Page 1

Version: 03/2016

HEAT

PUMP

for swimming pool water

heating & cooling

HP 1100 COMPACT PREMIUM

HP 1500 COMPACT PREMIUM

Installation and user manual

Page 2

Installation and user manual HP1100/1500 COMPACT PREMIUM

Version: 01 /2018 Page 2 /28

HEAT PUMP MICROW ELL HP

Thank you for purchasing Microwell swimming pool heat pump.

Before you use this device, it is necessary to carefully read the entire

Installation and user manual. It is not allowed to commence the heat

pump installation or operation unless full content of this Installation

and user manual is understood and acknowledged. Please keep the

Installation and user manual available in the case of any future

reference is required. Please provide this information also to each

user of the device. Please mind local regulations in your country

regarding installation and usage of this heat pump which are valid in

addition to this User manual.

Contents

1. INTRODUCTION ............................................................................................................................... 4

1.1 Product description ................................................................................................................. 4

1.2 Package checking ..................................................................................................................... 5

1.3 Waste disposal information .................................................................................................... 5

2. SAFETY MEASURES .......................................................................................................................... 6

2.1 Electrical safety ........................................................................................................................ 6

2.2 Usage precautions ................................................................................................................... 6

2.3 Handling precautions .............................................................................................................. 7

3. TECHNICAL SPECIFICATION ............................................................................................................. 8

3.1 Technical data .......................................................................................................................... 8

3.2 Swimming pool water parameters .......................................................................................... 8

3.3 Heat pump dimensions ........................................................................................................... 9

3.4 Description of the basic parts .................................................................................................. 9

3.5 Security and control systems ................................................................................................ 10

3.6 Block wiring diagram of the PCB board ................................................................................. 11

4. HEAT PUMP INSTALLATION AND CONNECTION ............................................................................ 12

4.1 Positioning ............................................................................................................................. 12

4.2 Connection to water filtration circuit .................................................................................... 13

4.3 Needed components for connection to water circuit ........................................................... 14

4.4 Electric connection ................................................................................................................ 16

4.5 Multiple heat pump connection ............................................................................................ 16

4.6 Control of the circulation pump ............................................................................................ 17

4.7 Separate water circuit ........................................................................................................... 18

4.8 Circulation pump connection ................................................................................................ 18

5. REGULATION .................................................................................................................................. 19

Page 3

HP1100/1500COMPACT PREMIUM Installation and user manual

Page 3 /28 Version:01 /2018

HEAT PUMP MICROWEL L HP

5.1 Description of the LCD panel ................................................................................................. 19

5.2 General heat pump control ................................................................................................... 20

5.3 Heat pump operational modes ............................................................................................. 21

5.4 Timer ..................................................................................................................................... 21

5.5 Child lock ............................................................................................................................... 22

5.6 Parameters check .................................................................................................................. 22

5.7 Setting of the operating parameters ..................................................................................... 23

6. ACCESSORIES ................................................................................................................................. 24

6.1 Winter module ...................................................................................................................... 24

6.2 Heat exchanger frost protection ........................................................................................... 24

6.3 Condensate tray defrost ........................................................................................................ 25

6.4 Protection cover .................................................................................................................... 25

7. HINTS AND TIPS ............................................................................................................................. 25

7.1 Water condensation .............................................................................................................. 25

7.2 Defrosting .............................................................................................................................. 26

7.3 Winterizing ............................................................................................................................ 26

7.4 Heat pump season start ........................................................................................................ 27

7.5 Failure reports ....................................................................................................................... 28

7.6 Troubleshooting – save time and money .............................................................................. 30

8. MAINTANANCE & WARRANTY ...................................................................................................... 31

8.1 Maintanance .......................................................................................................................... 31

8.2 Warranty ................................................................................................................................ 32

Page 4

Installation and user manual HP1100/1500 COMPACT PREMIUM

Version: 01 /2018 Page 4 /28

HEAT PUMP MICROW ELL HP

1. INTRODUCTION

In your hands you hold probably the most advanced and the most efficient heat pump currently

available on the market. This heat pump p rovides warm water in your pool at lowest possible cost.

The heat pump is manufactured in tightest accordance with related strict standards and norms, in

order to provide high quality operatio n and long-term reliability.

This Installation and user manual contains all the necessary information about the installation,

operation and maintenance of the heat pump. Please read this Installation and user ma nual carefully

before you start to use this product. The m anufa cturer is not responsible for any p ersonal or property

damage due to the improper installation, use or maintenance that is not in acco rdance with t his User

Manual.

This Installation and user manual is an inseparable p art of this product; therefore it must be kept in

good condition and must accompany the heat pump.

1.1 Product description

The heat pump is designed exclusi vely for swimm ing pool wa ter heating or cooling and maintaining its

temperature on the requested level. Other appropriate application is water temperature conditio ning

for fish tanks, wine ciders or horse cooling facilities. These applications should be discussed with local

installer or distributor. Any other form of application is considered inappropriate.

The heat pump achieves the highest efficiency at 15÷35°C air temperature. At ambient air

temperatures lo wer than -5°C the ef ficiency of the device decreases and at the temperatures higher

than +40°C the heat pump can get overheated which may result in its malfunction, damage or failure.

Do not use the prod uct out of the designated operational air temperature range which is stated

in

section 3.1 Technical data

.

This heat pump is designed for swimming pools with up to 40 m

3

- HP 1100 and up to 60 m3 - HP

1500 of pool water volume . For proper operations there must be water flow through the ex change r of

the heat pump (within water filtration circuit) in the range of 4-6 m

3

/h.

The heat pump enables heat gain from the external air surrounding the swimming pool t hrough the

compression – expansion cycles of the heat-carrying liquid. The air is driven by a fan through the

evaporator where it will deliver it s heat to the heat -carrying liquid (the air is being cooled at the sam e

time). The heat-carrying liquid is then delivered to t he spirals of the exchanger by the compress or

which pressurises it and thus he ats it up. In these spirals, the hea t-carrying liquid delivers its heat to

the swimming pool water. From the exchanger there is a cooled liquid flowing to the expansion valve

or capillary where its pressure decreases and it gets cooled down rapidly at the same time. This

cooled liquid flows to the evaporator again where it gets heated by the flowing air. The whole process

runs fully automatically and is monitored by the pressure and temperature sensors. The same

principle is applied when heat pump operates in cooling mode.

Using simple language, a heat pump is able to extract the heat/cold that is present in ambient

environment and leveraged pass it into the pool water. When heating, higher the ambient air

temperature is, more free energy can the heat pump extract and thus reach higher efficiency. At

favourable conditions you pay around 15% of heat, i.e. 85% of heat is free. Please review below

drawing of different ambient air conditions with subsequent efficiencies.

The heat pump efficiency grows by the increasing surrounding air temperature.

It takes some days to achieve the requested swimming pool water temperature. This time period

depends on heat loss and heat gain ba lance of your pool.

Example factors of heat losses: poor pool construction, used materials, usage of cover, air – water

temperature relationship, fresh water refilling, filtra tion, etc.

Example factors of heat gains: intensity of sun, winds, orientation of pool, air – water temperature

relationship, etc.

In order to avoid heat loss when the swimming pool is not being used, it is highly advised to use

pool’s cover.

Page 5

HP1100/1500COMPACT PREMIUM Installation and user manual

Page 5 /28 Version:01 /2018

HEAT PUMP MICROWEL L HP

Ideal water temperature for external pools is considered at levels from 27° to 32°C. This may change

based on particular demands of the user. When setting the desired air temperature higher than 32°C

please review the material characteristics of your pool parts. High water temperature can damage

these materials a nd contrib ute to creation of algea. Manufa cturer, distributor and reseller do not bear

responsibility resulting from inappropriate heat pump usage.

1.2 Package checking

The unit was delivered in carton box on a wooden palette. Do not accept the package if it shows

signs of damage. If the package appears intact, please unpack the unit and check the content. It

should include the following:

1. The heat pump – one compact piece. Please check section 3.4 Decription of the basic parts to see

how the heat pump looks like

2. This Installation and user manual

3. Four rubber silent blocks

1.3 Waste disposal information

When using this heat pump in the European countries, the following information must be

followed:

DISPOSAL:

Do not dispose this product as unsorted municipal waste. It is prohibited to

dispose this heat pump in domestic / household waste. It is prohibited to dispose this

appliance into forests or natural landscape. This could lead into local soil pollution.

Collection of such waste must be treated individually.

1. The municipality has established a collection system where electronic waste can be disposed.

DISPOSAL POSSIBILITIES:

2. When buying a new product, the retailer or the manufacturer may take back the

old appliance free of charge.

