Page 1

419

Go To Table Of Contents

Place Order

To purchase a printed copy of this manual,

click on the "Place Order" button below.

Style B

Service and

-003 thru -006

Power Procedure Table

Serial Number Prefixes:

LM, LN, LP, LR & V

Parts Manual

NO LONGER IN PRODUCTION

Some service parts may not

be available for this production

FOR USE BY MIDMARK TRAINED TECHNICIANS ONLY

SF-1604 Part No. 004-0249-00 Rev. J (01/19/12)

419

-011

thru

-006

Page 2

Go To Table Of Contents

RETURN TO TABLE

OF CONTENTS

Page 3

TABLE OF CONTENTS

TABLE OF CONTENTS

Section/Paragraph................................................Page Section/Paragraph ............................................... Page

IMPORTANT INSTRUCTIONS

General Safety Instructions ..........................................iii

Safety Alert Symbols .................................................... iii

Warranty Instructions ................................................. iii

SECTION I GENERAL INFORMATION

1.1 Scope of Manual .......................................... 1-1

1.2 How to Use Manual ...................................... 1-1

1.3 Description of 419 Power

Procedure Table ........................................ 1-1

1.4 Standard Torque Specifications.................... 1-6

1.5 Specifications ............................................... 1-6

1.6 Parts Replacement Ordering........................ 1-8

1.7 Special Tools ................................................ 1-8

SECTION II TESTING AND TROUBLESHOOTING

2.1 Operational Test ........................................... 2-1

2.2 Troubleshooting Procedures......................... 2-5

SECTION III SCHEDULED MAINTENANCE

3.1 Scheduled Maintenance ............................. 3-1

SECTION IV MAINTENANCE/SERVICE

INSTRUCTIONS

4.1 Introduction................................................... 4-1

4.2 PC Control Board Calibration

(Programmable Tables Only)..................... 4-1

4.3 PC Control Board Removal / Installation

(Non-Programmable Tables Only)............. 4-2

4.4 PC Control Board Removal / Installation

(Programmable Tables Only)..................... 4-3

4.5 Tilt Actuator Removal / Installation ............... 4-4

4.6 Tilt Capacitor Removal / Installation ............. 4-7

4.7 Back Actuator Removal / Installation ............ 4-8

4.8 Back Capacitor Removal / Installation........ 4-10

4.9 Foot Actuator Removal / Installation........... 4-11

4.10 Foot Capacitor Removal / Installation......... 4-13

4.11 Base Actuator Removal / Installation.......... 4-14

4.12 Base Capacitor Removal / Installation........ 4-19

4.13 Column Assembly Removal / Installation ...4-20

4.14 Typical Actuator Motor

Removal / Installation .............................. 4-25

4.15 Base Down Limit Switch Removal /

Installation / Adjustment.......................... 4-26

4.16 Base Up Limit Switch Removal /

Installation / Adjustment.......................... 4-27

4.17 Chain Tension Check / Adjustment ............ 4-29

4.18 Eccentric Bearings Adjustment .................. 4-30

4.19 Hand / Foot Control Inlet PC Board

Removal / Installation.............................. 4-32

4.20 Hand Control PC Board

Removal / Installation ............................. 4-33

4.21 Foot Control Top Removal / Installation

(Non-Programmable Units) ..................... 4-34

4.22 Foot Control Top Removal / Installation

(Programmable Units)............................. 4-35

4.23 Foot Control PC Board

Removal / Installation.............................. 4-35

4.24 Typical Foot Control Foot Pedal Switch

Removal / Installation.............................. 4-36

4.25 Typical Foot Control Function Button

Switch Removal / Installation .................. 4-37

4.26 Typical Foot Control Lamp

Removal / Installation.............................. 4-37

4.27 Dbl. Articulating Headrest Stop Pin

Removal / Installation.............................. 4-38

4.28 Headrest Slide Mechanism Adjustment..... 4-39

4.29 Arm Rest Locking Mechanism

Removal / Installation.............................. 4-40

4.30 Back Slide Bearing

Removal / Installation.............................. 4-40

4.31 Foot Rest Extension Limit Switch

Removal / Installation.............................. 4-41

4.32 Foot Actuator Limit Switch

Removal / Installation.............................. 4-42

4.33 Base Actuator Limit Switch

Removal / Installation.............................. 4-44

4.34 AC Receptacle Removal / Installation ........ 4-46

4.35 Fuse Holder Removal / Installation ............ 4-47

4.36 Foot Rest Extension Latch Spring

Removal / Installation.............................. 4-47

4.37 Foot Position Sensor Removal /

Installation /Adjustment

(Programmable Units Only) .................... 4-48

4.38 Tilt Position Sensor Removal /

Installation / Adjustment

(Programmable Units Only) .................... 4-51

4.39 Back Position Sensor Removal /

Installation / Adjustment

(Programmable Units Only) .................... 4-54

4.40 Base Position Sensor Removal /

Installation / Adjustment

(Programmable Units Only) .................... 4-58

(*) Indicates that there has been a serial number break for the illustration

and that there are additional point page(s) following the original page.

© Midmark Corporation 1999 SF-1604 Page i Printed in U.S.A.

Rev. 2/02

Page 4

TABLE OF CONTENTS

Return To Table Of Contents

Section/Paragraph................................................Page Section/Paragraph............................................... Page

SECTION V SCHEMATICS AND DIAGRAMS

5.1 Electrical Schematics /

Wiring Diagrams ....................................... 5-1

5.2 Fuse Specifications ...................................... 5-7

5.3 Error Codes Chart

(Programmable Units Only)....................... 5-7

SECTION VI PARTS LIST

6.1 Introduction................................................... 6-1

6.2 Description of Columns ................................ 6-1

6.3 Torque Specifications And Important

Assembly Notes ........................................ 6-1

Pictorial Index (419-003) ............................6-2.*

Pictorial Index (419-004) ............................6-3.*

Pictorial Index (419-005) ............................6-4.*

Pictorial Index (419-006) .............................. 6-5

Upholstery Kit............................................... 6-6

Articulated Headrest Assembly ...................6-7*

Arm Rest .....................................................6-8*

Backrest Assembly ......................................6-9*

Arm Linkage Components.......................... 6-10

Seat Components ...................................... 6-11

Top to Base Connections ........................... 6-12

Top Electrical Components (115 V. Units).. 6-13

Top Electrical Components (230 V. Units).. 6-14

Foot Components ...................................... 6-15

Program Position Components .................. 6-16

Base Reducer Assembly............................ 6-17

Foot Sensor Components .......................... 6-18

Back Sensor Components ......................... 6-19

Tilt Sensor Components ............................ 6-20

Base Cover Components ........................... 6-21

Base Electrical Comp. (115 V. Units) ......... 6-22

Base Electrical Comp. (230 V. Units) ......... 6-23

Power Inlet Components............................ 6-24

Column Components ................................. 6-25

Column Assembly ...................................... 6-26

Hand Control Assm (Non-Programmable) . 6-27

Hand Control Assm (Programmable) ......... 6-28

Footswitch Assm (Non-Programmable) ..... 6-29

Footswitch Assm (Programmable) ............. 6-30

COMMENTS ............................................................. 7-1

FAX ORDER FORM.................................................. 7-2

(*) Indicates that there has been a serial number break for the illustration

and that there are additional point page(s) following the original page.

© Midmark Corporation 1999 SF-1604 Page ii Printed in U.S.A.

Rev. 7/03

Page 5

TABLE OF CONTENTS

Return To Table Of Contents

General Safety Instructions

Safety First: The primary concern of Midmark Corporation is that this

of the patient and staff in mind. To assure that services

and repairs are completed safely and correctly , proceed

as follows:

(1) Read this entire manual before performing any

services or repairs on this table.

(2) Be sure you understand the instructions con-

tained in this manual before attempting to service or repair this table.

table is maintained with the safety

Safety Alert Symbols

Throughout this manual are safety alert symbols that

call attention to particular procedures. These items are

used as follows:

DANGER

A DANGER is used for an imminently

hazardous ope rating procedure, practice, or condition which, if not correctly followed,

will result in loss of life or serious personal

injury .

CAUTION

A CAUTION is used for a potentially haz-

ardous operating procedure, practice, or

condition which, if not correctly followed, could result

in minor or moderate injury. It may also be used to

alert against unsafe practices.

EQUIPMENT ALE RT

An EQUIPMENT ALERT is used for an

imminently or potentially hazardous operating procedure, practice, or condition which, if not

correctly followed, will or could result in serious, moderate, or minor damage to unit.

NOTE

A NOTE is used to amplify an operating procedure,

practice or condition.

Warranty Instructions

Refer to the Midmark “Limited Warranty” printed in the

Installation and Operation Manual for warranty information. Failure to follow the guidelines listed below will

void the warranty and/or render the 419 Power Procedure Table unsafe for operation.

WARNING

A WARNING is used for a potentially

hazardous ope rating procedure, practice, or condition which, if not correctly followed,

could result in loss of life or serious personal

injury.

• In the event of a malfunction, do not attempt to use

the examination table until necessary repairs have

been made.

• Do not attempt to disassemble table, replace malfunctioning or damaged components, or perform

adjustments unless you are one of Midmark’s

authorized service technicians.

• Do not substitute parts from another manufacturer

when replacing inoperative or damaged components. Use only Midmark replacement parts.

© Midmark Corporation 1999 SF-1604

Page iii

Printed in U.S.A.

Page 6

TABLE OF CONTENTS

Return To Table Of Contents

© Midmark Corporation 1999 SF-1604

Page iv

Printed in U.S.A.

Page 7

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

SECTION I

GENERAL INFORMATION

1.1

This manual contains detailed troubleshooting, scheduled maintenance, maintenance, service instructions,

and a complete illustrated parts breakdown for the

419 (-003 thru -006) Power Procedure Table. This manual covers both programmable and non-programmable

versions of this table. This manual is intended to be

used by Midmark’s authorized service technicians.

Scope of Manual

1.2 How to Use Manual

A. Manual Use When Performing Scheduled Mainte-

nance.

(1) Perform inspections and services listed in

Scheduled Maintenance Chart (Refer to

para 3.1).

(2) If a component is discovered to be faulty or out

of adjustment, replace or adjust component in

accordance with maintenance / service instructions (Refer to para 4.1).

