System Manual

The DrillMaster is designed to drive a Proportional Flow Control Valve using a PWM output. The Valve controls the ow in 1

to 3 Hydraulic Motors so it can be used with 1 to 3 Section Grain Drills or Fertilizer Applicators. All Motors are in series so they

all rotate at the same speed and apply the same amount of Seed or Fertilizer. Three toggle switches (top of Console) turn the

Sections o, bypassing a Motor, so the RPM of the remaining motors do not change.

The DrillMaster operates as a “ground speed based controller” using seed ow (from 1 of the 3 Sections) and a speed sensor

input to maintain a Target lbs/Acre of Seed as ground speed varies. An external Module is used to multiplex the Flow signal

so a dierent Section is used when a section is turned o. Going to Hold, turning all Sections O, or zero speed will stop auto

control and will also stop the PWM Valve drive if “Auto Shut O” is turned on (enabled). All Sections are automatically turned

o if the Speed goes to zero while in Auto mode. Seed ow is measured indirectly by measuring the Seed Drive Shaft RPM

instead of counting seed. It is assumed the Drill uses a one-point adjustable seed cup that is recognized as the most accurate

and trouble free available for a wide variety of agricultural seeds. DrillMaster also provides an early warning when Seed bins

are nearly empty by ashing a “FILL” message.

Toll Free in U.S. or Canada: (800) 328-9613 or (507) 257-3600

Fax: 507-257-3001

trakmail@micro-trak.com • www.micro-trak.com

P.O. Box 99

111 East LeRay Avenue

Eagle Lake, MN 56024-0099

© Copyright 2019

Micro-Trak Systems, Inc.

2

MicroTrak Systems, Inc.

Limited Warranty

MicroTrak Systems, Inc. (herein “Seller”) warrants to the original purchaser (herein “Buyer”) that, if any product or part of the

product (herein “Parts”) proves to be defective in material or workmanship, upon inspection and examination by Seller, within

three (3) years from the original dateofpurchase, and is returned to Seller with dated proofofpurchase, transportation

prepaid, within sixty (60) days after such defect is discovered, Seller will, at their option and sole discretion, either repair or

replace said part, except that the warranty for expendable Parts, including but not limited to, light bulbs and batteries shall

be thirty (30) days from the original dateofpurchase; and except that the warranty for Parts manufactured by someone

other than the Seller, including but not limited to, shutoff valves, control (servo) valves, flowmeters, pressure sensors, pumps,

compressors, tanks and tank accessories, DGPS receivers and related repeater and base stations shall be one (1) year from the

original dateofpurchase; and except that the warranty for Parts manufactured by someone other than the Seller, including

but not limited to, memory cards and drives, mapping software, terminals, PC’s, laptops, tablets and other computer devices

shall be thirty (30) days from the original dateofpurchase. Any damage or failure to said part resulting from abuse, misuse,

neglect, accidental or improper installation or maintenance, unauthorized modification, use with other parts and/or products,

or attributable to acts of God, as determined solely by the Seller, will invalidate the warranty. Said part will not be considered

defective if it substantially fulfills the performance specification. Buyer shall be responsible for all maintenance services, if

any, all in strict accordance with the procedures outlined in the manual. The warranty does not include labor, installation,

replacement parts or repairs, delivery of replacement parts or repairs or time and travel. Said warranty is nontransferable.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES OF MERCHANTABILITY, FITNESS FOR

PURPOSE AND OF ANY OTHER TYPE, WHETHER EXPRESS OR IMPLIED. THE SELLER’S LIABILITY, WHETHER IN CONTRACT,

IN TORT, UNDER ANY WARRANTY, IN NEGLIGENCE OR OTHERWISE, SHALL NOT EXCEED THE RETURN OF THE AMOUNT

OF THE PURCHASE PRICE PAID, AND UNDER NO CIRCUMSTANCES SHALL THE SELLER BE LIABLE FOR SPECIAL, INDIRECT,

CONSEQUENTIAL, INCIDENTAL OR PUNITIVE DAMAGES. SELLER NEITHER ASSUMES NOR AUTHORIZES ANYONE TO ASSUME

FOR IT ANY OTHER OBLIGATION OR LIABILITY IN CONNECTION WITH SAID PART. NO ACTION, REGARDLESS OF FORM, ARISING

OUT OF THE TRANSACTIONS UNDER THIS AGREEMENT MAY BE BROUGHT MORE THAN ONE (1) YEAR AFTER THE CAUSE OF

ACTION HAS OCCURRED.

Buyer accepts these warranty terms and limitations unless the part is returned to Seller, via proper distribution channels and

approved return authorization, with dated proofofpurchase, transportation prepaid, within sixty (60) days from the dateof

purchase for refund of the purchase price.

Doc: MTS Warranty Statement_010119a Rev 2_01012019

MAIL and UPS:

Micro-Trak® Systems, Inc.

ATTN: Service Department

P.O. Box 99

111 East LeRay Avenue

Eagle Lake, MN 56024-0099

At Micro-Trak® Systems, we believe a product that delivers quality and performance at a reasonable cost is what is needed to

help today’s operator and the operator of the future compete in the world mar ket.

It is our goal to provide operators with a line of electronic equipment that will help build and maintain an efficient and

profitable operation that can be passed on to future generations.

We thank you for your purchase and hope that we can be of service to you in the future.

Micro-Trak® Systems, Inc.

3

Table of Contents

Micro-Trak Warranty ............................................................................................................................................................................. 3

Table of Contents .................................................................................................................................................................................. 4

Component Parts and Assembly Hardware ..................................................................................................................................... 5

DrillMaster System Layout - Mounted Single Section ...................................................................................................................6

DrillMaster Wiring Diagram - Mounted Single Section .................................................................................................................7

DrillMaster System Layout - Drawn Multi Section ..........................................................................................................................8

DrillMaster Wiring Diagram - Drawn Multi Section ........................................................................................................................9

DrillMaster Seed Rate Controllers ....................................................................................................................................................10

Installation ......................................................................................................................................................................................11-13

Mounting the Display Console ........................................................................................................................................................................ 11

Attaching the Power and Run/Hold Control Switches ........................................................................................................................... 11

Electrical Installation ........................................................................................................................................................................................... 12

Speed Sensor Options ........................................................................................................................................................................................ 12

Remote Run/Hold .................................................................................................................................................................................................13

Care and Maintenance .......................................................................................................................................................................13

DrillMaster Console Functions ..........................................................................................................................................................14

Calibration ......................................................................................................................................................................................15-18

Selecting Measurement Units .................................................................................................................................................................................. 15

Entering Calibration Values ........................................................................................................................................................................16-17

Factory-loaded Calibration Values ................................................................................................................................................................. 17

Speed Cal for Radar or GPS ...............................................................................................................................................................................18

Determining the Speed Cal .............................................................................................................................................................................. 18

“Special” Calibration .....................................................................................................................................................................19-21

“Special” Cal - Page 1 and Two Values ......................................................................................................................................................... 19

Factory-loaded “Special” Calibration Values .............................................................................................................................................. 19

Entering “Special” Calibration Values - Page 1 .......................................................................................................................................... 20

Entering “Special” Calibration Values - Page 2 .......................................................................................................................................... 21

Operation ........................................................................................................................................................................................22-26

Console Switches and Buttons ........................................................................................................................................................................ 22

Console Switches and Inputs ........................................................................................................................................................................... 23

General Information ............................................................................................................................................................................................ 24

Rotary Positions ....................................................................................................................................................................................................24

Resetting System Counters ...............................................................................................................................................................................25

Clearing System Counters ................................................................................................................................................................................. 26

Pre-Field System Checkout ...............................................................................................................................................................26

Troubleshooting ............................................................................................................................................................................27-30

Message/Warnings...............................................................................................................................................................................................27

General ..................................................................................................................................................................................................................... 28

Checking Individual Components ..................................................................................................................................................................29

Checking Console Inputs ...................................................................................................................................................................................30

Appendices .....................................................................................................................................................................................31-38

Appendix A: Fine Tuning Speed/Distance Calibration Value With Run/Hold Switch Kit Installed ....................................... 32

Appendix B: Cal Test Fine Tuning Calibration Values ............................................................................................................................ 33

Appendix C: Meter Cal Fine Tuning Calibration Values ........................................................................................................................ 34

Appendix D: Bin Level Sensor Kit Installation ........................................................................................................................................... 35

Appendix E: Radar Adapter Cables ............................................................................................................................................................... 36

Appendix F: Conversion Chart........................................................................................................................................................................37

Appendix G: Replacement Parts List ............................................................................................................................................................ 38

4

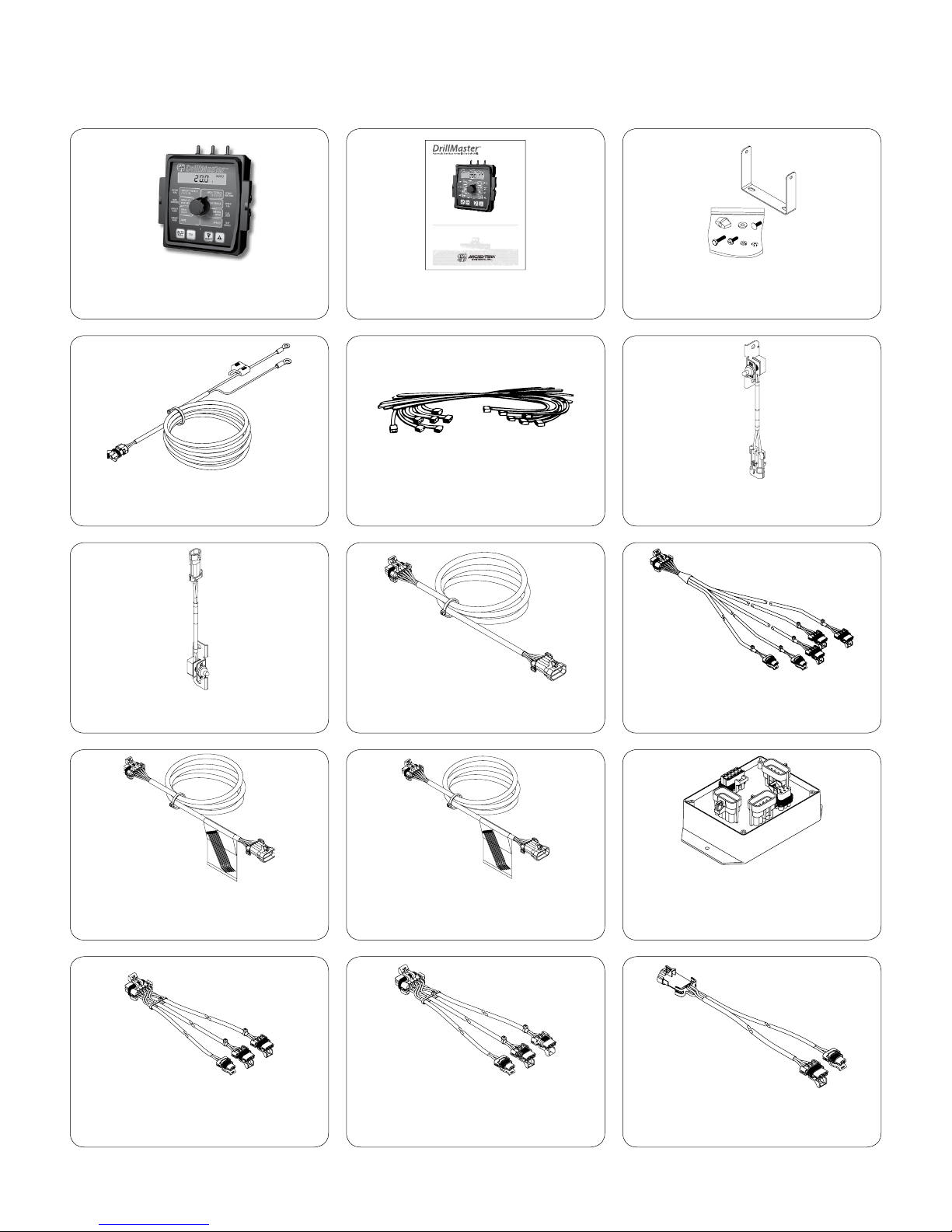

Component Parts and Assembly Hardware

Before beginning installation, check the carton contents for the following items:

DrillMaster Console

P/N 17899

Power Cable

P/N 14315

System Manual

System Manual

P/N 50318

14” Nylon cable ties (10)

P/N 12910

(2)

(2)

(2)

(2)

(2)

(2)

(2)

Console Mount Kit

P/N 13181

Run/Hold Switch

P/N 21778

Power Switch

P/N 21779

15’ Extension Cable

(Single Section)

P/N 13222

DrillMaster Cable

(Multi Sections 1 & 3)

P/N 17881

40’ 10-Pin

Extension Cable

P/N 17096

10’ Extension Cable

(SIngle & Multi Section)

P/N 13221

DrillMaster Cable

(Multi Section 2)

P/N 17882

DrillMaster Cable

(Single Section)

P/N 17894

DrillMaster Module

(Multi Section)

P/N 21612

DrillMaster Cable

(Multi Sect. PWM & R/H)

