Page 1

PRO6 Control Centre

Quick Reference Guide

Midas,

Klark Teknik Building,

Walter Nash Road,

Kidderminster.

Worcestershire.

DY11 7HJ.

England.

Tel: +44 1562 741515

Fax: +44 1562 745371

Email: info@uk.telex.com

Website: www.midasconsoles.com

PRO6 Control Centre - Quick Reference Guide

DOC04-DL3 Issue A - September 2008

© Telex Communications (UK) Limited

In line with the company’s policy of continual improvement, specifications and function may be

subject to change without notice. This Operator Manual was correct at the time of writing. E&OE.

Page 2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

The lightning flash with arrowhead symbol within an equilateral triangle is

intended to alert the user to the presence of uninsulated “dangerous voltage”

within the product's enclosure that may be of sufficient magnitude to constitute a

risk of electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert the user

to the presence of important operating and maintenance (servicing) instructions

in the literature accompanying the product.

1 Read these instructions.

2 Keep these instructions.

3 Heed all warnings.

4 Follow all instructions.

5 Do not use this apparatus near water.

6 Clean only with a dry cloth.

7 Do not block any of the ventilation

openings. Install in accordance with the

manufacturer’s instructions.

8 Do not install near any heat sources such

as radiators, heat registers, stoves, or

other apparatus (including amplifiers) that

produce heat.

9 Do not defeat the safety purpose of the

polarized or grounding-type plug. A

polarized plug has two blades with one

wider than the other. A grounding type

plug has two blades and a third grounding

prong. The wide blade or the third prong

are provided for your safety. If the

provided plug does not fit into your outlet,

consult an electrician for replacement of

the obsolete outlet.

10 Protect the power cord from being walked

on or pinched particularly at plugs,

convenience receptacles and the point

where they exit from the apparatus.

11 Only use attachments/accessories

specified by the manufacturer.

12 Unplug this apparatus during lightning

storms or when unused for long periods of

time.

13 Refer all servicing to qualified personnel.

Servicing is required when the apparatus

has been damaged in any way, such as

power-supply cord or plug is damaged,

liquid has been spilled or objects have

fallen into the apparatus, the apparatus

has been exposed to rain or moisture,

does not operate normally, or has been

dropped.

14 Use the mains plug to disconnect the

apparatus from the mains.

15 Warning: To reduce the risk of fire or

electric shock, do not expose this

apparatus to rain or moisture.

16 Warning: Do not expose this

equipment to dripping or splashing

and ensure that no objects filled with

liquids, such as vases, are placed on

the equipment.

17 Warning: The mains plug of the power

supply cord shall remain readily

operable.

Page 4

Page 5

Midas

EC-Declaration of Conformity

The undersigned, representing the following manufacturer

Manufacturer:

Telex Communications (UK) Limited

Address:

Klark Teknik Building,

Walter Nash Road,

Kidderminster.

Worcestershire.

DY11 7HJ.

hereby declares that the following product

is in conformity with the regulations of the following marked EC-directives and bears the -mark

accordingly

The conformity of the product with EC directives is provided by the compliance with the following standards:

Standards/date:

Place, date: Kidderminster, UK

5th September 2008

Managing Director Business Line R+D Director Business Line

Printed name: John Oakley Printed name: Simon Harrison

Product Type Number Product Description Nominal Voltage(s) Current Freq.

PRO6 Control Centre 115V AC

230V AC

2.9A

1.5A

50/60Hz

reference number title

2004/108/EC EMC Directive (EMC)

2006/95/EC Low-Voltage Directive (LVD)

reference number title

EN50081/1 Generic Standard Using EN55103 Limits and Methods

EN55103 Class B Conducted Emissions PAVI

EN55103 Class B Radiated Emissions PAVI

EN61000-4-4 Fast Transient Bursts at 2kV

EN61000-4-2 Static Discharge at 4kV

EN60204 Electrical Stress Test

EN60065 7

th

Edition

Electrical Safety

Page 6

Page 7

End-User License Agreement for Midas™ and Klark Teknik™ Software

IMPORTANT - Please read this document carefully before using this Midas™ or

Klark Teknik™ product. This is an agreement governing your use of software or

other machine instructions already installed on the Midas™ or Klark Teknik™

product, as well as other software that we provide for installation on the product.

The Midas™ or Klark Teknik™ product will not operate in accordance with its

documentation without this software.

THIS AGREEMENT ("AGREEMENT" OR "LICENSE") STATES THE TERMS AND CONDITIONS UPON WHICH

TELEX COMMUNICATIONS, INC. ("COMPANY") OFFERS TO LICENSE THE INSTALLED FIRMWARE,

SOFTWARE, AND/OR PROGRAM ("the SOFTWARE") WITH THE MIDAS™ OR KLARK TEKNIK™ CONSOLE

OR SIGNAL PROCESSING PRODUCT ("PRODUCT") IN WHICH IT WAS INSTALLED BY, OR PROVIDED

FOR BY, THE COMPANY. YOU ARE AGREEING TO BECOME BOUND BY THE TERMS OF THIS LICENSE. IF

YOU DO NOT AGREE TO THE TERMS OF THIS LICENSE, DO NOT USE THIS PRODUCT. PROMPTLY

RETURN THE PRODUCT TO THE PLACE WHERE YOU OBTAINED IT FOR A FULL REFUND. You agree to

notify any persons who you permit to operate this Product of the terms of this License, and to expressly

obligate them in writing to comply with these terms.

The installed software as supplied by the Company is licensed, not sold, to you for use only under the

terms of this License, and the Company reserves all rights not expressly granted to you. You own the

Product on or in which the Software has been installed by the Company, but the Company retains

ownership of all copies of the Software itself, including those stored on or in the Product.

1. License: This limited License allows you, and other persons you permit to operate the Product,

to use the Software only on the single Product unit in which it was installed.

2. Restrictions: (a) The Software and the accompanying written materials are copyrighted, and

contain trade secrets and other proprietary matter, including confidential information relating to

the specifications and performance characteristics of Company's products. The Software is

protected by state trade secret laws as well as U.S. and international copyright and intellectual

property laws and treaties. All rights to copyrights, trademarks and trade secrets in the Software

or any modifications to it are owned by Company. Unauthorized copying of the Software or any

portion thereof, or copying of the written materials, is prohibited. (b) You may not create,

market, distribute, or transfer copies of the Software to others or electronically transfer or

duplicate the Software, or rent, lease, or loan the Software, except in conjunction with the sale,

transfer, loan, rent, or lease of the Product on which it is installed, and subject at all times to this

License. YOU MAY NOT REVERSE ENGINEER, DECOMPILE, DISASSEMBLE, MODIFY, ADAPT, PORT,

OR TRANSLATE THE SOFTWARE OR CREATE DERIVATIVE WORKS BASED ON THE SOFTWARE OR

ANY ACCOMPANYING WRITTEN MATERIALS. (c) In the event you violate any term of this

Agreement, all licenses granted herein automatically terminate and you must stop using the

Software and destroy any copies of the Software or remove them from the Product.

3. Limited Warranty: Subject to your installation of any Software updates issued by the Company

as described herein, the Company warrants that the Software shall cause the Product to operate

in compliance with the Product's material specifications and documentation for a period of

90 days from your purchase of the Product. The Company does not warrant that the operation of

the Software will meet your requirements or operate free from error. The Company DISCLAIMS

ALL WARRANTIES AND CONDITIONS EITHER EXPRESS OR IMPLIED, INCLUDING THE

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND

NON-INFRINGEMENT OF THIRD PARTY RIGHTS. You understand that the Company may update

or revise the Software and in so doing incurs no obligation to furnish such updates to you.

However, the Company may in its discretion make updates available from time to time upon such

terms and conditions as it shall determine. It is a condition of any warranty granted pertaining to

either the Software or the Product, that you install any such Software updates, as may be issued

from time to time by the Company for the Product or the Software, in accordance with

Company's instructions. You may view current Software updates at http://www.klarkteknik.com

and http://www.midasconsoles.com

Page 8

4. Limited Liability: THE LIABILITY OF THE COMPANY FOR ANY CLAIMS ARISING OUT OF THIS

LICENSE AND/OR BASED UPON THE SOFTWARE, REGARDLESS OF THE FORM OF ACTION, SHALL

NOT EXCEED THE GREATER OF THE LICENSE FEE FOR THE SOFTWARE OR THE COST OF THE

PRODUCT. IN NO EVENT SHALL TELEX BE LIABLE FOR ANY LOSS OF DATA, LOST OPPORTUNITY

OR PROFITS, COST OF COVER, OR SPECIAL, INCIDENTAL, CONSEQUENTIAL, OR INDIRECT

DAMAGES, EVEN IF YOU ADVISE COMPANY OF THE POSSIBILITY OF SUCH DAMAGES. THIS IS

AN ESSENTIAL TERM OF THIS AGREEMENT AND YOU ACKNOWLEDGE THAT THE AMOUNT YOU

PAID FOR THE PRODUCT AND SOFTWARE REFLECTS THIS ALLOCATION OF RISK.

5. Other Third-Party Computer Programs: As referred to herein, the term "Software" refers

only to proprietary Midas™ or Klark Teknik™ Software, developed by Company, that has been

provided to you for installation on, or already installed in, your Midas™ or Klark Teknik™ Product.

In addition to this Software, you may have also been provided, at no additional charge, a version

of the widely-available Linux software, which is a modular operating system made up of hundreds

of individual software components, each of which were written and copyrighted individually by

various parties (collectively, the "Linux Programs"). Each component has its own applicable end

user license agreement. Many of the Linux Programs are licensed pursuant to a Linux End User

License Agreement ("Linux EULA") that permits you to copy, modify, and redistribute the

Software. However, you must review the on-line documentation that shares a directory or

otherwise accompanies each of the Linux Programs included in this Product, for the applicable

Linux EULA. Nothing in this license agreement limits your rights under, or grants you rights that

supersede, the terms of any applicable Linux EULA. If you wish to receive a computer-readable

copy of the source code for the Linux programs that have been provided with your Midas™ or

Klark Teknik™ product, send a check or money order (no cash accepted), your address, and

$10.00 to cover the cost of optical media, postage and handling, to:

Telex Communications, Inc.

ATTN: Linux Programs CD for Midas™/Klark Teknik™

12000 Portland Ave South

Burnsville, Minnesota 55337.

