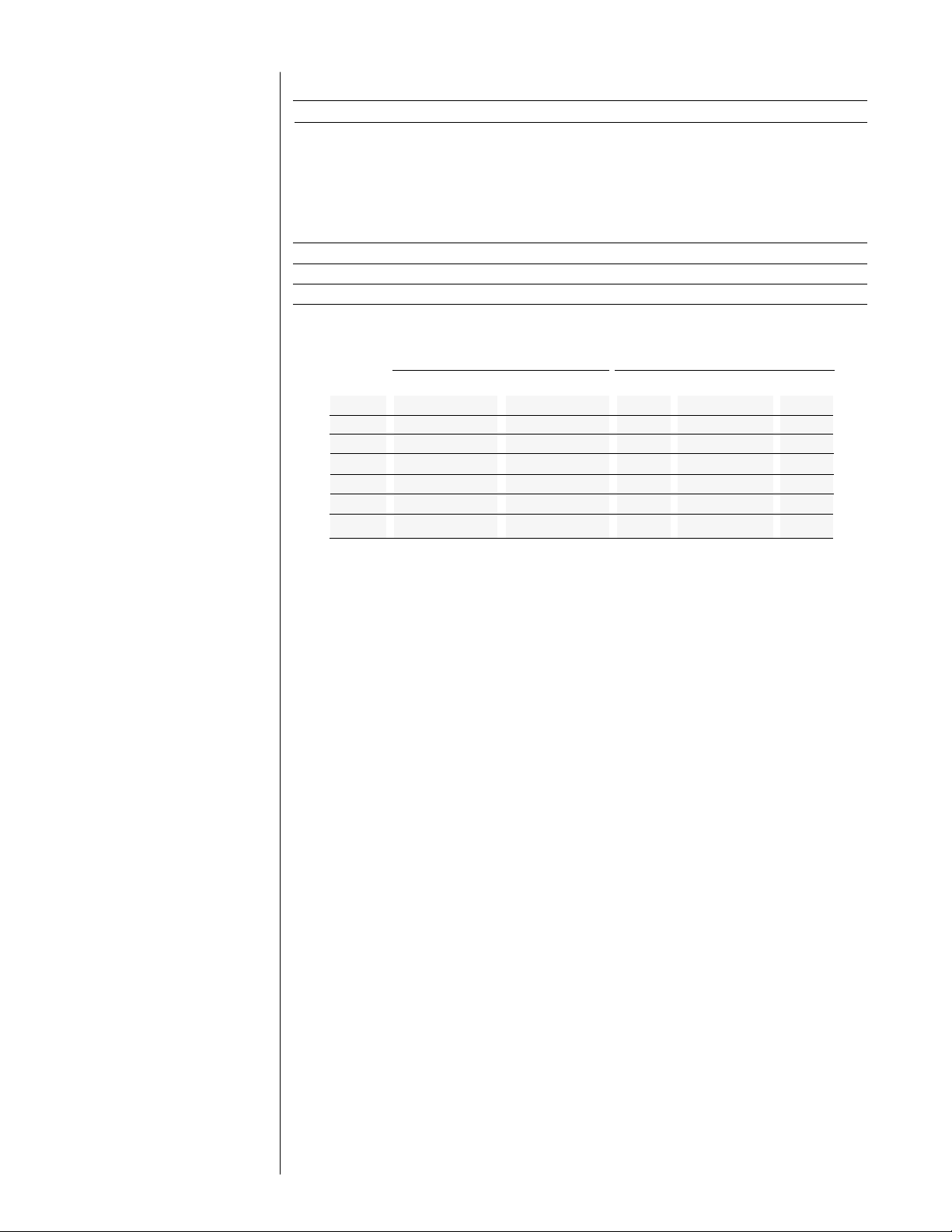

■■ The burner nozzle must not extend into the combustion chamber. It should be sealed into the

opening as shown in Figure 4. The burner mounting to the appliance front must be rigid and

sealed with

1

/4" soft refractory sheet or rope. See Figure 5 for mounting flange dimensions.

■■

■■ Allow a space of about 1" between the edges of the floor brickwork and the appliance base to

allow for expansion and creep. Where wall construction is such that both ends butt against rigid

appliance parts such as the base of a water leg, allow

1

/4" space between bricks every four feet

or so for expansion joints, particularly when reduced size combustion chambers are used.