P/N 17883

5

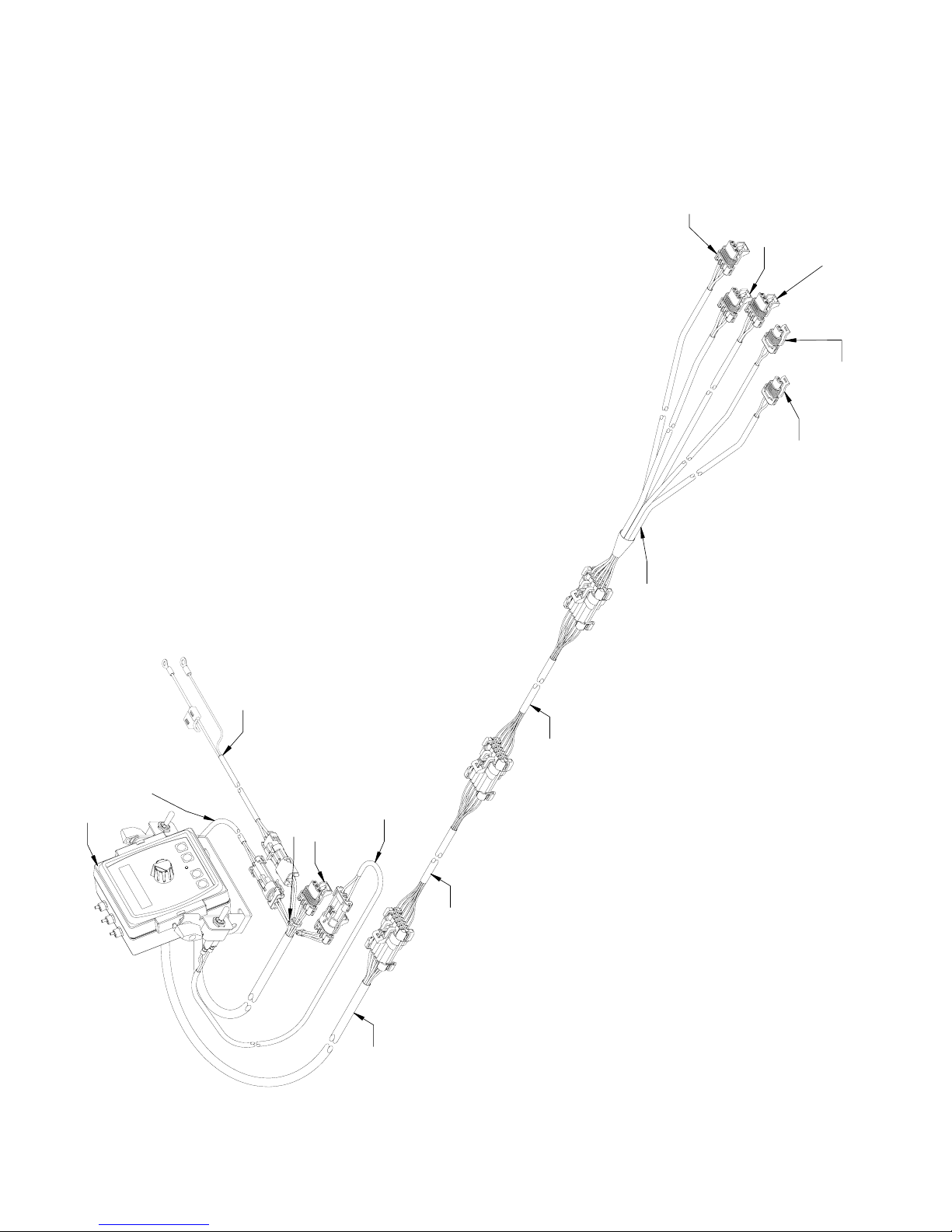

DrillMaster System Layout

Mounted Single Section

BIN LEVEL

SENSOR

REMOTE RUN/

HOLD SENSOR

SECTION 1 SEED

METER SENSOR

PWM CONTROL

VALVE

DRILLMASTER

CONSOLE

SECTION 1

ON/OFF VALVE

P/N 14315

P/N 17894 (10’)

P/N 21779

P/N 21778

YELLOW TIE

SPEED

P/N 13222 (15’)

P/N 13221 (10’)

P/N 21088

6

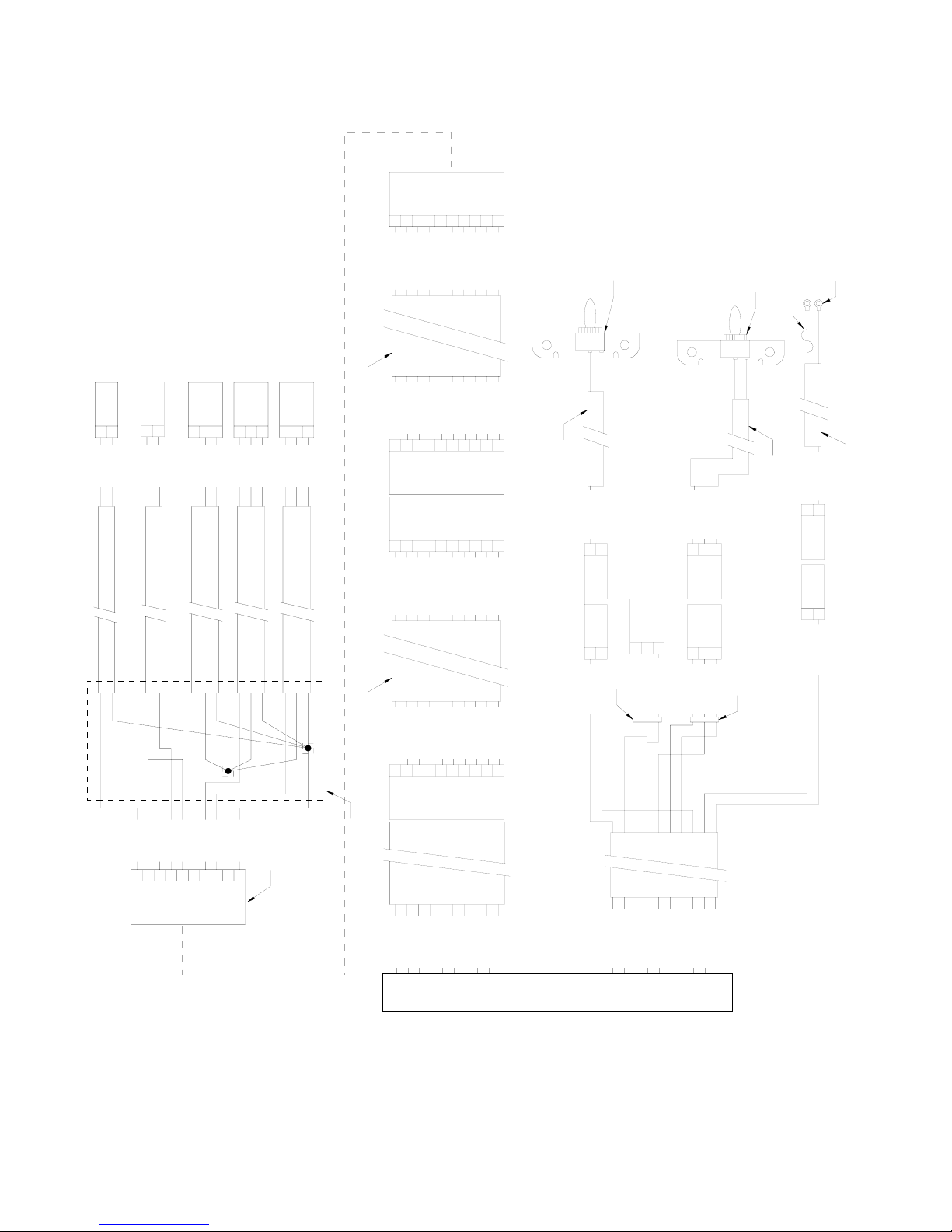

DrillMaster Wiring Diagram

POWER CABLE

TION 1 ON/OFF

TION 2 ON/OFF

TION 2 ON/OFF

RUN/HOLD SIGNA

SPEED GROUND

RUN/HOLD POWE

RUN/HOLD SIGNA

RUN/HOLD GROUND

Mounted Single Section

ABCDEDGHJ

10-PIN

M/P

SHROUD

K

SECTION 1

POPPET VALVE

SECTION 1 ON/OFF

GROUND

TOWER

2-PIN M/P

A

B

18 GA. RED

18 GA. BLK

120 IN.

PWM CONTROL VALVE

PWM -

PWM +

TOWER

2-PIN M/P

A

B

18 GA. BLK

18 GA. RED

120 IN.

SECTION 1 SEED

METER SENSOR

FLOW SIGNAL

+ VES

GROUND

M/P

3-PIN

TOWER

ABC

18 GA. RED

18 GA. WHT

18 GA. BLK

120 IN.

REMOTE RUN/HOLD

SENSOR

BIN LEVEL SENSOR

RUN/HOLD SIGNAL

+ VES

GROUND

BIN NEAR EMPTY SIGNAL

+ VES

GROUND

M/P

TOWER

18 GA. WHT

18 GA. BLK

120 IN.

M/P

3-PIN

ABC

18 GA. RED

18 GA. WHT

120 IN.

TOWER

18 GA. BLK

3-PIN

ABC

18 GA. RED

20 GA. BRN

20 GA. RED

20 GA. ORG

P/N 13221

20 GA. BRN

20 GA. RED

20 GA. ORG

ABCDEDGHJ

ABCDEDGHJ

20 GA. BRN

20 GA. RED

20 GA. ORG

20 GA. YEL

20 GA. GRN

20 GA. YEL

20 GA. GRN

10-PIN

10-PIN

20 GA. YEL

20 GA. GRN

20 GA. BLU

20 GA. VIO

20 GA. BLU

20 GA. VIO

M/P

TOWER

M/P

SHROUD

20 GA. BLU

20 GA. VIO

20 GA. GRY

20 GA. WHT

20 GA. GRY

20 GA. WHT

20 GA. GRY

20 GA. WHT

20 GA. BLK

20 GA. BLK

K

K

20 GA. BLK

P/N 21779

18 GA. RED

18 GA. BLK

A

B

SHROUD

2-PIN M/P

TOWER

2-PIN M/P

A

B

16 GA. BRN

20 GA. GRY

POWER SWITCH

5/16 IN. RING

RUN/HOLD SWITCH

CONN (2 PLCS)

10 A FUSE

FUSE HOLDER

14 GA. ORG

14 GA. BLU

P/N 21778

18 GA. RED

18 GA. BLK

ABC

SPEED

SHROUD

M/P

3-PIN

M/P

3-PIN

ABC

YELLOW TIE

16 GA. ORG

16 GA. RED

TOWER

16 GA. YEL

M/P

3-PIN

TOWER

ABC

20 GA. BLU

20 GA. GRN

20 GA. VIO

GRAY TIE

TOWER

2-PIN W/P

SHROUD

2-PIN W/P

16 GA. WHT

16 GA. BLK

P/N 14315

18 GA. RED

18 GA. RED

18 GA. BLK

18 GA. RED

18 GA. RED

18 GA. RED

18 GA. WHT

18 GA. BLK

ABCDEFGHJ

M/P

10-PIN

TOWER

P/N 17894

K

P/N 13221

HEAT SHRINK

20 GA. BRN

20 GA. RED

20 GA. ORG

20 GA. YEL

20 GA. GRN

20 GA. BLU

20 GA. VIO

20 GA. GRY

ABCDEDGHJ

M/P

10-PIN

TOWER

18 IN.

16 GA. BRN

16 GA. RED

16 GA. ORG

20 GA. YEL

20 GA. GRN

20 GA. BLU

20 GA. VIO

20 GA. GRY

DRILL MASTER CONSOLE

L

FLOW SIGNAL

PWM - SIGNAL

PWM + SIGNAL

SEC

SEC

SEC

BIN NEAR EMPTY SIGNAL

7

20 GA. WHT

20 GA. BLK

K

16 GA. WHT

16 GA. BLK

GROUND

+VES PROTECTED

18 IN.

16 GA. BRN

16 GA. RED

+VES

SPEED POWER

16 GA. ORG

20 GA. YEL

SPEED SIGNAL

20 GA. GRN

20 GA. BLU

20 GA. VIO

20 GA. GRY

L

R

SWITCHED VES

16 GA. WHT

16 GA. BLK

+VES

GROUND

DrillMaster System Layout

Drawn Multi Section

PWM VALVE

RIGHT SECTION

SEED METER

SENSOR

BIN LEVEL SENSOR

ON/OFF VALVE

360”

316”

366”

P/N 17881

P/N 14315

P/N 17883

34”

34”

120”

REMOTE RUN/HOLD

SENSOR

CENTER SECTION

SEED METER SENSOR

BIN LEVEL SENSOR

72”

120”

P/N 17882

ON/OFF VALVE

360”

SEED METER

LEFT SECTION

366”

316”

P/N 21612

SENSOR

ON/OFF VALVE

BIN LEVEL SENSOR

P/N 17881

P/N 17899

P/N 21779

YELLOW TIE

SPEED

P/N 21778

P/N 13221 (10’)

P/N 21088

P/N 17096 (40”)