In your request, indicate your Product's name and model number, serial number, and

version/release information. This offer made pursuant to the Linux EULA may expire according

to the terms of the Linux EULA, in which case your check will be returned to you or destroyed at

our option. Please note that the Linux distribution that may be available to you under this offer

consists of the Linux kernel only and does not contain any application software not

covered by the Linux EULA. Other updated Linux distributions containing application software

are widely available from a variety of Internet sources, and are often available at minimal or no

cost.

6. Termination: This License will terminate immediately if you violate any of the License terms.

Upon termination you must discontinue use of the Software, and either destroy, erase, or return

to Company all copies of the Software in your possession, custody or control, including those in

or on the Product.

7. General: This License constitutes the entire agreement between you and Company with respect

to this Software and supersedes any other communication (including advertising). If any

provision of this License is held unenforceable, that provision shall be enforced to the maximum

extent permissible so as to give effect the intent of this License, and the remainder of this

License shall continue in full force and effect. This License shall be governed by the laws of the

State of Minnesota, and the federal laws of the United States, without reference to conflict of

laws principles. You agree that the United Nations Convention on Contracts for the International

Sale of Goods is inapplicable to both this License and to the sale of the Product.

Page 9

ix

PRO6 Control Centre

Quick Reference Guide

Precautions

Before installing, setting up or operating this equipment make sure you have read and

fully understand all of this section and the “IMPORTANT SAFETY INSTRUCTIONS” at the

front of this guide.

This equipment is supplied by a mains voltage that can cause electric shock injury!

The following must be observed in order to maintain safety and electromagnetic compatibility (EMC)

performance.

Safety warnings

Signal 0V is connected internally to the

chassis.

To completely disconnect this equipment from

the AC mains, while observing full safety

precautions (see “Power” on page ix), switch off

the isolator switch (above the mains power

sockets on rear of control centre) and then

switch off the mains at the three mains outlets.

Unplug the three mains leads from the rear of

the control centre.

To avoid electrical shock do not remove

covers.

General precautions

In the event of ground loop problems,

disconnect the signal screen at one end of the

connecting cables. Note that this can only be

done when the equipment is used within a

balanced system.

Do not remove, hide or deface any warnings or

cautions.

Power

The system power supplies contain LETHAL

VOLTAGES greatly in excess of the mains

voltage and its rails can produce extremely large

currents that could burn out equipment and

wiring if shorted.

The internal power supplies are of the switch

mode type that automatically sense the

incoming mains voltage and will work where the

nominal voltage is in the range 100VAC to

240VAC.

Each mains inlet is to be sourced from its own

separate wall-mounted mains outlet socket.

Otherwise, their mains sources must be suitably

distributed so as to meet local safety

regulations.

During operation, a minimum of two of its three

mains inlets must be connected and supplying

power.

When removing the equipment’s electric plugs

from the outlets, always hold the plug itself and

not the cable. Pulling out the plug by the cable

can damage it.

Never insert or remove an electric plug with wet

hands.

Do not connect/disconnect a mains power

connector to/from the PRO6 Control Centre

while power is being applied to it. Switch the

power off first.

Before switching the PRO6 Control Centre on or

off, make sure that all monitor loudspeaker

power amplifiers are turned off or muted.

Handling the equipment

Completely isolate the equipment electrically

and disconnect all cables from the equipment

before moving it.

When lifting or moving the equipment, always

take its size and weight into consideration. Use

suitable lifting equipment or transporting gear,

or sufficient additional personnel.

Do not insert your fingers or hand in any gaps or

openings on the equipment, for example, vents.

Do not press or rub on the sensitive surface of

the GUI screens.

If the glass of the GUI screen is broken, liquid

crystals shouldn’t leak through the break due to

the surface tension of the thin layer and the

type of construction of the LCD panel. However,

in the unlikely event that you do make contact

with this substance, wash it out with soap.

Page 10

x Precautions

PRO6 Control Centre

Quick Reference Guide

Installation

Before installing the equipment:

• Make sure the equipment is correctly

connected to the protective earth conductor

of the mains voltage supply of the system

installation through the mains leads.

• Power to the equipment must be via a fused

spur(s).

• Power plugs must be inserted in socket

outlets provided with protective earth

contacts. The electrical supply at the socket

outlets must provide appropriate

over-current protection.

• Both the mains supply and the quality of

earthing must be adequate for the

equipment.

• Before connecting up the equipment, check

that the mains power supply voltage rating

corresponds with the local mains power

supply. The rating of the mains power supply

voltage is printed on the equipment.

Location

Ideally a cool area is preferred, away from

power distribution equipment or other potential

sources of interference.

Do not install the equipment in places of poor

ventilation.

Do not install this equipment in a location

subjected to excessive heat, dust or mechanical

vibration. Allow for adequate ventilation around

the equipment, making sure that its fans and

vents are not obstructed. Whenever possible,

keep the equipment out of direct sunlight.

Do not place the equipment in an unstable

condition where it might accidentally fall over.

Make sure that the mains voltage and fuse

rating information of the equipment will be

visible after installation.

Audio connections

To ensure the correct and reliable operation of

your equipment, only high quality, balanced,

screened, twisted pair audio cable should be

used.

XLR connector shells should be of metal

construction so that they provide a screen when

connected to the console and, where

appropriate, they should have Pin 1 connected

to the cable screen.

Radio frequency

interference—Class A

device

This equipment has been tested and found to

comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable

protection against harmful interference when

the equipment is operated in a commercial

environment. This equipment generates, uses,

and can radiate radio frequency energy and, if

not installed and used in accordance with the

instruction manual, may cause harmful

interference to radio communications.

Operation of this equipment in a residential area

is likely to cause harmful interference in which

case the user will be required to correct the

interference at his own expense.

Electric fields

Caution:

In accordance with Part 15 of the FCC

Rules & Regulations, “… changes or

modifications not expressly approved by

the party responsible for compliance could

void the user's authority to operate the

equipment.”

Should this product be used in an

electromagnetic field that is amplitude

modulated by an audio frequency signal (20Hz

to 20kHz), the signal to noise ratio may be

degraded. Degradation of up to 60dB at a

frequency corresponding to the modulation

signal may be experienced under extreme

conditions (3V/m, 90% modulation).

Safety equipment

Never remove, for example, covers, housings or

any other safety guards. Do not operate the

equipment or any of its parts if safety guards

are ineffective or their effectiveness has been

reduced.

Page 11

Precautions xi

PRO6 Control Centre

Quick Reference Guide

Optional equipment

Unless advised otherwise, optional equipment

must only be installed by service personnel and

in accordance with the appropriate assembly

and usage regulations.

Special accessories

To comply with part 15 of the FCC Rules, any

special accessories (that is, items that cannot be

readily obtained from multiple retail outlets)

supplied with this equipment must be used with

this equipment; do not use any alternatives as

they may not fulfil the RF requirement.

Page 12

xii Precautions

PRO6 Control Centre

Quick Reference Guide

Page 13

xiii

PRO6 Control Centre

Quick Reference Guide

Contents

Introduction

Chapter 1 Introducing The PRO6 . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview of the PRO6 Live Performance System . . . . . . . . . . . . . . . . . 3

System components (standard supply) . . . . . . . . . . . . . . . . . . . . . . . . 4

About this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2 About The PRO6 Control Centre . . . . . . . . . . . . . . . . . .5

Overview of the PRO6 Control Centre . . . . . . . . . . . . . . . . . . . . . . . . . 5

Bay and GUI layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

PRO6 control surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Front panel connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rear panel connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operation

Chapter 3 Working With The PRO6 Control Centre . . . . . . . . . .13

Basic GUI operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operating the GUI screen controls . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Using the GUI menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Text editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 4 Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

An introduction to PRO6 navigation . . . . . . . . . . . . . . . . . . . . . . . . . 17

About the navigational controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

About the navigation ‘select’ sections . . . . . . . . . . . . . . . . . . . . . . . . 19

How to navigate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Chapter 5 Patching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Function buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

About the patching procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Configuring the devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Configuring the PRO6 with the snake type . . . . . . . . . . . . . . . . . . . . . 27

Setting up the I/O rack devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

How to patch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Chapter 6 Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Principles of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Hints and tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Saving your work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Page 14

xiv Contents

PRO6 Control Centre

Quick Reference Guide

Setting a mic amplifier’s input gain . . . . . . . . . . . . . . . . . . . . . . . . . .34

Setting the high and low pass filters . . . . . . . . . . . . . . . . . . . . . . . . .35

Input equalisation (E zone) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Input dynamics processing (D zone) . . . . . . . . . . . . . . . . . . . . . . . . .37

Using VCA/POP groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Setting up a mix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Setting up the effects rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Simple routing to master stereo outputs . . . . . . . . . . . . . . . . . . . . . .46

Scene and show management (automation) . . . . . . . . . . . . . . . . . . . .46

Configuring the inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . .51

Using copy and paste . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Surround panning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Two-man operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Saving your show files to USB memory stick . . . . . . . . . . . . . . . . . . .55

Connecting And Setting Up The System

Chapter 7 Setting Up The System . . . . . . . . . . . . . . . . . . . . . . . 59

Initial set-up procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Unpacking the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Making up a rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Wiring instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Powering the PRO6 system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Switching the PRO6 Control Centre on/off . . . . . . . . . . . . . . . . . . . . .62

Setting up the DL351 Modular I/O unit ID . . . . . . . . . . . . . . . . . . . . .64

Appendices

Appendix A Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

No audio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Swapping the active master controller . . . . . . . . . . . . . . . . . . . . . . . .68

Page 15

PRO6 Control Centre

Quick Reference Guide

Volume 1:Introduction

Page 16

Page 17

3

PRO6 Control Centre

Quick Reference Guide

Chapter 1: Introducing The PRO6

Welcome to the PRO6 Control Centre. The PRO6 Control Centre is a user-friendly,

state-of-the-art, high performance digital console specifically designed for live use.

The PRO6 Control Centre, which forms an integral part of the PRO6 Live Performance

System, was conceived by Midas to offer audio professionals high-performance audio

equipment, designed to provide no-compromise sonic quality with a feature set that

offers all essential facilities and functions. It represents the very best of British design

and engineering combined with contemporary, efficient manufacturing methods, and

will give you many years of reliable service.

So, to obtain the best results with a minimum of effort, please read this Quick

Reference Guide and, finally, enjoy your Midas PRO6 Live Performance System!

Overview of the PRO6 Live Performance System

The PRO6 Live Performance System is a very powerful and flexible audio processing

system that provides a complete solution for any audio mixing and signal distribution

application in a live sound environment.

