Page 1

microTec

1

R

OTARY MICROTOME

CUT4060E

Operating Manual

MADE IN GERMANY

microTec Laborgeräte GmbH

Rudolf-Diesel-Str. 47

69190 Walldorf, Germany

Phone: + 49 (0) 6227 8222-0

Fax: + 49 (0) 6227 8222-30

mail@micro-tec.de

www.micro-tec.de

Page 2

microTec

2

Table of Contents

1. General Notes ………………………………………………………………… 4

1.1 Significance of the Operating Instructions ……………………………………4

1.2 Usage According to its Specification ………………………………………… 5

1.3 Improper Use ............................................................................................. 5

1.4 Warranty and Liability …………………………………………………………. 6

1.5 Warranty ………………………………………………………………………… 6

1.6 Brief Discription of Use, Function and Sequence ………………………….. 7

1.7 Edition, Date of Issue of the Operating Manual ……………………………. 8

1.8 Copyright ……………………………………………………………………….. 8

1.9 Address of Manufacturer ……………………………………………………… 8

2. Basic Safety Instructions …………………………………………………… 9

2.1 Heed the Notes and Instructions Given in this Operating Manual ……….. 9

2.2 Obligation on the Part of the Operator ………………………………………. 9

2.3 Obligations on the Part of the Operating Staff ……………………………… 9

2.4 Hazards and Dangers in Handling and Using the Instrument ……………. 10

2.5 Interpretation of Hazard Symbols ……………………………………………. 11

2.6 Informal Instructions Issued by the Manufacturer ………………………….. 12

2.7 Particular Zones of Danger …………………………………………………… 12

2.8 Servicing and Fault Clearance ……………………………………………….. 13

2.9 Structural Modifications and Replacements to the Instrument ……………. 13

2.10 Cleaning and Associated Care ……………………………………………….. 14

3. Transportation and Storage ………………………………………………… 15

3.1 Dimensions and Weights ……………………………………………………… 15

3.2 Instructions for Transportation …………………………………………………15

3.3 Packaging ………………………………………………………………………..15

3.4 Inspection upon Acceptance by the Recipient ……………………………….15

3.5 Reporting and Documenting Transportation Damage ………………………15

3.6 Storage temperature ……………………………………………………………15

4. Data and Information Concerning the Instrument ……………………… 16

4.1 Designation ………………………………………………………………………16

4.2 Scope of Supply …………………………………………………………………16

4.3 Packaging ………………………………………………………………………..17

4.4 Ambient Temperatures during Operation …………………………………….18

4.5 Performance …………………………………………………………………….18

5. Installation, Assembly, Commissioning …………………………………..19

5.1 Installation ………………………………………………………………………. 19

5.2 Transportation Locking Pieces and Securements ………………………….. 19

5.2.1 Rearview ………………………………………………………………………... 19

5.3 Controls, Indicators and Displays ……………………………………………. 20

5.3.1 Operating panel …………………………………………………………………21

Page 3

microTec

3

6. Operation ………………………………………………………………………. 22

6.1 Preparation, Orientation and Alignment of Specimen ………………………22

6.2 Commencing the Cutting Operation …………………………………………. 22

6.3 Instructions for Producing Sliced Microtomic Sections of the Specimen ... 22

6.4 Cutting Action …………………………………………………………………... 23

6.5 Handwheel ……………………………………………………………………… 23

6.6 Coarse Advanced Drive ………………………………………………………..23

6.7 Friction Clutch on the Coarse Advanced Drive Mechanism ………………. 24

6.8 The Handwheel of the Coarse Advanced Drive Mechanism (11) …………24

6.9 Collision Protection Device ……………………………………………………24

6.9.1 Emergency shutdown ………………………………………………………….24

7. Setting Up and Changing the Setup …………………………………….. 25

7.1 Specimen Fixture ………………………………………………………………. 25

7.2 Standard Specimen Clamping Fixtures ……………………………………… 25

7.3 Orientatable Adapter ……………………………………………………………26

7.4 Fixed Adapter …………………………………………………………………… 26

7.5 Cylindrical Specimen Insert and Prism ………………………………………. 27

7.6 Film (Thin Material) Clamping Fixture ……………………………………….. 28

7.7 Universal Cassette Clamping Fixture ………………………………………... 28

7.8 Specimen Orientation Device …………………………………………………. 29

7.9 Exchanging the Specimen Clamping Systems ……………………………… 30

8. Setting up the Knife …………………………………………………………... 31

8.1 Knife Holder …………………………………………………………………….. 31

8.2 Knife Holder Base ……………………………………………………………… 31

8.3 The “R“ Type Knife Holder ……………………………………………………. 32

8.4 The “RS“ Type Knife Holder ……………………………………………………33

8.5 Holder for Throw-away Blades ……………………………………………….. 34

8.6 Clearance Angle Adjustment …………………………………………………. 35

9. Optional Accessories …………………………………………………………35

10. Emergency Service, Customer Service …………………………………… 35

Page 4

microTec

4

1. General Notes

1.1 Significance of the Operating Instructions

Dear Customer,

Please read through the operating instructions carefully before using the equipment

and familiarize yourself with its functions and controls. This is imperative to ensure

proper use of the equipment.