1.3 Description Of 419 (-003 thru -006)

Power Procedure T able

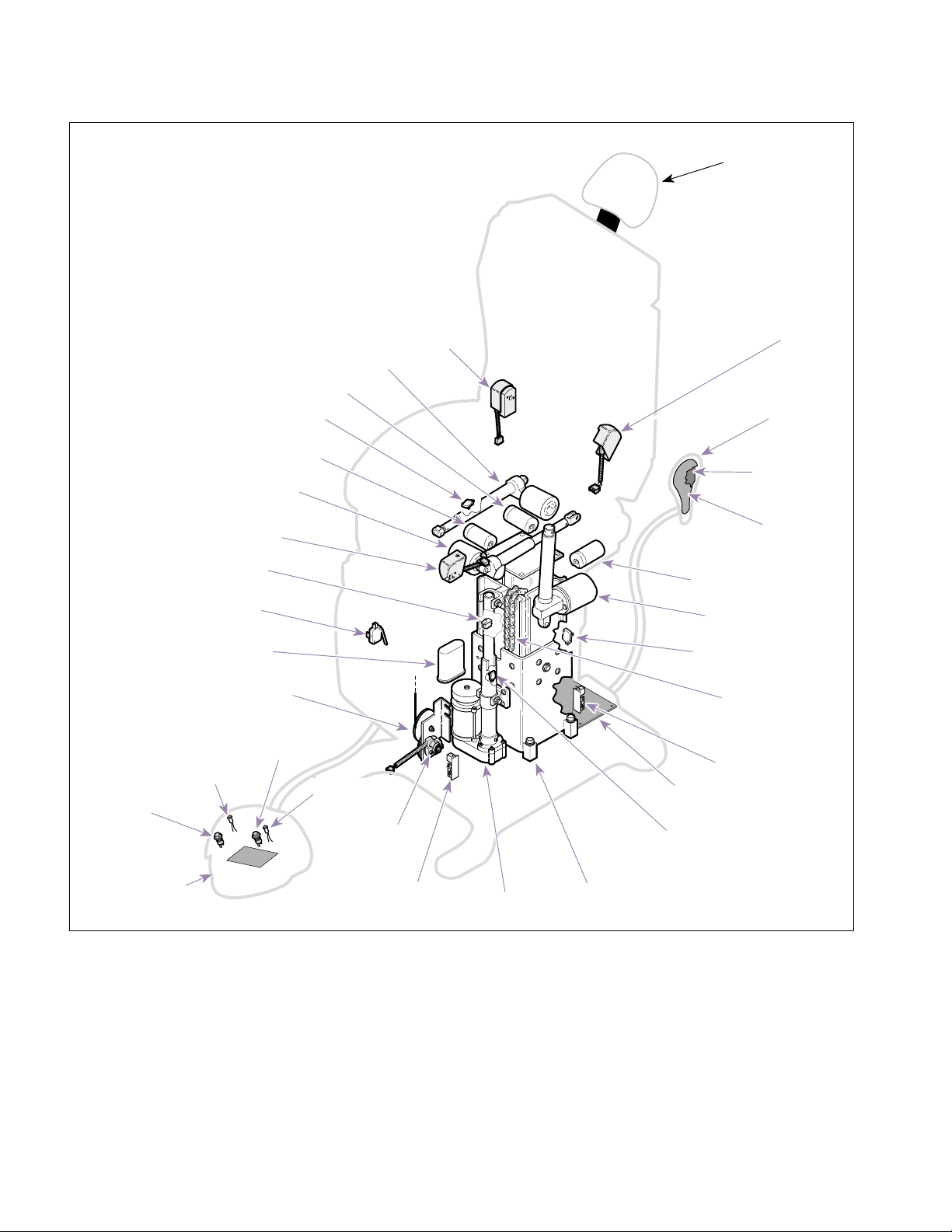

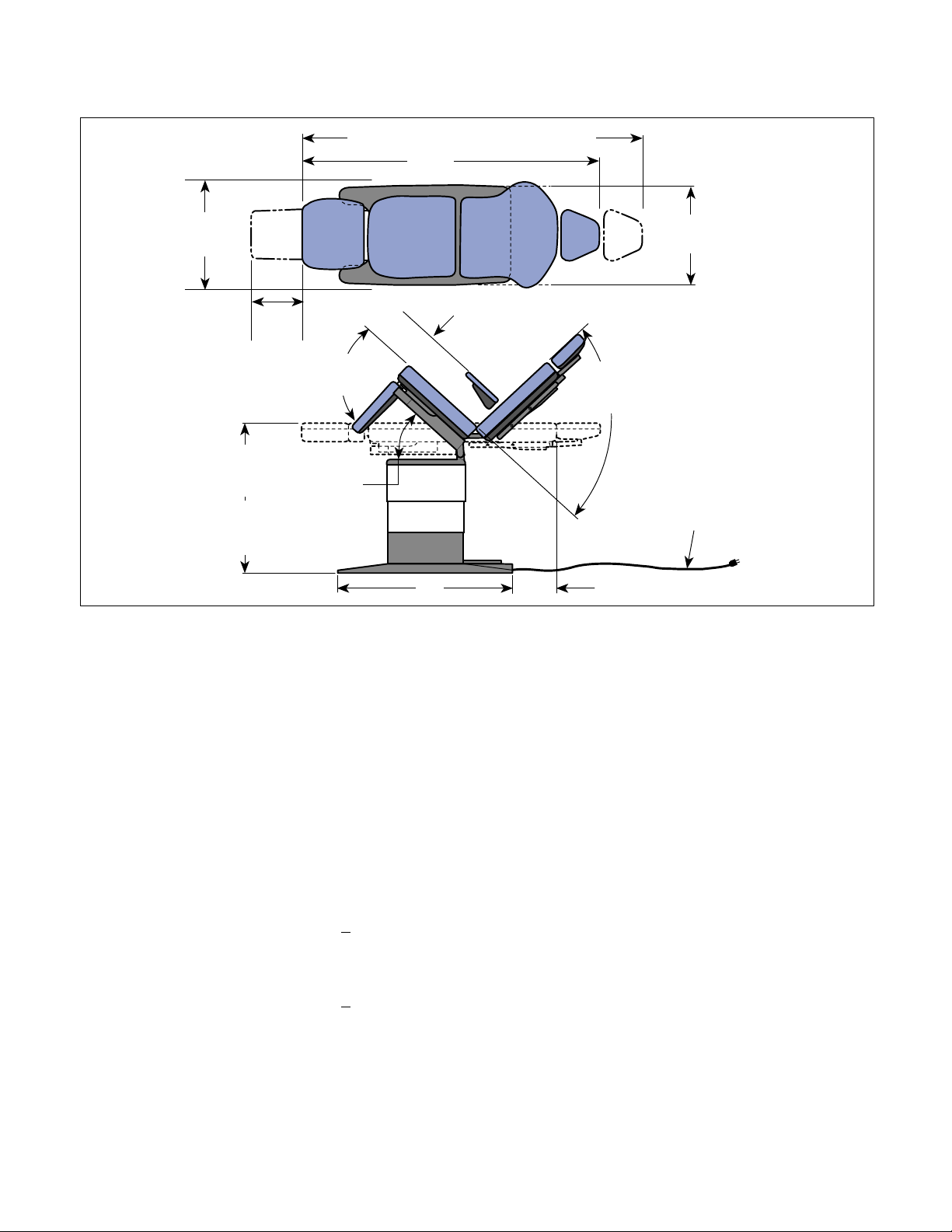

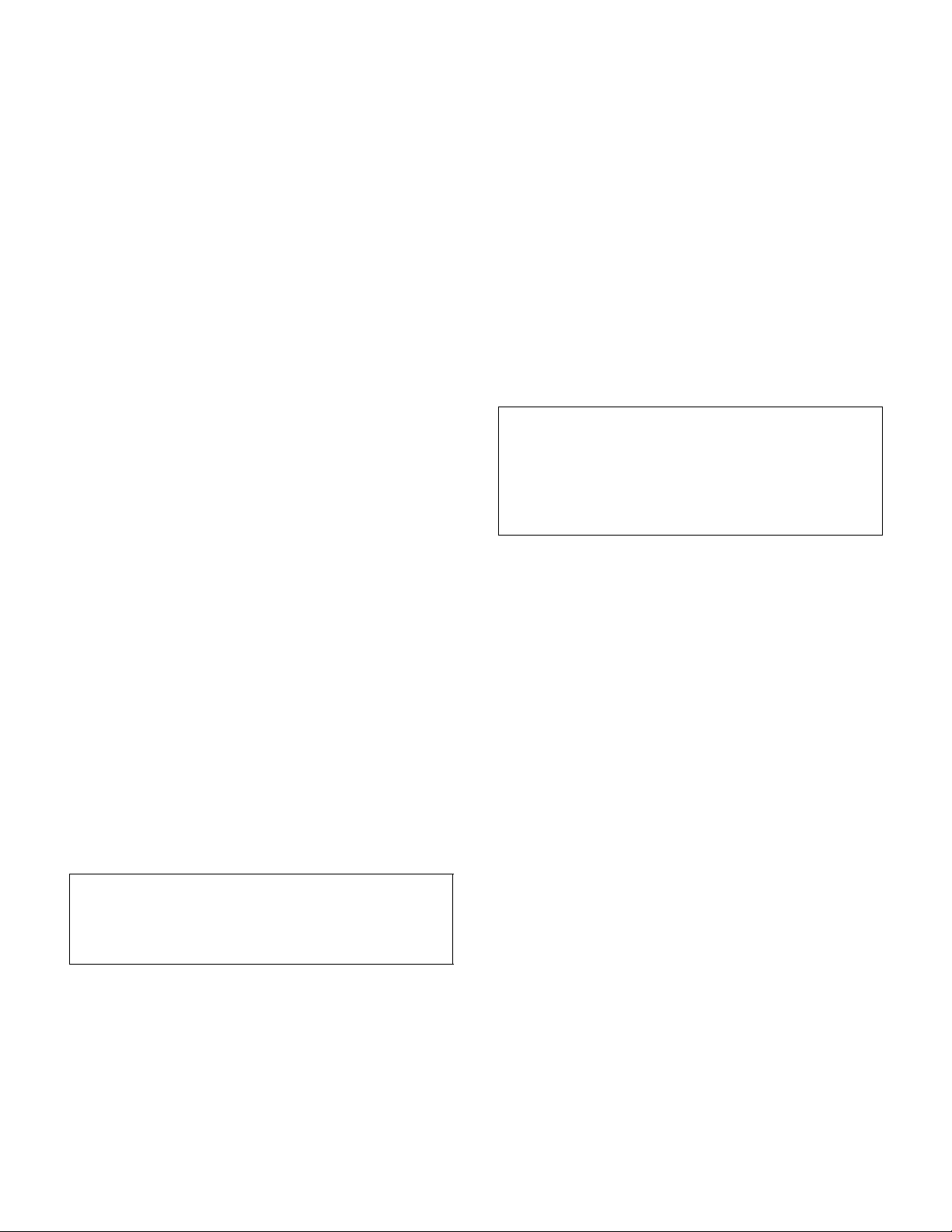

A. General Description (See Figure 1-1).

The 419 Power Procedure Table is a general purpose

examination table designed specifically for performing

general medical examinations and procedures. The

table is available with or without programming. The programmable versions have additional features such as

programmed positioning, a Home function, and audible

warning signals.

Listed below are descriptions of the models available

and their serial number prefixes:

419-003 (LM) .................115 VAC without programming

419-004 (LN).................. 115 VAC with programming

419-005 (LP) .................. 230 VAC without programming

419-006 (LR).................. 230 VAC with programming

B. Manual Use When Unit Is Malfunctioning And

Cause Is Unknown.

(1) Perform an operational test on unit (Refer to

para 2.1).

(2) Perform troubleshooting procedures listed in

Troubleshooting Guide (Refer to para 2.2).

(3) If a component is discovered to be faulty or out

of adjustment, replace or adjust component in

accordance with maintenance / service instructions (Refer to para 4.1).

C. Manual Use When Damaged Component Is Known.

(1) Replace or adjust component in accordance

with maintenance / service instructions (Refer

to para 4.1).

The major serviceable components of the table are:

the tilt actuator, tilt capacitor, back actuator, back capacitor, foot actuator, foot capacitor, base actuator, base

capacitor, base down limit switch, base up limit switch,

PC control board, foot & hand control inlet PC boards,

chain assembly, column assembly, headrest assembly,

non-programmable foot control which includes foot

switches and foot control interface board or a programmable foot control which includes foot switches, a foot

control interface board, indicator L.E.D.’s, and program

control footswitches, and the Foot Extension Crash Protection Circuit which includes the foot actuator limit

switch, foot rest extension limit switch, and base actuator limit switch.

apply to programmable units only:

back position sensor, foot position sensor, and base

reducer assembly which includes base position sensor.

The following serviceable components apply to the

optional hand control:

hand control PC board.

The following serviceable components

tilt position sensor,

hand control switch panel and

© Midmark Corporation 1999 SF-1604

Rev. 2/00

Page 1-1

Printe d in U.S .A.

Page 8

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

HEADLOCK

ASSEMBLY

FOOT EXTENSION

PROGRAM

CONTROL

FOOT

SWITCHES

(PROGRAMMABLE

FOOT CONTROL

ONLY)

FOOT

CONTROL

FOOT ACTUATOR

LIMIT SWITCH

ACTUATOR

FOOT

POSITION

SENSOR

BASE DOWN

LIMIT SWITCH

LIMIT SWITCH

BASE

CAPACITOR

REDUCER

ASSEMBLY

INDICATOR

L.E.D.'S

(PROGRAMMABLE

FOOT CONTROL

ONLY)

CAPACITOR

FOOT

CAPACITOR

FOOT

BASE

FOOT

SWITCHES

ACTUATOR

BACK

INDICATOR

L.E.D.'S

BACK

POSITION

POSITION

SENSOR

BASE

SENSOR

FOOT INLET

PC BOARD

TILT

BASE

ACTUATOR

COLUMN

ASSEMBLY

CAPACITOR

ACTUATOR

LIMIT SWITCH

PC CONTROL

BOARD

BASE

ACTUATOR

LIMIT SWITCH

CONTROL

PC BOARD

SWITCH PANEL

TILT

TILT

BASE UP

CHAIN

ASSEMBLY

HAND INLET

PC BOARD

BACK

POSITION

SENSOR

HAND

CONTROL

HAND

HAND

CONTROL

MA523501

© Midmark Corporation 1999 SF-1604 Page 1-2 Printed in U.S.A.

Rev. 2/02

Figure 1-1. Major Components

Page 9

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

B. Standard Theory of Operation (See Figures 5-1

thru 5-6 for wiring diagram / electrical schematic)

Electrical power

Line voltage is supplied thru two main fuses to the

table’s PC control board. These fuses prevent possible

damage to the PC control board due to excessive current draw. There is a transformer and associated followon circuitry on the PC control board which reduces the

line voltage to 12 VDC. The 12 VDC provides power to

operate the circuitry on the PC control board, foot control, and hand control.