Firing Door Installations

■■

■■ Greater care in planning will be required for firing door applications since flame impingement

on heat exchange surfaces is more probable. Do not fire a boiler containing a drop section

directly in the path of the flame, or over the water grate in a smokeless type boiler. The firebox

length must be great enough to exceed the combustion chamber lengths given in Table 2 by at

least 20%.

■■

■■ When raising the floor, maintain sufficient firebox volume to limit the heat release per cubic

foot to 50 MBH or less. Use the entire floor as a combustion chamber and cover any water leg

base to 6" from the bottom to avoid firing areas filled with sediment. Floor construction should

conform to Figures 1, 2 or 3.

■■

■■ The burner mounting in the door must be rigid and refractory lined as shown in Figure 9. The

burner nozzle must not protrude directly into the combustion chamber. The refractory liner must

be flush with or extend beyond the burner face as shown in Figure 4. A sheet metal rim should

encase the refractory up to the inside of the boiler wall. It should be intermittently bent inward to

retain the refractory or other means of anchoring should be provided. A refractory felt blanket

can be used in lieu of castable refractory, which will simplify construction at the burner entry.

IV Combustion Chamber

Continued

Figure 4: Construction at Burner Entrance

4

C

L

Page 5

IV Combustion Chamber

Continued

Detailed information is available on request.

■■

■■ Since firing door installations will generally leave no openings for flame observation, a peep

sight must be installed in the burner mounting plate.

Maximum

Input

MBH

685

1,125

1,750

2,250

2,500

3,000

3,500

4,000

5,000

6,000

Width

17"

21"

25"

27"

29"

32"

36"

39"

43"

45"

Length

33"

41"

50"

54"

58"

64"

72"

78"

86"

90"

C/L to Floor*

8"

10"

12"

12"

12"

12"

12"

12"

14"

14"