Despite its compact size the standard PRO6 offers 56 channel inputs, eight returns, 41

buses (16 auxes, 16 matrices, three masters and six solos), eight on-board effects

processors, PEQs (four-band on inputs and six-band on outputs), eight standard (up to

36 maximum) 31-band GEQs, eight configurable stereo effects

1

, 5.1 surround panning

and comprehensive, easy-to-use routing. PRO6 automation provides up to 1,000

scenes with snapshot save/recall capability and global edit, and show file archiving.

The PRO6 Control Centre forms the core of the PRO6 Live Performance System, which

also includes two 19” rack units — a DL351 Modular I/O (7U) and a DL371 DSP (7U) —

that are interconnected by a networked data system. The network carries both

proprietary control data and open architecture AES50 digital audio, and uses readily

available standard cabling and connectors. The PRO6 uses a proven stable Linux

operating system. All of the console’s internal and network routing (“patching”) is

managed via the graphical user interface (GUI).

Operation of the control surface is intuitive, unique and easy. Its layout is based on

familiar analogue lines to retain that ‘analogue’ feel. To manage the numerous

channels, the PRO6 Control Centre utilises VCA/POP groups and colours, and

additionally there are various navigational controls that aid quick channel/bus access

and selection. A daylight-viewable GUI at the top of the control surface assists

operation and provides extra functionality.

The PRO6 Live Performance System is tolerant of many types of hardware or software

failure. To achieve this the system employs dual redundancy, where a key component

has an identical redundant spare that is ready to take over should it fail. Other failure

scenarios are managed by the N+1 principle, where redundant components form an

acceptable fraction of the system.

The Klark Teknik DN9696 Recorder can be used with the PRO6 Live Performance

System for live multi-track recording and ‘virtual’ sound check. Optional equipment

includes the XL8 DL451 I/O and DL431 splitter, and the DN9331 RapidE for remote GEQ

operation.

1. Each can be configured to generate four additional GEQs, making a total of 36 available on the console

(plus one stereo effect).

Page 18

4 Chapter 1: Introducing The PRO6

PRO6 Control Centre

Quick Reference Guide

System components (standard supply)

The PRO6 Live Performance System is modular, allowing for some variations in physical

placement and system size. The standard PRO6 package touring system is configured

as a 14U rack (containing two DL3n1 units) in a single, easily portable flight case, with

an equally portable, flight-cased control surface and minimal cabling. This package

comprises:

• 1-off PRO6 Control Centre (in a flight case). Its user-configurable modular I/O rack

(rear panel) will be populated with the following modules (from top to bottom):

• DL443 analogue Jack I/O module, providing eight Jack line inputs and eight Jack

line outputs.

• DL441 analogue input (mic) module, providing eight balanced mic/line inputs.

• DL452 digital (AES3) I/O module, providing four stereo AES/EBU inputs and

outputs.

• 1-off main 14U rack (in a flight case), which houses:

• 1-off DL351 Modular I/O. This is populated with seven DL441 analogue input

modules (56 main inputs) and a DL442 analogue output module. There are a

total of 64-off XLR mic/line inputs provided on the system.

• 1-off DL371 DSP. This is populated with five cards, the two empty slots being

blanked off.

• 4-off interconnecting (N+1) rack cat5E copper cables.

• 2-off interconnecting (dual redundant) gigabit HyperMac Cat5E copper cables,

each 100 m long.

• 8-off mains cables.

About this guide

This is the Quick Reference Guide for the PRO6 Control Centre. Its purpose is to quickly

familiarise the user with the PRO6 Control Centre, show how to set up the PRO6 Live

Performance System and then show how to carry out some basic operations on the

PRO6 Control Centre in order to produce some audio. This guide is structured such that

it may also provide a useful introductory guide for training purposes.

This document is aimed at professionals, such as front of house (FOH) and monitor

(MON) engineers, who will be using this equipment in a live performance environment.

It is assumed that the reader has prior experience of using professional audio

equipment and has, most likely, undergone training on this system.

This guide has been structured specifically so that mix engineers and system

technicians can go straight to the areas applicable to them, that is, “Operation” on

page 11 and “Connecting And Setting Up The System” on page 57, respectively. The

rest of the guide is intended for general readership.

For full details on the PRO6 Live Performance System and the PRO6 Control Centre,

refer to the PRO6 Live Performance System Owner’s Manual (part number DOC02-DL3),

which can be found on our website at www.midasconsoles.com.

Note: The content of this guide does not supersede any information supplied with any

other item of the PRO6 Live Performance System.

Page 19

5

PRO6 Control Centre

Quick Reference Guide

Chapter 2: About The PRO6 Control

Centre

This chapter introduces you to the PRO6 Control Centre and provides a brief hardware

description.

Overview of the PRO6 Control Centre

The PRO6 Control Centre has a combined control surface and GUI that provide an array

of easy-to-use controls for the precise manipulation of audio.

The PRO6 Control Centre is of modular construction and is built on a robust Midas steel

frame chassis similar to those used for established Midas analogue products. The frame

houses three full size bays with a smaller one on the right. All of the bays are

controlled from a single processor and, collectively, provide the primary mixing needs

of the engineer.

All associated power supplies, computer motherboards, memory, graphics cards etc.

are housed within the PRO6 Control Centre, which also contains a digital audio router

box that supports local FOH (insert) I/O connectors on the rear panel. Substantial

forced air-cooling is provided by a bulkhead and large (but slow moving) internal fans.

These produce very low noise, suitable for seated areas theatres and concert sound.

Externally, the PRO6 Control Centre has three main areas: control surface, GUI and

rear panel. The control surface is populated with instantly recognisable controls that

are logically distributed in major sections. The GUI, which comprises two screens at the

top of the centre bays, enhances operation by providing visual representations of the

control surface and also gives you extra functionality. The rear panel provides all of the

console and network connectivity, and houses the mains power sockets and isolator

switch.

Being of modular design, the overall form and shape of the PRO6 is similar to Midas’

flagship XL8. The PRO6 is split into bays, each one containing a flat fader tray and

shallow raked control area. The centre bays also have a third area that houses a

steep-raked display screen.

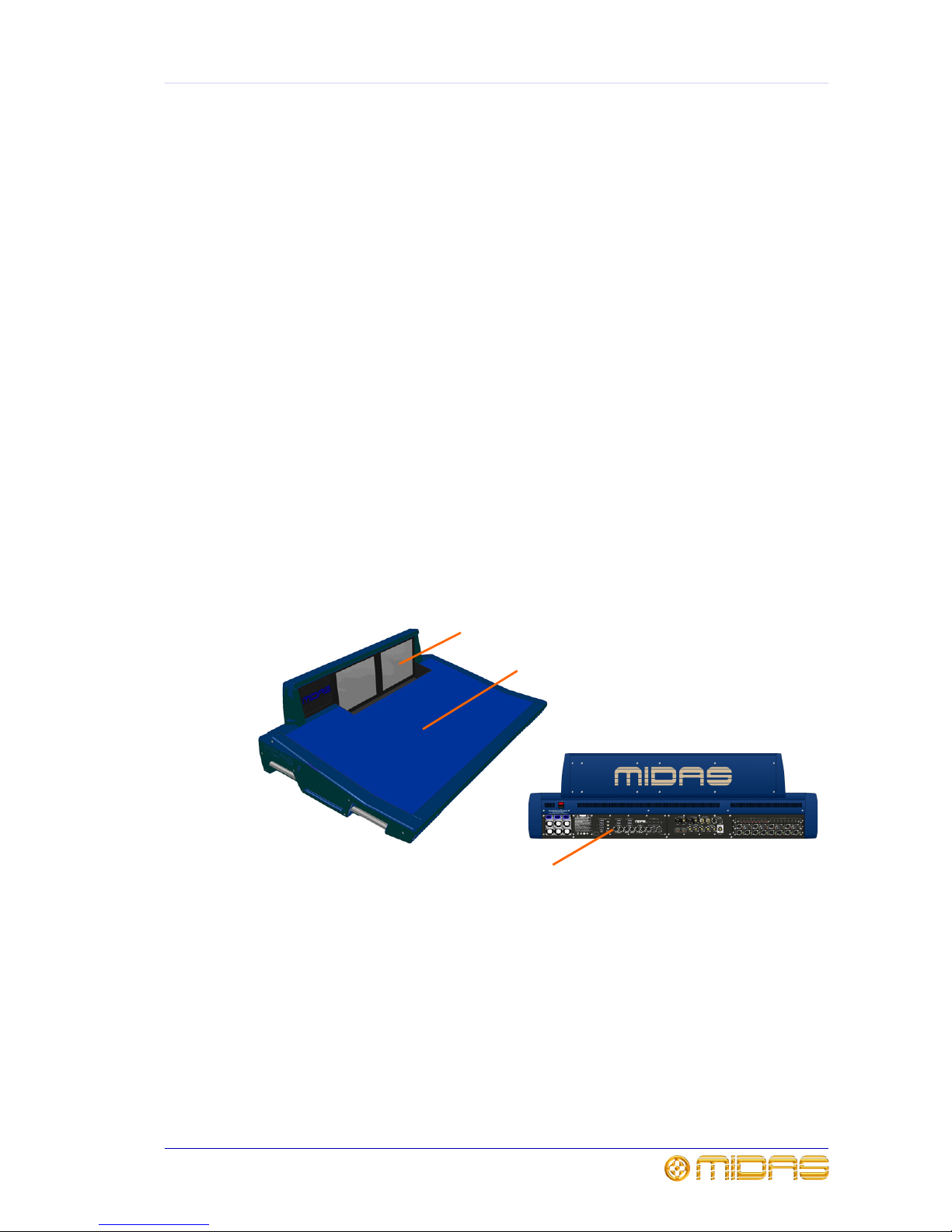

GUI screens

Control surface

Connector panel

Rear view

Page 20

6 Chapter 2: About The PRO6 Control Centre

PRO6 Control Centre

Quick Reference Guide

Multiple hardware fault types are tolerated by the PRO6 Control Centre without loss of

audio control due to the dual redundancy and N+1 methods incorporated in the system.

This is further helped by the modular nature of the bays and GUI independence. Either

of the GUI screens can be used to operate the whole PRO6 Control Centre, even if none

of the control surface hardware is working. The unit offers the facility of universal

input, N+1 redundant power supplies with three latching mains connectors.

