Midas Mida.Black 8, Mida.Black 10, Mida.Black 12, Mida.Black 14, Mida.Black 17 Installation Instructions Manual

...Page 1

SWIMMING POOL HEAT PUMP UNITS

Installation&Instruction Manual

Rev. PG. EN&DE 04906

14.02.2017

1101-2720

Page 2

Page 3

ATTENTION:Thi s manua l inclu des all t he nece ssary i nfo rmation wi th the us e and the installation o f you r

heat pump.

The installer must read the manual and attentively follow the instructions in implementation and maint-

enance.

The installer is responsible for the of the product and should follow all the instructions of the manufact-

urer and the regulations in application. incorrect installation against the manual implies the exclusion of

the entire guarantee.

The manufacturer declines any responsibility for the damage caused with the people, objects and of the

errors due to the installation that disobey the manual guideline. Any use that is without conformity at t-

he origin of its manufacturing will be regarded as dangerous.

WARNING: Pleas e always e mpty the water in h eat pump dur ing win ter t ime or wh en the am bient temp -

erature drops below 0 C, or else the titanium heat exchanger will be damaged because of being frozen,

in su ch case , you w ill los e warranty on the h eat pump.

Please always cut the power supply if you want to open the cabinet to reach inside theWARNING:

heat pump due to high voltage electricity.

WARNING: Please keep the display controller in a dry area, or close the plastic cover to protect

the display controller from being defected by humidity.

Dear Customers,

Tha nk you for usi ng Midas pool heat pu mp .Ple ase read thi s instruct ion carefully b efo re th e installat-

ion and application of this product, otherwise it may lead to damage to the instrument or operators as

wel l as financial loss . When yo u might need f urthe r information p lease contact your local di str ibuto r. With

the gradual advancement of science and technology the product series and specifications will change as,

well, so you are invited to keep up with the latest products. In reading this instruction if you need any te-,

chnical consultations, contact your local distributor.

SWIMMING POOL HEAT PUMP UNITS

Installation&Instruction Manual

Page 4

Contents

1. Performance and installation

1.1 P erform ance an d featur es

1.2 Working principles

1.3 Specification

1.3.1 Technical data

1.3.2 Dimension

1.4 L ocati on of heat p ump ins talla tion

1.5 Distance from the pool

1.6 Installation of the check-valve

1.7 P ool syste m set up

1.8 Connecting the by-pass

1.9 Electrical hook-up

1.10 First time start-up

1.11 Condensation

1

1

3

5

5

1

2

2

4

6

6

7

8

8

2.1 Controller illustration

2.2Power ON/OFF heat pump

2.3 H ow to cha nge mode

2.4 Adjust desired water temperature

2.5 C heck an d set para meter s

2.6 S etting Time

2.7 Param eter tab le over view

2.8 S etting Time r on/ Tim er off

2.9 Cancelling Timer on and Timer off

2.10 Key pad lock

2.Control of the heat pump ( New col or LED )

9

10

10

11

11

11

12

13

13

13

3. Protection systems

3.1 Water flow switch

3.2 R efrige rant gas h igh and l ow pres sure pro tecti on

3.3 Overheating protection on the compressor

3.4 A utoma tic defr ost cont rol

3.5 Temperature difference between inflowing and outflowing water

3.6 L ow temp eratur e cut-o ut

3.7 Anti-frost protection during winter

3.8 First anti-frost protection

3.9 Second anti-frost protection

14

14

14

14

14

14

14

14

14

4.1 Swimming pool water chemistry

4.2 Heat pump winterizing

4.3 R estart ing the p ump aft er winte r

4.4 Check-up

4.Direction

15

15

15

16

17

17

20

5.1 Maintenance

5.2 Trouble shooting guide

5.3 Fa ilure c ode tab le for plu g-in ty pe PCB

5. Maintenance and inspection

6.1Name plate

6.2 Wiring diagram

6.Name plate & wiring diagram

21

22

9

21

14

17

15

Page 5

1. Performance and installation

1.1 Performance and features

Cooler

De-energizedAir

War m

Air

Fan

Evaporator

(Energy Collector)

Capillary Tube

Condenser

(Water Heat Exchanger)

Pool Filter

Pump

Compressor

Swimming pool

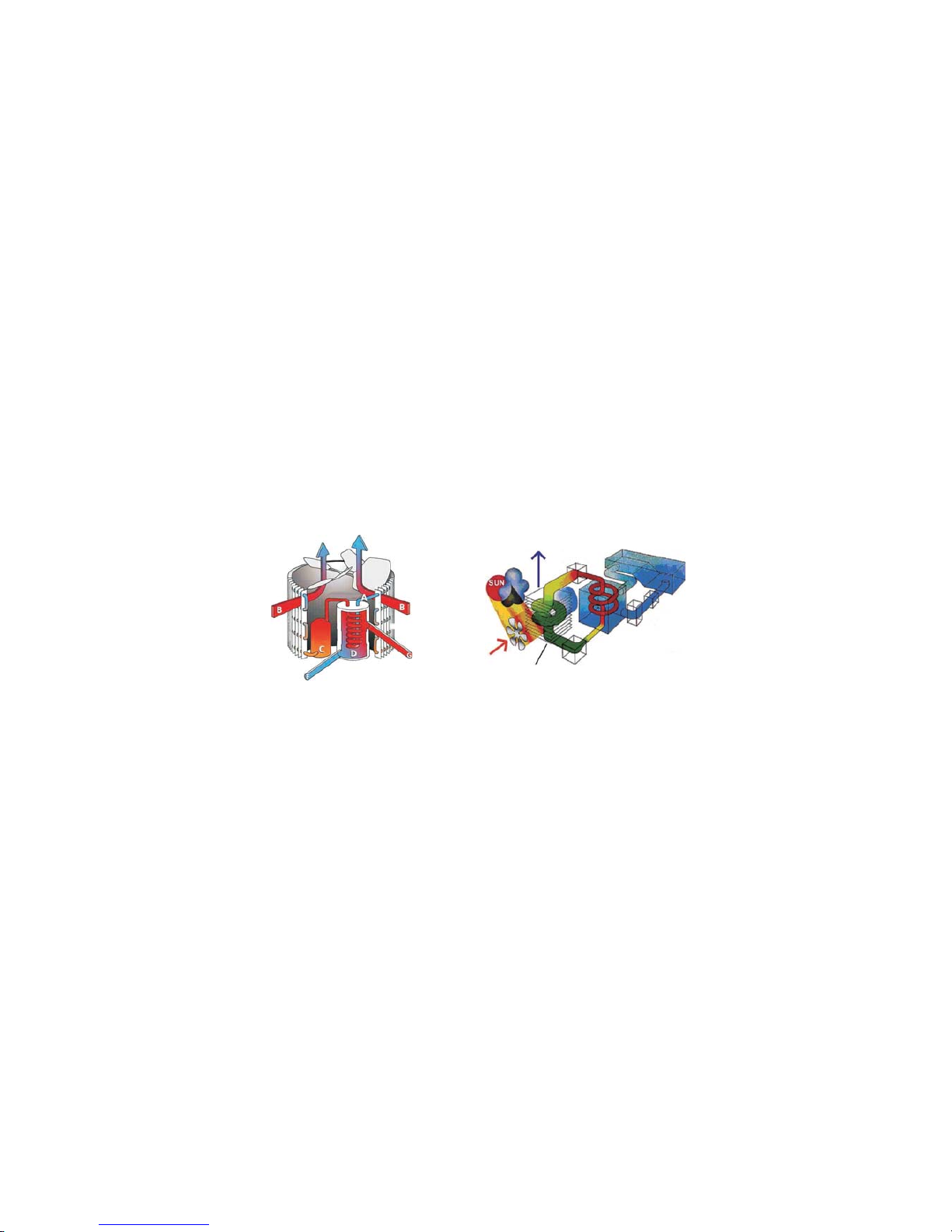

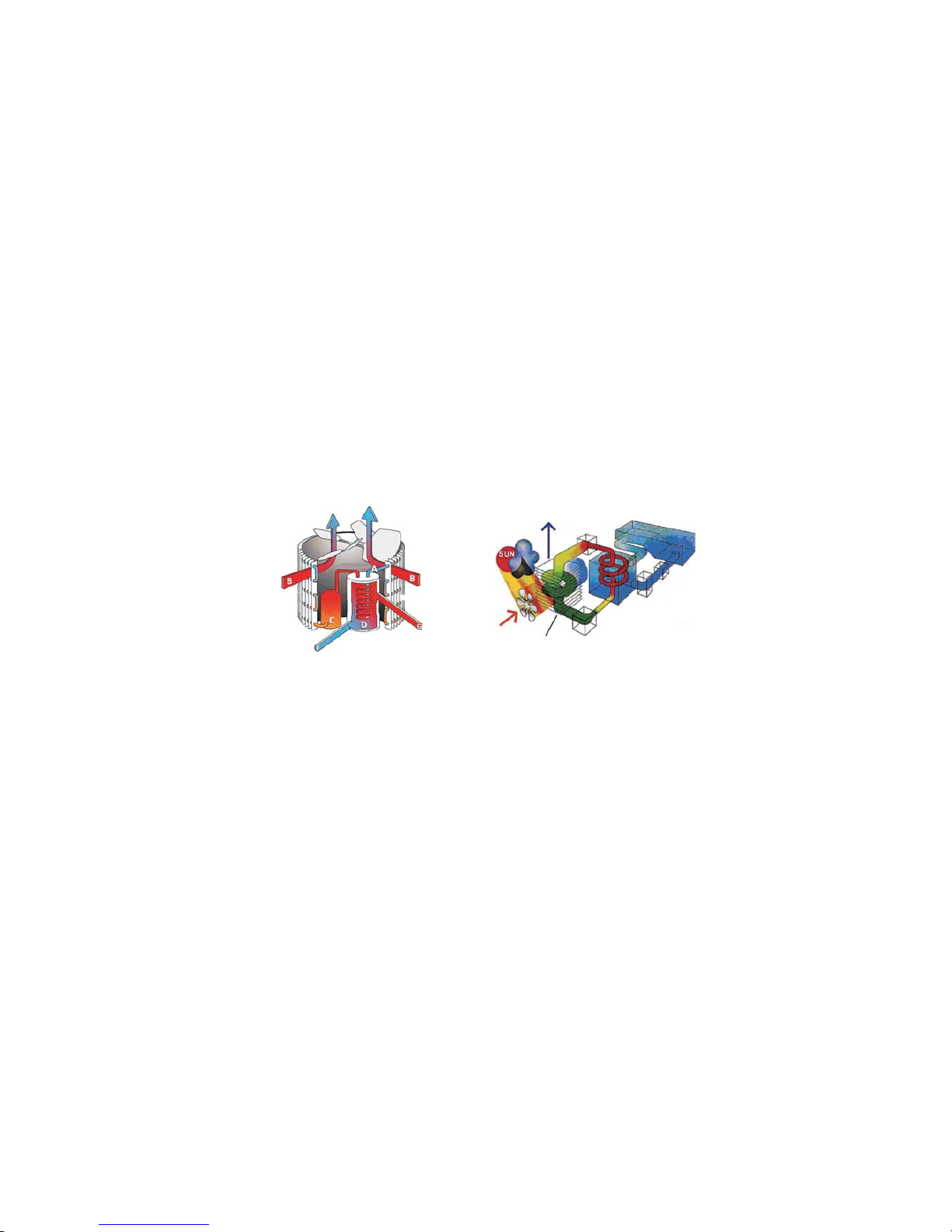

1.2 Working principles

√High efficiency

With aCOP valueup to 5.0our heat pumpsare very efficient when transferring heat from theair to

the swimmingpool water. Youcan saveas much as80% of costcompared toan electrical heater.

Long life-span√

The heat exchangeris made of PVC & Titanium tube, which can withstandand prolong exposure to

swimming pool water.

Easy√ control and operation

The u nit is ve ry easy to o perate : simpl y switch it on a nd set th e desired po ol water temperature.

The system includes a micro-computer controller, allowing all operation parameters to be set.

Operation status can be displayed on the controller with LCD display.

√Heat pumps utilize the sun s free heat by collecting and absorbing energy from the outside air. This'

ene rgy is then co mpressed and trans ferred to the p ool wat er. You r exis ting water pu mp c ircu lates the

water throu gh th e heater, usua lly nex t to th e pool eq uipme nt, and t he water warm s up. The heat p ump

tim er coul d be set to operate du ring dayli ght hou rs, for exa mple, u suall y 9am to 5pm.

The u nit contai ns a fan tha t draws in o utside air a nd directs i t ove r t he su rfa ce of the EVAPO RATOR√

(energy collector).The liquid refrigerant within the EVAPORATOR coil absorbs the heat from the

out side ai r becom es a ga s.

The w arm gas in t he coil p asses through t he COMP RES SOR con centratin g and i ncreasing the heat to√

form a ver y hot gas which the n passes to th e CON DENSE R (water heat exc hange r).It is here t hat t heheat

exchange occurs as the hot gas gives off heat to the cool swimming pool water circulatingthrough the coil.

The p ool water becom es wa rmer, and t he hot ga s coolin g as it flow s th roug h th e CONDENSE R coil ret-√

urns to its liquid form and, after passing on through the CAPILLARY TUBE the whole process begins again,.

7℃The state of the heat pump technology can efficiently collect heat from theoutsideair downto the to√

10 range . For t rop ic and subtropi cal c limates, t his means th at the po ol ca n be maintained at 26 to 32℃℃

