Microvideo Synergy SY800, Synergy SY810 Instruction Manual

1

Installation and Programming Manual

“SYNERGY” Copyright © 2012 Microvideo - http://www.microvideo.eu

For more information, updates, requests, please visit www.microvideo.eu, the official

website of Microvideo Company, specialized in Design, Manufacture and Distribution of

advanced Intrusion Systems.

DISCLAIMER

Every care has been taken in the creation, implementation, verification of this literature,

however, neither the author nor Microvideo Srl, can accept any responsibility for the accuracy of the information described nor provide any guarantee on the performance or results

obtained. The same applies to any person or company involved in the creation, production,

and distribution of this documentation.

Names and marks mentioned in this document are trademarks of their respective owners

"SYNERGY" Microvideo Copyright © 2012 - http://www.microvideo.eu

2

Installer Manual Microvideo srl www.microvideo.eu

Table of Contents

Warranty .................................................................................................................................................... 5

Limitation of Liability .................................................................................................................................. 5

Copyright ................................................................................................................................................... 5

CHAPTER 1 - Introduction................................................................................................................................ 6

Chapter 2 –Modules Description ....................................................................................................................... 7

Control Panel ................................................................................................................................................. 7

Keyboard (Mod. SY820) ................................................................................................................................ 9

LED .............................................................................................................................................................. 10

DISPLAY ...................................................................................................................................................... 10

DIRECTIONAL KEYS .................................................................................................................................. 10

INTEGRATED PROXIMITY READER ......................................................................................................... 10

NUMERIC KEYPAD .................................................................................................................................... 10

DELETE BUTTON ........................................................................................................................................ 11

ESC KEY ...................................................................................................................................................... 11

MACRO FUNCTION KEYS .......................................................................................................................... 11

GSM / GPRS Module (Mod. SY860) ............................................................................................................ 11

Expansion Module (Mod. SY840) ............................................................................................................... 12

Inserter Jack Module (Mod. SY825) ............................................................................................................ 13

Wall Inserter Module (Mod. SY826) ............................................................................................................ 13

LAN Module (Mod. SY881) ......................................................................................................................... 14

BUS Splitter (Mod. SY930) ......................................................................................................................... 14

DVR WALL 4N-8N ....................................................................................................................................... 15

Radio Receiver Module (mod. SY910) ........................................................................................................ 16

Radio Magnetic Contact Module (mod. SY920) ......................................................................................... 16

MAGNET + NC Configuration ................................................................................................................. 17

NC + NC Configuration ........................................................................................................................... 17

Configuration Magnet + Blinds ................................................................................................................ 18

Supervision Function .............................................................................................................................. 18

Report Open/Close Magnet/NC .............................................................................................................. 18

Inertial Radio Module (mod. SY921) ....................................................................................................... 18

Supervision Function .............................................................................................................................. 19

Motion Sensor Module (mod. SY925) ......................................................................................................... 20

Radio Remote Control (mod. SY915) ......................................................................................................... 21

Procedure for Inserting Through Key ...................................................................................................... 22

CHAPTER 3 – Installing ................................................................................................................................. 23

Installing Control Panel ............................................................................................................................... 23

Connection of Voice Module (Mod. SY-900) ........................................................................................... 23

Connecting siren to an output ................................................................................................................. 24

Sample connection of open collector outputs ......................................................................................... 24

Connecting Sensor Alarm to Zones ........................................................................................................ 25

Modules Installing on CAN BUS.................................................................................................................. 28

Keyboard Module SY920 Installation .......................................................................................................... 28

Installing the Expansion Module SY840-SY841-SY845 ............................................................................ 29

Installing GSM/GPRS SY860-SY861 Module ............................................................................................ 30

Installing LAN SY880-SY881 module ......................................................................................................... 31

Wall Installing of inserter SY826Module ...................................................................................................... 32

Installing the SY825 inserter Jack Module .................................................................................................. 33

Installing the SY930 Bus Isolator / Repeater Module ................................................................................. 33

Installing Radio SY920-SY921 Modules ..................................................................................................... 35

Installing SY925 Motion Sensor Module ..................................................................................................... 36

Configuring Module Address ....................................................................................................................... 37

Addressing Module Keyboards ........................................................................................................... 37

Addressing Expansion Module ........................................................................................................... 38

Addressing GSM / GPRS Module ...................................................................................................... 38

Testing System ............................................................................................................................................ 39

CHAPTER 4– Programming Control Panel ..................................................................................................... 40

Installer Menu .............................................................................................................................................. 40

General Parameters ................................................................................................................................ 40

ZONES .................................................................................................................................................... 42

RADIO ZONES ....................................................................................................................................... 43

3

Installer Manual Microvideo srl www.microvideo.eu

Outputs .................................................................................................................................................... 43

AND Zones .............................................................................................................................................. 44

Expansions .............................................................................................................................................. 44

Areas ....................................................................................................................................................... 44

Timer ....................................................................................................................................................... 45

Keyboards ............................................................................................................................................... 45

RFID Keys ............................................................................................................................................... 46

Readers ................................................................................................................................................... 46

WALL Modules ........................................................................................................................................ 46

Fog modules ........................................................................................................................................... 47

Radio Receivers ...................................................................................................................................... 47

Radio Modules ........................................................................................................................................ 48

Radio Remote Controls ........................................................................................................................... 48

Procedure of Remote Control Learning .................................................................................................. 48

User Code ............................................................................................................................................... 49

Installer Codes ........................................................................................................................................ 49

Macro ...................................................................................................................................................... 49

Actions .................................................................................................................................................... 50

Events ..................................................................................................................................................... 50

Address Book .......................................................................................................................................... 52

Vocal Messages ...................................................................................................................................... 52

GSM Transmission .................................................................................................................................. 52

LAN ..................................................................................................................................................... 53

Holidays .................................................................................................................................................. 53

Alarm Management ................................................................................................................................. 54

System Management .............................................................................................................................. 54

CHAPTER 5 – Plant Management by GSM/GPRS Module ........................................................................... 55

Incoming Calls and SMS. ............................................................................................................................ 55

Voice Menu .................................................................................................................................................. 55

SMS commands .......................................................................................................................................... 56

APPENDIX B – Phisic Terminals – SY800/SY810 .......................................................................................... 59

Zones (Inputs) ............................................................................................................................................. 59

APPENDIX B – Phisic Terminals – ST-SMOKE .............................................................................................. 61

Zones (Inputs) ............................................................................................................................................. 61

Output .......................................................................................................................................................... 61

Appendix C –Deafault Reset Procedure .......................................................................................................... 63

Appendix D –Vocal Messages ......................................................................................................................... 64

4

Installer Manual Microvideo srl www.microvideo.eu

CHAPTER 1 - Introduction

Warranty

Microvideo srl ensures that products are free from defects in materials and workmanship

for a period of 12 months from date of manufacture. Given that Microvideo srl does not

install directly the products mentioned here , and since these products can be used in

conjunction with products not manufactured by Microvideo , Microvideo srl can not

guarantee the performance of safety equipment . Obligation and liability of the seller is

limited to repairing or replacing, at its option, any product not meeting the specifications .

In no event Microvideo srl can be liable to the buyer or any other person for any loss or

damage, direct or indirect, consequential or incidental damages, including, without

limitation, any damages for lost profits, stolen goods, or claims by any other party caused

by defective goods or otherwise arising from the improper , incorrect or otherwise faulty

installation or use of these products.

The warranty covers only defects that result from the proper use of the product. It does not

cover :

• Misuse or negligence

• Damage caused by fire, flood, wind or lightning

• Vandalism

• Wear

Microvideo srl takes responsibility, at its option, for repairing or replacing any defective

product. Improper use, especially other than those specified in this manual, will nullify your

warranty. For more detailed informations about the warranty, refer to your dealer.

Microvideo srl is not responsible for any damage caused by improper use of the product.

5

Limitation of Liability

Installation and use of these products should be allowed only to authorized persons.

Specifically, the installation must strictly follow the instructions in this manual.

Copyright

The information contained in this document are the sole property of Microvideo srl. No

reproduction or modification is permitted without the prior permission of Microvideo s.r.l.

Tutti i diritti sono riservati.

Manual version: 1.02

Installer Manual Microvideo srl www.microvideo.eu

CHAPTER 1 - Introduction

CHAPTER 1 - Introduction

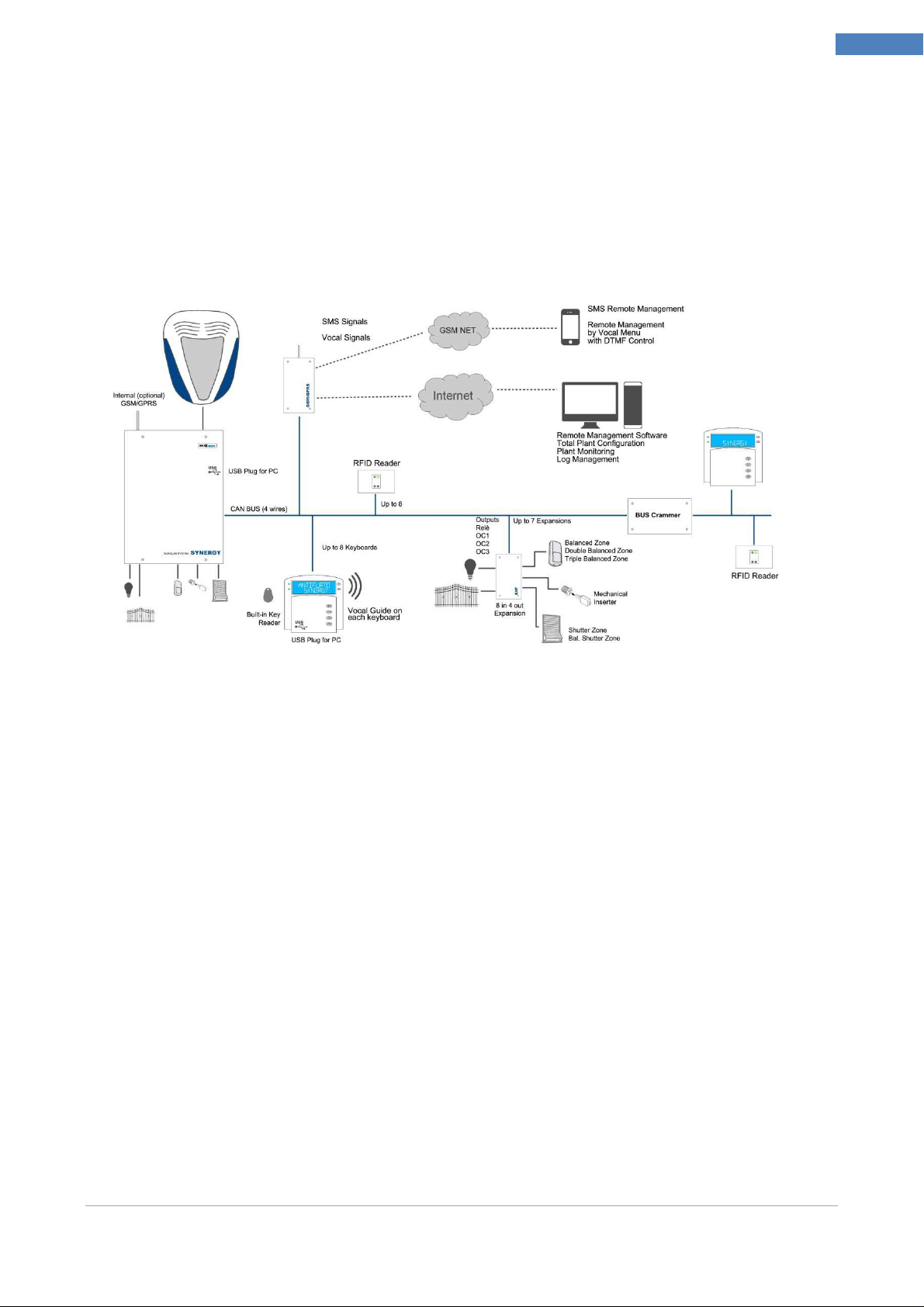

Security System SYNERGY

The SYNERGY Security System is a completely integrated and modular System, designed

to meet the security needs in most of the domestic and industrial installations. The

modular management allows to use and expand the features of the System according to

the customer's requirements.

