CodeRunner 4

Table of Contents

Section 1 - System Overview

Section 2 - System Installation

Section 3 - Operating Controls

Section 4 - Troubleshooting

Analog & Digital

Central Receiver

Section 5 - Remote Operation

Section 6 - Media Switch

Appendix A - Receiver Interconnections

Appendix B - Frequencies

Appendix C - Modules

Appendix D - Antenna Configurations

Document: 400438-1

Revision J September 2007

Operator’s Guide

PROPRIETARY NOTICE

The information and design contained within this manual was originated by and is the property of

Microwave Radio Communications (MRC). Microwave Radio Communications reserves all

patent proprietary design, manufacturing, reproduction use, and sales rights thereto, and to any

articles disclosed therein, except to the extent rights are expressly granted to others. The

foregoing does not apply to vendor proprietary parts.

To allow for the introduction of design improvements, specifications are subject to change

without notice.

©2007 Microwave Radio Communications

Printed in the U.S.A.

September 2007

Revision Date

A February 2000

B March 2000

C July 2000

D January 2001

E July 2001

F July 2002 ECO 2137

G October 2002 ECO 2195

H October 2002 ECO 2222

J September 2007

Microwave Radio Communications

101 Billerica Avenue – Bldg 6

North Billerica, MA 01862-1256

USA

TEL: 800.490.5700

978.671.5700

FAX: 978.671.5800

Safety Precautions

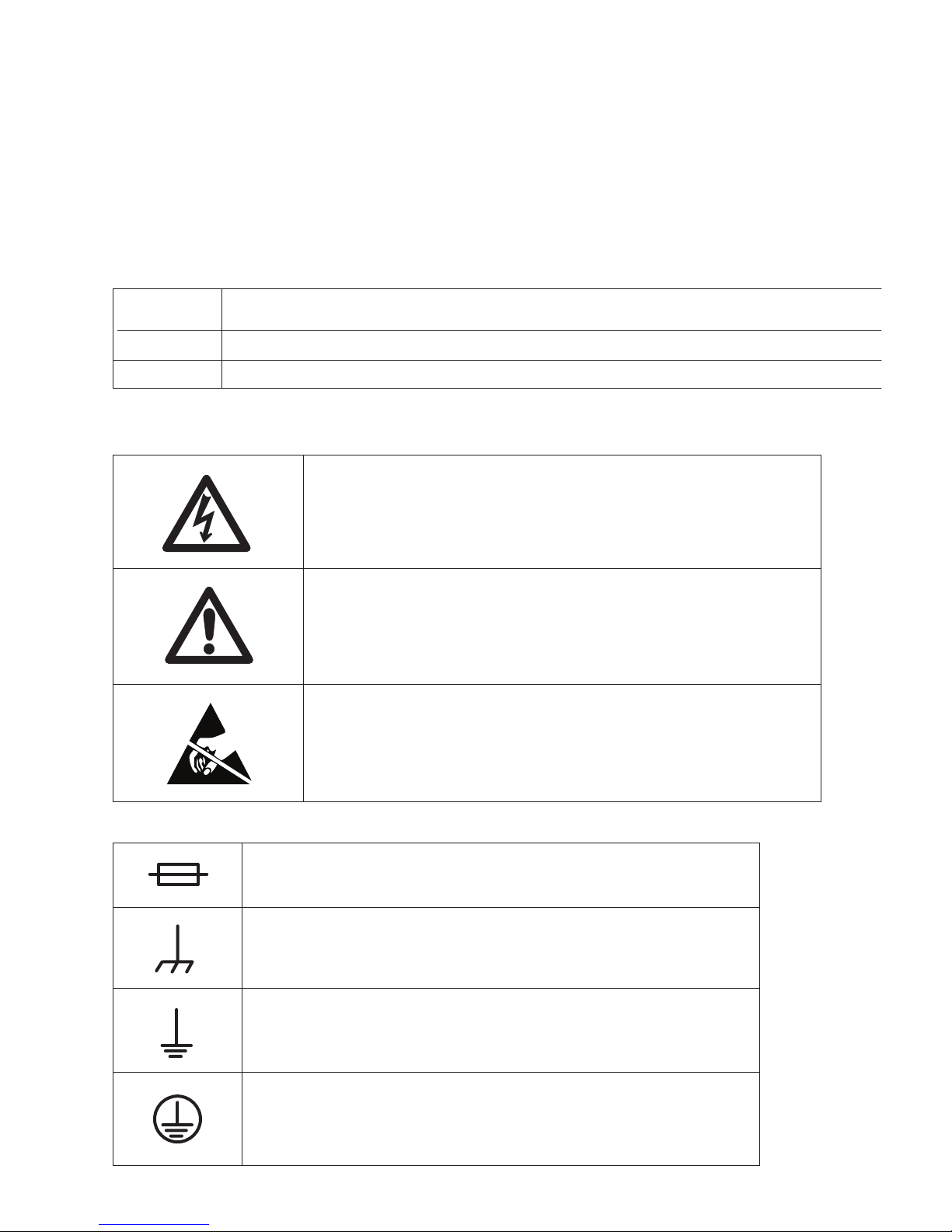

Warnings, Cautions, and Notes

Use the following table to interpret how to distinguish between Warnings, Cautions, and Notes

Warning

Caution

Note

Safety Symbols

The following safety symbols are used in this manual:

Gives information which, if strictly observed, will prevent personal injury or death, damage to personal

property, or the environment.

Gives information which, if strictly followed, will prevent damage to equipment or other goods.

Provides supplementary information.

WARNING:

Risk of Electric Shock

WARNING:

General Warning

Risk of Danger

CAUTION:

Electrostatic Discharge.

.

Possible Damage to Equipment

Nomenclature and Markings

Fuse - Identifies fuse boxes or their locations.

Frame or Chassis Ground - Identifies the frame ground

terminal.

Earth Ground - Identifies the earth ground terminal.

Protective Earth Ground - Identifies any terminal which is

intended for connection to an external conductor for

protection against electric shock in case of a fault, or the

terminal of a protective earth ground electrode.

.

Important Safeguards

Warning:

1. Read all of these instructions.

2. Save these instructions for later use.

3. Follow all warnings and instructions

marked on the units.

Read Instructions - All safety and

operating instructions should be carefully

1

read before operating the equipment.

Retain Instructions - The safety and

operating instructions should be retained

2

and stored in a convenient place for future

reference.

Heed Warnings - All warnings on this

equipment, and in the operating instructions

3

should be strictly adhered to.

Follow Instructions - All operating and user

instructions should be properly

4

implemented for optimum and safe

performance.

Cleaning - Do not use liquid cleaners or

aerosol cleaners. Instead, use only a damp

5

cloth for cleaning.

Attachments - Do not use attachments not

authorized by Microwave Radio

6

Communications. Using unauthorized

attachments may create safety hazards or damage

the equipment.

Water and Moisture - Indoor equipment is

not designed to withstand water or moisture

7

beyond the limits noted in the product

specifications.

Accessories - Do not place equipment on

an unstable cart, stand, tripod, bracket, or

8

table. The product could fall, causing

serious personnel injury or damage the equipment.

Use only equipment recommended by Microwave

Radio Communications. When mounting or installing

the equipment, follow the manufacturer's

instructions.

Grounding or Polarization - AC powered

10

This plug fits into a standard, grounded power outlet.

If you are unable to insert the plug into the outlet,

contact your electrician to replace your obsolete

outlet. Do not defeat the safety purpose of the

grounded plug.

11

equipment items. Pay particular attention to cords at

plugs, convenience receptacles, and at the point

where they enter and exit the equipment.

12

can result in fire or electric shock.

13

following conditions occur:

1. If the power supply cord or plug has been

2. If liquid has been spilled in the equipment, or

3. If the equipment does not operate normally by

When the equipment exhibits a distinct change in

performance indicating the need for service.

14

Unauthorized substitutions could result in fire,

electric shock, or damage to the equipment.

versions of this product are equipped with a

3-wire plug with an integral grounding pin.

Power Cord Protection - Power supply

cords should be routed so that they are not

likely to be walked on or pinched by other

Object or Liquid Entry - Never spill liquids

or insert objects of any kind through

openings in the equipment. Such actions

Damage Requiring Service - Unplug the

radio product from the power outlet and

contact service personnel when the

damaged.

objects have fallen into the equipment.

following the operating instructions and

adjusting only those controls that are covered by

the operating instructions. Improperly adjusting

or tampering with controls not covered in the

operating instructions may result in damage to

the equipment or require extensive work by a

qualified technician to restore the radio to its

normal operation.

Replacement Parts - When replacing

parts is required, use only parts authorized

by Microwave Radio Communications.

Power Sources - The equipment should be

operated only from the type of power source

9

indicated on the unit, or in the operating

instructions. For 220 VAC operation, the proper

power cord must be used.

Safety Check - Upon completing any

15

determine that the equipment is in proper operating

condition.

service or repairs to the equipment, ensure

that safety checks are performed to

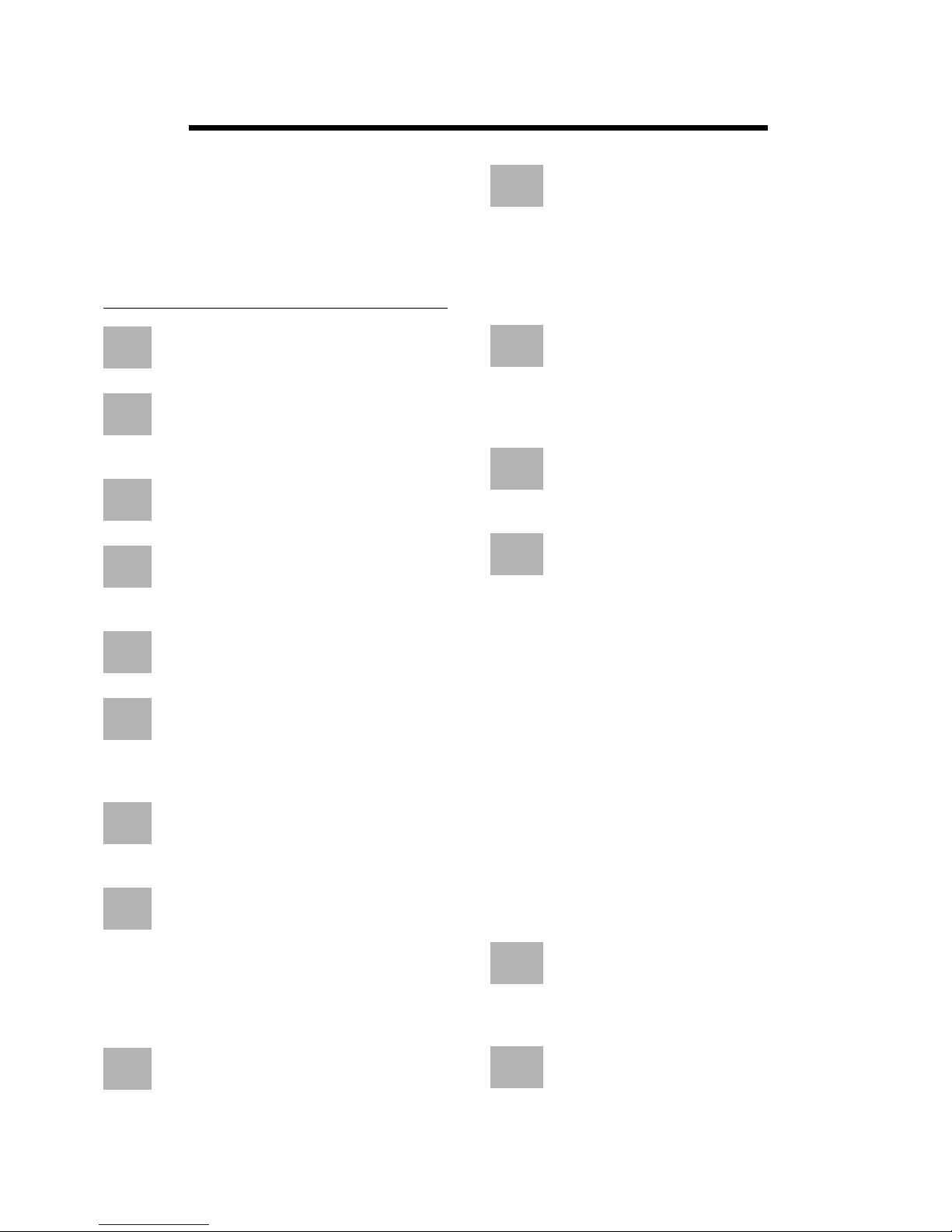

Table of Contents

1 System Overview .............................................................................................................1-1