Heat exchanger

Water flow out

Evaporator

Air flow

Compressor

Air flow

Water flow in

1

Figure 1-1

Figure 1-2

Page 6

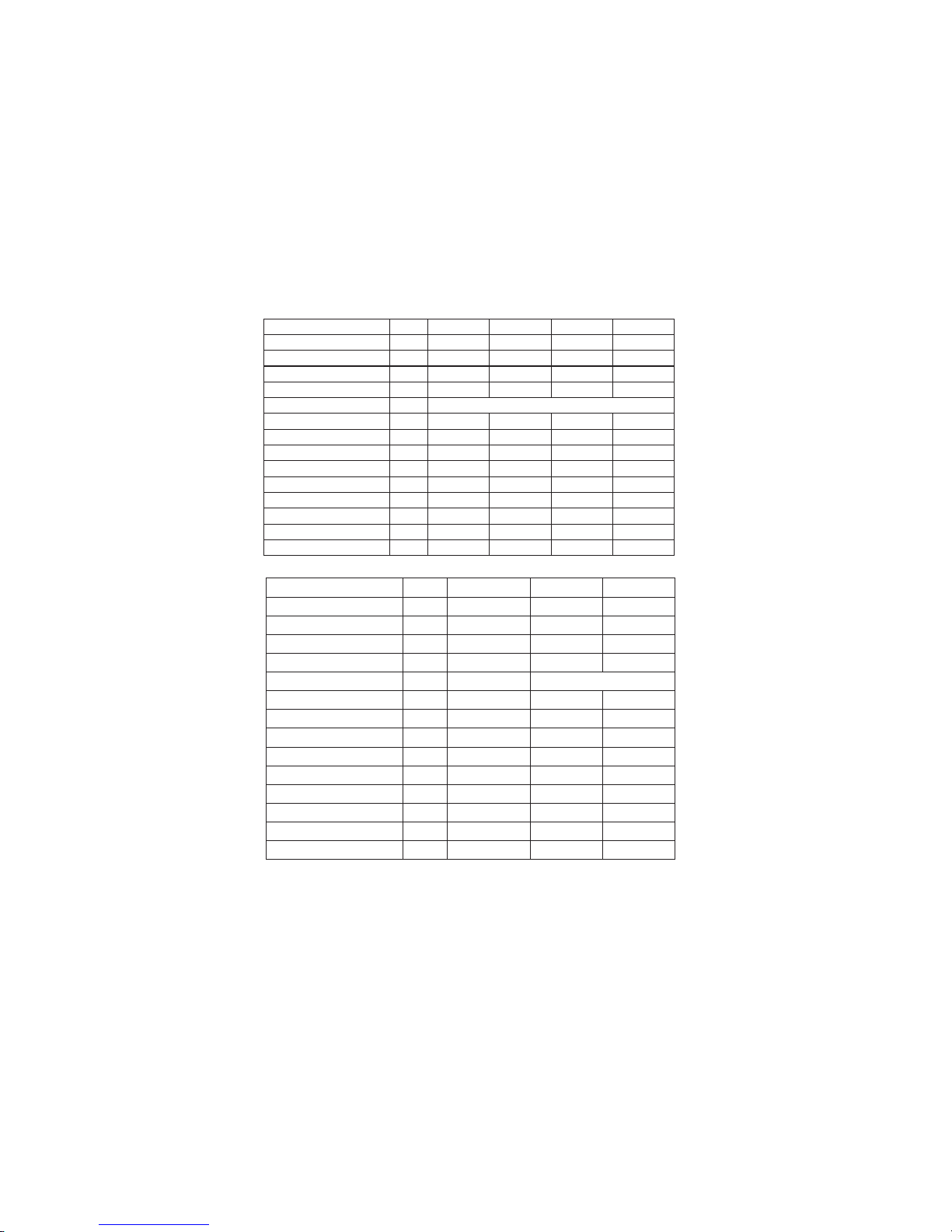

1.3 Specification

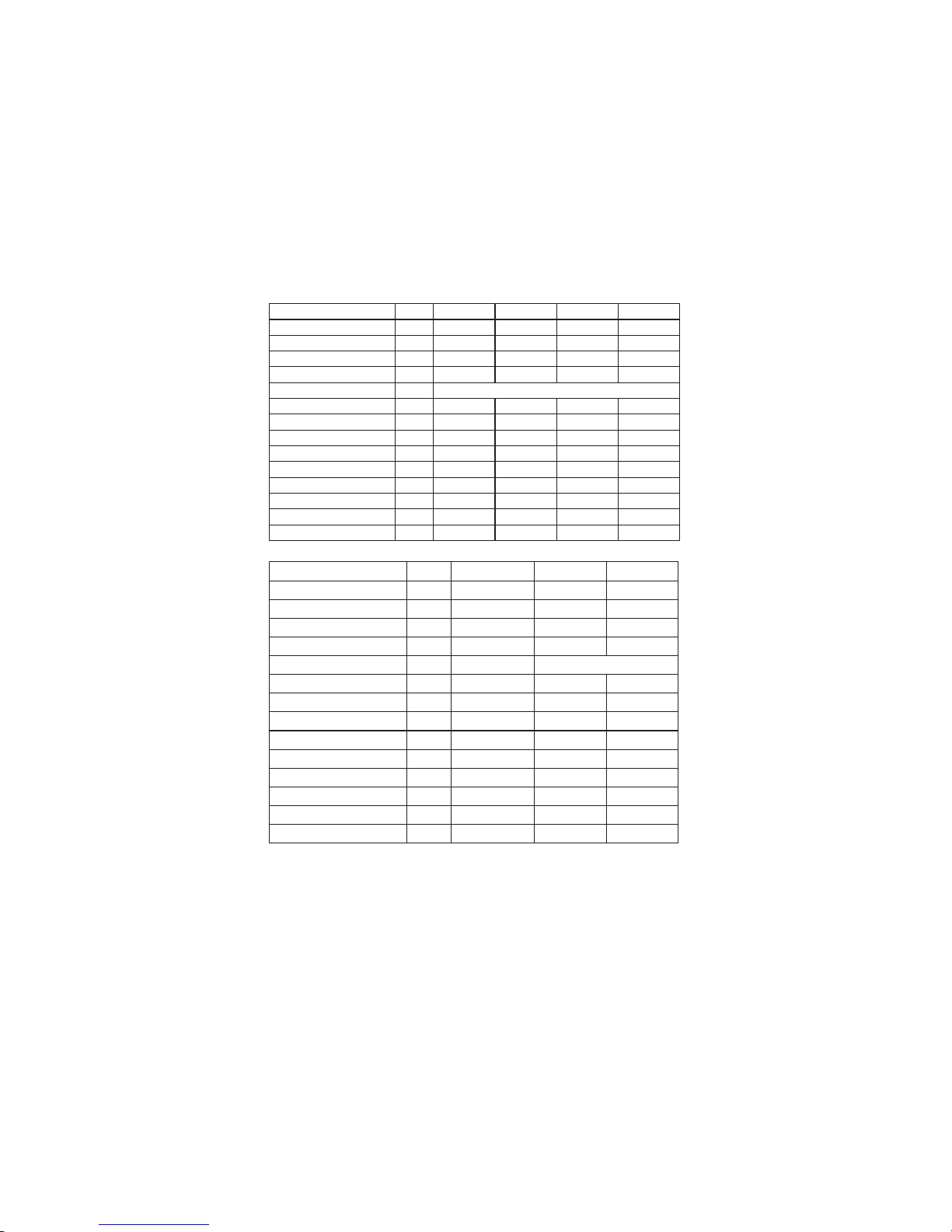

1.3.1 Technical data

2

*Data are subjects to modification without notice, data on nameplate of products are

of updated version.

Measuring conditions: Outdoor air temp: 24°C , Inflowing water temp: 26°C, rel. humidity: 65%

Mida Black 14.

14

2550

55.

11. 57

Rotating

120

850

43

50

7

14

1110 415 710**

81

220-240V/1PH/50HZ

Model

Heating capacity

Power input

Efficiency

Nominal current

Power supply

Compressor type

Fan power

Rotational frequency of the fan

Noise @10 meter

Water Connection

Nominal water flow

Max.water pressure drop

Net dimensions(L/W/H)

Gross weight

kW

W

C.O.P

A

V/Ph/Hz

w

RPM

dB(A)

mm

mh³/

kPa

mm

kg

Rotating

80

850

39

50

5

10

970 360 585**

55

Mida Black 10.

9.8

1730

565.

7.85

Rotating

120

850

42

50

6

12

1045 370 625**

62

Mida Black 12.

12.8

2360

545.

10.72

Rotating

120

850

42

50

7

12

1045 370 625**

67

Mida Black 26.

26

4480

58.

8.0

Scrolling

240*2

770

47

50

15

16

1110 445 1260**

137

380-400V/3PH/50HZ

Model

Heating capacity

Power input

Efficiency

Nominal current

Power supply

Compressor type

Fan power

Rotational frequency of the fan

Noise @ 10 meter

Water Connection

Nominal water flow

Max.water pressure drop

Net dimensions(L/W/H)

Gross weight

kW

W

C.O.P

A

V/Ph/Hz

w

RPM

dB(A)

mm

mh³/

kPa

mm

kg

Mida Black 17.

17

2790

6.1

13.3

Scrolling

240

770

43

50

10

14

1110 415 710**

99

Mida Black 21.

21

3620

58.

6.5

Scrolling

370

850

46

50

12

16

1110 445 960**

111

Mida Black 8.

.78

1440

.54

657.

220-240V/1PH/50HZ

Page 7

3

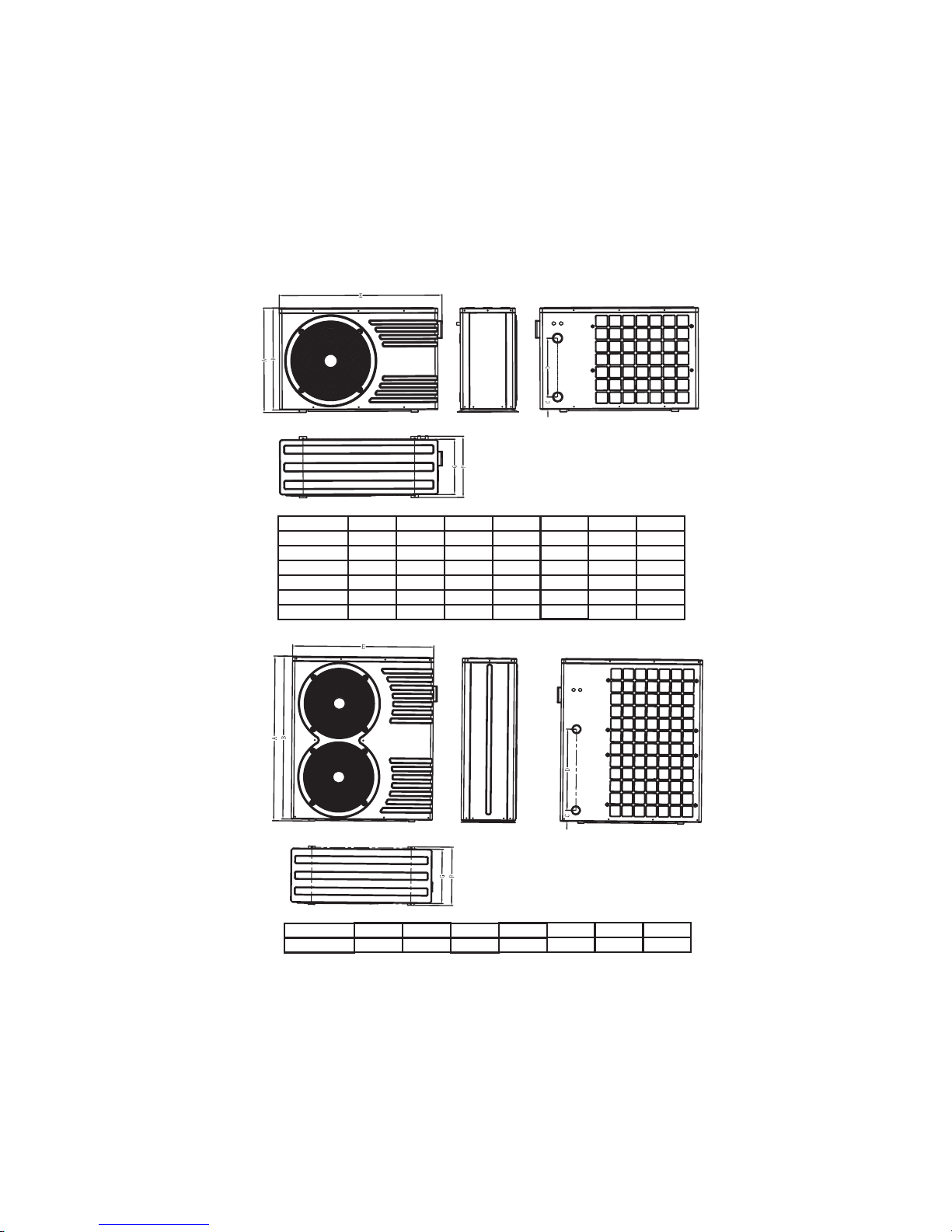

1.3.2 Dimension (mm)

Model

Mida. Black 8

Mida. Black 10

Mida. Black 12

Mida. Black 14

Mida. Black 17

Mida. Black 21

A

585

625

625

710

710

960

B

554

564

564

694

694

944

C

85

85

85

85

85

85

D

250

300

300

400

400

500

E

970

1045

1045

1110

1110

1110

F

360

370

370

415

415

445

G

313

340

340

386

386

420

Model

Mida. Black 26

A

B

C

D

E

F

G

1260

1244

85

620

1110

445

420

Page 8

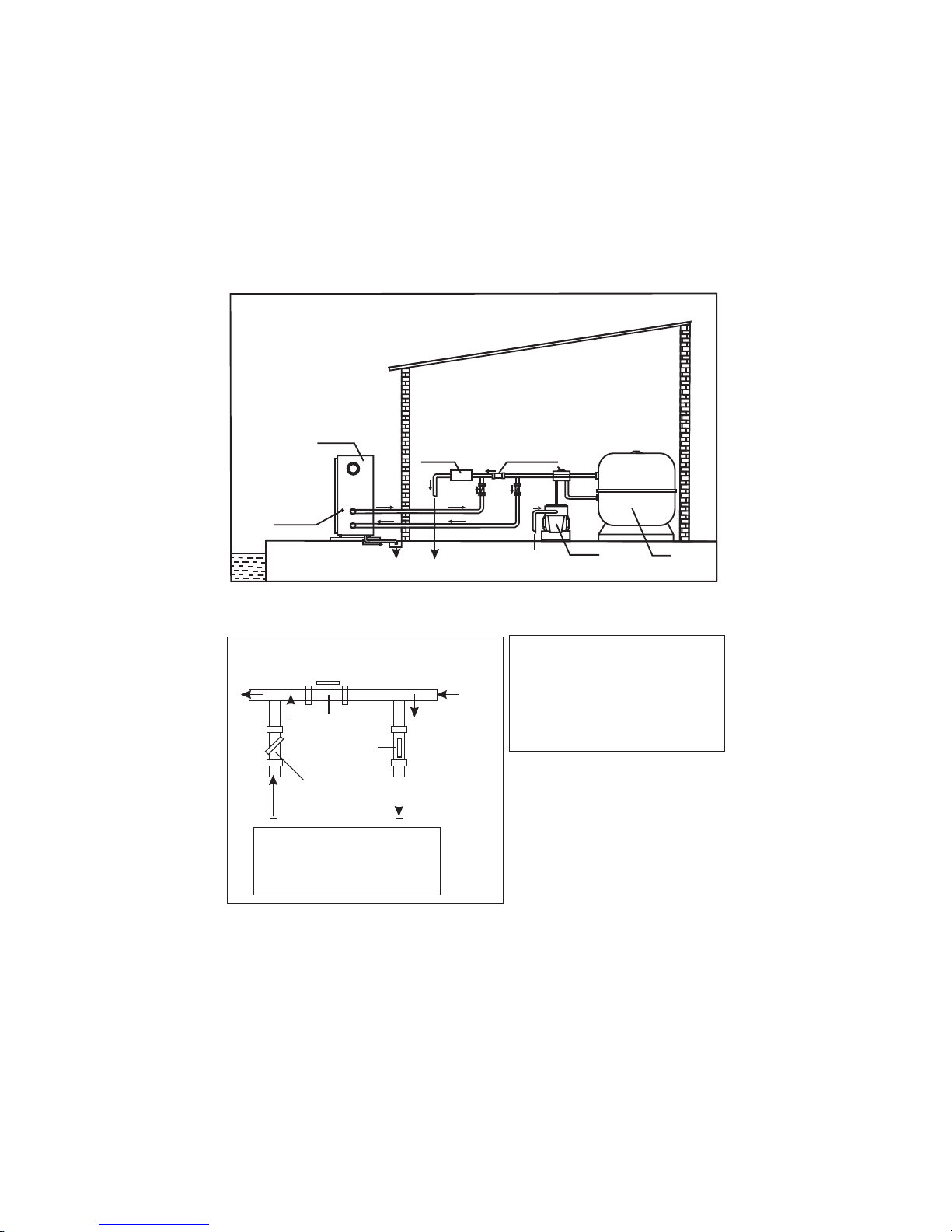

1.4 Location of heat pump installation

The unit will perform well on any location provided three factors are present:

1. Fresh air 2. Electricity 3. Pool filter piping

The unit may be installed virtually anywhere outdoors providingminimum distance requirements aremet

with respect to other objects (see diagram below).For indoor pools please consult your installer. If the

uni t is plac ed in a win dy area, no probl ems occ ur with e .g. the pilot li ght, as o ppo-sed to w hat i s often the

cas e with gas heaters .

Do no t place t he unit i n an encl osed ar ea wi th a limi ted air volu me where the u nit'sAttention:

discharged air will be re-circulatedor near shrubs that could block the air inlet. These locati-

ons deny the unit a continuous fresh air supply, which reduces its efficiency and may prevent a-

dequate heat yield.

See diagram below for minimum required distances.

Cautions

√Do no t put you r hands or any othe r object into the a ir outl et and fan. It coul d damag e the heat pum p and

cause injuries.

In case any abnormality was found in the heat pump, please cut off the power at once andcontact a√

professional technician.

It is strongly suggested to place a guard around the machine to keep children away from the heat pump.√

4

Figure 1-3

Model:Horizontal Unit

Fre e space re quire ment for t he hori zontal h eat pum p

Not less than 500mm

Air in

Not less than 500mm from the top

Air in

Not less

than 500mm

Not less than 2000mm

Air o ut

Not less

than 500mm

Page 9

1 5 Distance from the pool.

Normally, the pool heat pump is installed within a 7.5 meter radius of the pool. The greater the distance

from the pool, the greaterthe heat loss from thepiping. Sincethe piping is buried forthe most part,

hea t loss is mini mal for dista nces of u p to 30 meters (15 meters to and from the p ump= 30 m eters to tal),

unless thesoil iswet orthe water levelis high.Heat lossper 30 meters could roughly be estimated at 0.6

kw-hour (2000BTU) for every 5 temperature difference between the pool water and the soil℃

surrounding the pipe which translates to an operation time increase of 3-5,%.

1.6 Installation of the check-valve

Attention- When using automatic chlorine and PH dosage systems, it is ofuttermost importanceto protect

the h eat pum p fro m high conce ntrations o f these c hemic als that could co rro de the heat exc hanger.

Therefore, such systems should add thechemicals in the conduits locatedDOWNSTREAM of the heat

pum p and it is r eco mmended to i nstall a c heck- valve in order to prevent back flow when th ere is no water

circulation.

Damage to the heat pumpcaused by disregardinganyof theserecommendations will invalidate the warranty.