3. Old appliance may contain valuable resources which could be sold to scrap

material dealers.

4. Disposal of packaging materials such as carton box or plastic / bubble foil can be

recycled.

Page 6

Installation and user manual HP1100/1500 COMPACT PREMIUM

Version: 01 /2018 Page 6 /28

HEAT PUMP MICROW ELL HP

2. SAFETY MEASURES

It is necessary to follow instructions in this Installation and user manual and local regulations in

your country that regulate the installation and usage of this device. Incorrect, improper or

operations contradictory to this Installation and user manual may lead to an injury or property

damage and will lead to loss of warranty. To prevent injury or property damage the following

instructions must be followed:

2.1 Electrical safety

• The device operates at dangerous electrical current.

• Only authorized person with particular electro-technical qualification can manipulate with unit.

• Danger of electrical shock.

• Do not exceed the required power supply.

• Do not turn the device on that shows signs of possible damage such as broken packaging, broken or

otherwise damaged unit’s chassis or cover, smoke, smell, etc.

• It is necessary to use appropriate Residual current circuit breaker (RCD) for connection of the heat

pump to main power supply.

• Do not manipulate with the device with wet hands.

• Do not clean the device with water.

• Before cleaning the device, switch off the circuit breaker of the unit’s power supply.

• Installation, service or repair must be performed by qualified technician.

• When the device is not intended to be used for a longer time, we recommend switching the circuit

breaker of the unit’s power supply off.

• Unit must be installed in vertical position to avoid condensate water to enter electrical part of the

unit.

• It is forbidden to install the unit close to devices that may cause electrical or frequency disturbance

such as welding machines, motors or rotors, WIFI/WLAN routers or repeaters.

• It is forbidden to alter electrical installation of the device. It is also forbidden to alter any other part

or functionality of the device.

2.2 Usage precautions

Do not cover or block the intake or exhaust opening / ventilator and evaporator covers. It

is forbidden to block or cover the intake or exhaust openings with clothes, towels,

buckets, canoes, trees, etc. Such action would lead to a decrease of needed airflow. That

would result in heat pump inefficiency and underperformance, eventually to heat pump

overeat with subsequent security turning off, malfunction, failure or damage. Especially

during bloom months it is highly advised to keep the evaporator fins clean.

• Do not climb up on or sit on the unit.

• Do not place any objects on the top of the unit (e.g. boxes, flower vases, etc.).

• Do not spray any flammable substances into the equipment; this might lead to fire.

•

Do not clean the equipment with aggressive cleaning agents, this might lead to damage or

deformations.

• When cleaning plastic parts do not use any cleaning agents unsuitable for plastic (household

cleaning agents, solvents, bleaching agents, benzene, d

iluents, rough cleaning powder, cresol,

chemical agents). Instead, sweep the heat pump cover with a soft cloth or a sponge.

• Never throw or insert any objects into any hose or opening.

• The cover is made of metal. Do not manipulate with lighted cigarette, cigarette ashes, or any other

kind of fire in vicinity to this part.

•

Use this device exclusively for the intended purpose, as described in the attached instruction

manual. Do not use parts which are not recommended.

• Never block the air opening of the product. Protect the air openings from clogging by particles.

•

Do not drink or use the condensate water drained from the unit. Do not return the water back to the

Page 7

HP1100/1500COMPACT PREMIUM Installation and user manual

Page 7 /28 Version:01 /2018

HEAT PUMP MICROWEL L HP

swimming pool. The water may be contaminated with bacteria.

• Children are not allowed to operate, touch or play with the unit.

• Children are not allowed to manipulate with packaging, plastic / bubble foil. Risk of suffocation!

• Prevent the children from injury or harm caused by any manipulation with the unit, its parts or its

packaging. Small parts like screws may be swallowed and cause harm to health.

• Do not leave the children in the swimming pool / at the swimming pool unattended.

• The positioning of the heat pump must be in accordance with the STN 33 2000-7-702 standard, i.e.

it must be placed at least 3,5 m from the swimming pool´s external border.

• For heating/cooling the swimming pool by the heat pump, the filtration pump must run and the

water must flow through the heat exchanger.

• Never turn on the heat pump if it is without water and if the filtration device is not operating.

•

Protect the heat pump from freezing. Eliminate the water from the filtration and from the heat

pump’s water heat exchanger and prepare the product for the winter time.

• At low surrounding ambient temperature level (below 10°C) and high relative air humidity level (e.g.

after rain, during the night, etc.), the evaporator may get iced up. Heat pump will automatically

defreeze itself. Its operations or functionality is not harmed but the efficiency decreases.

• Manufacturer does not bear any responsibility concerning damages caused by inappropriate heat

pump performance and/or model selection, installation or application. Heat pump is considered

undersized in the case it works usually and in long-term more than 18 hours daily. General warranty

void applies for damages on the device or other damages if the device works usually in long-term

more than 18 hours daily.

• The heat pump must be correctly sized for its application.

• Do not pressurize the water heat exchanger higher than 0.15MPa (1.5bar). By pressure of 0.2MPa

(2bar) the water heat exchanger gets irreversibly damaged. It is advised to install a security valve

with pressure threshold at 0.15MPa (1.5Bar) before the heat exchanger.

• Do not apply or use water of higher temperature than 40°C in water heat exchanger. Water

temperature above 45°C irreversibly damages the water heat exchanger.

2.3 Handling precautions

• Leave the unit in vertical upright position for at least 2 hours before the installation.

• Transport in lying position or turning the device over may harm the compressor resulting in unit’s

malfunction, failure or damage and will lead to loss of warranty.

• The device must be handled with care and special attention avoiding any mechanical damage.

• It is forbidden to apply any improper mechanical force onto the unit. This may cause mechanical

damage to the device.

•

It is forbidden to let the device fall freely onto the ground or any solid surface resulting in hard

impact.

• Please notify your reseller or distributor if you suspect that the unit was delivered damaged. Unit

may seem to work well at start but small damage can make the unit go out-of-order in short time.

In such case the unit must be inspected and approved for further use by your reseller.

• Please notify your reseller o

r distributor if directly after installation you suspect that unit is not

working in perfect order.

•

In the case of device failure resulting from improper handling or mechanical damage (impact, hit,

fall, etc.), the manufacturer reserves the right to evaluate the continuity of warranty.

Page 8

Installation and user manual HP1100/1500 COMPACT PREMIUM

Version: 01 /2018 Page 8 /28

HEAT PUMP MICROW ELL HP

3. TECHNICAL SPECIFICATION

3.1 Technical data

HP 1100 COMPACT

PREMIUM

HP 1500 COMPACT

PREMIUM

Air temperature/water temperature

25°C/10°C

25°C/20°C

25°C/10°C

25°C/20°C

Heating output (kW) 10.06 9.55 13.01 12.28

Power consumption (kW)

1.49

1.51

1.92

1.95

Coefficient of Performance (C.O.P.)

6,7

6.3

6.7

6.3

Recommended swimming pool volume (m3) (with

a cover/without a cover)

40/30 60/40

Energy class A A

Operating temperature – air (°C)

-5 (-15)**... +40

-5 (-15)**... +40

Optional swimming pool water temperature range (°C)

+5...+40

+5...+40

Air flow (m3/h)

2520

2520

Recommended water flow (m3/h)/pressure loss (kPa)

4-6/1-5

4-6/1-5

Feeding voltage/Protection (V/A) 230 / 20A/C 230/ 20A/C

Current-carrying capacity/max. current (A) 7/9 9/10

Coverage/Protection

IP X4/by grounding

IP X4/by grounding

Heat exchanger

Titanium

Titanium

Acoustic pressure level dB (A) 1m/2m/4m/8m

54/48/42/36

55/49/43/37

Water circuit connection (mm/inch, thread) 50/ 6/4“ internal 50/ 6/4“ internal

Max. recommended water pipe length (m)

30

30

Max. operational water pressure

0.15MPa (1.5bar)

0.15MPa (1.5bar)

Net unit dimensions (w/h/d)

870/950/320

870/950/320

Gross unit dimensions (w/h/d)

1020/1080/450

1020/1080/450

Net/Gross weight (kg) 67/73 69/75

Refrigerant/filling weight (type/kg)

R410A/1,25

R410A/1,60

* The manufacturer reserves the right to change the parameters without notice.

** In the case Winter module, condensate tray antifreeze or heat exchanger frost protection is installed.

The refrigerant circuit is filled with R410A refrigerant that consists of 2 components (R32/R125).