6

Installer Manual

This installer manual contains informations needed for proper installation / programming

of a SYNERGY plant.

It 's important to read carefully the manual to understand all the concepts necessary for the

proper installation and to familiarize yourself with the functions of the System.

Usually this manual is provided only in electronic form (pdf format)

User Manual

The user manual contains all the informations required for the correct use of the System

by the user. It 's important that the installer could check the correct comprehension of the

manual by the customer.

Installer Manual Microvideo srl www.microvideo.eu

Chapter 2 –Modules Description

Specifications

SY800

SY810

Chapter 2 –Modules Description

Control Panel

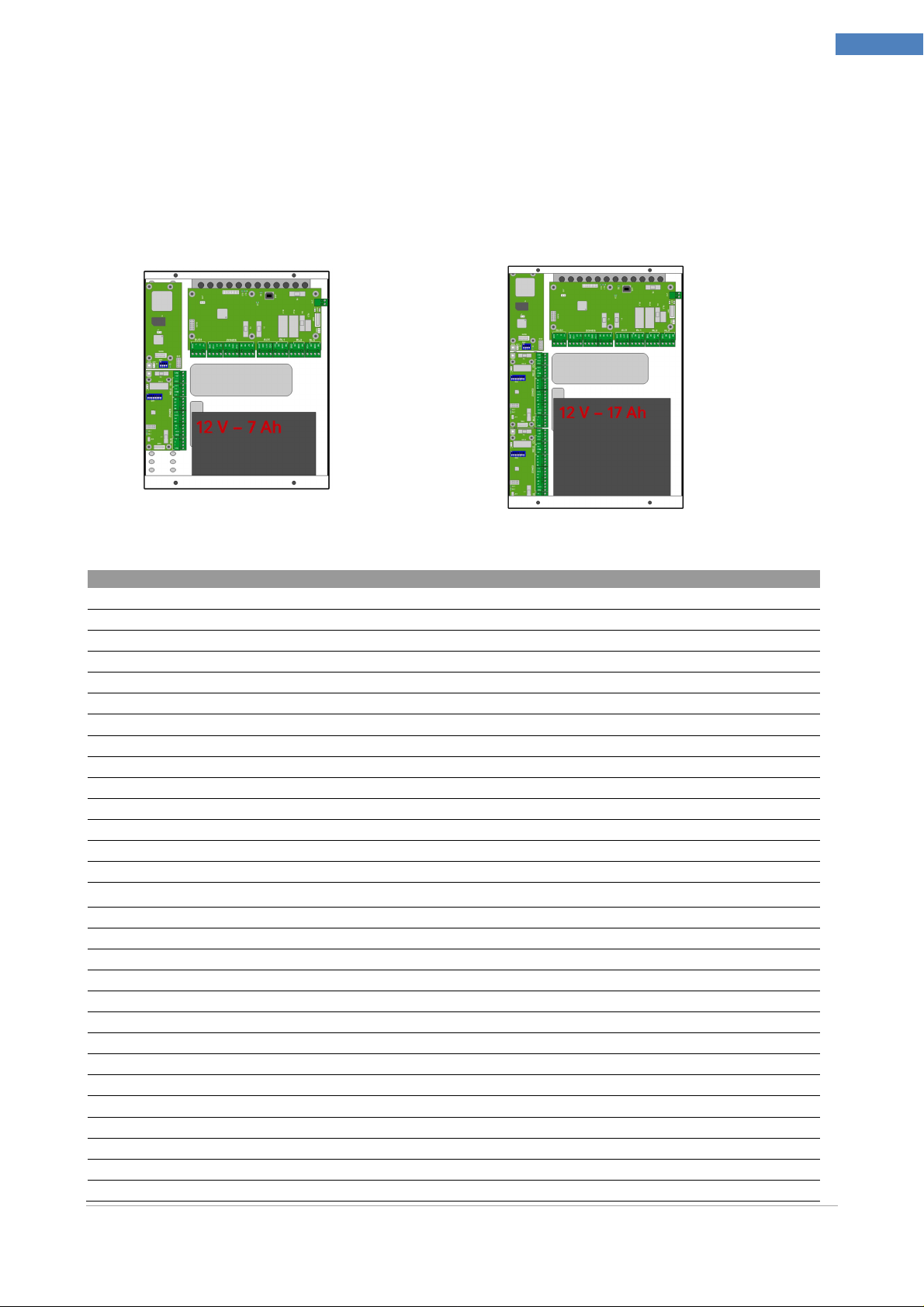

SYNERGY Control Panel is available in two models according to the features of the

System. There are also two box models, with the larger version you can insert a 17 Ah

battery and install up to three modules inside.

SY800 Control Panel

SY810 Control Panel

7

Inputs aboard 8

24h input 1

Programmable relays aboard 2

Areas managed by the system 8 12

Check the efficiency of battery Yes

Firmware upgrading of the central Yes

Firmware upgrading modules by central Yes

USB port (Programming) Yes

Removable Connectors Yes

GSM Aboard Yes (optional)

Module Expansion Board Yes

Keyboards 4 8

Expansions 7

Proximity Readers 4 8

GSM / GPRS 1

Dual Frequency Radio Receivers 2 4

Dual Frequency Radio Modules 10 64

Radio Areas 10 64

Installer Codes 2

User Code 16 64

Proximity Keys 8 64

Keys Equipment combinations 4 294 967 269

Dual Frequency Radio Remote Controls 4 32

Macro (all associated with timer) 18 36

Macro signaling Activation Event Yes

Macro Reset signaling event Yes

Actions 64

Configurable events 422

Weekly timer 25

Installer Manual Microvideo srl www.microvideo.eu

Features

SY800

SY810

SY810

managing Holidays 16 (periods)

Number of recordable events 2000

Supply Voltage 220V 220V

Maximum Power Consumption --- ---

Open Collector output current 50mA 50mA

Backup Battery 12V 7Ah. 12V 17Ah.

Power Pack 14V 2.6Ah. 14V 2.6Ah.