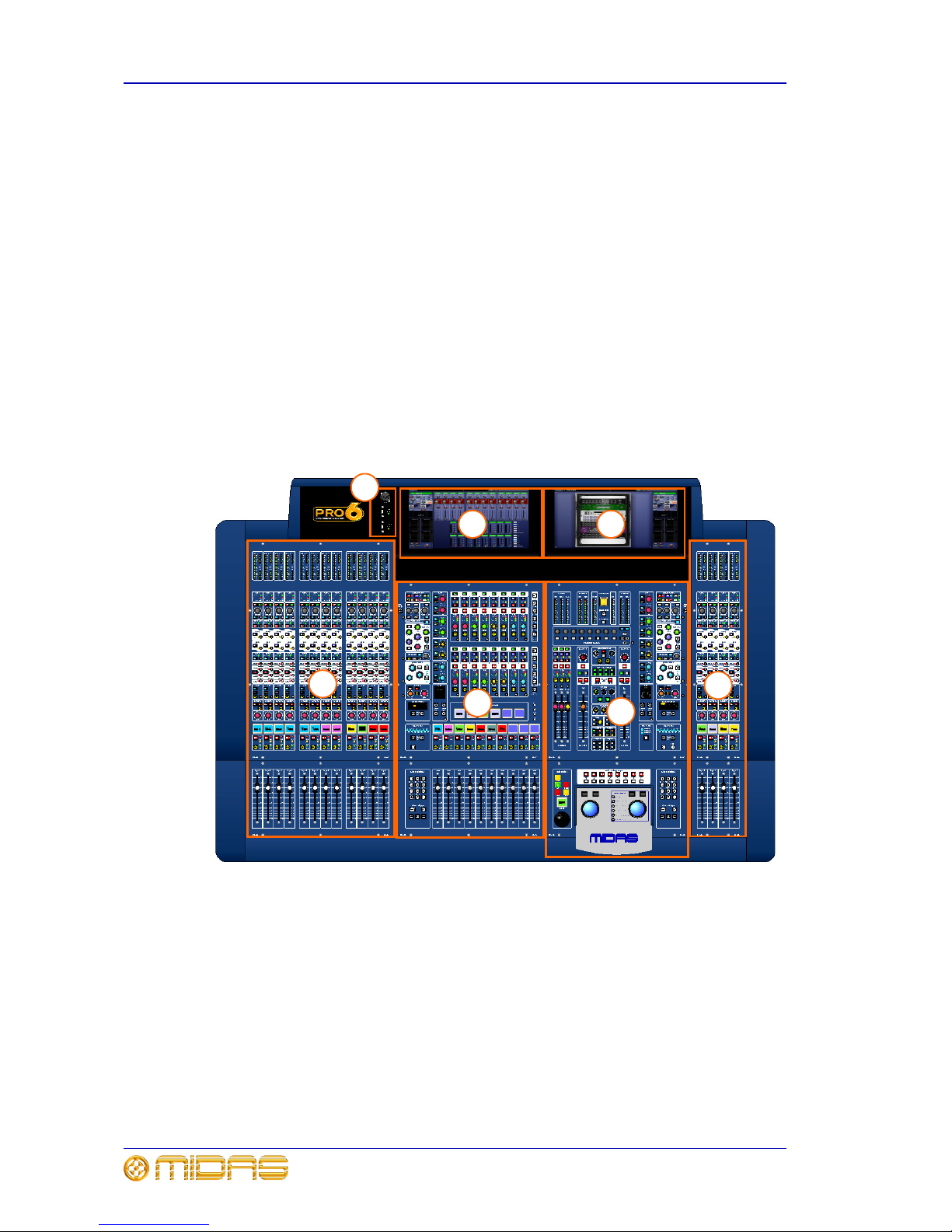

Bay and GUI layout

The PRO6 Control Centre has four discrete bays that house the following control surface

controls:

• Input bays (12-channel and 4-channel) — two input bays provide fast access to

input faders and important signal processing controls.

• Mix bay — provides access to outputs and groups, a detailed processing controller

(all channels) and navigational controls.

• Master bay — provides access to the master output mixes, monitor (A and B)

faders, automation, comms control, assignable effects control, and another set of

detailed processing and navigational controls.

Figure 1: Bay and GUI layout

Two GUI display screens at the top of the central bays provide extensive screen support

(standard configuration) and extra functionality for the channels and buses. For

example, when mixing or processing. They also facilitate the use of the GUI menu,

which gives you access to the many powerful features of the PRO6, such as patching,

effects, GEQs, diagnostics etc.

6

1

2

5

3

4

1 Input bay (12-channel).

2 Mix bay.

3 Master bay.

4 Input bay (4-channel).

5 Mix bay GUI screen.

6 Master bay GUI screen.

7 Talk mic and USB

connectors.

7

Page 21

PRO6 control surface 7

PRO6 Control Centre

Quick Reference Guide

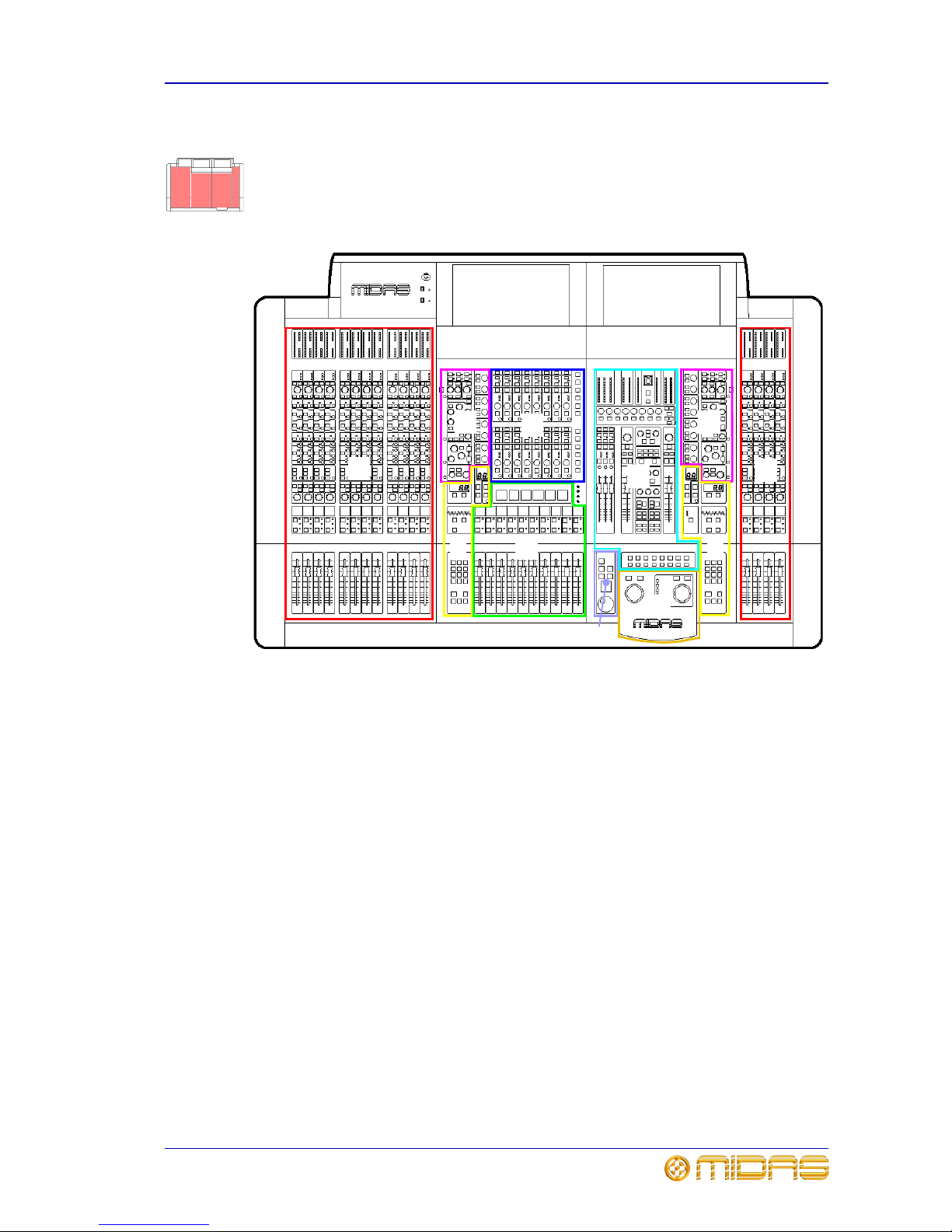

PRO6 control surface

The control surface of the PRO6 Control Centre is divided into areas (see Figure 2)

whose function is, largely, dependent on bay location. Each bay has assorted control

elements with local feedback and/or support from the two centrally located GUI display

screens. The screens can be remoted via external VGA connections, and third party

systems can also be viewed/controlled via an integrated KVM switch on the rear panel.

Figure 2: Main areas of the control surface

A A

B

D

E

G

H

A — input fast zone: 16 input fast

strips across the 12-channel and

4-channel input bays provide the

operator’s ‘must have now’ controls.

B — channel strip and mixes:

processing areas, such as the D-zone

(dynamic), E-zone (EQ) and mix controls,

provide a more comprehensive control by

allowing detailed adjustments to a single

channel’s audio parameters.

C — channel and bus navigation

zone: sections for channel and bus

navigation and selection. For details, see

Chapter 4 “Navigation”.

D — output fast zone: 16 output fast

strips can be used for mixing and

processing aux, return, matrix and

master channels. Navigation and flip

buttons are on the right of the output fast

strips.

E — VCA and POP groups: VCA faders

and POP group sections.

F — miscellaneous: master fast strips,

A and B signal path monitoring,

communications, I-zone, surround

monitoring and mute groups.

G — primary navigation zone:

trackballs for mix and master bay GUI

screen control, and a screen access panel

(between trackballs) for direct access to

GUI menu options.

H — automation: scene store/recall

and system edit.

C

C

F

B

Page 22

8 Chapter 2: About The PRO6 Control Centre

PRO6 Control Centre

Quick Reference Guide

During show time the screen functions that require fast access are controlled by control

knobs, pushbutton switches, faders etc. More complex functions that do not require

this fast access are controlled by the trackballs and navigational keys. A keyboard

integral to the flight case is used for text entry via the master bay GUI screen. An

external USB keyboard can be used to operate the mix bay GUI screen.

The choice of controls provided by each bay type are prioritised by access time

importance. Fast zone areas, which contain fast strips, give instant access to specific

functions across the bay and channel strips give greater control of the selected fast

strip.