Please check the production serial number against the number given on the microTec

identification plate of your unit. It will facilitate faster service and response to queries by

quoting the production serial number.

microTec Production Serial-Number:

60-_____

microTec Laborgeräte GmbH

Rudolf-Diesel-Str. 47

69190 Walldorf, Germany

Phone: + 49 6227 8222-0

Fax: + 49 6227 8222-30

mail@micro-tec.de

www.micro-tec.de

Page 5

microTec

5

1.2 Usage According to its Specification

The CUT 4060E rotary microtomes are manually operated instruments for use in all

work involving paraffin wax and solid cut microtomology within the disciplines of

biology and medicine, and within industry at large.

The specimen can be moved back and forth by means of the coarse wheel mechanism

so to attain rapid advance of the specimen in relation to the knife during cutting.

Owing to the design of its drive, the CUT 4060E rotary microtome enables the user, to

carry out the cutting action manually by means of the handwheel, with locked handle,

and semi -automatically by means of the hand control panel.

The micro-drive mechanism enables feed settings to be made within the range of 0,5

to 60 microns.

The user friendly throw-away blades and universal knife holder with its integrated knife

guard enables trouble-free clamping and setting of the knife blade. The integrated

safety device to prevent any collisions occurring, which is incorporated in the

micrometre mechanism, disables any adjustment to the feed setting being made upon

reaching its maximum setting.

The CUT 4060E rotary microtome is equipped with an electronic cutting counter, which

indicates the total number of cuts made.

To prevent damage occurring to the knife or the specimen, the rotary CUT 4060E

microtome imparts an action of slight retraction of the specimen by approx. 80 microns

during the motion of advancement.

The following kinds of drive may be carried out by means of the hand control panel:

Inching service, single stroke, and continuous stroke. A foot switch is optionally

available.

1.3 Improper Use

The rotary microtome is designed and manufactured to the latest state-of-the-art

technology and to recognized principles of technical and engineering safety.

Nevertheless, dangers can arise during its use to endanger life and limb of the

operator or third persons or damage to the instrument or to other property. The

instrument is only to be used

• for use according to its specification of intended use

• in a proper technical state of repair, free of any defects

Page 6

microTec

6

1.4 Warranty and Liability

The company – microTec GmbH – certifies that this instrument has been carefully

tested and inspected. Verification to ensure adherence to the technical specification

data published has been carried out prior to shipping out the instrument from the

factory.

No liability is assumed for the correctness of technical data and other data or drawings.

Reserve technical changes.

The instrument is assigned to Class 4 of the MedGV (legislation governing medical

supplies). Observance of existing legislation and regulation is assured.

1.5 Warranty

Warranty is provided for this microTec product in the event of any deficiencies or

defects in material or workmanship for a period of 12 months. Defective parts will be

repaired or replaced free of charge during this period of time. Any additional claims

made under the warranty of whatsoever nature are excluded. Neither does the

warranty provide cover for any claims arising from services and supplies provided by

third parties.

In principle, our “General Conditions of Sale and Supply“ shall apply. These

conditions are made available to the prospective operator of the instrument, by, at the

latest, the signing of the contract. Warranty and liability claims for personal injury and

material damage are excluded if attributable to one or more of the following causes:

• Improper use of the instrument!

• Incorrect installation and assembly, commissioning, operation and servicing of

the instrument!

• Operating the instrument with the safety devices defective or safety

mechanisms and guards inappropriately fitted!

• Disregarding instructions given in the operating manual concerning

transportation, storage, installation, commissioning, servicing and equipping of

the instrument!

• Unauthorized tampering and structural modification to pneumatic, electrical and

mechanical components!

• Ineffective or incorrect monitoring of machine parts which are subject to wear!

• Improperly effected repairs!

• Catastrophes caused by external influences and force majeure!

Page 7

microTec

7

1.6 Brief Description of Use, Function, and Sequence

Use

The CUT 4060E rotary microtomes are manually operated instruments for use in all

work involving paraffin wax and solid cut microtomology within the disciplines of

biology and medicine, and within industry at large.

Function and Sequence

Manually rotating the handwheel on the rotary microtome translates into vertical

movement of the fixture holding the specimen. To produce the cut, resharpenable

knives or throw-away blades are used, which are adapted and attached to the various

knife holders.

A microtomic cut is made during the downward motion of the specimen (cutting action).

By continuing to rotate the handwheel further in a clockwise direction the specimen

starts to rise again in its return motion.

Owing to the different types of operation, cuts may be carried out manually by means

of the handwheel, semi-automatically by means of the hand control panel, and by

means of the foot switch, that will have to be separately ordered.

The selected feed for the thickness of cut is instigated at top dead center.

Rapid advance of the specimen towards the knife is achieved by means of the coarse

feed mechanism.

A universal clamping fixture for holding a variety of specimens is provided.

As a result, simple alignment to the plane of cut is possible using the facility for

orientating the specimen.

The various knife holders enable trouble-free use of a variety of knife types and

thereby provide facility for making adjustment to suit the application in question.

Page 8

microTec

8

1.7 Edition, Date of Issue of the Operating Manual

Edition: Version 004.96

Date of issue: 13. February 1996

1.8 Copyright

Copyright : microTec Laborgeräte GmbH

Copyright to this operating manual remains with microTec GmbH. This operating

manual is only intended for use by the operator and his staff.