Manual Operation of Tilt, Back, and Foot Actuator

Assemblies:

When a function is selected using the foot control, the

foot control sends a signal to the PC control board. The

signal causes the appropriate relay on the PC control

board to energize (i.e., if the TILT UP button is

depressed on foot control, the Tilt Up relay on PC control board is energized). Line voltage is continuously

supplied to all relays on PC control board. So, when a

relay is energized, the line voltage flows thru the relay

and is applied across the windings of the actuator

motor, causing it to run. When the foot control button is

released, the relay de-energizes, removing the line voltage from the windings of the actuator motor and causing it to stop running.

The Tilt, Back, and Foot actuators are ball screw driven.

The actuator assemblies contain a pivot point on the

end of the ball screw. If an actuator assembly is run to

the end of its stroke, the ball screw shaft spins inside

the nut, which allows the actuator assembly to run without damaging or advancing the nut.

The Tilt, Back, and Foot actuators have internal braking

mechanisms which use friction to hold the actuator in

place. When the actuator is run, the actuator overcomes

the force of the friction, allowing it to move. When actuator is stopped, friction holds the actuator in place.

Manual Operation Of Base Actuator Assembly:

continuously supplied to the relays on PC control board.

So, when the base up or down relay is energized, the

line voltage flows thru the relay and is applied across

the windings of the actuator motor, causing it to run. At

the same time, line voltage flows thru the brake relay

and is applied across the solenoid coil of the base

brake, causing the brake to disengage. When the foot

control button is released, the relays de-energize,

removing line voltage from the coils of the actuator

motor, causing it to stop and at the same time, removing

line voltage from the solenoid coil of the base actuator

brake, causing the base brake to engage.

The base actuator is different from the other three actuators; it does not freewheel at the end of its stroke limit.

This is because the base actuator operates under

heavier loads. To prevent the base actuator from reaching its stroke limits, which could damage the actuator,

two limit switches are used; a base down limit switch

and a base up limit switch. These limit switches are normally closed (N.C.) switches. When the base actuator

reaches the end of the travel (up or down), the appropriate limit switch is tripped, opening the circuit. The PC

control board then de-energizes the motor relay and

base brake relay, causing the base actuator motor to

stop running and the base brake to engage.

Foot Extension Protection Circuit:

To prevent the foot extension from accidentally being

run into the floor, three limit switches are used: the foot

rest extension limit switch, foot actuator limit switch, and

base actuator limit switch. These limit switches are connected in parallel and table functions will operate normally unless

all three

switches are

open

. If all three

limit switch circuits are open, the PC control board will

prevent movement of Tilt Down, Table Down, and Foot

Down functions and illuminate the Foot Rest Extension

lamp on the hand control until any (one or all) of the limit

switches are closed.

The foot rest extension limit switch (located behind the

foot slide weldment) is a normally open (N.O.) switch.

However, when the foot rest extension is in its fully

retracted position, the limit switch is tripped, creating a

closed circuit.

When a BASE UP or BASE DOWN function is selected

using the foot control, the foot control sends a signal to

the PC control board. The signal causes the base up or

down relay, and the base brake relay on the PC control

board to energize (i.e., if the BASE UP button is

depressed on hand control, the base up and base brake

relays on PC control board energize). Line voltage is

© Midmark Corporation 1999 SF-1604

Rev. 2/00

Page 1-3

The foot actuator limit switch (mounted on the foot actuator) is a normally closed (N.C.) switch. When the foot

section is between -40° and -90°, the limit switch is

tripped, resulting in an open circuit.

Printe d in U.S .A.

Page 10

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

The base actuator limit switch (mounted on the base

actuator) is a normally closed (N.C.) switch. When the

base actuator is between full down and 1/2 way up, the

limit switch is tripped resulting in an open circuit.

General Information:

All actuator motors have a thermal overload switch

which will activate if the actuator is run continuously and

overheats. The actuator motor is not designed for continuous operation; it is designed for intermittent operation. The normal cool off period for the thermal overload

switches is 10 - 20 minutes.

Each actuator motor has a capacitor which provides

start up power and motor run power.

There are two 0.10 amp Time Lag fuses providing overcurrent protection to the input of the PC control board

on the non-programmable table and two 0.15 amp Time

Lag fuses providing over-current protection to the input

of the PC control board on the programmable table.

There is a 5 amp, “Slo-Blo” Time Lag fuse to provide

over-current protection for each function's relays (i.e, Tilt

fuse protects TILT UP and TILT DOWN relays).

C. Program m able Table Theory of Operation (Se e

Figures 5-1 thru 5-6 for wiring diagram / electrical schematic) (Applies only to tables with programmed posit ioning)

Operation Of Programmable Software:

The previous paragraphs have outlined the theory of

operation for manual functions on both the programmable and non-programmable tables. The following paragraphs will describe control system functions on the

programmable tables.

When the table is powered up, the control system initializes the PC control board and then checks for inputs.

There are two functions which can be initiated by the

operator using the foot control; a function to initiate the

“Calibration” mode and a function to initiate the “Clear

Diagnostics Codes” mode. Also, the PC control board

checks if error codes are stored in memory to determine

if the “error” mode should be initiated.

Additionally, there are two functions that may be initiated by depressing switches mounted on the PC control

board; a function to initiate the “Calibration/Clear Data”

mode (SW 2 on PC board) and a function to initiate the

“Program/Fault Clear ” mode (SW 1 on PC board)

The “Calibration” function

be initiated by the tech-

must

nician if a new PC control board or position sensor is

installed, the position sensor is adjusted, the table is not

moving to a programmed position properly, or the table

begins acting erratically. When the calibration mode is

initiated, the PC control board runs all actuators to their

up and down limits and measures the voltage output of

the position sensors at the limits. These voltage values

are stored in the PC control board’s memory and used

as the basis for storing programmed positions into

memory. Also, the error codes for incorrect direction and

no sensor output change are cleared from the PC control board’s memory. If the calibration procedure is not

successful due to a position sensor reading being out of

limits, the error code indicating why will be stored into

the PC control board’s memory along with an error code

indicating the table is not calibrated. The PC control

board emits a 1 second warning beep at 1.5 second

intervals to indicate to the operator that the calibration

procedure is taking place. The calibration procedure is

described in Section IV, Maintenance.

The “Clear Diagnostics Codes” function must be initiated to reset the PC Control Board, after the PC control

board initiates any error code(s). The PC control board

displays the error code(s) by alternately flashing the

PROGRAM lamp and the FOOT REST EXTENSION

lamp to form a code (See Diagnostic code [error code]

operation later in this section). When the table is in the

error code mode, only manual positioning of the table

will work. To resume normal operation, the “Clear Diagnostic Codes” procedure must be completed. If the PC

control board is replaced or the position sensor is

replaced or adjusted, this procedure will not work; in this

case, the “Program/Fault Clear” mode followed by the

Calibration procedure must be performed. This step is

described in the appropriate procedures in Section IV,

Maintenance.

The “Calibration/Clear Data” mode is initiated when it is

desired to clear the PC control board’s memory where

the calibration data is stored. This step is described in

the appropriate procedures in Section IV, Maintenance.

The “Program/Fault Clear” mode is initiated when it is

desired to clear the PC control board’s memory where

the error codes and program position data are stored.

This function should be used if the PC control board

seems locked up or if a position sensor is replaced /

adjusted. The “Program/Fault Clear” function is

described in the appropriate procedures in Section IV,

Maintenance.

© Midmark Corporation 1999 SF-1604

Rev. 2/00

Page 1-4

Printe d in U.S .A.

Page 11

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

Operation of Home Position Function:

When the operator presses the Home position button,

the PC control board lowers the base actuator until the

base down limit switch is tripped. The Home position

button can be pressed and released; it does not have to

be held down to continue movement. If the base down

limit switch is not detected as being tripped (open circuit) within 18 seconds from the time the Home position

button was pressed, the PC control board de-energizes

the base actuator. If Base Up function button is pressed

while the table is moving toward the Home position, the

Home position function is terminated and Base Up is

initiated until button is released.

Stop Function Operation:

When the Stop button is pressed, the PC control board

terminates all functions, stopping table movement.

When the Stop button is released, the stop mode is cancelled and normal table operation may resume.

Program Mode Operation:

The Program Mode is used to allow the operator to program up to four different table top positions into memory. When the Program Mode button is pressed, the

Program Mode function stays active for five seconds, or

until the operator has pressed one of the four Programmed Position buttons, or the Stop button is

pressed. Also, the Program Mode lamp is illuminated

and stays illuminated until the 5 seconds are up or an

action is taken. When a Programmed Position button is

pressed, the PC control board stores the position sensor voltage values for each axis into its memory. Then, if

the position was stored correctly, the PC control board

flashes the Program Mode lamp three times.

Programmed Position Recall Mode:

To recall a program that is stored in memory, the operator selects one of the four Programmed Position Recall

buttons. The button must be pressed and held to continue table movement. The PC control board determines

which direction to run the actuators by comparing the

current position sensor voltage output for each axis with

the voltage values stored in memory for each axis. The

PC control board energizes the relays for the actuators

requiring movement and then monitors the position sensor voltage output for each axis. When the position sensor voltage output of each position sensor matches the

value stored in the PC control board’s memory, the PC

control board de-energizes the actuator relays.

The PC control board has a maximum run time it allows

for each actuator at any one time. This feature prevents

damage to an actuator motor because of an actuator

relay sticking. When a Programmed Position button is

pressed, the PC control board starts a countdown of the

maximum time allowed for that actuator. At the end of

the countdown, if the button is still sensed by the PC

control board as being pressed, and the actuator has

not reached its limit, the PC control board de-energizes

the relay for the actuator. The maximum run time for

each function is:

• Base Up / Base Down - 18 seconds

• Back Up / Back Down - 25 seconds

• Foot Up / Foot Down - 25 seconds

• Tilt Up / Tilt Down - 25 seconds

During the Programmed Position Recall mode, the PC

control board monitors for several error conditions:

If it is detected that a position sensor’s voltage is

increasing when it should be decreasing, decreasing

when it should be increasing, or data input from a position sensor is invalid, the PC control board stops the

table and sets an error code condition. An explanation

of the error codes is given in para 5.2.

If data stored for the Programmed Position Recall button being pressed is invalid, the Program lamp will flash

on and off until the button is released.

If the base down limit switch or base up limit switch is

tripped (open circuit), the PC control board disables the

Programmed Position Recall mode.

If the Foot Extension Crash Protection Circuit is open

(

all three

control board disables the Program Positioning mode

and the Foot Rest Extension lamp will flash on and off

until the button is released.

If the Stop button is pressed, the Programmed Position

Recall mode is disabled.

Manual Positioning Table Operation:

During manual positioning operation, the control system

for the programmable table works like the control system for the non-programmable table except for some

additional controls:

If there is invalid data inputs from any position sensor,

the PC control board still allows manual positioning

operation.

If conflicting functions are attempted such as Base Up

and Base Down, the PC control board disables all functions until all buttons are released.

limit switch circuits must be

open

), the PC

© Midmark Corporation 1999 SF-1604

Page 1-5

Printe d in U.S .A.

Page 12

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

Diagnostic Code (Error Code) Operation:

When the PC control board detects an error condition, it

disables the Home position and Programmed Position

functions. When these buttons are pressed, there is no

movement. By unplugging the table power cord for a

minimum of ten seconds, and then plugging it back in,

the PC control board is put into the “diagnostic code”

mode, described as follows: At power up, if an error

code is stored in memory, the PC control board outputs

the error code to the foot control in the form of a code.

The Program Mode lamp flashes on and then off for the

number of times equal to the first digit of the error code

stored in memory. Then the Foot Extension lamp

flashes on and then off for the number of times equal to

the second digit of the error code stored into memory.

The PC control board then waits one second, repeats

the error code a second time, then waits one second

and repeats the error code a third time. The next error

code is also displayed three times consecutively. This is

repeated until all error codes have been displayed.

Then, the PC control board continuously displays the

error codes on the foot control until a manual function is

selected.