Figure 1-1 CodeRunner 4 Block Diagram....................................................................... 1-2

Figure 1-2 Front Panel..................................................................................................... 1-3

Figure 1-3 Rear Panel Connections - Typical.................................................................. 1-3

2 System Installation ..........................................................................................................2-1

2.1 Unpacking and Handling ........................................................................................................2-1

2.1.1 Inspection ........................................................................................................................2-1

2.1.2 Damage in Shipment ....................................................................................................... 2-1

2.2 Installation Prerequisites ........................................................................................................2-2

Figure 2-1 Rack Clearances – Top View......................................................................... 2-2

2.2.1 Grounding the Equipment Rack ......................................................................................2-3

2.3 Rack Installation .....................................................................................................................2-4

Figure 2-2 Rack Installation ............................................................................................ 2-4

2.4 Equipment Rack Installation ..................................................................................................2-4

Table 2-1 Equipment Rack Specifications ..................................................................... 2-4

Figure 2-3 Equipment Rack Template............................................................................. 2-5

Figure 2-4 Equipment Rack – Front View ...................................................................... 2-6

2.5 Initial Power-up Procedure .....................................................................................................2-6

3 Operating Controls ..........................................................................................................3-1

3.1 Common Key Functions ......................................................................................................... 3-1

3.2 Receiver Screens ....................................................................................................................3-1

Figure 3-1 Receiver Screens............................................................................................ 3-1

3.2.1 Main Screen .....................................................................................................................3-2

Figure 3-2 Main Screen ................................................................................................... 3-2

3.2.2 Menu Screen .................................................................................................................... 3-3

Figure 3-3 Menu Screen ................................................................................................. 3-3

3.2.3 Remote Control Menu .....................................................................................................3-4

Figure 3-4 Remote Control Menu.................................................................................... 3-4

3.2.4 Configuration Screen .......................................................................................................3-5

Figure 3-5 Configuration Screen ..................................................................................... 3-5

3.2.5 Modify Channel Plan Screen ...........................................................................................3-5

Figure 3-6 Modify Channel Plan Screen ......................................................................... 3-5

3.2.6 RF Tray Screen ................................................................................................................3-6

Figure 3-7 RF Tray Screen .............................................................................................. 3-6

3.2.7 Power Supply Status Screen ............................................................................................ 3-7

Figure 3-8 Power Supply Status Screen .......................................................................... 3-7

3.2.8 Digital Demodulator Screen ............................................................................................3-8

Figure 3-9 Digital Demodulator Screen .......................................................................... 3-8

3.2.9 Video Demodulator Screen ............................................................................................. 3-9

Figure 3-10 Video Demodulator Screen.......................................................................... 3-9

3.2.10 Audio Screen .................................................................................................................3-10

Figure 3-11 Audio Screen.............................................................................................. 3-10

4 Troubleshooting ..............................................................................................................4-1

4.1 Front Panel Indicators .............................................................................................................4-1

CodeRunner 4 Operator’s Guide

400438-1 Rev. J

v

Figure 4-1 Front Panel LEDs........................................................................................... 4-1

4.2 System Alarms ........................................................................................................................4-2

Figure 4-2 Main Screen .................................................................................................. 4-2

Table 4-1 System Alarms ................................................................................................ 4-2

4.3 Replacing the Fuse .................................................................................................................4-3

Figure 4-3 CodeRunner 4 Rear Panel - Typical ............................................................. 4-3

5 Remote Operation ...........................................................................................................5-1

5.1 Local and Remote Operation ..................................................................................................5-1

5.2 Command Inputs to the Remote Connector ...........................................................................5-2

Table 5-1 Remote Interface Connections ........................................................................ 5-2

5.2.1 Control Functions ............................................................................................................5-3

Table 5-2 RF Channel Selection...................................................................................... 5-3

Table 5-3 Offset Selection, – Active High ...................................................................... 5-3

Table 5-4 Band Select – Active High .............................................................................. 5-3

Table 5-5 IF Bandwidth Select – Active High ................................................................ 5-3

Table 5-6 Squelch Control – Active High ....................................................................... 5-4

Table 5-7 Digital Mode Select/Active High.................................................................... 5-4

Table 5-8 Digital Mode Select/Active High.................................................................... 5-4

5.2.2 Vdc Bias Supply ..............................................................................................................5-4

5.2.2.1 Ground .....................................................................................................................5-4

5.2.3 Status Outputs – Remote Connector J7 ...........................................................................5-4

5.2.3.1 Receiver Signal Strength Indication - Analog .........................................................5-4

5.2.3.2 Remote Mode Status ................................................................................................ 5-4

5.2.3.3 Squelch Alarm ..........................................................................................................5-4

6 Media Switch ....................................................................................................................6-1

6.1 Overview ................................................................................................................................6-1

Figure 6-1 Media Switch Block Diagram........................................................................ 6-1

6.2 Mounting the Media Switch ...................................................................................................6-2

Figure 6-2 Media Switch on CR4 Rear Panel ................................................................. 6-2

6.3 Media Switch Connections .....................................................................................................6-2

Figure 6-3 Media Switch Connections ............................................................................ 6-2

6.4 System Interconnection ..........................................................................................................6-3

Figure 6-4 System Interconnection.................................................................................. 6-3

6.5 Harness Assemblies ................................................................................................................6-4

Figure 6-5 Power & IF Control Harness (907008).......................................................... 6-4

Figure 6-6 Audio Harness (906978) ................................................................................ 6-4

A Receiver Interconnections ............................................................................................A-1

A.1 Cabinet Connections .............................................................................................................. A-1

Figure A-1 CodeRunner Rear Panel Connectors - Typical ............................................ A-1

A.2 Remote Interface Connector ..................................................................................................A-2

Table A-1 Remote Interface Connections (J7) ............................................................... A-2

Table A-2 Serial Port (J8)............................................................................................... A-3

Table A-3 Summary Alarm (J3) ..................................................................................... A-3

Table A-4 Rx Status (J13) .............................................................................................. A-3

vi

CodeRunner 4 Operator’s Guide

400438-1 Rev. J

Figure A-2 Receiver Interconnection Diagram - RF Shelf............................................. A-4

Figure A-3 Receiver Interconnection Diagram - Backplane .......................................... A-5

B Frequencies ....................................................................................................................B-1

B.1 Channel Frequencies ............................................................................................................. B-1

Table B-1 2 GHz Channel Guide (17 MHz Channel Plan) ............................................ B-1

Table B-2 2 GHz Channel Guide (12 MHz BAS Channel Plan) ................................... B-2

Table B-3 7 GHz Channel Guide.................................................................................... B-2

Table B-4 13 GHz Channel Selection Guide.................................................................. B-3

C Modules .........................................................................................................................C-1

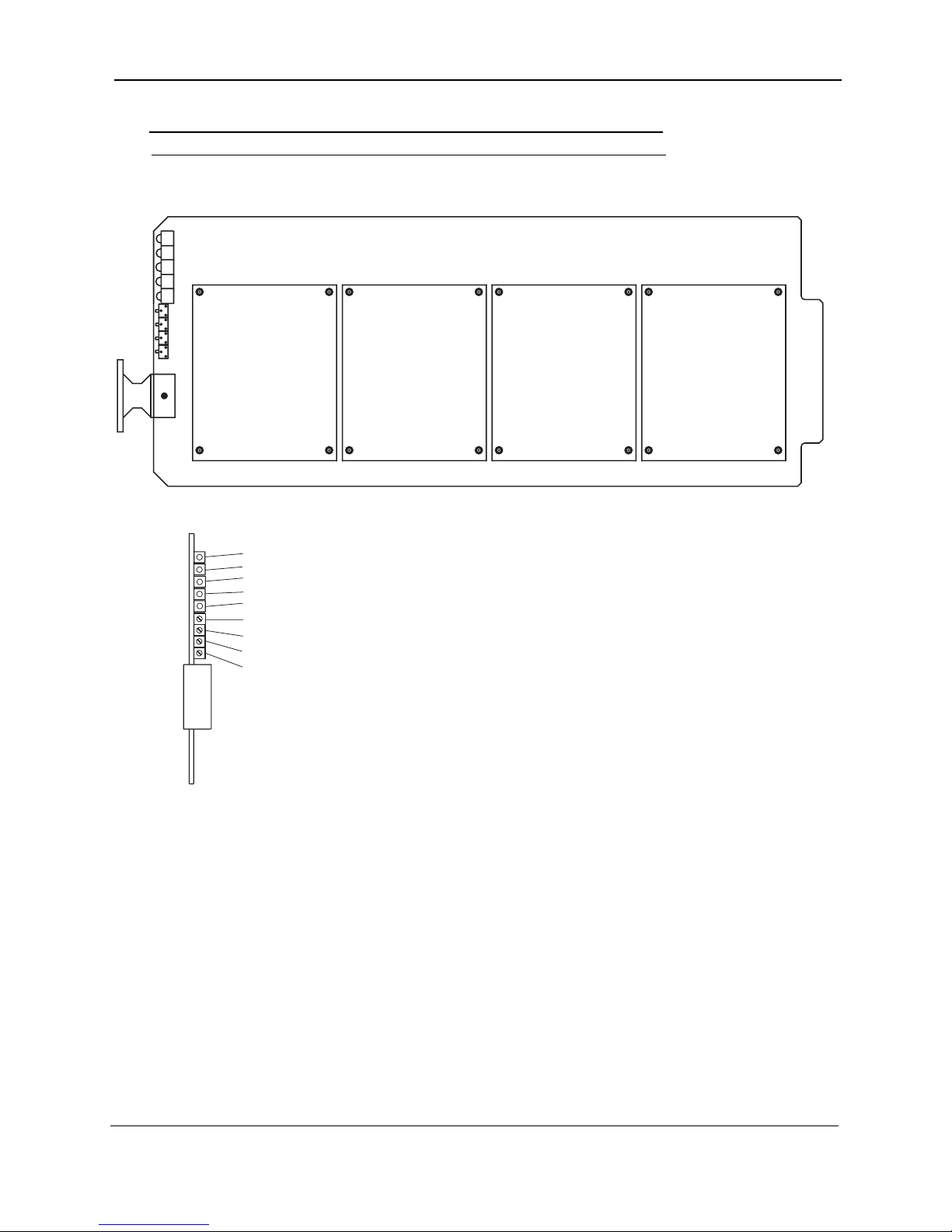

Figure C-1 Receiver Components - Top View ............................................................... C-1

C.1 Rx Video Demodulator .......................................................................................................... C-2

Figure C-2 Rx Video Demodulator Adjustments .......................................................... C-2

C.2 Audio SubCarrier Motherboard ............................................................................................. C-3

Figure C-3 Audio Subcarrier Motherboard ................................................................... C-3

D Antenna Configurations ................................................................................................D-1

D.1 Overview ............................................................................................................................... D-1

Figure D-1 Central Receive - Analog/Digital ................................................................ D-1

Figure D-2 Central Receive with Analog/Digital Media Switch.................................... D-2

CodeRunner 4 Operator’s Guide

400438-1 Rev. J

vii

This page intentionally left blank.

viii

CodeRunner 4 Operator’s Guide

400438-1 Rev. J

Preface

Purpose

This manual explains how to install, operate, and configure the MRC CodeRunner 4 Central Receiver.

Audience

This manual is intended for qualified installers and service technicians who need to perform the

following tasks:

• Install the receiver in a standard rack mount.

• Power up and configure the system for either analog or digital system configurations.

• Troubleshoot common system problems.

For commonly used abbreviations and acronyms, see the Glossary on page x.

Related Documents

• MAC-1000 Master Antenna Controller

• ASC-140 Slave Antenna Controller

• MRC 2000 Antenna Controller

• ProScan Antenna

• MicroScan Antenna

• UltraScan Antenna

• SectorScan Antenna

• Ellipse CR Antenna

• Sector CR Antenna

• Omnipole Antenna

Customer Service

Customer Service Hours: Monday through Thursday

8 AM to 7 PM, Eastern Time (US)

Friday

8 AM to 5 PM, Eastern Time (US)

Telephone: 800-490-5700 (Press 3)

978-671-5700 (Press 3)

Fax: 978-671-5948

Technical Support

Technical Support Service Hours: Monday through Friday

8 AM to 7 PM

Telephone: 800-490-5700 (Press 4)

978-671-5700 (Press 4)

Fax: 978-671-5948

After regular business hours and on weekends and holidays, you can also reach our expert staff as

follows:

Telephone: 978-671-5929

Your call will be automatically forwarded to the on-call Technical Support Specialist.