8

DrillMaster Wiring Diagram

TION 1 ON/OFF

PWM + SIGNAL

RUN/HOLD SIGNA

BIN NEAR EMPT

SPEED GROUND

RUN/HOLD POWER

RUN/HOLD SIGNA

RUN/HOLD GROUND

Drawn Multi Section

FLOW SIGNAL SECTION 3

BIN NEAR EMPTY SIGNAL 3

SECTION 1 ON/OFF

M/P

M/P

3-PIN

3-PIN

TOWER

TOWER

TOWER

2-PIN M/P

ABC

18 GA. RED

ABABC

18 GA. WHT

18 GA. BLK

18 GA. RED

18 GA. WHT

18 GA. BLK

18 GA. RED

18 GA. BLK

K

360 IN.

276 IN.

J

366 IN.

H

18 GA. BLK

G

18 GA. RED

D

18 GA. BLK

E

18 GA. WHT

D

18 GA. RED

C

18 GA. BLK

B

18 GA. WHT

A

18 GA. RED

M/P

TOWER

10-PIN

SHROUD

M/P

10-PIN

K

J

GROUND

H

SECTION 1 ON

G

GROUND

D

+VES

E

D

GROUND

C

+VES

B

A

RUN/HOLD

M/P

3-PIN

TOWER

ABC

18 GA. RED

18 GA. WHT

18 GA. BLK

34 IN.

18 GA. RED

18 GA. WHT

18 GA. BLK

M/P

SHROUD

M/P

TOWER

+VES

GROUND

R/H SIGNAL

FLOW SIGNAL SECTION 2

M/P

3-PIN

ABC

18 GA. RED

18 GA. WHT

120 IN.

18 GA. RED

18 GA. WHT

ABCDEDGHJ

+VES

FLOW SIGNAL SECTION 2

MODULE

DRILLMASTER

MULTI-SECTION

PWM

TOWER

2-PIN M/P

A

B

18 GA. RED

18 GA. BLK

34 IN.

P/N 17883

18 GA. RED

18 GA. BLK

ABCDEABCDEDGHJK

5-PIN

5-PIN

ABCDE

PWM - SIGNAL

PWM + SIGNAL

BIN NEAR EMPTY SIGNAL 1

FLOW SIGNAL SECTION 1

3-PIN

TOWER

ABC

18 GA. BLK

18 GA. RED

18 GA. BLK

18 GA. RED

18 GA. WHT

10-PIN

10-PIN

+VES

GROUND

BIN NEAR EMPTY SIGNAL 2

BIN NEAR EMPTY SIGNAL 2

M/P

18 GA. WHT

34 IN.

18 GA. BLK

M/P

TOWER

M/P

SHROUD

GROUND

SECTION 2 ON/OFF

TOWER

2-PIN M/P

A

18 GA. BLK

18 GA. RED

120 IN.

18 GA. RED

18 GA. BLK

GROUND

SECTION 2 ON

TOWER

B

18 GA. BLK

K

P/N 17882

A

FLOW SIGNAL SECTION 3

B

+VES

C

GROUND

D

BIN NEAR EMPTY SIGNAL 3

E

+VES

F

GROUND

G

SECTION 3 ON

H

GROUND

J

K

10-PIN

M/P

SHROUD

10-PIN

M/P

TOWER

A

B

C

D

E

F

G

H

J

K

18 GA. RED

18 GA. WHT

18 GA. BLK

18 GA. RED

18 GA. WHT

18 GA. BLK

18 GA. RED

18 GA. BLK

3-PIN

ABC

18 GA. RED

FLOW SIGNAL SECTION 1

BIN NEAR EMPTY SIGNAL 1

SECTION 3 ON/OFF

M/P

M/P

3-PIN

TOWER

TOWER

TOWER

2-PIN M/P

A

B

ABC

18 GA. WHT

18 GA. BLK

18 GA. RED

18 GA. WHT

18 GA. BLK

18 GA. RED

18 GA. BLK

360 IN.

276 IN.

366 IN.

P/N 17881

P/N 21612

SECTION 1 ON

SECTION 2 ON

ABCDEDGHJ

ABCDEDGHJ

ABCDEDGHJ

20 GA. BRN

20 GA. RED

P/N 17096

20 GA. BRN

20 GA. RED

ABCDEDGHJ

ABCDEDGHJ

20 GA. BRN

20 GA. RED

P/N 13221

20 GA. BRN

20 GA. RED

ABCDEDGHJ

ABCDEDGHJ

20 GA. BRN

20 GA. RED

SECTION 3 ON

PWM + SIGNAL

PWM - SIGNAL

FLOW

M/P

10-PIN

TOWER

M/P

10-PIN

SHROUD

20 GA. ORG

20 GA. YEL

20 GA. GRN

20 GA. BLU

20 GA. ORG

20 GA. YEL

20 GA. GRN

20 GA. BLU

M/P

10-PIN

TOWER

M/P

10-PIN

SHROUD

20 GA. ORG

20 GA. YEL

20 GA. GRN

20 GA. BLU

20 GA. ORG

20 GA. YEL

20 GA. GRN

20 GA. BLU

M/P

10-PIN

TOWER

M/P

10-PIN

SHROUD

20 GA. ORG

20 GA. YEL

20 GA. GRN

20 GA. BLU

R/H SIGNAL

BIN NEAR EMP

+VES

GROUND

K

K

K

20 GA. VIO

20 GA. GRY

20 GA. WHT

20 GA. BLK

20 GA. VIO

20 GA. GRY

20 GA. WHT

20 GA. BLK

K

K

20 GA. VIO

20 GA. GRY

20 GA. WHT

20 GA. BLK

20 GA. VIO

20 GA. GRY

20 GA. WHT

20 GA. BLK

K

K

20 GA. VIO

20 GA. GRY

20 GA. WHT

20 GA. BLK

P/N 21779

18 GA. RED

A

2-PIN M/P

2-PIN M/P

A

16 GA. BRN

POWER SWITCH

18 GA. BLK

B

SHROUD

TOWER

B

YELLOW TIE

20 GA. GRY

3-PIN

ABC

16 GA. ORG

SPEED

M/P

16 GA. RED

P/N 17881

5/16 IN. RING

FUSE HOLDER

P/N 21778

10 A FUSE

14 GA. ORG

14 GA. BLU

TOWER

2-PIN W/P

SHROUD

2-PIN W/P

16 GA. WHT

16 GA. BLK

CONN (2 PLCS)