5

Water Pu mp

P-trap

Filter

Chlorinator

Check-valve

Swimming Pool

Figure 1-4

Page 10

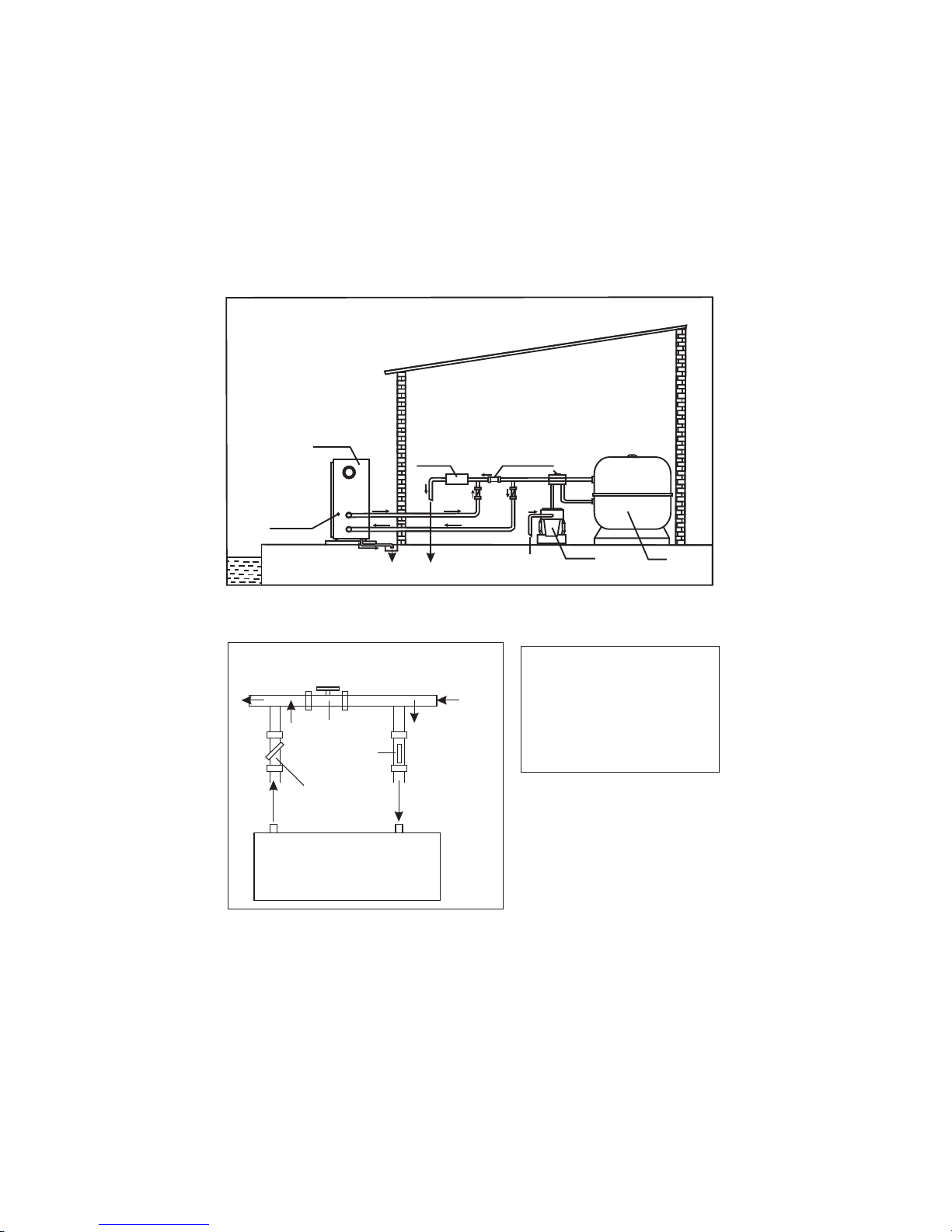

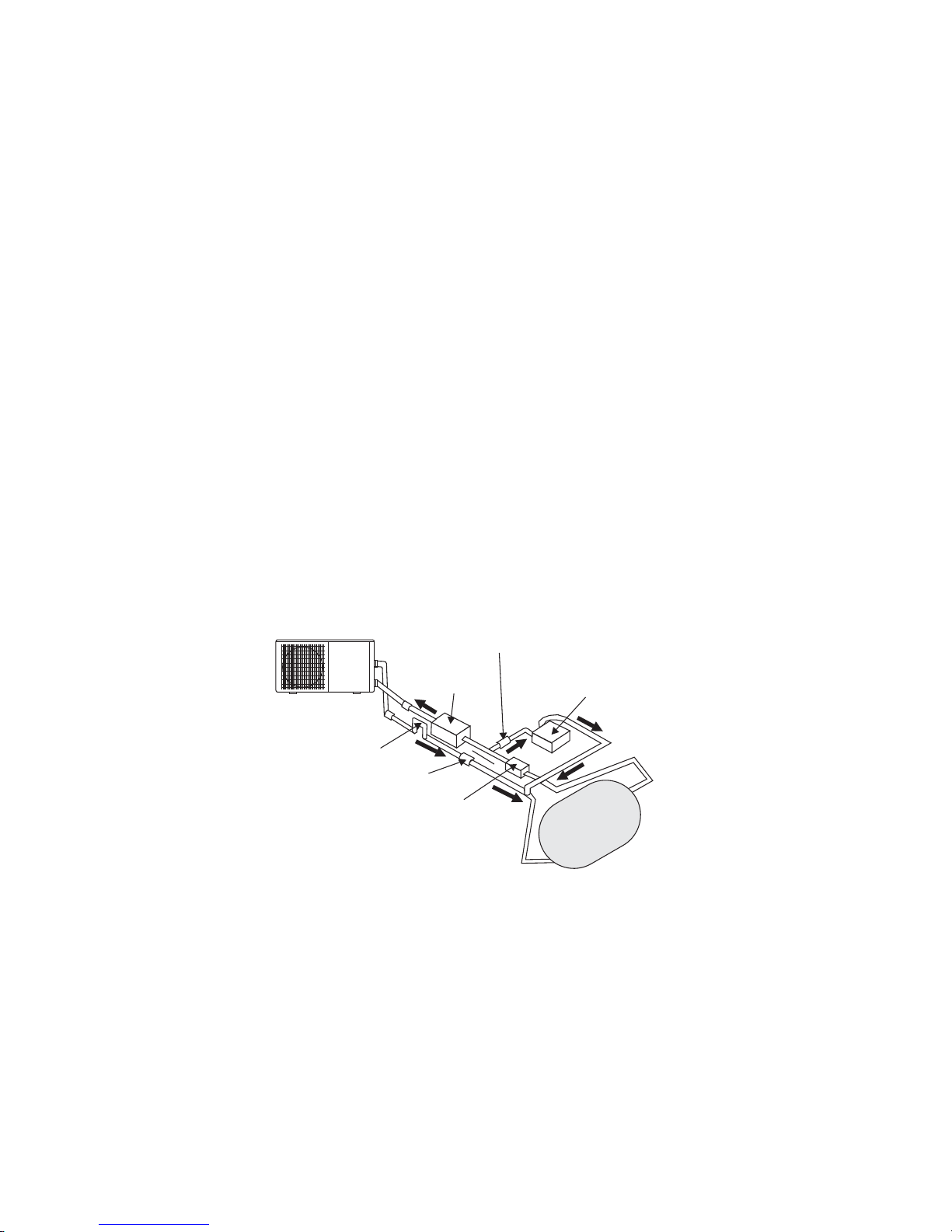

1.7 Pool system set up

1.8 Connecting the by-pass

Valve 1

Valve 2

Valve 3

BY-PASS

F

r

o

m

f

i

l

t

e

r

T

o

p

o

o

l

OUT IN

HEATPUMP

Powe r cable i nlet

Heat Pump

Outlet

Inlet

Condensed water draining pipe

Draining nozzle

Discharge water to pool

Pool w ater inl et

Water pu mp

Filter

Water p roces sor

Side connection valve

6

Figure 1-5

Figure 1-6

Adjust the by-pass as follows:

open the 3 valves completely

slightly close valve 1 until water

pressure has increased with approximately 100 to 200 grams,

close valve 3 about halfway to

adjust the pressure of the refrigerant gas in the un it

Page 11

Although the heat pump is electrically isolated from the rest of the unit, this only preventsImportant—

the passage of electricity to or from the pool water. Grounding the unit is still required to protect

yourself from short circuits inside the unit. Make for adequate ground connection.

Check ifthe electrical mains voltage corresponds with the operating voltageof the heat pump prior to

hoo king up t he unit .

It is recommended to use a separate fuse(slow type-D-curve)as well as adequate wiring(see table below).

For h ori zontal models : remo ve th e panel o n the rig ht of the fa n openi ng.

For vert ica l model s: remove th e cur ve pane l in the front s ide.

Connect the electrical wires with the terminal block labelled Power Supply .“”

Next to this connection, thereis a second terminal block labelled Water Pump ,to which the filter“”

pump (max.5A/240V)can be connected. This is connectionmakes it possible to control filter pump

operation with the heat pump. See further at Parameter setting table (Parameter 9) for the different

possibilities.

Remarks

—for mo dels wi th 3 phas es, swi tch ing 2 pha ses may caus e in inve rsio n in the rotational direction

of electrical motors, which could damage the unit. Therefore,a protection device has been built in, which

wil l interrup t the circuit if th e conne ction has no t been performe d correctly.

1.9 Electrical hook-up

7

Figure 1-7

Figure 1-8

2x2.5+2.5

2x2.5+2.5

2x2.5+2.5

2x4.0+4.0

2x4.0+4.0

4x2.5+2.5

4x2.5+2.5

Mida.Black 8

Mida. Black10

Mida. Black 12

Mida. Black 14

Mida. Black 17

Mida. Black 21

Mida. Black 26

220-240

220-240

220-240

220-240

220-240

380-400

380-400

16

16

20

25

32

16

20

6.57

7.85

10.72

11.57

13.3

6.5

8.0

Cable diameter(mm )

2

(for a max.length of 10 meters)

Model

Voltage( )V

Fuse(A)

Nominal

Current(A)

Page 12

1.11 Condensation

1.10 First time start-up

Time delay— the unit is equipped with a built-in3-minute start delayincluded to protectelectrical

components and contacts. After this time delay, the unit will automatically be restarted. Even a

brief interruption of the power supply willactivate the startdelay and preventthe unit from starting

immediately. Additional interruptions of the power supply during the delay period will have no effect

on the 3-minute countdown.

Water flo w switch— the uni t is equi pped with a fl ow switch th at is switch ed on when eno ugh wate r has

flowed through the unit and that isswitched off when the waterflow becomes too low. (E.g. When the

filter pump is switched off).

Whe n the swi mming pool w ater is be ing hea ted b y the heat pum p, the incoming a ir is coo led down qui te

a bit , which c an ca use con densatio n on the fins of t he evaporat or. Con densed vol umes can atta in several

litres per hourunder highatmospheric humidity.Sometimes, this is wrongfullyinterpretedas a waterleak.

Dep endin g on the start ing temperature of the po ol wa ter a nd the ai r temperature, it can take s everal days

for the water to reach th e desired tempe rature. Coveri ng the pool ca n dra sti cal ly redu ced this per iod.

When all connections have been made and checked, you should follow these steps:

1. Turn on th e filte r pump. Chec k for l eaks and verify f low to and from the p ool.

2. Turn on the electrical power supply to the unit, then press the ON/ OFF key on the electronic control

pan el. The u nit sho uld start wh en the time de lay period h as lapsed .

3. When the unit has been running for a couple of minutes, check if the air leaving the unit is cooler.

4. Check the performance of the flow switch as follows: with the unit running, turn the filter pump off.

The unit should also switch off automatically. If not, the flow switch must be readjusted.

5. Al l the uni t and fil ter pum p to ru n 24 hours a day until the d esired pool water tempe rature is reache d.

When theset temperature is reached,the unitswitches itself off.The unitwill now automatically restart

(as long as your filter pump is running) when the temperature of the pool water experiences a drop of

more than 1 below the set temperature.℃

Note- Inorder for the unitto heat the pool(or spa),the filterpump must be running sothat thewater can

circulate through the heat pump. Without this circulation, the heat pump will not start.

8

Page 13

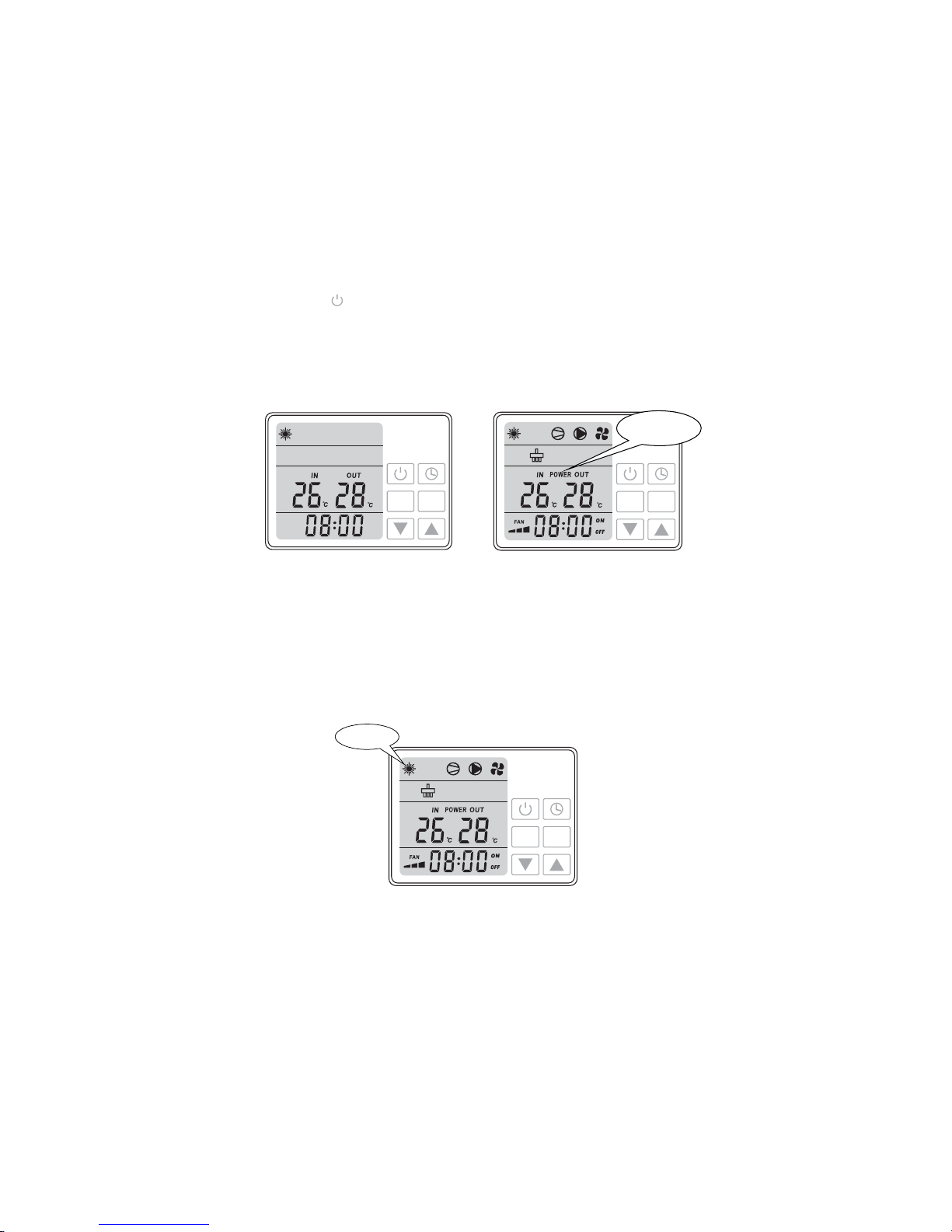

2.Control of the heat pump (New color LED )

MODE

MENU

2.1 Controller illustration:

When heat pump is supplied with power, controller will display with full screen, shows that it is already

connected. If connection fails in 10 seconds, please check connections between communication cable

and control display, or replace with another control display.

Button functions:

button: ON/OFF switch to start or stop heat pump.

MODE button: To swi tch b etween heatin g, cooling a nd auto m ode.

but ton :Timer button to set t imer on and ti mer off.

MENU button: To enter pa ram ete r settin gs and co nfirm setting s.

button: To increase or decrease value.

Icons definitions:

--h eatin g ico n, show ing heat pum p is in heatin g mod e.

--c ooling ico n, showing h eat p ump is in c ooling mod e.

--a uto icon, sh owing h eat p ump is in a uto mod e.

--compressor icon, showing compressor status.

--w ater pum p icon, s howing water pump status.

--fan ic on, showin g fan status.

--d efrost icon, sh owi ng defrost status.

--four way valve icon, sho wing four way valve status .

--electric heatericon, showing electricheater status(onlywhen external electric heater isconnected)

--alarm icon, showing system alarm.

--fan sp eed ico n, showing h igh (3), med ium(2) and l ow(1) fan sp eed.

--key pad loc k ico n, show ing button s on the control displ ay are locked .

Note: 1. Heat pump is not equipped with electric heater internally, only provides terminal for external

connection.