Position Sensor Operation:

There are position sensors mounted to pivot points on

the Back, Tilt, and Foot axis and a position sensor

mechanism (called a base reducer assembly) attached

to the column assembly for the base function. As each

axis moves, the corresponding position sensor’s inner

wheel rotates with the axis. The position sensor is a

variable resistor which changes resistance in a linear

manner when rotated. So when the axis moves, the

position sensor’s voltage output changes, due to its

resistance change, based upon how far the axis has

moved. The PC control board interprets the voltage

value to determine the location of an axis. When a programmed position is programmed by the operator, the

PC control board stores each sensor’s voltage value

into memory. When the operator wishes to return to that

stored position later, the programmed position button for

the desired programmed position is depressed. The PC

control board determines the current position the table

based on the voltage output of the position sensors, and

then determines which axis’ must be moved and in what

direction. The PC control board energizes the relays for

these actuators and moves the table section(s) to the

desired programmed position. The PC control board

stops the actuators when the voltage value of the position sensors matches the values stored in the PC control board’s memory.

1.4 Standard Torque Specifications

The following torque specifications in Table 1-1 apply to

the various hardware used on the unit unless otherwise

listed elsewhere in the service procedures or parts illustrations:

Table 1-1. Torque Specifications

Hardware Size Torque Values

#6 ............................ 11 to 21 inch / lbs. (1.2 to 2.3 N•m)

#8 ............................ 20 to 30 inch / lbs. (2.2 to 3.3 N•m)

#10 .......................... 32 to 42 inch / lbs. (3.6 to 4.8 N•m)

1/4 inch ................... 75 to 85 inch / lbs. (8.5 to 9.6 N•m)

5/16 inch .................18 to 22 ft. / lbs. (24.4 to 29.8 N•m)

3/8 inch ...................31 to 35 ft. / lbs. (42.0 to 47.5 N•m)

1/2 inch ...................50 to 60 ft. / lbs. (67.8 to 81.4 N•m)

1.5 Specifications

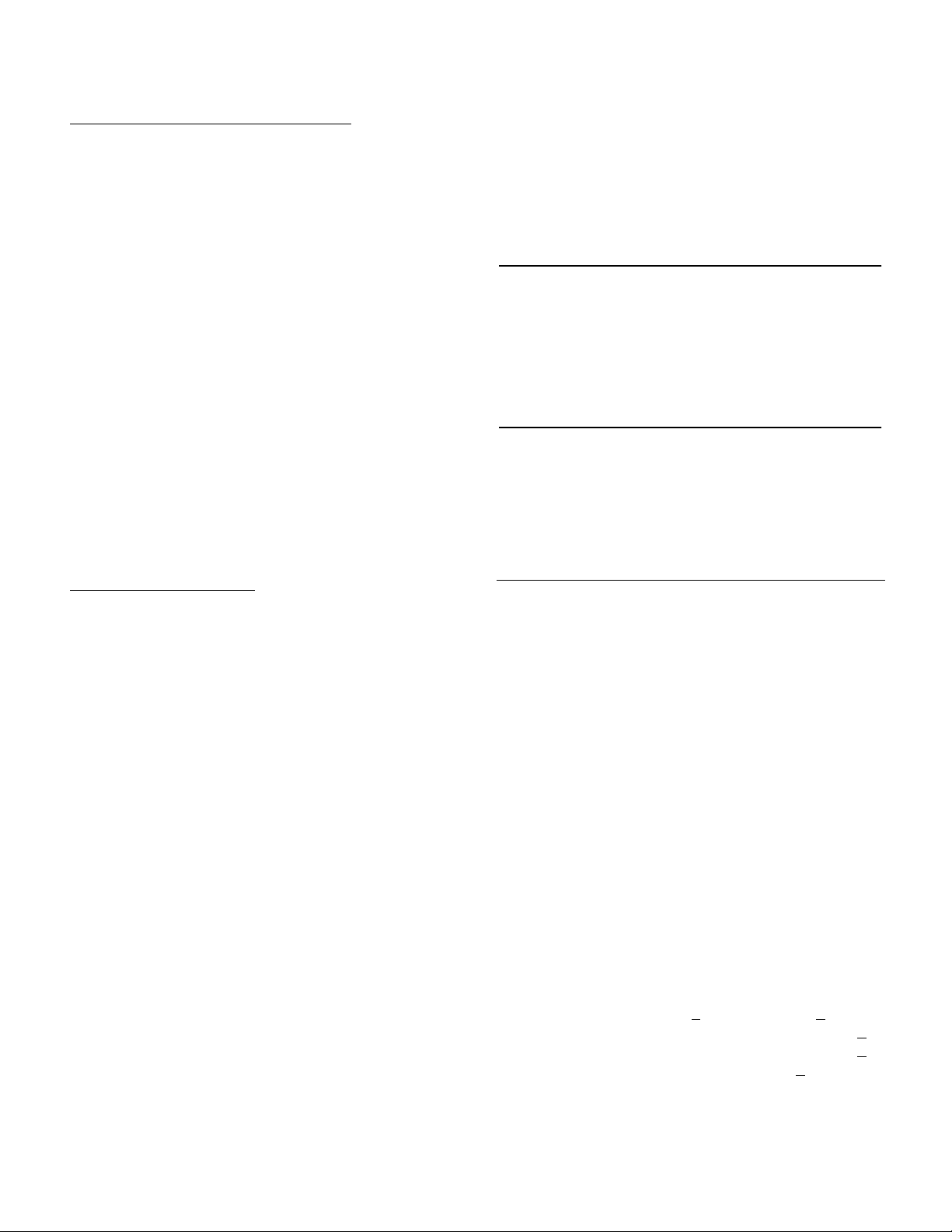

Factual data for the 419 Power Procedure Table is provided in Table 1-2. Also, see Figure 1-2.

Table 1-2. Specifications

Description Data

Weight:

Without Shipping Carton.................515 lbs. (233.6 kg)

With Shipping Carton...................... 550 lbs. (249.5 kg)

Shipping Carton: ..... 54 in. "L" x 32 in. "W" x 33 in. "H"

(137.1 cm x 81.2 cm x 83.8 cm)

Maximum Patient Load: .................. 325 lbs. (147.4 kgs)

Dimensions (See Figure 1-2):

Table Top Length (w/headrest retracted)

(w/back down & foot up) ..............65.0 in. (165.1 cm)

(headrest extended)

Dbl. Articulating Headrest ....... adds 11 in. (27.9 cm)

Triple Articulating Headrest..... adds 15 in. (38.1 cm)

Footrest Extension (adjustable) .... adds 0.0 in to 8.0 in

(0 cm to 20.3 cm)

Table Top Width ...................................23 in. (54.4 cm)

Overall Width .......................................24 in. (61.0 cm)

Table Top Positioning:

Table Top Height ...................... 22 in. to 40 in. ±0.5 in.

(Adjustable) (55.9 +

Back Section ....................... 0° (horizontal) to +85° +

Foot Section......................... 0° (horizontal) to -90° +

Tilt Range...............0° (horizontal) to +30° +

1.3 cm to 101.6 + 1.3 cm)

5°

5°

5° (foot up)

© Midmark Corporation 1999 SF-1604 Page 1-6 Printed in U.S.A.

Rev. 2/02

Page 13

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

Dbl. Articulating Headrest 76" (193.0cm)

Triple Articulating Headrest 80" (203.2 cm)

65

"

(165.1 cm)

23"

58.4

(

(TABLE

cm)

)

40"

(+/- 5")

(101.6 cm)

(MAX.)

22"

(+/- 5")

(55.9 cm)

(MIN.)

8"

(20.3 cm)

90°

(+/- 5°)

(MAX.)

30°

(+/- 5")

(MAX.)

REMAIN HORIZONTAL WITH SEAT

+/- 5

° AS BACK SECTION IS

POSITIONED

32"

(81.28 cm)

6.75"

(17.15 cm)

Figure 1-2. Dimensions

85°

(+/- 5°)

(MAX.)

24"

(61 cm)

(BASE)

POWER

CORD

(98.0" [248.9 cm])

MA524101

Table Speeds (@ 60 Hz):

Base Up ..................................... 18 - 31.5 seconds ±3

Back Up.................................................11 seconds ±3

Tilt Up....................................................17 seconds ±3

Foot Up ................................................... 8 seconds ±3

Power Cord:.............................. 98.0 in. (248.9 cm) long

A black jacketed molded cord to fit

IEC appliance inlet with destination

specific attachment plug

Electrical Requirements:

Model 419(-003 & -004)

115 VAC Units ......................115 VAC +

10%, 50/60 Hz

12 amp, single phase

Model 419 (-005 & -006)

230 VAC Units .....................230 VAC +

10%, 50/60 Hz

8 amp, single phase

Duty Cycle: .................................. Intermittent Operation

[15 seconds on/5 minutes

off (motor run time)]

Recommended Circuit:

A separate (dedicated) circuit is recommended for this

table. The table should not be connected to an electrical

circuit with other appliances or equipment unless the

circuit is rated for the additional load.

Classifications: ................ Class 1, Type B, Applied Part,

Ordinary Equipment,

Intermittent Operation

Certifications:

Midmark Corporation ISO-9001 Certified

Model 419(-003 & -004)

115 VAC Units............................................... UL2601-1

CAN/CSA 22.2, #601.1-M90

Model 419 (-005 & -006)

230 VAC Unit......... Complies to the applicable revision

of the MDD 93/42/EEC, Annex VII.

Complies to the applicable requirements

of EN6060-1-1, EN60601-1-2, EN60601-4

© Midmark Corporation 1999 SF-1604 Page 1-7 Printed in U.S.A.

Rev. 2/02

Page 14

SECTION I

MA520001i

MODEL

NUMBER

SERIAL

NUMBER

Return To Table Of Contents

GENERAL INFORMATION

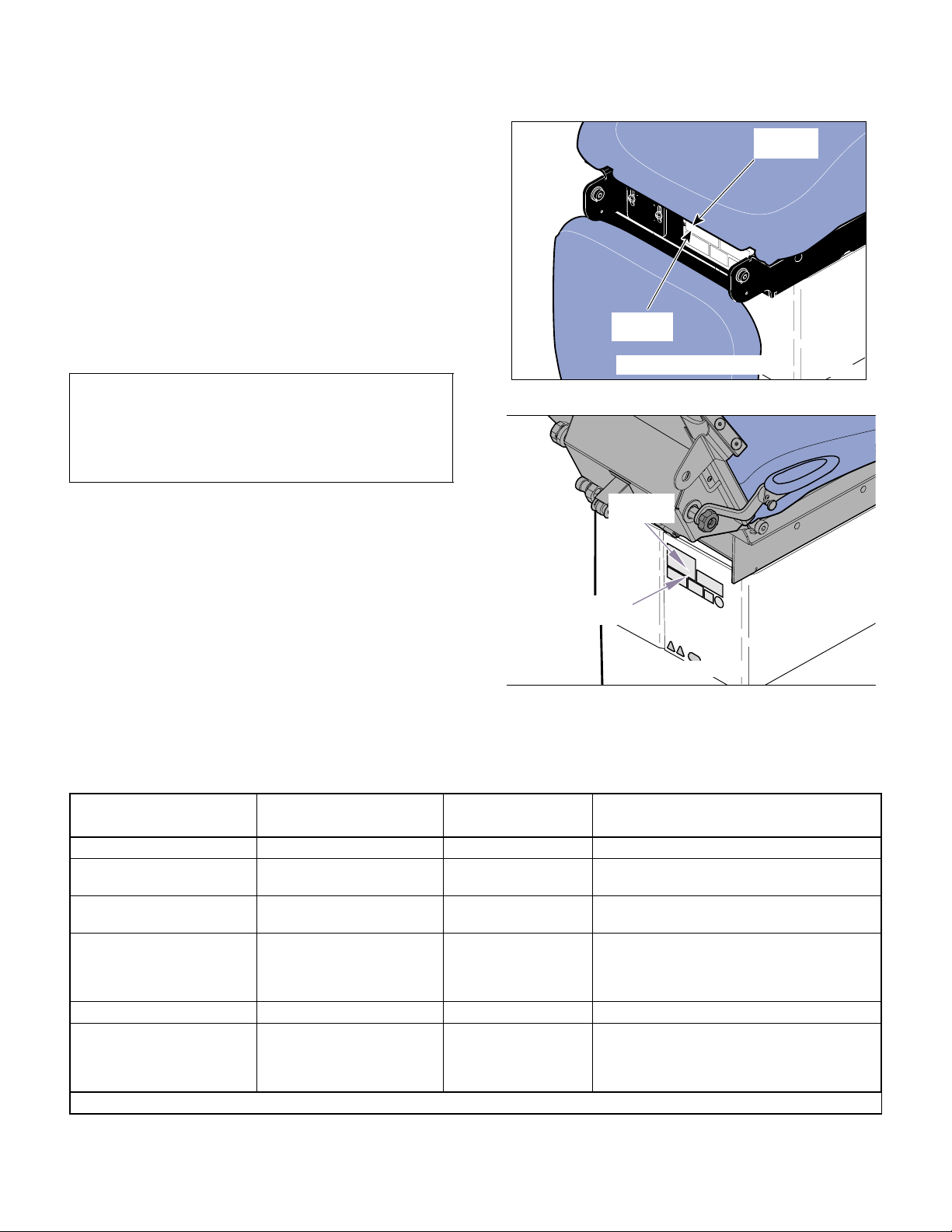

1.6 Parts Replacement Ordering

If a part replacement is required, order the part directly

from the factory as follows:

(1) Refer to Figure 1-3 to determine the location of

the model number and serial number of the unit

and record this data.