P/N 14315

POWER CABLE

RUN/HOLD SWITCH

18 GA. RED

18 GA. BLK

ABC

M/P

3-PIN

SHROUD

M/P

TOWER

3-PIN

TOWER

ABC

GRAY TIE

16 GA. YEL

20 GA. BLU

20 GA. GRN

20 GA. VIO

16 GA. BRN

SEC

18 IN.

16 GA. RED

16 GA. ORG

20 GA. YEL

20 GA. GRN

20 GA. BLU

FLOW SIGNAL

PWM - SIGNAL

SECTION 2 ON/OFF

SECTION 2 ON/OFF

9

20 GA. VIO

20 GA. GRY

L

Y SIGNAL

P/N 21088

16 GA. WHT

16 GA. BLK

GROUND

+VES PROTECTED

18 IN.

16 GA. BRN

16 GA. RED

16 GA. ORG

20 GA. YEL

DRILLMASTER CONSOLE

+VES

SPEED POWER

SPEED SIGNAL

20 GA. GRN

20 GA. BLU

20 GA. VIO

20 GA. GRY

16 GA. WHT

16 GA. BLK

L

+VES

GROUND

SWITCHED VES

PRESSURE

RIGHT FLOW SENSOR

CHECK VALVE

FLOW SENSOR

CHECK VALVE

DrillMaster Seed Rate Controllers

Single Drive Closed Center Single Drive Open Center

RETURN

PWM VALVE

POPPETVALVE

Multi-Drive Closed Center

FLOW SENSOR

POPPET VALVE

RETURN

PWM VALVE

PRESSURE

RETURN

PRESSURE

LEFT POPET VALVE

CENTER POPPET VALVE

PWM VALVE

LEFT FLOW SENSOR

RIGHT POPET VALVE

CENTER FLOW SENSOR

CENTER POPPET VALVE

RETURN

PRESSURE

CENTER FLOW SENSOR

RIGHT FLOW SENSOR

RIGHT POPPET VALVE

PWM VALVE

LEFT FLOW SENSOR

LEFT POPPET VALVE

Multi-Drive Open Center

10

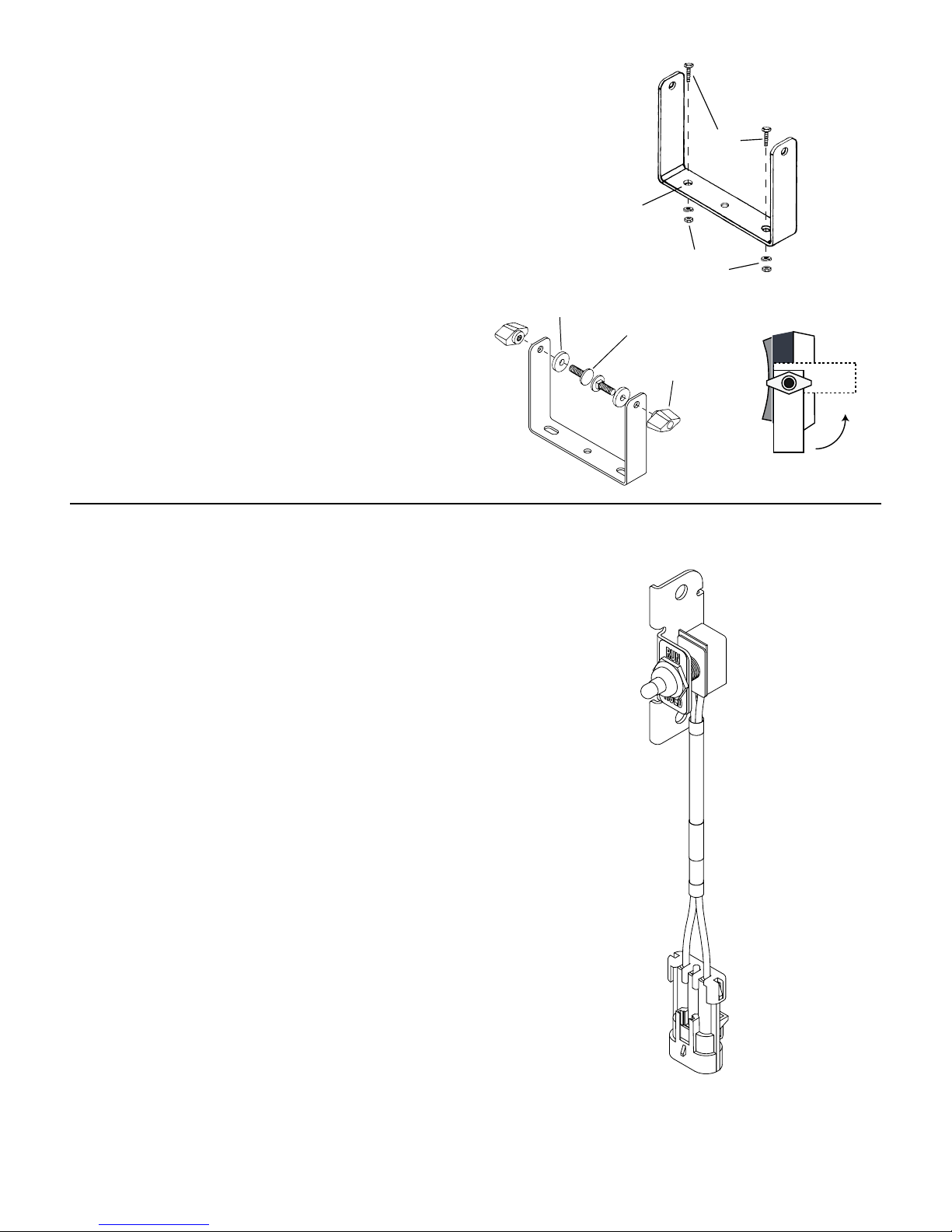

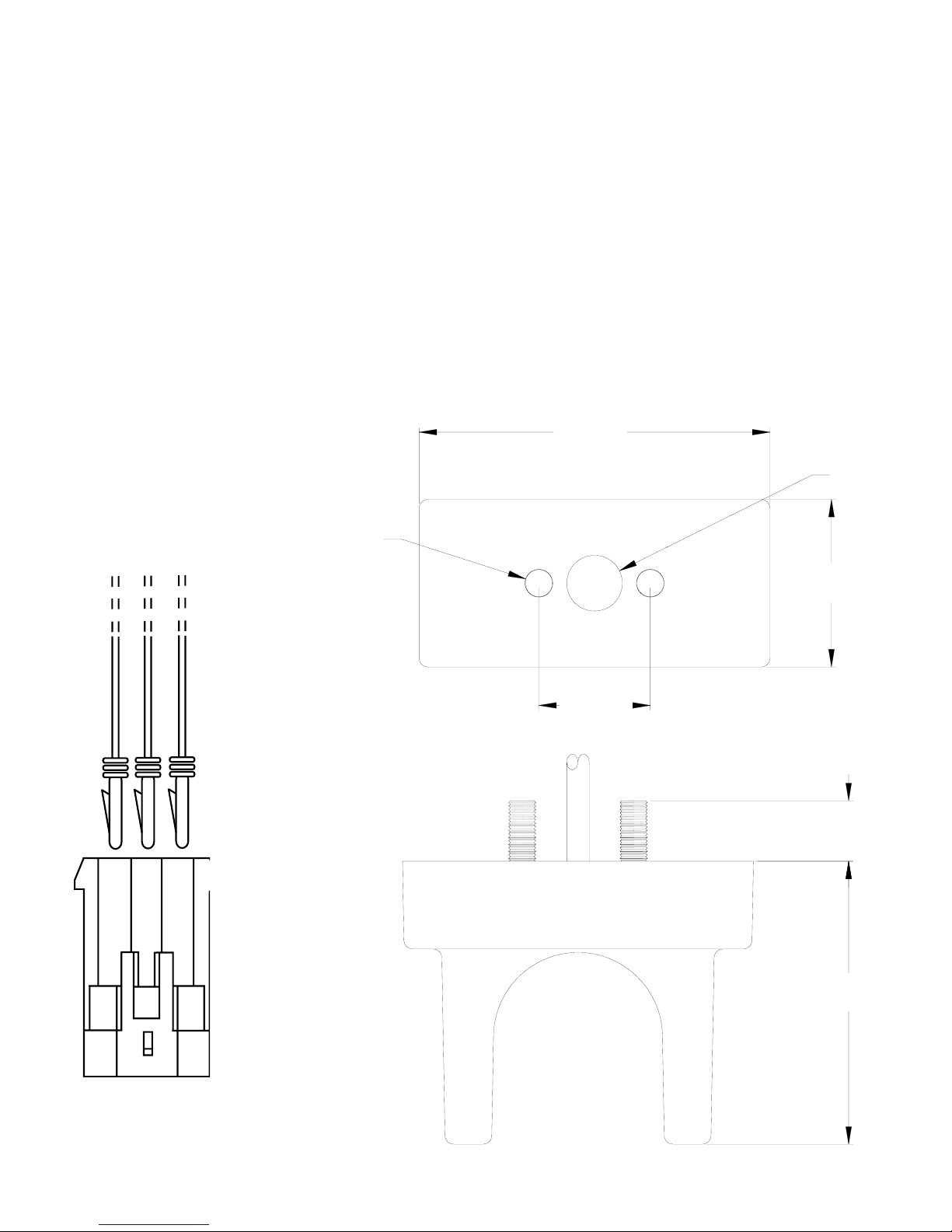

Installation

side or dashboard mounting

Mounting the Display Console

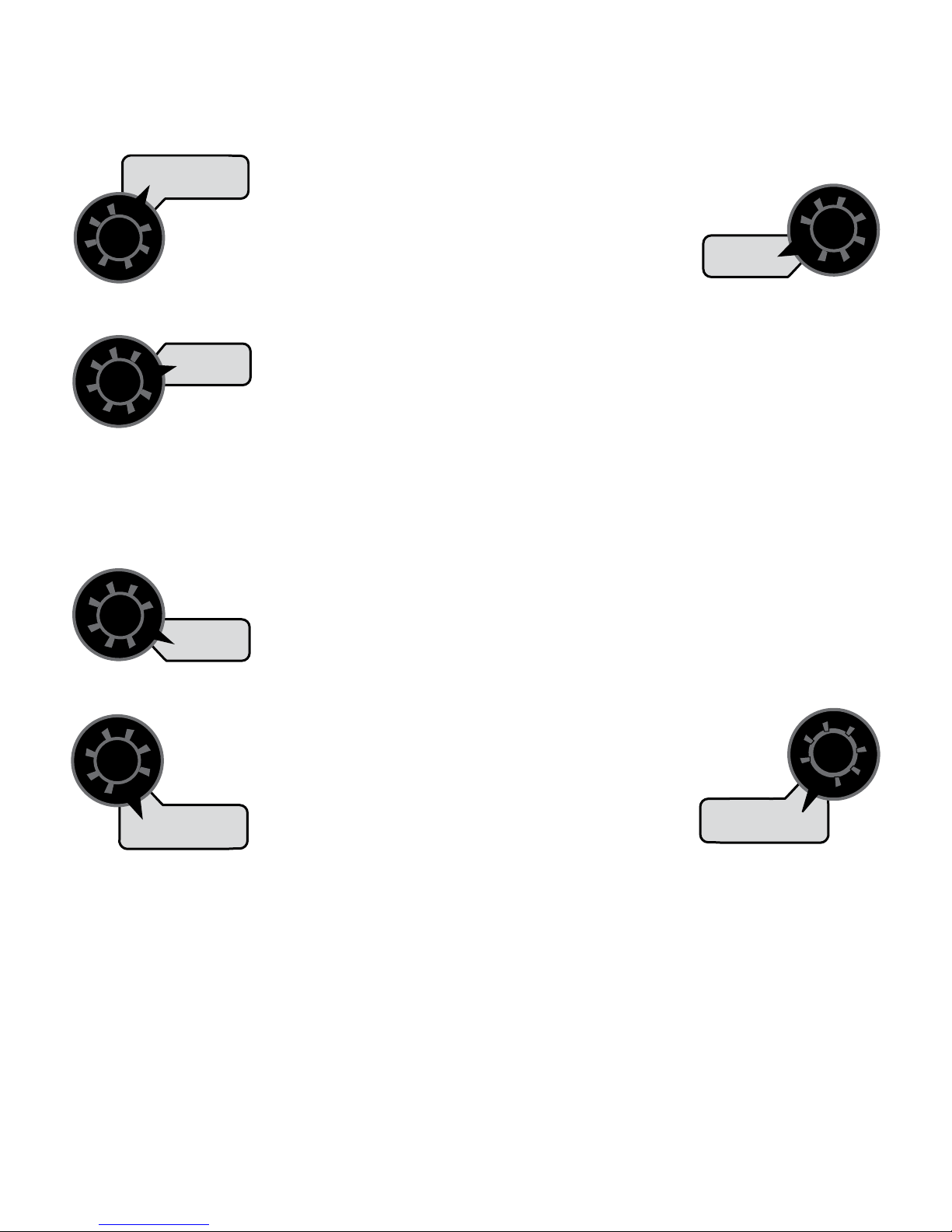

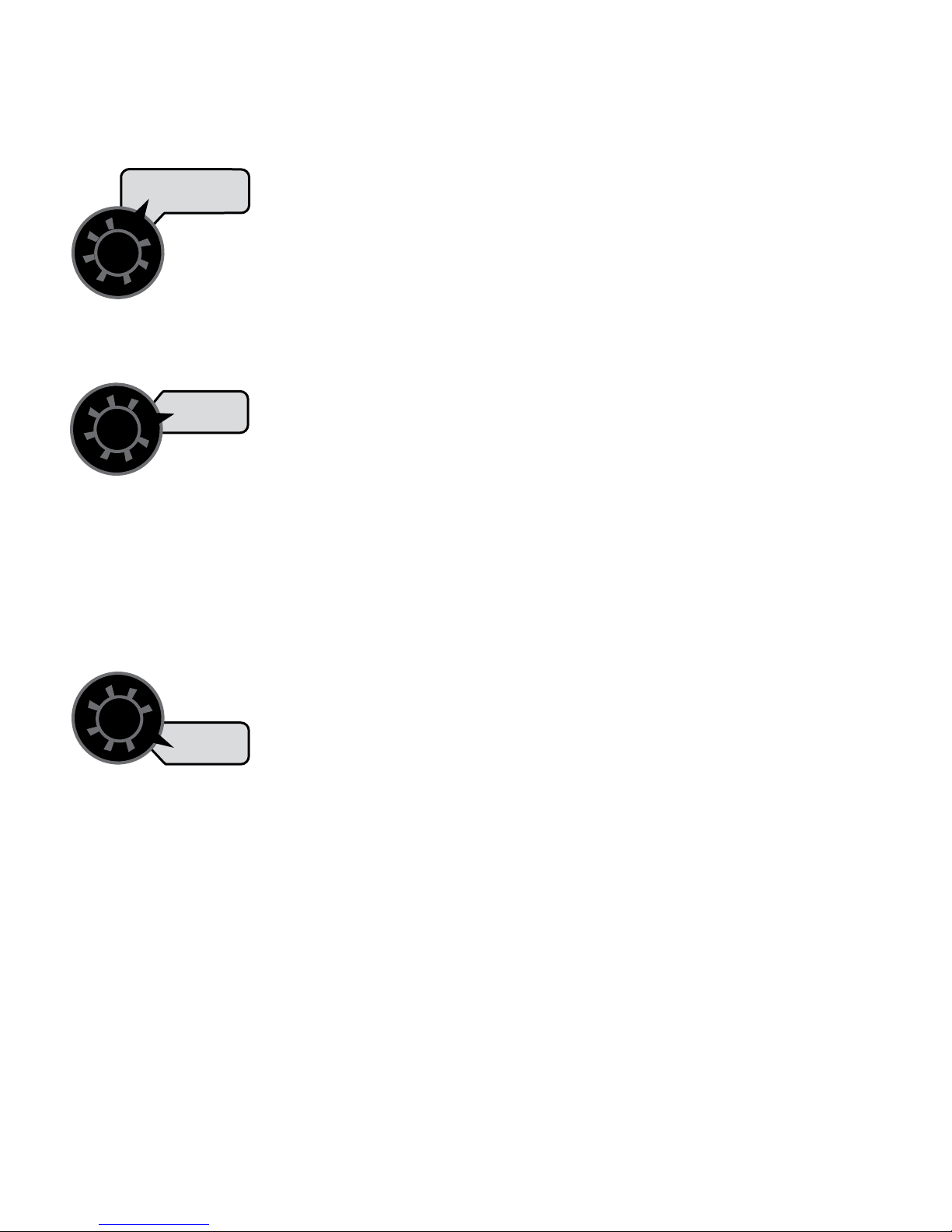

Illustration 1A

Select a mounting location which seems most workable,

and that best fits your needs. It should be con ve nient to

reach and high ly vis i ble to the op er a tor. DO NOT IN STALL

IN A POSITION THAT OB STRUCTS THE VIEW OF THE ROAD

OR WORK AREA. Whenever pos si ble, avoid lo ca tions that

ex pose the con sole to direct sun light, high tem per a ture,

strong chem i cals or rain.

Place the mounting bracket in selected lo ca tion, mark holes,

drill 1/4” (7mm) holes and mount bracket with bolts, lockwash ers and nuts pro vid ed. (Use self-tap ping screws if not

prac ti cal to use bolts.) See Illustration 1A.

Put rubber washers on carriage bolts and put the bolts

through the bracket holes from the inside out. Loosely

attach the mount knobs onto the bolts. Place console over

carriage bolt heads and tighten knobs to se cure the console.

See Il lus tra tion 1B.

Illustration 1B

Drill ¼” (7mm)

holes for bolts,

or 3/16“ (5mm)

holes for selftapping screws.

Rubber washer

Installing Run/Hold and Power Control Switches

Install the Run/Hold switch assembly into the bracket

using the steps below:

1. Remove the mount knob from right side of the console.

2. Install the bracket over the carriage bolt and along side

the console bracket.

3. Install the mount knob on the carriage bolt and tighten

to secure the console and run/hold switch bracket in

place.

4. Mate the switch harness connector into the

corresponding connector (gray tie) on the console

harness.

Lockwashers

and nuts

Carriage bolts

Mount knob

Bolts

CONSOLE END VIEW

Console easily adjusts for

.

NOTE: Install Power Switch on the left side of console,

same general steps as described above. Then, connect

the Power Switch cable connector (2 pin) to the mating

connector on the console harness.

Console Run/Hold Switch PN 21778

Illustration 2

11

Installation (cont)

Electrical Installation

This section explains how to connect your DrillMaster to a

12-volt power source, and how to connect your oil bypass

valves or dump valves.

NOTE: The DrillMaster must be connected to a 12-volt DC

negative ground electrical system.

POWER/BATTERY CONNECTION

Locate the power cable for the DrillMaster and route to the

battery. When routing cable to con sole, avoid ar eas where

the ca ble may be sub ject ed to abra sion or exces sive heat.

At tach the BLUE wire (ground) to a screw or bolt on the

equipment frame. See Il lus tra tion 3. Be sure there is a good

metal-to-metal con tact. Connect the ORANGE wire to the

positive battery terminal.

Connect the power to the DrillMaster console by plugging

the 2-pin W/P tower on the power cable into the 2-pin W/P

shroud of the display console.

Speed Sensor Options

In addition to the standard Hall-effect magnetic speed

sensor, the DrillMaster may be interfaced with a va ri ety of

other speed sensing equipment. Several options are listed

below.

Illustration 3

+12 VDC

(Orange)

10 - Amp in-line

fuse required

(+)

Ground

(Blue)

Astro 5 or other GPS Speed Sensor Interface

The DrillMaster may also be used with most GPS speed

sensors that output a pulsed signal, such as the Micro-Trak

Astro 5, SkyTrak or Dickey-John GPS speed sensors. An

adapter cable may be required.

VanscoTM Radar Speed Sensor

The Vansco radar speed sensor uses a microwave (radar)

signal to deliver a reliable, accurate speed signal for electronic

equipment. It features state-of-the-art electronic design/

manufacturing, rugged aluminum housing and complete

testing and certification.

Radar Interface

The DrillMaster may also be interfaced with most popular

radar ground speed sensors. An adapter cable is re quired for

proper interface.

SEE APPENDIX E FOR LIST OF ADAPTER CABLES FOR RADAR.

Contact a Micro-Trak sales representative for de tails on any of these products,

or call Mi cro-Trak Systems, Inc. at 1-800-328-9613.

Astro 5 GPS Speed Sensor

Vansco Radar Speed Sensor

12

Installation (cont)

Remote Run/Hold

NOTE: An optional remote run/hold sensor can be used in

place of the provided Run/Hold switch.

The run/hold sensor cable has a BLACK body and mates

with the main har ness ca ble having a GRAY cable tie near

the 3-pin M/P con nec tor. Make certain that you install the

correct sen sor cable and connect it to the correct connector

on the main harness.