CodeRunner 4 Operator’s Guide 400438-1

Rev. J

ix

Preface

When contacting Customer Service or Technical Support, please have the following

information available:

• Model number and serial number of the unit.

• Approximate purchase date.

• Unit identification markings and revision.

• Be prepared to accurately describe the problem.

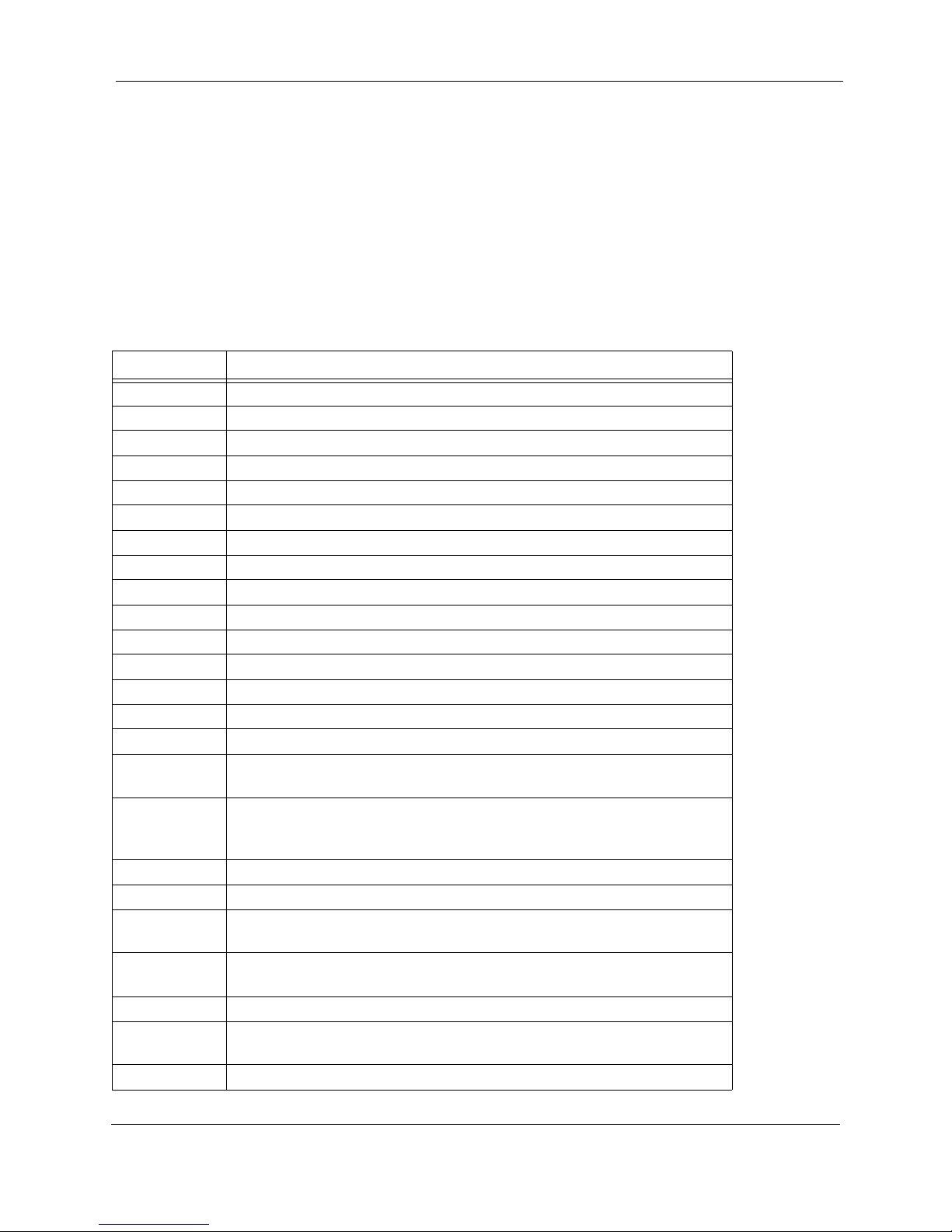

Glossary

This section describes commonly used acronyms and abbreviations used in

telecommunications and those specific to MRC Broadcast Products Group.

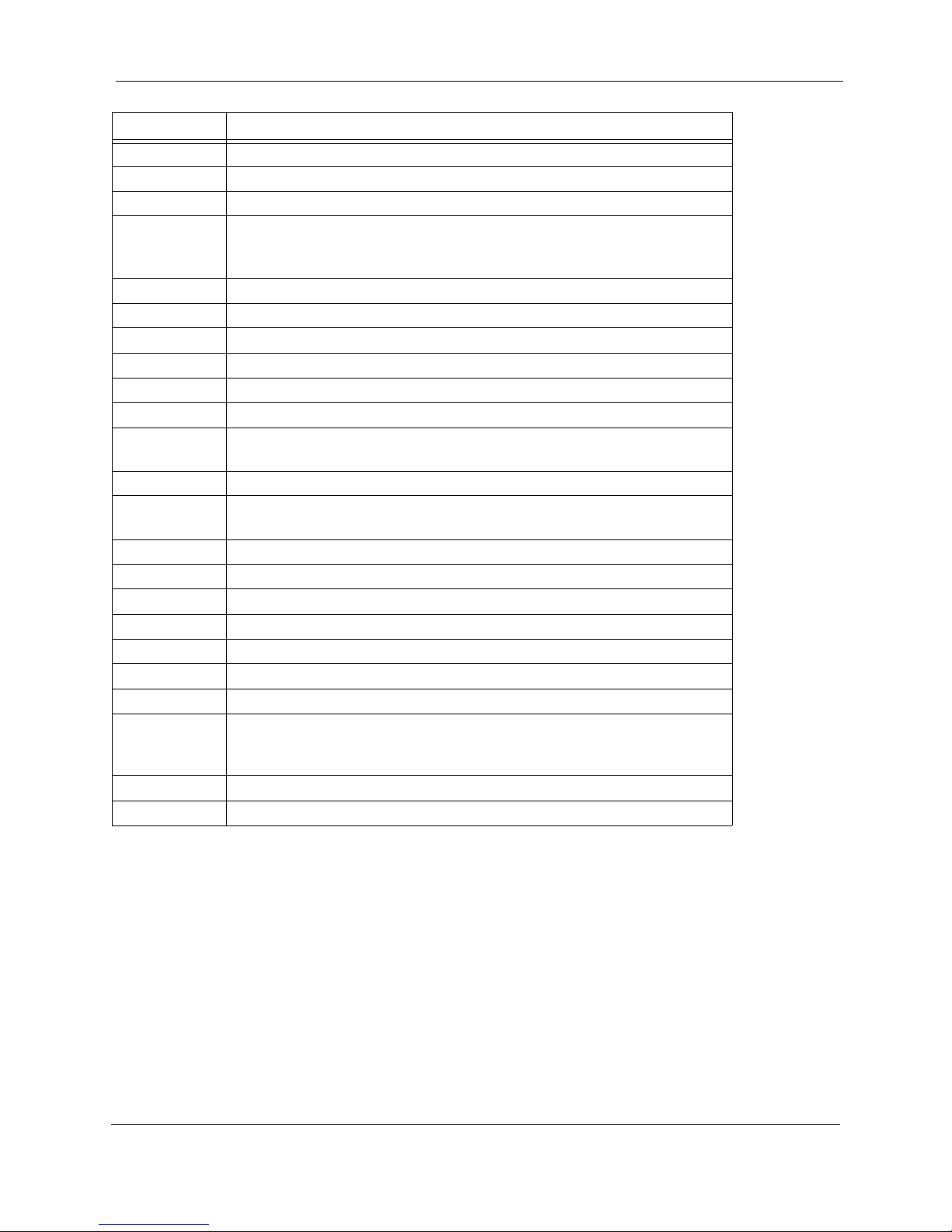

Term Definition

ØLK Phase Lock

3RU 3 Rack Unit height

A & C Alarm and Control

ADPCM Adaptive Differential Pulse Code Modulation

AFC Automatic Frequency Control

AGC Automatic Gain Control

AIS Alarm Indication Signal (all one’s)

AMI Alternate Mark Inversion, line code format for traffic data.

AVG Average

B8ZS Bipolar 8 Zero Substitution, line code format for traffic data.

BB Baseband

BER Bit Error Rate

BNC Bayonet lock coaxial connector

BPF Band Pass Filter

BPS Bits per second

CCITT International Telegraph and Telephone Consultative Committee, a

telecommunications standardizing committee of the ITU.

Composite A band or grouping of frequencies and/or subcarriers, including video,

occupied by the signal in a radio transmission system. Same as

baseband signal.

dB Decibel

dBm A unit of measurement referenced to one milliwatt.

DMUX,

DEMUX

Duplex A channel capable of transmitting information simultaneously in either

E1 2.048 Mbps traffic rate

EIA Electronic Industries Association, an industry association that

EMC Electromagnetic compatibility

Demultiplexer

direction

establishes various standards.

x

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Preface

Term Definition

EOW Engineering Order Wire

ERRS Errors

ESD Electrostatic discharge

FCC Federal Communications Commission, the United State's

communications regulatory agency.

FIFO First in, first out buffer

FIR Finite Impulse Response

FLR MRC's model designation for frequency modulated (FM) remodulating

radio systems from 2 to 15 GHz. FLR2 is the 2 GHz band version;

FLR4, the 4 GHz band version, etc.

FPGA Field Programmable Gate Array

GND Ground

H/W Hardware

HDB3 High Density Bipolar 3 line code format for traffic data

HPF High Pass Filter

I In phase

ID Identification

IF Intermediate Frequency

IRE 1. Institute of Radio Engineers, an international professional radio

engineering association that establishes various standards.

2. A unit of measurement, established by the IRE, in which 1 IRE Unit

=.00714 volts peak-to-peak (Vp-p) and 140 IRE units equals 1 Vp-p.

Kbps Kilobits per second

KHz Kilo (1,000) cycles per second

LCD Liquid Crystal Display

Lcl Local

LED Light emitting diode

LO Local Oscillator

LOS Loss of Signal

LPF Low Pass Filter

Mbps Megabits per second

MHz Million (1,000,000) cycles per second

MRC Microwave Radio Communications

MUX Multiplexer

NRZ Near Return to Zero

PER Parity Error Rate

PLL Phase Lock Loop

Q Quadature phase

QPSK Quadrature Phase Shift Keying

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

xi

Preface

Term Definition

RCL Received Carrier Level

RSL Received Signal Level

Rcvr Receiver

RF Radio Frequency, any frequency of electromagnetic radiation or

alternating currents in the range from 3 kHz to 300 GHz; as in RF

Signal or RF Transmission.

RF Level RF Power from the transmitter

Rx Receiver

S/W Software

SC Service Channel

Setpt Set point

Simplex A channel capable of transmitting information in only one direction.

Site ID A physical location where any number of modems, transmitters, or

receivers are installed.

STDBY Standby

Subcarrier An electromagnetic signal that is used as a medium for placing an

information channel above another information channel.

SYNTH Synthesizer

T1 1.544 Mbps traffic rate

Tx Transmitter

VCO Voltage Controlled Oscillator

VCXO Voltage Controlled Crystal Oscillator

VDC Volts Direct Current

VF Voice Frequency

Video A term pertaining to the bandwidth and spectrum of the signal that

results from television scanning and which is used to reproduce a

picture.