(2) Refer to the Parts List to determine the item

numbers of the parts, part numbers of the parts,

descriptions of the parts, and quantities of parts

needed and record this data (Refer to para 6.1).

NOTE

Ask the Purchasing Department of the company that

owns the unit for this information. Otherwise, this

information may be obtained from the dealer that sold

the unit.

SERIAL

NUMBER

Before: (7/26/2002)

MODEL

NUMBER

MA520000

(3) Determine the installation date of the unit and

record this data.

(4) Call Midmark with the recorded information and

ask for the Medical Products Technical Services

Department. See back cover of this manual for

the phone number or use the Fax Order Form

(See page 7-2 for Fax Order Form).

1.7 Special Tools

Table 1-3 lists all of the special tools needed to repair

the unit, how to obtain the special tools, and the purose

Figure 1-3. Model Number / Serial Number

After: (7/26/2002)

Location

of each special tool.

Description of Special Tool

Multimeter (with testing hooks) * Commercially Available Any Type Used to perform continuity and voltage checks.

Protractor * Commercially Available Any Type Used to check the angle of motion for all movable

T15 Torx Wrench Commercially Available Any Type Used to loosen / tighten the screws securing the

5/16 in. - 18 x 1-1/4 Bolt

(Quantity of 2)

Torque Wrench * Commercially Available Any Type Used to tighten nuts or screws to specified values.

Sensor Holder Tool (tool comes

with a position sensor kit).

Manufacturer’s

Name / Address / Phone

Midmark Corporation

60 Vista Drive

Versailles, Ohio 45380

(937) 526-3662

Midmark Corporation

60 Vista Drive

Versailles, Ohio 45380

(937) 526-3662

* Tool should be calibrated annually to ensure proper specifications are met.

Manufacturer’s

Part Number

table top sections.

position sensors, allowing adjustments to be made.

505-702308 Used to remove tension from eccentric bearings so

they may be adjusted.

046-0008-00 Used to hold the 5/16” hex drive while a position

sensor is being installed.

Purpose of Special Tool

© Midmark Corporation 1999 SF-1604 Page 1-8 Printed in U.S.A.

Rev. 2/03

Page 15

TESTING AND TROUBLESHOOTING

Return To Table Of Contents

SECTION II

TESTING AND TROUBLES HOOTING

SECTION II

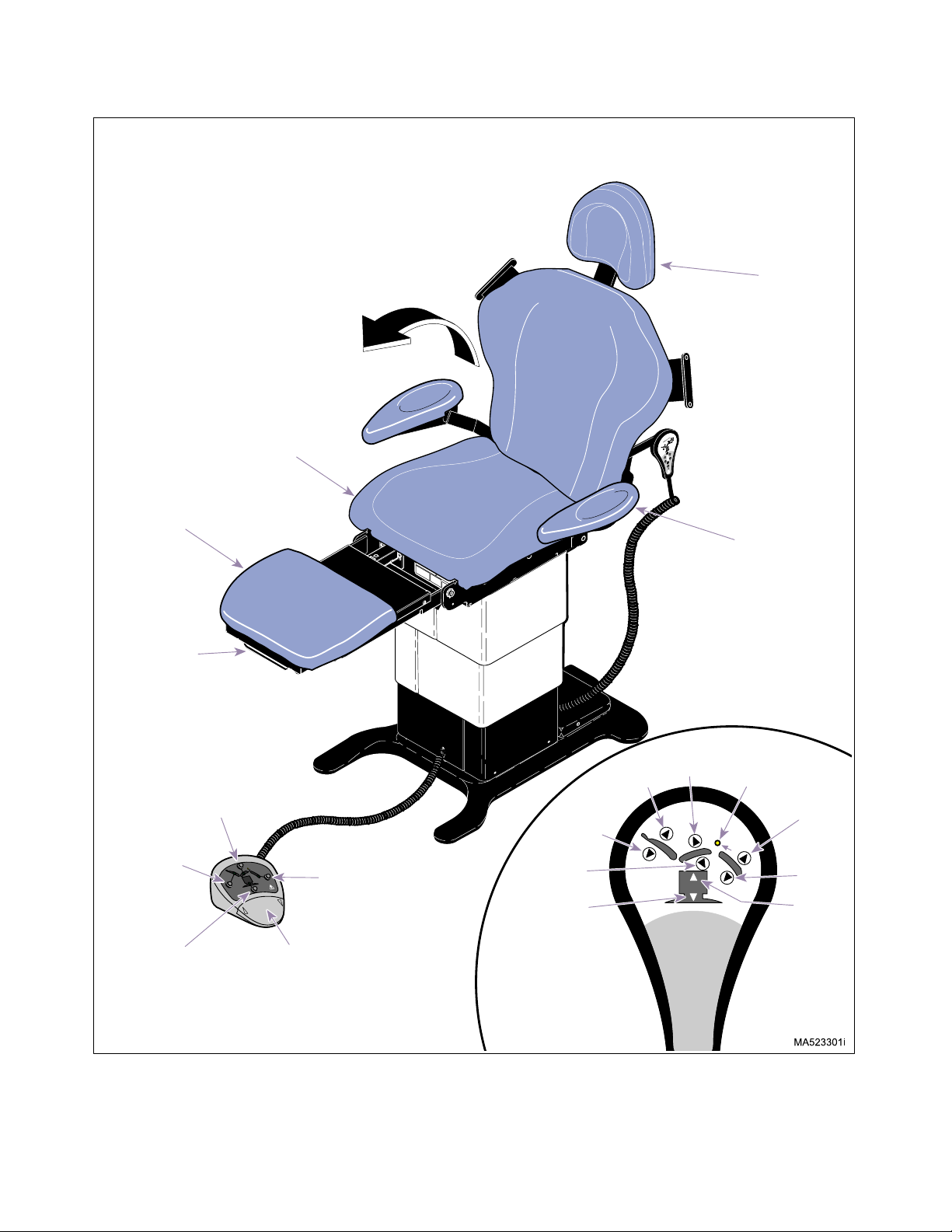

2.1 Operational Test (See Figure 2-1,

Sheets 1 and 2)

In order to effectively diagnose a malfunction of the 419,

it may be necessary to perform an operational test as

follows:

WARNING

Refer to the Operator Manual for com-

plete instructions on operating the

table. Failure to do so could result in personal

injury.

NOTE

The Operational Test only describes what should

happen when the table is operated. If the table does

something other than described, a problem has been

discovered. Refer to the Troubleshooting Guide to

determine the cause of the problem and its correction.

(1) Plug the table power cord into a properly rated

receptacle.

(2) Using the foot control, operate each table func-

tion (Base Up &Down, Back Up & Down, Tilt Up

& Down, Foot Up & Down)

Range of Motion:

Base down to Base up ......22.38 to 40.38 in.±0.5 in.

(56.8 to 102.5 cm ±1.3 cm)

Back down to Back up........................ 0° to +85° +

Tilt down to Tilt up.............................. 0° to +30° +

Foot down to Foot up ..........................-90° to 0° +

(3) If the table has an optional hand control, repeat

step 2 using the hand control.

(4) Raise foot section to the horizontal position;

then squeeze foot rest extension release handle and pull foot rest extension out as far as it

will go.

(5) Depress BASE UP, and TILT UP buttons on foot

control and hold until each function reaches

maximum height; then depress FOOT DOWN

button and hold until foot section is approximately 1/2 way down.

(6) Depress BASE DOWN, FOOT DOWN, and

TILT DOWN buttons on foot control and hold.

Observe. Table should go approximately 1/2

way down then BASE DOWN, FOOT DOWN,

and TILT DOWN functions should stop and the

Foot Rest Extension lamp on the foot control

should flash.

5°

5°

5°

Observe. When a fucntion is initiated, the table

should move accordingly. No section of the

table top should drift after the foot control pedal

is released. Actuator assembly should not

make excessive squealing noises. Movement

should be steady and should match the speeds

and range of motions listed below:

Table Speeds (@ 60 Hz):

Base down to Base up ......... 18 - 31.5 ±3 seconds

Back down to Back up......................11 ±3 seconds

Tilt down to Tilt up ............................17 ±3 seconds

Foot down to Foot up..........................8 ±3 seconds

© Midmark Corporation 1999 SF-1604 Page 2-1 Printed in U.S.A.

Rev. 2/02

(7) Squeeze foot rest extension handle and push

foot rest extension inward until it locks into its

stowed position; then depress BASE DOWN,

FOOT DOWN, and TILT DOWN buttons on foot

control and hold.

Observe. Foot Rest Extension lamp on foot

control should go out and all functions should

lower to their minimum heights.

(8) Place approximately 325 lbs. (147.4 kg) of

weight on the seat section of the table top.

(9) Depress BASE UP button on foot control.

Observe. The base actuator should not squeal

or make excessive noise when lifting the

weight. The base actuator should be able to lift

the weight. The base actuator should not hum

or make any other type of noise when the table

top reaches maximum height. The base up limit

Page 16

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

switch should trip, stopping the base actuator

from running. The base actuator brake should

engage properly and hold the load without drifting down.

(10) Depress BASE DOWN button on foot control.

Observe. The base actuator should not squeal

or make excessive noise when lowering the

weight. The actuator assembly should not hum

or make any other type of noise when the table

top reaches its minimum height. The base down

limit switch should trip, stopping the base actuator from running.

(11) Remove weight from seat section of table top.

(12) Using either the release button (old style), or

release handle (new style) on the headrest,

reposition headrest at each pivot point.

Observe. Headrest should release and move

easily at each pivot point. Headrest should lock

securely into position when button is released

or handle is returned to locked position.

(13) Slide the headrest assembly in and out of the

headrest slide mechanism releasing at various

positions to observe.

Observe. Headrest assembly should not move

out of position on its own, or require excessive

force to be positioned.

(14) Pull outward on arm rest knob and rotate arm

rest 180°.

Observe. Arm rest should rotate freely when

release knob is pulled, and lock securely in

place 180° from point of origin.

Observe. When the HOME POSITION button

is pressed, the table top should begin to lower.

When the STOP button is pressed, the table top

should stop lowering.

(17) Press the HOME POSITION button and allow

the table top to lower completely.

Observe. When the table top is completely low-

ered, the base actuator should stop running

automatically, indicating that the base down

limit switch is tripped.

(18) If the table has an optional hand control, repeat

steps 15 thru 17 using the hand control.

NOTE

After the PROGRAM button is pressed, the operator

has approximately 5 seconds to press one of the four

Program Position buttons. At the end of the 5 seconds, the PROGRAM MODE lamp turns off, indicating that the program mode has ended.

(19) Press the PROGRAM button and then within 5

seconds, press the Program Position “1” button.

Observe. When the PROGRAM button is

pressed, the PROGRAM MODE lamp will illuminate. Then, when the Program Position “1”

button is pressed, the PROGRAM MODE lamp

will go off and then flash three times to indicate

that the table position data was successfully

stored into the PC control board’s memory.

(20) Use any of the foot control buttons to move the

table top to a new position.

(21) Press and hold the Program Position “1” button

until the table stops moving.

NOTE

The remaining steps apply to programmable units

only. Refer to Figure 2-1 (Sheet 2 of 2) for these

steps.

(15) Depress BASE UP button on foot control until

table reaches its maximum height.

(16) Press the HOME POSITION button for one sec-

ond and then release it. After the table top lowers halfway, press the STOP button.

© Midmark Corporation 1999 SF-1604 Page 2-2 Printed in U.S.A.

Rev. 2/02

Observe. The table top should move back to

the position programmed in step 19.

(22) Repeat steps 19 thru 21 three more times using

Program Position buttons “2”, “3” and then “4”.

(23) If the table has an optional hand control, repeat

steps 19 thru 21 using the hand control.