2. Fan speed is automatically controlled by ambient temperature, not manually.

Figure 2-1

9

Page 14

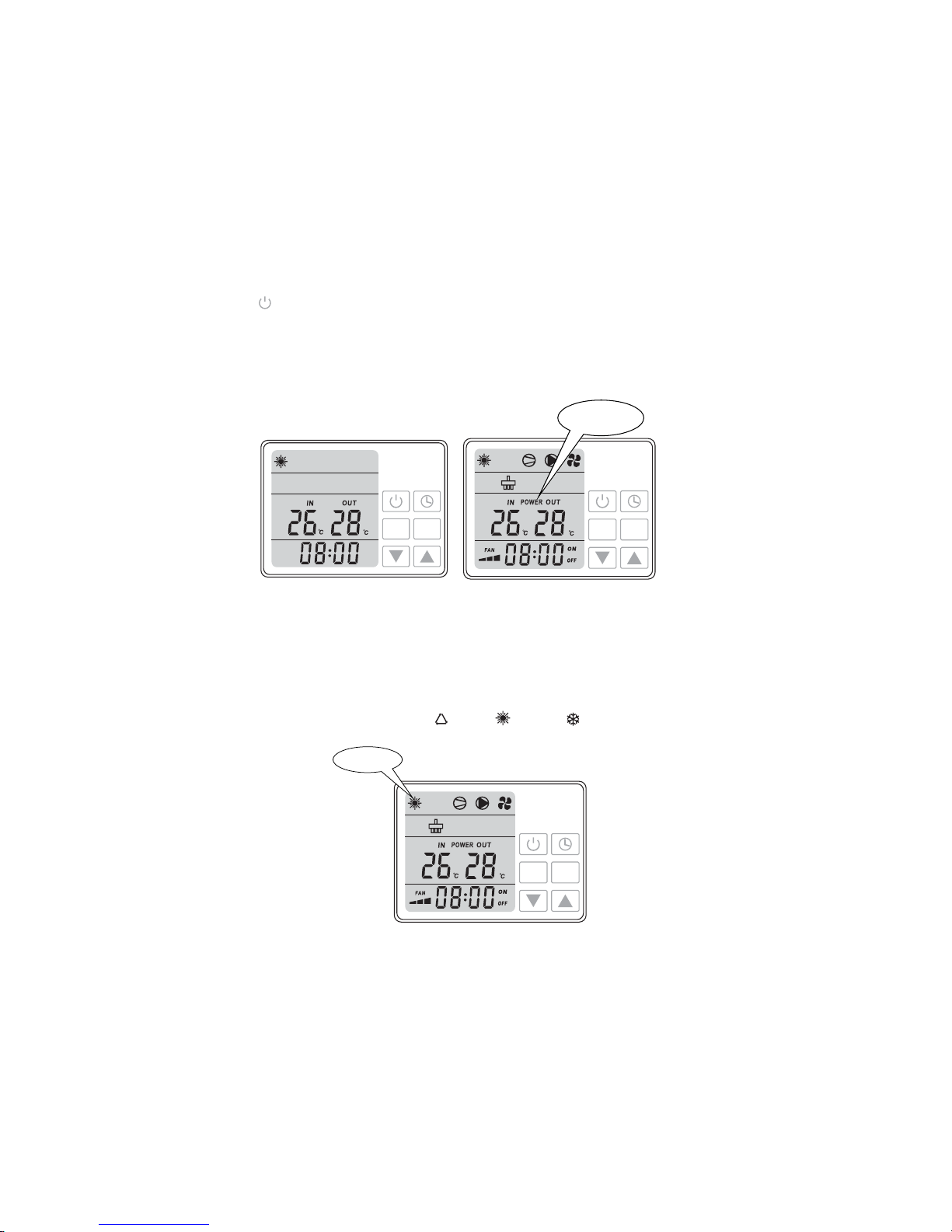

2.2 Power ON/OFF he at pump

Press button to switch on heat pump.

Figure 2-2

Once the heat pump is powered on all related running component icons will be lightened as well as

POWER displayed in the middle of display to show system is in running status.

Figure 2-2 shows heat pump in standby status and figure 2-3 shows heat pump in running status.

The l eft temperature sh ows f low wate r tem peratu re while the r ight tempe rature is the r etu rn water

temperature.

Figure 2-3

MODE

MENU

Press MODE button to select auto, heating or cooling mode, related indicator icon will be lightened as a

symbol t o show heat pump is i n eithe r auto , he ati ng or coolin g mode.

2.3 How to change mode

Figure 2-4

10

MODE

MENU

running status

MODE

MENU

heating mode

Page 15

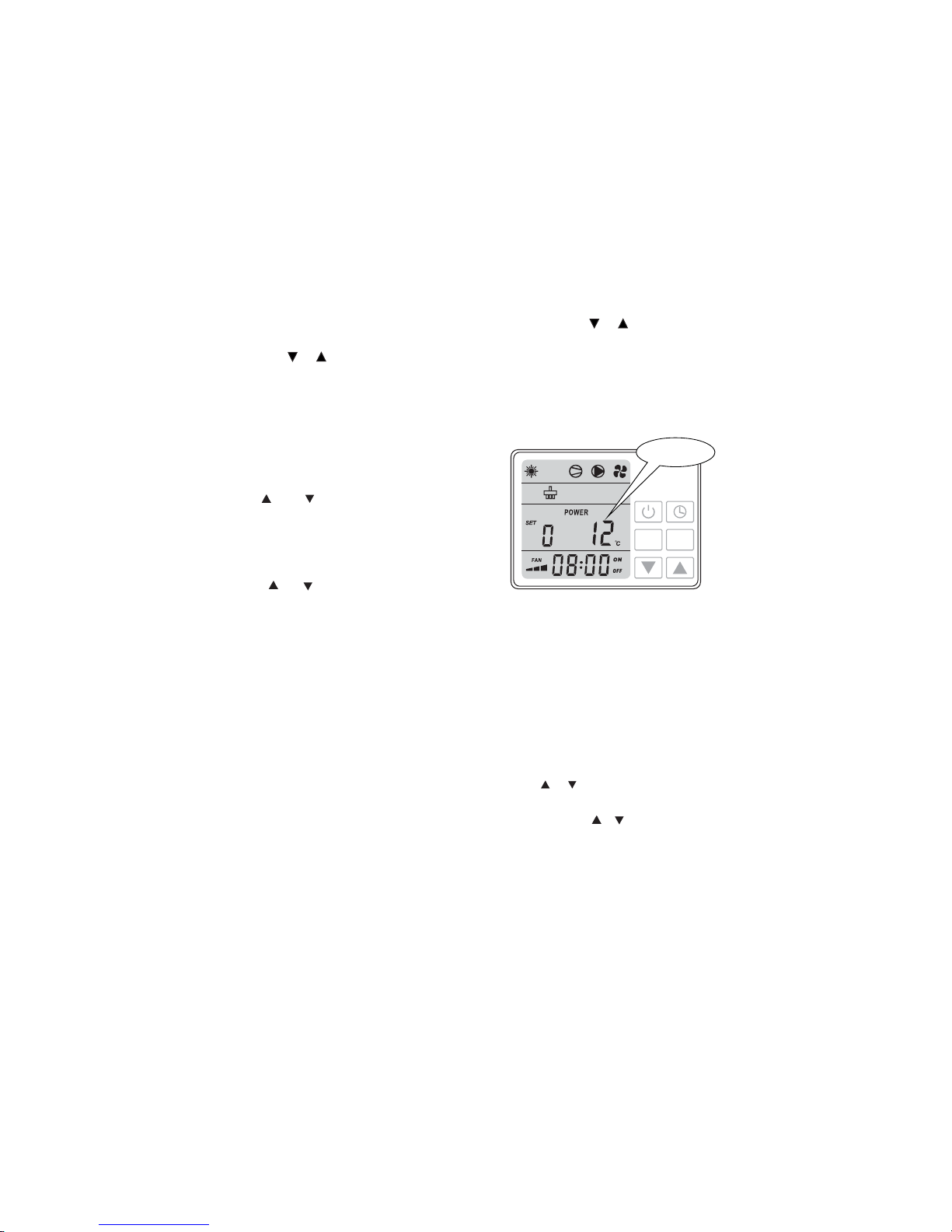

2.5 Check and set parameters

Press button for 5 seconds display willMENU

sho w parameter num ber with value fl ashin g

together.

Mov e and b utton to che ck re quired

parameter settings.

Select desired parameter and press Menu button

for resetting pa ram ete r. Param eter numbe r stays

fixed wh ile para meter valu e rem ains flash ing.

Move and button to adjust the value.

Press Me nu button to conf irm the setting .

Without any further movement on the display button

in 5 seconds it will return to main interface automatically.

Note: All parameters can be changed ONLY under standby status !

2.4 Adjust desire d water temperature

1.First select desired mode, auto, heating or cooling.

2.No matter the heat pump is under standby status or running status, press or , display will

show the desired water temp. of selected mode with a flashing value, then change the water temp.

by mo ving or as reques ted .

11

Press ME NU button in a q uick stop to acti vate time setting.

Whe n hour nu mbers are fl ash ing it is avai lab le for revision m ove o r to fix ho ur numbers.

Press ME NU button to conf irm hour settin g.

Min ute num bers start fl ashin g once th e hour nu mbers are confirme d, move or to fix minute nu mbers.

Press ME NU button to conf irm minute setting .

2.6. Setting Time

MODE

MENU

parameter

value

Figure 2-5

Page 16

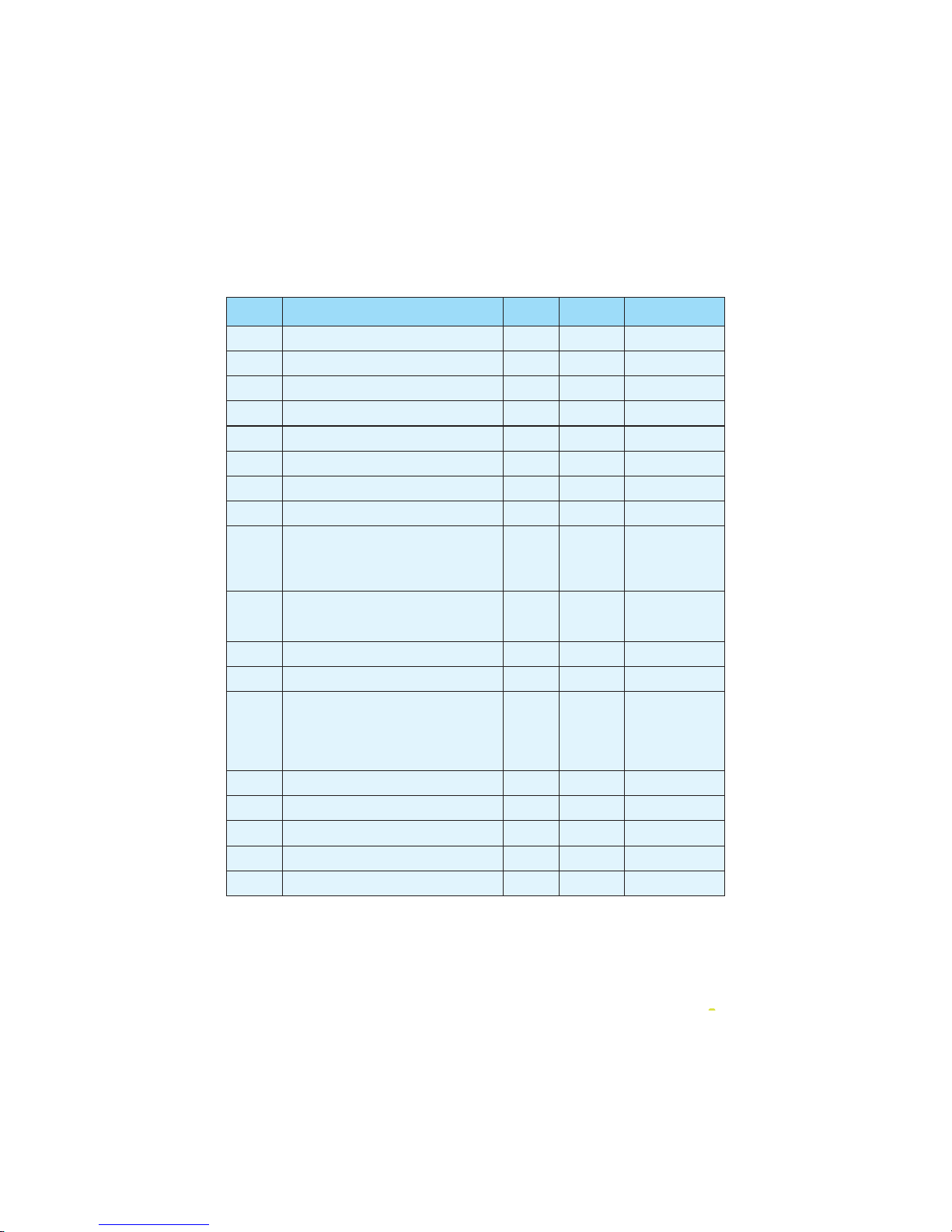

Parameter

Definition

Range

Default Remark

Type o f unit:

0=Cooling only

1=Heating &cooling

2=Heating & cooling + Auxiliary heating

3=Heating only

837~ ℃

~840℃

~10 90Min

-30 0~ ℃

~230℃

~112Min

14~

01~

03~

01~

28℃

28℃

45Min

-7℃

13℃

8Min

1

1Yes()

1

0

Adjusted

by Technicians

Adjusted

by Technicians

Adjusted

by Technicians

Adjusted

by Technicians

Adjusted

by Technicians

Adjusted

by Technicians

Adjusted

by Technicians

Adjusted

by Technicians

Des ired wat er temp eratur e in auto mo de

Act ual inl et water t emp.

Actual outlet water temp.

Coi l temp. i n system 1

Ambient temp.

840~ ℃ 30℃

Adjusted

by Technicians

-9 99~ ℃

-9 99~ ℃

-9 99~ ℃

Measured Value

Coi l temp. i n system 2

-9 99~ ℃

Measured Value

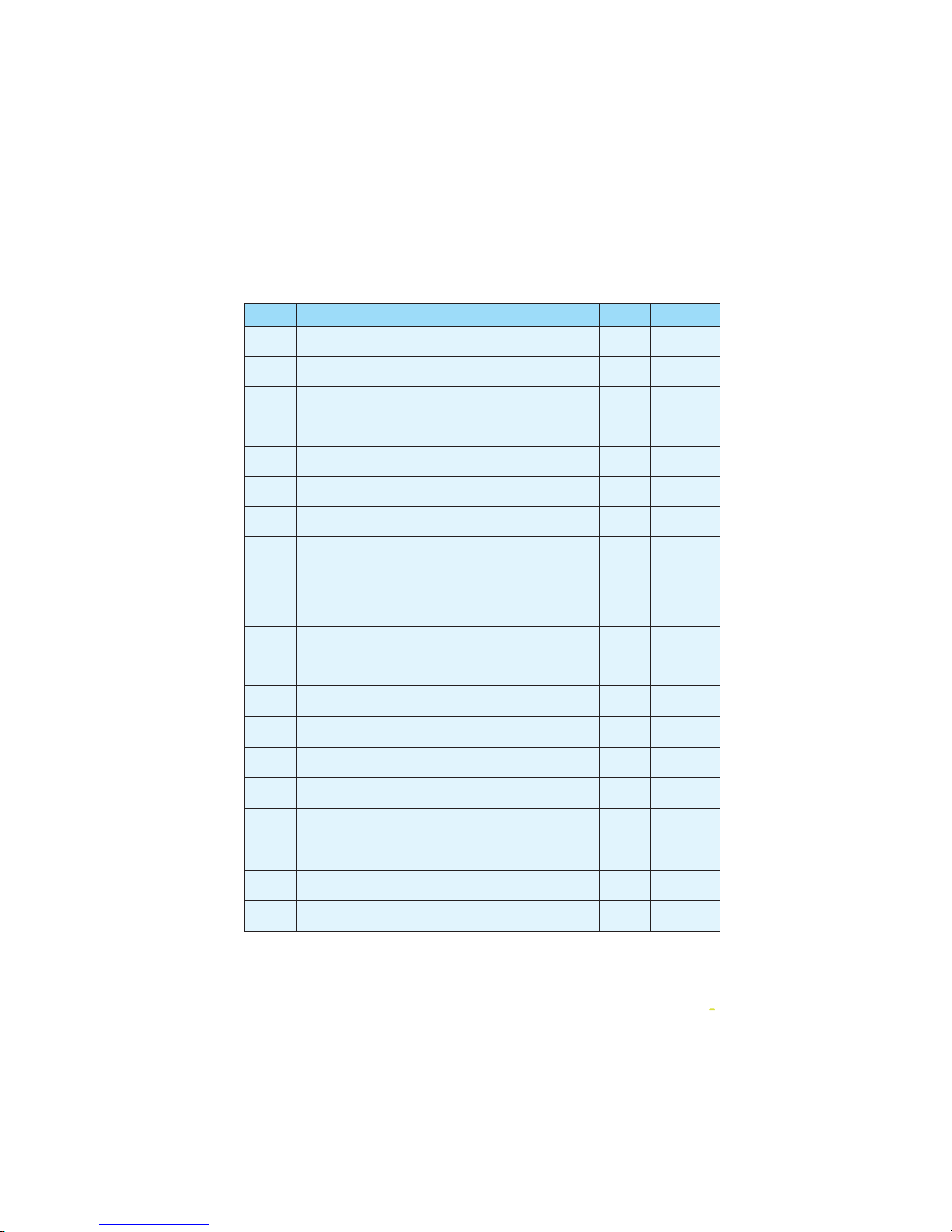

2.7 Parameter table overview

12

0

1

2

3

4

5

6

7

Desired water temperaturein cooling mode

Desired water temperaturein heating mode

Defrosting cycle

Evaporatortemperature setpoint for starting defrosting

Evaporatortemperature setpoint for stopping defrosting

Maximum duration for defrosting

Quantity ofsystem

Restart after powerfailure

Adjusted

by Technicians

Adjusted

by Technicians

Water temperaturedifference setting for restarting

Low pressure switch detection:

0 = Low pressure switch will detect after compressor

has been running for 10 min

1=Low pressure switch will detect after compressor

has been running for 60 min

2=Low pressure switch will never detect

0

-9 99~ ℃

120℃~ 2℃

Measured Value

Measured Value

Measured Value

Adjusted

by Technicians

Adjusted

by Technicians

Dif ferent wo rking m ode of wa ter pum p:

0= wat er pump i s always o n

1 = water pump is only running when the heat

pump is switched on

0/1/2

9

10

11

12

A

b

C

d

E

8

Page 17

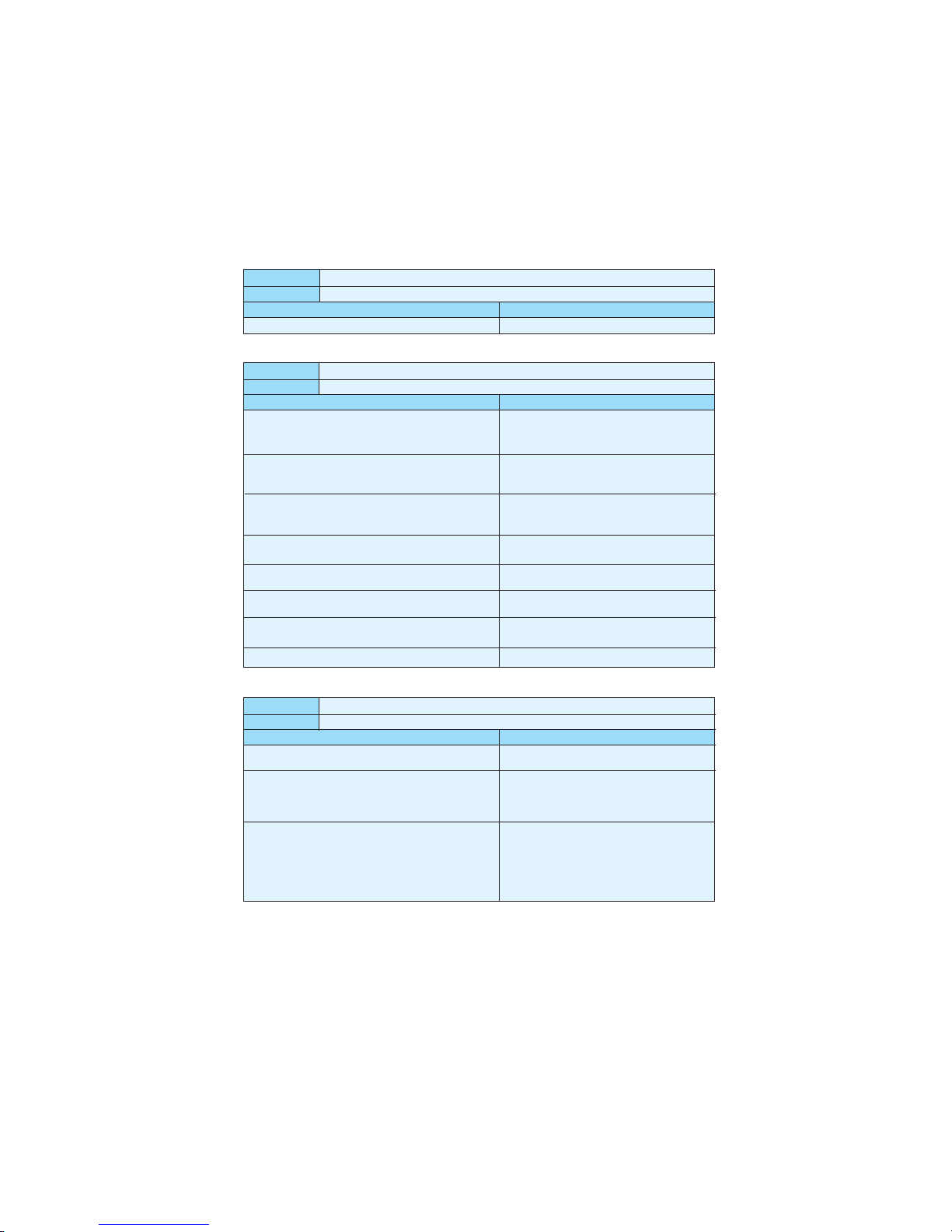

2.7 Setting Timer on/ Timer off

2.8 Cancelling Timer on and Timer off

Press bu tton to acti vate, time an d ON /OFF s tar ts flashin g together.

Press but ton to can cel the time r and ON/ O FF icon s wil l disap pear on t he disp lay.MENU

Press and button together for 5 seconds, display will show lock icon. Do this again to unlock.

Press bu tton to enter timer se tti ng.

Hou r data will be f lashing wi th ON, mo ve or t o set i t.

Con firm timer o n hour se tti ng by pressing bu tton.

Min ute data starts flas hing once ho ur setting i s confirme d, move or to set it.

Con firm timer o n minut e settin g by pressin g button.

Onc e Timer o n is set an d con firme d Timer off wi ll be activated.

Follow t he same s tep s as setti ng Time r on to set T ime r off.

2.9 Key pad lock

13

MODE

MENU

Key pad locked

Figure 2-6

Timer ON/OFF

Page 18

3. Protection systems

3.1 Water flo w switch

Equipped with flow switch the heat pumpwill not work when the filter pumpis not working (and the

water is not ci rculatin g).

Thi s system p revent s the heat pum p fro m heating only th e water present in the h eat pum p its elf.

The p rotectio n also sto ps the he at pump i f water ci rcu lat ion is cu t off or stopp ed.

3.3 Overheating protection on the compressor

Thi s protecti on prote cts the c ompressor from overhe ating .

3.2 Refrigerant gas high and low pressure protection

The h igh pre ssu re protection m akes sure the heat pum p is not damag ed in case of over press urisatio n of

the gas. The lowpressure protection emitsa signal when refrigerant isescaping fromthe conduits and the

unit can not be kept running.

3.4 Automatic defrost control

Whe n the air i s very hu mid and cold , ice can fo rm on the evaporator. In that event, a thin layer of ice a pp-

ears that will grow increasingly bigger as long as the heat pump is running. When the temperature of the

evaporator has b eco me too lo w, auto matic d efrost cont rol w ill b e activated, wh ich wil l revers e the heat

pum p cycle s o that hot refrigerant gas i s sent th rou gh the evaporato r durin g a brief p eriod of tim e to

def rost it.

3.5 Temperature difference between inflowing and outflowing water

Dur ing nor mal ope ration of th e hea t pump, the te mperat ure d ifference b etween inf lowing and o utflowin g

water will approximate 1to 2 In the event that the pressure switch does notwork and that the water℃.

stops circulating, the temperature probe monitoring the outflowing water will always detect a rise in

temperature.As soonas the temperature difference between inflowingand outflowing waterexceeds 13℃,

.the heat pump will be automatically turned off

3.6 Low temperature cut-out

If, dur ing coolin g, the tempe rature of the o utflo wing water reaches 5 or drops below th is temp erature,℃

the heat pump will turn itself off until the water temperature reaches or exceeds 7 again.℃

3.7 Anti-frost protection during winter

Thi s protecti on ca n only be a ctivated if the h eat pum p is in S TAND-BY stat us.

14

3.8 First anti-frost protection

If the filter pump is controlled by the heat pump (regardless of the value for parameter 9) and when the

water temperature lies between2 and 4 and the airtemperatureis lower than 0 the filter pumpwill℃, ℃,

be automatically turnedon to prevent the water from freezing in the piping.This protectionis deactivated

whe n the tem peratu re ri ses again.

3.9 Second anti-frost protection

If thewater temperaturedrops even more, that is, below2 (during long frost periods), the heat pump℃

will also start running to heat the water until its temperature approximates 3 When this temperature℃.

is reach ed, the h eat pum p will stop, but ant i frost protec tio n wil l rem ain act ive u ntil condi tions c hange .-

Page 19

4. Direction

4.1 Swimming pool water chemistry

pH

Free chlorine(mg/1)

TAC(mg/1)

Salt(g/1)

Important: failure to comply with these limits will invalidate the warranty.

Not e: exceedin g one or se veral li mits can damage the heat pump beyond repair. Always install water

treatment equipment past the heat pump s water outlet,especially ifthe chemicalsare automatically'

added to the water.

A check valve should also be installed between the outlet of the heat pump and this equipment inord er to p revent p rod ucts from flowi ng back into the he at pu mp if the filter pump s top s.

Spe cial attentio n should be pa id to t he chem ical ba lance of the p ool water. The pool water values s hould

always stay within the following limits:

Min

7.0

0.5

80

Max

7.4

1.2

120

3

4.2 Heat pump winterizing

Important: failu re to take the neces sary precauti ons for winteri zing can dam age t he heat pump ,

which will invalidate the warranty.

The heat pump, filter pump, filter and conduits must be protected in areas where the temperature can drop

bel ow the freez ing point, Evacuate all water from the heat pump a s follows:

1. Interrupt the electrical power supply to the heat pump

2. Close the water supply to the heat pump: completely close valves 2 and 3 of the by-pass

3. Di sconn ect the water inlet an d outlet couple r fittings o f the hea t pump and let t he wa ter d rai n out of the

unit.

4. Lo osely reattach water inlet a nd outlet co upler fitting s to th e heat pu mp in order to prevent dirt

from setting into the conduits.

Note: these precautions should not be taken if you choose to use the built-in anti-frost protection.

4.3 Restarting the pump after winter

If you purgedyour heat pumpfor winterizing, you shouldundertakethe following steps torestart it inspring:

1. Check first if there is no dirt in the conduits and if there are no structural problems

2. Ch eck if th e water inlet and o utlet coup ler f ittin gs are adequately fastened to the h eat p ump

3. St art t he filt er pump to start the water flow to t he he at pump . Set the by-p ass agai n.

4. Reconnect the electrical power supply to the heat pump and turn it ON.

15

Page 20

Condensation canoccur whenthe heatpumpis running. Thiscondensationcan flow away throughan opening

in the base pan of the unit. The amount of condensation water will increase when atmospherichumidityis

high. Remove any dirt that could possibly hamper the evacuation of condensation.

10 to 20 litres of condensation water can be produced while the unit is running. If more condensation is

produced, stop the heat pump and wait for one hour before checking for leaks in the conduits.

a quickway toverify that the water running through the condensation drain is indeedNote:

.condensation, is to shut off the unit and keep the pool pump running Ifthe water stops running out

of thecondensation drain, it is condensation. AN EVEN QUICKER WAY is to TEST THE DRAIN

WATER FOR CHLORINE. If no chlorine is detected, the drain water is a result of condensation.

Also take care toleave air inletand exhaustpassages free. Prevent exhaust airfrom immediately re-entering

the unit through the inlet.

4.4 Check-up

Our heat pumps have been developed and built to last, that is, if they have been installed correctly and can

run undernormal conditions. Regular check-ups areimportant if you want your heat pump tofunction

safely and effic ientl y for years on end.

1. Ma ke for easy acc ess t o the ser vice panel .

2. Keep the area surrounding the heat pump free of contingent organic waste.

3. Prune the vegetation near the heat pump so that there is enough free space around the pump.

4. Removecontingent water sprinklersfrom thevicinity ofthe heat pump. They can damagethe heat pump.

5. Prevent rain from directly running off a roof onto the heat pump. Install proper drainage.

6. Do not use the heat pump if it has been flooded. Immediately contact a qualified technician to inspect

the heat pump and repair it if should prove necessary.

16

Page 21

5. Maintenance and inspection

5.1 Maintenance

Che ck the water inle t and drainage of ten . The wate r and air infl ow into the system s hould be suf fic ient√

so that its performance and reliability doesnot get compromised. You should clean the pool filter

regula rly to avoid dama ge to the unit c aused by clo gging o f the filter.

The area around the unit should be spacious andwell ventilated. Clean the sides of the heat pump√

regula rly to ma int ain g ood hea t exchange an d to save en erg y.

Che ck if all p rocesses i n the uni t are operation al and pay specia l attention t o the operation perssure of√

the refrigerant system.

Check the power supply and cable connections regularly. Should the unit begin to function abnormally√

or should you notice a smell from an electrical component, arrange fro timely repair or replacement.

Youshould alsopurge the waterif the unit will not work for an extended periodof time. You should√

check allparts of the unit thoroughly and completely fill the system withwater before turning it on

again afterwards.

Improper installation mayresult in an electrical dischargethat could lead to deathof-or serious injury

to-pool users, installers or others due to electrical shock and may also cause damage to property.

attempt to modif y the int ern al conf igurat ion of the hea t pump.DO NOT

1. Keep your hands and hair clear of the fan blades to avoid injury.

2. If you are not familiar with your pool filtering systems and heat pump:

a. attempt to adjustor service without consulting your dealer oryour professional poolor airDo not

conditioning contractor.

b.Read the entire installation and user manual before attempting to use, service or adjust the unit.

C.Start the heatpump at least 24hours after itsinstallation in order to preventdamage to the compressor.

5.2 Trouble shooting guide

Note: Switch off thepower priorto maintenance orrepairs.

IMPORTANT REMARK: if amalfunction can not be resolved immediately, in order to analyse the

,

problem itself we will need to know the message(error code) that isdisplayed on thecontroller, as

well as the values for the settings(parameter 00-10 for LCD display while parameter 0-Afor LED

display) andforstatus of the heat pump (ambient temperature water inlet outlet temperature

,/

and system coil temperature) justbefore the failure or, if thisis impossible, just after it.

Please keep this information at hand when calling customer service.

On the following pages, you willfind anoverview ofthe different types offailure problems thatcan occur,

along with directions to solve them.

17

Page 22

Problem:

Observation:

Possible cause

Solution

the h eat pum p works no rmall y but the re is no or i nsuff icien t heatin g

The s creen d isplay s the tem peratu re but no e rror cod es

1. In s uffic ient cap acity o f the hea t pump in p ropor tion to t he

size o f the swi mming p ool

2. Th e compre ssor wo rks but t he fan do esn't

3. Th e fan work s but the c ompre ssor do esn't

4. Th e heat pu mp has no t been pl aced on a n optim al locat ion

5. Fau lty tem peratu re sett ing

6. By -pass n ot adju sted

7. Ma ssive i ce forma tion on t he evap orator

8. Not enough refrigerant

1. In stall a la rger si zed mode l or an ext ra heat pu mp.

Cov er the po ol to limi t heat lo ss

2. Ch eck the e lectr ical wi ring of t he fan. Re place t he

con dense r or the fan m otor if n ecess ary.

3. Ch eck the e lectr ical wi ring of t he compr essor.

Replace thecondenser or the compressor ifnecessary.

4. Ma ke for suf ficie nt air cir culat ion(s ee manu al for

details)

5. Se t the cor rect tem peratu re

6. Have the by-pass readjusted by the installer

7. Ha ve the set tings fo r autom atic de frost co ntrol

checked by the installer

8. Ha ve the hea t pump ch ecked by a r efrig eratio n

technician

Problem:

the h eat pum p doesn 't work

Observation:

the s creen d oes not l ight up an d the fan /compr essor d oesn' t make a sou nd

Possible cause

No electrical power supply

Solution

Check power supply (wiring, fuses, )…………

Problem:

the h eat pum p doesn 't stop

Observation:

the s creen d isplay s the tem peratu re but no e rror cod es

Possible cause

Solution

1.Wrong setting of parameters

2. Pr essure s witch o ut of ord er

3. Electrical failure

1.Check the setparameters and adjust themif necessary

(settings justabove the capacityof the heatpump)

2. Ch eck ope ration o f the pre ssure s witch by t urnin g

off t he filte r pump an d resta rting i t. If the h eat pump

doe sn't re act to thi s, the pr essur e switch m ust be

adjusted or replaced.

3. Contact your installer

The h eat pum p works no rmall y but the w ater is co oling d own ins tead of h eatin g up

The s creen d isplay s the tem peratu re but no e rror cod es

Problem:

Observation:

Possible cause

Solution

1.The wrong mode has been selected

2. The controller is out of order

3. Th e 4-way va lve is ou t of order

1.Verify the parameters, select the correct mode

2. Ch eck the v oltage i n the ele ctric al wiri ng to the

4-way valve. If no electric potential is measured,

replace the controller

3. Ch eck the v oltage i n the ele ctric al wiri ng to the

4-way valve. If electric potential is measured,

rep lace th e coil. If t he prob lem per sists, h ave the

hea t pump ch ecked by a r efrige ratio n techni cian

18

Page 23

Problem:

Observation:

Possible cause

Solution

abnormal amount of ice formed on the evaporator

the e vapora tor is for t he most p art cove red in ic e

1.Insufficient air inflow

2.High water temperature

3.In correc t setti ng of aut omati c defros t contro l

4.Th e 4-way va lve is ou t of order

5.Not enough refrigerant

1.Ch eck the l ocati on of the h eat pump a nd remo ve any

dir t that co uld be pre sent on t he evap orator

2.If t he pool w ater is al ready q uite ho t (warme r than

29?),the probability of ice formation increases.

