Page 1

WinCNC Controller 2.2

Revision 1

Copyright © 1999 – 2005

Microsystems of Buckhannon Inc.

14 East Lincoln Street, Buckhannon, WV 26201

(304) 472-7206

Microsystems of Buckhannon, Inc. makes no warranties, either expressed or implied, including any implied

warranties of fitness for a specific purpose, for this software. This package is provided solely on an “as is” basis.

All risk involved in the use of this software is the responsibility of the purchaser.

Program errors, improper software configuration, hardware failures, or other problems can result in damage to the

machinery being controlled. Failure of limit switches, cabling, or port components can result in machine

movement past limits, potentially damaging the machine and endangering operators. It is imperative that a

separate Emergency Stop system be in place, which bypasses all computer control. Software features to abort

motion from the keyboard and limit switch inputs are provided as conveniences only, and must not be relied upon

to stop motion in an emergency.

Microsystems of Buckhannon, Inc. disclaims all liability for any and all damages, including incidental and

consequential damages in connection with use of this software. The sole and exclusive liability of Microsystems of

Buckhannon, Inc. will be limited to the purchase price of this software package.

If you do not understand and agree with these disclaimers, please do not use this product. Return all materials to

the place of purchase for a full refund.

Page 2

WinCNC Controller Contents

Installation 1 – 1

Screen Display 2 – 1

System Configuration 3 – 1

Screen Configuration 4 – 1

Program Operation 5 – 1

Command Reference 6 – 1

Macro Configuration 7 – 1

Messages and Error Codes 8 – 1

Appendix 9 – 1

Index 10 – 1

WinCNC Users Guide

Page 3

WinCNC Controller Installation

Installation:

CAUTION: DO NOT USE THIS SOFTWARE ON A COMPUTER CONNECTED TO A MACHINE UNLESS

THERE IS AN EMERGENCY STOP READILY AVAILABLE WHICH WILL INDEPENDENTLY STOP THE

MACHINE.

Software features to abort moves from the keyboard and limit switch inputs can NOT be relied upon in emergency

situations and are provided as conveniences only!

Requirements:

WinCNC Controller 2.2 requires a Windows NT/2000/XP computer system with Pentium 4 1GHz or faster

processor, 128 or more megabytes of RAM, and a hard drive. Slower computer systems may result in abnormal

acceleration and other problems.