Page 17

SEAT

Return To Table Of Contents

SECTION

180

SECTION II

TESTING AND TROUBLESHOOTING

HEADREST

RELEASE

BUTTON/HANDLE

o

FOOT

SECTION

FOOT

EXTENSION

RELEASE

HANDLE

BACK

FUNCTION

BUTTON

AND LAMP

TABLE

FUNCTION

BUTTON

AND LAMP

TILT

FUNCTION

BUTTON

AND LAMP

D

M

ARMREST

KNOB

TILT

BACK

UP

BACK

DOWN

BACK

FUNCTION

I

AR

M

BUTTON

AND LAMP

TILT

DOWN

TABLE

DOWN

UP

FOOT REST

EXTENSION

LAMP

FOOT

UP

FOOT

DOWN

TABLE

UP

FOOT

PEDAL

© Midmark Corporation 1999 SF-1604 Page 2-3 Printed in U.S.A.

Rev. 2/02

Figure 2-1. Operational Test (Sheet 1 of 2)

Page 18

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

180

SEAT

SECTION

HEADREST

RELEASE

BUTTON/HANDLE

o

FOOT

SECTION

FOOT REST

EXTENTION

RELEASE

HANDLE

PROGRAMMED

POSITION

BUTTONS

AND LAMPS

BACK

FUNCTION

BUTTON

AND LAMP

HOME

FUNCTION

BUTTON

AND LAMP

PROGRAMMED

AND LAMPS

PROGRAM

BUTTON

P

2

1

MA

R

D

MI

TABLE

FUNCTION

BUTTON

AND LAMP

POSITION

BUTTONS

3

4

FOOT

PEDAL

TILT

FUNCTION

BUTTON

AND LAMP

FOOT

FUNCTION

BUTTON

AND LAMP

STOP

BUTTON

BACK

DOWN

TILT

DOWN

TABLE

DOWN

STOP

HOME

POSITION

PROGRAM

BACK

UP

TILT

UP

ARMREST

KNOB

FOOT REST

EXTENSION

LAMP

FOOT

UP

FOOT

DOWN

TABLE

UP

PROGRAM

POSTION

BUTTONS

PROGRAM

MODE LAMP

Figure 2-1. Programmable Units Operational Test (Sheet 2 of 2)

© Midmark Corporation 1999 SF-1604 Page 2-4 Printed in U.S.A.

Rev. 2/02

Page 19

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

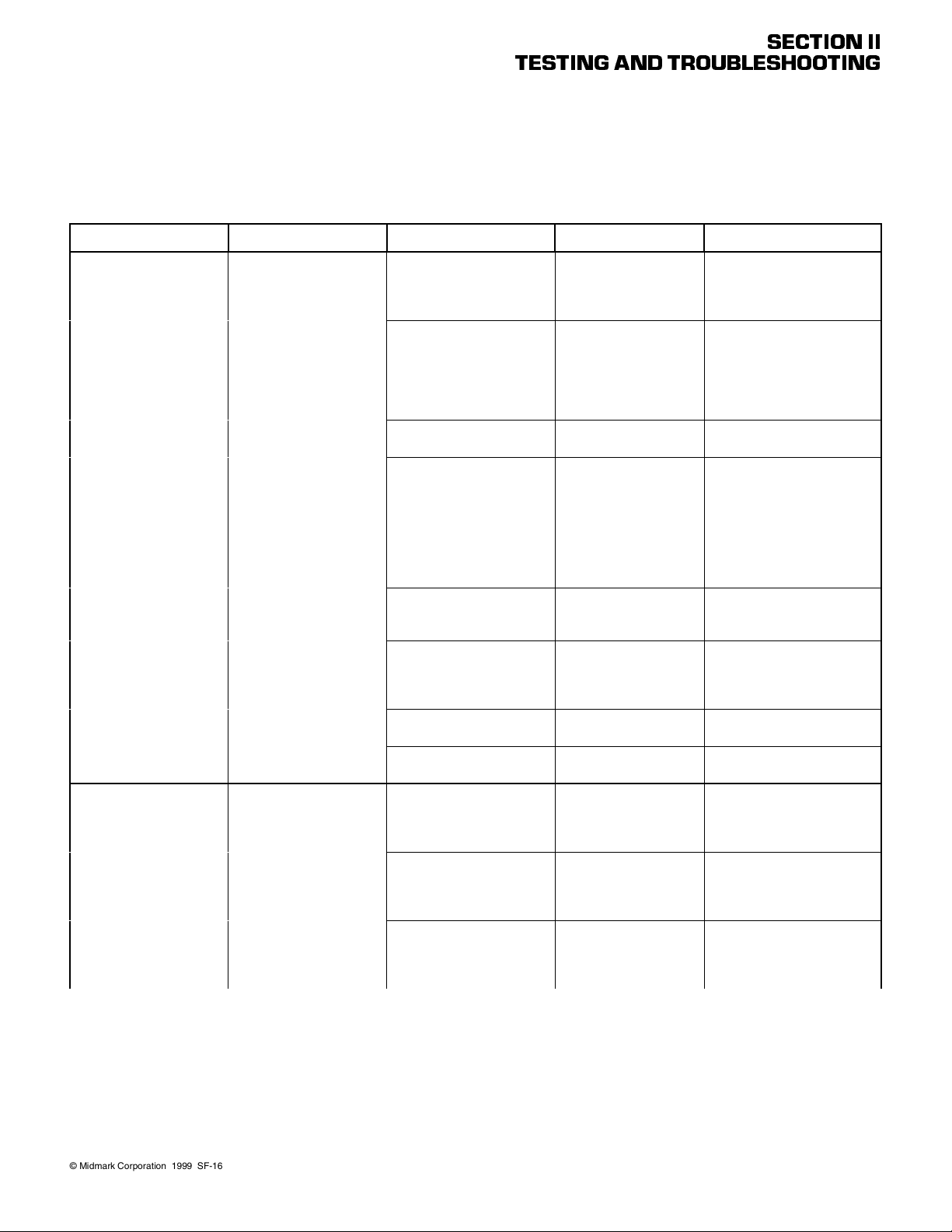

2.2 Troubleshooting Procedures

Table 2-1 is a Troubleshooting Guide which is used to

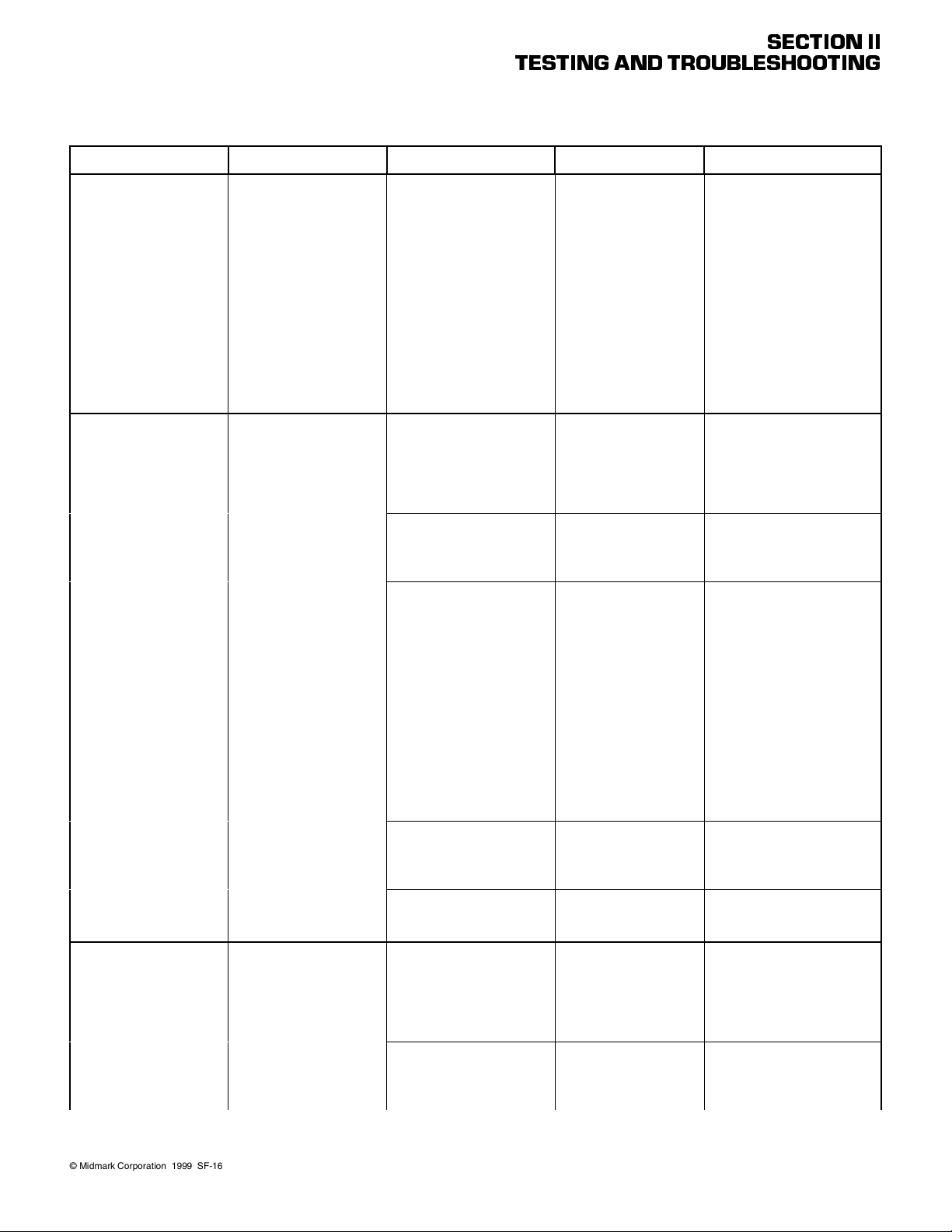

Table 2-1. Troubleshooting Guide

Problem Symptom Probable Cause Check Correction

Table will not operate when

any of the functions on the

foot control or hand control

are selected.

No actions can be initiated

from hand control.

When any foot/hand control button is pressed,

nothing happens.

Table has power, but no

functions can be initiated

from hand control. Foot

control works properly.

Power cord is not plugged

into wall outlet and/or AC

receptacle.

Facility circuit breaker providing power to unit is

tripped.

Fuse(s) at power inlet blown. Perform continuity check

Wire connections loose. Check all wiring connec-

Primary fuse(s) on PC control board is blown.

PC control board is malfunctioning.

Fuse holders malfunctioning. Perform continuity check

AC receptacle malfunctioning.

Coil cord is not plugged into

hand control or receptacle

on table properly.

Hand control switch panel is

malfunctioning.

Hand control PC board is

malfunctioning.

determine the cause of the malfunction.

Check to see if power

cord is plugged in.

Check to see if facility circuit breaker for unit is

tripped. One way of

checking this is to plug a

lamp into wall outlet that

table was plugged into.

on fuses.

tions from power cord to

terminal block. Perform

continuity check on

wires. Use multimeter to

check for proper voltage

levels. See Figures 5-1

thru 5-6.

Refer to Figure 2-2 for

this check. Perform continuity check on fuses.

Replace suspect PC control board with known

working PC control

board.

on fuse holder.

Perform continuity check

on AC inlet.

Check if coil cord is

plugged in properly.

Replace suspect hand

control switch panel with

known working hand control switch panel.

Replace suspect hand

control PC board with

known working hand control PC board.

Plug power cord into facility

wall outlet and/or AC receptacle.

If facility circuit breaker is

tripped, determine what

caused the circuit breaker to

trip, correct the problem, and

then reset / replace the circuit

breaker.

Replace blown fuse(s). Refer

to para 5.2.

Clean any dirty connections.

Tighten any loose connections. Replace any damaged

connections.

Replace blown fuse(s). Refer

to para 5.2.

Replace PC control board.

Refer to para 4.3 or 4.4.

Replace fuse holder. Refer to

para 4.33.

Replace AC receptacle. Refer

to para 4.34

Plug coil cord into hand control or receptacle on table.

Clean any dirty connections.

Replace hand control switch

panel. Refer to para 4.20

Replace hand control PC

board. Refer to para 4.20.

© Midmark Corporation 1999 SF-1604

Page 2-5

Printe d in U.S .A.

Page 20

Problem Symptom Probable Cause Check Correction

Return To Table Of Contents

No actions can be initiated

from hand control.

- Continued

One or more functions cannot be initiated from hand

control.

No actions can be initiated

from foot control.

Table 2-1. Troubleshooting Guide - Continued

Table has power, but no

functions can be initiated

from hand control. Foot

control works properly.

- Continued

Some functions may be initiated with hand control,

but at least one may not.

Table has power, but no

functions can be initiated

from foot control. Hand

control works properly.