Low ering t he set tem perat ure is a pos sible o ption

3.Ch eck the s etting o f the def rosti ng func tion tog ether

with your installer.

4.Ch eck the v oltage i n the ele ctric al wiri ng to the 4

-way valve. If electric potential is measured, replace

the c oil. If t he probl em pers ists, h ave the he at pump

checked by a refrigeration technician.

5.Ha ve the hea t pump ch ecked by a r efrig eratio n

technician.

Problem:

Observation:

Possible cause

Solution

water leak

the re's an a mount of w ater un der the h eat pum p

1.Condensation due to atmospheric humidity

2.Water leak

1.No action required

2.Try to l ocali ze the le ak and ch eck for th e prese nce

of ch lorin e in the wat er. If that i s the cas e, the he at

pump must be temporarily replaced during repair.

19

Page 24

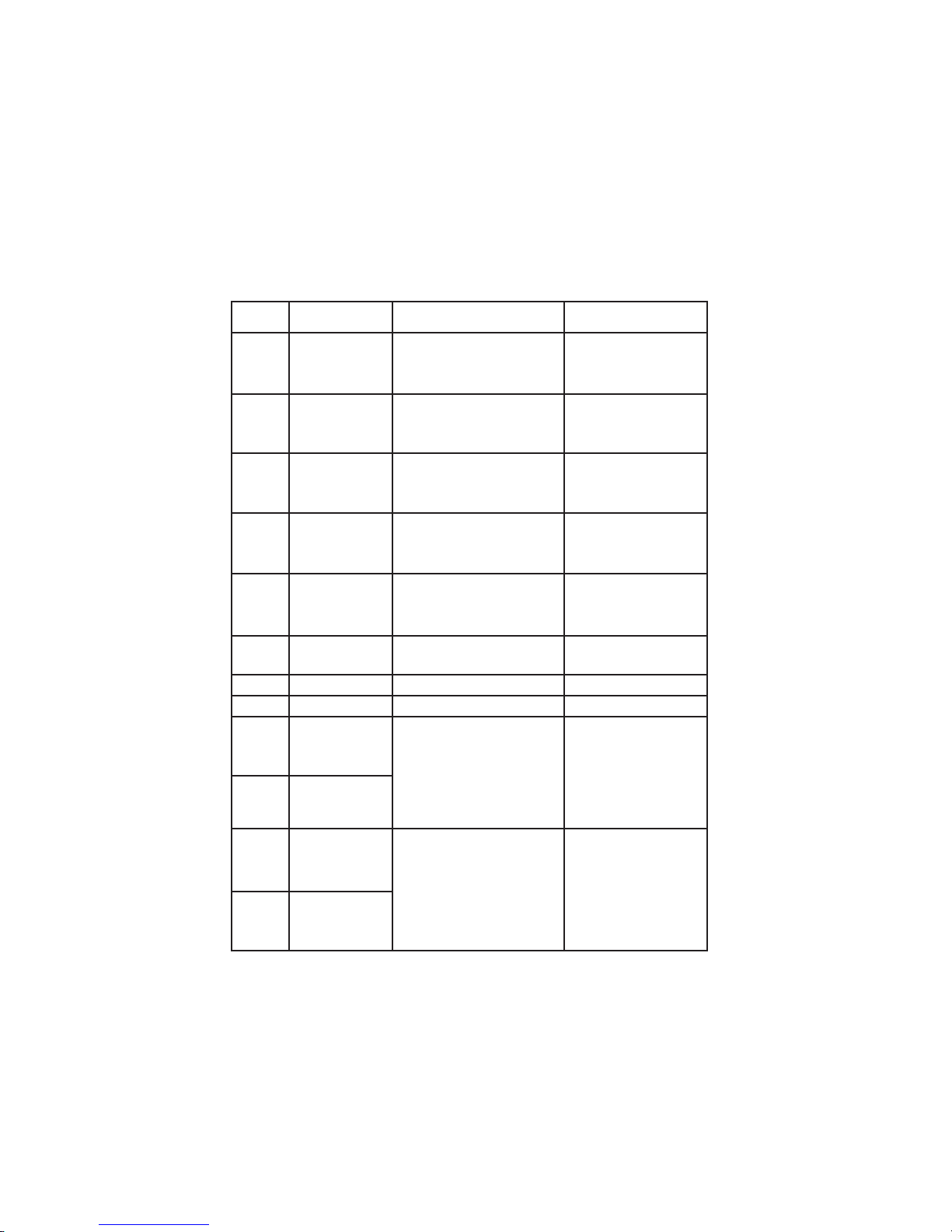

5.3 Failure code table for plug-in type PCB

20

Protection/Failure

Wire

controller

E3/EE3

No display

Check Solution

P1/PP1

1. Ch eck the conne ction o f inlet w ater

sensor.

.2. C heckif thesensor isbroken

1. Reconnect the sensor.

2. Rep lace th e senso r.

P2/PP2

1. Checkthe connection ofoutlet water

sensor.

.2. Check ifthe sensor isbroken

1. Reconnect thesensor.

2. Replace thesensor.

P3/PP3

1. Ch eck the co nnect ion of co il 1

temperature sensor.

.2. Check ifthe sensoris broken

1. Reconnect thesensor.

2. Replace thesensor.

P10/PP10

1. Ch eck the co nnect ion of co il 2

temperature sensor

2. Check ifthe sensoris broken.

1. Reconnect thesensor.

2. Replace thesensor.

P5/PP5

1. Ch eck the co nnect ion of am bient

temperature sensor.

.2. Check ifthe sensoris broken

1. Reconnectthe sensor.

2. Replace thesensor.

E12/EE12

1. Checkif wiring connectionof flow switch

is incorrect position.

2. Checkif enough waterflow.

3. Checkif flow switchis broken.

4. Check ifwater pump is working.

1. Reconnect the wiring.

2. Increase enough water flow.

3. Replace flow switch.

4. Repair or replace water pump.

E4/EE4

1. Che ck if high pressure switch is broken.

'2. Checkifthere sjaminwatercircuitor

waterflow n otenough.

3. Ch eckif refrigerantcircuit ja m.

E14/EE14

1. Check if thereis enough water flow volume.

2. Chec k if inle t/o utl et water temp sensor is working..

1. In crease w ater fl ow.

2. Rep lace re lated se nsor.

E8/EE8

Che ck the con necti on

Reconnect the connection wire.

P7/PP7

No action required

Water flow switch failure

Defrosting

Inl et water t emp. se nsor fai lure

Out let wate r temp. s ensor fa ilure

Coi l 1 temp. se nsor fa ilure

Coi l 2 temp. se nsor fa ilure

Ambient temp. sensor failure

Anti-freeze protection for cooling

High pressure protection Ⅰ

Failure of excessive temp. difference

bet ween wat er inlet & o utlet

Communication failure

Winter anti-freeze protection Ⅰ

Winter anti-freeze protection Ⅱ

P7/PP7

No action required

Orde r of phas es inco rrect

Reconnect thephases inright order

Orde r of phas es inco rrect

(on ly for 3 pha se mode l)

E1/EE1

1. Ch eck if hig h or low pressure switch is broken.

2.Checkiflackofrefrigerant.

3. Ambienttemp. and waterinlet temp.is

too low.

E6/EE6

Low pressure protection Ⅱ

High pressure protection Ⅱ

E5/EE5

1. Replace high pressure switch.

2. Remove cause of blockage or

increase water flow.

3. Send heat pump to dealer for

detailed check.

Low pressure protection Ⅰ

E2/EE2

1. Replace l ow pressure swit ch.

2. Fill up with enough refrigerant.

3. Remove cau se of blockage or

decreas e water flow.

4. Send he at pump to dealer for

detailed check.

1. Check ifthere isany jam inthe watercircuit.

2. Checkif the waterflow volumeis enough.

3. Check ifthe waterpump isworking.

E14/EE14

1. Rem ove the j am.

2. Increase thewater flowvolume.

3. Repair orreplace thew aterp ump.

Protection for excessive temp. difference

between water inlet & outlet

Page 25

6.Name plate & wiring diagram

6.1Name plate

21

Page 26

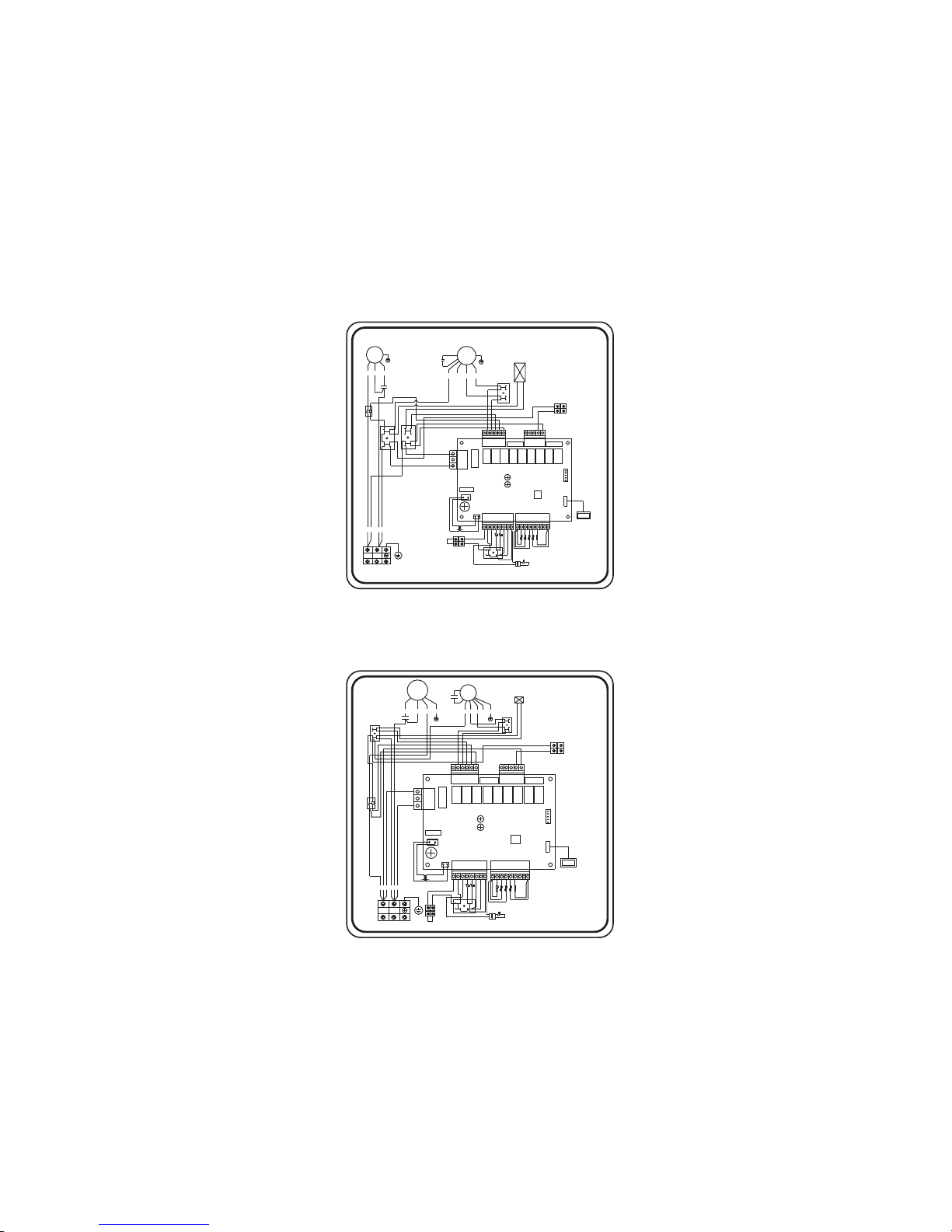

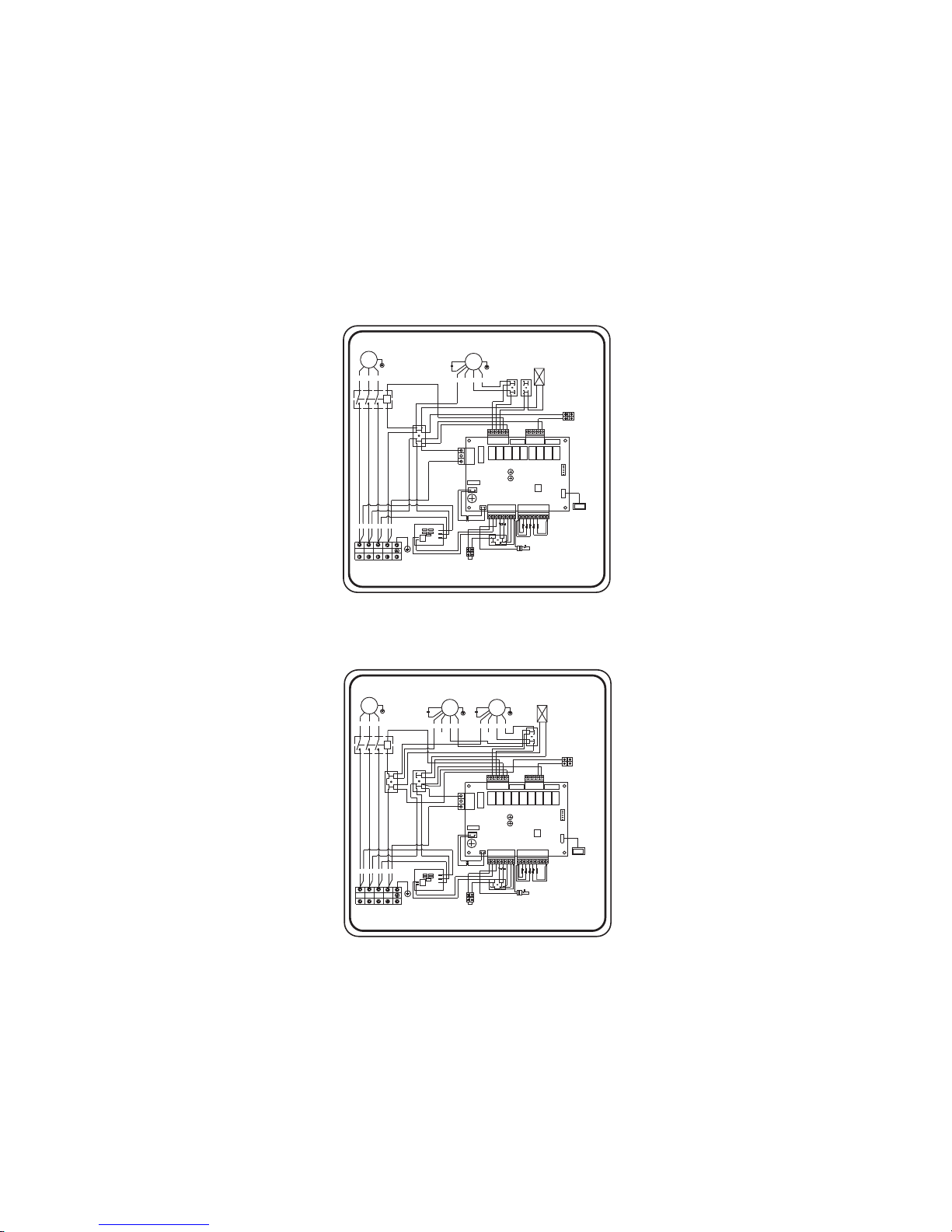

6.2 Wiring diagram

22

BLU

RED

BLURED

L

N

RED

ORG

WHI

YEL

BLU

BLK

C

4-way valve

FM

CM

KA9 5A/KA8 5A/KA75A/KA6 5A/KA55A/KA4 5A/KA3 5A/KA2 5A/KA1 5A/

IC

AC L- AC L-

AC N-

AC L-

220V AC/

12V AC/

Transformer

Wire controller

PP

N5

GND

FUSE

FUSE

FUSE

L

N2

Y01

KM

L

L

32 3028 29

LN

POWER SUPPLY

BLK

A1

A2

C

R

S

C

T1:

T2:

T3:

T4:

Ambient temp

Coil temp

Outlet water temp

Low Pressure switch

High Pressure switch

K1:

K2:

Inlet water temp

CM:Compressor

FM:Fan

KM:AC contactor

I15A<.

water pump

N6

B01

NOTE:

For cur rent of w ater pu mp

above 1.5Amp.

please externally equip

suitableA/C contactor.