IMPORTANT

• The basic idea is to attach a magnet to a lever or some

part of the equipment that moves when the im ple ment

is raised and lowered. The Hall-effect Run/Hold sensor is

sensitive ONLY to the south pole of the magnet. Install

the magnet with the dashed line facing the sensor.

When the mag net is near the sen sor, the con sole will be

in HOLD and the area and distance counting functions

will be disabled.

Hydraulic Cylinder Mounting

Remote Run sensor on hydraulic cylinder. Magnet and sensor are in line

when equipment is lowered and operating.

Illustration 4

Magnet

Hold

Position

Sensor

(Black body)

Run

Position

North

South

DrillMaster Care and Maintenance

Store the console in a cool dry location if it will not be used for an extended period of time, such as

during the off-season. As with any electronic equipment, use care in cleaning so that water or other

liquids do not enter the case.

13

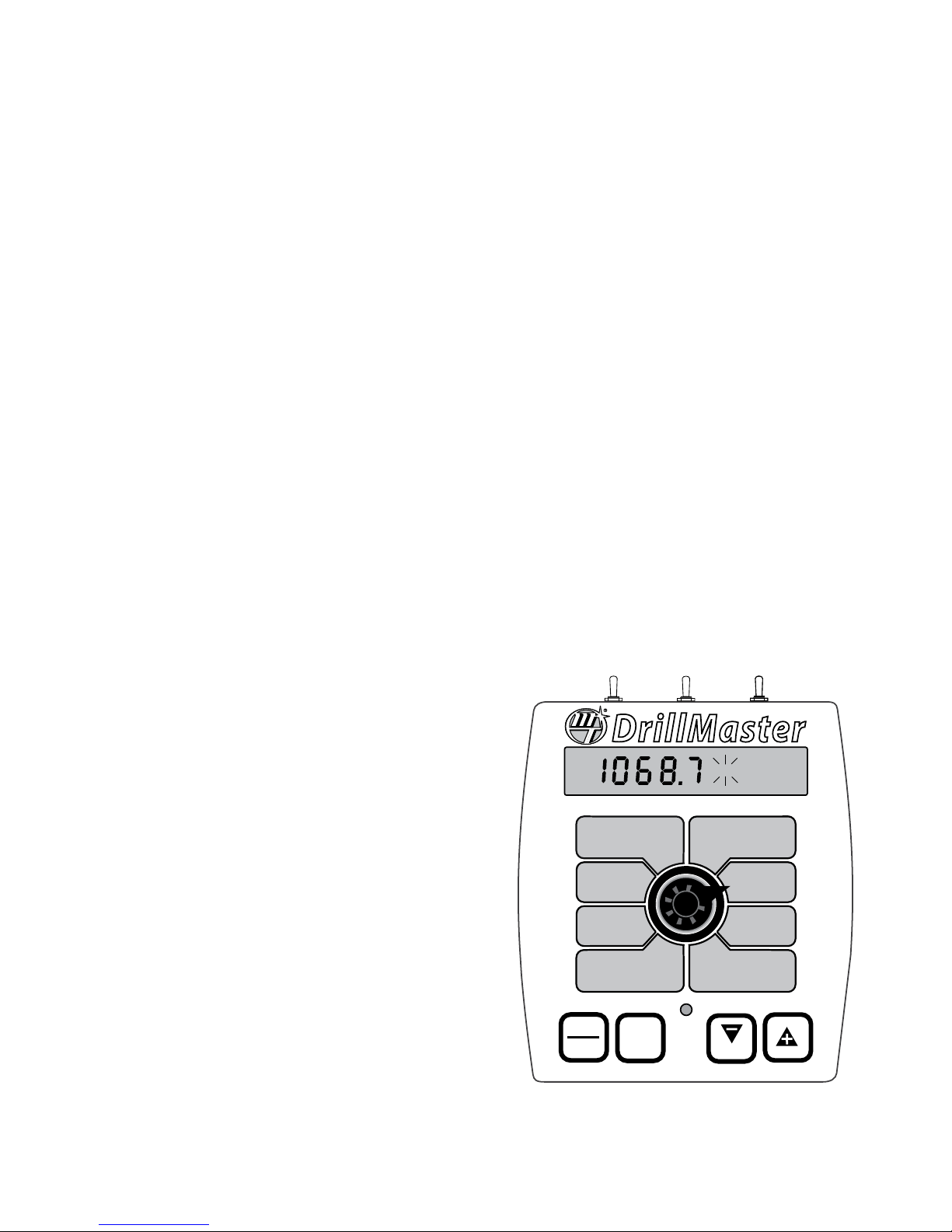

DrillMaster Console Func tions

The DrillMaster features a large, easy-to-read liquid crystal display, easy-to-use rotary dial and lighted panel for night use.

SECTION ON/OFF: The Console has three Section ON/OFF toggle switches on top of the Console. The toggle switches turn

Drill Sections on and off directly and also signal the Console which Sections are on or off.

WEIGHT TOTALS 1 2 3 : Displays total product lbs.

(kg) applied. Tons (metric tons) on rollover.

May be reset. (NOTE: WEIGHT and

AREA counters work in pairs, if

WEIGHT counter 1 is reset, it also

resets AREA counter 1).

WEIGHT/MINUTE: Displays lbs.

(kg) of product dispensed per

minute.

AREA/HOUR: Displays

calculated Acres/Hour (Eng),

Hectares/Hour (Metric) or kFt2/

Hour (Turf).

RATE: Displays application

rate in lbs. /acre, kg/hectares

or lbs./kFt2.

AREA TOTALS 1 2 3: Keeps a running count of the

total acres, hectares or kFt2 worked. May be

reset. (NOTE: WEIGHT and AREA

counters work in pairs, if AREA

counter 1 is reset, it also resets

WEIGHT counter 1).

DISTANCE: Displays distance

traveled in feet (meters). May

be reset.

METER RPM: Displays Seed

Drive shaft RPM.

SPEED: Displays ground

speed in miles per hour

(kilometers per hour).

WARNING LIGHT: Indicates

over or under application of

10% of the Target Rate in

AUTO or Loss of Sensor Signal

in MAN. Also lit when in CAL.

METER CAL: Used in calibration mode to enter the Meter Cal

in Pulses/Lbs/Row (English/Turf) or Pulses/Kg/Row (Metric).

ROW SPACING: Used in the calibration mode to enter the

Row Spacing in inches (cm).

ADJUST RATE: Used in calibration mode to enter an

amount of change for on-the-go adjustments to the

target rate lbs/acre (kg/hectares).

TARGET RATE: Used in calibration mode to enter the target

application rate Lbs/Acre (Eng). Kg/Hectares (Metric) or Lbs/

KFt2 (Turf).

Soft Key Functions

RESET

PROGRAM KEYS:

Used to increment and decrement the different calibration values.

• RESET when not in CAL, clears the selected counter when held for two sec onds.

• When in CAL, the “+” key increases and the “-” decreases the value displayed.

Adjusts Target Rate in AUTO or Application Rate in MAN.

AUTO

MAN

CAL

Key which changes

operation from automatic

control to manual valve

control.

This key is used to enter &

exit the calibration mode.

Calibration PositionsCalibration Positions

ROWS SECTION: Used in calibration mode to enter the Rows

per Section from 0 to 255 rows for the Section selected.

SPEED CAL: Used in calibration mode to enter the speed

calibration number in inches (cm) per pulse edge.

CAL TEST: Not a true “Calibrate Factor” but rather a method

of testing the Drill to determine if the correct Meter Cal factor

is being used and to test if each Row is dispensing the correct

amount of seed.

TEST SPEED: Not a true “Calibrate Factor” but rather a

method of testing the Drill. Typically it is used to confirm

that Auto Control can be maintained across a range of

expected ground Speeds.

14

Calibration

Selecting Measurement Units

English, Metric or Turf?

The DrillMaster is capable of displaying in for ma tion in Amer i can

En glish or standard Metric measurement. The DrillMaster is

shipped from the factory programmed for English.

NOTE: The following procedures will also load factory

default calibration values. To simply change units without

loading defaults, see the “Special Calibration” section.

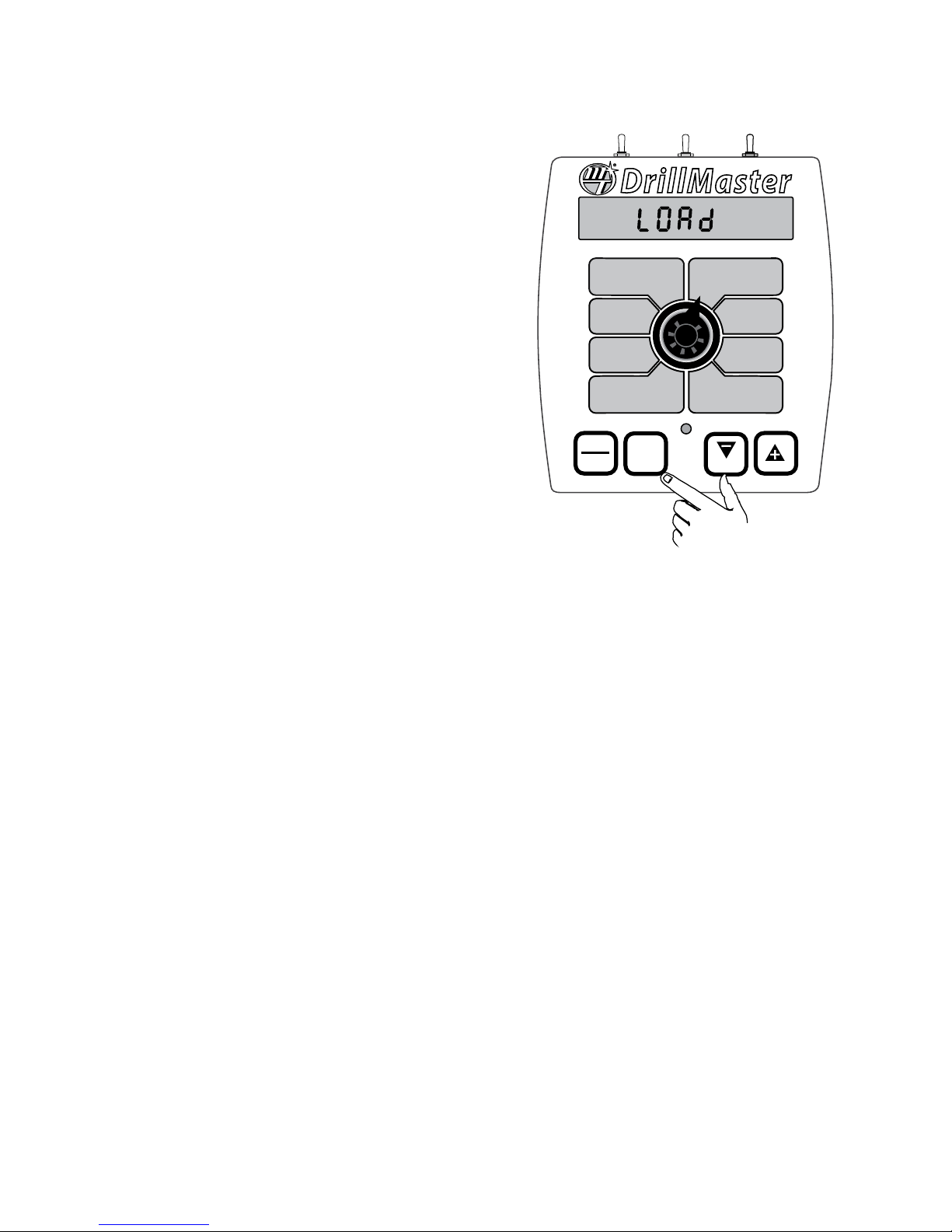

METRIC

• You must be in HOLD or have all Sections OFF to enter

Cal. To activate the Metric mode, turn power OFF and

place the ro ta ry switch at “AREA TOTALS.” Hold down

both the “CAL” and “-” keys and turn power ON. See

Il lus tra tion 5. The con sole will display LOAd for two

seconds. Once LOAd is displayed, release the two keys.

To “lock-in” Metric mode you must enter and exit cali bra tion. Press and hold the CAL key until “CAL” icon

appears on the display. The con sole is now in cal i bration and Metric mode is selected. Exit CAL by pressing

and holding the “CAL” key until CAL disappears from the

display (ap prox i mate ly 1 second).

NOTE: You MUST exit CAL to lock in Metric units.

ENGLISH

• You must be in HOLD or have all booms OFF to enter Cal.

To activate the English mode, turn power OFF and place

the ro ta ry switch in the WEIGHT TOTALS position. Hold

down both the “CAL” and “-” keys and turn power ON.

The con sole will display LOAd. Once LOAd is displayed,

release the two keys. To “lock-in” English mode you

must enter and exit cal i bra tion. Press and hold the CAL

key until “CAL” lights on the display. The console is now

in cal i bra tion and English mode is selected.

METER

CAL

ROW

SPACING

ADJUST

RATE

TARGET

RATE

DrillMaster

WEIGHT TOTALS

(1) (2) (3)

WEIGHT /

MINUTE

AREA/

HOUR

RATE

AUTO

MAN

CAL

AREA TOTALS

RESET

(1) (2) (3)

DISTANCE

METER

RPM

SPEED

Illustration 5

ROWS/

SECTION

SPEED

CAL

CAL

TEST

TEST

SPEED

NOTE: You MUST exit CAL to lock in English units.

Exit CAL by pressing and holding the “CAL” key until CAL

disappears from the display (approximately 1 second).