TESTING AND TROUBLESHOOTING

Control inlet PC board is

malfunctioning.

Cord running from control

inlet PC board to PC control

board is disconnected or

broken.

PC control board is malfunctioning.

Hand control switch panel is

malfunctioning (switch membrane is malfunctioning).

Hand control PC board is

malfunctioning.

Fuse for non-operating (suspect) function is blown.

Relay for non-operating

(suspect) function is malfunctioning.

Coil cord is not plugged into

foot control or receptacle on

table properly.

Foot control PC board is

malfunctioning.

Control inlet PC board is

malfunctioning.

Plug foot control into suspect control inlet PC

board and check for

proper operation

Check cord to see if it is

properly connected.

Replace suspect cord

with known working cord

or perform continuity

check on cord.

Replace suspect PC control board with known

working PC control

board.

Replace suspect hand

control switch panel with

known working hand control switch panel.

Plug foot control into suspect control inlet PC

board and check for

proper operation

Refer to Figure 2-2 for

this check. Perform continuity check on suspect

fuse.

Refer to Figure 2-2 for

this check. When hand

control button is pressed,

observe relay L.E.D’s on

PC control board. The

L.E.D. for the function

which was selected

should illuminate to indicate that its relay is operating correctly.

Check if coil cord is

plugged in properly.

Plug hand control into

suspect control inlet PC

board and check for

proper operation.

Replace suspect control

inlet PC board with

known working control

PC board.

SECTION II

If necessary, replace control

inlet PC board. Refer to para

4.19.

Replace cord.

Replace PC control board.

Refer to para 4.3 or 4.4..

Replace hand control switch

panel. Refer to para 4.20.

If necessary, replace hand

control PC board. Refer to

para 4.20.

Replace blown fuse(s). Refer

to para 5.2.

If relay L.E.D. does not illuminate properly, replace PC control board. Refer to para 4.3 or

4.4.

Plug coil cord into foot control

or receptacle on table. Clean

any dirty connections.

Replace foot control PC

board. Refer to para 4.23.

Replace control inlet PC

board. Refer to para 4.19.

© Midmark Corporation 1999 SF-1604

Page 2-6

Printe d in U.S .A.

Page 21

Problem Symptom Probable Cause Check Correction

Return To Table Of Contents

No actions can be initiated

from foot control.

- Continued

BACK UP and BACK

DOWN functions do not

work. All other functions

work.

Table 2-1. Troubleshooting Guide - Continued

Table has power, but no

functions can be initiated

from foot control. Hand

control works properly.

- Continued

Some functions may be initiated with foot control, but

at least one may not.

When BACK UP and

BACK DOWN buttons are

pressed, table will not

move (all other functions

work).

TESTING AND TROUBLESHOOTING

Cord running from control

inlet PC board to PC control

board is disconnected or

broken.

PC control board is malfunctioning.

A footswitch for a function is

malfunctioning.

Foot control PC board is

malfunctioning.

Fuse for non-operating (suspect) function is blown.

Relay for non-operating

(suspect) function is malfunctioning.

Back capacitor is weak or

blown.

Thermal overload switch in

back actuator motor is activated.

5 amp BACK fuse for BACK

UP and BACK DOWN functions is blown.

Wire connections loose. Check all wiring connec-

Back actuator assembly is

malfunctioning.

Check cord to see if it is

properly connected.

Replace suspect cord

with known working cord

or perform continuity

check on cord.

Replace suspect PC control board with known

working PC control

board.

Perform a continuity

check on footswitch.

Replace suspect foot

control interface board

with known working foot

control interface board.

Refer to Figure 2-2 for

this check. Perform continuity check on suspect

fuse.

Refer to Figure 2-2 for

this check. When a footswitch is depressed,

observe relay L.E.D’s on

PC control board. The

L.E.D. representing the

function which was

selected should illuminate to indicate its relay

is operating correctly.

Replace suspect back

capacitor with known

working back capacitor.

_ Wait 10 to 20 minutes to allow

Refer to Figure 2-2 for

this check. Perform a

continuity check on 5

amp BACK fuse.

tions to back actuator

assembly.

Replace suspect back

actuator assembly with

known working back

actuator assembly.

SECTION II

Replace cord.

Replace PC control board.

Refer to para 4.3 or 4.4.

Replace footswitch. Refer to

para 4.25.

Replace foot control PC

board. Refer to para 4.23.

Replace blown fuse(s). Refer

to para 5.2.

If relay L.E.D. does not illuminate properly, replace PC control board. Refer to para 4.3 or

4.4.

Replace back capacitor. Refer

to para 4.8.

back actuator motor to cool.

Replace blown fuse(s). Refer

to para 5.2.

Clean any dirty connections.

Tighten any loose connections. Replace any damaged

connections.

Replace actuator motor or

back actuator assembly. Refer

to para 4.14 or 4.7.

© Midmark Corporation 1999 SF-1604

Page 2-7

Printe d in U.S .A.

Page 22

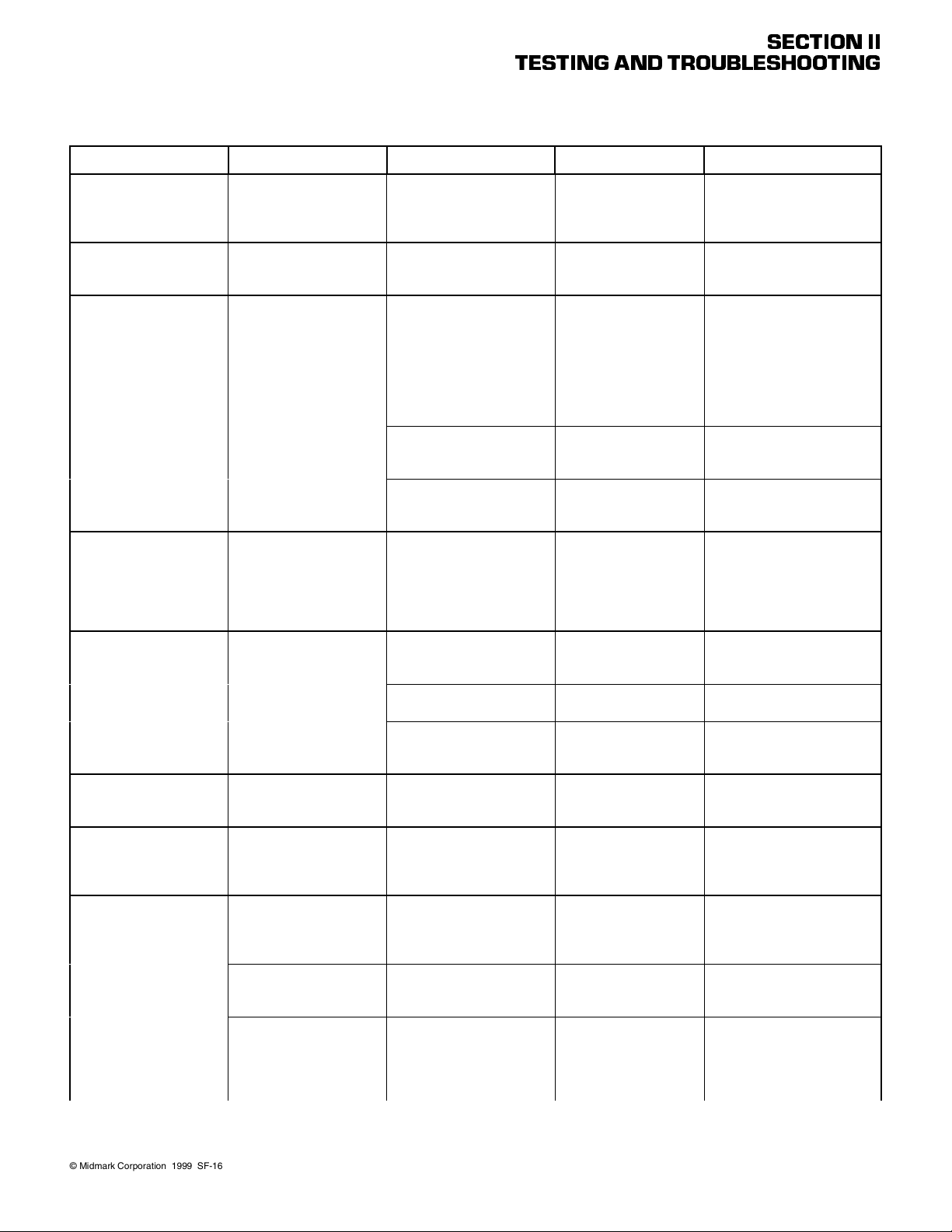

Problem Symptom Probable Cause Check Correction

Return To Table Of Contents

BACK UP and BACK

DOWN functions do not

work. All other functions

work. - Continued

TILT UP and TILT DOWN

functions do not work. All

other functions work.

TABLE UP and TABLE

DOWN functions do not

work. All other functions

work.

Table 2-1. Troubleshooting Guide - Continued

When BACK UP and

BACK DOWN buttons are

pressed, table will not

move (all other functions

work). - Continued

When TILT UP and TILT

DOWN buttons are

pressed, the table will not

move (all other functions

work).

When TABLE UP and

TABLE DOWN buttons are

pressed, the table will not

move (all other functions

work).

TESTING AND TROUBLESHOOTING

PC control board is malfunctioning.

Tilt capacitor is weak or

blown.

Thermal overload switch in

tilt actuator is activated.

5 amp TILT fuse for TILT UP

and TILT DOWN functions is

blown.

Wire connections loose. Check all wiring connec-

Tilt actuator assembly is

malfunctioning.

PC control board is malfunctioning.

Base capacitor is weak or

blown.

Thermal overload switch in

base actuator motor is activated.

Refer to Figure 2-2 for

this check. Press BACK

UP and then BACK

DOWN button while

observing the PC control

board. The BACK UP

L.E.D. should illuminate

when the BACK UP button is pressed and the

BACK DOWN L.E.D.

should illuminate when

the BACK DOWN button

is pressed. If, not, the PC

control board is malfunctioning.

Replace suspect tilt

capacitor with known

working tilt capacitor.

_ Wait 10 to 20 minutes to allow

Refer to Figure 2-2 for

this check. Perform continuity check on 5 amp

TILT fuse.

tions to tilt actuator

assembly.

Replace suspect tilt actuator assembly with

known working tilt actuator assembly.

Refer to Figure 2-2 for

this check. Press TILT

UP and then TILT DOWN

button while observing

the PC control board.

The TILT UP L.E.D.

should illuminate when

the TILT UP button is

pressed and the TILT

DOWN L.E.D. should illuminate when the TILT

DOWN butt on is press ed.

If not, the PC control

board is malfunctioning.

Replace suspect base

capacitor with known

working base capacitor.

_ Wait 10 to 20 minutes to allow

SECTION II

Replace PC control board.

Refer to para 4.3 or 4.4.

Replace tilt capacitor. Refer to

para 4.6.

tilt actuator motor to cool.

Replace blown fuse(s). Refer

to para 5.2.

Clean any dirty connections.

Tighten any loose connections. Replace any damaged

connections.

Replace actuator motor or tilt

actuator assembly. Refer to

para 4.14 or 4.5.

Replace PC control board.

Refer to para 4.3 or 4.4.

Replace base capacitor. Refer

to para 4.12.

base actuator to cool.

© Midmark Corporation 1999 SF-1604

Page 2-8

Printe d in U.S .A.

Page 23

Problem Symptom Probable Cause Check Correction

Return To Table Of Contents

TABLE UP and TABLE

DOWN functions do not

work. All other functions

work. - Continued

FOOT UP and FOOT

DOWN functions do not

work. All other functions

work.

Table 2-1. Troubleshooting Guide - Continued

When TABLE UP and

TABLE DOWN buttons are

pressed, the table will not

move (all other functions

work). - Continued

When FOOT UP and

FOOT DOWN buttons are

pressed, the table will not

move (all other functions

work).

TESTING AND TROUBLESHOOTING

5 amp BRAKE/ BASE fuse

for TABLE UP, TABLE

DOWN, and base brake

functions is blown.

Wire connections loose. Check all wiring connec-

Base actuator assembly is

malfunctioning.

PC control board is malfunctioning.

Brake on base actuator is

malfunctioning.

Foot capacitor is weak or

blown.

Thermal overload switch in

foot actuator is activated.

5 amp FOOT fuse for FOOT

UP and FOOT DOWN functions is blown.

Wire connections loose. Check all wiring connec-

Foot actuator assembly is

malfunctioning.