External control

terminal

Water flow switch

LN

PE

PE

1103-1708

CC395-V1.0

GND

GND

GND

T2T1 T3 T4

K1K2

R=5K

KA9 5A/KA85A/KA7 5A/KA6 5A/KA5 5A/KA4 5A/KA3 5A/KA2 5A/KA1 5A/

AC L- AC L-

AC N-

AC L-

LN

RED

BLU

POWER SUPPLY

220V AC/

12V AC/

Transformer

YG/

YG/

REDBLU

BLK

ORG

BLU

C

C

C

R

S

BLKWHI

RED

N2

4-way valve

FM

CM

Wire controller

KM

A1

A2

N

N1

L

N5

Y01

FUSE

FUSE

FUSE

L

L

L

T1:

T2:

T3:

T4:

Ambient temp

Coil temp

Outlet water temp

Low Pressure switch

High Pressure switch

K1:

K2:

Inlet water temp

CM:Compressor

FM:Fan

KM:AC contactor

32 3028 29

PP

GND

YEL

A

I15A<.

water pump

N6

B01

NOTE:

For current of water pump

above 1.5Amp.

please externally equip

suitableA/C contactor.

External control

terminal

Water flow switch

N

PE

1108-1726

CC395-V1.0

IC

GND

GND

GND

T2T1 T3 T4

R=5K

K2 K1

Mida.Black 8 / 10 / 12

Mida.Black 14 / 17

Page 27

CC159 V1 0-.

CP4

CP3

T

S

R

BLURED BLKWHI

AB NC

WHIBLKRED

642

531

TSR

A2

A1

W

V

U

N1

L

RED

ORG

WHI

YEL BLU

BLK

C

POWER SUPPLY

4-way valve

FM

CM

KA95A/KA85A/KA75A/KA65A/KA55A/KA4 5A/KA3 5A/KA2 5A/KA1 5A/

IC

AC L- AC L-

AC N-

AC L-

220VAC/

12V AC/

Transformer

T1:

T2:

T3:

T4:

Ambient temp

Coil temp

Outlet water temp

Wire controller

PP

Low Pressure switch

High Pressure switch

K1:

K2:

N5

GND

FUSE

FUSE

FUSE

L

N

L

N2

Y01

KM

LL

32 3028 29

Inlet water temp

CM:Compressor

FM:Fan

KM:AC contactor

AB

I15A<.

water pump

N6

B01

NOTE:

For current of water pump

above 1.5Amp.

please externally equip

suitableA/C contactor.

External control

terminal

TSRN

PE

Water flowswitch

1110-1756

CC395-V1.0

T2T1 T3 T4 R 5K=

GND

GND

GND

K2 K1

Mida.Black 21

CC159 V1 0-.

CP4

CP3

T

S

R

BLURED

BLK

WHI

AB NC

WHIBLKRED

642

531

TSR

A2

A1

W

V

U

N1

L

N

RED

ORG

WHI

YEL

BLU

BLK

C

POWER SUPPLY

4-way valve

FM

CM

KA95A/KA8 5A/KA7 5A/KA6 5A/KA5 5A/KA45A/KA35A/KA2 5A/KA1 5A/

IC

AC L- ACL-

AC N-

AC L-

220VAC/

12V AC/

Transformer

T1:

T2:

T3:

T4:

Ambient temp

Coil temp

Outlet water temp

Wire controller

PP

Low Pressure switch

High Pressure switch

K1:

K2:

N5

GND

FUSE

FUSE

FUSE

L

N2

Y01

KM

32 3028 29

Inlet water temp

RED

ORG

WHI YEL BLU

BLK

C

FM

CM:Compressor

FM:Fan

KM:AC con tacto r

1# 2#

A

I15A<.

water pump

N6

B01

NOTE:

For current of water pump

above 1.5Amp.

please externally equip

suitableA/C contactor.

Water flowswitch

External control

terminal

TSRN

PE

1111-1721

CC395-V1.0

GND

GND

GND

T2K1T3T4

R=5K

K

2

Mida.Black 26

23

Page 28

ACHTUNG: Dieses Hanbuch beinhaltet alle infomrationen die für die Benutzung und die Installation ihrer

Wärmepumpe erforderlich sind.

Der Installateur mussdas Handbuch gründlichdurchlesen durchlesen und den Anweisungenstrikt folgen,

sowo hl bei der I mpl ement ierung als a uch bei d er Wartung.

Der Installateur ist verantwotlich für die Installation des Produkts und sollte allen Anweisungen des Herst-

ellers sowie allen Vorschriftenin denAnwendungen folgen.Inkorrekte Installationgegen dieAnweisungen des

Handbuchs macht dieGarantie nichtig.

Der Hersteller lehnt jede Verantwortung ab für Schäden die durch Menschen, Objekte oder Fehler

die auf Nichtbefolgung von Anweisungen im Hanbuch beruhen. Jede Nutzung die bei Herstellung nicht

vorgesehen war wird als gefährlich eingestuft.

WARNUNG: Bitte le eren Sie das Wa sser in d er Wärmepumpe i m Win ter o der w enn d ie Temperatur unter 0° C

sin kt, son st wird der Titanium -Wechsler d urch Frost besch ädi gt. In diese m Fall ist d ie Garantie nic hti g.

Bitte schalten Siesimmer die Stromversorgung aus, wennsie die Kabine ffnen wollen umins InnereWARNUNG: ö

der Wärmepumpe vorzudringen, da drinnen Hochspannung herrscht.

WARNUNG:Bittebewahren Sie denKontrolldiplay aneinem trockenenOrt, oder schlie en Siedie Isolationsabdec-β

kungsorgältig, um es vor Beschädigung durch Nässe zu schützen.

SCHWIMMBAD-WÄRMEPUMPE

Gebrauchsanweisung Installation und Instruktion

Page 29

Contents

1

1

2

2

3

4

5

5

6

6

7

8

14

14

14

14

14

14

15

15

16

16

16

17

18

18

21

9

10

10

11

11

11

12

13

13

13

6.1Name plate

6.2 Wiring diagram

6.Name plate & wiring diagram

23

24

1. Leistung und Eigenschaften

1. Leistung und Eigenschaften1

1.2 System schema

1.3. Spezifikationen

1.3.1 Technische Daten

1.3 2 Abmessungen.

Lage der Wärmepumpe1.4

1.5 W ie weit vo n Ihrem S chwim mbad en tfernt ( dista nce from t he pool )

1.6 Installation von Verschlussventilen (Check-Malve)

71. Typische Aufstellung

1.8 Durch fluss regulierung

1.9 Elektroanschluss

1.10 Inbetriebnahme

2. Bedienung mittels LED Schalttafel

2.1 Wiedergabe der LED-Schalttafel

2.2Die Wärmepumpe einschalten

2.3 Die Einstellung der Funktion

2.4 Die gewünschte Wassertemperatur einstellen

2.5 Anzeigen und ändern von Parametereinstellungen

2.6 Einstellen der Uhrzeit

2.7 Pa ramet er übers icht

2.8 Die Zeitschaltuhr ein-/ausschalten

2.9 Stornieren der Funktion “Schaltuhr An“oder “SchaltuhrAus

2.10 Schalttafel (de)blockieren

3. Sicherungen

3.1 Schalter fließen

3.2 Drucksicherung auf das Kühlgas

3.4 Automatische Entladung

3.5 Temperaturunterschied zwischen ein- und ausgehendem Wasser

3.6 Temperatursicherung bei Abkühlung.

3.7 F rostsc hutz im W inter

3.8 Erste Frostsicherung

3.9 Zweite Frostsicherung

4. Richtlinien

4.1 C hemie d es Schw immba dwass ers

4.2 Überwintern der Wärmepumpe

Inbetriebnahme nach dem Winter4.3

4.4 Kontrolle

5. Unterhalt und Betrieb

5.1 Pflege

5.2 Fehlermeldung und Lösungen

5.3 bersicht der Fehlermeldungen auf der LED-AnzeigeÜ

Page 30

1. 1. Leistung und Eigenschaften

Cooler

De-energized Air

Warm

Air

Fan

Evaporator

(Energy Collector)

Capillary Tube

Condenser

(Water Heat Exchanger)

Pool Filter

Pump

Compressor

Swimming pool

1.2 System schema

√Hohe Wirksamkeit

Unsere Wärmepumpen sind beider Wärmeübertragung aus derLuft in das Schwimmbeckenwasser sehr

wirkungsvoll.Gegenüber einem elektrischenHeizkörperkönnenSie bis zu80 % Energie sparen.

Lange Lebensdauer

√

Der Wärmetauscher ist aus einem Rohr aus dem Verbundmaterial PVC-Titan hergestellt, dass einer

langzeitigen Einwirkung des Schwimmbeckenwassers standhält.

√Einfache Steuerung und Bedienung

Die Einrichtung ist sehr einfach zu bedienen: schalten Sie sie einfach ein und stellen Sie die gewünschte

Wassertemperatur im Schwimmbecken ein.

Das System beinhaltet eine Mikrocomputersteuereinheit, die Einstellung aller Betriebsparameter ermöglicht.

Der Betriebszustand kann an der Steuereinheit mit LCD angezeigt werden.

Wärmepumpennutzendie kostenlose Sonnenwärme dadurch,dass sie Energie ausder Umgebungsluftsammeln

und absorbieren.

Diese Einrichtung beinhalteteinen Ventilator, derdie Außenluft einsaugt unddiese zur Strömung über der

Oberfl äche des VERDAMPFERS (Energiesammler) zwingt. Dasflüssige Kühlmittel in derRohrleitung des

VERDAMPFERS resorbiert die Wärme der Außenluftund dasKühlmittelwird gasförmig.

Das warme Gasin der Rohrleitungwandert durch den KOMPRESSOR, derdie Wärmekonzentriertund die

Temperatur steigert, damiter ein sehrheißes Gasbildet, das dann inden KONDENSATOR (Wasserwärmetauscher)

wandert. Dies ist der Ort, wo es zum Wärmeaustausch kommt, wenn das heißeGas die Wärmean das kältere

Schwimmbeckenwasserabgibt, das durch dieSchleifezirkuliert.

Das Beckenwasser wird erwärmtund das heißeGas wir beiseiner Strömungdurch die Rohrleitungdes

KOND ENSATORS abgekü hlt – es wird wiede r flüssig und na ch der Ström ung durch die KAP ILARRÖHR E

beg innt der Prozess von Vorne.

Die gegenwärtige Technologie der Wärmepumpe ermöglicht eine wirkungsvolle Nutzung der Wärme

aus derAußenluft bei einer Temperaturvon bereits 7 bis 10 °C. Fürtropische und subtropicsche

Klimaverhältnisse bedeutet dies, dass im Becken eine Temperatur von 26 bis 32 °C unter fast allen

Bedienungen Während des gesamtenJahres aufrecht erhalten werdenkann. In nördlichen Klimazonen

verlängert die Wärmepumpe die

Badesaison merklich.

1

Heat exchanger

Wate r flow out

Evaporator

Air flow

Compressor

Air flow

Wate r flow in

Figure 1-1

Figure 1-2

Page 31

1.3. Spezifikationen

1.3.1 Technische Daten

2

*über die Technischen Daten, Wie nderungen, ohne vorankündigung.Die Daten sindä

auf dem namensschild ist die Neueste version.

Messbedingungen: Außenlufttemperatur: 24°C, Temperatur einströmendes Wasser: 26°C,

65% rel.Feuchtigkeit

Mida Black 14.

14

2550

55.

11. 57

Rotating

120

850

43

50

7

14

1110 415 710**

81

220-240V/1PH/50HZ

kW

W

C.O.P

A

V/Ph/Hz

w

RPM

dB(A)

mm

mh³/

kPa

mm

kg

Rotating

80

850

39

50

5

10

970 360 585**

55

Mida Black 10.

9.8

1730

565.

7.85

Rotating

120

850

42

50

6

12

1045 370 625**

62

Mida Black 12.

12.8

2360

545.

10.72

Rotating

120

850

42

50

7

12

1045 370 625**

67

Mida Black 8.

.78

1440

.54

657.

Mida Black 26.

26

4480

58.

8.0

Scrolling

240*2

770

47

50

15

16

1110 445 1260**

137

380-400V/3PH/50HZ

kW

W

C.O.P

A

V/Ph/Hz

w

RPM

dB(A)

mm

mh³/

kPa

mm

kg

Mida Black 17.

17

2790

6.1

13.3

Scrolling

240

770

43

50

10

14

1110 415 710**

99

Mida Black 21.

21

3620

58.

6.5

Scrolling

370

850

46

50

12

16

1110 445 960**

111

220-240V/1PH/50HZ

Gerät

Wärmekapazität

Aufnahmeleistung

Nutzleistung

Nominalstrom

Speisung

Kompressorentyp

Leistung Ventilator

Drehzahl Ventilator

Geräuschpegel (10M)

Wasseranschluss

Nominelle Wasserbelastung

Max. Wasserdruckverlust

Netto-Abmessung (L/B/H)

Liefergewicht

Gerät

Wärmekapazität

Aufnahmeleistung

Nutzleistung

Nominalstrom

Speisung

Kompressorentyp

Leistung Ventilator

Drehzahl Ventilator

Geräuschpegel (10M)

Wasseranschluss

Nominelle Wasserbelastung

Max. Wasserdruckverlust

Netto-Abmessung (L/B/H)

Liefergewicht

Page 32

1. 2 Abmessungen (mm)3.

3

Modus

Mida. Black 8

Mida. Black 10

Mida. Black 12

Mida. Black 14

Mida. Black 17

Mida. Black 21

A

585

625

625

710

710

960

B

554

564

564

694

694

944

C

85

85

85

85

85

85

D

250

300

300

400

400

500

E

970

1045

1045

1110

1110

1110

F

360

370

370

415

415

445

G

313

340

340

386

386

420

Modus

Mida. Black 26

A

B

C

D

E

F

G

1260

1244

85

620

1110

445

420

Page 33

1.4 Lage der Wärmepumpe

Das Gerät wird an jedem Ort gut arbeiten, vorausgesetzt, dass drei Aspekte vorhanden sind:

1. Frische Luft - 2. Elektrizität - 3. Schwimmbad-Filterrohre

Das Gerät darfpraktisch überall installiert werden,vorausgesetzt,dass ein Mindestabstandzu and-außen

eren Gegenständen beachtet wird(siehe Zeichnung unten).Für Hallenschwimmbäder fragen SieIhren Ins-

tallateur.

Es besteht kein Problem mit windigeren Stellen, wie es z.B. bei einem Gaserhitzer der Falls ist

(u.a. Zündflammenproblem).

WICHTIGER HINWEIS:Stellen Sie das Gerätnicht in einem geschlossenenRaum mit einembeschränkten

Luf tvolu men auf, wo rin die B rauchluf t erneut ver wen det wird, od er nahe z u Gartensträuche rn, die den

Lufteinlass blockieren können. Diese Stellen behindern einen kontinuierlichen Zustrom an frischer Luft,

wodurch die Effizient vermindert und adäquater Wärmeertrag verhindert werden kann.

Siehe die unten stehenden Zeichnungen für die Mindestabmessungen.

Hinweis:

√GreifenSie niemit den Händen inden Luftaustrittund denVentilator und haltenSie auch keine Gegenstände

hinein. Dies könnte die Einrichtung beschädigen und zu Unfällen führen.

Im Fall de s Auftretens von jed wed en Abno rmali täten sc halten Sie s ofort die St romversorgun g aus und√

kontaktieren Sie einen professionellen Techniker.

Im Fall der Notwendigkeit platzieren Sie rund um die Einrichtung einer Barriere, damit Kinder keinen√

Zugang zu der laufenden Wärmepumpe haben.

4

Figure 1-3

Model:Horizontal Unit

Fre e space re quire ment for t he hori zontal h eat pum p

Not less than 500mm

Air in

Not l ess tha n 500mm f rom the to p

Air in

Not less

than 500mm

Not less than 2000mm

Air o ut

Not less

than 500mm

Page 34

1.5 Wie weit von Ihrem Schwimmbad entfernt (distance from the pool)

Water Pu mp

P-trap

Check-valve

Filter

Chlorinator

Check-valve

Swimming Pool

5

Figure 1-4

Normalerweise installieren Sie die Wärmepumpe innerhalb eines Radius von 7,5 m um das Schwimmbad.

Je we ite r der Abstand des S chw immba ds, des to größe r der Wärm eve rlust durch die Rohre. Da d er Groß-

tei l der Rohr e unter de m Grund l iegt, ist de r Wärmeverl ust geri ng für Ab sta ndswerte bis 30 m ( 15 m vo n

und z ur Pumpe = 30 m ge samt), auß er dass der Bo den nass ode r der Wasserpeg el hoch ist. Eine g robe

Schätzung des Wärmeverlusts pro 30 m ist 0,6 kWh, (2000BTU) für jeweils 5 ºC Temperaturunterschied

zwi schen dem Sc hwimm badwasse r und dem Grun d rund um d as Rohr, was zu ei ner Verläng erung der

Betriebsdauer von 3% bis 5% führt.

1.6 Installation von Verschlussventilen (Check-Malve)

Achtung – Bei Gebrauch automatischer Dosierungssysteme für Chlor und P+L ist es sehr wichtig, die

Wärmepumpe vor allzu starken Konzentrationen zu schützen, die den Wärmewandler antasten können.