TURF

• Selected only in “Special” Calibration. See Page 23.

NOTE: In metric, the width will have a decimal point, in

English there is no decimal point. Also, changing from En glish

to Met ric mode may change or alter any previously en tered

cal i bra tion values. After switch ing mea sure ment modes, confirm that all cal i bra tion val ues are correct.

15

Calibration (cont)

Entering Calibration Values

To enter or change any of the system’s calibration values,

turn all used Sections OFF or put the console in HOLD and

press and hold the CAL button until the “CAL” icon appears

(approximately one second).

NOTE: Calibration may be entered while moving, but

it is not rec om mend ed, for safety reasons, to attempt

calibration while the vehicle is mov ing.

The console will remain in calibration mode, with the RED

warning light illuminated until you exit calibration or turn

power OFF.

NOTE: The Console must be in Hold or all used Sections

OFF in order to toggle Calibrate Mode on, however, it can

be in Run, Hold or Sections ON or OFF to toggle Calibrate

Mode off.

Once in calibration mode, you may change any one, all, or

none of the values, in any order.* To select a calibration

position, simply turn the rotary selector to the desired

po si tion. Calibration positions are identified by the White

labeling on each side of the rotary selector. All values are

entered and adjusted using the “+” and “-” but tons on the

front panel.

Test speed must be last.

*

Hold the “CAL key again for 1 second to exit calibration.

“CAL” will disappear from the display.

NOTE: You MUST exit CAL to save changes.

ROWS/SECTION: This displays the Rows Per Section from

0 to 255 rows for the Section selected. Unused Sections must

AREA TOTALS

(1) (2) (3)

up to three Sections. The total width of

the Drill (sum of all Section widths) must

not exceed 65,535 inches or 65.535 meters

(Number Rows X Row Spacing).

ROWS/

SECTION

To adjust the number of Rows of a

particular Section simply turn that Section on and

all others Off. The corresponding Section Icon

1 - 3 will turn on and the number of rows in that

section can be adjusted. Actually the first Section

turned on, from left to right, will be selected.

For example if Section 1 is off and Sections 2

and 3 are on, then Section 2 is selected since

it is the “first” Section on, and Section 2 Rows

can be adjusted. If no Sections are turned on, it

will display “no SECtn” (alternating “no” and

“Section”) to remind the user to turn a Section on,

and/or select RUN to enable the Sections.

be programmed

to zero rows. The

DrillMaster can have

SPEED CAL: This position is used to calibrate the speed

sensor for ac cu rate speed and dis tance measurement. When

this position is selected,

DISTANCE

is the number shown along with “CAL” on

the display. See details for determining

SPEED CAL on page 17.

SPEED

CAL

the display will show

the SPEED CAL value.

The SPEED CAL value

CAL TEST: This is not a true “Calibrate Factor” but rather

a method of testing the Drill to determine if the correct

Meter Cal factor is being used and to test if a particular Row

is dispensing the correct amount of seed.

When RUN is selected it will use Test Speed

and AUTO control to dispense Sample Size

METER

RPM

The “Cal Test” is recommended for a quick spot check to

ensure proper operation. It can be used to:

• Test the accuracy of ‘Meter Cal’ (make sure it matches

what the Drill is actually planting).

• Test one Row, or many Rows, or the entire Drill at once.

• Test the consistency of the Rows (see variation from one

row to another).

• Find the minimum and maximum Row (lowest and

highest planting rate).

• Find the AVERAGE planting rate for the entire Drill.

This procedure is different than the “Fine Tuning” found in

the Meter Cal section in the following ways:

1. This procedure is a quick method to test the accuracy

of Meter Cal. It DOES NOT require weighing entire Drill.

Instead only a small sample from one Row is needed

and it can be performed in the field. But it can also test

multiple Rows at once if desired.

2. This procedure uses AUTO to make sure the planter is

running at the Target Speed. This is important because

the Seed Meter planting mechanism is speed sensitive

so it must be tested at the proper speed. In the Meter

Cal Fine Tuning procedure, the user can use AUTO

or MANUAL mode and use a lower or higher speed if

desired.

3. This procedure uses a fixed Sample Size (another cal

factor) making it more repeatable. In the Meter Cal Fine

Tuning procedure the sample size is up to the operator

and can be any size.

4. This procedure automatically stops when the sample

size is reached. In the Meter Cal Fine Tuning procedure

the operator must stop the test at the appropriate time.

5. This procedure will not affect or change any of the three

Weight Totals counters. In the Meter Cal Fine Tuning

procedure one of the three Weight Totals counters must

be cleared.

NOTE: See the Cal Test Fine Tuning procedure in Appendix C.

amount of Seed per row

CAL

and then automatically

TEST

stop.

16

Calibration (cont)

Entering Calibration Values (cont)

TEST SPEED: Test Speed is not a true “calibrate factor” but

rather a method of testing the Drill. Typically it is used to conrm that Auto Control can be maintained across a range of

expected ground Speeds. In addition, the Test Speed is used

in “Cal Test” mode.

Each time Calibration is selected the Test

Speed will be reset to 0 mph (turned o) so it

does not interfere with any other calibration

procedures. If the opera-

SPEED

TEST

SPEED

adjust it above zero mph. Any non-zero Test Speed will make

the CAL icon ash to remind the operator that a “Test Speed”

is running and Calibration is no longer fully operating. He

can no longer change any Calibrate factors. Instead, the normal operating modes are enabled except they will all use the

Test Speed instead of the actual speed input. The WARN LED

will remain on, as reminder that Test Speed is selected. Hold

will operate normally and Speed will operate using the Test

Speed and Weight, Area/Hour, Rate, and Weight/Minute will

also operate. The Area and Distance will not change while in

the Test Speed Mode.

If AUTO is selected the Console will try to run the PWM Valve

to reach the Target Rate (lbs/Acre). The “+”/”-” keys can be

used as normal to change the Target Rate in steps equal to

the “Adjust Rate”.

To exit “Test Speed” the user must hold the CAL key for 1 sec-

ond (or turn the Console o) and the CAL icon will stop ashing, the WARN LED will turn o and it will exit Test Speed and

CAL Mode. The Test Speed cannot be turned o by reducing it

to zero because the minimum Test Speed is 0.1 mph.

tor wants to use a Test

Speed he must select

the Speed position and

then use the “+” key to

TARGET RATE: Enter the value for the

desired or Target Rate in Lbs/Acre (English)

or Lbs/ kFt2 (Turf ) or kg/hectare (Metric) with

one or more decimal places as follows. It can

range from 0.00 to 99,999. This is the

application rate that

the console will lock

TARGET

RATE

RATE

onto when operating

in AUTO.

ADJUST RATE: Enter the value for the desired amount

of change in lbs. per acre, kg per hectare or

lbs./ kFt2 to be used for making on-the-go

rate adjustments when operating in AUTO.

For example, if a value

“1.0” is entered, you

will be able to increase

ADJUST

RATE

AREA/

HOUR

or decrease your

application rate in one-lb. (kg) increments during operation

in AUTO. To disable this feature, simply enter “.0” for a val ue.

ROW SPACING: Adjusts Row Setting value to the nearest

tenth of an inch (tenth

of a centimeter).

ROW

SPACING

WEIGHT /

MINUTE

METER CAL: Adjusts Meter Cal value from 1 to 65,535 Pulses/

Lbs/Row (English,

Turf) or Pulse/Kg/

Row (Metric). NOTE:

METER

CAL

WEIGHT TOTALS

(1) (2) (3)

See Appendix D for

additional information.

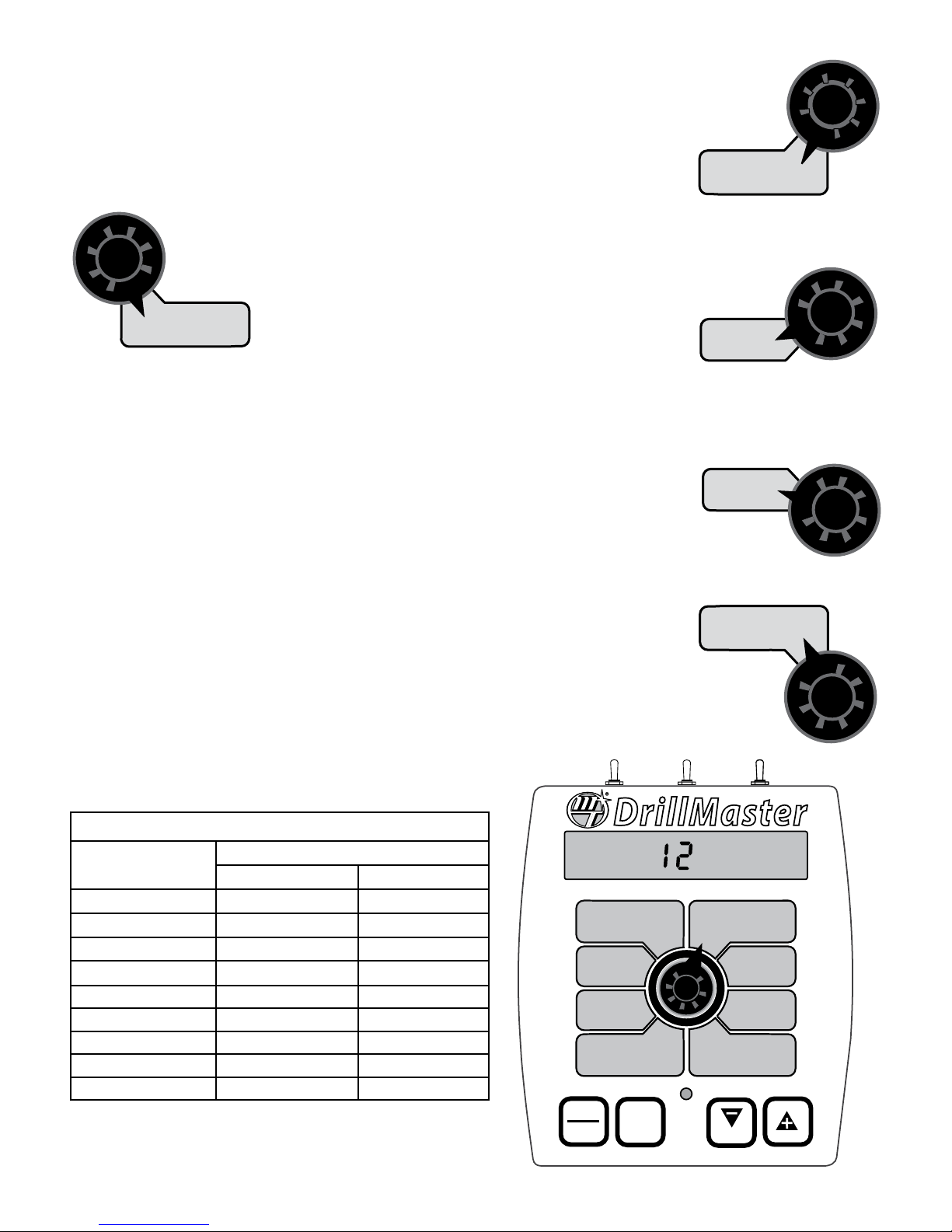

Factory-Loaded Calibration Values

Calibration Factor

TARGET RATE 60.0 lbs/acre 70.0 kg/hectare

ADJUST RATE 1.0 lbs/acre 1.0 kg/hectare

ROW SPACING 10.0 inches 25.4 centimeters

SPEED CAL 0.189 in/edge .48 cm/edge

METER CAL 2767 Pulses/Lbs/Row 6104 Pulses/Kg/Row

Distance 0 0

Area 1, 2, 3 0 0

Volume 1, 2, 3 0 0

ROWS/SECTION 1, 2, 3 12 12

Default Values

English Metric

17

METER

CAL

ROW

SPACING

ADJUST

RATE

TARGET

RATE

DrillMaster

WEIGHT TOTALS

(1) (2) (3)

WEIGHT /

MINUTE

AREA/

HOUR

RATE

AUTO

MAN

CAL

AREA TOTALS

RESET

CALHOLD

(1) (2) (3)

DISTANCE

METER

RPM

SPEED

ROWS/

SECTION

SPEED

CAL

CAL

TEST

TEST

SPEED

Calibration (cont)

Speed Cal for Radar or GPS Speed Sensors

See the table below for SPEED CAL numbers to enter for

various radar models or GPS speed sensors. To fine tune the

SPEED CAL number, see Appendix B.

Radar or GPS Speed Sensor Calibration

Radars

Vansco .150 .38 58.90

Raven .148 .38 59.80

Magnavox .154 .39 57.40

Dickey-john

(NOTE: Dickey-john

radars may be factory

calibrated for any of

these four settings).

English

Cal #

.149 .38 58.94

.199 .51 44.21

.319 .81 27.64

.518 1.32 17.034

GPS Speed

Astro 5 .189 .48 46.56

SkyTrak (Std) .150 .38 58.94

SkyTrak (MT) .910 2.31 9.82

Dickey-john .210 .53 42.00

John Deere

(In-cab speed signal) .197 .50 44.70

Metric

Cal #

Hz/MPH

18

“Special” Calibration

Entering “Special” Calibration

“Special” Calibration is used to set up system parameters

that rarely need to be changed or adjusted. To enter Special

Cal, put the system in HOLD, turn the console OFF, press

and hold both the AUTO/MAN button and CAL button while

turning console ON. The console will display SPEC for 2

seconds to show that the console is in “Special” Calibration.