It contains specifications and instructions, which may not be

copied, distributed or otherwise divulged to others in their entirety or in part.

Infringements can lead to legal proceedings being brought against the perpetrators.

1.9 Address of the Manufacturer

microTec Laborgeräte GmbH

Rudolf-Diesel-Straße 47

69190 Walldorf, Germany

Phone: + 49 (0) 6227 82 22-0

Fax: + 49 (0) 6227 82 22-30

mail@micro-tec.de

www.micro-tec.de

Page 9

microTec

9

2. Basic Safety Instructions

2.1 Heed the Notes and Instructions Given in this Operating

Manual!

A prime prerequisite for safe handling and malfunction-free operation of this instrument

is the awareness and recognition of basic safety instructions and regulations.

This operating manual contains the most important instructions for operating the

instrument in a safe manner.

This operating manual, especially the instructions on safety, are to be heeded by all

personnel who operate the instrument.

In addition, compliance with the regulations and specifications on accident prevention

applicable for the site of installation and use is to be maintained.

2.2 Obligation on the Part of the Operator

The operator is obliged to only allow personnel to operate the instrument, who

• are familiar with basic regulations on safety at work and accident prevention,

and are trained in the use and operation of the instrument.

• have read the chapter on safety and the warning notes and instructions given in

this operating manual.

• have been taught to have due regard to aspect of safety during the execution of

their work.

2.3 Obligations on the Part of the Operating Staff

All personnel who are delegated with the task of operating this instrument are obliged

before starting work

• to heed the basic regulations on safety at work and accident prevention.

• to read and to comprehend the chapter on safety and the warning notes and

instructions given in this operating manual.

Page 10

microTec

10

2.4 Hazards and Dangers in Handling and Using the Instrument

Important!

The following precautionary measures must be undertaken during any

operation carried out using the instrument. Non-compliance with these

precautionary measures will infringe recognized principles and rules of

technology and the intended and proper use of the instrument. The

manufacturer – microTec GmbH – accepts no

liability in the event of such infringement.

Risk of Injury

The finger guard must be used when setting the knife and specimen,

in order to reduce the risk of injury on the knife/blade.

Always insert the specimen first.

Then insert the knife into the knife holder.

Before exchanging the clamping device, always remove the knife or

blade. Knives, which are not being used, must

always be stored in the knife box. Never attempt to

catch a falling knife. Take care when cutting or

removing a sliced section.

Risk of Infection

Appropriate measures regarding protection and disinfection are to be

taken when working with infected material.

Danger due to Radio Activity

The current applicable regulations for the protection against radiation

must be observed at all times when working with radio active

materials or specimens.