GUI

The GUI comprises two screens that provide a pictorial representation of the control

surface layout so that its displays are easy to follow at a glance. Not only does it reflect

what is happening on the control surface, but it also provides extra functionality via a

GUI menu. This menu provides access to all the screens that you will require to set up,

configure, manage and operate the entire PRO6 Control Centre, all from a single dropdown list of easy to follow options.

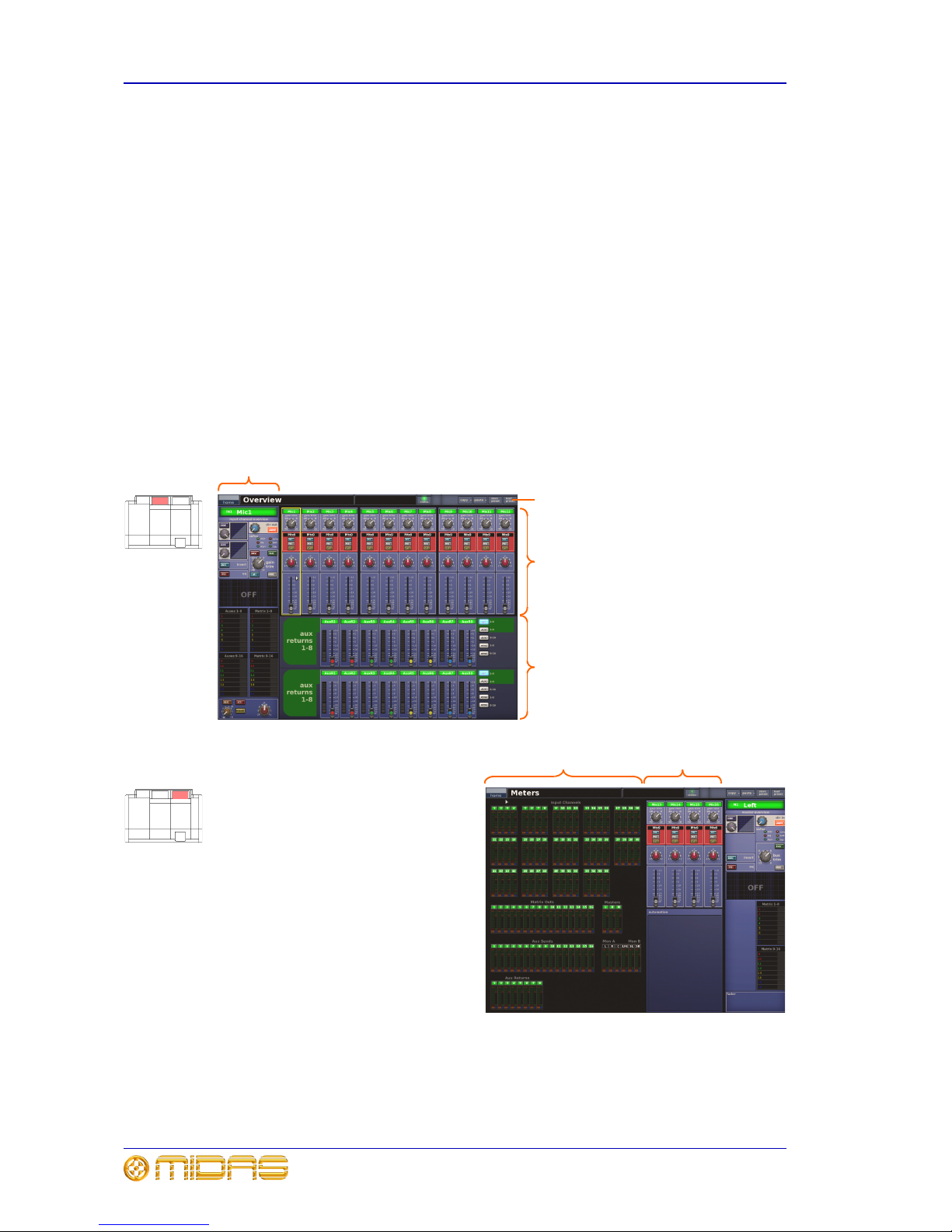

Figure 3: Layout of the GUI screens

Channel

strip

Overview screen

(mix bay GUI screen)

InputsOutputs

All meters display

Inputs and

automation

summary

Meters screen

(master bay GUI screen)

Banner

Page 23

Front panel connections 9

PRO6 Control Centre

Quick Reference Guide

Each GUI screen has its own default display (Overview and Meters as shown in

Figure 3), although either is selectable via the GUI main menu. The Overview screen

displays 12 inputs and two sets of eight outputs, and the Meters screen shows all the

meters, four inputs and a summary of the automation. Both screens have a banner at

the top, which is constantly displayed, and a channel strip down the outermost side.

The channel strips have a similar function to the ones on the control surface (see

Figure 2 on page 7), but provide extra functionality. Each displays an ‘overview’ of the

associated selected channel, which is divided into specific sections that provide access

to processing areas.

Front panel connections

The panel to the left of the mix bay GUI screen (item 7 in Figure 1) has an XLR socket

and two USB sockets for connecting a talk mic and USB devices, respectively. For

example, you can connect a USB memory stick for show file backup and transfer, or a

USB keyboard for text editing on the GUI.

Rear panel connections

A connector panel on the rear of the PRO6 Control Centre has three main sections (see

below). On the left are three mains power inlet and ventilation assemblies, with a

DC power switch above. The mid-section contains connections for the audio, network,

communications, intercoms, synchronisation, external remote devices and peripheral

devices. The section on the right is the user-configurable modular I/O section.

The modular I/O section can house up to three of any of the following I/O modules in

any combination: DL441 analogue input module; DL442 analogue output module;

DL443 analogue insert input/output module; and DL452 digital in/out (AES/EBU)

module. This gives a maximum of 24 inputs and 24 outputs, if the appropriate cards

are fitted. The following diagram shows the standard I/O module configuration in which

the DL443 (top), DL441 (middle) and DL452 (bottom) are fitted.

Mains power

and ventilation

Audio, control

and networking

I/O

Page 24

10 Chapter 2: About The PRO6 Control Centre

PRO6 Control Centre

Quick Reference Guide

Page 25

PRO6 Control Centre

Quick Reference Guide

Volume 1:Operation

Page 26

Page 27

13

PRO6 Control Centre

Quick Reference Guide

Chapter 3: Working With The PRO6

Control Centre

Although many controls on the PRO6 Control Centre are similar to their equivalent

analogue-type counterparts, some have been specifically designed for the PRO6,

particularly those for navigation and GUI operation. As you will probably have had

experience on analogue consoles, you will already be familiar with most of the PRO6

controls and their operation. Therefore, this chapter only deals with the GUI controls

that may be new to you.

The navigational controls, such as quick access buttons and scroll buttons, are

described in Chapter 4 "Navigation" on page 17, and the ones specifically for

automation can be found in “Managing the scenes” on page 48.

Basic GUI operation

This section explains the basic procedures you can perform at the GUI screens. In

general, you will control and operate the GUI by combining the operations described

here.

Figure 4: Controlling the GUI

Each trackball controls the movement of a pointer on its respective GUI screen (see

Figure 4). The left trackball operates the mix bay GUI screen and the right one

operates the GUI screen in the master bay. Each trackball has two buttons, which have

similar functionality to the buttons on PC/laptop mouse. The left button is used in click

and drag operations, while the right button is generally used for editing and finer

control operations.

>> To operate a trackball

Rotate it by placing a finger on it and then moving your finger. The on-screen pointer

will move accordingly.

Trackball

Left trackball button

Right trackball button

Page 28

14 Chapter 3: Working With The PRO6 Control Centre

PRO6 Control Centre

Quick Reference Guide

Click

Moving the pointer to a specific point of the GUI screen and pressing the left button is

called “clicking”. This is fundamental to GUI operation and forms the basis of many of

its operations, such as switching a button on/off, selecting list and menu items, text

editing etc. Doing the same with the right button is called “right-clicking”.

Drag

Moving the pointer to a specific point of the GUI screen and then pressing the left

button while moving the pointer up/down/left/right is called “dragging”. Dragging is

used mainly to adjust control knobs and faders, and to move sliders (attached to

drop-down lists)—although it is also used to select blocks of connectors when patching.

The pointer disappears when the control has been selected to show that it is ready for

adjustment.

Operating the GUI screen controls

This section shows you how operate GUI screen elements, such as buttons, control

knobs, drop-down lists and sliders.

>> To switch a GUI button on/off

Click the button. If it has a status indicator, this will illuminate/extinguish to show that

it is on/off, respectively.

>> To adjust a GUI control knob or fader

Use a drag operation. Move the pointer up/down/left/right for adjustment.

>> To select an option from a drop-down list

1 Click the drop-down arrow. The drop-down list

will unfold to display some or all of its contents,

depending on how many items it contains.

2 Do one of the following:

• Click the option you require.

• If necessary, scroll the list (see “To scroll a

drop-down list” below) to display the option, and then click it.

>> To scroll a drop-down list

With the drop-down list displayed, do one

of the following:

• A. Drag the scroll box.

• B. Click the scroll bar. The scroll box

will ‘jump’ in the direction of the click

to another position in the scroll bar.

• C. Click an up/down scroll arrow. The

scroll box will ‘jump’ in the direction of

the scroll arrow to another scroll bar

position. Clicking a scroll arrow when

the scroll box is adjacent to it has no

effect.

Drop-down

arrow

Currently selected

list item

Scroll arrow

Scroll bar

Scroll box

B

C

A

Page 29

Using the GUI menu 15

PRO6 Control Centre

Quick Reference Guide

Using the GUI menu

You can access the GUI main menu by clicking the home button, which is constantly

displayed at the upper-left corner of both GUI screens. Menu options with an arrow on

the right have a submenu. The background colour of a menu option will be blue when it

is available for selection.

Throughout this guide, menu/submenu option selection sequences are shown in the

following format (for example, for choosing the general preferences screen):

home

PreferencesGeneral

>> To access the GUI main menu

Click home.

>> To select a GUI menu option

Click the menu option, for example, Monitors. The background of the menu option will

change to blue when it is ready for selection.

>> To access the submenu of a GUI menu option

Move the pointer over the arrow on the right of the menu option. The submenu will

appear automatically to the right of the arrow. Click an option in the submenu to select

that option.