Release the AUTO/MAN and CAL buttons. The CAL icon and

Warn LED will turn on. The number 1 will also appear in the

lower right display area to indicate that page 1 of Special

Cal is selected. To select page 2 of Special Cal, momentarily

Special Cal

DrillMaster

CALHOLD

Page 1

Auto Shutoff On/Off

Auto Delay Time

METER

CAL

ROW

SPACING

ADJUST

RATE

TARGET

RATE

WEIGHT TOTALS

(1) (2) (3)

WEIGHT /

MINUTE

AREA/

HOUR

RATE

1

AREA TOTALS

(1) (2) (3)

DISTANCE

METER

RPM

SPEED

ROWS/

SECTION

SPEED

CAL

CAL

TEST

TEST

SPEED

press the CAL button and the number 2 will appear in the

lower right display area. To go back to page 1, momentarily

press the CAL button again. The desired “Special” Calibration

parameter(s) can then be accessed with the rotary switch.

See Illustration below.

To exit “Special” Calibration, press and hold the CAL button

for 2 seconds. The console will store any changes and revert

to normal operation.

NOTE: You must exit “Special” Calibration to save changes.

Special Cal

Page 1

Units

Sample Size

Control Speed

PWM Version

Page 2

PWM Frequency

Max PWM

Min PWM

Shaft CAL

AUTO

CAL

MAN

RESET

The following table describes the “Special” Cal parameters

and shows the factory settings. More detailed descriptions

follow the table.

Factory-Loaded “Special” Calibration Values

“Special” Calibration

Parameter

Units

Sample Size 1.00 Lbs 0.50 Kg

Control Speed -1 -1

Shaft Cal 60 60

Auto Shuto On On

Auto Delay Time 1 Sec 1 Sec

PWM Frequency 100 Hz 100 Hz

Max. PWM 90% 90%

Min PWM 30% 30%

Default Factory Setting

English Metric

0 (EnG) (English) 1 (nnEt) (Metric)

19

“Special” Calibration (cont)

Entering Page 1 “Special” Calibration Values

UNITS: Chooses the system of units desired. Turf units are

the same as English

AREA TOTALS

(1) (2) (3)

ROWS/

SECTION

units except Area is in

thousands of square

feet. Use the “+” and

“-” buttons to choose between EnG (American

English Units), MEt (Metric) and TurF (Turf

units). NOTE: Always Check ALL Calibration

Factors after changing UNITS.

SAMPLE SIZE: Sample Size can be adjusted from 0.00 to

655.35 lbs or kg. This

DISTANCE

SPEED

will determine how

much seed is dispensed

CAL

per Row during the Cal

Test. The default is 1.00

pound (0.50 Kg) but it can be adjusted for

various Seed types.

When the Sample Size is set to 0.00 it will stop the “Cal Test”

as soon as it is started. This effectively disables it so the user

can not accidently run the “Cal Test”.

CONTROL SPEED: Control Speed can be adjusted from

-4 to 3. It is normally set in the middle (-1) but if needed, it

allows the user to either decrease or increase

the Control Speed for his particular system.

METER

RPM

CAL

TEST

AUTO SHUTOFF ON/OFF: Area/Hour allows the user to

turn the Auto Shut O feature On or O by using the “+”/”-”

(RESET) keys and the display will show On or Off.

ON OPERATION

While in AUTO mode, when the “Auto Shut

O” feature is turned

on (typical), it will automatically turn the

ADJUST

RATE

AREA/

HOUR

PWM Valve o when HOLD is selected, or when all used Sections are turned o, or when Speed goes to zero. Zero speed

has the same eect as turning all Sections o because of the

“Automatic Section O” feature (Sections automatically turn

o when speed goes to zero). This is useful in most systems

where HOLD must stop hydraulic ow to a drive shaft. The

“Auto Shut O” feature also operates while in Test Speed

mode, it just skips the test for zero speed since Test Speed

can’t be set to zero.

OFF OPERATION

While in AUTO mode, when the “Auto Shut O” feature is

turned o, it will stop automatic control and simply “maintain”

the PWM Valve at the current ow when HOLD is selected, or

when all used Sections are turned o, or when Speed goes

to zero.

NOTE: In the MANUAL mode, selecting Hold, or turning all

used Sections o, will override the Auto Shut feature and

always stop the PWM output independent of Auto Shut O

setting.

SHAFT CAL: Allows the user to enter the Shaft Cal in Pulses

Per Revolution. It can be changed from 1 to 255

(pulse/rev) using the “+”/”–” (RESET) keys. It

should be set to the number of pulses from the

Seed Meter Sensor that result in one revolution

of the Seed meter Shaft.

SPEED

TEST

SPEED

AUTO DELAY TIME: Allows the user to change the Auto

Delay Time. Pressing “+” and “-” buttons will adjust the Delay

Time from 0 (O) to 1, 2, 3, or 4 seconds.

Automatic control is delayed for “Delay Time”

seconds when going from Hold to Run or from

all used Sections o to one or more Sections

on. This provides

time for motorized

valves to operate and

allows the ow to stabilize.

TARGET

RATE

RATE

20

“Special” Calibration (cont)

SPEED

Entering Page 2 “Special” Calibration Values

PWM FREQUENCY: It can be adjusted from 50 Hz to 500

Hz in 1.0 Hz steps. It should be set to the optimum frequency

AREA TOTALS

(1) (2) (3)

ROWS/

SECTION

MAX PWM: It can be adjusted from 0% to 100% in 1%

steps. The PWM duty cycle will remain below this limit in

both manual and auto operation, when in Run. For proper

DISTANCE

maximum PWM function can be used to

ensure the hydraulic flow never exceeds a

maximum amount. This could be used to make sure a drive

shaft never exceeds a maximum RPM, etc. It can also be

used to optimize operation with a particular PWM valve. For

example, if a valve is at max flow when the duty cycle is at

85%, then the max PWM should be set to 85%.

for the particular valve

being used.

operation, it should be

set to some value greater

CAL

than the Minimum

PWM duty cycle. The

MIN PWM: It can be adjusted from 0 to 100% in 1%

steps. The PWM duty cycle will remain above this limit in

both Manual and Auto operation, when in Run. For proper

operation, it must be set to some value less

that the maximum PWM duty cycle.

The minimum PWM

METER

RPM

METER

CAL TEST

a set amount. This could be used to make sure a drive shaft

never stops turning, etc. It can also be used to optimize

operation with a particular PWM valve. For example, if a

valve is set at minimum flow when the duty cycle is 35%,

then Min PWM should be set to 35%.

function can be used

to ensure the hydraulic

flow never drops below

21

Operation

Illustration 6

Console Switches and Buttons

Make sure your system is properly calibrated before beginning

to apply product. We also recommend completion of

Pre-Field System Checkout described on page 27 prior to

beginning any field operations.

CONSOLE POWER/SYSTEM ON/OFF

The system can be turned ON and OFF by using the ON/OFF

switch and bracket kit. When the console is turned on, it will

display the number of hours of operation for 1.5 seconds,

then it will display PULSE for 1.5 seconds and then displays

the Software Number and Software Revision for 1.5 seconds.

The Sections will be disabled (turned off) and the PWM

output will remain off.

DISPLAY

During normal operation, the console will display information

selected by the rotary switch position. Typically the rotary

switch will be set on RATE, as shown in Illustration 6 to

the right. With RATE selected, the console will display the

Application Rate in units in lbs/acre, kg/hectares or lbs./

kFt2. See Rotary Positions on the next page for additional

information about data displayed.

RUN/HOLD SWITCH

The RUN/HOLD is the master switch for turning all (active)

sections on and off.

NOTE: The DrillMaster system can be operated in either

Manual (MAN) or Automatic (AUTO) mode. The following

contains additional information.

AUTO/MAN BUTTON

This button will switch the control status of the system from

fully automatic to manual control. Each press of the button

will change the status. The display will show the AUTO icon

when automatic control mode is active and the MAN icon

when manual control mode is active. NOTE: IF IN “AUTO”

MODE AND NO SPEED SIGNAL IS PRESENT, SYSTEM WILL

SHUT OFF THE BOOMS AUTOMATICALLY.

MANUAL

In MAN , Select RATE then the PWM can be adjusted using

the “+” and “-” (Reset) buttons from Min PWM to Max PWM

in 0.1% steps. The longer the “+” and “-” (Reset) key is

pressed the faster the PWM is changed.

AUTOMATIC

To turn on the AUTO mode, press AUTO/MAN button so

the AUTO icon appears in upper right portion of display.

See Illustration 10. In automatic mode, the system will

control the flow rate to maintain the calibrated application

rate when the vehicle speed changes, or when sections are

turned on or off. To operate the system in automatic mode,

simply turn on the hydraulic system, turn on the desired

number of sections, place the RUN/HOLD switch in the RUN

position and drive.

NOTE: In AUTO mode, the system will not turn the sections

or conveyors on until it has a speed signal. Use either the

RUN/HOLD switch to turn the system off and on when

turning around or to stop spreading at any time. See the

following sections for operation details.

DrillMaster

MANAUTO

CALHOLD

V 1 2 3 4

METER

CAL

ROW

SPACING

ADJUST

RATE

TARGET

RATE

WEIGHT TOTALS

(1) (2) (3)

WEIGHT /

MINUTE

AREA/

HOUR

RATE

AUTO

MAN

CAL

AREA TOTALS

(1) (2) (3)

DISTANCE

RESET

Turn rotary dial to display desired readout.

“+” AND “” BUTTONS

During normal operation, when automatic “AUTO” control is

active and the rotary dial is set to RATE, each press of the “+”

or “-” buttons will increase or decrease the target application

rate by the amount of the calibrated adjust rate (Delta).

During normal operation, when MAN control mode is active

and the Run/Hold switch is in the RUN position, pressing the

“+” or “-” buttons will increase or decrease the application

rate via the control valve.

During normal operation, when either automatic (AUTO)

or manual (MAN) is active, the RUN/HOLD switch is in the

HOLD position and the rotary switch is turned to WEIGHT/

MINUTE, pressing the “+” or “-” (Reset) button will increase

or decrease weight/minute rate.

ONTHEGO “DELTA” RATE ADJUSTMENTS ADJUST RATE

The calibrated target rate in lbs./acre, kg/hectare or lbs./ kFt2

represents the amount of product that you typically want to

apply. However, under certain conditions, you may want to

increase or decrease this rate. This “DELTA” feature allows you

to easily make on-the-go rate adjustments by simply using

the “+” or “-” buttons. Each press of a button changes the

calibrated target rate by the amount of calibrated adjust rate.

To use the “DELTA” feature, the console must be in automatic

“AUTO” mode active and the rotary switch must be set to the

RATE position.

EXAMPLE: Adjust Rate = 50.00 and Target Rate = 500

With AUTO selected and the rotary selector turned to RATE,

pressing the “+” key once will increase the target rate from

500 to 550. The display will momentarily show the new target

rate of 550 and then show the actual application rate. Pressing

the “-” key once will decrease the target from 550 to 500.

NOTE: When you “DELTA” the target rate, the display will

momentarily show you the new target rate (approximately

two seconds) and then resume showing the actual

application rate. The new target rate is maintained until

further adjustments are made using the “DELTA” feature

or calibration changes occur, or the unit is turned off.

22

METER

RPM

SPEED

ROWS/

SECTION

SPEED

CAL

CAL

TEST

TEST

SPEED

Operation (cont)

Console Switches and Inputs

SECTION ON/OFF

The Console has three Section On/Off toggle switches on top

of the Console. The toggle switches turn Drill Sections ON

and OFF directly and also signal the Console which Sections

are on or off.

Sections are NOT under software control and CAN NOT be

turned on and off with VRA control.

When in the RATE mode then the Number Icons (1, 2, 3) will

indicate which Sections are turned on. However, if a Section

has zero Rows/Section then the icon for that Section will

remain off (except during calibration) even if the toggle

switch is accidentally turned on.

If using a multi-section adaptor module to control more

than one section, the output of the switches is used by the

module to determine if a flow signal should be present. If the

module senses a Section On signal, a Flow signal is expected

from the corresponding section.

NOTE: To avoid having unused sections cause a No Flow

or Emergency Stop condition, the unused section switches

must remain off.

Turning all used Sections off will not select the Hold mode.

Distance will continue to operate but Area counters will not

change since the Width is zero with all used Sections off.

When all used Sections are turned off the Console will stop

accumulating Weight even if a Seed Shaft (flow) signal is

present.

Turning all used Sections off may or may not turn the PWM

Valve off (stop hydraulic flow) depending on the setting

of the AUTO SHUT OFF cal factor (see AUTO SHUT OFF

information on page 21).

Turning all used Sections off will disable Automatic Control

(even if PWM output continues).

WIRELESS INPUT

An optional Wireless Remote Module can be added to

provide Wireless Run, Hold and +/- functions.

BIN LEVEL SENSOR INPUT

When the Bin Level Sensor input goes low, the Seed Bin

is near empty and the Console will begin to flash "FILL"

(alternating with normal display data).

When used with a single Section Drill (single Seed Bin) the Bin

Level Sensor drives the Bin Level Sensor input directly.

When used with a three Section Drill, then an external

Module is used to multiplex up to three Bin Level Sensors

(three separate Seed Bins). When any one of the three Bin

Level Sensor inputs are low, the Module will signal the

console flash “FILL”.

SEED SIGNAL Flow INPUT

When used with a single Section Drill (single Seed Bin) there

is only one Seed Meter drive shaft. The Sensor on that shaft

drives the Seed Signal input directly.