Xmitr Transmitter

Xmtr Transmitter

xii

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Section

1 System Overview

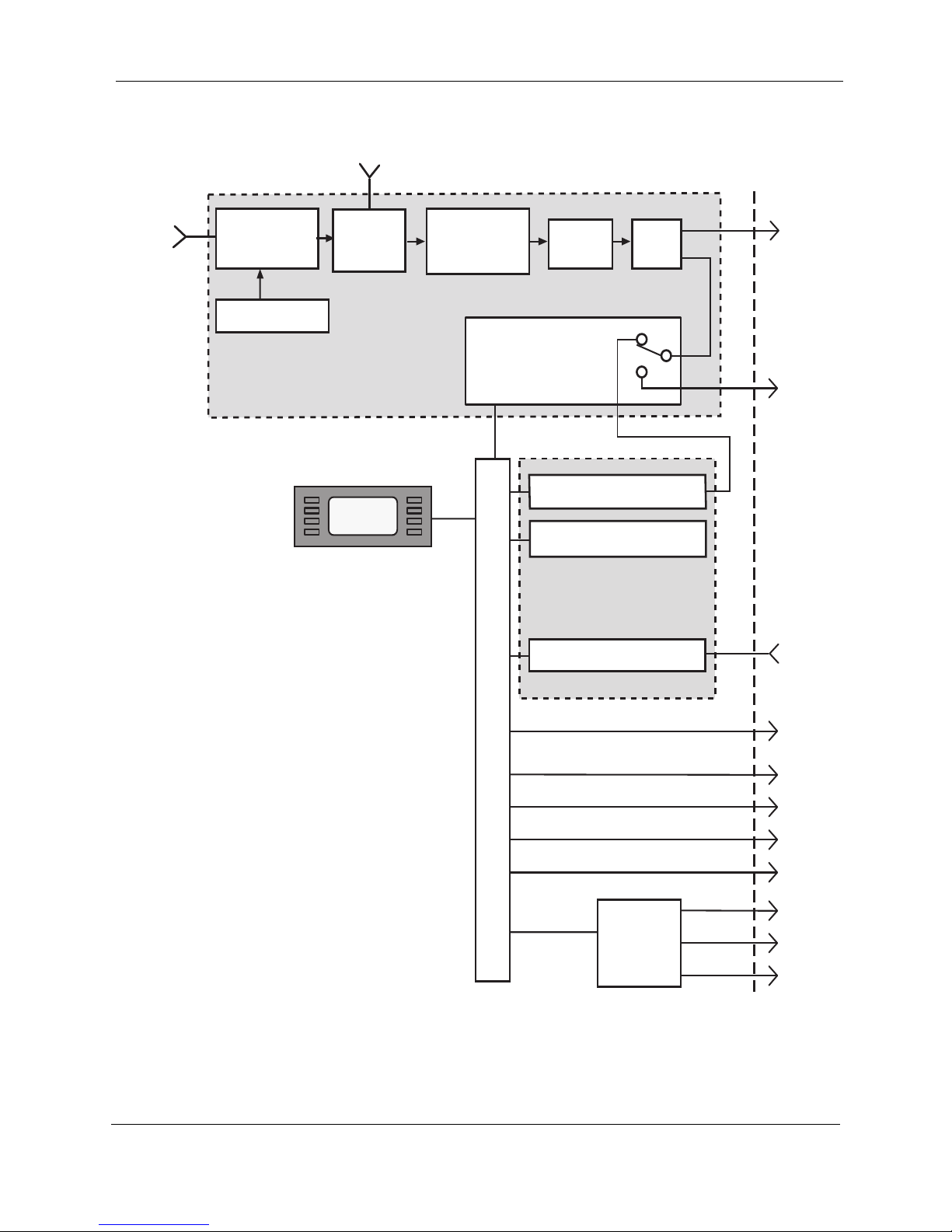

This section provides an overview of the MRC CodeRunner 4 Central Receiver. For a

system block diagram of the receiver, see

The CodeRunner 4 Central Receiver is capable of receiving in both analog or digital mode.

In the analog mode, the receiver outputs an NTSC signal with 4 audio channels, baseband,

and filtered video. In digital mode, the receiver outputs a digital data stream using either an

internal or external modem.

The incoming RF signal is down-converted to 70 MHz, filtered, and amplified. The output

from the IF Amplifier is split into two paths:

• A +5 dBm signal is routed to an analog demodulator, if one is installed.

• A second –10 dBm signal is routed to the power distribution board on the RF shelf.

Here the IF is switched to a direct rear panel connection. The switch is controlled

from the front panel display and keypad.

Power is brought to the receiver via a rear panel receptacle mounted on the plug-in power

supply. The power is routed through the rear panel backplane to the front panel display and

to the power distribution board on the RF tray,

All receiver functions are controlled from the front panel display and keypad. The receiver

can be controlled remotely and switched between analog or digital mode from either the

local or remote location.

The front panel displays common system faults with four LED indicators for power,

squelch, summary alarm, and remote/local status. Summary alarm messages appear as

scrolling text on the front panel LCD, A list of summary alarms and troubleshooting guide

can be found in

Section 4, Troubleshooting on page 4-1.

Figure 1-1 on page 1-2.

1

For remote cabling and interconnections, see Appendix A, Receiver Interconnections.

For more information on the operating controls, see Section 3, Operating Controls on

page 3-1.

The receiver mounts in a standard 3RU rack unit. See Section 2, System Installation on

page 2-1.

CodeRunner 4 Operator’s Guide

400438-1 Rev. J

1-1

System Overview

Figure 1-1 CodeRunner 4 Block Diagram

815 MHz OUT

RF

INPUT

LOW

NOISE

CONVERTER

SYNTHESIZER

RF SHELF

12 dB

COUPLER

LCD

DISPLAY

&

KEYPAD

2ND

DOWN

CONVERTER

DISTRIBUTION

IF

FILTER

POWER

BOARD

VIDEO DEMODULATOR

AUDIO DEMODULATOR

POWER SUPPLY

PLUG-IN MODULES

IF

AMP

EXTERNAL

MODEM

REAR PANEL

IF

OUTPUT

AC

INPUT

1-2

AUDIO

OUTPUT

(4 Chan.)

VIDEO

REAR PANEL BACKPLANE

REMOTE

I/0

BASEBAND

SUMMARY

ALARM

Rx STATUS

SERIAL

PORT

REMOTE

INTERFACE

PGM I/O

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Figure 1-2 Front Panel

System Overview

MRC CodeRunner 4

Figure 1-3 Rear Panel Connections - Typical

(J1)

(J12)

(J11)

(J15)

(J16)

SUM

ALARM

(J3)

VIDEO BB

(J2)

~AC POWER

120/240; .4A

50/60 HZ

FUSE:

T1A 250 VA C

"CAUTION

DOUBLE-FUSE

NEUTRAL/FUSING"

AUDIO

1

2

3

4

RX STATUS

(J13)

(J9)

PGM I/O

REMOTE

INTERF

SERIAL

PORT

ACE

POWER

REMOTE

SQUELCH

ALARM

DIGCR_FR

815 MHz OUT

RF IN

(J7)

(J8)

IF I/O

EXT MODEMDATA OUT

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

1-3

System Overview

This page intentionally left blank.

1-4

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Section

2 System Installation

This section explains how to install the MRC CodeRunner 4, Digital Central Receiver. The

following topics are covered:

• Unpacking and Handling

• Installation Prerequisites

• Rack Installation

2.1 Unpacking and Handling

Each unit is shipped assembled, wired, and factory tested. Each unit is packaged in

appropriate shipping containers. Care should be taken when removing equipment from the

container to prevent damage to the unit. Check that all parts and accessories are removed

from the container and packing material before they are discarded. Verify that the

equipment items shipped agree with those listed on the sales order.

Note: DO NOT discard the container or any packing material until the

mechanical inspection has been satisfactorily completed. This

material must be available in the event that a damage claim needs to

be filed with the shipping carrier.

2

2.1.1 Inspection

Inspect the equipment for any shipping damage. Check that the equipment is clean and that

no cables or connectors are broken, damaged, or loose.

Note: At the time of inspection, DO NOT make any adjustments to internal

controls or adjustments. The equipment has been factory adjusted for

proper operation prior to shipment.

2.1.2 Damage in Shipment

Should any damage be discovered after unpacking the unit, use the following procedure:

1. Immediately file a claim with the shipping carrier.

2. Forward a copy of the damage report to MRC.

3. Contact Customer Service at which time they will determine the disposition of the

equipment.

For Customer Service information, see the Preface section of this manual.

CodeRunner 4 Operator’s Guide

400438-1 Rev. J

2-1

System Installation

Installation Prerequisites

2.2 Installation Prerequisites

Complying with installation prerequisites prevents problems from arising during

installation or future maintenance of the unit. Use the following guidelines:

1. Where possible, provide easy access to the front and rear of the equipment rack

(Figure 2-1).

- Allow a minimum of 18 inches [45.72 mm] clearance at the rear of the

equipment rack.

- To service and maintain the equipment, allow a minimum of 36 inches of

clearance in front of the equipment rack.

Caution: Reduced Air Flow – Installation of the equipment in a rack should

be such that the amount of air flow required for safe operation of

the equipment is not compromised.

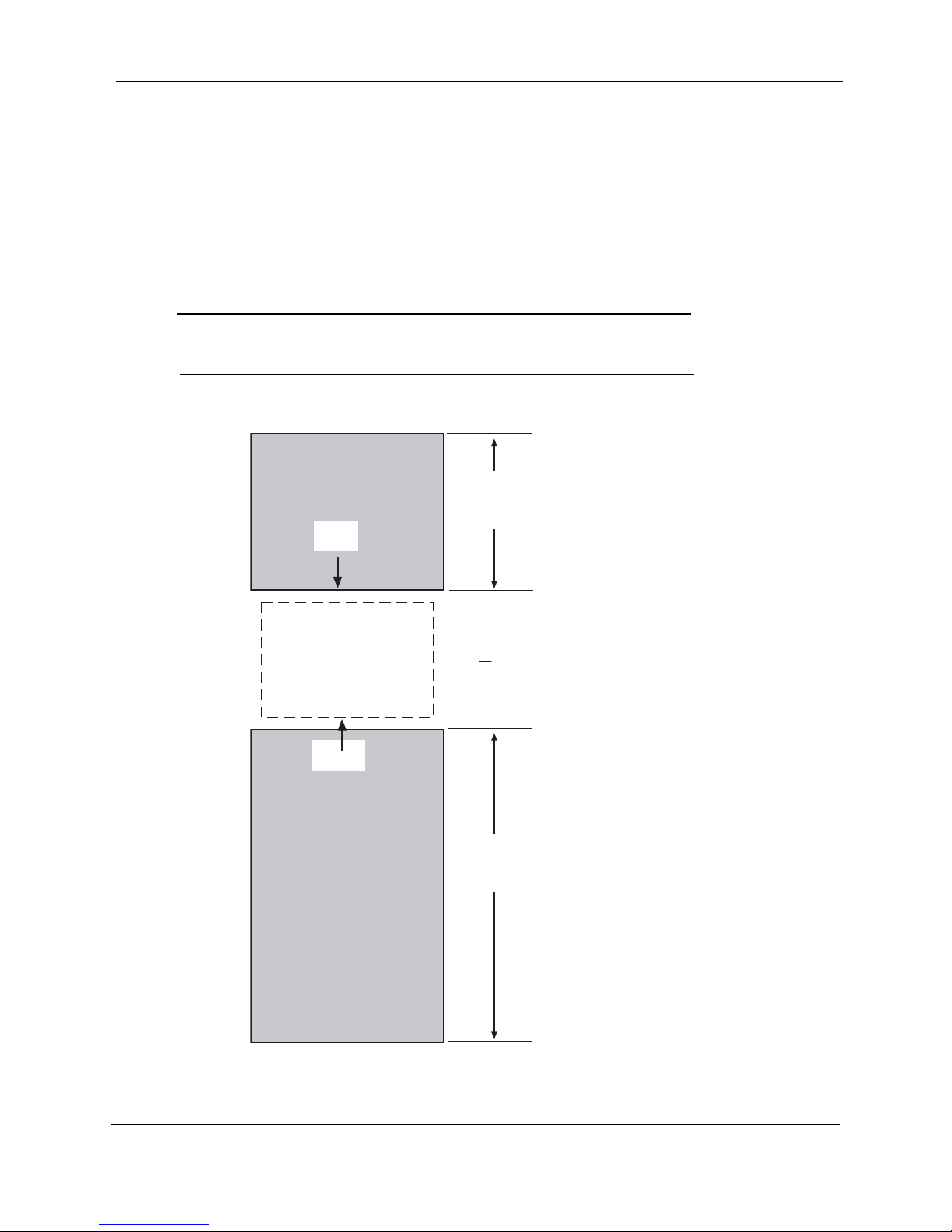

Figure 2-1 Rack Clearances – Top View

18"

[45.72 mm]

CLEARANCE

REAR

CR4 Receiver

FRONT

MOUNTING

RAILS

36"

[89.9 mm]

CLEARANCE

2-2

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Installation Prerequisites

2. Avoid direct heat to the unit. If unavoidable, use deflector plates or install the unit in

a climate controlled environment.