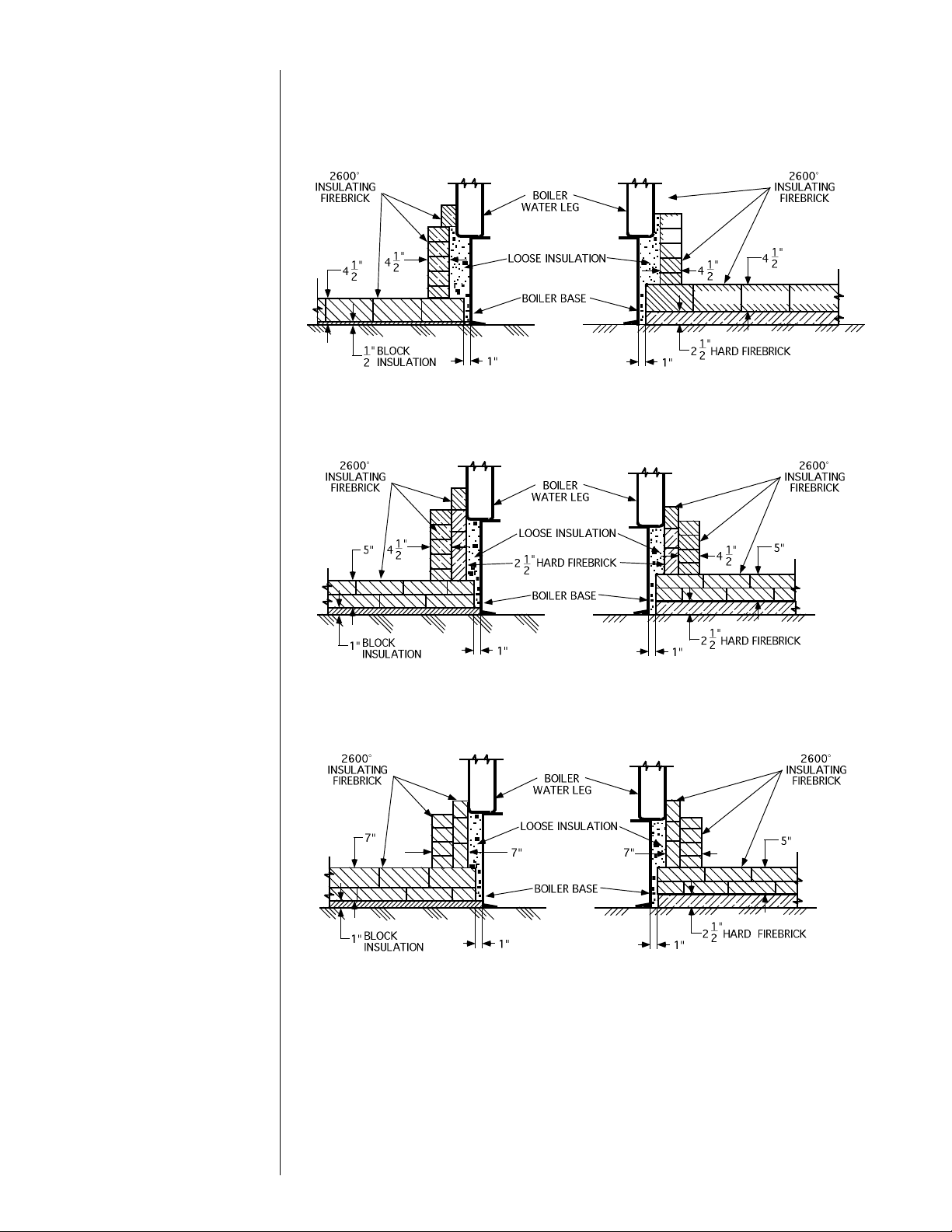

Recommended Combustion

Chamber Dimensions

Table 2: Recommended Combustion Chamber Dimensions

Figure 5: Mounting Flange and Burner Nozzle

Figure 6: Conventional Boiler—Large Firebox

* Dimension given is from centerline of burner nozzle to combustion chamber

floor.