Refer to Figure 2-2 for

this check. Perform continuity check on 5 amp

BRAKE/BASE fuse.

tions to base actuator

assembly and base

brake solenoid.

Replace suspect base

actuator assembly with

known working base

actuator assembly.

Refer to Figure 2-2 for

this check. Press TABLE

UP and then TABLE

DOWN button while

observing the PC control

board. The TABLE UP

L.E.D. and BRAKE/BASE

L.E.D. should illuminate

when the TABLE UP button is pressed and the

TABLE DOWN L.E.D.

and the BRAKE/BASE

L.E.D. should illuminate

when the TABLE DOWN

button is pressed. If not,

the PC control board is

malfunctioning.

_ Replace base actuator. Refer

Replace suspect foot

capacitor with known

working foot capacitor.

_ Wait 10 to 20 minutes to allow

Refer to Figure 2-2 for

this check. Perform continuity check on 5 amp

FOOT fuse.

tions to foot actuator

assembly.

Replace suspect foot

actuator assembly with

known working foot actuator assembly.

SECTION II

Replace blown fuse(s). Refer

to para 5.2.

Clean any dirty connections.

Tighten any loose connections. Replace any damaged

connections.

Replace base actuator assembly. Refer to para 4.11.

Replace PC control board.

Refer to para 4.3 or 4.4.

to para 4.11.

Replace foot capacitor. Refer

to para 4.10.

foot actuator motor to cool.

Replace blown fuse(s). Refer

to para 5.2.

Clean any dirty connections.

Tighten any loose connections. Replace any damaged

connections.

Replace actuator motor or foot

actuator assembly. Refer to

para 4.14 or 4.9.

© Midmark Corporation 1999 SF-1604

Page 2-9

Printe d in U.S .A.

Page 24

Problem Symptom Probable Cause Check Correction

Return To Table Of Contents

FOOT UP and FOOT

DOWN functions do not

work. All other functions

work. - Continued

BACK UP function works,

but BACK DOWN function

does not or BACK DOWN

function works, but BACK

UP function does not. All

other functions work.

TILT UP function works but

TILT DOWN function does

not or TILT DOWN function

works, but TILT UP function does not. A ll other

functions work.

Table 2-1. Troubleshooting Guide - Continued

When FOOT UP and

FOOT DOWN buttons are

pressed, the table will not

move (all other functions

work). - Continued

One function operates

properly, but the other

does not.

One function operates

properly, but the other

does not.

TESTING AND TROUBLESHOOTING

PC control board is malfunctioning.

Wire connections loose. Check all wiring connec-

Back actuator assembly is

malfunctioning.

PC control board is malfunctioning (relay for up or down

function is malfunctioning).

Hand control switch panel of

hand control is malfunctioning (switch membrane is

malfunctioning).

BACK UP or BACK DOWN

footswitch is malfunctioning.

Wire connections loose. Check all wiring connec-

Tilt actuator assembly is

malfunctioning.

Refer to Figure 2-2 for

this check. Press FOOT

UP and then FOOT

DOWN button while

observing the PC control

board. The FOOT UP

L.E.D. should illuminate

when the FOOT UP button is pressed and the

FOOT DOWN L.E.D.

should illuminate when

the FOOT DOWN button

is pressed. If not, the PC

control board is malfunctioning.

tions to back actuator

assembly.

Replace suspect back

actuator assembly with

known working back

actuator assembly.

Refer to Figure 2-2 for

this check. Press BACK

UP and then BACK

DOWN button while

observing the PC control

board. The BACK UP

L.E.D. should illuminate

when the BACK UP button is pressed and the

BACK DOWN L.E.D.

should illuminate when

the BACK DOWN button

is pressed. If not, the PC

control board is malfunctioning.

Replace suspect hand

control switch panel with

known working hand control switch panel.

Perform a continuity

check on suspect foot

switch.

tions to tilt actuator

assembly.

Replace suspect tilt actuator assembly with

known working tilt actuator assembly.

SECTION II

Replace PC control board.

Refer to para 4.3 or 4.4.

Clean any dirty connections.

Tighten any loose connections. Replace any damaged

connections.

Replace actuator motor or

back actuator assembly. Refer

to para 4.14 or 4.7.

Replace PC control board.

Refer to para 4.3 or 4.4.

Replace hand control switch

panel. Refer to para 4.20.

Replace footswitch. Refer to

para 4.25.

Clean any dirty connections.

Tighten any loose connections. Replace any damaged

connections.

Replace actuator motor or tilt

actuator assembly. Refer to

para 4.14 or 4.5.

© Midmark Corporation 1999 SF-1604

Page 2-10

Printe d in U.S .A.

Page 25

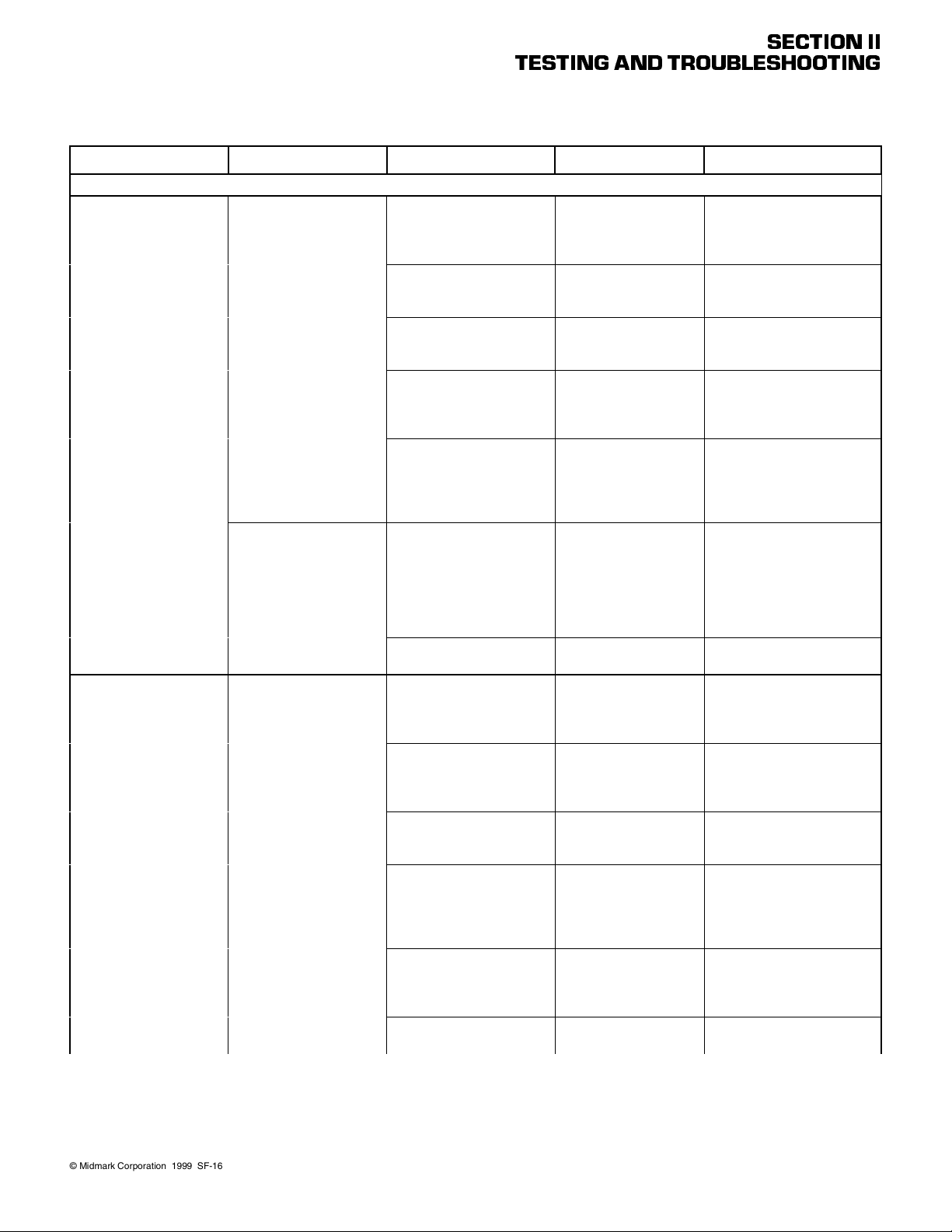

Problem Symptom Probable Cause Check Correction

Return To Table Of Contents

TILT UP function works but

TILT DOWN function does

not or TILT DOWN function

works, but TILT UP function does not. All other

functions work.

- Continued

TABLE UP function works,

but TABLE DOWN function does not or TABLE

DOWN function works, but

TABLE UP function does

not. All other functions

work.

Table 2-1. Troubleshooting Guide - Continued

One function operates

properly, but the other

does not. - Continued

One function operates

properly, but the other

does not.

TESTING AND TROUBLESHOOTING

PC control board is malfunctioning (relay for up or down

function is malfunctioning).

Hand control switch panel of

hand control is malfunctioning (switch membrane is

malfunctioning).

TILT UP or TILT DOWN footswitch is malfunctioning.

Wire connections loose. Check all wiring connec-

Either base down limit switch

or base up limit switch is

malfunctioning.

Base actuator assembly is

malfunctioning.

PC control board is malfunctioning (relay for up or down

function is malfunctioning).

Hand control switch panel of

hand control is malfunctioning (switch membrane is

malfunctioning).

Refer to Figure 2-2 for

this check. Press TILT

UP and then TILT DOWN

button while observing

the PC control board.

The TILT UP L.E.D.

should illuminate when

the TILT UP button is

pressed and the TILT

DOWN L.E.D. should illuminate when the TILT

DOWN butt on is press ed.

If not, the PC control

board is malfunctioning.

Replace suspect hand

control switch panel with

known working hand control switch panel.

Perform a continuity

check on suspect footswitch.

tions to base actuator.

Perform continuity check

on N.C. limit switches

(limit switch tripped =

open).

Replace suspect base

actuator assembly with

known working base

actuator assembly.

Refer to Figure 2-2 for

this check. Press TABLE

UP and then TABLE

DOWN button while

observing the PC control

board. The TABLE UP

L.E.D. and BRAKE/BASE

L.E.D. should illuminate

when the TABLE UP button is pressed and the

TABLE DOWN L.E.D.

and the BRAKE/BASE

L.E.D. should illuminate

when the TABLE DOWN

button is pressed. If not,

the PC control board is

malfunctioning.

Replace suspect hand

control switch panel with

known working hand control panel.

SECTION II

Replace PC control board.

Refer to para 4.3 or 4.4.

Replace hand control switch

panel. Refer to para 4.20.

Replace footswitch. Refer to

para 4.25.

Clean any dirty connections.

Tighten any loose connections. Replace any damaged

connections.

Replace base up limit switch

(Refer to para 4.16) or base

down limit switch (Refer to

para 4.15).

Replace base actuator assembly. Refer to para 4.11.

Replace PC control board.

Refer to para 4.3 or 4.4.

Replace hand control switch

panel. Refer to para 4.20.

© Midmark Corporation 1999 SF-1604

Page 2-11

Printe d in U.S .A.

Page 26

Problem Symptom Probable Cause Check Correction

Return To Table Of Contents

TABLE UP function works,

but TABLE DOWN function does not or TABLE

DOWN function works, but

TABLE UP function does

not. All other functions

work. - Continued

FOOT UP function works,

but FOOT DOWN function

does not or FOOT DOWN

function works, but FOOT

UP function does not. All

other functions work.

TA B L E D OW N, FO OT

DOWN, AND TILT DOWN

functions do not work. All

other functions work.

Table 2-1. Troubleshooting Guide - Continued

One function operates

properly, but the other

does not. - Continued

One function operates

properly, but the other

does not.

When TABLE DOWN,

FOOT DOWN, or TILT

DOWN buttons are

pressed, the table will not

move (all other functions

work). Foot Extension lam p

on hand control illuminates.

TESTING AND TROUBLESHOOTING

TABLE UP or TABLE DOWN

footswitch is malfunctioning.

Wire connections loose. Check all wiring connec-

Foot actuator assembly is

malfunctioning.

PC control board is malfunctioning (relay for up or down

function is malfunctioning).

Hand control switch panel of

hand control is malfunctioning (switch membrane is

malfunctioning).

FOOT UP or FOOT DOWN

footswitch is malfunctioning.

Foot rest extension is not

pushed in all the way.

Foot rest extension limit

switch, foot actuator limit

switch, and/or base actuator

limit switch malfunctioning.

PC control board is malfunctioning.

Perform a continuity

check on suspect footswitch.

tions to foot actuator

assembly.

Replace suspect foot

actuator assembly with