Page 11

microTec

11

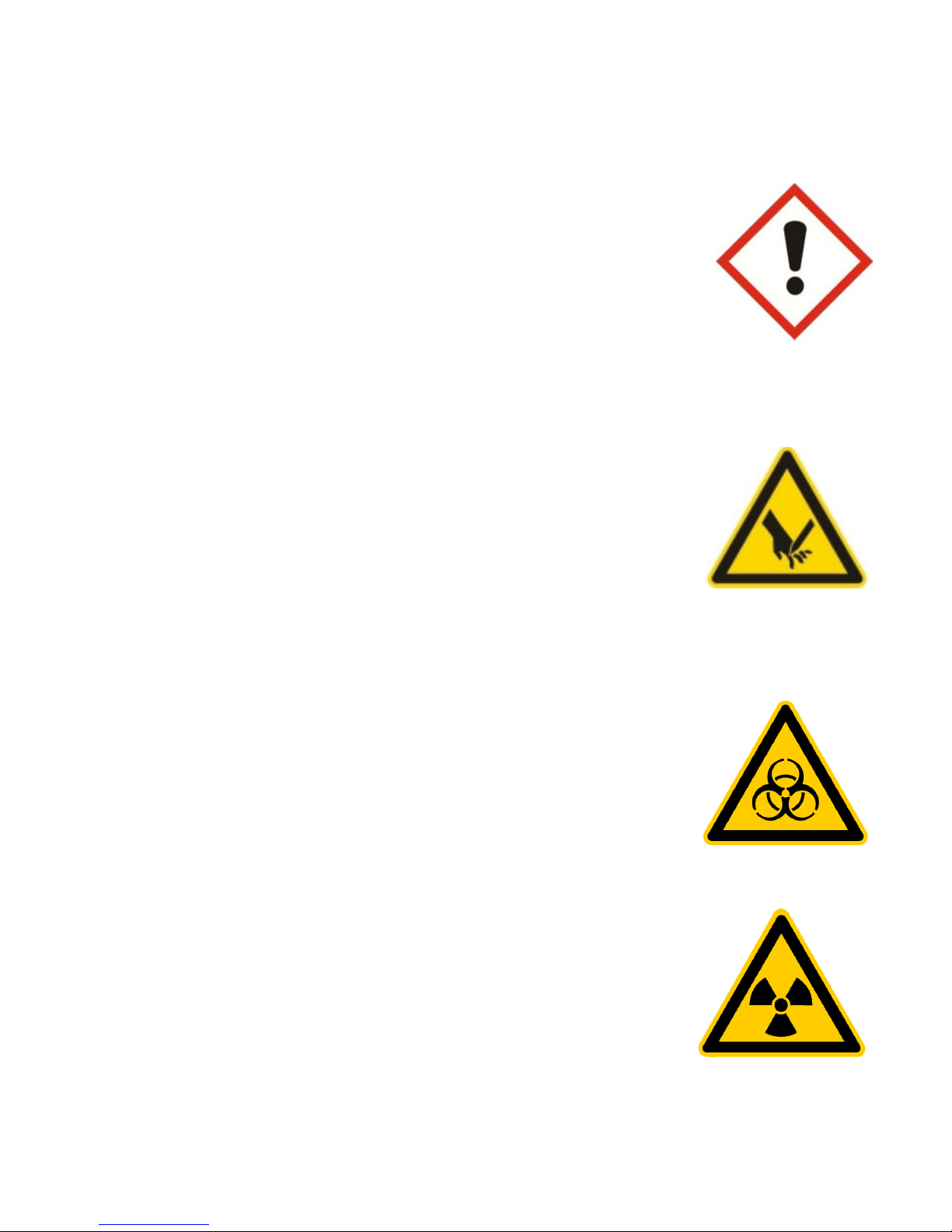

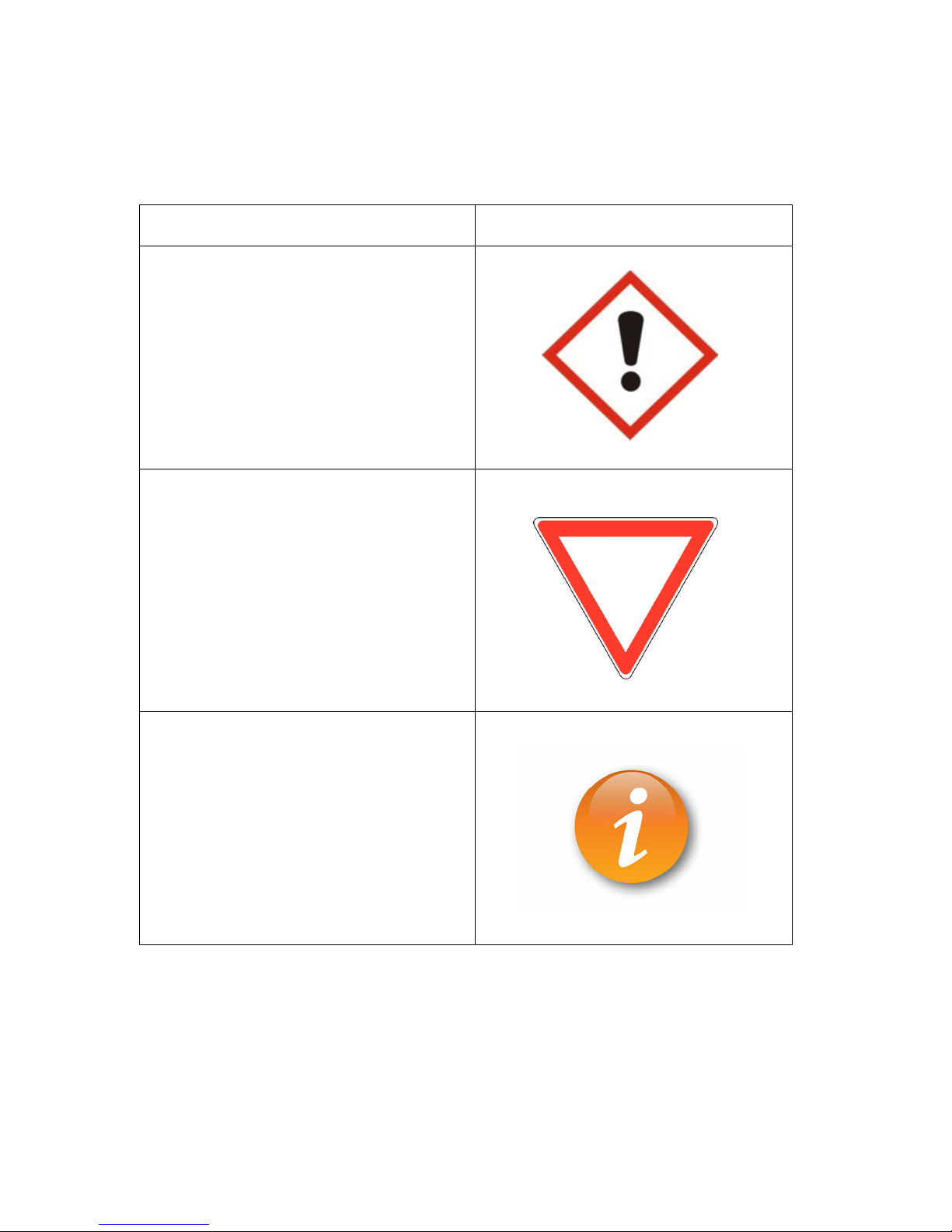

2.5 Interpretation of Hazard Symbols

Interpretation

Symbol

• Danger

• Warning

• Caution

• Note

• Important !

• Information

Page 12

microTec

12

2.6 Informal Instructions Issued by the Manufacturer

Preparation of the Specimen

Due attention should be paid in the preparation of specimens with regard to making the

correct choice of the medium used for embedding and encapsulation of the specimen

and its curing and infiltration time.