5

Page 6

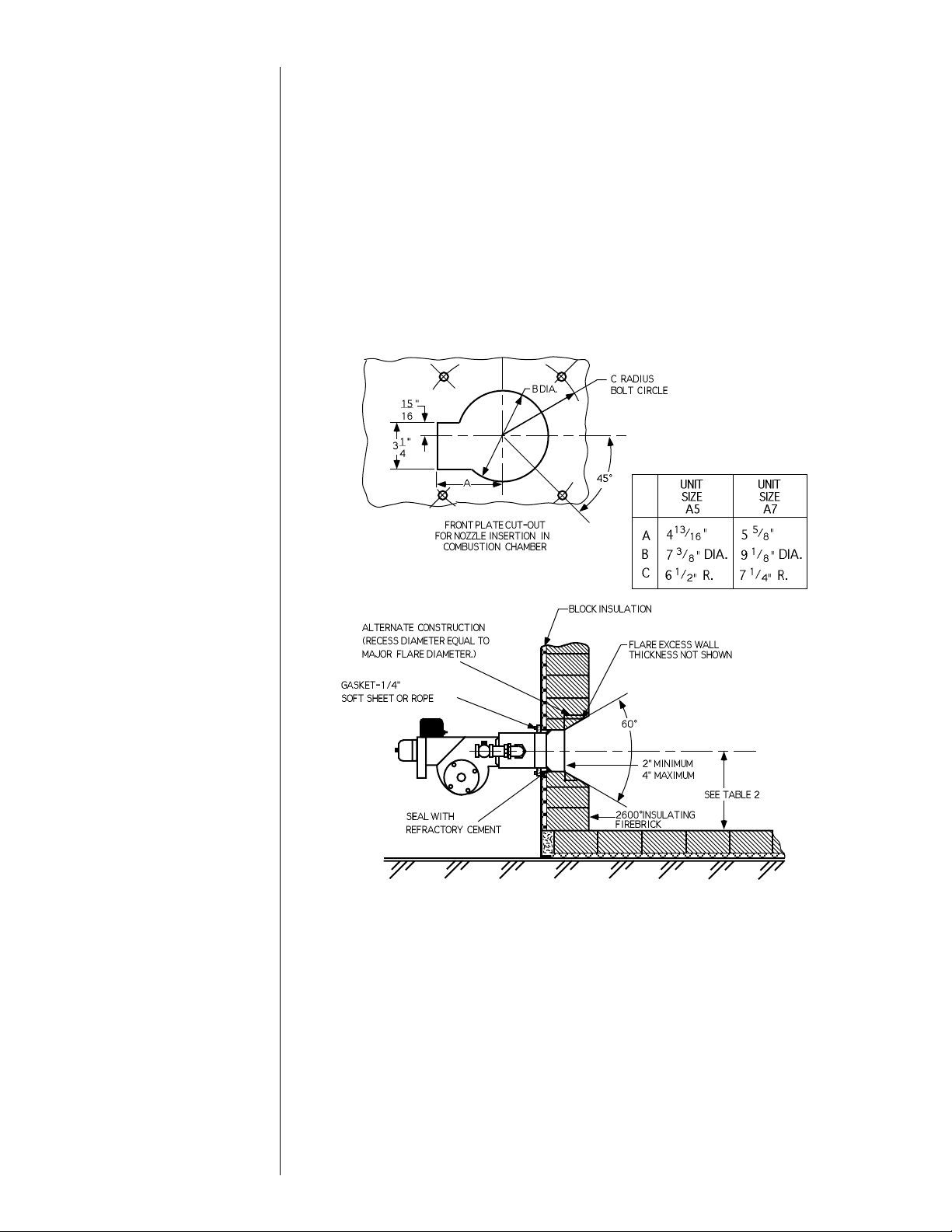

Figure 7: Conventional Boiler—Small Firebox

Figure 8: Tubular Combustion Chambers

Figure 9: Firing Door Installation in Three Pass Boiler

IV Combustion Chamber

Continued

6

Page 7

V Chimney and Flue Pipe

The chimney should be inspected for unsafe conditions such as deteriorated masonry

and excessive soot or other blockage or potential blockage.

■■

■■ All combustion air is furnished by the Unipower burner, and therefore the only function of the

chimney is to vent the flue products.

■■

■■ For the conventional appliances where a slight negative pressure in

the combustion chamber is desirable, the chimney and flue pipe sizes

given in Table 3 are recommended. Where chimney height exceeds

15 feet, a draft control should be installed per Figure 10 and set to

produce a draft of approximately .04" W.C.

■■

■■ The barometric draft control should be of the double swing type,

which opens freely outward to afford downdraft protection

regardless of the setting made to the balancing weights for updraft

control. For a chimney of the recommended diameter in Table 3, the

draft control should be sized from 80% to 100% of the flue pipe

area, or per manufacturer's recommendations. It should be located in

the same room as the heating appliance, clear of any obstruction

which could interfere with its operation.

■■

■■ The flue pipe must be of durable construction, preferably

galvanized steel of sufficient strength, and securely supported. When

passing through a combustible wall or partition, ventilated metal

thimbles or suitable insulation and clearances must be provided to

keep surface temperatures of exposed combustible material below 194° F.

■■

■■ Do not arbitrarily reduce the flue pipe size, since a back pressure can build up in the

combustion chamber, leading to possible

leakage of flue products into the building.

However, if an undersized flue pipe or

chimney must be used and the appliance

is carefully sealed, or if it is built for

pressurized firing, the areas can be

reduced to accommodate 14,000 BTU per

square inch or more, particularly if the

chimney is 30 feet high or more.

■■

■■ If the flue pipe must be extra long, the

area of the pipe and chimney should be

increased, or the chimney height should

be increased, or both. Never allow the

horizontal length of the flue pipe to

exceed the height of the chimney.

■■

■■ If the chimney is of greatly excessive

height, draft may be so great as to cause

the barometric draft control to float in the

wide open position all the time, destroying

its effectiveness. The use of an adjustable

non-floating damper in the flue pipe will

prove useful in this instance by reducing

the draft to a point where the barometric

draft control can operate effectively. It

should be placed in the flue pipe between

the barometric draft control and the

chimney. Its' area must be less than that

of the flue pipe so that total blockage of

the flue pipe is impossible. The

construction of the flue pipe damper and

its adjusting mechanism must be rugged,

so that no flutter or vibration occurs. After

final setting, the damper must be welded

into position to prevent tampering.

■■

■■ In the case of a motorized flue pipe

damper or mechanical flue exhauster, an

electrical interlock must be provided—see

Section VI Electrical.