Container Size 270x330x85 270x380x105

Weight (without batteries) --- ---

Chapter 2 –Modules Description

8

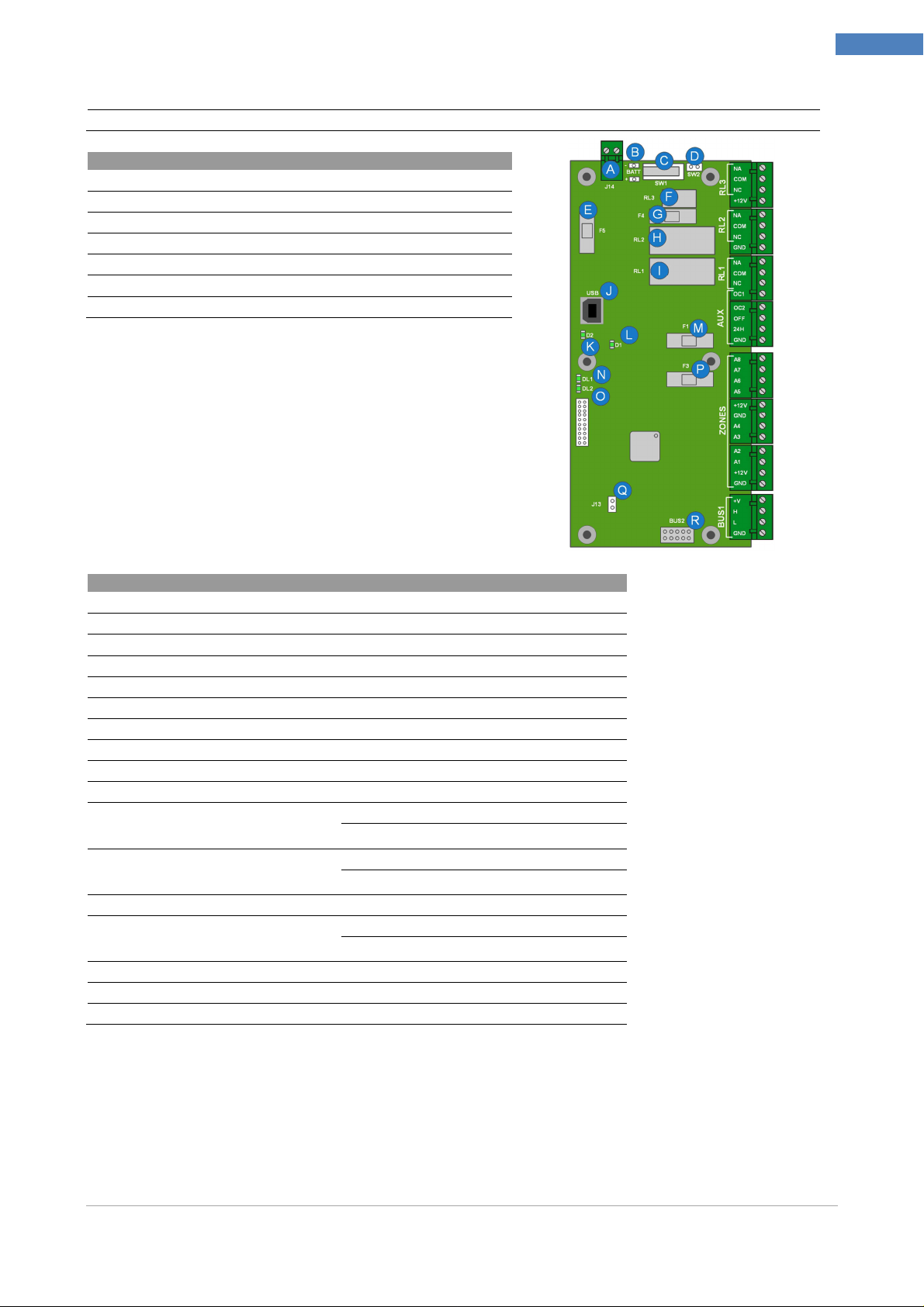

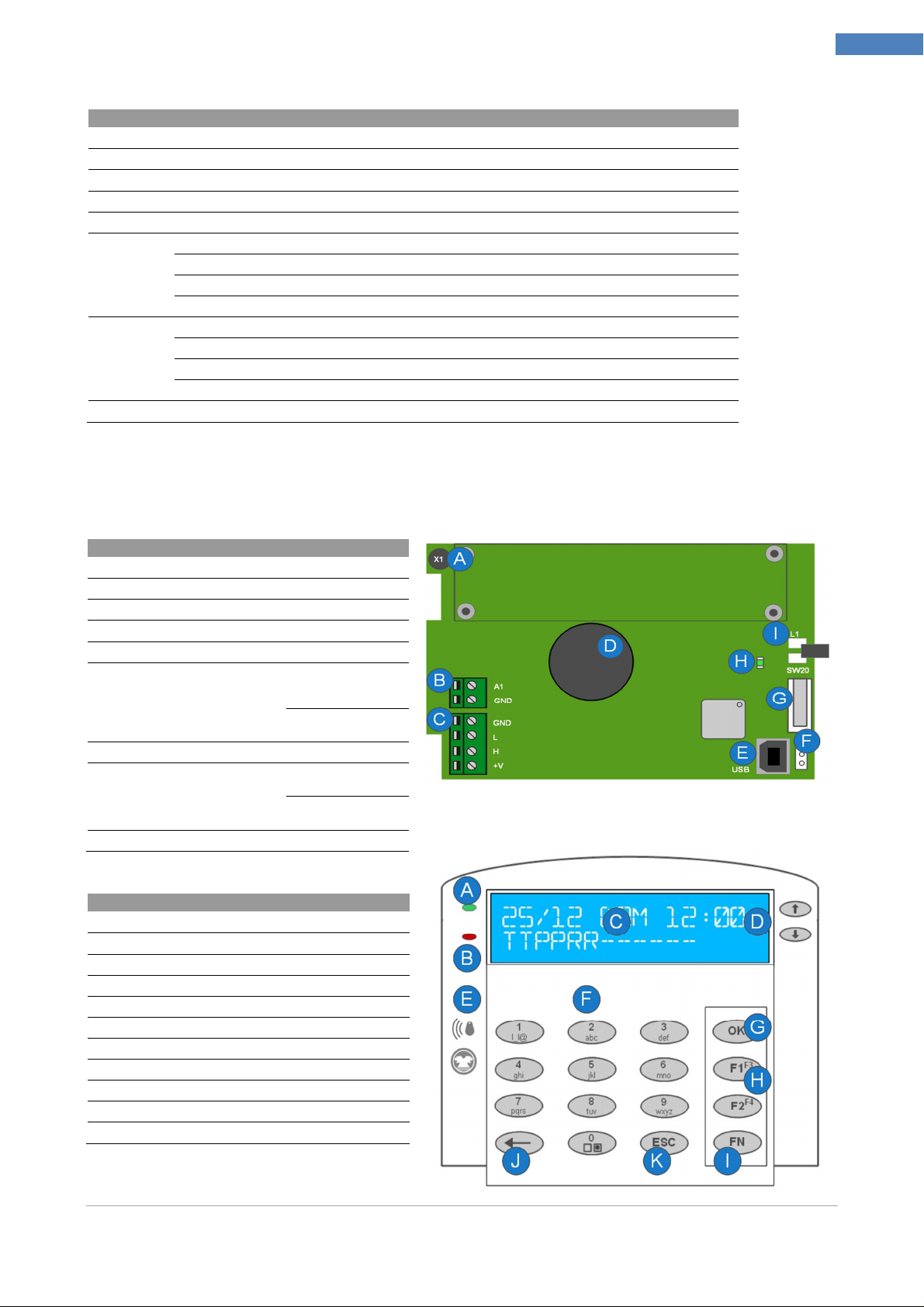

A Power supply connection terminals

B Battery Contacts

C tamper

D tamper Thornproof

E Fast acting fuse (2A) of +12 V power supply line protection

F Relay 3 (RL3) 0.5A - 24VDC

G Fast fuse (2A) of protection

H Relay 2 (RL2) 3A - 24VDC

I Relay 1 (RL1) 3A - 24VDC

J USB connector (Programming, Update FW Monitor)

K Link LED USB cable connection

ON: cable plugged

Off: Power cord not plugged in

L Link LED PC Connection

On: correct connection

Off: driver not recognized on PC

M F1: Fast acting fuse (2A) the protection of the +12 V INPUTS

N,O Alternate Flashing

Led STATE: correct operation

Off-fault

P Fast fuse (2A) of protection

Q Reset Factory setting (See Appendix C)

R Internal BUS connector (only for GSM / GPRS)

Link LED USB cable connection ON: cable plugged

Off: Power cord not plugged in

Link LED PC Connection On: correct connection

Off: driver not recognized on PC

Alternate Flashing Led STATE: correct operation

Off-fault

Installer Manual Microvideo srl www.microvideo.eu

Chapter 2 –Modules Description

Section

Conne

ctor SY810

SY820

SY820

RL3 NA,COM,NC Free connectors of the relay 3

+12V Power Connector 12V auxiliary

RL2 NA,COM,NC Free terminals of Relay 2

GND Power Supply Ground Connector

RL1 NA,COM,NC Relay 1 Free connectors

AUX OC1, OC2 Open Collector Connectors

OFF Terminal State System

24h 24h Input

GND Power Supply Ground Connector

ZONES A8, A7, A6, A5 Input connectors of the 5-6-7-8 areas

+12V, GND Auxiliary Power and Ground connectors

A4, A3, A2, A1 Input connectors of the 1-2-3-4 areas

+12V, GND Auxiliary Power and Ground Connectors

BUS1 +V, H, L, GND CAN Bus Connectors

Keyboard (Mod. SY820)

9

A Microphone capsule (Listening ambient)

B Input Connector A1

C Connector CAN Bus

D speaker

E USB connector (Programming, Log, Monitor Zone)

F Exclusion Tamper Snatch

Closed: EXCLUDED tamper

Open: tamper ENABLED

G Snatch connector

H Led Link USB On: USB

cable included

Off USB cable not

connected

I Proximity key reader

Exclusion Tamper

Snatch Closed:

EXCLUDED tamper

Open: tamper

ENABLED

Led Link USB On: USB

cable included

Off USB cable not

connected

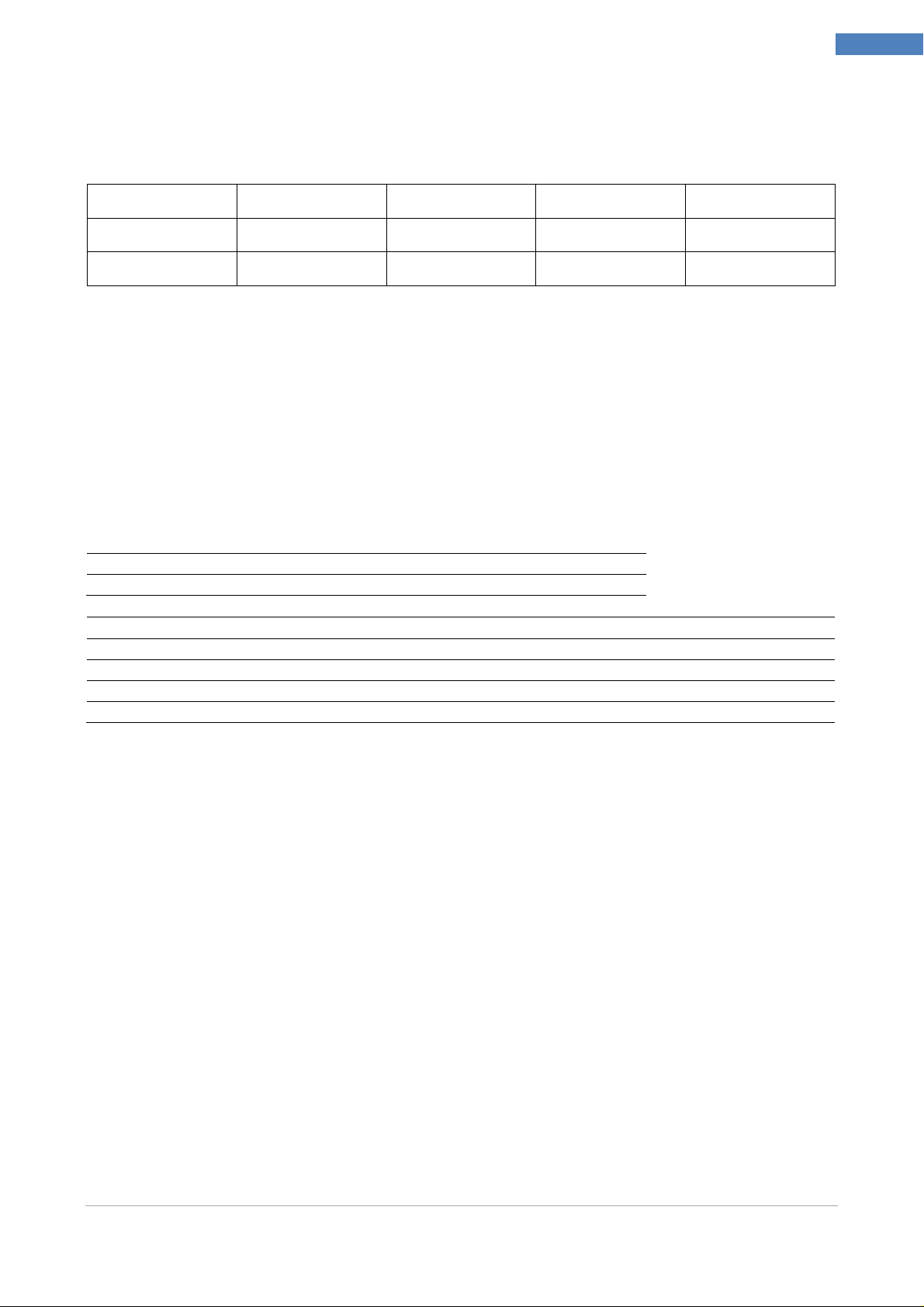

A LED SIGNALS

B LED Status System

C Display

D Arrow keys to scroll through the menus

E Location Proximity Reader

F Numeric keypad for entering the parameters

G Ok button

H Macro keys (F1, F2, F3, F4)

I Function button to select F3 and F4 macro

J DEL key

K ESC key

Installer Manual Microvideo srl www.microvideo.eu

LED

Chapter 2 –Modules Description

Off Slow Flashing Fast Flashing On

10

Led SIGNALS

(red led)

Led STATE

(green led)

Proper operation of the

system

Disarmed At least one inserting open

Alarm Low 220 V network Diagnostics Alarm (Areas,

area

Tamper, Modules)

--- At least ona alarmed area

DISPLAY

The display is composed of two lines with large characters for a very easily reading.