Caution: Elevated operating ambient temperature – If installed in a closed

3. Locate the equipment to allow for an adequate number of AC power outlets for test

equipment and power tools.

Caution: Circuit Overloading – Consideration should be given to the

4. Check that the rack mounting rails are sufficiently rigid to support the rack and

equipment.

Warning: Mechanical Overloading – Mounting of equipment in a rack should

System Installation

or multi-unit rack assembly, the operating ambient temperature of

the rack may be greater than the room ambient temperature.

Therefore, considerations should be given to the Template

Multiple Rack Assembly (TMRA).

connection of the equipment to the supply circuit and the effect

that overloading of circuits could have on over-current protection

and supply wiring. Appropriate consideration of equipment

nameplate ratings should be used when addressing this concern.

be such that a hazardous condition is not achieved due to uneven

loading.

5. Eliminate any conditions that could cause water to drip onto the equipment and

penetrate waveguide or cable openings.

2.2.1 Grounding the Equipment Rack

The equipment rack must be connected to the station ground using a #6 copper wire or

equivalent. The ground wire should be routed in as straight and direct a route as is practical.

Warning: Grounding the equipment rack is mandatory.

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

2-3

System Installation

Rack Installation

2.3 Rack Installation

The MRC CodeRunner 4 mounts within a standard 19 inch equipment rack. The unit

occupies a 3 rack unit (3RU) height. The MRC CodeRunner 4 attaches to the equipment

rack using four 12–24 mounting screws. See

Figure 2-2 for the correct mounting hole

locations.

Figure 2-2 Rack Installation

MRC CodeRunner 4

MOUNTING SCREWS

For detailed information on assembling and installing a standard equipment rack, see

Section 2.4, Equipment Rack Installation on page 2-4.

2.4 Equipment Rack Installation

Step 1 Remove the top and sides of the shipping container and packaging material, free

the rack from the pallet by removing the nuts and bolts securing it in place. Refer

Table 2-1 for equipment rack specifications.

to

Table 2-1 Equipment Rack Specifications

Component Description

Finish Black baked enamel

Uprights Channel 3.0” (76.20 mm) deep x 1.4” (34.825 mm) wide x 0.25” (6.35

mm) thick.

Base Angles 4.0” (100.016 mm) high x 6.5” (162.40 mm) deep x 0.38” (9.50

mm) thick.

To p 1” (25.40 mm) high x 0.38” (9.50 mm) thick.

Step 2 Remove the rack from its crate by lifting it off the mounting bolts and place it near

its final mounting location. After the rack has been raised to a vertical position,

remove the shipping support brackets the rack side rails.

Step 3 A template can be used for marking the floor location drilling holes for anchoring

the hardware (Figure 2-3). However, if the rack is available when these holes are

drilled, it is recommended that the rack base itself be used as a template.

2-4

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Equipment Rack Installation

0

4

Figure 2-3 Equipment Rack Template

[5.34 mm]

Step 4 Hole size is determined by the type of anchor to be used. On concrete floors, use

the following hardware:

- Bolts: 3/8”, 16 x 2.

- Washers: 3/8”, Lock and flat (1 each per bolt).

- Anchors: 3/8” 16 x 2.

- Caulking Anchors:, “Diamond” type 03060,

2.125"

System Installation

1.25"

[3.175 mm]

6.00"

[15.24 mm]

3.00" [7.62 mm]

21.

[53.3

12.00"

[30.48 mm]

20.25"

[51.44 mm]

Note: These anchors require 3/4” holes. On wood floors, use 3/8” x 1 - 1/2”

lag bolts with lock and flat washers.

Step 5 Secure the rack to the adjacent racks and existing superstructure where

applicable. Fasten the rack’s top braces to the superstructure using J-bolts.

Caution: If there is not an existing superstructure, the top of the rack should

be braced to a ceiling or wall.

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

2-5

System Installation

Figure 2-4 Equipment Rack – Front View

MOUNTING

HOLES

Initial Power-up Procedure

84.00"

[2.13M]

2.5 Initial Power-up Procedure

The following procedure provides instructions for initially applying power to the modem.

Before proceeding, verify the following:

Step 1 Is the other end of the communications link operational?

Step 2 Is prime power available and correct?

Step 3 Have all electrical interface connections been made?

Step 4 Are signal sources operational and correct?

2-6

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Section

3 Operating Controls

This section describes the front panel display and function screens.

3.1 Common Key Functions

Common key functions for all screens

• If the screen display dims, press any key to illuminate the screen.

• Press the Menu key to display the Menu Screen

3.2 Receiver Screens

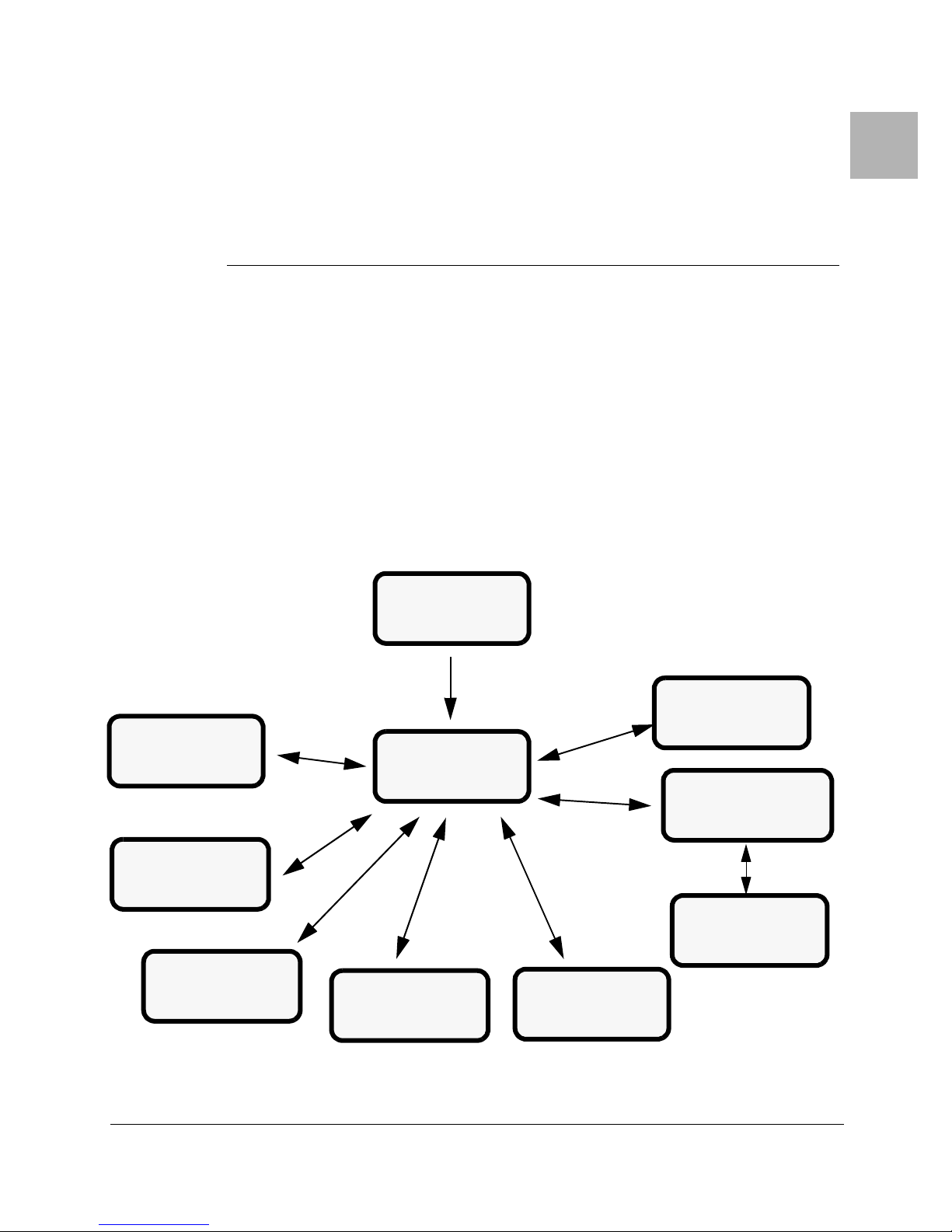

Figure 3-1 shows the navigation scheme for the CodeRunner 4 menu screens. When the

receiver is powered up, the Main Screen is displayed (See Figure 3-2 on page 3-2).

Figure 3-1 Receiver Screens

3

AUDIO

SCREEN

VIDEO

DEMOD

SCREEN

POWER

STATUS

SCREEN

SUPPLY

MAIN SCREEN

MENU SCREEN

DIGITAL

DEMOD

SCREEN

RF TRAY

SCREEN

REMOTE

CONTROL

SCREEN

CONFIGURATION

SCREEN

MODIFY

CHANNEL

PLAN SCREEN

CodeRunner 4 Operator’s Guide

400438-1 Rev. J

3-1

Operating Controls

Receiver Screens

3.2.1 Main Screen

The Main Screen appears when the receiver is powered up. It contains the following display

options:

• Message Bar – display current software as a default. If a system error occurs, the

Message Bar displays diagnostic or error messages. For interpreting diagnostic

messages, see

Section 4, Troubleshooting on page 4-1.

• Displays Receive Frequency and Receive Signal Level (RSL).

• Channel Plan Bandwidth (12 MHz or 17 MHz)

• Local or Remote Control Mode

• IF Bandwidth:

– NRM – Normal

–NRW – Narrow

– WDE – Wide

• Change the following setting from the Main Screen:

– IF Bandwidth

– Band – 2, 7, or 13 GHz

– Channel – 1-10 (2 GHz), 1-14 (7 GHz), or 1-22 (13 GHz)

– Offset: 0, –, + or ++ (++ Offset applicable to 13 GHz band only)

Figure 3-2 Main Screen

Message Bar:

Normal display of Software Release

or Fault Message (See Note)

Frequency

CodeRunner.4 Rel. 2.00

1995.750MHz

RSL-89.2dBm Band:2

BW:NRM LOCAL Offset:–

Menu DIGITAL

To Menu Screen

Bandwidth: “NRM” (Normal)

“NRW” (Narrow)

“WDE” (Wide)

17MHz Chnl:1

“LOCAL” or “REMOTE”

Receive mode: “DIGITAL” or “ANALOG“

Band

POWER

REMOTE

SQUELCH

ALARM

Channel

Channel Offset

Receive Signal Level

Note: When any operating fault is detected, the fault message is displayed

in place of the “Software Release.”

3-2

Channel Plan (12MHz or 17MHz)

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Receiver Screens

3.2.2 Menu Screen

The Menu Screen lets you navigate to all of the following menu screens:

Figure 3-3 Menu Screen

Operating Controls

• Digital Demodulator Screen – Sets demodulator parameters, if installed.

• Power Supply Screen – Reports power supply voltage levels with features to refresh

current voltage levels.

• RF Tray Screen – Set up receiver for frequency, channel, bandwidth, and offset.

• Remote Control Screen – Use to set baud rate for dial-up or direct line from a

remote control site, to enable or disable parallel or serial interfaces, and to turn the

modem on or off.

• Configuration Screen – Adjust screen contrast, select backlight settings, and to

modify the channel plan.

• Video Demodulator Screen – Use to enable/disable the video demodulator in analog

mode, including setting the squelch point.

• Audio Demodulator Screen – Reports if audio is OK or if audio demodulator is not

installed.

“Power Supply” Screen

“Digital Demodulator”

Screen

Dig Demod Remote

Pwr Supply Config

RF Tray Video

Main Screen Audio

“Main Screen” Screen

“RF Tray” Screen

“Configuration” Screen

“Remote Control” Screen

MENU

POWER

REMOTE

SQUELCH

ALARM

“Audio Demodulator” Screen

“Video Demodulator” Screen

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

3-3

Operating Controls

3.2.3 Remote Control Menu

The Remote Control Menu sets options for remotely controlling the CodeRunner 4

Receiver.

Options include:

• Transmit and Receive Baud Rate for serial remote control.