These components are considered as fluorocarbon greenhouse gases. The product contains

fluorocarbon greenhouse gases listed in the Kyoto Protocol:

R410A with the global warning potential (GWP) 1720 (R-32/125 50/50) CH2F2 + CF3CHF2.

3.2 Swimming pool water parameters

The heat pump is designed for heating the swimming p ool water. Although the water heat exchanger

is made from the most durable titanium, in order to ensure long term reliability of the heat pump the

pool water must be in accordance with the related sanitary requirements.

The limit values for the heat pump operation are the following:

- pH val ue ranging from 6.8 to 7.9,

- total chlorine amount not exceeding 3 mg/l,

- salt content 6% wt/wt.

Should you have different values of pH, chlorine or salt please try to apply appropriate agents or

contact your swimming pool builder to resolve the situation. Above mentioned values are

recommended for pools in general.

Page 9

HP1100/1500COMPACT PREMIUM Installation and user manual

Page 9 /28 Version:01 /2018

HEAT PUMP MICROWEL L HP

It is also advised to keep the water hardness on the lower limit of the optimal range, i.e. closely above

8 °N.

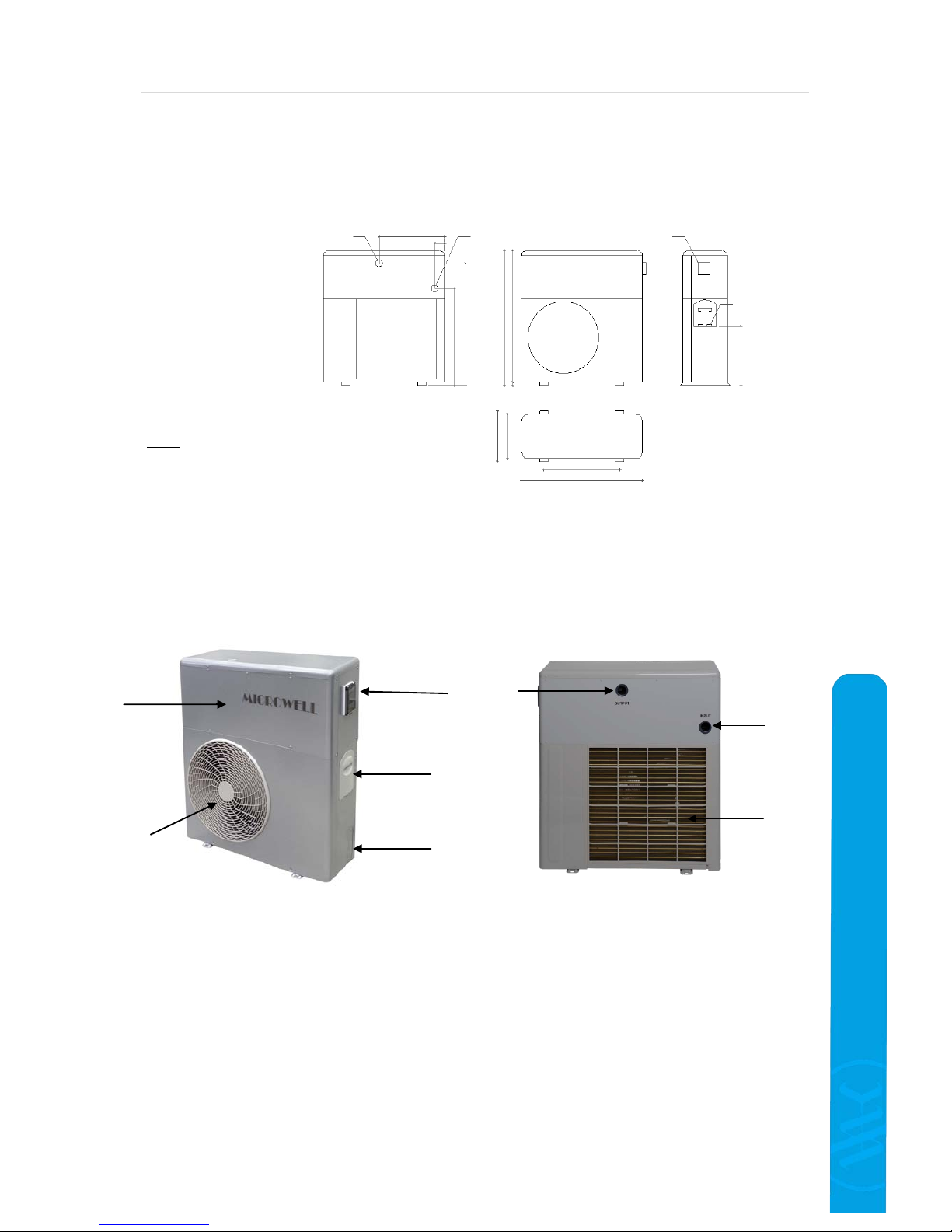

3.3 Heat pump dimensions

3.4 Description of the basic parts

Legend: 1

– Protecting grates of the fan (air outlet) / ventilator cover

2 – Cover / metal chassis

3 – Control panel

4 – Valve for refilling the refrigerant (under the cover)

5 – Power supply connection (underneat h the cover)

6 – Water outlet connection hub

7 – Water inlet conne ction hub

8 – Evaporator (air inlet)

Note: The illustr atio ns an d des cr iptio ns fou nd

in this Installatio n and user manual are not

binding. The manufacturer reserves the right

to make corrections or changes without

notice.

2

1 3 5

4

6 7 8

Power supplz

230V/50Hz

695

965

940

425

875

320

360

546

875

Water outlet

6/4“ internal d 50mm

Water inlet

6/4“ internal d 50mm

Control display

Page 10

Installation and user manual HP1100/1500 COMPACT PREMIUM

Version: 01 /2018 Page 10/28

HEAT PUMP MICROW ELL HP

3.5 Security and control systems

In order to ensure long term reliability and fully automatic operations of the heat pump, the pump is

pump is equipped with following security systems:

Temperature based control of the heat pump operation:

The heat sensor placed on t he heat exchange r, ensures sw itching off of the heat pump when

the requested water temperature is reached. The normal operating mode gets renewed if the

water temperature in the exchanger drops by 3 °C (manufacturing setting) below the

requested value.

Safety systems:

Water flow sensor (flow switch) placed on the water heat e xchanger inlet.

The water flow sens or switches on the hea t pump when there is wate r flowing through the

heat pump exchanger, and switches it off when the water flow stops or is too high or low.

Sensor of the minimal and maximal gas pressure in the refrigerant circuit.

Heat sensor on the refrigerant outlet from the compressor.

Time protection

The unit is equipped with a switching time delaying device with a preset 3 minutes delay

period for protecting the control elements in the circuit and eliminating repeated restarts and

contactor vibrations. This time delay will automatically restart the unit app. 3 minutes after

every single interruption of t he heat pum p operati on. Even if there i s only a sh ort inte rruption

of the power supply, the time protection will get activated so the unit cannot start the

operation earlier t han the pressure s in the refrigerant circ uit of the heat p ump get balanced.

Interruption of the power supply during the pause time does not influence t he time interval.

Antifreeze protection

If an ambient air temperature is low (e.g. below 7°C), it is normal to have ice creations on the

evaporator of your heat pump. This is freezing condensated water. Your heat pump is

equipped with automatic defrosting.

Manufacturer has preset the conditions when automatic defrosting gets activated in order to

ensure optimal operations and performance of the heat pump. For more information please

refer to section 5.7 Setting of the operating parameters

and

section 7.2 Defrosting

.

If your heat pump freezes up on often basis it is advised to reconsider the efficiency of heat

pump running (heating) in such conditions.

If a failure occurs to any of above systems there will be an error message shown on the display

starting with ‘EE’. Please check

section

7.5

Failure reports

of this Installation and user manual.

Warning:

Elimination or disabling from operation any of the control or security systems results in

warranty void.

Page 11

HP1100/1500COMPACT PREMIUM Installation and user manual

Page 11/28 Version:01 /2018

HEAT PUMP MICROWEL L HP

3.6 Block wiring diagram of the PCB board

Legend:

FM – Fan motor

CM - Compressor

OUT 1 – Compressor L

OUT 2 – Compressor N

OUT 3 – output of 4-w ay valve L

OUT 4 – output of 4-w ay valve

OUT 5 - fan L

OUT 6 – circulation pump L

Sensors:

T1 – Evaporator / defrosting

T2 – Inlet water temperature

T3 – Ambient air temperature

T4 – Compressor discharge temperature

T5 – Outlet water temperature

FM

CM

Fan

Compressor

4-way

valve

OUT3 4 5 6 7

PCB board

OUT2

OUT1

CN4

CN6

CN7

CN2

Water flow sensor /

Flow switch

Connector

A, B, C

Transformer

Display

L N 3 4

Compressor

capacitor

Fan

capacitor

Sensors

T5

T4

T3

T2

T1

Heat pump power

supply

L N

Circulation pump

connection

230VAC

max. 500W

Picture: Power supply connection of the heat pump and of the

auxiliary circulation pump.