Dah er müss en solc he Vorricht ungen st ets i n den Lei tunge n angebracht werden, die sic h HINTER der

Wärmepumpe befinden, und er wird empfohlen, ein Verschlussventil anzubringen, um Rückfluss bei

Abwesenheit von Wasserzirkulation zu verhindern.

Schäden an der Wärmepumpe, die durch mangelnde Berücksichtigung dieser Vorkehrungen verursacht

wurden, fallen nicht unter die Garantie.

Page 35

1. Typische Aufstellung7

1. Durch fluss regulierung8

Valve 1

Valve 2

Valve 3

BY-PASS

F

r

o

m

f

i

l

t

e

r

T

o

p

o

o

l

OUT IN

HEATPUMP

Powe r cable i nlet

Heat Pump

Outlet

Inlet

Condensed water draining pipe

Draining nozzle

Dis charge w ater to po ol

Pool w ater inl et

Water pu mp

Filter

Water processor

Side connection valve

6

Figure 1-5

Figure 1-6

Folgen Sie diesen Schritten, um den

Bypass zu regulieren:

*Öf fnen Si e die 3 Häh ne vollstän dig

*Schließen Sie Hahn 1leicht bis der

Wass erdru ck mit 10 0 bis 200 G ramm

erhöht ist

*Schließen Sie Hahn 3 ungefähr halb,

um de n Druck d es Kühlgases im Gerät

zu regeln.

Page 36

Kabeldiameter(mm )

2

Lng )ä(Max . e von 10 m

Modus

Spannung(V)

Sicherung(A)

Nominal

strom(A)

Wichtig – Obschon die Wärmepumpe elektrischvom Rest derSchwimmbad Installation isoliert ist,verhi-

ndertdies alleine den Elektrizitätsfluss von und in das Schwimmbadwasser. Erdung ist noch zu jeder Zeit

nötig, um Sie gegen Kurzschluss im Gerät zu beschützen. Sorgen Sie daher für eine gute Erdung.

Prüfen Sie vorab, ob die elektrischeNetzspannung übereinstimmtmit der Arbeitsspannung der Wärmep-

umpe.Es wird empfohlen, eine gesonderte Sicherung zu verwenden (Trägheitstyp –D-Kurve), zusamm-

en mit einer wirksamen Verkabelung (siehe Tabelle unten).

Für die horizontale Modelle: Entfernen Sie die Platte rechts von der Ventilatorenöffnung.

Für die vertikale Modelle : Entfernen Sie die Eckplatte mit der elektronischen Bedienung.

Verbinden Sie die elektrischen Drähte mit dem Klemmenblock „ZUR STROMVERSORGUNG“.

Neben diesemAnschluss befindet sich einzweiter Klemmblock„ZUR PUMPE“,wo die Filterpumpe

(max. 5A/240V) angeschlossen werden kann. Hierdurch kannman die Funktion der Filterpumpe durch die

der Wärmepumpesteuern lassen.

Anmerkung – Für die 3-phasigen Modelle kann das Auswechseln von 2 Phasen die Folge haben, dass

Elektromotoren sich in die entgegen gesetzte Richtung drehen, mit möglicher Schadensfolge. Daher is-

t eine Sicherung eingebaut, die denStrom unterbricht, fallsder Anschlussnicht korrekt ist. Wenn maneine rote LEDüber diesen Sicherungen leuchten sieht, dann muss man 2 Phasendrähte austauschen. be-

en bu ilt in, w hich wi ll interru pt the circuit if t he co nnect ion has not been p erformed correct ly.

1. Elektroanschluss9

7

Figure 1-7

Figure 1-8

2x2.5+2.5

2x2.5+2.5

2x2.5+2.5

2x4.0+4.0

2x4.0+4.0

4x2.5+2.5

4x2.5+2.5

Mida.Black 8

Mida. Black10

Mida. Black 12

Mida. Black 14

Mida. Black 17

Mida. Black 21

Mida. Black 26

220-240

220-240

220-240

220-240

220-240

380-400

380-400

16

16

20

25

32

16

20

6.57

7.85

10.72

11.57

13.3

6.5

8.0

Page 37

1.10 Kondensation

1.10 Inbetriebnahme

Zeitverzögerung – Das Gerät ist miteiner eingebauten Startverzögerungvon 3 Minutenzum Schutz der Elektrik

ausgerüstet und umdie Kontaktezu schonen. Nach diesemZeitintervalwird das Gerät automatisch hochfahren.

Selbst ein kurzer Stromausfallwird diese Sicherung aktivierenund somit verhindern, dassdas Gerätunmittelbar

startet. Weitere Stromausfälle während dieser Sicherung haben keinen Einfluss auf die 3 Minuten dauernde

Verzögerung.

Schalter fließen –Das Gerät istmit einem Druckschalter ausgerüstet,der anschlägt, wenn genügendWasser

durch Gerät strömt, und der abschaltet, wenn der Durchfluss zu klein wird (z.B. wenn die Filterpumpedas

abschaltet).

Durch de n Betri eb der Wär mepumpe wi rd die anges augte Lu ft beim E rwärm en des Schwi mmbadwassers

stark abgekühlt undes kann Wasser auf denVerdampferflächen kondensieren. Bei einerhohen Luftfeuchtigkeit

können dies selbst mehrere Liter pro Stunde sein. Manchmal wird dies fälschlicherweise als ein Wasserleck

betrachtet.

Abhängig von der Ausgangstemperaturdes Schwimmbadwassers undder Lufttemperatur, sind mehrerTage

dazu nötig, um das Wasser aufdie benötigte Temperatur zu bringen.Eine gute Abdeckung desSchwimmbads

kann diese Periode drastisch verkürzen.

Nachdem alle Anschlüsse angelegt und kontrolliert wurden, müssen folgende Schritte befolgt werden:

1.Stellen Sie die Filterpumpe an. Überprüfen Sie auf undichte Stellen und vergewissern Sie sich, dass das

Wasser von un d zum S chwim mbad strömt.

2.Schließen Sie den Strom an die Wärmepumpe an und drücken Sie den Schalter AN/AUS “ ” auf der3.

elektronischen Bedienung. Das Gerät startet zeitverzögert (siehe unten).

3.Üb erprü fen Sie nach e inigen Minute n, ob die Luft , die aus d em Gerät geblas en wird, kühler i st.

4.Überprüfen Sie die Funktion des Druckschalters wie folgt: Stellen Sie die Filterpumpe aus während die

Wärmepumpe läuft. Das Gerät wird automatisch die Funktion anhalten.

5.LassenSie das Gerätund die Filterpumpe24 Stunden amTaglaufen, bis die gewünschte Wassertemperatur

erreicht wurde. Zudiesem Zeitpunkt stoppt die Wärmepumpe den Betrieb.Das Gerät wird jetztautomatisch

hochfahren (solange dieFilterpumpe in Betrieb ist)während die Schwimmbadtemperatur unter1 Grad unter

die programmierte Temperatur sinkt.

Hinweis – Umdas Schwimmbad (oder eventuell Mineralbad) aufzuwärmen, muss die Filterpumpearbeiten,

um Heißwasser durchdie Wärmepumpe zirkulieren zu lassen.Ohne dieseZirkulation wird die Wärmepumpe

nicht hochfahren.

8

Page 38

2. Bedienung mittels LED Schalttafel

MODE

MENU

2.1 Wiedergabe der LED-Schalttafel

Key-Funktionen:

:- -Ein /Ausschalten der Swimmbad Wärmepumpe

MODE: Einstellmodus: Heizen, Kühlen oder auto

:Einstellen timer on/off

MENU :Anzeige Parameter und/oder bestätigen

:Einst el le n de r Werte: n ie dr ig er o de r erhöhen

–He izung Symb ol zeigt an, dass d ie Pumpe in He izbet rieb läuft

–Kühl Sy mbol zei gt an, dass di e Pumpe i n Kühlbetr ieb läuft

–Au tomatic Symbo l zeigt an, dass di e Pumpe i n Automatic bet rieb läuft

–Kompr essor Symb ol, zeigt den S tatus des Ver dichters

–Wasserpumpe Symbol, zeigt den Status der Wasserpumpe

–Fan Symbol , zeigt den Status des Ve ntilators

–De fro st Symbo l, zeigt den Status de s abtauen

–4-Wege-Ventil Symbol, zeigt den Status des 4-Wege-Ventil

–Elektroheizung Symbol, anzeigt, ob der externe elektrische Heizeinrichtung aktiviert wird oder nicht

–Betrieb elektrische Heizung Symbol gibt an, ob die externe elektrische Heizung in Betrieb ist oder nicht

–Al arm symbol , deutet auf e ine Stö rung

–Fan speed symbol ,zeigt die Ventilatorgeschwindigkeit:Niedrig(1),mittel(2) oder hoch (3)

–Schloss-Symbol zeigt an, dass das Panel gesperrt ist

Figure 2-1

9

Bedeutung Display-Symbole:

Page 39

Dr ücken Sie a uf d ie Tas te ¨ MO DE ¨, u m di e je weilige Fun kt io n au sz uw äh le n: automa ti sc h, e rw är me n

oder kühlen In der jeweiligen Anzeige an der rechten Seite der Schalttafel wird die ausgewählte Funktion.

aufleuchten.

2.3 Die Einstellung der Funktion

MODE

MENU

verwarmen

Figure 2-4

10

Figure 2-2

MODE

MENU

MODE

MENU

werkingsstatus

Figure 2-3

2.2Die Wärmepumpe einschalten

Drü cken Sie die Taste um d ie Wärme pumpe zu aktivi eren. We nn die Wär mepumpe ak tiviert ist, li cht

in der Mitte des Wortes „Power“ auf. Auch leuchten alle aktivierte Komponenten auf. Die linke Abbildung

zeigt das Bedienfeld während„Standby“, rechts zeigt die Abbildung das Bedienfeld in Betriebsmodus. Die

inke Temperatur gi bt da s einge hende Wa ssertemperatur e in un d die rec hte Tem peratu r die ausgeh ende

Wassertemperatur.

Page 40

2.5 Anzeigen und ändern von Parametereinstellungen

1.Drücken Sie 5 Sekunden „Menu“. Der Parameter Anzahl und

ihr Wert werden gleichzeitig blinken.

2.Blättern Sie mithilfe der Pfeiltasten bis zum gewünschten

Parameter.

3.D rücken Sie „Men u“, um einen Parameter auszuwähl en.

Nachdem bleibt den Wert blinken.

4.Stellen Sie mithilfe der Pfeitasten den gew nschten Wert ein.

ü

Dieser Wert wird nun 5Sekunden lang blinken und dann

aut omatisch gesp eichert. D ie Anzeige wird dann a utomatis ch

zum Hauptbildschirm zurückschalten.

Sie können die eingestellten Parameter jederzeit einsehen. Sie können jedoch die Einstellungen nur

ändern, wenn die Wärmepumpe sich im Standby-Modus befindet.

2.4 Die gewünschte Wassertemperatur einstellen

1 Wählen Sie zuerst die gewünschte Funktion: automatisch erwärmen oder kühlen.,.

.2 Wählen Sie nun mithilfe der Pfeiltasten die gewünschte Wassertemperatur. Auf der LCD- Anzeige wird

der ausgewählte Wert angezeigt.

Figure 2-5

11

1. Drücken Sie kurz “Menu”, um die Zeiteinstellung an zu Zeigen.

2. Die Stunden blinken und können Sie anpassen mit den Pfeiltasten.

3. Drücken Sie “Menu” um die Einstellung zu bestätigen.

4. Jenseits blinken die Minuten und können Sie dieser anpassen mit den Pfeiltasten.

5. Drücken Sie “Menu” um die Einstellung zu bestätigen.

6. Da s Bedie nfeld wird jetzt aut omatisch zum Ha uptbi ldschirm z urückkehren.

2.6. Einstellen der Uhrzeit

ACHTUNG!

MODE

MENU

parameter

value

Page 41

12

2.7 Parameter übersicht

Beschreibung

Gewünschte Wassertemperatur im Kühlmodus

Gewünschte Wassertemperatur im Wärmemodus

Abtauzyklus

Verdampfer-Temperaturregler zum Abtaustart

Verdampfer-Temperaturregler zum Abtaustopp

Höchstdauer des Abtauvorgangs

Kompresso r Anzah l im System

Neustart nach Stromausfall (0=nein, 1=ja)

Modus:

0=nur kühlen,

1=kühlen + erwärmen,

2=k ühlen + erwär men + Zusatzwärme,

3=nur erwärmen

Modus:

0=Wasserpumpe läuft ununterbrochen,

1=Wasserpumpe läuft gemäß Schaltung,

mit der Wärmepumpe

Gewünschte Wassertemperatur in Automodus

Niederdruck-Schutz: 0=Standard, 1-2=verzögern

Aktuelle Zufuhr der Wassertemperatur

Aktuelle Abfuhr der Wassertemperatur

Batterietemperatur im System 1

Batterietemperatur im System 2

Umgebungstemperatur

Einteilung

8~37°C

8~40°C

10~90 min

-30~0°C

2~30°C

1~12 min

1~4

0~1

0~3

0~1

840~°C

1~20°C

0/1/2

-9~99°C

-9~99°C

-9~99°C

-9 ~99°C

-9~99°C

Standard

28°C

28°C

45 min

-7°C

13°C

8 min

1

1 (Ja)

1

0

30°C

2°C

0

Vom Techniker

einzustellen

Anmerkung

Vom Techniker

einzustellen

Vom Techniker

einzustellen

Vom Techniker

einzustellen

Vom Techniker

einzustellen

Vom Techniker

einzustellen

Vom Techniker

einzustellen

Vom Techniker

einzustellen

Vom Techniker

einzustellen

Vom Techniker

einzustellen

Vom Techniker

einzustellen

Vom Techniker

einzustellen

Gemessener

Wert

Gemessener

Wert

Gemessener

Wert

Gemessener

Wert

Gemessener

Wert

0

1

2

3

4

5

6

7

10

11

12

A

b

C

d

E

Parameter

8

9

Vom Techniker

einzustellen

Wassertemperaturdifferenz-Einstellung

für Neustart

Page 42

2.8 Die Zeitschaltuhr ein-/ausschalten

2.9 Stornieren der Funktion “Schaltuhr An“ oder “SchaltuhrAus

Dr ücken Sie d ie Taste um di e Ti me r au sz uw ählen Die Zei t, O N un d OFF werde n je tz t bl in ke n möchten...

.Dr ücken Sie n ac hd em M EN U um d ie e ingestell te T im er a b zu b re ch en Der ON und OFF S ym bo le n werden

von Schirm verschwinden.

Drü cken Sie die Taste um d ie Timer-E instellungen zu öf fnen.

Die Stunden blinken jetzt mit“ON”. Stell Die gewünschte Minuten ein mit den Pfeiltasten.

Bestätigen Sie die eingestellte TIMER ON Stunde- Einstellung mit der Taste.

Die Minuten blinken jetzt mit“ON”. Stell die gewünschte Minuten ein mit den Pfeiltasten.

Bestätigen Sie die eingestellte TIMER ON Minuten-Einstellung mit der Taste.

Die Wärmepumpe schaltet sich zur eingestellten Zeit ein.

2.10 Schalttafel (de)blockieren

Figure 2-6

MODE

MENU

Key pa d locked

Timer ON/OFF

13

Wen n Si e di e TI ME R ON eingeste ll t ha be n kö nn en S ie d ie TIMER OF F ei ns te ll en i n de r gl eichen,

Weise.

Sie können die Schalttafel blockieren indem Sie beide Pfeiltasten 5 Sekunden lang gleichzeitig eingedrückt,

halten Das Schloss Symbol leuchtet auf dem Bildschirm.- .

,-,Um die Blockierung aufzuheben wiederholen Sie diesen Schritt. Eine (De )Blockierung ist nicht möglich

wenn Sie sich im Parametermenu befinden.

Page 43

3. Sicherungen

3.1 Schalter fließen

Um zu verhindern, dass die Wärmepumpe bei einer stillstehenden Filterpumpe (und somit keine

Wasserzir kulation vorh anden i st) nur d as Wasse r aufwärmt, das s sich in der Wärmepum pe selbst befin det ,

sol l der Dru cksch alter ve rhind ern, da ss die Wärmepum pe startet. Die se Sicheru ng sorgt a uch vor, da ss die

Wärmepumpe stillsteht, wenn die Wasserzirkulation gestoppt wird.

3.3 Temperatursicherung auf dem Kompressor

Die se Sich erung s oll ver hin dern, d ass der Komp resso r überhitz t wird

3.2 Drucksicherung auf das Kühlgas

Tdie Hochdrucksicherung sorgt auch vor, dass die Wärmepumpe nicht beschädigt wird, wenn der Gasdruck

zu hochwird. Die Niedrigdrucksicherung zeigt an, dasseine Menge anKühlmittel ausden Leitungen ausgetreten

ist u nd der Betri eb nicht mehr fortge set zt werden kann.

3.4 Automatische Entladung

Bei sehrfeuchter Luftund kaltenLufttemperaturenbesteht dieMöglichkeit derEisformungauf dem Verdampfer.