• Enabling or Disabling the Parallel Interface

• Enabling or Disabling the Serial Interface

Figure 3-4 Remote Control Menu

Serial Transmit Baud Rate

(150, 300, 1200, 4800,

9600, 19200)

Serial Receive Baud Rate

(150- 300, 1200, 4800, 9600, 19200)

Remote Control Menu

Receiver Screens

POWER

Baud Baud

Tx 9600 9600 Rx

P Rmt ENABLED

S Rmt DISABLD

Menu

Return to Main Menu

OFF

Serial Port Interface (ENABLED or DISABLD)

Modem

Modem (ON or OFF)

Parallel Port Interface (ENABLED or DISABLD)

REMOTE

SQUELCH

ALARM

3-4

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Receiver Screens

3.2.4 Configuration Screen

The Configuration Menu Screen controls the screen contrast for the Front Display. The

screen also allows access to the Channel Plan Screen.

Figure 3-5 Configuration Screen

Operating Controls

Backlight (ON or Timed)

Configuration Menu

POWER

REMOTE

Return to Main Menu

3.2.5 Modify Channel Plan Screen

The Modify Channel Plan Screen sets the Channel Plan frequency, channel, and offset and

saves the current settings.

Figure 3-6 Modify Channel Plan Screen

Cursor

Contrast

Contrast

Menu

Move Cursor Right

Modify 2GHz

02020.750

Channel

Offset

2

+

Save

Exit

BklightTimed

Mod CP

Select Modify Channel Plan Screen

Increase Screen Contrast

Decrease Screen Contrast

Move Cursor Left

<-

->

+

-

SQUELCH

ALARM

POWER

REMOTE

SQUELCH

ALARM

Exit Channel

Plan Screen

Save Settings

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Decrease Selected Digit

Increase Selected Digit

Select Channel

Select Offset

3-5

Operating Controls

3.2.6 RF Tray Screen

The RF Tray Screen sets the following parameters for operating the receiver:

• Band – 2, 7, and 13 GHz

• Channel Offset: 0, –, +, or ++ (++ Offset applicable to 13 GHz band only)

• IF Bandwidth:

– NRM – Normal

–NRW – Narrow

– WDE – Wide

• Remote Control – Enabled or Disabled

• Local Phase Lock Loop (PLL) – Lock or Unlock

• Second Downconverter – Lock or Unlock

• Receive Signal Level

• Channel Plan (Chplan) - 12 MHz or 17 MHz

Figure 3-7 RF Tray Screen

2nd Downconverter

“LOCK” or “UNLK” states

Receive Signal Level

Receiver Screens

Receive Frequency

1999.0 MHz

RSL –89.3 dBm

2 DN CNV UNLK 1 Channl

LO PLL UNLK 0 Offset

Chplan 17MHz NRM IFBW

Menu 2 BAND

Channel Plan Bandwidth

12 MHz or 17 MHz

Local Oscillator Phase Lock Loop

“LOCK” or “UNLK” states

Channel Select (See Note)

RF TRAY

POWER

REMOTE

SQUELCH

ALARM

Channel Offset

Band (2, 7, or 13 GHz)

IF Bandwidth “NRM, WDE, or NRW”

Note: The number of channels depends on the frequency band selected.

For available channels, see Appendix B, Frequencies.

3-6

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Receiver Screens

3.2.7 Power Supply Status Screen

The Power Supply Status Screen displays voltage levels. In addition, minimum and

maximum values can be reset.

Figure 3-8 Power Supply Status Screen

Operating Controls

Current Reading

Power Supply Status

Curr. Min. Max.

+15V +14.9 +14.9 +15.0

–15V –15.0 –14.9 –15.0

+5V +5.04 +4.95 +5.12

Menu Rst Min/Max

Minimum Reading

Maximum Reading

POWER

REMOTE

SQUELCH

ALARM

Resets Current Readings

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

3-7

Operating Controls

3.2.8 Digital Demodulator Screen

The Digital Demodulator Screen contain the following display and command options:

• Switches between using a digital or analog demodulator. The DIGITAL setting to

active, an internal or external digital demodulator needs to be installed.

• Switches between using an internal and external digital demodulator. For the

INTERNAL setting to activate, an internal digital demodulator needs to be

installed. For the EXTERNAL setting to activate, an external digital demodulator

needs to be installed.

• Reports demodulator status: Fault, Disabled, or OK

Figure 3-9 Digital Demodulator Screen

Status Indicator

(FAULT, DISABLED, or OK)

Digital Demod

DEMOD STATUS: OK

Receiver Screens

POWER

Mode Mode:DIGITAL

Menu Demod:INTRNL

Return to Menu Screen

Note: If the Video Demodulator is not installed, the Analog mode is

disabled.

“DIGITAL” or “ANALOG” modes (See Note)

“INTRNL“ or “EXTRNL” modes

(Internal)

(External)

REMOTE

SQUELCH

ALARM

3-8

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Receiver Screens

3.2.9 Video Demodulator Screen

The Video Demodulator Screen contains the following display and command options:

Figure 3-10 Video Demodulator Screen

Operating Controls

• Receive Signal Level (RSL)

• Receiver Squelch, Digital Mode:

– Digital Mode: DISABLED

• Receiver Squelch Analog Mode:

– TRP PNT BASED – Trip Point Based

– FORCED ON

– FORCED OFF

• Set Squelch Point - Front Panel Squelch LED lights if RSL falls below squelch

point.

If Video Demod is not installed, screen Reads:

“Video Demod Not Installed”

Decrease

Squelch Level

Video Demod

VIDEO: SQUELCHED

Sql Pt -80dBm Sql Pt

Mode ANALOG

Squelch TRP PNT BASED

Menu RSL –98.7 dBm

“ANALOG” or “DIGITAL” mode

Receive Signal Level

“DIGITAL MODE” (Digital Mode)

“ON” or “SQUELCHED” (Analog Mode)

Squelch Trip Point

or

Increase

Squelch Level

“SQUELCH” LED

lights if RSL drops

below Squelch Point

(Analog Mode only)

POWER

REMOTE

SQUELCH

ALARM

Digital Mode: always “SQUELCHED”

Analog Mode: “TRP PNT BASED”

“FORCED ON”

“FORCED OFF”

Note: In analog mode, Squelch states are interpreted as follows:

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

TRP PNT BASED – The video squelches based on the squelch set.

FORCED ON – The video is squelched.

FORCED OFF – The video is always on.

3-9

Operating Controls

3.2.10 Audio Screen

The Audio Screen reports status of the audio demodulator.

• Audio Mode:

– No Audio Installed

– Agile Audio

– Fixed Audio

• Audio Status: OK or FAULT

Figure 3-11 Audio Screen

“NO AUDIO INSTALLED“

“AGILE AUDIO”

“FIXED AUDIO”

(See Note)

FIXED AUDIO

Receiver Screens

POWER

AUDIO: OK

Menu

Note: Screen displays the following:

“NO AUDIO INSTALLED” – No Audio Demodulator installed.

“AGILE AUDIO” – (Future Product Option)

“FIXED AUDIO” – Audio Modulator Installed.

REMOTE

SQUELCH

ALARM

“OK" or “FAULT”

3-10

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

4 Troubleshooting

This section explain how to interpret alarm indicators and messages.

4.1 Front Panel Indicators

Figure 4-1 shows the front panel LED indicators.

Figure 4-1 Front Panel LEDs

When on, indicates power to receiver

POWER

When on, indicates receiver

REMOTE

has been placed in remote mode

See Section 3.2.1, Main Screen on page 3-2

Section

4

SQUELCH

ALARM

When on, the receiver is in analog mode,

and the video is squelched.

See Section 3.2.9, Video Demodulator Screen on

When on, indicates summary alarm.

See Section 4.2, System Alarms on page 4-2

CodeRunner 4 Operator’s Guide

400438-1 Rev. J

4-1

Troubleshooting

4.2 System Alarms

Common system faults are displayed in the scrolling area of the main menu (Figure 4-2)

and in the related menu. For more information on menus, see Section 3, Operating

Controls on page 3-1.

Figure 4-2 Main Screen

SCROLLING MESSAGE AREA

System Alarms

POWER

1995.750MHz

REMOTE

RSL-89.2dBm Band:2

17MHz Chnl:1

SQUELCH

BW:NRM LOCAL Offset:–

Menu DIGITAL

Table 4-1 lists common system faults and their probable cause.

Table 4-1 System Alarms

Alarm Cause Comments

Rsl low Occurs when Received Signal Level drops below 99dBm

Synthesizer Unlocked When Local Oscillator PLL unlocks

2nd Dwn Cnv Unlocked When second down converter PLL unlocks

CH A Audio Alarm Channel A fault or agile audio card.

CH B Audio Alarm Channel B fault for agile audio card.

Audio Alarm Any Fault for Fixed Audio card.

External Demod Fault In Digital mode, external demod selected, external signal from

demod low or demod not attached.

Internal Demod Fault Digital mode, internal selected. Card fault.

Note 1 The receiver detects the difference between agile audio, fixed audio, or no audio installed.

ALARM

See Note 1

See Note 2

4-2

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Replacing the Fuse

4.3 Replacing the Fuse

The power supply fuse is accessed from the rear of the unit.

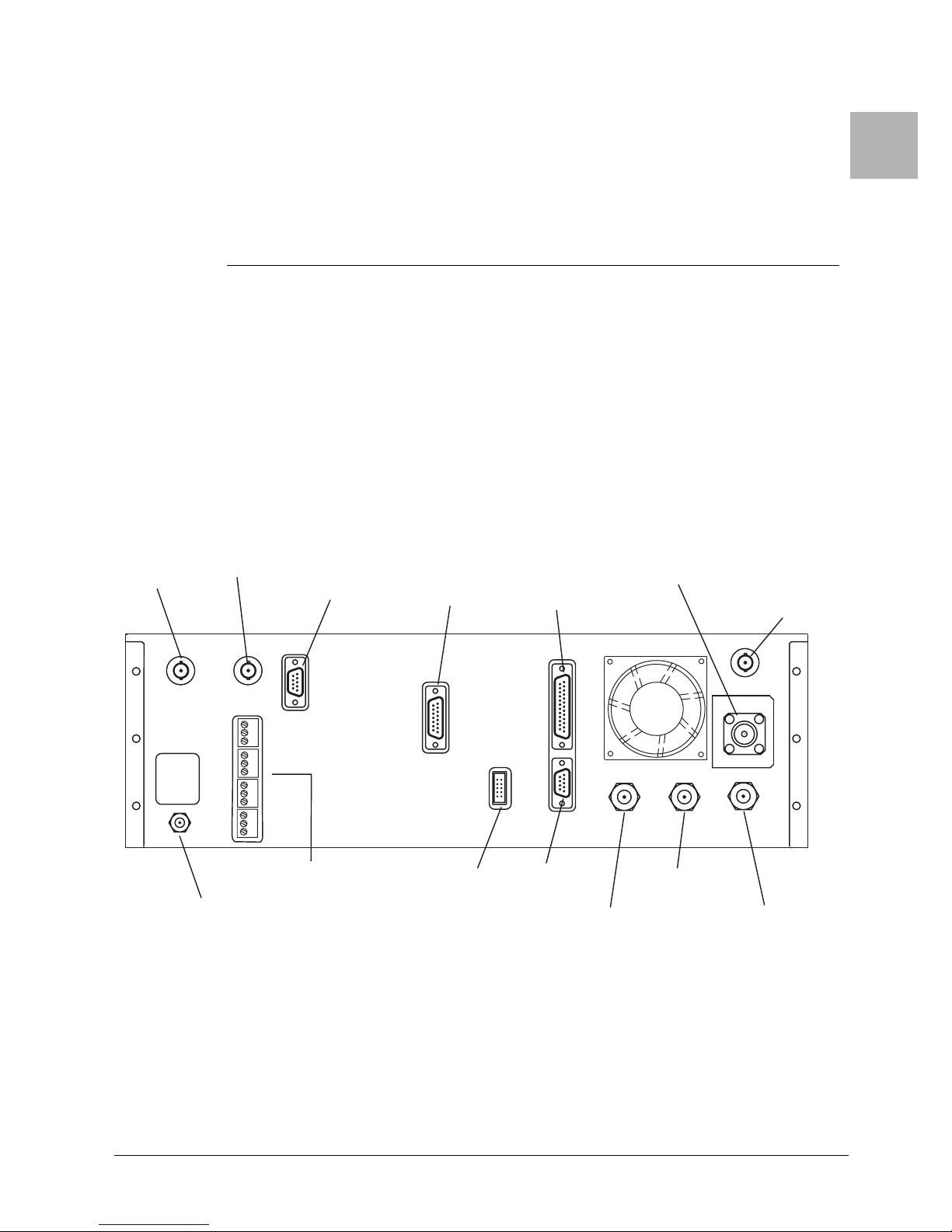

Step 1 The fuse is located on the left side of the rear panel as shown in Figure 4-3.