Notice: Manufacturer reserves the right to change electrical wiring

without notice.

Page 12

Installation and user manual HP1100/1500 COMPACT PREMIUM

Version: 01 /2018 Page 12/28

HEAT PUMP MICROW ELL HP

4. HEAT PUMP INSTALLATION AND CONNECTION

4.1 Positioning

The heat pump is designed for outdoor installation. It must be installed on a stable and levelled base.

The pump can be installed in vertical position only.

a)

The heat pump should be installed in spaces where it can have

sufficient supply of fresh ambient air.

Do not install the heat

pump in closed s paces with li mited air ac cess and where

the air cannot circulate sufficiently. The air inlet and outlet

must be completely accessible. The heat pump should have

minimal distances from surrounding object s as show n on picture

on the right. Do not put the heat pump near bushes or trees

either, as these can also influence the air access. E very single

barrier of free air flow reduces the ef ficiency of the he at

pump and may lead to heat pump’s malfunction, damage or

failure.

b) Although the heat pump is designed for exterior installation (sunlight, rain, snow) it is

suggested to make a shelter / roof in order to protect its metal parts and thus ensure long term

stability of color, metal chassis, etc.

c) Do not install the device near road networks, as increased concentration of dust gradually

decreases the heat exchange effectiveness.

d) When hea t pump is in f ull heating oper ation, it ge nerates conside rably colde r air than ambi ent

air temperature. It is thus advised not to in stall the heat pump at places, where cold air flow

could cause any inconvenience (windows, terraces, etc.). Also, do not place the air outlet

against the dominant winds.

e) The distance between the swimming pool edge and the hea t pump should not exceed 30 m.

Please note that the longer interconnecting water piping is, the higher heat loss occurs, i.e.

lower heating output and less ef ficiency is achieved. Practically t his results in longer heating

times and higher electricity bill. It is not advised to install the heat pump very close to

swimming pool water surface.

f) The heat pump must be placed on a flat, stable and levelled surface. The pum p housing must

be fixed to this surface with screws and rubber anti-vibration elements ( silent blocks). Rubber

anti-vibration elements not only reduce the noise level of the heat pump, but also help to

eliminate the vibra tions and thus they cont ribute to smoother hea t pump operations and long

term reliability.Please note t hat heat pum p should be i nstalled above the closest t errain level to

allow the condensation water leak out of the heat pump. Please refer to

section 7.1 Water

condensation

.

g) The surface of the evaporator consists of aluminum fins. The fins are soft and can get

mechanically damaged very easily. Please be careful when manip ulating with th e unit to avoid

any damage.

h) It is advised to install the heat pump on a stand 300-500mm above surrou nding ground

in the case the heat pump is to operate in low ambient air temperatures. Heat pump installed

directly on a surrounding ground can by easily immersed into snow and/or into frozen

condensation. This can decrease heat pump’s efficiency and performance and lead to heat

pump malfunction, damage or failure.

Notice: Please discuss particular details of heat pump positioning and connection to the swimming

pool water circuit with your swimming pool builder, distributor or reseller!

Picture: Minimal distances from surrounding

objects.

Page 13

HP1100/1500COMPACT PREMIUM Installation and user manual

Page 13/28 Version:01 /2018

HEAT PUMP MICROWEL L HP

4.2 Connection to water filtration circuit

The heat pump must be connected to water circuit (filtration circuit) of the swimming pool in order to

provide desired heating/cooling performance. The water flow through the exchanger of the heat pump

must be in accorda nce with the designed value (

see chapter 3.1 Technical data

). Normally the heat

pump is connected through a by-pass. It is then possible to adjust the water flow accordingly as

filtration pumps may have different water flow performances.

The by-pass consists of 3 valves connected as shown in the picture below. Wa ter normally flows from

the filtration pump (right side) to the swimming pool (left side) through Valve 1. Heat pump is

connected through Valve 2 (heat pump inlet) and Valve 3 (heat pump outlet).

Complete closure of Valves 2 and 3 with Valve 1 fully open means no water flow through the heat

pump which means no heating or cooling provided by the heat pump.

Complete closure of Valve 1 with Valve 2 and 3 fully open means maximum amount of water flowing

through the heat pump.

Normally the by-pass is set as shown on below picture.

The heat pump is eq uipped wit h 2 threads e nabling the conne ction of input and output fitt ing (d50).

For connection wit h the filtration circuit use the d50 PVC pipe or 50/38mm adapters (6/4”). Please

refer

to section 3.4 De scription of the basic parts

in order to m ake sure which t hread is water input

and which water output. It is advised to apply lubricating oil on threads before tightening the

connection.

Please consider using fast connector for the heat pump inlet and outlet in order to make the

disconnection of the heat pump from the rest of the filtration circuit simple (for water draining from

the heat pump before winter time and for service purposes).

The heat pump must be conne cted to the filtrat ion circuit of the sw imming pool b ehind the filter and

in front of the device for water conditioning (automatic chlorine dozing machine, ozone machine).

For illustration please refer to Scheme: Connection of the compact heat pump into the water

filtration circuit of the swimming pool on page 15.

Note: In case of using the automatic chlorine dozing machine in the filtration circuit it is

necessary to install a backward titanium spring in front of it. If this valve is missing, b y shutt ing

down the filtration, the chlorine concentration around the heat pump exchanger may be

increased to critical level and exceed the allowable level (3 ppm) causing damages.

Back to the swimming

pool

From the filtration

pump / swimming

pool

Connection of the by-pass

VALVE

VALVE

VALVE

To the heat pump

From the heat pump

Page 14

Installation and user manual HP1100/1500 COMPACT PREMIUM

Version: 01 /2018 Page 14/28

HEAT PUMP MICROW ELL HP

4.3 Needed components for connection to water circuit

It is advised to use hose nut with external thread PN16 50 x 6/4” and a pressure hose D50 or PVC

pipe D50.

Particular component selection depends on individual condition at your pool. Your seller,

distributor or pool builder may decide on how the actual connection is performed. These

components are not part of heat pump package or delivery.

Sample connection scheme and application example

Important: For proper operations, there must be a water flow through the heat pump

exchanger in range of 4-6 m

3

/hour. In the case of water flow exceeding 10m3/h the

heat pump will turn itself off and an error notice EE5 will pop up. Repeated error

notice or repeated exposure of the heat pump to the wat er flow higher than 8m

3

/h

will cause irreversible damage to flow switch wit h permanent error notice EE5. The

heat pump will be turned off. Please contact your distributor or service department,

the flow switch needs to be replaced.

Picture: Pressure hose

D50

Error code ‚EE5‘ advising of low / high water

flow or damaged flow switch.

Picture: Hose nut with external thread PN16.

G=6/4” D=50mm

Picture: PVC pipe, various

dimesions

Picture: Sample water connection to the heat pump. Flexible hose glued

onto hose nut adapter with external thred that is tightened into the heat

pump exchanger thread.

Page 15

HP1100/1500COMPACT PREMIUM Installation and user manual

Page 15/28 Version:01 /2018

HEAT PUMP MICROWEL L HP

Scheme: Connecti on of t he compact heat pump into the water filtration circuit of the

swimming pool

Note:

WALL

(fence,

house)

The manufacturer su pplies the heat pump only. The other parts and components shown in the

picture are not included in heat pump package.

HEAT PUMP

Water outlet

Water inlet

Air suction

Exhaust air

By-pass valves

Skimmer

SWIMMING POOL

TECHNOLOGICAL

CHAMBER

Water supply from

water mains

Water discharge

Condensate drain

Filtration tank

Filtration valve

Filtration pump

Bottom outlet

Reversible

nozzle

Chlorine dozing

machine

Page 16

Installation and user manual HP1100/1500 COMPACT PREMIUM

Version: 01 /2018 Page 16/28

HEAT PUMP MICROW ELL HP

4.4 Electrical connection

IMPORTANT: The electric connection of the heat pump can only be

performed by an authorized electrician in accordance with local electrical

standards and requirements.

WARNING: The device operates at dangerous electrical current and

voltage.