Temperature of the Specimen

Microtomic sectioning is generally carried out at room temperature (except in the case

of frozen specimens). Increases in temperature will soften the paraffin wax. The

heating up of paraffin wax specimens due to direct exposure to sunlight or their

proximity to any other source of heat is to be avoided.

Choosing the Knife

Depending upon the ground facet in question, a clearance setting at an angle of 18 to

20 degrees is to be selected. In the case of re-sharpened knives, use the knife height

adjustment facility to set the height of the knife.

Levers and Clamping Screws

Securely tighten all levers and clamping screws on the knife holder and the specimen

orientation device. > Overtightening could result in damage of knife holder!!

Cutting Speed

Rule: “The harder the material, the slower the cutting speed“.

Starting the Cut

Take care when approaching the knife or the specimen.

2.7 Particular Zones of Danger

Important!

Knives are sharp!

Always set the knife guard in its proper position after completing the operation – even

if it’s for a brief moment of time – and make sure it is properly seated.

Page 13

microTec

13

2.8 Servicing and Fault Clearance

Servicing

To secure the quality of the microtomic section and operational reliability of the rotary

microtome, a routine service should be carried out once a year. Servicing should only

be carried out by a trained service engineer.

Service Contract

microTec offers a service contract which guarantees that your instrument will remain in

a perfect operational condition.

Fault Clearance

Malfunctions, which can adversely affect safety, are to be rectified immediately.

2.9 Structural Modifications and Replacements to the Instrument

• No modifications, conversions or enhancements may be made to the instrument

without the approval being given by the manufacturer.

• All conversions require written confirmation issued by microTec.

• Replace components which are not in proper working order immediately.

• Only use original replacement and consumable parts and items.

• It cannot be guaranteed that parts sourced from other suppliers are

designed and manufactured to meet safety and reliability conditions.

Page 14

microTec

14

2.10. Cleaning and Associated Care

Cleaning

Depending upon the level of dirt and contamination and upon the

frequency of use, regular cleaning and care of the rotary microtome is

recommended. The instrument is best cleaned using a mild domestic

cleaning agent. Do not use harsh solvents or cleaning compounds,

because paintwork and plastic components can be damaged by their

use.

Always remove the knife and stow in the knife box

prior to cleaning the instrument.

Important!

Never place a knife on a table or surface with the cutting edge

facing upwards. Thoroughly clean the bearing surfaces and contact

faces and the guide of the knife holder.

Associated Care

When the instrument is not in use, turn back the cylinder by means of

the coarse drive mechanism and lock the handwheel. Cover the instrument

with the cover supplied.

Page 15

microTec

15

3. Transportation and Storage

3.1 Dimensions and Weights

Dimensions

Width: .…….…… ……………. 460 mm

Depth: ….……...…………….… 460 mm

Height: ..…………………..…….. 280 mm

Weight

Weight (without accessories) ……..48 kg

3.2 Instructions for Transportation

Lock the handwheel.

Remove all knives, knife holders, specimen

fixtures and specimens from the rotary

microtome.

3.3 Packaging

The rotary microtome has been supplied in a

special packaging designed for transportation.

Do not commission (start-up) the instrument

until al least 24 hours have elapsed following transportation.

Please ensure the specified procedures are strictly!

Important!

The unit is heavy – do not lift or carry the instrument by means of

the handwheel.

3.4 Inspection upon Acceptance by the Recipient

Firstly, check that all items ordered are supplied in the transportation crate. Inspect the

transportation crate and the rotary microtome for any damage incurred during transit.

3.5 Reporting and Documenting Transportation Damage

In the event of damage caused in transit, the manufacturer and the forwarding agent

are to be advised immediately in writing.

3.6 Storage temperature

Storage temperature range +5° C to + 55° C.

Page 16

microTec

16

4. Data and Information Concerning the

Instrument

4.1 Designation

Rotary Microtome, model CUT 4060E

4.2 Scope of Supply, i.e.

According to order confirmation.

Page 17

microTec

17

4.3 Packaging

1st Step

Remove all side and top sitting

screws sides and take the complete

cover of the transportation crate.

2nd Step

Remove all hexagon headed

screws around and the packaging

frame.

3nd Step

With both hands lift the instrument

out from the transportation crate.

Important!

The unit is heavy – do not lift or

carry the instrument by means of

the hand wheel.

Page 18

microTec

18

4.4 Ambient Temperatures during Operation

+ 10°C to +35°C

Contamination level 2

Overvoltage categorie II (CUT 4055E & CUT 4060E)

4.5 Performance

Range of section thickness: 0.5 - 60 µm

Increments: 0.5 µm from 0.5 µm to 2 µm

1 µm from 2 µm to 10 µm

2 µm from 10 µm to 20 µm

5 µm from 20 µm to 60 µm

Horizontal object advance Max. 40 mm

Vertical stroke Max. 70 mm

Specimen size: standard: 55 x 50 mm

Specimen orientation: X- and Y-Axes 8°, Z-Axis till 360°

Cutter drive: motorized manual switchover

Power consumption: P max. 150 Watt

Max. speed 150 rpm

*according to contractual agreement

Page 19

microTec

19

5. Installation, Assembly, Commissioning

5.1 Installation

Protect the instrument from:

• sources of heat such as fan heaters or hot air outlets ;

• extremely low temperatures;

• direct sunlight;

• excessive dust;

• moisture or rain;

• mechanical vibration or impacts;

• equipment which contain magnets or generate magnetic fields.