Step 2 Open the fuse cover.

Step 3 Remove the fuse from the receptacle and insert the new fuse using the following:

Step 4 Replace the fuse and close the fuse cover.

Figure 4-3 CodeRunner 4 Rear Panel - Typical

Troubleshooting

Warning: Disconnect power before removing cover. Service of this

equipment should only be performed by trained personnel.

- Use T2A/250V for 120 VAC Operation

- Use T1A/250V for 240 VAC Operation

FUSE

VIDEO BB

(J2)

~AC POWER

120/240; .4A

50/60 HZ

FUSE:

T1A 250 VA C

"CAUTION

DOUBLE-FUSE

NEUTRAL/FUSING"

SUM

ALARM

(J1)

AUDIO

(J12)

1

2

(J11)

3

(J15)

(J16)

4

(J3)

RX STATUS

(J13)

(J9)

PGM I/O

REMOTE

INTERF

SERIAL

PORT

ACE

(J7)

(J8)

IF I/O

815 MHz OUT

RF IN

EXT MODEMDATA OUT

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

4-3

Troubleshooting

Replacing the Fuse

This page intentionally left blank.

4-4

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Section

5 Remote Operation

The receiver can be set to operate in local or remote mode using the front panel keypad and

LCD display. For the receiver to operate from a remote location, a connection must be made

between the receiver and the master antenna controller or control device. This section

describes how to assemble the control cable and interpret the various control states.

5.1 Local and Remote Operation

The receiver is set to local or remote mode using the front panel keypad and LCD. See

Section 3, Operating Controls on page 3-1.

When the receiver is set to local mode, the following conditions occur:

• All receiver functions are controlled using the front panel keypad, and remote

device commands have no effect.

• If a remote device is connected to the receiver, front panel controls override any

commands from the remote device. However, the remote device status outputs

remain functional.

When the receiver is set to remote mode, the following conditions occur:

• All receiver functions are controlled by the remote device using the interface cable.

• Commands from the remote device control all functions of the receiver and override

the front panel controls. If the remote device line connection should become open,

the receiver remains under local mode even though the device is set to remote.

• The remote setting does not force the REMOTE mode, but rather allows the remote

device to determine whether the receiver will be in the local or remote mode.

• If no remote device is connected to the receiver, the receiver will remain in local

mode, even if the front panel controls are to set to remote.

5

CodeRunner 4 Operator’s Guide

400438-1 Rev. J

5-1

Remote Operation

Command Inputs to the Remote Connector

5.2 Command Inputs to the Remote Connector

The remote device connects to the rear of the receiver using the remote interface connector

(J7) as shown in

J7 is shown in Table 5-1.

Pin functions are grouped into two categories: Control functions and Status Outputs.

Commands are sent by the remote device using the following logic states:

• The logic 1 is +5 V nominal (3.5 to 5.5 V).

• The logic 0 is 0 V nominal (-0.5 to +0.8 V) or open. Inputs have 10 K ohm pulldown resistors to ground. +5 Vdc is available at the remote interface.

A logic level of “1” is equal to +5 V, which is supplied on Pin 10 of the Remote Interface

Cable.

For remote commands to be functional, the following conditions must occur:

• The front panel control must be set to the remote mode.

• The remote mode command at J7 pin 8 must be set to 1.

• All commands must be sustained for the duration of the desired mode.

Table 5-1 Remote Interface Connections

Pin No. Function Remarks

1 GROUND GND

2 N/C

3 N/C

4 N/C

5 12/17 MHZ SCBO

6 IF BANDWIDTH LSB IFB0

7 IF BANDWIDTH MSB IFB1

8 REM CONTROL REMC

9 REM MODE STATUS REMS

10 + 5 VDC +5V

11 SQUELCH ALARM SQLA

12 SQUELCH DISABLE SQLF

13 RCL ANALOG RCLA

14 CHANNEL SEL LSB CHN0

15 CHANNEL SEL CHN1

16 CHANNEL SEL CHN2

17 CHANNEL SEL MSB CHN3

18 N/C

19 N/C

20 DIGITAL MODE SELECT DMODE

21 OFFSET SEL LSB OFS0

22 OFFSET SEL MSB OFS1

23 LNA GAIN REDUCTION GAIN

24 BAND SEL LSB BND0

25 BAND SEL MSB BND1

Appendix A, Receiver Interconnections. The combined logic table for

5-2

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Command Inputs to the Remote Connector

5.2.1 Control Functions

Table 5-2 RF Channel Selection

Function J7 Pin No.

17 16 15 14

Channel 1 0 0 0 1

Channel 2 0 0 1 0

Channel 3 0 0 1 1

Channel 4 0 1 0 0

Channel 5 0 1 0 1

Channel 6 0 1 1 0

Channel 7 0 1 1 1

Channel 8 1 0 0 0

Channel 9 1 0 0 1

Channel 10 1 0 1 0

Channel 11 1 0 1 1

Channel 12 1 1 0 0

Channel 13 1 1 0 1

Channel 14 1 1 1 0

Remote Operation

Table 5-3 Offset Selection, – Active High

Function J7 - Pin No.

22 21

- Offset 0 1

NO Offset 0 0

+ Offset 1 0

++ Offset 1 1

Table 5-4 Band Select – Active High

Function J7 Pin No.

2 GHz Band (1.99 to 2.50 and 2.3 to 2.7 GHz) 0 0

7 GHz Band (6.425 to 7.125 GHz) 0 1

12 GHz Band (12.7 to 12.95 GHz) 1 0

13 GHz Band (12.95 to 13.25 GHz) 1 1

Table 5-5 IF Bandwidth Select – Active High

Function J7 Pin No.

7 6

10 MHz (Narrow) 0 1

15 pr 20 MHz (Medium) 0 0

20 or 30 MHz (Wide) 1 0

25 24

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

5-3

Remote Operation

Table 5-6 Squelch Control – Active High

Function J7 Pin No. 12

Squelch Disabled. 1

Note: The automatic squelch circuitry in the Receiver may be overridden by

Remote commands when in the REMOTE mode. Applying a logic 1

to pin 12, “SQUELCH DISABLE”, results in the receiver delivering

video and IF output independent of the quality (or presence) of

received signal.

Table 5-7 Digital Mode Select/Active High

Function J7 Pin No. 20

Digital Mode Selected 1

Table 5-8 Digital Mode Select/Active High

Function J7 Pin No. 23

High Gain Selected 1

5.2.2 Vdc Bias Supply

Command Inputs to the Remote Connector

A +5 Vdc (+/- 0.25 V) is made available on J7 pin 10 for loop-back as a command function

and for operating low power circuitry in the remote interface equipment. This output is

current limited and should not exceed 4 mA of load.

5.2.2.1 Ground

Signal (and chassis) ground is made available on J7 pin 1 for loop-back as a command

function and as the return for the +5 V bias supply.

5.2.3 Status Outputs – Remote Connector J7

Status outputs are functional in both LOCAL and REMOTE modes.

5.2.3.1 Receiver Signal Strength Indication - Analog

A buffered S meter output is made available on J7 pin 13.

• No signal strength (no RF input) = 0 V.

• Maximum signal strength (-35 dBm RF input) = +1V. Output impedance is 1 K

ohm.

5.2.3.2 Remote Mode Status

Active Low - J7 Pin 9

• Ground = Receiver is in the REMOTE control mode

• Open circuit = Receiver is in the LOCAL control mode.

5.2.3.3 Squelch Alarm

Dry Contact Closure - J7 Pin 11 to Ground (Pin 1).

• Open circuit = Receiver is operating correctly with an adequate received signal.

• Contact closure = Receiver has squelched video output due to inadequate received

signal.

A contact closure (i.e., alarm) also occurs when the Receiver is turned OFF.

5-4

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Section

6 Media Switch

6.1 Overview

The optional Media Switch lets operators switch between analog and digital modes where

both applications are used. The switch provides for separate video and audio or for

baseband composite.

The Front Panel Keypad and Display controls the operating mode as shown in Figure 3-10,

Video Demodulator Screen on page 3-9. The same “IF CNTRL” signal used to change

modes in the receiver is routed to the media switch using an optional cable allowing

simultaneous switching between both the analog and digital sources.

Figure 6-1shows a block diagram of the CR4 Receiver and Media Switch when used with

the Alteia Receiver for switching both video and audio.

Figure 6-1 Media Switch Block Diagram

VIDEO

ALTEIA

RECEIVER

AUDIO

6

CodeRunner 4

RECEIVER

DISPLAY

RF SHELF

IF

VIDEO

DEMODULATOR

AUDIO

DEMODULATOR

IF

VIDEO

AUDIO

(D)

(A)

IF

IF

CNTRL

MEDIA

SWITCH

(D)

(A)

(D)

(A)

VIDEO

OUT

AUDIO

OUT

(4 CHAN.)

CodeRunner 4 Operator’s Guide

400438-1 Rev. J

6-1

Media Switch

DIGITAL AUDIO IN

ANALOG AUDIO IN

Mounting the Media Switch

6.2 Mounting the Media Switch

The Media Switch attaches to the rear panel of the CodeRunner 4 Receiver using

5mounting screws as shown in

• Media Switch and Connector Assembly (906896)

• Audio Cable - Analog and digital audio outputs (906978)

• Remote Control Cable - Change analog or digital IF state (907008)

Figure 6-2 Media Switch on CR4 Rear Panel

VIDEO

(J2)

AC

INPUT

1

2

3

4

BB

(J1)

AUDIO

ALARM

(J3)

(J12)

(J11)

(J15)

(J16)

Figure 6-2. It requires the following components:

SUM

VIN

1

V

OUT

VIN

2

BBIN

1

BB

OUT

DIGITAL AUDIO IN

ANALOG AUDIO IN

BBIN

2

OUT

AUDIO 4

AUDIO 3AUDIO 2

OUT OUT

OUT

AUDIO 1

POWER/

CONT

RX STATUS

(J13)

(J9)

PGM I/O

REMOTE

INTERFACE

SERIAL

PORT

(J7)

(J8)

DATA OUT

IF I/O

815 MHz OUT

RF IN

EXT MODEM

MEDIA SWITCH

ASSEMBLY

MOUNTING SCREWS

(5 PLACES)

6.3 Media Switch Connections

Figure 6-3 shows the locations of the input and output connections.

Figure 6-3 Media Switch Connections

VIDEO INPUT 1

VIDEO OUTPUT

VIDEO INPUT 2

ANALOG & DIGITAL

AUDIO INPUTS

(4 ANALOG CHANNELS &

4 DIGITAL CHANNELS)

POWER/IF CONTROL

AUDIO OUTPUT

(4 CHANNELS)

BASEBAND INTPUT 1

BASEBAND OUTPUT

6-2

BASEBAND INPUT 2

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

System Interconnection

OUT

AUDIO4

VIN

2

POWER/

V

OUT

1

VIN

CONT

OUT

AUDIO1

OUT

AUDIO3

OUT

AUDIO2

OUT

DIGITAL AUDIO IN

BBIN

2

BB

BBIN

1

ANALOG AUDIO IN

A

UDIO #2

RIGHT/AES/EBU

A

UDIO #1

RIGHT/AES/EBU

A

UDIO #2 LEFT

A

UDIO #1 LEFT

DIGIT

AL

VIDEO

ANALOG

VIDEO

GENLOCK

MPLC-2-SPI-TSO

RS-232 D ATA

RX-422 DATA

RCTRL RX 232/485

RF INPUT

BB INPUT

6.4 System Interconnection

Figure 6-4 shows a typical interconnection between the CR4 REceiver, Media Switch, and

the Alteia Receiver. In this configuration, separate audio and video sources are switched.