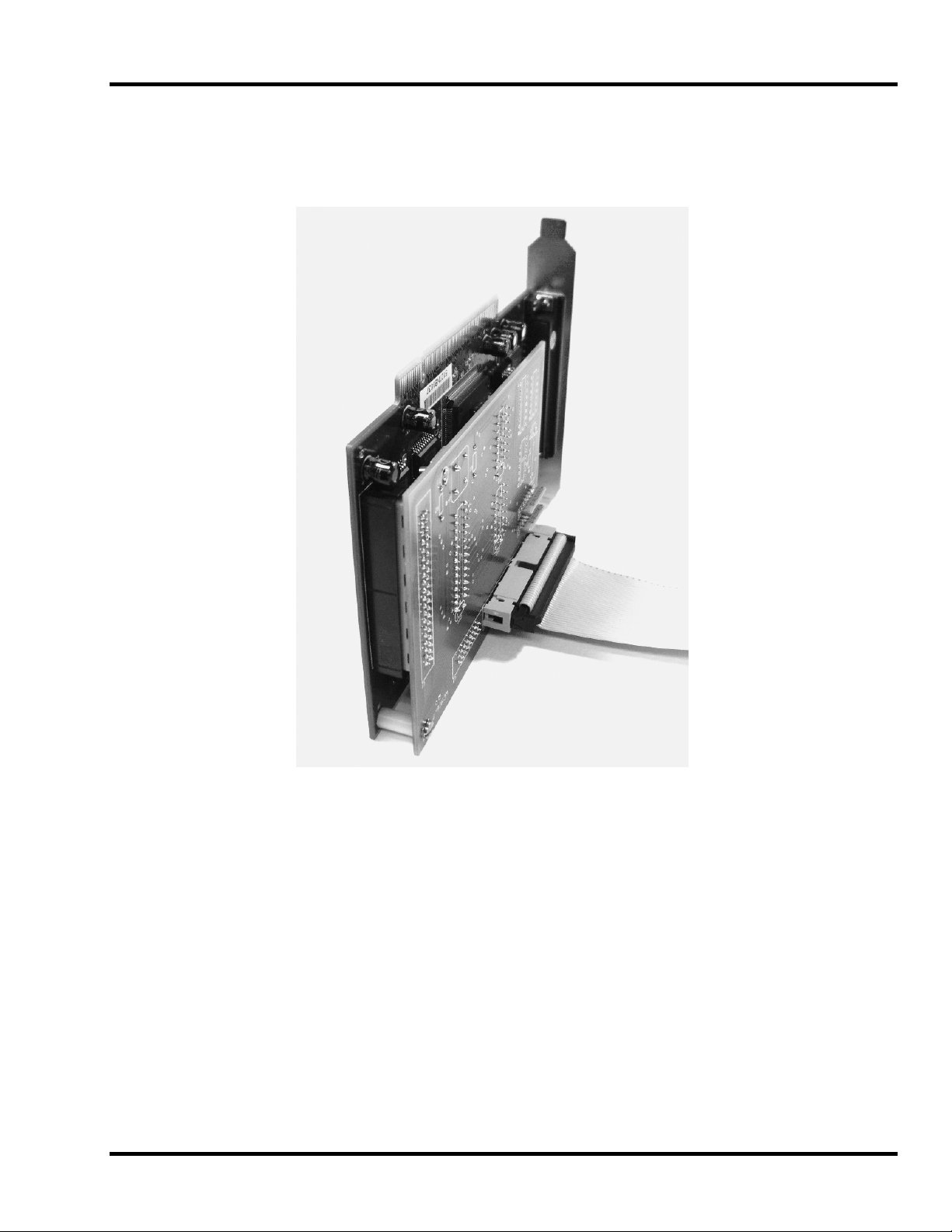

Installation and configuration of PCI-7200 card

Below are the components for the PCI-7200 installation. These include a PCI-7200 card, a Daughter Board, and

a ribbon cable connector.

WinCNC Users Guide 1 - 1

Page 4

WinCNC Controller Installation

Insert the ribbon cable connector into the Daughter Board.

Below is the PCI-7200 card on the left, the Daughter Board on the right and the spacer/screw assembly.

Note the matching holes in the Daughter Board and the PCI-7200 card. The small washer is included for a

precise fit and must be installed between the boards, at one end of the spacer or the other.

WinCNC Users Guide 1 - 2

Page 5

WinCNC Controller Installation

Insert the Daughter Board on to the 40-pin connector of the PCI-7200 card. Attach the two cards with the

included spacer, washer and screws. This will insure constant connection between the two boards.

WinCNC Users Guide 1 - 3

Page 6

WinCNC Controller Installation

Power Down the PC.

Insert PCI-7200 card into an empty PCI slot on the motherboard. Install the extra 37-pin or 25-pin connector into

an empty cover slot.

Make sure the PCI-7200 card is using its own IRQ.

IRQ settings must be altered from the BIOS to insure no conflicts occur between the PCI-7200 card and other

system resources. Changing these settings from within Windows alone will not insure this.

A driver is required for the PCI-7200 card. The driver is included in a PCI-7200 folder on the root directory of the

CNC installation disk for user convenience, if the installation disk isn’t available, the driver can be downloaded

from the MicroSystems website. From the web, go to

bottom of the page. From there, open the “CNC Windows” folder, the “Device Manager” folder, and the

“PCI7200” folder. Download and unzip the driver file to a folder on your computer (we suggest that the folder be

placed on your Desktop).

To install the PCI-7200 driver go into the device manager (Start->Settings->Control Panel->System->Hardware>Device Manager) and select the unknown PCI device, click properties, click driver tab then click update driver.

Next specify location. If you are using the installation CD, browse to the CD, and then PCI-7200 folder. If you are

using the file from the FTP site, browse to the folder that you created.

www.cnccontroller.com, and click on the FTP link at the

Software Installation:

Insert the WinCNC Controller CD-ROM into the CD-ROM drive and run the Setup. The install routine will create

the specified directory if it does not exist and copy the necessary files into it. If there is a previous installation of

WinCNC controller the files will be overwritten. Run the program by double clicking the WinCNC icon on your

Windows desktop.