The first line contains informations of the date, day of the week and time set in the system,

and the second line always indicate the status of all areas of the system.

Depending on the model of Control Panel, the first few characters of the second line

represent the areas and in every position a symbol indicates the status of the

corresponding area.

SY810 12 Areas managed by the system 12 characters representing areas Status

SY800 8 Areas managed by the system 8 characters representing areas Status

AREA STATUS Description

T TOTAL All The Zones associated to the area are armed

P PARTIAL At least one zone in the area was not armed

- NOT CONFIGURED The zone has NO area associated

R REST All areas

DIRECTIONAL KEYS

The directional keys allow you to scroll up and down menu appear in the display

The arrow keys are displayed on the keyboard macro .

If a valid code is entered, using the arrow keys you can scroll through the menu and

pressing ok you can access the menu / parameter selected

INTEGRATED PROXIMITY READER

The SY820 keyboard has a built-in proximity reader . Approaching the key on the left side

of the keyboard, next to the graphic indication , if the key is properly configured, it

activates the display on the 4 macro associated with the reader and the one macro

associated with the key. When you remove the key , the System runs the macro you see

on the display in that moment.

NUMERIC KEYPAD

Using the numeric keypad , you can enter the value of all the parameters and descriptions.

In addition, through the 0 button , you can select / deselect the areas of belonging in their

own menu.

Installer Manual Microvideo srl www.microvideo.eu

Chapter 2 –Modules Description

SY860

Report

LED D1

DELETE BUTTON

The Delete key erases the alphanumeric characters entering descriptions and parameters.

ESC KEY

The esc key is used to return to the previous menu, moreover if you are modifying a

parameter by pressing the esc key you return to previous menu without saving the

changes of the parameter.

MACRO FUNCTION KEYS

The shortcut keys allow macros to run

If you do not enter a Master / User Code, when you press a shortcut key, YOU RUN THE

RELATIVE macros associated with the keyboard

If you authenticate by code, pressing the shortcut keys you run the macro associated with

the user.

The execution of the macro is subject to various types of confirmation, depending on the

programming.

You can configure the execution of a macro, as immediate confirmation, ok button, code

11

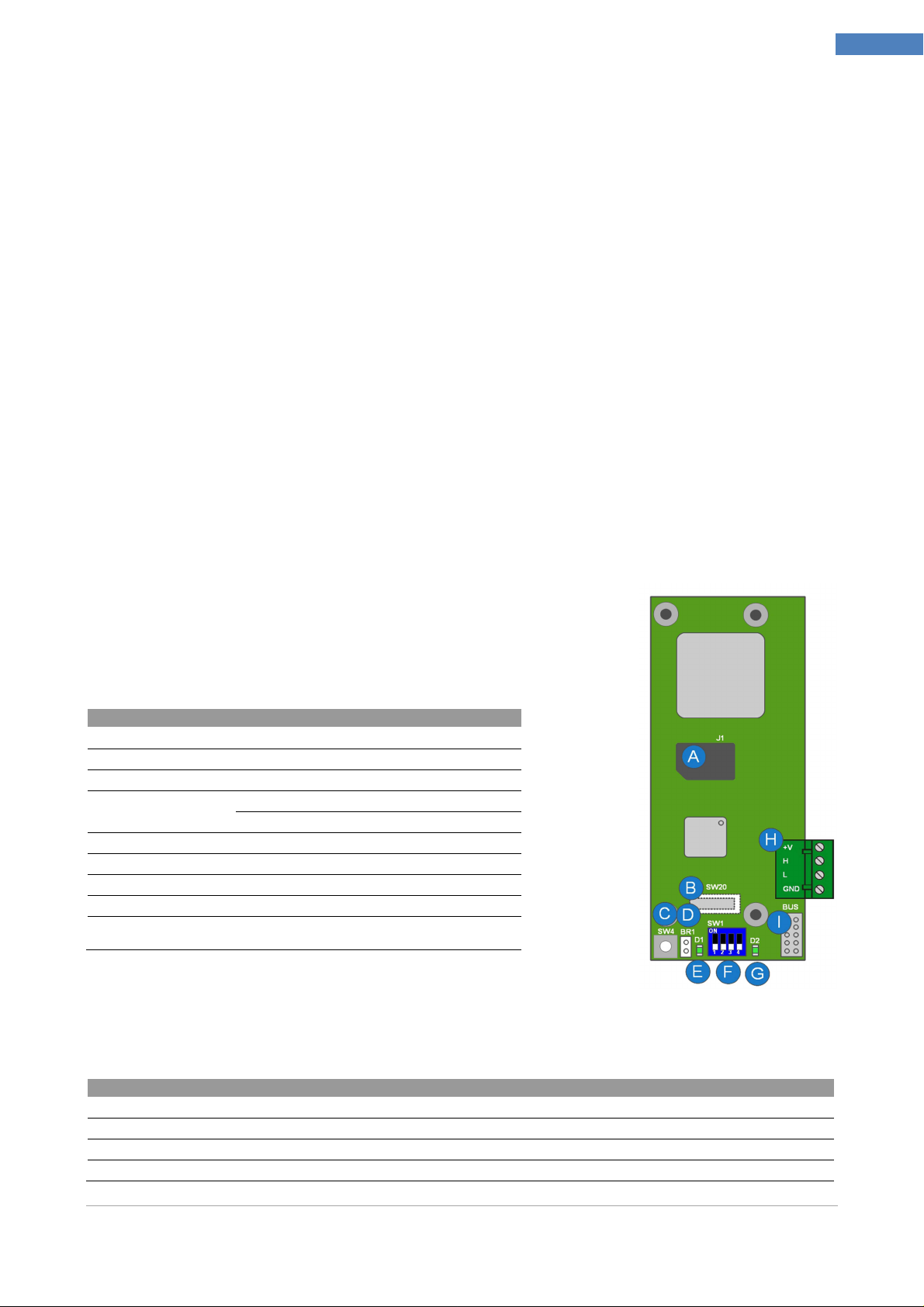

GSM / GPRS Module (Mod. SY860)

The module has two separate connectors to the bus allowing the

installation inside the box in the Control Panel or anywhere in the

plant by the CAN bus.

A Door SIM holder

B Tearproof tamper

C tamper

D Tamper Exclusion Closed Tamper: Tamper EXCLUDED

Open: tamper ENABLED

E STATUS LED

F Switch for the configuration ID (future use)

G STATUS LED

H Outside Bus for the connection of the module

I Interior Bus (Direct) to connect module when it is installed in the Control

LED D1 Description:

D1 is the GSM network:

Panel box

OFF Module not working

64ms On/ 800ms Off Module is not connected to the network

64ms On/ 3000ms Off Module properly connected to the network

64ms On/ 300ms Off GPRS connection is established

Installer Manual Microvideo srl www.microvideo.eu

Chapter 2 –Modules Description

Report

LED D2

Rif SY840

OFF No Faults

3 quick flashes at the boot

(100ms On /100ms Off x 3 times at the boot)

100ms On /300ms Off x 3 every 3 sec

100ms On /300ms Off x 2 every 3 sec CAN BUS communication error

End initialization module

SIM900-MCU communication error

Setting the Dip-Switch

We need the dip-switch for future use, so actually it must be configured as in the figure

below:

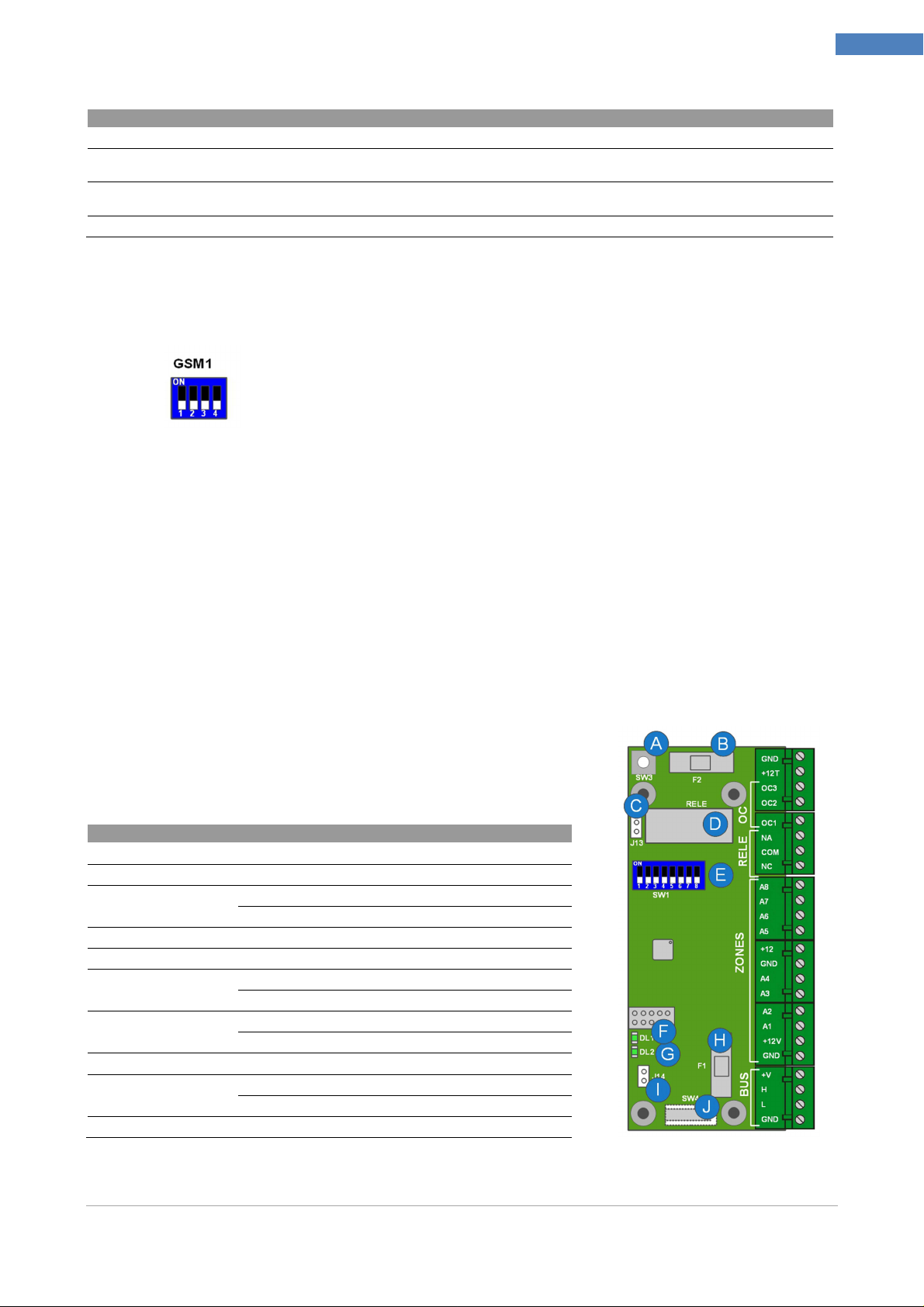

Expansion Module (Mod. SY840)

The expansion module allows to extend the number of inputs and outputs that the system

can handle.