GUI main

menu

Right arrow

shows that the

option has a

submenu

Page 30

16 Chapter 3: Working With The PRO6 Control Centre

PRO6 Control Centre

Quick Reference Guide

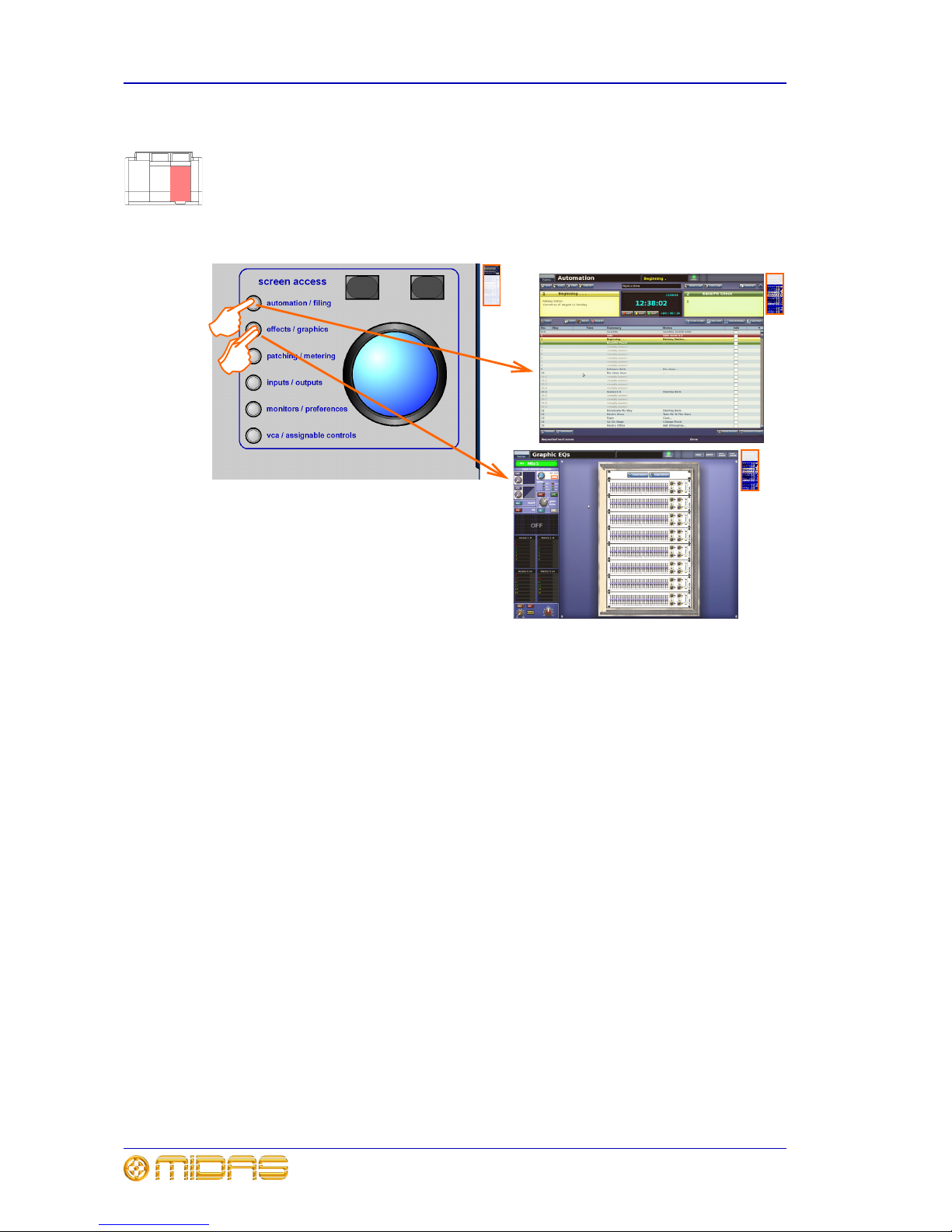

Accessing a GUI menu screen using the screen access buttons

You can access some of the GUI menu screens simply by pressing a button, instead of

using the GUI menu. This is done by using the screen access buttons in the primary

navigation zone. Each button provides direct access to two screens, the title of which

are printed next to the button. The first screen mentioned is accessed by a single

button press, while the next is accessed by a double press. An example of each is

shown in the following diagram.

Text editing

A keyboard is used to type in text on the GUI, for example, to configure input and

output channel names. Editable text on the GUI is contained in text boxes, which

generally consist of a single line of limited length. Although all text editing can be done

using the normal keyboard functions, the GUI can be used to assist you, for example,

by highlighting portions of text (using drag).

>> To enter/edit text via the keyboard

1 At the GUI, click in the text box to place an insertion point in it. The pointer will

change to an I-beam shape.

2 Using the keyboard, type in the new text. If the text box already contains some

text, you can delete this first or edit it, which can be done via the keyboard or by

using the cut, copy and paste options after right-clicking.

3 Press Enter on the keyboard to exit the text box (or click on an empty area of the

GUI screen). The pointer’s shape will change back to an arrow.

Page 31

17

PRO6 Control Centre

Quick Reference Guide

Chapter 4: Navigation

This chapter introduces you to PRO6 navigation and shows you how to use the

navigational tools of the PRO6 Control Centre.

For information on navigating the scenes in automation, refer to “Managing the scenes”

on page 48.

An introduction to PRO6 navigation

The PRO6 provides you with unique navigational controls to quickly and easily access

the items, such as channels, buses, groups and processing areas, that you will require

for mixing.

Navigation is an important feature of the PRO6 Control Centre. One of the advantages

digital consoles have over analogue ones is that their channel count is not limited by

the control surface hardware. However, this means that only a certain amount of

channels can be at the control surface at any time, while the others are ‘hidden’. So,

navigation is required to access these hidden channels whenever you need them.

The way the PRO6 is set to operate may alter the function of some of the navigational

controls. For more information, see “Operating modes” on page 31.

How the input channels are managed

To aid navigation the 56 input channels are grouped into 14 ‘banks’ of four channels

each. The banks contain the following consecutively numbered channels: 1 — 4,

5 — 8, 9 — 12 etc., up to 53 — 56. (Figure 5 shows the number of consoles required to

show all of the available inputs simultaneously.)

Figure 5: All inputs

During normal operation, four banks of input channels populate the input bays (see

Figure 6 “Input channels in the input bays” on page 18). These are displayed across

the control surface in ascending order from left to right.

Note: The rigid bank (four-channel) structure does not apply to groups, as their

contents are dependent on what channels are selected as group members.

1-12 13-16 17-28 28-32 33-44 45-48 49-56

Page 32

18 Chapter 4: Navigation

PRO6 Control Centre

Quick Reference Guide

Figure 6: Input channels in the input bays

About the navigational controls

The PRO6 navigational controls can be broadly divided into two main areas: those that

operate the channels currently populating the control surface (quick access buttons and

LCD select buttons) and the ones that navigate channels to/from the control surface

(scroll buttons and output select buttons)—although there may be some overlapping.

Quick access buttons

Quick access buttons help you to quickly select the channel, mix bus or processing area

you want. The buttons, which are round and translucent, illuminate (blue) when active.

The quick access buttons in fast strips select their local channel and assign their local

processing area to the associated channel strip. The ones in the channel strips select

their local processing area, but don’t affect channel selection.

LCD select buttons

LCD select buttons select their local input channel/group (VCA/POP). The buttons are

square and have an LCD display, which can be backlit. The display provides useful

feedback by showing you information, such as channel/group name, and by identifying

the group from the user-configured backlight colour. When selected, the display

changes to a ‘negative’ image.

For more information on how to use the group LCD select buttons, see “Using VCA/POP

groups” on page 39.

Scroll buttons

You can scroll through the channels/mixes by using the pairs of scroll buttons located in

the ‘select’ sections of the mix and master bays (see Figure 7 on page 20). The

direction of scrolling matches the analogue convention, where channels are left/right

and mixes are up/down. The buttons are translucent and have a blue backlight that

illuminates when pressed.

The scrolling action of the buttons (or the number of channels/buses scrolled per press)

varies according to their location. For more details, see “About the navigation ‘select’

sections” on page 19.

Output select buttons

The output select buttons navigate their associated bank of outputs to the control

surface. The buttons are translucent and have a blue backlight that illuminates when

pressed; the backlight stays on to show you which bank of outputs is currently

populating the control surface.

Three banks of four

input channels each

(12 channels in total),

which are also shown

on mix bay GUI screen

A single bank of four

input channels,

which are also shown

on master bay GUI

screen

Page 33

About the navigation ‘select’ sections 19

PRO6 Control Centre

Quick Reference Guide

Channel select (lower) and channel type sections

The Channel select (lower) and channel type sections are used in combination to

navigate a single channel to the control surface, which is generally used for rectifying a

fault on a problem channel.

ALIGN button

The ALIGN button (both input select sections) navigates the currently selected

channel to the local input bay. This is useful, for example, if you have scrolled away

from the selected channel on the control surface and you want to get the fader back.

B button

The B button (master bay input select section only) assigns the 4-channel input bay

as area B. This operates with the channel strip on the right (in the master bay).

Right arrow (to right channel) button

The right arrow (to right channel) button — to the right of the top output select

buttons — assigns the channel strip, navigation controls and sends in the master bay to

the top row of outputs.

About the navigation ‘select’ sections

The ‘select’ sections in the mix and master bays (see Figure 7 on page 20) are used for

navigating the channels and mixes, and also show you which ones are currently

selected. They have the following functions:

• channel select (upper) section — scrolls either the input or output fast strips

(depending on selected channel type) channel-by-channel. Current channel

selection follows the scroll, which is shown on the section’s display, along with the

channel type.

• input select section — scrolls the inputs in banks (of four). Shows you which banks

of inputs currently populate the control surface by illuminating the appropriate bank

LEDs. When using VCA/POP groups, an LED will flash if its bank contains a

channel(s) that are members of the selected group, but don’t currently populate the

control surface. This section also has an ALIGN button and a B button (master bay

only).

• mix section — scrolls the mix buses singly or in banks of eight. Shows you the you

the number and type (aux or matrix) of the currently select mix bus. The quick

access button assigns the currently selected mix bus to the channel strip.

• channel select (lower) and channel type sections — see “Channel select (lower)

and channel type sections” above.

How to navigate

This section shows you how to navigate the channels, mixes and groups, and how to

select the ones you want. Refer to Figure 7 “Location of the navigational controls on

the control surface” on page 20 throughout this section.

In many cases there are a number of navigational methods you can choose from to

carry out a particular task. Some may be more suitable than others in a given situation

and there may even be a combination of methods you an use. Experience should guide

you to the most appropriate and the ones you most prefer.