■■

■■ The information given in this section is by necessity of a general nature. Special cases may

require special treatment.

Maximum

Input

MBH

Flue

Pipe

Diameter

900

1,250

1,750

2,250

3,000

3,750

4,500

6,000

12"

14"

16"

18"

20"

22"

24"

26"

Table 3: Recommended

Size of Flue Pipe and

Chimney

Figure 10: Draft Hoods

Figure 11: Barometric Dampers

7

Page 8

VI Electrical

VII Gas Piping

■■

■■ The burner when installed, must be wired and grounded in accordance with local codes or in

the absence of local codes, with the National Electric Code ANSI/NFPA No. 70-latest edition.

In Canada, refer to CSA Standard C22.1, "Canadian Electrical Code Part 1" and/or local

codes.

Refer to the separate wiring diagram included with this burner for specific wiring

details. The wiring diagram number for your burner is listed on the front cover of this

manual.

■■

■■ When wiring, be sure that the electrical power take-off is connected to a permanently live

circuit and that the burner is electrically grounded. Use copper conductors not lighter than those

given in Table 4.

■■■■

Standard Unipower A-

Series burners are equipped

with Honeywell Flame

Safeguards.

■■

■■ The RM7895 Flame

Safeguard provides pre-purge

and intermittent pilot

operation. See Section I

Specifications for application.

When mounting the chassis,

be sure electrical power has

been turned off. Check all

plug-in components for

security.

■■

■■ The RM7840M Flame Safeguard provides pre- and post-purge and interrupted pilot operation.

See Section I Specifications for application. Burners over 2500 MBH are equipped with a highlow gas pressure switch which prevents operation if gas line pressure exceeds or falls below

certain preset limits.

■■

■■ For further information on both flame safeguards, see Part 2 Service.

■■

■■ Where safe operation of the burner depends on factors external to the burner, an interlock

must be included which will prevent or delay burner operation until safe conditions exist. For

example, in the case of a motorized flue pipe damper or mechanical flue exhauster, the initial call

for heat must first energize the damper or exhauster motor, with burner start-up following only

when the above components are in effective operation as monitored by flow or draft pressure

switches in the flue pipe. If burner operation is made dependent on damper or exhauster control

relays, the system must "fail safe" so that malfunction or failure of these components will not

result in unsafe operations of the burner. See wiring diagrams for proper location of auxiliary

controls.

■■

■■ For the usual low pressure gas supply system, i.e. 5" to 14" W.C., use Table 5 to find the

recommended gas line size.

■■

■■ Piping follows normal practice and should be arranged as shown in Figure 12 with a drip leg at

the end of the vertical drop. The piping must be firmly supported independent of the

burner.

■■

■■ The burner is shipped with the main and pilot valve train completely assembled except for the

manual gas valves and regulators which should be mounted in a location convenient to the

burner. If the main gas train must be rearranged because of space limitations, maintain the

relationship of the components.

■■

■■ The gas line

pressure must be

within the limits

given in Section I

Specifications. If

higher than normal

gas delivery pressure

is encountered, as is

the case in many

industrial plants, the

gas line size may be

reduced to allow for

a greater pressure

drop (use the

multipliers given in

Table 5 for the

allowable size

variations) however, the size must be sufficient to deliver burner rating pressure.

Motor

H.P. Fuse Wire

115/1/60

Fuse Wire

230/1/60

Fuse Wire

230/3/60*

1

/

3

1

/

2

3

/

4

11/

2

2

30A

30A

45A

65A

75A

#14

#14

#12

#10

#10

#14

#14

#14

#12

#12

15A

15A

25A

35A

40A

—

—

#14

#14

#14

—

—

15A

15A

20A

Table 3: Fuse and Wire Sizes

* When 3 phase motor is used, the 120V. 1 phase control circuit

should be fused for 10A minimum and wired with #14 conductors.

Figure 12: Gas Piping Schematic

8

Page 9

VII Gas Piping Cont.

VIII Burner Start-Up

■■

■■ In higher gas pressure systems (over 14" W.C.) it is very important to install the proper

pressure reducing regulators at the burner. A high pressure regulator must be used in the line

ahead of the burner main manual gas valve, but it must be of the tight shut-off type and must

have a minimum flow regulating capacity suitable for the pilot (20,000 BTU/hr.)