The model SY840 has 8 inputs, 1 relay, and 3 open collectors. Equipped with tamper

protection that can be turned off as needed by easy tamper.

All inputs of the expansion can be configured as:

- NO, NO Balanced

- NC, NC WB, NC Double Bil Triple Bil

- Blinds

- InsImpImp

- InsImpLiv

All outputs:

- FIXED Output

- SIREN Output

- PULSE Output

12

A Tearproof Tamper

B F2: Fuse rapid (2A) to protect the net +12 T outputs

C Tamper Exclusion OFF: EXCLUDED tamper

ON: ENABLED tamper

D Relay: 3A - 24VDC

E Switch for ID configuration

F StatusLED Flashing: Corretto funzionamento

Off: anomalia

G Power LED On: module has power

Off : fault

H F1: rapid fuse (2A) to protect lines +12v of inputs

I Tearproof

Tamper Exclusion

J Tearproof Tamper

Off: excluded tamper

On: enabled tamper

Installer Manual Microvideo srl www.microvideo.eu

Chapter 2 –Modules Description

SY825

SY825

Expansion 1

Expansion

2

Expansion

3 Expansion

4 Expansion

5

Expansion

6

Expansion

7

Reader 1 Reader 2

Reader 3

Reader 4 Reader 5 Reader 6 Reader 7 Reader 8

Reader 1 Reader 2

Reader 3

Reader 4 Reader 5 Reader 6 Reader 7 Reader 8

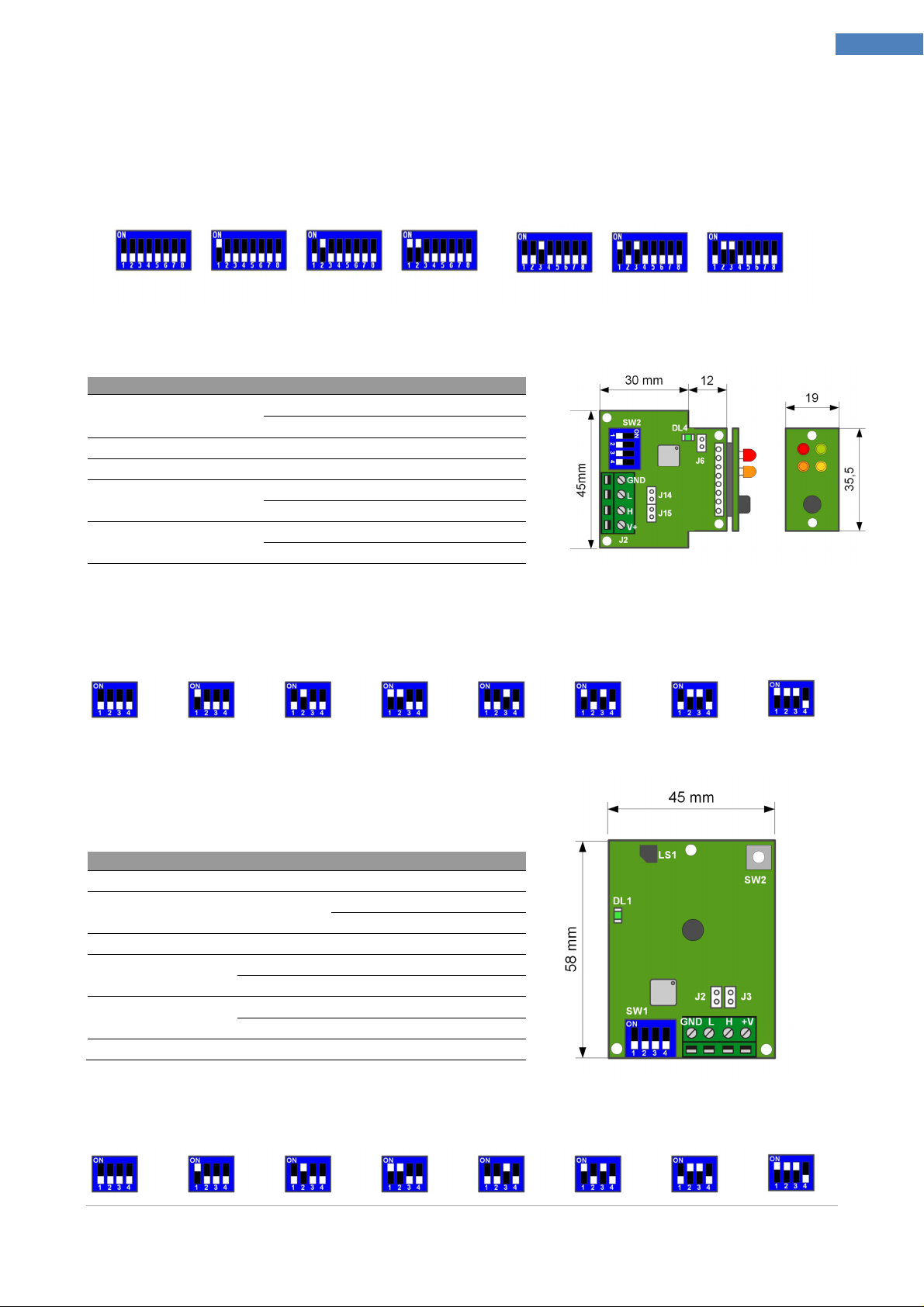

It’s important to correctly configure the switch identifying the expansion module.

Depending on the number of expansions in the system, it is essential to configure the

switch as in the following figures

Inserter Jack Module (Mod. SY825)

13

J6 Tearproof Tamper

SW2 Dip-Switch per la configurazione dell'ID

J2 Bus System Connector (Can Bus)

J14-J15

DL4

End line Jumper

Status Led

Chiuso: tamper ESCLUSO

Aperto: tamper ABILITATO

Off: Inserted Jumper

On: NOT Inserted Jumper

Flashing: Correct function

Off: Fault

Configuration of dip switch for ID assignment

Wall Inserter Module (Mod. SY826)

LS1 Signal Buzzer

SW2 Tamper

Bus System Connector (Can Bus)

J2-J3 End line Jumper Off: Inserted Jumper

DL1

SW1 Dip Switch for ID Configuration

Status Led

On: NOT Inserted Jumper

Flashing: Correct function

Off: Fault

Pressed = Rest

Released = Alarm

Configuration of dip switch for ID assignment

Installer Manual Microvideo srl www.microvideo.eu

SY881

SY930

LAN Module (Mod. SY881)

Chapter 2 –Modules Description

14

SW2

J3-J4

JP1 Jumper By-Passing tearproof tamper

DL3 Future use

DL2 Led di stato Lampeggiante = corretto funzionamento

F2 Fusibile Protezione (uso futuro)

SW1 Tamper

JP2 Jumper By-Passing tamper

Tamper AntiStrappo

End line Jumper

Premuto = Riposo

Rilasciato = Allarme

Off: Inserted Jumper

On: NOT Inserted Jumper

Off = DISABLED Tamper

On = ENABLED Tamper

Pressed = Rest

Released = Alarm

Off = DISABLED Tamper

On = ENABLED Tamper

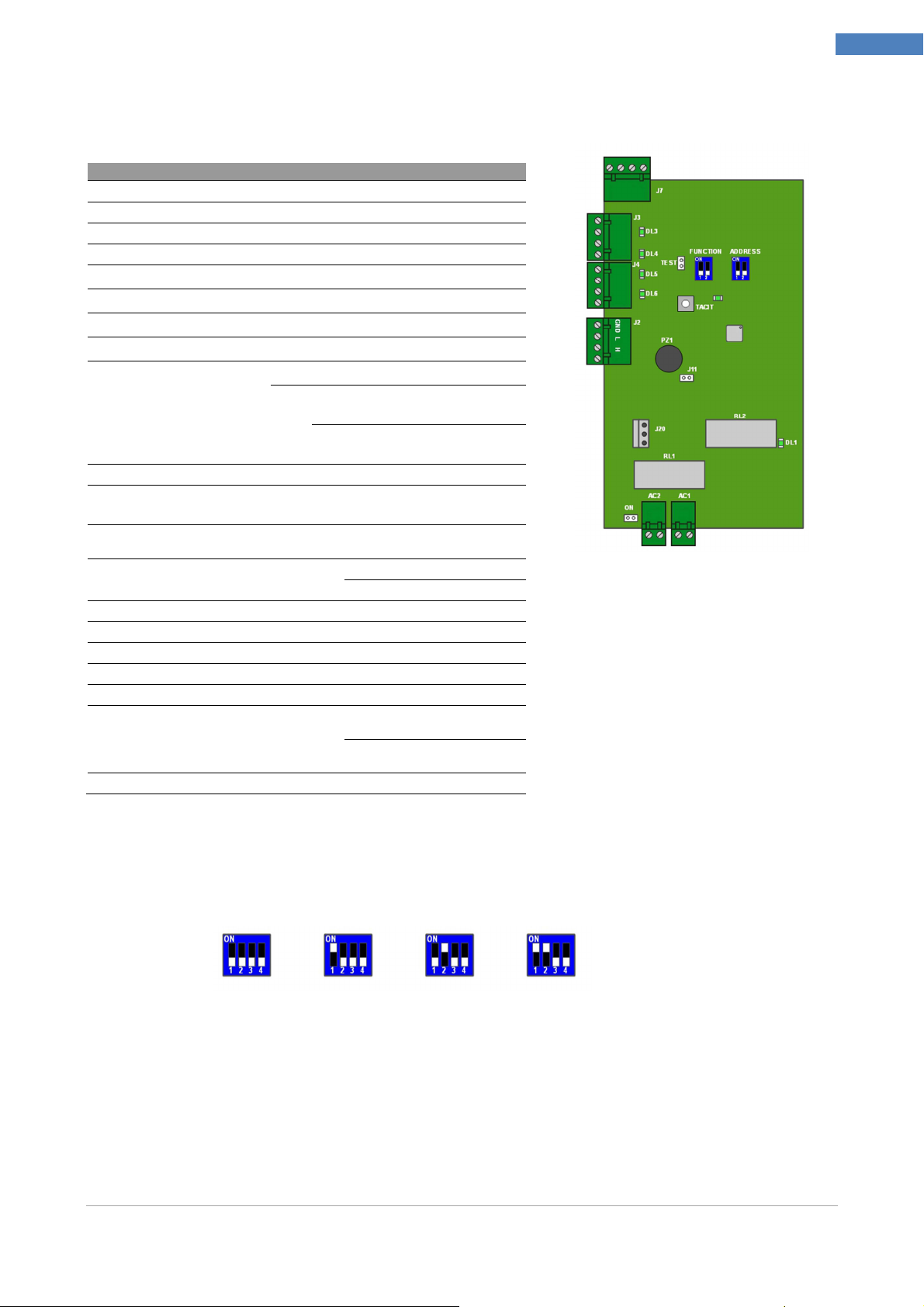

BUS Splitter (Mod. SY930)