5.2 Transportation Locking Pieces and Securements

Remove all locking pieces and adhesive tape used for securement during transportation.

• Place the instrument on a rigid, vibration-free table or bench.

• Align the instrument on the table. Lift up the instrument a little at the front.

• Put the mains plug into the socket provided for this purpose.

• See to correct voltage of your unit and of the mains.

Important! Allways use a 3-conductor, grounded wall outlet.

• Connect the hand control panel to the socket provided for this purpose at the

rotary microtome (see figure).

• Connect the optionally available foot switch.

• Connect the optionally available flush-mounted illumination.

5.2.1 Rearview of the rotary microtome

Picture 3

Page 20

microTec

20

5.3 Controls, Indicators, and Displays

Item Description

1 Handwheel for cutting operation

2 Handwheel handle for handwheel 1

3 Handwheel locking device

4 Handwheel control panel

5 Rotary knob for setting the thickness of slice

6 Inspection window for setting and inspecting slice

thickness

7 Locking lever for knife holder

8 Lever for trimming adjustment

9 LCD-display (cutting counter)

10 Reset for LCD-display

11 Handwheel for coarse drive

12 Clamping mechanism for knife holder

13 Guide bars for knife holder

14 Foot switch

15 Step Operation

16 Single stroke

Continuous stroke

17 High Speed Key Foot switch

20 Emergency shutdown

LCD-display

6

15

7

5

2

3

1

8

9

11

4

12

13

20

16

17

10

14

Page 21

microTec

21

5.3.1 Control

Connect the operating panel as shown on the previous pages.

If supplied, you may as well connect the following accessories:

Foot switch: Order No. H150078 (optional on request)

Inching service

Upon pushing the „Inching service“ key, the vertical object fixture will carry out a cutting

action. If the “Inching service” key is continuously pressed, the vertical object fixture will

carry out a continuous cutting action.

The speed of the vertical object fixture depends on the position of the turn switch. Range:

0-150 strokes/min.

Single stroke

By pressing the “Single stroke/foot switch” key, the vertical object fixture will carry out a

cutting stroke and a reverse stroke.

The speed of the vertical object fixture depends on the position of the turn switch.

Stop

By pressing the „Stop“ key, the microtome stops at any position.

Continuous stroke

Upon the „Continuous stroke“ key and the „Single stroke” key, the vertical object fixture

will carry out a ontinuous cutting action.

For safety reasons, the continuous stroke is enabled only by pressing both keys!

Speed regulator for number of strokes

The number or strokes per minute is continuously adjustable by turning the speed

regulator for the number of strokes from the left to the right. Range of number of strokes:

0-150 strokes per min.

High Speed

By pressing the „High Speed“ key, the speed of the microtome will be increased to the

maximum speed.

LED – lights, when the motor is in operation

Speed regulator for number of strokes

LED – lights, when the unit is on

Stop key

High Speed key

Inching service

Stoke-key = Single-stroke operation

(Important: first press Step-key and hold and then press Stroke key)

Page 22

microTec

22

6. Operation

6.1 Preparation, Orientation, and Alignment of

the Specimen

Prior to starting to cut the specimen, the specimen must be

suitably prepared and embedded and encapsulated in an

appropriate medium. Various molds and plastic cassettes are

used for encapsulation purposes.

By using the microTec adapter system, the specimen can be

aligned to the plane of cut.

6.2 Commencing the Cutting Operation

Macro positioning of the specimen in relation to the knife cutter

is accomplished by moving the base of the knife holder, or by

operating the hand wheel of the coarse feed drive (Fig. 4.11).

With continued operation, cutting of the

specimen commences up to the required depth

of slice. The residues of the cut specimen so produced must be

wiped away from the knife in an upwards direction from

underneath using a brush.

Important!

Do not touch the knife with your fingers!

6.3 Instructions for Producing Sliced Microtomic

Sections of the Specimen

The following aspects are to be heeded in order to produce

effective sliced microtomic sections of the specimen:

• always use a sharp knife,

• as wear occurs at the point of cut, slide the knife to the left or

to the right, in order to be able to continue working with a

sharp section of the knife,

• Always keep the front and rear face of the knife clean. It is

important to thoroughly remove any traces of paraffin wax.

Page 23

microTec

23

6.4 Cutting Action

The cutting action of the rotary microtome is generated by rotating

the hand wheel in a clockwise direction. The cut is accomplished

on the down stroke and retraction on the upwards directed stroke

by further rotation of the hand wheel in a clockwise direction.

6.5 Handwheel

The handwheel 5.3 (1) is integrated in the casing of the

microtome.

The position of the handle corresponds to the vertical position of

the specimen.

The handwheel locking device is situated on the handwheel.

Releasing the handwheel locking device

Press down the knob (refer to illustration)

Locking the handwheel

Press the handwheel locking device

(refer to illustration).

Handwheel engages in one of the 24 locking positions.

handwheel operation

Important!

For personal safety, the handwheel should

always be locked in the upper region of

vertical travel when exchanging specimens.