DANGER: Danger of electric shock!

a) The heat pump must be connected through a single circuit-breaker specified

in section 3.1

Technical data

for a particular model. The dimensioning o f the power supply must be sufficient

(the suggested cross section of the conductors is 3 x 2,5 mm

2

). It is important to make sure and it

is nonconditionned r equirement of the m anufacturer to instal l the heat pump tog ether with RCD

(Residual Circuit Breaker) with the actuating current up to 30mA. The power supply

characteristics (voltage, phase and fre quency) m ust be in complete compliance with the operat ing

parameters of the device (please refer

to section 3.1 Technical data

).

b) The electri c co nnection must be performed by an authorized electrician and must be in accord anc e

with the valid local electro-technical requirements.

c) The electric installation of the heat pump must be grounded appropriately. The grounding

distributor´s impedance must be in compliance with local valid electro-technical requirements.

d) The electro connection of the heat pum p must be simple, clear and comprehensible. It is highly

advised to have the connection performed in a way that would allow a third party electrician to

understand the connection at no time. Unnecessary cross connections are not appropriate.

e) It is important to carefully check and measure the electric installation before putting it into live

operation.

f)

The suggested protection is stated in the chart below:

Heat pump model

HP 1100

HP 1500

RCD parameters

Current-carrying

capacity

16 A/C 20 A/C

Actuating current

30 mA 30 mA

Circuit breaker characteristic

16 A/C 20 A/C

g)

Block wiring diagram is included

in section 3.6 Block wiring diagram of the PCB board

.

h) In order to protect the unit from weather anomalies it is recommended to install power surge

protection class 1. B+C+D.

Note: Should above points a) to h) be in contrary with local electrical standards or requirements,

please contact your distributor or reseller.

4.5 Multiple heat pump connection

Sometimes it is necessary to install multiple heat pumps into a single swimming pool in order a chieve

requested water temperature. Such installation is particularly advised on public venues where

continuity of operation / service is paramount.

Installation of the multiple heat pumps follows t he same procedure as single heat pump described

above. It is only necessary to install the heat pump s in pa rallel connection. Ser ia l connection w ould

significantly decrease the heating/cooling capacit y and efficiency of heat pumps second in line. It is

advised to insert individual valves into connecting water piping for each single heat pump. This will

Page 17

HP1100/1500COMPACT PREMIUM Installation and user manual

Page 17/28 Version:01 /2018

HEAT PUMP MICROWEL L HP

simplify the particular heat pump by-pass (disconnection) in the case of reinstallation, testing or

service. Please refer to below illustration.

By multiple heat pump connection it is possible have all the heat pumps always on and running

when heating / cooli ng is require d or to have the he at pumps gra dually turning on and off so at

certain conditions (e.g. when requested water temperature is few degrees off the current water

temperature) not a ll the he at pumps w ould run. Gra dual t urning on and off is ac hieved by s etting the

different requested water temperatures on multiple heat pumps. For example:

Heat pump 1 30°C

Heat pump 2 28°C

4.6 Control of the circulation pump

Microwell swimming pool heat pump is able to control the circ ulation pump. In principle should the

heat pump be in need for heating/cooling it will automatically turn the circulation pump on.

In order to enabl e this con trol, the cir culation p ump must b e connecte d to the heat pump electricall y

(please

refer to section 3.6 Block wiring diagram of the PCB board

). Normally the circulation pump is

controlled by a time control of the filtration. It is thus advised to make the parallel connection

through power relay enabling both sources of regulation (by the heat pump and by the time

control).

Please note that both heat pump and the time control must be

powered by the same single phase!

Please be advised that when circulation pump control is enabled and ele ctrically connected with t he

heat pump, it is normal to have a situation when both the heat pump and the time control give

command to circulation pump to operate at the same time. It is thus stric tly forbidden to power

the heat pump and the time control by different phases!

The control is available in three modes:

1. Periodical mode

Heat pump will turn the circulation pump on only when it needs to heat or cool (i.e. requested water

temperature is off the current temperature by at least 2°C).

Periodical mode can be set in manufact uring se ttings n umber 07, figure 0. (please refer

to section

5.7 Setting of the operating parameters

)

Periodical mode is also equipped with sampling, i.e. re gular wate r tem perat ure reading. Pra cticall y

this means that as soon a s the heat pump reaches r equested temperature it turns itself and the

Heat pump number 1

Heat pump number 2

Swimming pool

Filtration

tank

6-way

valve

Circulation

pump

By-pass for

heat pump

Main by-pass

Page 18

Installation and user manual HP1100/1500 COMPACT PREMIUM

Version: 01 /2018 Page 18/28

HEAT PUMP MICROW ELL HP

circulation pump off. In the case the water temperature will not trigger the heat pump in following

60 minutes, the heat pump will a utomatica lly turnt the circulatio n pump on for a 1 minute time in

order to recirculate water from to the pool into the heat exchanger in order to read the actual

current water temperature.

2. Continous mode

In continuous mode w ill the heat pum p have the circ ulation pump turne d on and running all t he

time the heat pump is in operational mode (please

refer to section 5.2 General heat pump control

for explanation of operational mode).

Continous mode achieves better water temperature readings but means higher energy

consumption of the system as the circulation pump is always on.

Continous mode can be set in manufacturing settings number 07, figure 1. (please refer

to section

5.7 Setting of the operating parameters

)

3. microECONOMY+ Mode

microECONOMY+ mode provides optimum water temperature conditioning at lowest cost. Heat

pump will have t he circulation p ump running only i n time when the heat pump ne eds to heat or

cool the water. Once the requested water temperature is achieved the heat pump goes into sleep

for 30 minutes. After these 30 minutes are passed, the heat pump will have the circulation pump

running for about a minute to receive actual accurate water temperature. Should heating or

cooling be required, t he heat pumps starts. Should no action be required, the heat pump goes

into 30 minute sleep ag ain. This 30 min ute per iod can be cance lled by p ressi ng a ny butto n on the

controller.

microECONOMY+ mode can be set in manufacturing settings number 07, figure 2. (please refer

to

section 5.7 Setting of the operating parameters

)

Please note that all heat pump models may not be equipped with microECONOMY+ mode.

4.7 Separate water circuit

In order to save energy it is possible to install the heat pump on a separate water circuit with small

circulation pump. This is appropriate in the case the power consumption of circulation pump for

filtration is considered high or simply if the whole filtration circuit ru nning is not de sired when he ating

/ cooling is required.

Normally swimming pool circulation pumps with water flow performance betwee n 4-6m

3

/h consume

up to 0.5kW of energy.

Such installation must be discussed with your swimming pool supplier, distributor or reseller.

4.8 Circulation pump connection

Manufacturer sugge sts connection of circulation pump through switchi ng relay. Please refer to below

drawing for more information. Direct connection of the circulation pump is not advised.

HEAT PUMP

Circulation pump

Switching phase 230VAC

Relay 230VAC

Circulation pump power supply

Circulation

pump

Page 19

HP1100/1500COMPACT PREMIUM Installation and user manual

Page 19/28 Version:01 /2018

HEAT PUMP MICROWEL L HP

5. REGULATION

5.1 Description of the LCD panel

Cooling symbol

- Heating symbol (lit

contantly)

- Defrosting (blinking)

AUTO mode symbol

General indication

Screen lock

(displayed when

child lock is applied)

Indication of

manufacturing’s

settings

Current water

temperature

Requested water

temperature

Main power on/off

button.

- Mode change (heating,

cooling, auto mode)

- Operational parameters

setttings

Up / down

selection,

water

temperature

settings

Timer (displayed

when timer is

activated with preset

time-out period)

Timer – heat pump

to turn itself on/off

(displayed when

timer is activated)

Checking of technical

parameters

Forced

defrosting

Water pump modes

indicator

Defrosting (blinking)

Page 20

Installation and user manual HP1100/1500 COMPACT PREMIUM

Version: 01 /2018 Page 20/28

HEAT PUMP MICROW ELL HP

5.2 General heat pump control

After the installation, the heat pump is to be controlled by digital display only. Directly after

installation with still no power supply to your heat pump, the digital controller will be blank. This

means a complete shut down of the heat pump.

When heat pump receives required power supply, for a moment the display will show all its

indications.

After few moments the heat pump will go into STAND-BY mode. This means that the heat pump is off

but it is connected to the mains at the same time. The display will show the mode of the heat pump

(in below picture a triangle that indicates AUTO mode) and the current water temperature, in below

particular case 30°C.