For more information on the Alteia Receiver, see the following manual:

• Alteia Instruction Manual – ST.TM.E9200.2R1

Figure 6-4 System Interconnection

Figure 6-6, Audio Harness (906978) on page 6-4

Figure 6-5, Power & IF Control Harness (907008) on page 6-4

VIDEO OUTPUT

(ANALOG)

Media Switch

RF INPUT

VIDEO

AC

INPUT

BB INPUT

AUDIO

RX-422 D

BB

1

2

3

4

MPLC-2-SPI-TSO

SUM

ALARM

ANALOG AUDIO IN

RS-232 D

VIN

1

V

OUT

VIN

2

BBIN

1

BB

OUT

DIGITAL AUDIO IN

BBIN

2

RCTRL RX 232/485

AUDIO4

AUDIO3

AUDIO2

AUDIO1

POWER/

CONT

OUT

OUT

OUT

OUT

RX STATUS

GENLOCK

PGM I/O

DIGIT

ANALOG

REMOTE

INTERFACE

SERIAL

PORT

AL

VIDEO

VIDEO

UDIO #1 LEFT

AUDIO OUTPUT

(4 CHANNELS)

DATA

OUT

UDIO #1

RIGHT/AES/EB

UDIO #2 LEFT

IF I/O

UDIO #2

RIGHT/AES/EB

815 MHz OUT

RF IN

EXTERNAL

MODEM

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

6-3

Media Switch

6.5 Harness Assemblies

Figure 6-5 Power & IF Control Harness (907008)

7.00 ± .25"

[17.78 mm ± .635 mm]

5.00 ± .25"

[12.70mm ± .635 mm]

N/C

6

N/C

5

N/C

4

ORN

+15V

GND

IF CNTRL

3

2

1

BLK

WHT/RED

1

Harness Assemblies

158

+15V

GND

IF CNTRL

1

9

8

14

4

ORN

BLK

WHT/RED

CABLE ASSY, CONTROL

Figure 6-6 Audio Harness (906978)

72.00 ±3.00

1

251413

11X

5.0

WIRING DIAGRAM

ANALOG

1

2

3

4

5

6

7

8

9

10

11

12

13

AUDIOT/RP/O #1

21

2

2

2

2

2

2

2

2

2

2

2

N/C

PIN

1

2

3

1

2

3

2

1

3

2

1

3

COLOR

RED

YEL1

BLK1

GRN2

YEL2

BLK2

WHT3

YEL3

BLK3

BLU4

YEL4

BLK4

USAGE

CR-4

CR-4

CR-4

CR-4

CR-4

CR-4

CR-4

CR-4

CR-4

CR-4

CR-4

CR-4

P/O #1

T/R

14

1

15

1

1161

17

1

18

1

19

1

20

1

21

1

22

1

1234

24

1

25

1

DIGITAL

AUDIO

1

1

2

2

2

3

3

3

4

4

PIN

3

1

3

1

2

3

1

2

3

2

1

2

7.00 +/-.50

6.00 +/-.50

8X

COLOR

RED

YEL

BLK

GRN

YEL

BLK

WHT

YEL

BLK

BLU

YEL

BLK

8X

USAGE

FUTURE

FUTURE

FUTURE

FUTURE

FUTURE

FUTURE

(MEDIA SWITCH)

CM-4

CM-4

CM-4

CM-4

CM-4

CM-4

AUDIO CABLE FOR MEDIA SWITCH

BLU

YEL

GRN

YEL

B

W

HT

B

L

K

BLU

B

YEL

LK

WIRE HARNESS ASSY

TR/1

AUDIO 4

EL

Y

LK

B

L

RED

GRN

K

YEL

TR/1

T

H

AUDI O 3

W

EL

Y

BLK

LK

B

BLK

D

E

R

Y

E

L

1

2

3

1

2

3

1

2

3

TR/2

AUDIO 4

BLK

YEL

1

2

3

1

3

2

TR/2

AUD

TR/2

AUDIO 3

DIGITAL

TR/1

AUDIO 2

TR/1

3

AUDIO 1

21

TR/2

AUDIO 1

IO 2

ANALOG

6-4

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Appendix

1

2

AC

INPUT

REMOTE

INTERFACE

IF

OUTPUT

SERIAL

PORT

REMOTE

INTERFACE

DATA

OUTPUT

RECEIVER

STATUS

SUMMARY

ALARMS

PGM

I/0

AUDIO

1 THRU 4

VIDEO

BASEBAND

OUTPUT

RF

INPUT

EXTERNAL

MODEM

GROUND

CONNECTION

A Receiver Interconnections

A.1 Cabinet Connections

This appendix shows the cabinet enclosure internal and external connections. Refer to the

following diagrams:

• Figure A-1, CodeRunner Rear Panel Connectors - Typical, on page A-1

• Figure A-2, Receiver Interconnection Diagram - RF Shelf, on page A-4

• Figure A-3, Receiver Interconnection Diagram - Backplane, on page A-5

Figure A-1 CodeRunner Rear Panel Connectors - Typical

A

OUTPUT

(J2)

(J1)

VIDEO

3

4

BB

AUDIO

SUM

ALARM

(J12)

(J11)

(J15)

(J16)

(J3)

(J13)

RX STATUS

(J9)

PGM I/O

SERIAL

PORT

(J8)

(J7)

DATA OUT

IF I/O

815 MHz

OUTPUT

815 MHz OUT

RF IN

EXT MODEM

CodeRunner 4 Operator’s Guide

400438-1

Rev. J

A-1

Receiver Interconnections

A.2 Remote Interface Connector

Table A-1 Remote Interface Connections (J7)

Pin No. Function Remarks

1 GROUND GND

2 SUB CXR A MSB SCA1

3 SUB CXR A LSB SCA0

4 SUB CXR B MSB SCB1

5 12/17 MHZ SCB0

6 IF BANDWIDTH LSB IFB0

7 IF BANDWIDTH MSB IFB1

8 REM CONTROL REMC

9 REM MODE STATUS REMS

10 + 5 VDC +5V

11 SQUELCH ALARM SQLA

12 SQUELCH DISABLE SQLF

13 RCL ANALOG RCLA

14 CHANNEL SEL LSB CHN0

15 CHANNEL SEL CHN1

16 CHANNEL SEL CHN2

17 CHANNEL SEL MSB CHN3

18 N/C

19 N/C

20 DIGITAL MODE SELECT DMODE

21 OFFSET SEL LSB OFS0

22 OFFSET SEL MSB OFS1

23 LNA GAIN REDUCTION GAIN (future use)

24 BAND SEL LSB BND0

25 BAND SEL MSB BND1

Remote Interface Connector

A-2

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Remote Interface Connector

Table A-2 Serial Port (J8)

PIn # Description Comment

1 NA

2 SERP3

3 SERP1

4 NA

5 NA

6 GND

7 SERP2

8 SERP0

9 NA

Table A-3 Summary Alarm (J3)

PIn # Description Comment

1 LOF_X

2 M_SUM_X

3 +5V

4 Relay COMM

5 Relay N/O

6 NC

7 GND

8 NC

9 Relay N/C

Receiver Interconnections

Table A-4 Rx Status (J13)

PIn # Description Comment

1 SCA_FAULT

2 SCB_FAULT

3 AN_EN

4 IF_CNTRL

5 N/U

6 MW_LK

7 AGC

8 +15V

9 –15 V

10 RXSUM

11 M_SUM_X

12 M_SUM_I

13 IF_LK

14 GND

15 +5V

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

A-3

Receiver Interconnections

E

Figure A-2 Receiver Interconnection Diagram - RF Shelf

BNC-F

REAR PAN

806440-11

+5 DBM

+5 DBM

Remote Interface Connector

906587-1

IF AMP

845133-5

IF FILTER

906789/906776

845133-7

EQL

BPF

+6 DB

MODE

RUN IN DIGITAL

SQUELCH LOGIC

LINEAR AGC

&

V

D

V

AGC

EQL

BPF

906611-4

906840-5

EQL

SW CTRL

BPF

+15V

GND

BW0

BW1

SELA - WHT

900344-6

SELB - BLU

MODEM

DIGITAL

TO

J3

J2

J4

BC

BNC-F

REAR PANEL

2ND DOWN CONV

815 MHZ

12 dB

LNC

906768/906756

COUPLER

2-1

90674

"SMA"

"N"

52190-1 & 89396-11

BPF

+24 DB

745/885 MHZ

+15V

GND

LO

0 - WHT

FREQ-BLU

LOHL

IF_LK

IF_CTRL

POWER

DISTRIBUTION

834

906

TO

DEMOD

VIDEO

A

Continued on Figure A-3 on page A-5

SCLK

SDAT

SEN1

MW_LK

VTUNE

+15V

LO

GND

906839-5

906752/906734

SYNTHESIZER

TO BACKPLANE

906888-9

SER PLL

2.75

906670-

A-4

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

Remote Interface Connector

Figure A-3 Receiver Interconnection Diagram - Backplane

Continued from Figure A-2 on page A-4

Receiver Interconnections

900344-15/16

IF IN

901358-n

+15V

-15V

ANALOG

GND

B/B

B

VID

SCXR

TO

AN_EN

AGC

IF AMP

NOTE: CONNE CTS

BB OUT

SYNTHESIZER

BNC-F

RE AR PANEL

TO J2 WHEN NO

INTE RNAL MODEM

VIDEO OUT

2ND DC

IF FILTER

IF 2 OUT

123

AGC IF

902571-nn

AUDIO 2

AUDIO 1

123

INTER NAL MODEM

EXTERNA L MODEM

DUAL AUDIO

AF1A

AF1B

AF2A

AF2B

900414-1/900172-n

ANALOG DEM OD

POWER DIST

SCXR

AUDIO

+15V

-15V

GND

REMOTE

ALARM RELA Y

ACLK

AEN1

ADAT

SCA_FAULT

SER CHN

AEN2

845133-10/1

MODEM

906748

POWER SU PPLY

IF IN

C

+15V

-15V

+5V

+9V

BNC-F

REAR PANEL

DATA OUT

DATA OUT

GND

M_SUM_I

M_P-I

902571-nn

906800

PWR SUPPLY

RXSUM

+15V

348

-15V

+5V

AC LINE

+9V

+24VSQLS

1

GND

ACLK

AEN1

AEN2

AGC

LOHL

SDAT

SCLK

SEN1

BW0

BW1

MW_LK

IF_LK

LOF_I

M_SUM_I

LOF_X

M_SUM_X

M_SUM_I

LOF_X

M_SUM_X

RX STATUS

AN_EN

RXSUM

SCA_FAULT

IF_CTRL

SCB_FAULT

-15V

BOARD

DISTRIBUTION

TO POWER

Continued from Figure A-2 on page A-4

A

51700-35

51700-36

AGC

+15V

+5V

815714613512411310291

RELAYS

BAND SELECT

GND

MW_LK

IF_LK

LOF_I

LMTR

AN_EN

SCA_FAULT

SCB_FAULT

594837261

ADAT

+5V

SUMMARY ALARM I/O

M_SUM_X

GND

TXDR

RXDR

LOF_X

RXSUM

SQLS

SERP0

SERP1

SERP0

SERP1

SERP2

SERP3

SERP2

SERP3

+15V

-15V

+5V

SQLA

+9V

GND

AGC

TXDR

MICRO-P

+5V

GND

123456789

J6

123456789101112131415

RXDR

+5V

GND

AGC

SQLA SQLA

TXDR

RXDR

SERP0

10111213141516

SQUELCH REL AY

SERP1

SERP2

906828906826

BACKPLANE

SERP3

16

7

REMOTE I/O

12345

SCA0

SCA1

CHN1

GND

CHN0

J9

PGM I/O

MICROCONTROLLER

906146

DISPLAY

J8

SER PORT

9 PIN D M

594837261

RCLA

BND1

SQLD

BND0

SQLA

GAIN

OFS1

REMS

OFS0

REMC

GND

J7

25 PIN D

REMOTE INTERFACE

+5V

13251224112310229218207196185174163152141

IFB1

DMODE

IFB0

CHN3

SCB0

CHN2

SCB1

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

A-5

Receiver Interconnections

Remote Interface Connector

This page intentionally left blank.

A-6

CodeRunner 4 Operator’s Guide 400438-1 Rev. J

B.1 Channel Frequencies

Refer to the following tables for a list the U.S. domestic frequency channels.

• 2 GHz (17 MHz Channel Plan) - Table B-1 on page B-1

• 2 GHz (12 MHz BAS Channel Plan) - Table B-2 on page B-2

•7 GHz - Table B-3 on page B-2

•13 Ghz - Table B-4 on page B-3

Note: When powering on the receiver, and when switching to another RF channel, there is a delay

until phase lock of the synthesizer occurs.

Table B-1 2 GHz Channel Guide (17 MHz Channel Plan)

Channel Offset Switch Position

Appendix

B Frequencies