6.6 Coarse Advanced Drive

To rapidly alter the distance between the knife and the specimen, the rotary microtome is

equipped with a coarse advancement drive (11). The specimen fixture can be moved

forwards or backwards horizontally by the handwheel for the coarse advancement drive

(11).

handwheel

middle position

handwheel

Pos. 1

Page 24

microTec

24

6.7 Friction Clutch on the Coarse Advanced Drive Mechanism

On reaching the front and rear positions of the specimen feed, a friction clutch built into

the coarse advanced drive prevents the blocking of this coarse advanced drive. As soon

as an audible engagement is triggered by the coarse drive, the feeding operation of the

specimen stops. Upon rotation of the hand wheel of the coarse advanced drive in the

opposite direction, the feeding motion is restored.

If the feeding motion is not restored by this procedure, the hand wheel of the coarse

advanced drive mechanism must be pressed inwards against the casing. Only a short

forward or backward movement is needed to ultimately activate the feeding motion.

Important!

Avoid touching the specimen or the specimen holder containing the knife when

operating the hand wheel of the coarse advanced drive mechanism.

6.8 The Handwheel of the Coarse Advanced Drive Mechanism (11)

The hand wheel of the coarse advanced drive mechanism is integrated in the casing.

6.9 Collision Protection Device

On the specimen feed system reaching its forward terminal position, a

red mark is visible on the cylinder. From this mark there is a further

distance of adjustment of max. 2500 microns available. A second red

mark then becomes visible, and the cylinder must be rotated back by

means of the hand wheel of the coarse advanced drive (11), before

further cuts can be made.

Important!

As soon as the remaining distance of adjustment of 2500 microns is exceeded, the

preselected thickness of cut is disabled by the in-built collision protection device.

Any automatic adjustment by rotating the hand wheel is now inactivated.

6.9.1. Emergency shutdown

After pressing the emergency shutdown key the rotary microtome stops immediately.

After releasing the emergency shutdown key, it takes approx. sec until the rotary

microtome operates normal.

Page 25

microTec

25

7. Setting Up and Changing the Setup

7.1 Specimen Fixture

To hold the specimens during cutting, various adapters and clamping fixture systems are

available, based on the microTec principle of modular construction. In conjunction with

the specimen orientation device, it is possible to orientate and align the specimen to the

plane of cut is simple manner. An adapter piece is inserted at the orientation point where

operations do not require such orientation.

7.2 Standard Specimen Clamping Fixtures

The standard specimen clamping fixture is used for paraffin wax or plastic molded blocks

of square or rectangular form. When using, the specimen is placed against the top fixed

jaw and clamped by the clamping screw.

Important!

On the grounds of stability, the specimen should not be allowed

to protrude too far beyond the clamping jaws.

Page 26

microTec

26

7.3 Orientable Adapter

The orientable adapter can optionally be attached by screws to the various specimen

clamping systems and be used only in combination with the specimen orientation device.

Specimen clamping systems of orientable design are supplied ex works equipped with

the orientable adapter.

Example

The orientable adapter is shown in this illustration attached to the standard specimen

clamping fixture by 4 screws and can be removed if required.

Dismantling the standard specimen clamping fixture: Loosen 4 screws

7.4 Fixed Adapter

This adapter is used as a fixed attachment directly on to the cylinder, and can be

optionally fitted to various specimen clamping systems.

Page 27

microTec

27

7.5 Cylindrical Specimen Insert and Prism

To clamp cylindrical specimens, the cylindrical specimen insert, or the prism, can be

inserted into the standard specimen clamping fixture, having the diameters

- Ø 6 mm

- Ø 15 mm

- Ø 19 mm

- Ø 25 mm

*Ø special diameters on request

The location pin engages the movable clamping jaw. Springs on the cylindrical

specimen insert enable easy removal of the cylindrical specimens from the inserts.

Page 28

microTec

28

7.6 Film (Thin Material) Clamping Fixture

The film clamping fixture is a clamping system for film and foil materials or flat and thin

specimens. To insert the specimen, the three threaded pins are loosened, and the

movable jaw against the two compression springs, the setting of which is made by the

two threaded pins, moved laterally. The specimen is held by the force of the springs,

but can be repositioned. By screwing in the threaded pins, the specimen is securely

clamped between the jaws of the film clamping fixture.

7.7 Universal Cassette Clamping Fixture

The universal cassette clamping fixture is a quick change specimen system, and is

used for the clamping of cassettes.

Inserting and removing the cassette

Pull clamping lever in the direction of the arrow.

Important!

Optimal clamping is only achieved if the bearing faces are

clean of any paraffin wax residues.

Thread pin

Page 29

microTec

29

7.8 Specimen Orientation Device

Specimen clamping systems are attached to the orientation device by means of the

orientable adapter. This way, orientation of the specimen in relation to the plane of cut

is accomplished.

Rotate the eccentric cam lever towards the front.

Specimen clamping fixture is released. Range of specimen clamping: 360º (Z axis).

Turn orientation screws.

It is possible to orientate the specimen 8º in each direction (X axis, Y axis).

The spring loaded pin acts upon the orientation screws.

After orientating the specimen, press the eccentric cam lever upwards into the

clamping position.

Specimen is clamped.

Cutting of the specimen can now commence.

Important!

The spring loaded pin must remain fully screwed in, in order to

keep the orientation screws loaded under spring pressure.