Page 34

20 Chapter 4: Navigation

PRO6 Control Centre

Quick Reference Guide

Figure 7: Location of the navigational controls on the control surface

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

2

1

1

1

5

3

3

3

2

3

4

Key:

1 Quick access buttons

2 LCD select buttons

3 Scroll buttons

4 ALIGN button

5 Output select buttons

6 Right arrow button

7 FLIP button

A Input fast strip

B Channel strip

C channel select

(upper) section

D input select section

E channel select

(lower) section

F channel type section

G mix section

H VCA group strip

I Output fast strip

J population groups

(POP groups) section

K Master fast strips

Note: Items A to G are replicated on the far right side of

the control surface, although the master bay’s input

select section also has an area B button.

A

B

C

D

E

F

G

I

K

H

J

5

6

7

Page 35

How to navigate 21

PRO6 Control Centre

Quick Reference Guide

Switching between inputs and outputs

You can easily change from working with inputs to working with outputs, and vice

versa. To switch channel type, simply select any channel of the type you want to switch

to. The channel select (upper) section shows which type of channel is currently in

operation (and the channel number selected).

>> To change channel type

Do one of the following:

• Press a quick access button in a fast strip of the required channel type.

• To change to inputs from outputs, press an LCD select button in any input fast strip.

Navigating channels and mix buses to the control surface

There are a number of ways in which you can bring channels and mix buses to the

control surface, particularly using the scroll buttons.

>> To navigate a channel to the control surface

With the channel type you require currently in operation, do one of the following:

• Scroll to the channel using the scroll by 1 buttons in the channel select (upper)

section. This will also select the channel.

• If you are currently operating the inputs, scroll the bank containing the input

channel you require to the control surface using the scroll by 4 buttons in the input

select section.

• If you are currently operating the outputs, navigate the bank containing the output

channel you require to the control surface by pressing its output select button (in

either the top or bottom output fast strip sections).

>> To navigate an input channel to a fast strip on the control surface

Press ALIGN.

>> To navigate a mix bus to the control surface

Do one of the following:

• Scroll to the mix bus using the scroll by 1 buttons in the mix section. This will also

select the mix bus.

• Scroll the bank containing the mix bus you require (aux or matrix) to the control

surface using the scroll by 8 buttons in the sends section.

Selecting channels, mix buses and groups

There are a number of ways you can select a channel/mix bus from those currently

populating the control surface, particularly by using the quick access buttons.

>> To select an input channel

Do one of the following:

• Press its LCD select button.

• Press any of its quick access buttons. This will also assign the channel to the

channel strip and its processing area to the GUI channel strip.

Page 36

22 Chapter 4: Navigation

PRO6 Control Centre

Quick Reference Guide

• Scroll to the input channel using the scroll by 1 buttons in the channel select

(upper) section.

>> To select an output channel

Do one of the following:

• Press its quick access button. This will also assign the channel to the channel strip

(control surface and GUI).

• Scroll to the output channel using the scroll by 1 buttons in the channel select

(upper) section.

>> To select a mix bus

Scroll to the mix bus using the scroll by 1 buttons in the mix section.

>> To select a group

Press its LCD select button.

Navigating a processing area or mix bus to a channel strip

You may want a specific processing area assigned to a channel strip, for example, to

carry out processing or for copying to other channels. Or, you may want to carry out

detailed processing on the currently selected mix bus, but it may not necessarily be

assigned to its associated channel strip.

>> To navigate a processing area to a channel strip

Do one of the following:

• If its channel is already selected, press its quick access button in the channel strip.

This will also assign the channel to the channel strip (control surface and GUI).

• If its channel is at the control surface, but is not currently selected, press its quick

access button in the fast strip.

>> To navigate the selected mix bus to a channel strip

Press the quick access button in the mix section. This does not affect the current

population of the output fast zone.

Fault finding a problem channel

If you know the number of the channel that has a problem, you can quickly navigate it

to the control surface by typing in its channel type and number via the channel select

(lower) and channel type sections.

>> To navigate a channel using its number

1 In the channel type section, press the button corresponding to the channel’s

type. For example, if the channel is an input, press INPUT.

2 In the channel select (lower) section, type in the channel’s number. For

example, press 4 and then 7 for channel 47.

3 Press ENTER.

Page 37

23

PRO6 Control Centre

Quick Reference Guide

Chapter 5: Patching

This chapter describes the patching feature of the PRO6.

Introduction

Patching is a GUI-only feature that allows you to carry out all the routing requirements

of the PRO6. The GUI main menu has a Patching option that takes you to the

Patching screen (shown below), which contains all of the available patching connectors

on the PRO6. This screen provides an easy-to-use interface, where you can select your

source and destination patching options, facilitated by a panel of function buttons.

Additionally, the Patching screen allows you to set up the units (devices). For

example, you can adjust the analogue gain, select +48V phantom voltage etc., of the

line I/O units connected to the system.

1

1 Function button panel, contains the

function buttons that enable patching and

device configuration (see “Function buttons” on

page 24).

2 Patching area, contains all of the patch

connectors on tabs.

3 From section, has tabs that contain all of

the patch connector sources.

4 To section, has tabs that contain all of the

patch connector destinations.

5 Tab n am e s .

43

2

5

Page 38

24 Chapter 5: Patching

PRO6 Control Centre

Quick Reference Guide

>> To access the Patching screen

Do one of the following:

• At the GUI, choose home

Patching.

• Press the routing/metering button in the primary navigation zone.

• At the appropriate GUI screen, click the src (source) or dest (destination) button.

The Patching screen will open at the appropriate tab/configuration window.

Function buttons

The function buttons are described in Table 1 “Description of the function buttons”.

Click a function button to select it; its background colour will change to a lighter shade

when selected.

Table 1: Description of the function buttons

Button Description

Allows you to patch a single source to a single destination or multiple destinations.

See “Single patching (SINGLE)” on page 30.

Lets you select multiple sources and patch them one by one to their destinations. In

this method, each source can only have one destination. See “Sequence patching

(SEQ.)” on page 30.

Allows you to select a block of sources and patch them all automatically, simply by

selecting a single destination. Any existing patches within the destination range will

be replaced by the new ones.

Clears all currently selected patch connectors from all tabs in the From and To

sections. The green triangles will disappear accordingly.

Changes the tooltip type from standard to list, but is only available when carrying out

a sequence patching operating via the SEQ. button. The list tooltip, which has a

distinctive translucent orange background, appears in the To section when you are

patching the destinations of a number of selected sources. The list contains a queue

of sources waiting to be patched; the first in the queue is at the bottom of the list.

Sets a patching store point that contains the patching status at that instant. There is

only one checkpoint available, so each time CHECKPOINT is clicked the previous

checkpoint is overwritten.

Reverts patching status to the last checkpoint or, if no checkpoints have been

created, it will revert patching status to the power up condition. All patching done in

the intervening period will be lost.

Undoes the latest single patch, even if it was part of a multiple patching operation.

Repeated clicks will undo the preceding patching operations, going back to the last

checkpoint, or power up if no checkpoints have been created.

Redoes an undo. This can be repeated for each undo in the previous undo operation.

Clears all current selections and their patches.

Important:

Unlike the NONE button, which merely removes the current selections

(highlighted in yellow), CLEAR SEL. goes a step further by removing the

patch as well. This will stop any audio that may have been going through

the patched signal.

Page 39

About the patching procedure 25

PRO6 Control Centre

Quick Reference Guide

About the patching procedure

Although patching can be thought of as routing/rerouting the console’s incoming,

internal and outgoing signals, in the context of the Patching screen, patching also

encompasses the setting up and configuration of the stage and FOH rack I/O devices.

The patching procedure is initially carried out after system installation and comprises:

• Device configuration: Configure the devices by adjusting their parameters (see

“Configuring the devices” on page 25).

• Snake selection: Configure the PRO6 according the type of ‘snake’ you are using

for the X and Y networks (see “Configuring the PRO6 with the snake type” on

page 27). This is important, as the PRO6 Control Centre will not work unless

the snake type is correctly configured.

• Setting up the I/O rack devices: Set up the system devices, such as line I/O,

DN9696 and generic AES50, to the I/O tabs in the From and To sections of the

Patching screen (see “Setting up the I/O rack devices” on page 27).

• Patching: Carry out all of the required routing, for example, mics to input channels

(see “How to patch” on page 29).

Configuring the devices

You have the option to configure the devices from the Patching screen. Parameters,

such as gain and +48V phantom voltage, can be adjusted or switched on/off,

respectively via a device-specific configuration window.

These configuration settings can be independent of channel data, as (until patched)

they only control the physical unit. If a device is subsequently patched to one or more

channels, the channel(s) control the device, and vice-versa.

The device configuration area also allows control of audio parameters when the device

is used as a direct connection to another device, for example, FOH to stage via a digital

snake, instead of through the DSP. In this case the settings are also saved in the show

file and can be automated, even though the signals are not routed through the console

DSP.

Device configuration procedure

Although the procedure for configuring the devices is similar, their parameters are

dependent on device type. The procedure for configuring the devices of a similar type

involves:

• Opening the configuration window of the device.

• Selecting one of the device’s cards/channel ranges and configuring the available

parameters.

• Repeating for the other cards/channel ranges of the device.

Clears all patching.

Important:

Exercise great caution when using this function. Observe the warning that

appears after clicking this button.

Opens the input/output setup window, from where you can set up the I/O tabs in

the Patching screen (see “To add a device or change its set up” on page 28).

Button Description

Page 40

26 Chapter 5: Patching

PRO6 Control Centre

Quick Reference Guide

• Repeating for the other devices.

• Closing the device’s configuration window.