By pressing the m ain power on/off butto n you ca n turn your heat pump on to OPERATIONAL

mode. The display will show the mode of the heat pump (in below picture a triangle that indicates

AUTO mode), requested or desired water temperature on the left, showing 30°C in below picture, and

current water temperature on the right, showing 30°C.

You are able to set the requested water temperature. By pressing the up and down

buttons the requested water temperature increases or decreases by 1°C. You will see immediate

change of desired temperature on the left. The preset water temperature range is +5°C ~ +40°C.

Note: Some heat pump models require confirmation of requested water temperature if

changed. This is done by pressing the main power on/off button .

By pressing the M butt o n you can chan g e the ope ra tional mode of the hea t p ump. Please refer

to

section 5.3 Heat pump operational modes

of this Installation and user manual.

By pressing the main power on/off butt on you can turn your heat pump off.

Picture: Blank display indicates no power supply and

complete shutdown of the heat pump.

Picture: Display showing all its indication for a moment only when

the heat pump receives power supply.

Picture: Stand-by mode.

Picture: Operational mode.

Page 21

HP1100/1500COMPACT PREMIUM Installation and user manual

Page 21/28 Version:01 /2018

HEAT PUMP MICROWEL L HP

5.3 Heat pump operational modes

Auto mode

- display shows a triangle symbol and a description ‘AUTO’. Heat pump automatically keeps the

requested water temperature. This means that heat pump automatically heats or cools when the

difference between water temperature and the requested water temperature is 2 degrees of Celsius.

The temperature difference of 2 degrees o f Celsius is called Hysteresis. It is possible to change this

settings (please

see section 5.7 Setting of the operating parameters

, point 10).

Heating

- display shows a sun symbol. Heat pump only heats the water. This means that the heat

pump turns itself off after a requested water temperature is reached. Heat pump turns itself on again

when the water temperature decreases by 2 degrees of Celsius below the requested water

temperature. The temperature difference of 2 degrees of Celsius is called Hystere sis. It is possible to

change this settings (please

see section 5.7 Setting of the operating parameters

, point 10).

Cooling

- display shows a snow flake symbol. Heat pump turns itself off after a requested water

temperature is reached. Heat pump turns itself on again when the water temperature increases by 2

degrees of Celsius below the requested water temperature. The temperature difference of 2 degrees

of Celsius is called Hysteresis. It is poss ible to change this settings (plea se

see section 5.7 Sett ing of

the operating parameters

, point 10).

Recommendation: Manufacturer recommends heat

pump regulation by AUTO-MODE.

Warning:

5.4 Timer

Manufacturer does not recommend changing of

hysteresis settings. It may be changed by an experienced user only.

It is possible to have your heat pump turned on and/or off automatically by timer function.

Automatic turning on

You can use this f un cti o n w hen you w ould li ke yo ur he a t p ump t ur ned o n afte r some time period. You

set the ‘Timer on’ function in STAND-BY mode (heat pump off and connected to the mains) by

pressing the ‘Clock’ button .

By pressing the buttons, you can set the number of hours after which the heat pump will

automatically turn itself on. The time setting range is 1-24 hours.

To confirm the settings, please no action for few seconds. You will see preset desired number of

hours, clock icon and icon ‘ON’ as shown on below picture.

Picture: Timer set on. Heat pump to

start in 6 hours.

Picture: Timer set on. Heat pump to

turn off in 6 hours.

Page 22

Installation and user manual HP1100/1500 COMPACT PREMIUM

Version: 01 /2018 Page 22/28

HEAT PUMP MICROW ELL HP

Automatic turning off

You can use this functi on when you would like your heat pump turned off after some t ime p eriod. You

set the ‘Timer on’ function in operating mo de (heat pump on) by pressing the ‘Clock’ button .

By pressing the buttons, you can set the number of hours after which the heat pump will

automatically turn itself off. The time setting range is 1-24 hours.

To confirm the settings, please no action for few seconds. You will see preset desired number of

hours, clock icon and icon ‘OFF’ as shown on above picture.

To cancel the timer, press the clock button again and you leave timer settings mode.

5.5 Child lock

Your heat pump controller allows you to lock its settings in order to protect them from undesired

changes. This is mainly used in the case of a risk that children would unintentionally change the

settings of the heat pump.

By pressing and holding both buttons for 5 seconds at t he same time, the child lock gets

activated. In order to disactivate the child lock, please repress and hold the buttons again for 5

seconds.

5.6 Parameters check

During heat pump operations (heating or coo ling) you can read severa l basic technical paramet ers.

This is mainly useful for a service technician.

Following parameters can be checked:

14 – Input water temperature (T2)

(-9°C + 99°C)

15 – Ambient air temperature (T3)

(-9°C + 99°C)

16 – Temperature on the compressor discharge (T4)

(0°C + 159°C / values above 100°C showed

as Axx, e.g. 105°C showed as ‘A05’)

17 – Evaporator temperature (T1)

(-9°C + 99°C)

18 – Output water temperature (T5)

(-9°C + 99°C)

In order to enter the Parameters check reading please press and hold the clock button for 3

seconds during the heat pump’s operational mode. The parameters will be displayed starting with

Picture: Parameters check, input

water temperature 30°C.

Picture: Child lock activated. A lock icon is

showed on the left.

Page 23

HP1100/1500COMPACT PREMIUM Installation and user manual

Page 23/28 Version:01 /2018

HEAT PUMP MICROWEL L HP

parameter ‘14’ (showing at position of requested water temperature – on the left) with particular

measured value, e.g. ‘30’ (showing at position of current water temperature – on the right). For

example 14 30 would mea n that the water tempera ture on the input to the heat pump (swimming

pool output) is 30°C.

Then repress the „clock“ button to display the parameters in sequence (parameters from 14 to 18).

Note: 10 seconds a fter the la st pressing of the button, the display switches o ver to the display of the

operational mode.

5.7 Setting of the operating parameters

It is possible to change pre set technical parameters of your heat pump. Plea se be advised that the

manufacturer has fine -tuned the technical parameters in order to achieve the best possible operations

and efficiency. Thus a change in these settings is not advised.

Should there be a need to change ma nufa ctur i ng se tt ings pl ea se discuss the ma tte r w it h your sel ler or

distributor alternatively with the manufacturer. Change in preset settings may lead into heat pump

undesired performance issues, inefficiency, malfunction, failure or damage. Change can only be

performed by trained technician.

Your heat pump enables settings of 11 operational parameters. Please note that only trained

technician is allowed to perform change in manufacturing preset settings.

In STAND-BY mode (heat pump off) press and hold the „M“ button for 3 seconds. The

parameters will be displayed starting with param eter ‘00’ (showing at position of requested

water temperature – on the left) with particular preset set ting, e.g. ‘ 0’ (showi ng a t position o f

current water temperature – on the right).

Then repress the „M“ button to display the parameters in sequence (parameters from 00 to

11, see the chart below).

The requested value is adjusted by pressing the

and buttons on the particular

parameter.

By keeping the „M“ button pressed for 3 seconds in the operating mode, you can

enter the reading of preset technical parameters, however you cannot change

them. For more information please

see section 5.6 Parameters check

.