When used with a three Section Drill there are three Bins and

three Seed Meter drive shafts and they can be turned on and

off independently. In that case an external Module is used

to select one of the three possible Seed signals. The Module

will normally use the Seed Signal from Section 1 but if that

Section is turned off then the Module will automatically

select one of the other two Seed Signals (which ever is still

running).

It should be noted that Seed Signal (flow) input does not

count Seeds directly and blocked Seed tubes or empty bins

(no Seeds) will not be detected.

PWM OUTPUT

The Console is designed to drive a Proportional Flow Control

Valve. The PWM duty cycle will vary from the Min PWM to

Max PWM calibrate values.

The Proportional Valve controls the hydraulic flow in 1 to 3

Hydraulic Motors so it can be used with 1 to 3 Section Grain

Drills or Fertilizer Applicators.

NOTE: All hydraulic Motors MUST BE plumbed in series so

they all rotate at the same speed so all Sections dispense

the same amount of seed per revolution of the Seed drive

shaft.

23

Operation (cont)

General Information

WARNING DEVICE

The console is equipped with a RED warning light. In AUTO,

the light will flash when the actual application is plus or minus

10 percent of the calibrated target rate. In MAN the light

will flash when the Seed Flow signal is lost. The RED warning

light will also be illuminated when calibration is active on the

console.

EMERGENCY STOP

If the Seed Shaft (flow) Sensor ever breaks (or is disconnected)

it is possible the user will not see the “no SEED” warning

message. In Automatic control, the Console will automatically

increase the planting rate to maximum, trying to compensate

for low Rate. This can create a severe over application that

will waste seed. The Emergency Stop feature helps protect

against this condition.

Rotary Switch Positions

ROTARY SWITCH

During normal operation, you can view any one of eight

monitored functions by turning the rotary switch to the

appropriate position. The functions that are active during

normal operation are the GREEN boxes. Calibration positions

are identified by the WHITE labeling on each side of the

rotary selector (please refer to Calibration section starting on

page 17 for details).

RATE

Rate displays the planting rate in lbs/Acre or lbs/kFt2 or kg/

hectare with one or more decimal places depending on the

planting rate as follows. It can range from 0.01 to 99999. The

Number icons (1-3) will indicate which Sections are turned

on.

NOTE: Rate will display .00 when in Hold or when all used

Sections are turned off even if there is a flow signal.

AREA/HOUR

Area/Hour is computed in Acres/Hour if English Units, or

hectares/Hour if Metric Units, or kFt2/Hour if Turf Units.

Area/Hour is normally displayed in 0.1 increments. However

when in English or Metric units the decimal point is dropped

when Area/Hour exceeds 655.3 and returns when Area/Hour

drops below 491.5. When in Turf units the decimal point is

dropped when Area/Hour exceeds 6553.5 and returns when

Area/Hour drops below 4915.2.

WEIGHT/MINUTE

Displays the pounds (kg) per minute being applied.

WEIGHT TOTALS 1 2 3

Displays the pounds (kg) applied since the active counter

was last reset to zero. To select a pair of AREA and WEIGHT

counters, use the “+” button to select set 1, 2 or 3, indicated

by the small numbers in the lower right on the display.

DO NOT use the “-” button to select counters because the

button will clear them. (See Resetting System Counters on

page 24.) This active pair of counters may be reset to zero

independent of other system counters. When the counter(s)

reach 99,999 lbs (English or Turf) or Kg (Metric), then the

counter automatically switches to Tons (English/Turf) or

Metric Tons (Metric). When this change occurs, the letter

“t” will be displayed in the left most position of the display.

Once the counter reaches “t9999” Tons (Metric Tons), OFL

will be displayed.

AREA TOTALS 1 2 3

Displays the acres (hectares) covered since the counter was

last reset to zero. The area counters do not accumulate area

when the console is in HOLD or if all booms are turned OFF.

To select a pair of AREA and WEIGHT counters, use the “+”

button to select set 1, 2 or 3, indicated by the small numbers

in the lower right on the display. DO NOT use the “-” button

to select counters because the button will clear them. (See

Resetting System Counters on page 24.) The selected pair of

counters may be reset to zero independent of other system

counters.

DISTANCE

Shows Distance traveled in 0.1 increments from 0 to 9,999.9

feet or meters and then in 1 Foot or Meter increments from

10,000 to 99,999. Once it reaches 99,999 it will display

“OFL” (Overflow) and stop counting. The user must clear the

counter to resume counting.

METER RPM

Meter RPM will display the Seed Drive shaft RPM from 0.01 to

9,999 rpm independent of Run or Hold.

The Number Icons are turned off in the Meter RPM Mode.

SPEED: Displays the ground speed in miles (kilometers)

per hour.

IMPORTANT: All sections automatically shut off if system is

in “HOLD” or if in AUTO with NO SPEED.

24

Operation (cont)

Resetting System Counters

The AREA, DISTANCE and WEIGHT totals counters maintain

a running count during operation regardless of the position

of the rotary switch. When any of these counters reach

their maximum capacity, or when you want to start a new

count, the value may be reset to zero by performing the

following routine. Counters may be reset independently of

each other.

1. Turn the sections OFF or put the system in HOLD.

2. Turn the rotary switch to the counter to be reset.

3. To reset distance turn the rotary switch to DISTANCE

and simply press and hold the RESET button until the

display reads zero. The display will show the word

CLEAr during this process, and will show 0.0 when

reset to zero is complete.

4. To reset the weight and area counters; there are three

independent AREA counters, paired with three WEIGHT

counters. The active pair of counters is indicated by the

small numbers in the lower right area of the display (1,2,

or 3) when the rotary switch is in the AREA or WEIGHT

TOTALS position. Select the pair of counters you want

to use by pressing the “+” button. The small number

will increment each time the “+” button is pressed

(from 1 to 3, then rolls back to 1). DO NOT attempt

to select the counter number by using the “-” button,

because that will clear the active pair of counters if held

for 1 second. If the “-” button is accidentally pressed,

the console will display CLEAr to alert the user that the

counters will be cleared. If the user continues to hold

the “-” button for 1 second CLEAr will disappear and

be replaced by 0.0, indicating that the selected pair of

counters has been cleared.

DrillMaster

MANAUTO

CALHOLD

V 1 2 3 4

METER

CAL

ROW

SPACING

ADJUST

RATE

TARGET

RATE

WEIGHT TOTALS

(1) (2) (3)

WEIGHT /

MINUTE

AREA/

HOUR

RATE

AUTO

MAN

CAL

AREA TOTALS

(1) (2) (3)

DISTANCE

RESET

METER

RPM

SPEED

ROWS/

SECTION

SPEED

CAL

CAL

TEST

TEST

SPEED

Display indicates counter pair #2 is selected

DrillMaster

MANAUTO

CALHOLD

V 1 2 3 4

METER

CAL

ROW

SPACING

ADJUST

RATE

TARGET

RATE

WEIGHT TOTALS

(1) (2) (3)

WEIGHT /

MINUTE

AREA/

HOUR

RATE

AUTO

MAN

CAL

AREA TOTALS

(1) (2) (3)

DISTANCE

RESET

METER

RPM

SPEED

ROWS/

SECTION

SPEED

CAL

CAL

TEST

TEST

SPEED

DrillMaster

MANAUTO

CALHOLD

V 1 2 3 4

METER

WEIGHT TOTALS

CAL

(1) (2) (3)

WEIGHT /

ROW

SPACING

MINUTE

ADJUST

AREA/

RATE

HOUR

TARGET

RATE

RATE

AUTO

CAL

MAN

AREA TOTALS

(1) (2) (3)

DISTANCE

METER

RPM

SPEED

RESET

ROWS/

SECTION

SPEED

CAL

CAL

TEST

TEST

SPEED

25

Display indicates counter pair #3 is selectedDisplay indicates counter pair #1 is selected

METER

CAL

ROW

SPACING

ADJUST

RATE

TARGET

RATE

DrillMaster

MANAUTO

CALHOLD

V 1 2 3 4

WEIGHT TOTALS

(1) (2) (3)

WEIGHT /

MINUTE

AREA/

HOUR

RATE

AUTO

MAN

CAL

AREA TOTALS

RESET

(1) (2) (3)

DISTANCE

METER

RPM

SPEED

ROWS/

SECTION

SPEED

CAL

CAL

TEST

TEST

SPEED

Operation (cont)

Clearing System Counters

When the desired counter number is displayed, press the “-”

(RESET) button and CLEAr will be displayed. See Illustration

to the right.

WARNING: Holding the “-” (RESET) button for 12 seconds

will clear both the #3 AREA counter AND the #3 WEIGHT

counter whether the rotary switch is in the AREA or the

WEIGHT TOTALS position.

If the “-” button is released before 1 second has elapsed, the

counters will not be cleared and the CLEAr message will be

replaced with the previous total.

After the “-” (RESET) button has been held for 1 second,

the CLEAr message will be replaced by 0.0, indicating that

counter pair #3 has been cleared. See Illustration below.

MAN HOLD

CALHOLD

3

Pre-Field Sys tem Checkout

METER

CAL

ROW

SPACING

ADJUST

RATE

TARGET

RATE

DrillMaster

MANAUTO

CALHOLD

V 1 2 3 4

WEIGHT TOTALS

(1) (2) (3)

WEIGHT /

MINUTE

AREA/

HOUR

RATE

AUTO

MAN

CAL

AREA TOTALS

RESET

(1) (2) (3)

DISTANCE

METER

RPM

SPEED

ROWS/

SECTION

SPEED

CAL

CAL

TEST

TEST

SPEED

Before beginning actual planting, perform the following

“Pre-field” procedure to ensure that your settings, oil flow

and desired speed range will allow the DrillMaster to provide

the required application control. This procedure should be

repeated for each application rate or setting change. By

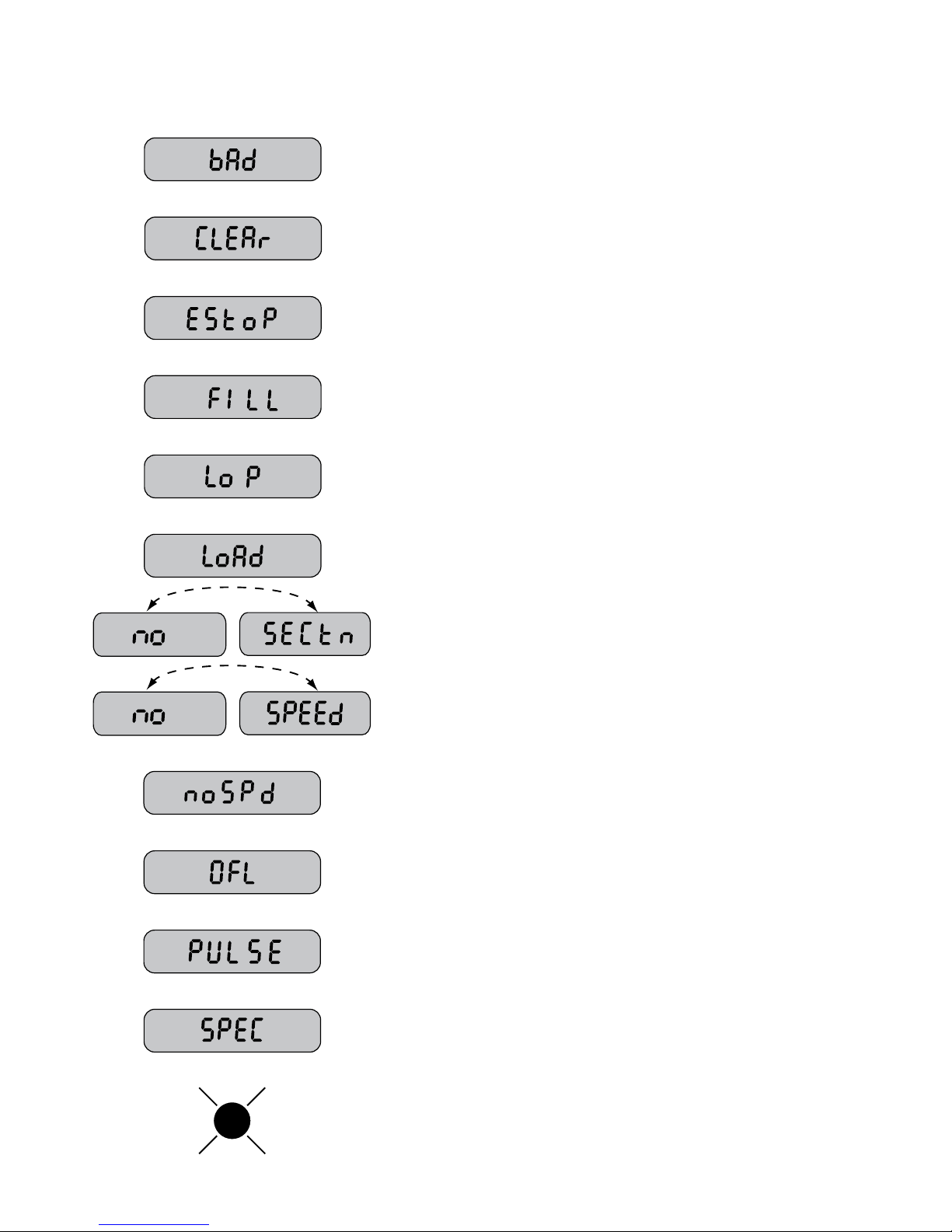

performing all of the steps listed below, you set up your