J8 System BUS Connector (Can Bus)

JP1-JP2 CAN Bus End line Jumpers

SW2 Dip-switch for ID configuration

J7 System BUS Connector (Can Bus)

DL1 Status Led Flashing = correct function

DL2 Report Buzzer

Off: Inserted Jumper

On: NOT Inserted Jumper

Dip Switch Configuration for ID assignment

ID1 ID2 ID3 ID4

Installer Manual Microvideo srl www.microvideo.eu

WALL 4N

-8N

DVR WALL 4N-8N

J7 Bus connectionIRBox

J3 Channels 1 and 2 for camera supply

J4 Channels 3 and 4 for camera supply

J2 SYNERGY BUS connector

DL3

DL4

DL5

DL6

FUNCTION

ADDRESS Dip-switch for ID configuration

TEST

TACIT

J11 Jumper excluding Buzzer

PZ1 Buzzer reporting alarms

J20 Power supply jack for central unit synergy

DL1 Presence of electrical network

AC1 Power Connector

AC2 Power Connector

ON

DL2 Status Led flashing = correct function

Fuse status line 1

Fuse status line 2

Fuse status line 3

Fuse status line 4

SW-1: Future use

Function Switch

Puts the card in "test mode" mode in which the alarms do not generate

alarms on the alarm relay or buzzer

Temporary Silencing of the buzzer, canceled by closing and reopening

the door tamper

Jumper supplying DVR and

Cameras

ON → Disable recording and general

alarm, excluding the relay and the Buzzer

SW-2:

OFF → Enable recording and general

alarm, including the relay and buzzer

Close = Excluded Buzzer

Open = Active Buzzer

Closed = DVR and Cameras

powered

Open = DVR and Cameras not

powered

Chapter 2 –Modules Description

15

Dip Switch Configuration for ID assignment

ID1 ID2 ID3 ID4

Installer Manual Microvideo srl www.microvideo.eu

SY910

SY920

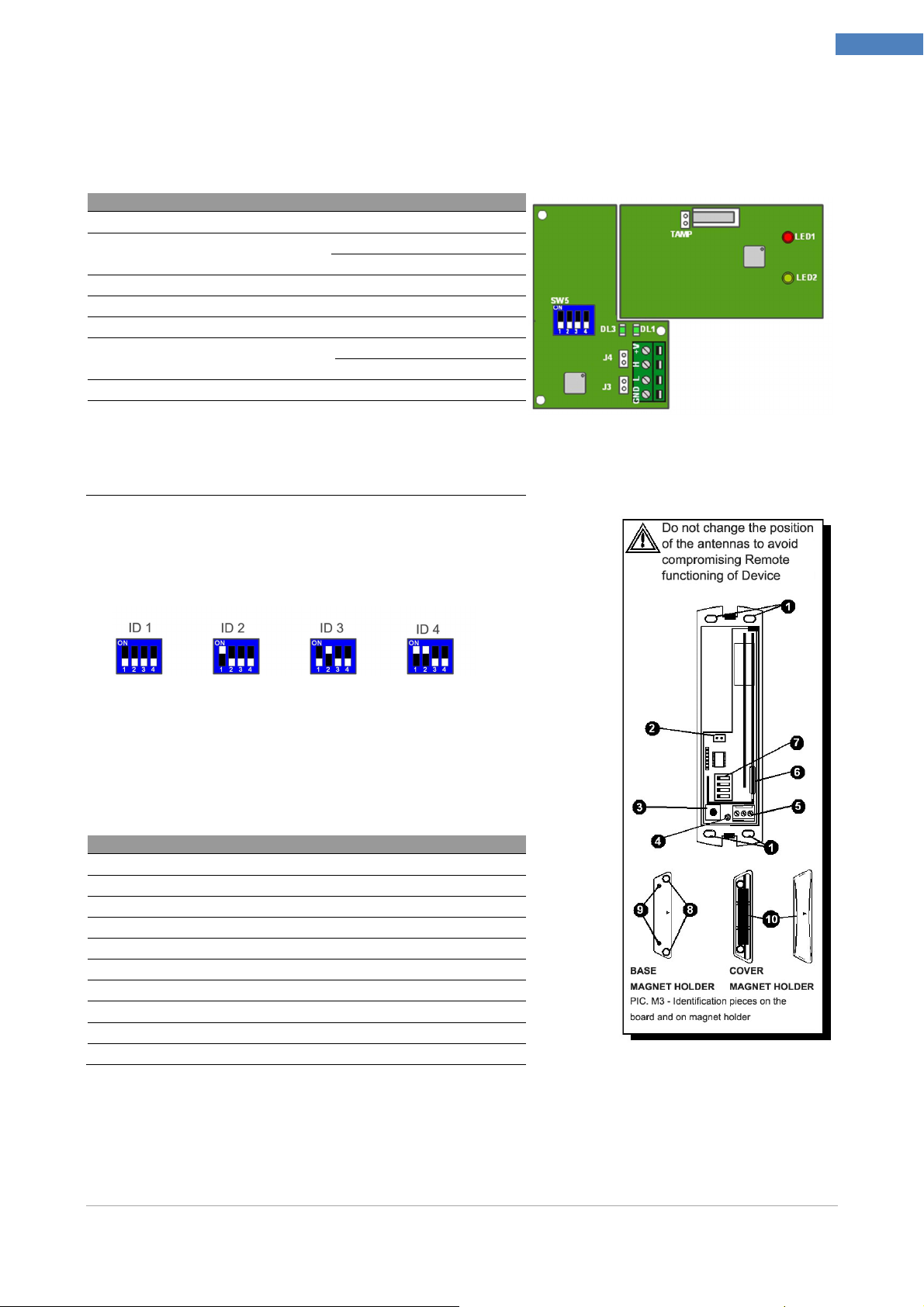

Radio Receiver Module (mod. SY910)

System BUS connector (Can Bus)

JP3-JP4 CAN Bus end line jumpers

SW5 Dip-switch for ID configuration

DL3 Status Led Flashing = correct function

DL1 Future use (Not used)

TAMP Jumper By-Passing tamper

LED1 Status Led flashing = correct function

Led Reception:

LED2

Flashes every time it receives a

communication from a remote control / radio

sensor

Chiuso = terminazioni inserite

Aperto = terminazioni NON inserite

Off = ENABLED Tamper

On = DISABLED Tamper

Chapter 2 –Modules Description

16

Dip Switch Configuration for ID assignment

Radio Magnetic Contact Module (mod. SY920)