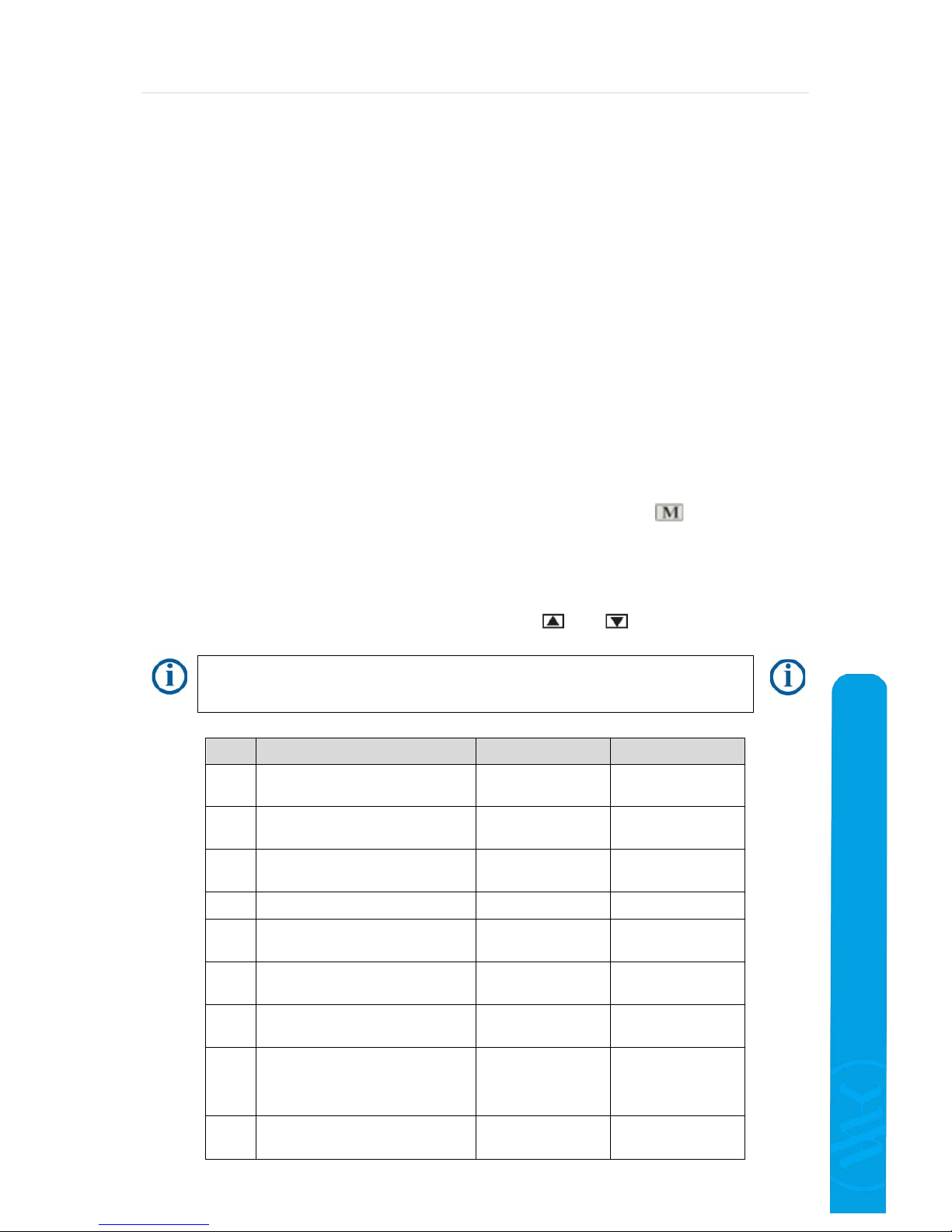

Figure Meaning Range Manufacturing setting

00 Setting of the requested max. water

temperature

0/1~45/60°C

0

01 Temperature setting for the beginning

of the defrosting

-20°~10°C

-7°C

02 Temperature setting for the end of the

defrosting

5°~45°C

13°C

03 Setting of the defrosting time period

30 ~150 min.

45 min.

04 Setting of the forced defrosting time

period

1 ~15 min.

3 min.

05 Setting of the compressor´s

protection temperature

70 ~110°C

95°C

06 Temperature for 4-way valve

activation

0 ~60°C

7°C

07 Working mode of the circulation pump

(0 = Periodical / 1 = Continouos / 2 =

microECONOMY+)

0 ~2

2*

08 Restart after power cut

0 ~1

(0-no, 1-yes)

1

Page 24

Installation and user manual HP1100/1500 COMPACT PREMIUM

Version: 01 /2018 Page 24/28

HEAT PUMP MICROW ELL HP

Figure Meaning Range Manufacturing setting

09 Type (0-only heating, 1-

heating+cooling, 2heating+cooling+two exchangers)

0 ~3

1

10 Hysteresis - difference between the

current and requested water

temperature for the regulation startup

1 ~10°C

2°C

11 Sensor T2 correction -10…+10

0

12 Water temperature outlet limit (0 = -

5°C / 1 = +5°C)

0-1

1**

13 Sensor T5 correction -10…+10

0

* - only available at certain heat pump models. If not available then mode 0 is preset.

** - do not set this setting to “0” unless only a non-freezing liquid instead of water

is circul ated through the heat pump!

Note: The manufacturing settings may differ from the data in the chart.

Note:

6. ACCESSORIES

10 seconds after the last pressing of the button, the display switches over to the standard

display of the requested water temperature/current water temperature (while running), or the

current water temperature in STAND-BY mode.

6.1 Winter module

Winter module has been designed for effective operations of the heat pump at subzero ambient air

temperatures. It heats the lower part of the compressor (oil tank) resulting in higher oil viscosity

which subsequently easies the compressor operations. Winte r module is automatically activated when

the compressor is off and ambient air temperature is below -5°C. After t he heat pump is turne d on,

i.e. after compressor is turned on, winter mod ule turns itself automati cally off. U ser is not required to

perform any action towards heat pump regulation. System works fully automatically. Power

consumption is 45W. In the case the heat pump will not be used in winter time, along with

winterizing, it is suggested to turn the heat p ump’s circuit breaker off in order to avoid unnecessary

energy consumption. Winter module is on demand and is not supplied with each heat pump by

standard.

6.2 Heat exchanger frost protection

Frost protection for heat exchanger ensures protection of the water heat exchanger against rapid

ambient air temperature variation under the subzero temperatures. It is a heating spiral which is

attached onto the heat exchanger body. Heat exchanger frost protection can generally protect the

heat exchanger; however it is not advised to expose the heat exchanger to extremely low

temperatures (e.g. -15°C) for long term with water filtration turned off.

Please be advised that local ambient air temperature around your condensing unit may be lower than

the one measured for example at the external wall of your house. This may be caused by various

factors (for example wind). Please be advised that connection water piping outside of the water heat

exchanger is not protected by the heat exchanger frost protect ion. Heat exchanger frost protection is

automatically regulated. It turns itself on if the ambient air temperature decreases below 2°C. Power

consumption is 64W. In the case the heat pump will not be used in winter time, along with

winterizing, it is suggested to turn the heat pump’s circuit breaker off in order to avoid unecessary

energy consumption. Heat exchanger frost protection is on demand and is not supplied with eac h he at

pump by standard.

Notice: Manufacturer reserves the right to change parametres or controller functions without notice.

Page 25

HP1100/1500COMPACT PREMIUM Installation and user manual

Page 25/28 Version:01 /2018

HEAT PUMP MICROWEL L HP

6.3 Condensate tray defrost

Condensate tray defrost ensures protection of the tra y against frost. This is created in the case the

heat pump works in subzero ambient air temperatures. When heat pump defreezes itself, water drops

are flowing from the evaporator fins into the conden sate tray. In the case, the tray is not equipped

with active defrost , gathered water continuously transforms into ice. In the case the ice reaches the

evaporator, it can cause its damage. Condensate tray defrost is a heating spiral which is attached onto

the tray.

Please be advised that local ambient air temperature around your condensing unit may be lower than

the one measured for example at the external wall of your house. This may be caused by various

factors (for example wind). Please be advised that connection water piping outside of the water heat

exchanger is not protected by the heat exchanger frost protection. Heat exchanger frost protection is

automatically regulated. It turns itself on if the ambient air temperature decreases below 2°C. Power

consumption is 64W. In the case the heat pump will not be used in winter time, along with

winterizing, it is suggested to turn the heat pump’s circuit breaker off in order to avoid unecessary

energy consumption. Co ndensate tray frost protection is on demand and is not supplied with each

heat pump by standard.

6.4 Protection cover

Protection cover /braced up PVC/ is designed for heat pump coverage for a period when the heat

pump is not in operations (it is winterized or water is removed from heat exchanger and the electricity

is disconnected). Prot ection cove r should be p ut onto the hea t pump from abo ve and shoul d be fixed

with a string at the bottom against wind. It is strictly forbidden to turn the heat pump on and operate

it with the protection cover on. This situation would caus e insufficie nt amou nt of air (e nergy) for hea t

pumps operations w hich would lead to almost none performance both by heati ng and cooling. This

situation would almost immediately lead to heat pump overheating which could cause a malfunction,

damage or a complete failure of the heat pump. Warranty does not cover any heat pump damage or

other damage caused by heat pump operations with the protection cover on.

7. HINTS AND TIPS

7.1 Water condensation

It is normal to have water dropping or leaking from the evaporator during heat pump operations,

particularly during heating. During heating, the evapo rator is normally cold. It can easily reach dew

point conditions. Dew point means that at given air temp erature and relative humidity any surface

that is of below dew point temperature condensates the water from surrounding air.

Condensation can result even in liters of water being leaked out of the heat pump. If you suspect a

leak on water circuit, as a first step it is advise d to check if it is condensation. The condesated water

flows over the evaporator lamellas into the casing base. Then flows out through a plastic fitting

designed for connection to the ¾“ PVC tube by which the conde nsate can b e taken to a n appropriate

drain.