CAUTION: If the gas supply pipeline is to be pressure tested, it should be done

before the burner is connected in order to prevent damage to the burner pressure

regulators and main gas valve. Use air or inert gas under pressure (DO NOT USE

OXYGEN).

■■

■■ Before gas is turned into the system, a

check must be made to see that there

are no open fittings and to make sure

the burner main manual valve and pilot

manual valve are closed. Purge the gas

line up to the burner inlet. Discharge

purged gas outside of the building, do

not purge into the combustion chamber.

Each burner is supplied with an individual initial start-up procedure. The start-up

instructions number for your burner is listed on the front cover of this manual.

■■

■■ After the initial start-up procedure the following steps can be followed for routine start-up and

shut-down on a seasonal basis.

Extended Burner Shut-Down

1. Turn off burner switch.

2. Close main manual valve.

3. Close pilot manual valve.

4. Turn off line switch.

Burner Start-Up

1. Make sure line switch and burner switch are off.

2. Set controller to call for heat.

3. Open firing door.

4. Open main and pilot manual gas valves.

5. Depress flame safeguard reset button.

6. Reset low gas pressure switch (if used).

7. Turn on line switch.

8. Turn on burner switch and allow burner to run through firing cycle.

9. Close firing door.

10. Reset controller to desired setting.

Table 5: Recommended Gas Piping

* Multiplier for Propane: 1.57

** Multiplier for alternate pressure drops: 0.3" W.C.-.77,

1.0" W.C.-1.40, 2.0" W.C.-2.00, 4.0" W.C.-2.80.

Feet

From

Meter

11/4"

11/2"

2"

3" 4"

21/2"

Maximum Capacity for Natural Gas*

MBTU/hr. Based on 0.5" W.C. Pressure Drop**

Pipe Size

25

40

60

80

100

125

150

175

200

760

660

1175

1000

810

690

620

2375

1900

1520

1300

1150

1020

950

850

800

3900

3000

2400

2050

1850

1650

1500

1370

1280

6000

5300

4300

3700

3250

2950

2650

2450

2280

5500

5000

4600

9

Page 10

Part 2 Service

CAUTION: Do not tamper with the unit or controls. If trouble occurs contact your

serviceman.

CAUTION: Be sure that the main and pilot manual valves are closed and the burner

power supply is turned off before removing any parts for service. Do not push relay

contacts in manually.

■■■■

Maintenance of the burner box and nozzle is minimal, due to the simplicity of the parts and

the absence of small air or gas passages. An occasional inspection of the parts in contact with the

flame will suffice. The burner nozzle parts should show no severe loss of metal or warping.

■■

■■ If the burner mounting flange shows evidence of overheating, check the tightness of the

burner mounting. The burner is intended to be sealed into the appliance face as shown in Figure

4 to prevent blow-back of hot flue products around the nozzle and flange.

■■

■■ The pilot is of the premix, blast type. Undampered blower air is brought into the pilot body

through the air orifice where the proper amount of gas is added through the pilot gas orifice. The

mixture is discharged through the alloy flame retention pilot tip. The pilot is rated for an

approximate capacity of 20 MBH and a normal operating pressure of 2.5" to 4" W.C. for both

Natural Gas and Propane.

■■

■■ The pilot regulator is factory set for an outlet pressure of about 3

1

/2" W.C. which will be

suitable for average conditions. Do not indiscriminately increase orifice sizes. Pilot troubles are

rarely cured in this manner. Adjust the pilot as described in the start-up instructions included with

the burner.

■■

■■ The spark rod is located on the center line of the pilot and is arranged to arc to the inside of

the central port. Spark current is supplied by a 6000V, 20 milliampere (minimum) end point

grounded ignition

transformer.

■■

■■ Service of the pilot

will generally consist

only of inspection and

cleaning. Check that the

air tube, pilot body and

the tip ports are free of

lint and dirt and that the

pilot tip is free of serious

corrosion. The spark rod

insulator must be clean,

dry and free of cracks.

See Figure 13.

■■

■■ The high tension

cable for the spark

electrode should be

checked for cracks and

abrasions.