1 Holes for fixing screws

2 Connector Battery 3.6 V 2.4 Ah

3 tamper

4 Report LED: lights whenever the module sends a message

5 Terminal block for connecting auxiliary sensors

6 Reed Contact

7 Dip-Switches programming functions

8 Holes for base fixing screws

9 Pegs closing the magnet holder

10 Magnet Holder Lid with magnet

Installer Manual Microvideo srl www.microvideo.eu

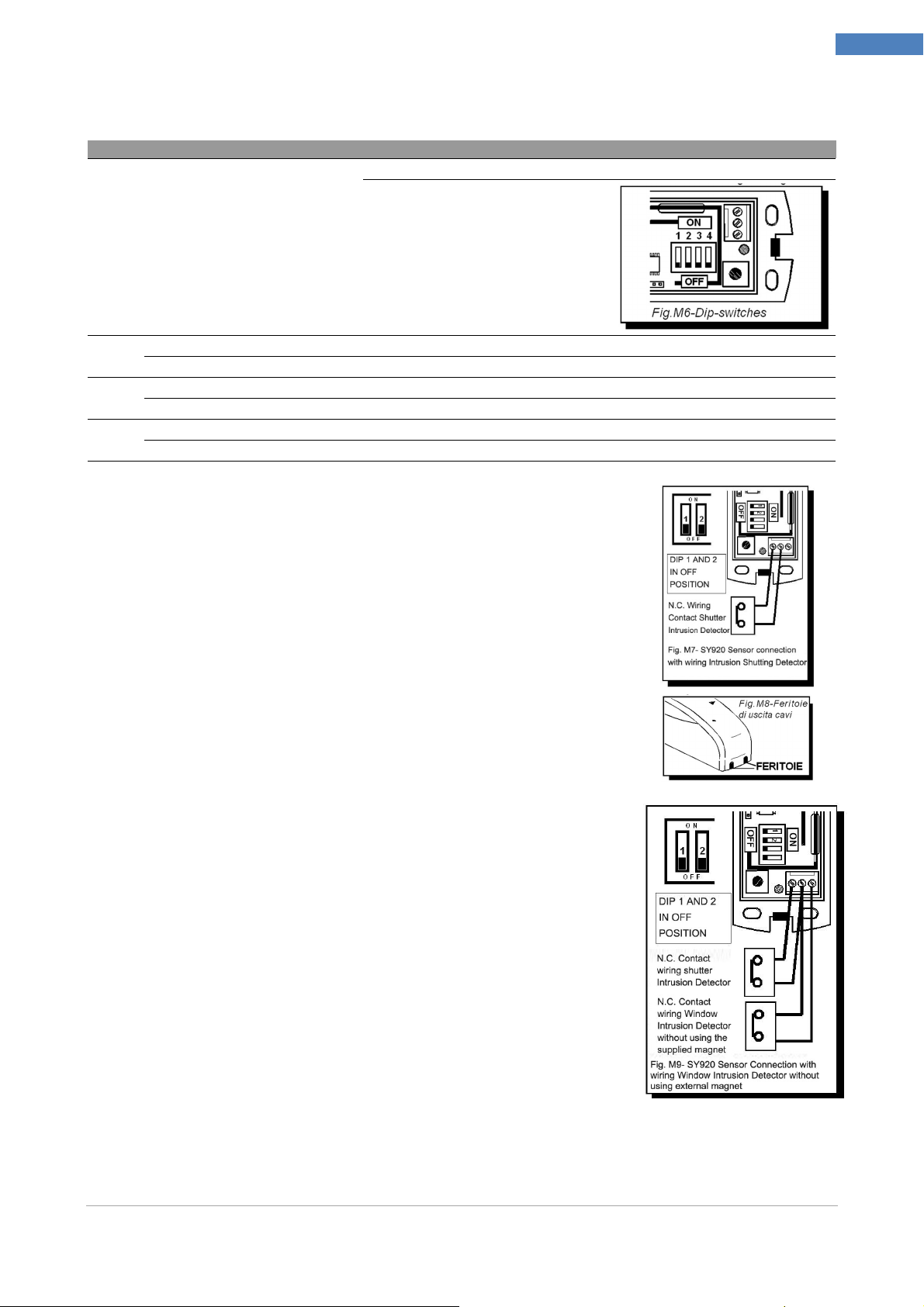

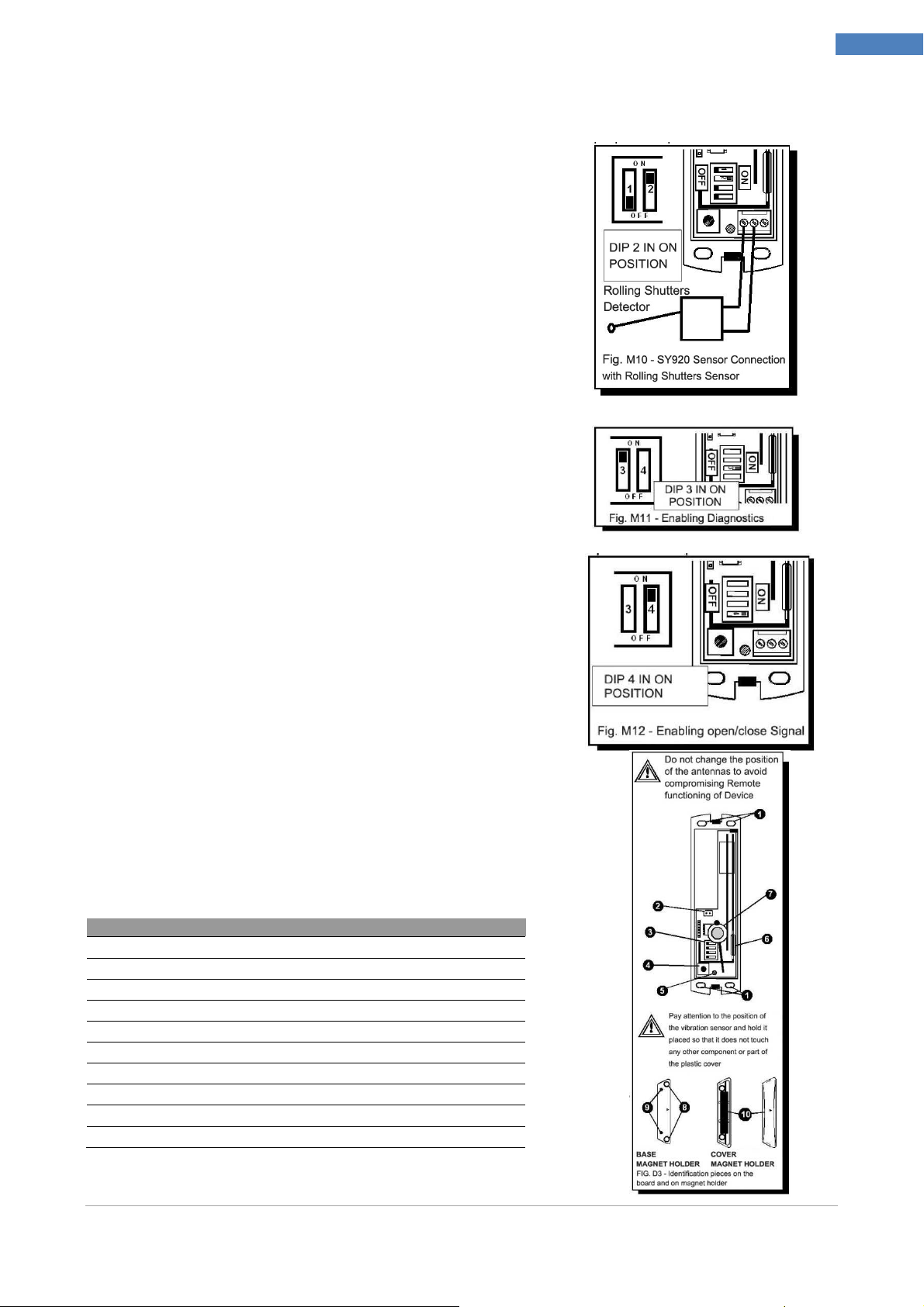

Dip-Switch

- SY920

Dip Switch Configuration

DIP n°1 Use only if dip number 2 is ON

Chapter 2 –Modules Description

OFF: medium sensibility of the pulse counter

ON: max sensibility of the pulse counter

17

DIP n°2

DIP n°3

DIP n°4

OFF: connection to the terminal block of a wire N.C.contact

ON: connection to the terminal block of a wire detector for for roller blinds (roller shutter protection). The sensor operates as pulse counter

OFF: supervision disabled

ON: supervision enabled

OFF: alert opening / closing disabled

ON: alert opening / closing enabled

MAGNET + NC Configuration

Connect the NC contact to the terminal block and make sure that

the dip switches # 1 and # 2 are in the OFF position.

WARNING! The device is only intended for connection to low

voltage safety. The connection to circuits with dangerous voltage

may cause danger.

For the cables, you can remove the preset forms provided on the lid

with a cutter, as shown in Figure M8.

N.B. You can connect multiple NC contacts in series with a single

sensor SY920. In this case, the control panel will not be able to

identify which of the NC contacts caused alarm.

NC + NC Configuration

You can connect an NC wired contact as an alternative to reed

contact provided on the device.

Connect the contact directly to the terminal block as shown in

Figure M9.

WARNING! In this case, DO NOT use the supplied external

magnet.

Installer Manual Microvideo srl www.microvideo.eu

Chapter 2 –Modules Description

SY921

Configuration Magnet + Blinds

Connect the sensor to terminal block shutter and make

sure that dip switch # 2 is in the ON position to enable the

counter function.

WARNING! The device is only intended for connection to

low voltage safety. The connection to circuits with

dangerous voltage may cause danger.

N.B. Connect only one sensor shutter module SY920.

Diagnostics Function

If enabled by DIP switch No. 3, on the ON position, the

sensor transmits a signal every four hours of attendance at

Control Panel.

18

Report Open/Close Magnet/NC

If enabled by DIP switch No. 4, the sensor transmits to the

Control Panel each change of state of the Magnet:

example from the closed window to the open window and

conversely. Similarly for the wired NC contact connected

to the clamps, of course with the dip switch No. 2 in the

OFF position.

Inertial Radio Module (mod. SY921)

1 Holes for fixing screws

2 Connector Battery 3.6 V 2.4 Ah

3 Setup functions Dip-Switches

4 Tamper

5 Reporting Led

6 Reed Contact

7 Vibration Sensor

8 Holes for fixing screws of the base

9 Pegs closing the magnet holder

10 Magnet Holder Lid with magnet

Installer Manual Microvideo srl www.microvideo.eu

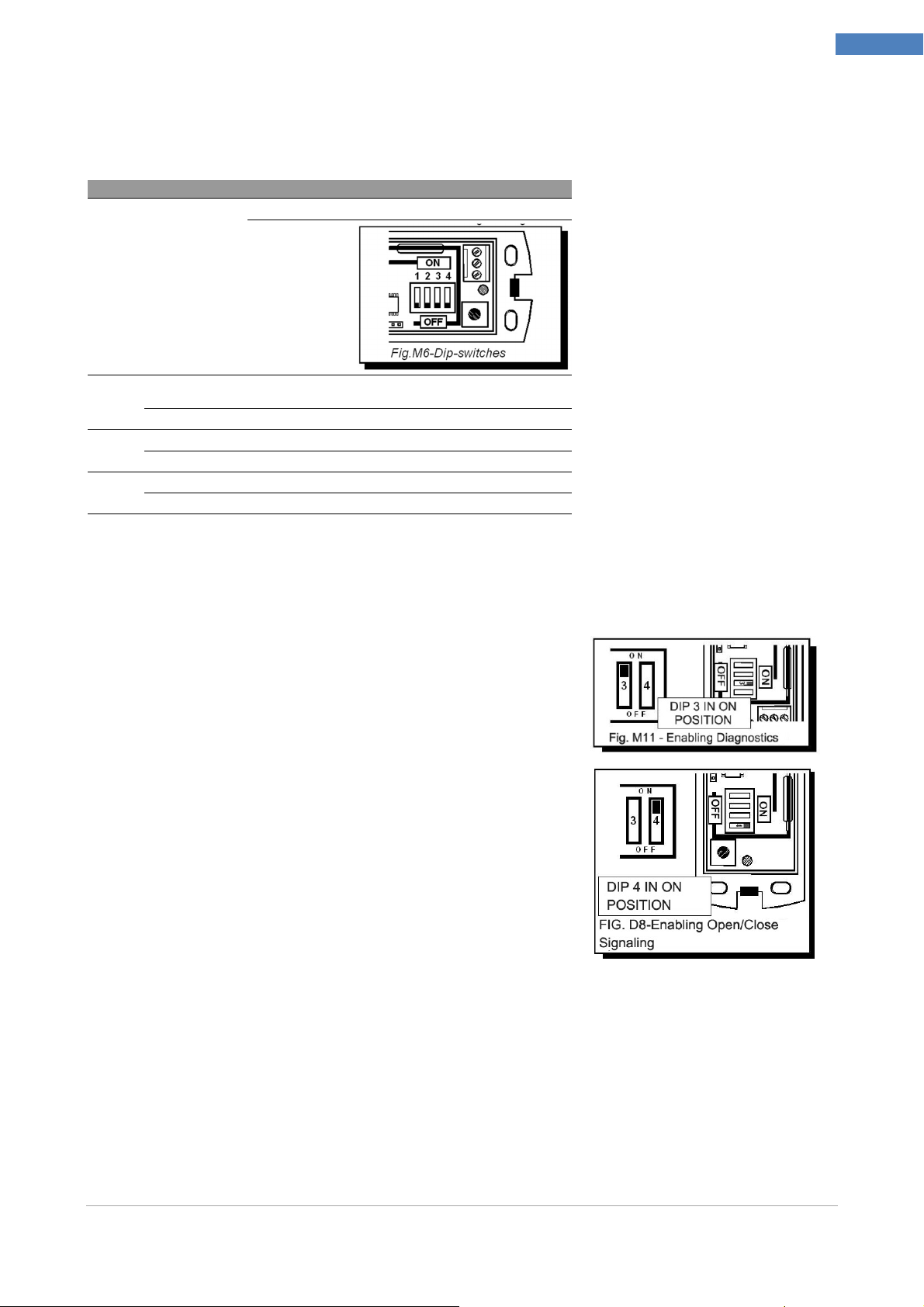

Dip-Switch

- SY921

Dip Switch Configuration

OFF: Average sensitivity of the vibration sensor

ON: max

sensitivity of the

vibration sensor

DIP n°1

DIP n°2

DIP n°3

DIP n°4

Use only if dip n.2

is in pos. ON

OFF: Vibration sensor disabled

ON: Vibration sensor activated

OFF: Supervision disabled

ON: Supervision enabled

OFF: Indication open / close disabled

ON: Indication open / close enabled

Chapter 2 –Modules Description

19

Supervision Function

If enabled by DIP switch No. 3, on the ON position, the

sensor transmits a signal every four hours of attendance at

Central.