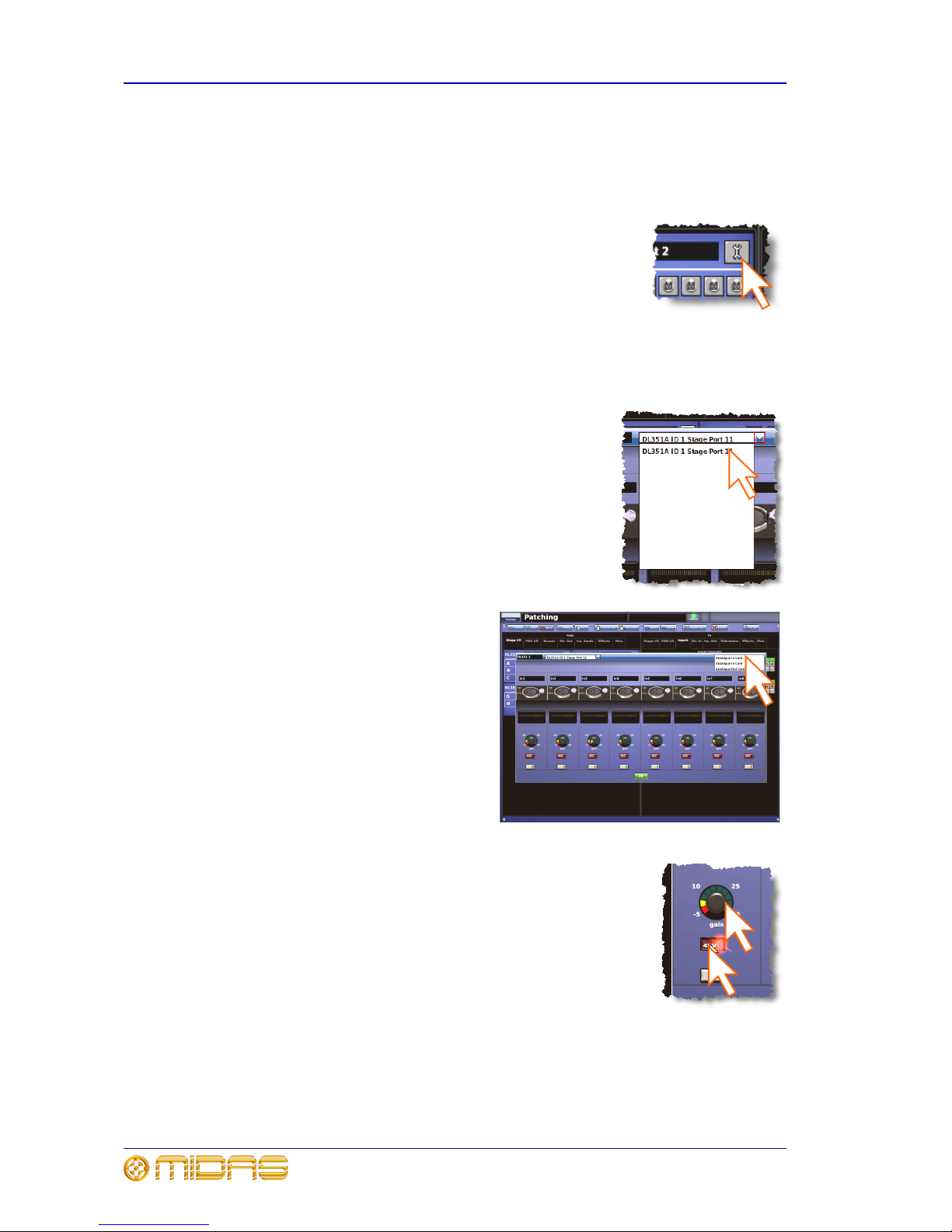

>> To open the configuration window of a device

Click the device’s spanner button.

>> To set up/change the configuration of an I/O device

1 Open the configuration window of the I/O device you want to configure (see “To

open the configuration window of a device” on page 26).

2 Select the I/O device from the drop-down list at the

top of the configuration window.

3 Select the card/channel you want to

configure/change, from the

drop-down list at the upper-right

corner of the configuration window.

For example, the “Analogue In

Card”.

4 In a channel, configure the parameters. For example, in

channel “In1”, adjust the gain and switch the +48V phantom

voltage on (shown right).

5 Repeat step 4 for the other channels in the card.

6 Repeat step 3 to step 5 for the other cards.

7 If you want, you can configure other I/O devices by

repeating step 2 to step 6. Otherwise, click OK (bottom of

configuration window) to save the configuration changes and

close the window.

Page 41

Configuring the PRO6 with the snake type 27

PRO6 Control Centre

Quick Reference Guide

Configuring the PRO6 with the snake type

Important:

The snakes must be correctly configured before operating the PRO6.

Otherwise it will not work.

You can connect the DL371 DSP to the PRO6 Control Centre with either copper or

fibre-optic snakes. The PRO6 needs to be configured with this information before

operation can begin. This is done via the GUI menu.

>> To configure the PRO6 with the snake type information

1 At the GUI, choose homePreferencesGeneral.

2 Under the Stage Link X heading, click the Fibre or

Copper option, according to whichever is fitted to the X

network. For example, click the Copper option (shown

right). A selected option will contain a red circle.

3 Repeat for the Y network, under the Stage Link Y

heading.

Setting up the I/O rack devices

You can add, remove and set up the devices, such as line I/Os, mic splitters, DN9696s

etc., that are connected to the Stage I/O and FOH I/O racks. This is done via the

input/output setup window. Here, you can set up the device ID and also the type of

cards (modules) fitted to the physical unit. Figure 8 “input/output setup window”

shows a typical example of what the input/output setup window looks like with one

of the DL351 devices selected. The options are context-sensitive, so some may be

blank, depending on the type of device.

The DL351 Modular I/O has four devices (A, B, C and D) per unit, and each one has its

own port. The four devices represent the following:

• DL351A - cards A, B and C.

• DL351B - cards D, E and F.

• DL351C - cards G and H.

• DL351D - redundant AES50 port.

Page 42

28 Chapter 5: Patching

PRO6 Control Centre

Quick Reference Guide

Figure 8: input/output setup window

>> To add a device or change its set up

1 Click SETUP (shown right) to open the input/

output setup window.

2 In the list of ports (far left in the

input/output setup window), click the port

you want to allocate the device to. For

example, “FOH Port 3 (unused)”. The text in

the device type: field will change accordingly. (A port that has no device

allocated to it will have the text “(unused)” after its name.)

3 In the device type: drop-down list, click the type of device. For example,

“DL351A”.

4 In the device ID: drop-down list, click the ID you want for the device. For

example, “ID6”.

5 In the device options: drop-down list, click the type of card fitted physical unit.

For example, “Analogue 8 Input”. If there is more than one device options:

drop-down list, repeat for the remaining ones, making sure they match the actual

cards fitted.

6 Click OK. This will save any changes and close the input/output setup window.

1 List of Stage and FOH ports with current

device assignments.

2 device type: drop-down list, contains a

list of the available devices to choose from.

3 device ID: drop-down list, contains a full

list of IDs for the selected device type. Those

already in use will be prefixed with the text

“(In use)”.

4 device options: drop-down list(s), from

which you can select the card that is actually

fitted in the physical unit. The positions of the

drop-down lists are relative to the card

positions in the physical unit.

5 OK button, closes the input/output

setup window.

1

2

3

4

5

Page 43

How to patch 29

PRO6 Control Centre

Quick Reference Guide

How to patch

Patching, basically, involves selecting the source patching connectors in the From

section of the Patching screen and then selecting their destination(s) in the To section.

You can select patches singly, or in multiples by using the sequence and automatic

operations.

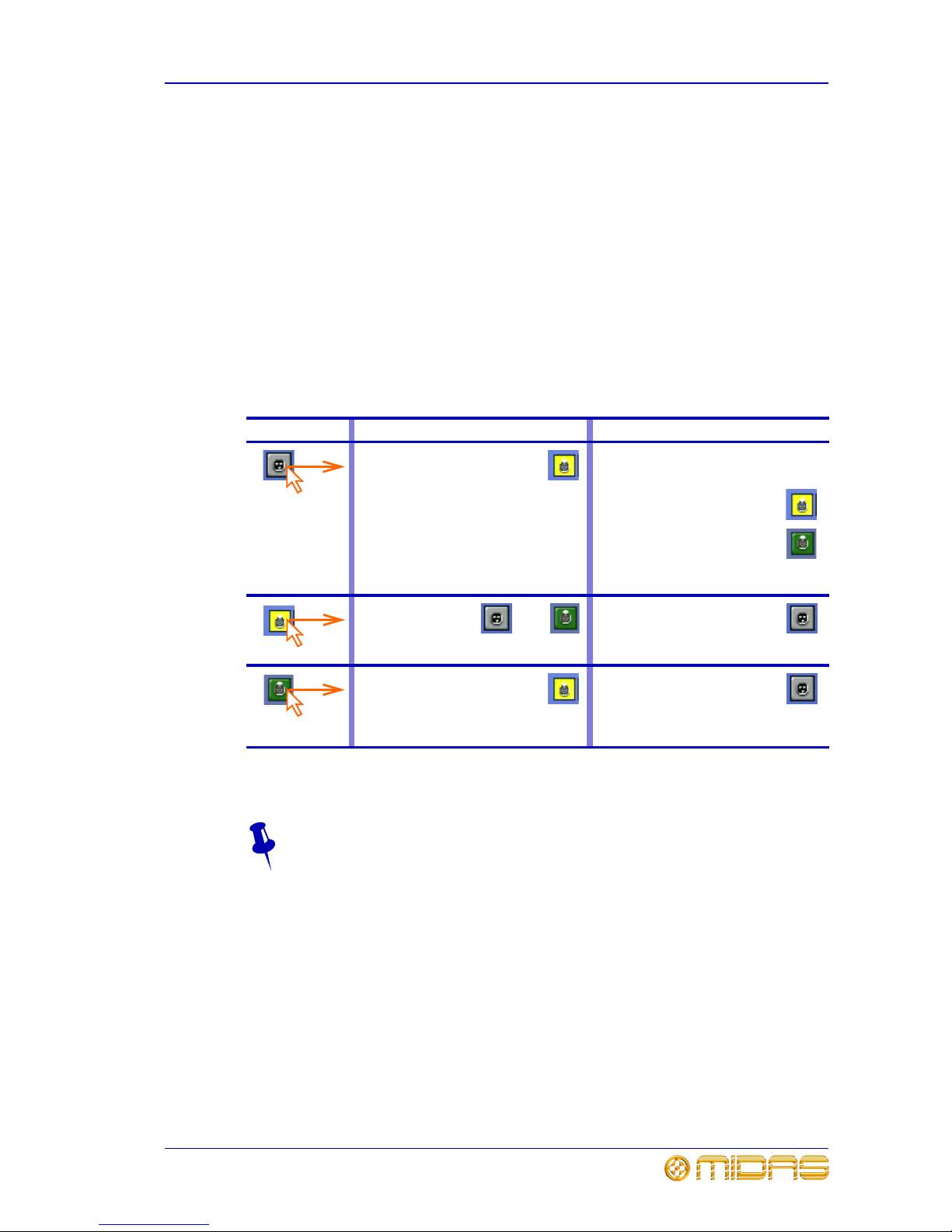

>> To open a tab in the From or To sections