■■

■■ Proper operation of

the flame safeguard

depends on a reliable

current flow through

the flamerod, pilot

flame and the burner

frame. The flamerod

must be free of any

contact with conductive

burner parts. The

insulator must be clean, dry and free of cracks. While the rod is made of heat resistant alloy, it

may eventually deteriorate at the point of flame contact and should be replaced if it is seriously

corroded.

X Pilot and Flame Sensor

IX Burner Box and

Nozzle Assembly

Model

A50G

Air Orifice

Natural

Propane

5

/16" (Brass)

#45 (.082)

#47 (.078)

#50 (.070)

Pilot Orifice Sizing

9

/32" (Aluminum)

A52-A55G A73-A77G

Figure 13: Pilot Assembly

10

C

L

Page 11

XI Blower and Motor

XII Gas Pressure Regulator

XIII Main Automatic Safety

Shut-Off Valve

V48 Diaphragm Gas Valve

(Not for use in Canada)

V5055 Valve Body

with Motorized Actuator

■■

■■ No routine service is necessary on the blower system other than cleaning the blower wheel

when necessary.

■■

■■ Blowers using three-phase motors will run in either direction depending on the connection of

the power supply. On new installations, motor replacement or power supply disturbance, the

rotation must be checked. Corrections can be made by interchanging any 2 wires of the threephase power supply.

■■

■■ If replacement motors for standard burners are procured from a source other than Midco, they

should conform to the following specifications: 3450 RPM, Frame 56C, end mounted open motor

with ball bearings. Capacitor start and thermal overload protection if single phase.

■■

■■ Proof of blower operation is provided by the diaphragm type blower air switch, which must

close its normally open contacts and maintain them closed when the blower is running. A check

for proper operation can be made by disconnecting the air pressure tube during burner

operation, which should result in burner shut-down. In case of malfunction, it is recommended

that the air switch be completely replaced.

■■

■■ A three wire self-testing hookup of the air switch is used on burners equipped with flame

safeguards, such as the RM7840, which have a 120V air proving interlock circuit. The N.C.

contacts of the air switch are wired into the start interlock circuit, which prevents burner start-up

unless the air switch proves operational by returning to its normally off position after every burner

run. Failure of the burner to start may be caused by a faulty air switch.

■■

■■ The gas pressure regulator is used to automatically reduce and maintain constant gas pressure

at the burner.

■■

■■ To adjust the outlet pressure, remove the seal cap for access to the adjusting screw. Turning

the screw clockwise will increase outlet pressure, counter-clockwise will decrease outlet pressure.

■■

■■ The vent in the upper diaphragm case normally breathes only air and must be connected to the

outside air to prevent escape of gas into the building in case of a ruptured diaphragm. The vent

line must be of sufficient diameter, otherwise the restriction of air flow may cause sluggish

opening of the regulator. The effect can be checked by comparing main flame start-up time with

the vent line connected and unconnected.

The vent must never be connected to the burner or combustion chamber

■■

■■ Although regulators seldom require servicing, the most vulnerable part is the diaphragm.

Periodic service should be limited to a diaphragm inspection, which should be checked for

punctures of stiffness.

■■

■■ The Honeywell V48A diaphragm gas valve is of the slow opening type with a maximum closing

time of 5 seconds. It requires a bleed tube which discharges into the combustion chamber

adjacent to the pilot. Closing force combines a gas pressure differential, diaphragm weight and

spring.

■■

■■ For general service a check for gas tightness will suffice. Start the burner and observe through

at least one cycle to be sure the valve functions properly and that the main flame has

extinguished completely.

■■

■■ Leak test per Section XVI Special Equipment. If leakage is observed, turn off the electrical

power and the main manual gas valve, remove the diaphragm case and make the following

checks: (1) the diaphragm must be pliable, free of holes and must have sufficient slack when set

in position; (2) the valve seat must be free of gum, tar or other dirt and must be free of cuts,

nicks and worn spots.

■■

■■ If the valve fails to close, make sure power is off at the terminals and gas flow is in the

direction of the arrow on the valve body. When malfunction is determined to be caused by the

valve operator head, the operator head should be completely replaced.

■■

■■ If the valve will not open, make sure normal gas pressure is available at the valve, the bleed

line is unobstructed, and power is available at the terminals.