Report Open / Close Magnet

If enabled by DIP switch No. 4, the sensor transmits to the central each change of state of

the Magnet: example from closed window to open window and so on.

Installer Manual Microvideo srl www.microvideo.eu

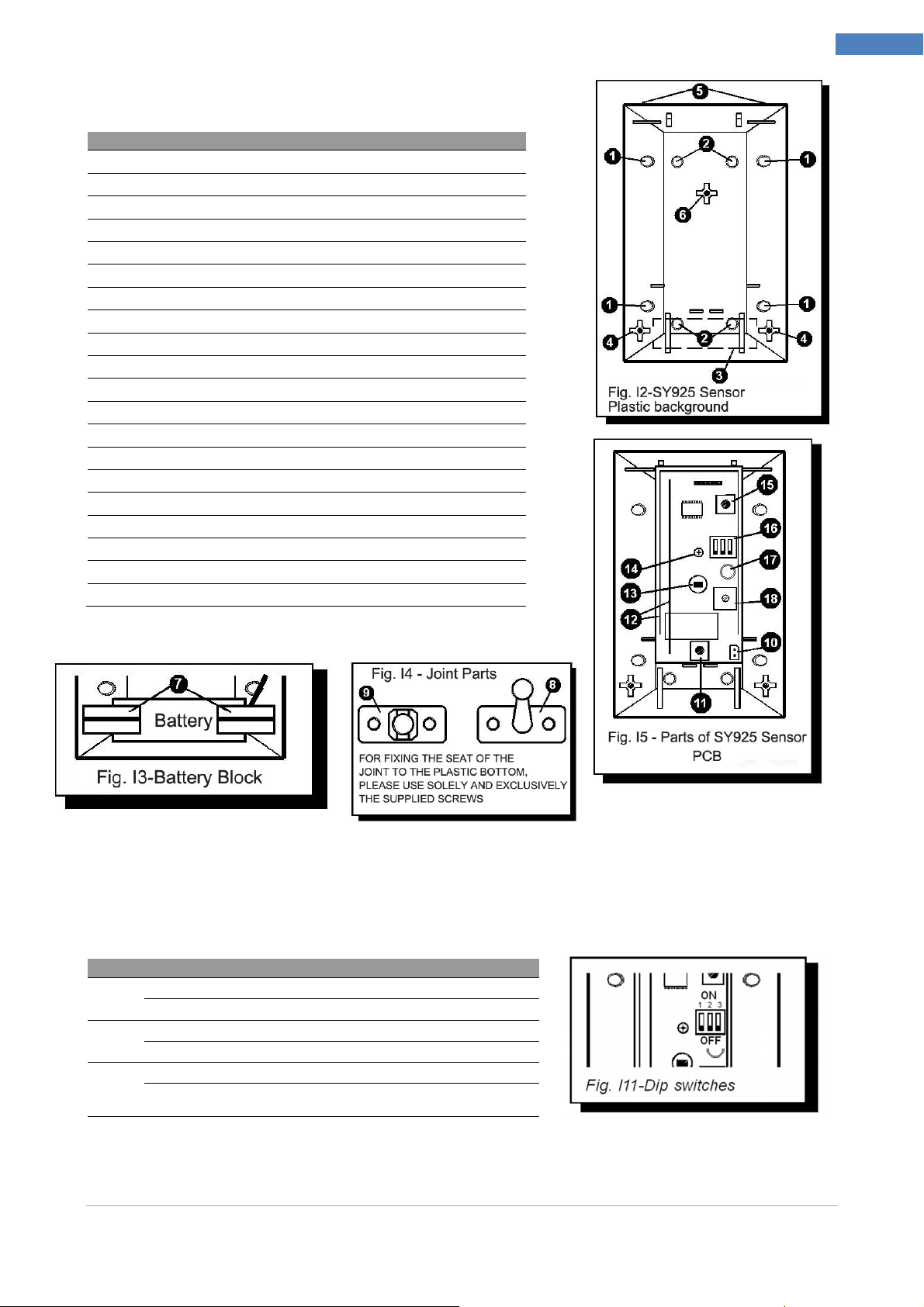

SY925

Dip-Switch

- SY921

Motion Sensor Module (mod. SY925)

1 Arrangement for fastening holes on the wall so the angular

2 Arrangement for wall mounting holes

3 Battery Seat

4 Holes for insertion battery lockers

5 Holes for plastic cover fixing

6 Hole for circuits fixing screw

7 Plastic Stops battery locking (supplied)

8 Joint to fix on the wall

9 Swivel seat to be fixed to plastic background

10 3.6 V 2.4 Ah battery connector

11 Tamper with spring

12 Antennas

13 Pyroelectric Sensor

14 PCB Fixing Screws

15

16

17

18

19

20

Reset Button

Dip-Switches

Report Led

Sensitivity adjustment trimmer

Spring Seat tamper button

Plastic Cover Hooks

Chapter 2 –Modules Description

20

Dip Switch Configuration

DIP n°1

DIP n°2

DIP n°3

OFF: LED Warning Light off

ON: LED Warning Light on

OFF: Inhibition time between two readings always 5 sec.

ON: Inhibition time between detections 5 sec. For 1 hour, then 4 min.

OFF: Supervision disabled

ON: supervision enabled, the sensor transmits a presence signal every 4 hours

to control Panel

Installer Manual Microvideo srl www.microvideo.eu

Chapter 2 –Modules Description

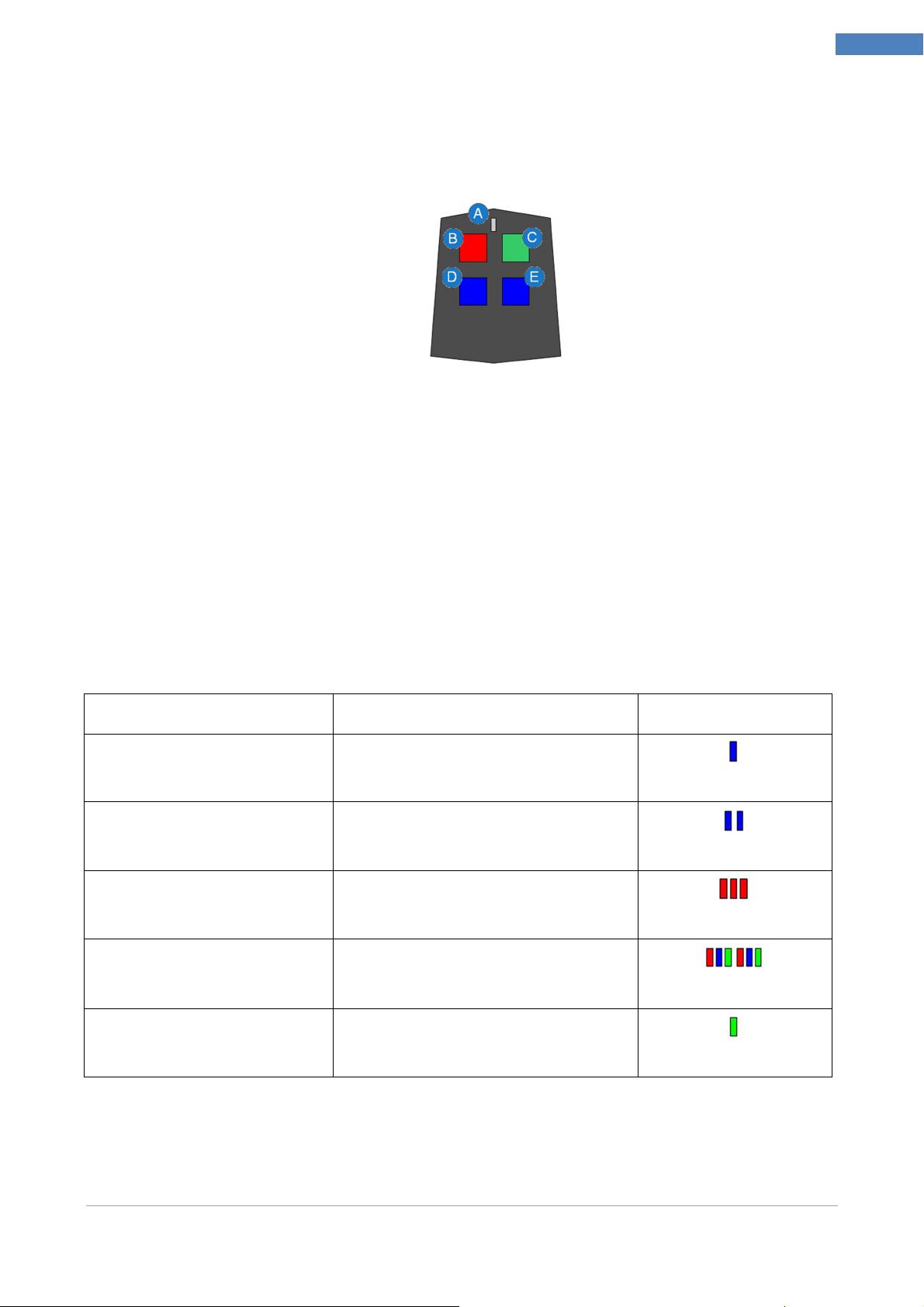

Radio Remote Control (mod. SY915)

The figure below shows a reproduction of the SY-915 Radio Remote Controls. Through the

Remote Control you can interact with the system and receive information on the status of

the loan with the LED. The Remote Control consists of 5 main parts:

A. Led Reporting

B. Red Button

C. Green Button

D. Blue Button 1

E. Blue Button 2

Interacting with Keys

Each key of remote control can be associated with 3 categories of actions:

Entries

Closings

21

Actions

To implement an action associated with a button you need to press the desired button and

wait until the LED flashes once RED light, this signal indicates that the remote control has

forwarded the request to perform the action to the Control Panel.

Once you press the button you have to wait for an answer from the Central always by the

flashing LED, the possible responses are:

Event Blink Sequence Example

Action Successfully

Performed

Action Executing failed 2 Blue

Arming System Completed

Successfully

Arming System Failed,

Zones in Alarm

1 Blue

3 Red

1 Green

1 Red - 1 Green - 1 Blue (3 times)

Disarming the Alarm System

Executed Successfully

N.B.

Each time you press a key (and the command is accepted by remote control through a

flashing red), you should always wait for the response from the plant, indicated by the

sequence of LEDs in the table above: if the answer is not displayed by the LED means

Installer Manual Microvideo srl www.microvideo.eu

1 Green

Loading...

Loading...