Spring bolt

Page 30

microTec

30

7.9 Exchanging the Specimen Clamping Systems

Exchanging the specimen clamping system

Release (press downwards) the eccentric cam lever.

Withdraw from the left out of the specimen orientation device.

Screw out the orientation screws and spring loaded pin little way.

Withdraw the specimen clamping fixture from the front from the specimen orientation

device.

Important!

After exchanging the clamping system, make sure that the spring

loaded pin is screwed in again, otherwise there will be insufficient

spring pressure imparted.

Note

In order to increase leverage at the handle of the eccentric cam

lever, the handle sleeve can be pulled out. After releasing, the handle

sleeve springs back into its

nominal position.

Page 31

microTec

31

8. Setting up the Knife

8.1 Knife Holder

The knife holders are user friendly designed and easy to clean due to its special

surface treatment. The risk of injury during the setting up of the knife and the

specimen is minimized by a laterally movable finger guard.

8.2 Knife Holder Base

The knife holder base is designed for universal use, and can be used for the “R“

type knife holder and also for the holder for throw-away blades.

Mounting the base of the knife holder.

Release clamping lever by rotating to the left.

Push the base of the knife holder on the guide bars.

Push the base of the knife holder centrally over the clamping mechanism.

Take note of the prism guide.

When in the required position, rotate clamping lever to the right until it reaches the

stop.

Knife holder R

Angle marking

Base of knife holder

Page 32

microTec

32

8.3 The “R“ type knife holder

Assembling the “R“ type knife holder on the base of the knife holder

Release clamping lever in opposite direction to that of the arrow.

Introduce the “R“ type knife holder into the clamping mechanism.

Clamp at the required clearance angle position.

Inserting the knife

Slightly unscrew clamping screws.

Push the knife in from the side.

or

Hinge up knife guard in direction of arrow.

Insert knife from above.

Clamp knife by means of the clamping screws.

Push finger guard to center each time when

Carrying out setting-up operation.

Clamping levers are fitted to both sides of the knife holders to facilitate easier operation.

Knife height adjustment device

Loosen clamping screws.

Adjustment to the height of the knife (1) is accomplished by screwing the knurled screws

to the left or the right.

Tighten the clamping screws.

Clamp screw

Knife holder R

Angle marking

Base of knife holder

Page 33

microTec

33

8.4 The “RS“ type knife holder

Stable version for Tungsten carbide conventional

steel knives with the central clamping plate

providing optimal stability. The knife is stabilized

exactly, where the highest cutting forces are

applied. Full use of the knife length

.

Assembling the „RS“ type Knife Holder on the base of the Knife Holder

Release clamping lever in opposite direction to that of the arrow.

Introduce the „RS“ type knife holder into the clamping mechanism.

Clamp at the required clearance angle position.

Inserting the blade

Slightly unscrew clamping screws.

Lift the valve completely bent up.

Insert the blade and adjust with the knife height adjustment device the blade-edge to

the white strip.

Fit the valve and clamp it evenly with the two clamp screws.

Open the blade guard

Move the movable protection for opening outwards. Finger-blade guard when setting

always closed hold.

Page 34

microTec

34

8.5 Holder for Throw-away Blades

Assembling the holder for throw-away blades on the base for the knife holder.

Release clamping lever in opposite direction to that of the arrow.

Introduce the holder of the throw-away blades into the clamping mechanism.

Clamp at the required clearance angle position.

Inserting the throw-away blades

Release clamping lever.

Insert throw-away blades from the side in the gap between the bars and the clamping

plate.

Push throw-away blades to the center of the throw-away blade holder.

Tighten clamping lever.

Suitable Knife blades

Blades type Manufacturer Dimensions

ACCU-EDGE FEATHER 0,25 x 8,0

ACCU-EDGE FEATHER 0,32 x 14,1

Inscription of clamping plate

MS24, MS33, MS100, MS200, MS300 MICROS Austria 0,25 x 8,0 CUT 2511A Low Profile I

EDGE-RITE Thermo Scientific 0,30 x 8,0 CUT2511AE Low Profile I

Plasma High Profile MICROS Austria 0,32 x 14,0 CUT 2511B High Profile I

Fig. 17

Holder for throw-away blades

Space for inscription

Fig. 17

Base for the knife holder

Page 35

microTec

35

Utilization of the blades

In order to utilize the entire cutting edge of the blades. These blades can be pushed to

the right or to the left.

Release clamping lever. Push blade with the clamping plate to the left or the right.

Tighten clamping lever.

8.6 Clearance Angle Adjustment

Release clamping lever. Pivot the knife holder and /or the holder of the throw-away

blades into the clearance position.

The clearance angle can be read off from scale markings on both sides as an actual

value.

Tighten the clamping lever.

Empirically, suitable microtomic sections are produced at a

clearance angle of 15º. This clearance angle position is

characterized by a longer mark on the knife holder base.

9. Optional Accessories

Foot switch: Order number H150078

10. Emergency Service, Customer Service

microTec Laborgeräte GmbH

Rudolf-Diesel-Str. 47

69190 Walldorf, Germany

Phone: + 49 6227 8222-0

Fax: + 49 6227 8222-30

mail@micro-tec.de

www.micro-tec.de

Page 36

microTec

36

Notice

Loading...

Loading...