■■

■■ The Honeywell V5055 main valve body is of the slow opening, fast closing type and does not

require venting. It is powered by a motorized valve actuator which supplies the motive power for

opening and closing the valve. The V4055 Actuator is used for On-Off and Full Modulating

operation. The V4062 Actuator is used for both the On-Off control and to provide High-Low

firing rate control. The full open position should be reached in 26 seconds after energization, the

closed position in one second or less.

■■

■■ For general service, the valve should be checked for gas tightness and proper operation. If

leakage is detected, the valve seat should be examined for dirt, damage or obstruction.

■■

■■ For access to the valve for inspection and cleaning, turn off the electrical power and the main

manual gas valve, then loosen the two Allen setscrews in the actuator collar and remove the

actuator. Remove the valve bonnet assembly by removing the bolts holding it to the valve body.

Inspect the valve seat for dirt, cuts, nicks and other defects. Do not disassemble the valve bonnet.

The valve seat is not replaceable; if defective, the entire valve body should be replaced.

11

Page 12

V5055 Valve Body with

Motorized Actuator Cont.

XIV Automatic Gas

Valve Leak Test

XV Flame Safeguard

XVI Special Equipment

■■

■■ Do not disassemble the valve actuator, it is not field repairable. If malfunction occurs, replace

the entire actuator.

1. Turn off power to burner.

2. Fully close the manual test cock (located downstream of the gas input adjuster.

3. Remove the

1

/8" pipe plug from the test tap located:

a. with diaphragm valve (in one of the pipes nipples between the valve and test cocks, or

b. with motorized valve (in the bottom of the valve body on its downstream side, or in the

tee connecting the high gas pressure switch tube to the valve train.

4. Install a pet cock in the test tap and attach a short length of

1

/4" flexible tubing. The open

end of the tubing should be cut at a 45° angle.

5. Immerse the open end of the tubing to a depth of

1

/2" in a container of water.

6. Open the pet cock. If bubbles appear, wait until the rate stabilizes, then count the number

appearing in ten seconds. An excess of 23 bubbles over a ten second period (approximately

.023 CFH of gas) indicates that the valve should be repaired or replaced.

7. If there are two automatic gas valves in the valve train, check the downstream valve first and

then the upstream valve. Use the appropriate tap in one of the motorized valve bodies, or

when a diaphragm and solenoid valve are furnished, in the pipe nipple between the valves.

8. After the test is completed, be sure to replug the test taps and fully open the test cock.

■■

■■ Standard Unipower burners are equipped with a Honeywell RM7895 microprocessor based

burner control, employing a flame rectification system of flame detection. Burner construction for

special codes and/or insurance requirements such as Factory Mutual or Industrial Risk Insurers (IRI)

may require alternate controls. Refer to Section XV Special Equipment. A safe start and run

control sequence is provided with instantaneous response to presence or loss of flame signal.

Flame failure response time is 3 seconds. Pilot Flame Establishing Period (PFEP) is field selectable

from 4 or 10 seconds. The RM7895 features a pre-purge time (30 seconds for On-Off, 90

seconds for 2-Step or Modulating burners) and a plug-in amplifier. An airflow circuit is also field

selectable to allow either lockout or recycle upon loss of airflow. Five LED's (light emitting diodes)

are provided to display sequence information. Refer to the Honeywell RM7895 literature for

detailed operating information, configuration requirements, testing and service.

■■

■■ Special Equipment, such as high-low gas pressure switches, main valve, proof of closure

switches etc., can affect the start-up and operation of the burner. Refer to your burner wiring

diagram and specific start-up instructions, as well as equipment manufacturer's literature included

with the burner for further information.

■■

■■ If any doubt exists concerning burner operation when special equipment is involved, contact

the installing contractor or Midco International Inc.

Burner

Model 0" W.C. .25" W.C. .50" W.C. .75" W.C. 1.0" W.C.

A50G

A52G

A53G

A55G

A73G

A75G

A77G

1500

2000

2500

3000

4200

5000

6000

—

—

—

—

4200

5000

5800

1300

1700

2500

2800

4000

5000

5600

—

—

—

—

3850

5000

5400

*

1525

2500

2575

3650

5000

5200

Combustion Chamber Back Pressure

Table 6: Maximum Capacities at Specified Back Pressures

12

Loading...

Loading...