1. Turn off the device and leave only the swimming pool pump (circulati on pump ) in operation.

If the water stops to flow out, then it is condensing water.

2. Test, whether there is any chlorine or salt found in the outflowing water (if chlorine or salt are

used). If there is no chlorine or salt, then it is a condensate.

Page 26

Installation and user manual HP1100/1500 COMPACT PREMIUM

Version: 01 /2018 Page 26/28

HEAT PUMP MICROW ELL HP

7.2 Defrosting

As described

in section 3.5 Security and control systems

, your heat pump is equipped with active

defrost protection. Defrost protection has following modes:

1. Normal d efrosting – de frosting gets activated in the case heat pump measures low

temperature of the evaporator (sensor T1) (-7°C). It is possible to change this

setting. Manufacturer has preset the settings for optimal heat pump operations.

2. Cyclical defrosting – this mode gets activated if evaporator temperature sensor

fails (T1). In this situation your heat pump does not have a measured input if

defrosting should be activated or not. Thus in orde r to protect the heat pump it wil l

automatically defreeze itself in 45min intervals.

3. Forced defrosting – this mode can only be activated manually by pressing and

holding button for 5 seconds.

Heat pump signalizes defrosting by blinking the ‘sun’ icon of he ating or .

7.3 Winterizing

Your heat pump continuo usly contains water in its water hea t exchanger. This water will freez e up

and damage irreversibly the heat exchanger if exposed to sub-zero air temperatures, normally during

winter time. It is then necessary to prepare the heat pump for sub-zero air temperatures (e.g. winter

time). Generally, the water from inside the water heat exchanger must be removed. Winterizing is

done on heat pumps which do not ope rate all yea r round. In th e case you operate your heat pump all

year round and/or also in winter months when ambient air temperature decreases below 0°C it is

necessary to ensure continuous water circulation through the water heat exchanger with water of

temperature at least 20°C. In the case this is not done, water inside the water heat exchanger may

cool down and subseque ntly freeze up which cause s destructive damage to heat exchanger and the

heat pump will no longer be operational. Warranty excludes such damage.

Winterizing:

1. Disconnect the heat pump from the mains (e.g. by turning the circuit breaker off).

2. Close the bypass valves number 2 and 3 (Please refer

to section 4.2 Connection to water

filtration circuit

).

3. Make sure tha t the h eat p ump is dis connec ted f rom the mains (elec tricity ). Do not

continue if the heat pump still has power supply or shows signs of it.

4. Unscrew t he hose nut s of both wate r inlet and out let in order to allow air to enter t he water

heat exchanger (please refer

to section 4.3 Needed components for connection to water

circuit

). This will actually allow you to drain water from the heat exchanger.

5. Unscrew the front fixation screws (silent blocks).

6. Bent the heat pump a bit to the back in order to remove as much water as possible from the

heat exchanger. Once the heat pump is bent over (from original 90° angle to approximately

80°) and no water leaks out, you have removed the water. To get graphic visualition please

view below drawings and/or video from below QR code .

90°

app.

80°

Video

Page 27

HP1100/1500COMPACT PREMIUM Installation and user manual

Page 27/28 Version:01 /2018

HEAT PUMP MICROWEL L HP

7. After the water leaked out, please repeat the steps in reversed order from point 5 of this

section.

Please make sure that all water is removed from the heat

exchanger before sub-zero air ambient temperatures period

(e.g. winter time). Damage of the heat exchanger resulting

from frost is excluded from warranty.

7.4 Heat pump season start

After winter time you need t o prepa re your hea t p ump for new sea son. In general please refer to this

Installation and user Manual. Heat pump must be connected to the mains, water circuit; it must

comply with positioning requirements.

During the initial start of the heat pump it is possible to have EE5 error. This sign als low, high or none

water flow and results in heat pump turning off. If your water piping is intact, circulation pump

operates in order; the reason for this initial report may be air bubbles in water system. These tend to

gather around the flo wswitch and thus cause incorrect indication of water flow.

In order to remove the water bubbles from the system you need to bleed the water circuit to remove

any outstanding air.

Position 1: Heat pump in

normal position.

Position 2: Heat pump bent

over for water bleeding.

Page 28

Installation and user manual HP1100/1500 COMPACT PREMIUM

Version: 01 /2018 Page 28/28

HEAT PUMP MICROW ELL HP

7.5 Failure reports

Please find below table containing list of failure reports with their explanation and suggested solutio n.

In order to physically locate the se nsor please refer

to section 3.6 Block wiring diagram of the PCB

board

.

Failure

report

(displayed

on diplay)

Operating status of

the heat pump

Description of the failure

report

Sensor

characteristic

Failure report resolution

EE1

Heat pump

decommissioned;

acoustic warning

Water temperature sensor

failure (T2) / interrupted

or short-circuited sensor

5kΩ

Check the sensor, possibly

change the sensor

EE2

Heat pump

decommissioned

Surrounding air

temperature sensor

failure (T3) / interrupted

or short-circuited sensor

5kΩ

Check the sensor, possibly

change the sensor

EE3

Heat pump

decommissioned;

Acoustic warning

Compressor discharge

sensor failure (T4) /

interrupted or shortcircuited sensor

50kΩ

Check the sensor, possibly

change the sensor

EE4

Optical warning

Timed defrosting

Evaporator temperature

sensor failure (T1) /

interrupted or shortcircuited sensor

5kΩ

Check the sensor, possibly

change the sensor

EE5

Heat pump

decommissioned

in app. 1-2

minutes after

turning on;

acoustic warning

None/Weak/High water

flow; No closure of the

flow switch or failure of

the flow switch

Flow switch

Set the water flow to 4-

6m3/h or check the flow

switch

EE6

Heat pump

decommissioned;

acoustic warning

High temperature on

compressor discharge

(T4)

50kΩ

Please refer

to section 7.6

Troubleshooting

EE7

Optical warning

Electric leakage

protection

-

Check the power supply of

the unit, circuit breaker. In

order to remove EE7 optical

warning, power supply needs

to be turned off and on

EE8

Acoustic warning

Failure of the cable

communication of the

controller

-

Check the control cable

between the control board

and the control digital panel

EE9

Heat pump

decommissioned

High/Low pressure switch

protection

In order to remove EE9

optical warning, power

supply needs to be turned off

and on

-09

Heat pump

decommissioned

Temperature sensor(s)

failure

5kΩ

Temperature sensors or their

bus inputs are burnt out.

Sensors and/or possible the

whole regulator with

motherboard must be

replaced.

EE C

Heat pump

decommissioned

Ambient air temperature

lower than -15°C

-

Please check ambient air

temperature of the

Page 29

HP1100/1500COMPACT PREMIUM Installation and user manual

Page 29/28 Version:01 /2018

HEAT PUMP MICROWEL L HP

condensing unit. Should the

temperature be lower than 15°C, the heat pump will not

work due to security reasons.

In such case there is

seemingly nothing wrong with

your heat pump. Should the

air temperature be higher

than -13°C, the sensor must

and/or motherboard must be

replaced.

Page 30

Installation and user manual HP1100/1500 COMPACT PREMIUM

Version: 01 /2018 Page 30/28

HEAT PUMP MICROW ELL HP

7.6 Troubleshooting – save time and money

Problem

Cause

Solution

The unit does not work, the

display is blank.

The heat pump is not connected to

the mains or does not have power

supply or circuit breaker is off.

Check the heat pump’s connection to

the mains and circuit breaker. Check

the power supply connection to terminal

of the heat pump.

The heat pump does not

heat (cools) the water.

Desired water temperature equals

current.

Everything is OK. It is normal that the

heat pump does not operate.

Heat pump does not work for 3

minutes and then it starts.

This is normal. It is time protection for

compressor.

The heat pump is set for cooling

(heating) only.

Set the heat pump to heating (cooling)

or Auto mode.

The heat pump is in stand-by

mode.

Turn the heat pump on.

There is no water flow through the

heat pump (possibly EE5 is

signalled).

Ensure proper water flow of 4-6m3/h

through the heat pump.

Heat pump has technical problem

signalled through failure reports

(EE.).

Please

check section 7.5 Failure

reports.

Heat pump has iced up evaporator

but does not defreeze.

Check value for figure 17 /

Section 5.6

Parameters check

. The figure must be

sub-zero. If it’s below zero your heat

pump should initiate defrosting shortly.

If it’s above zero, then it is likely

displaced. Sensor must be placed

correctly.

EE4 failure report is signalled by digital

control panel. Your heat pump will

automatically defreeze itself in 45min

cycles. You can force your heat pump to

immediate defrosting /