WinCNC Users Guide 1 - 4

Page 7

WinCNC Controller Screen Display

g

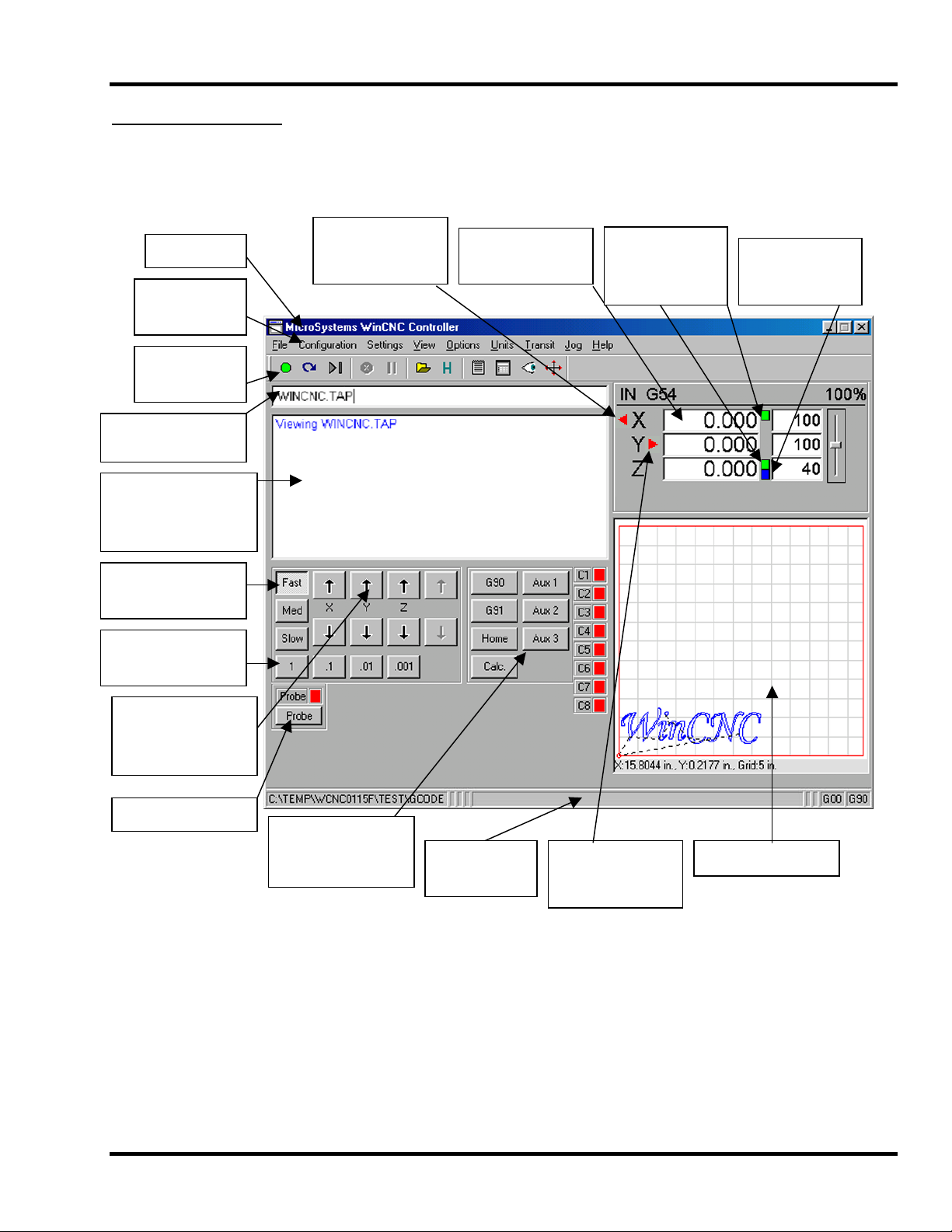

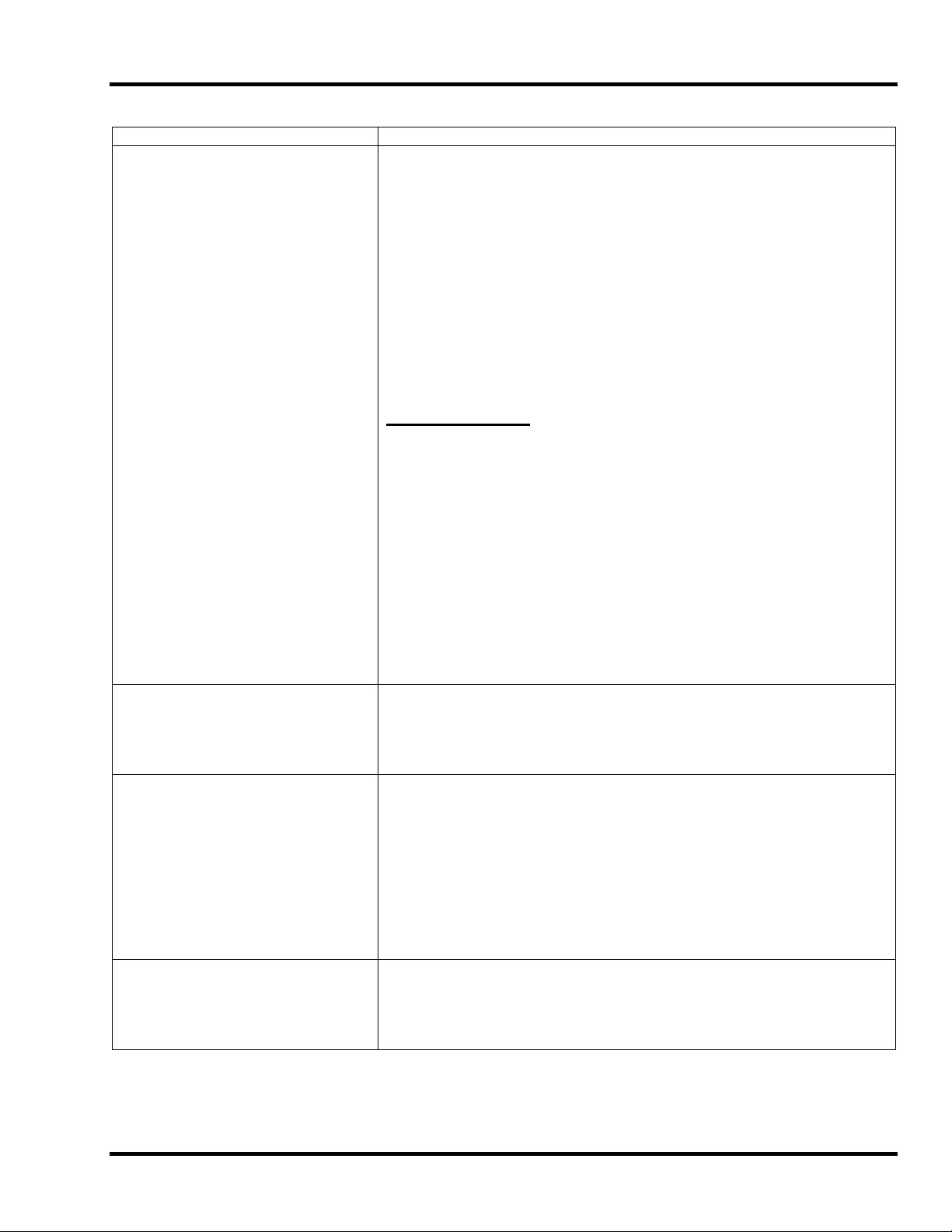

SCREEN DISPLAY:

The following section contains a sample of the WinCnc software display. Common components are labeled to

provide clarity. Under the title of selected components is a reference to a page containing the detailed

explanation of the given component.

Title Bar

Menu Bar

See Page 2-2

Tool Bar

See Page 2-7

Command Line

See page 2-8

Message Display

Window

See Page 2-8

Transit Speeds

See Page 2-8

Jog Increments

See Page 2-9

Transit/Jog

Buttons

See Page 2-9

Probe Enable

Low Limit Switch

Hit Notification.

Red Triangle to Left

of Axis Label

Custom Screen

Buttons Section

See Page 2-9

Axis Window

See Page 2-8

Status Bar

See Page 2-9

Display to show

G92 is set for X

and Z.

Green Box

High Limit Switch

Hit Notification.

Red Triangle to

ht of Axis Label

Ri

Top

Display to show

Tool Measure set

for Z. Bottom

Blue Box

Viewer Window

WinCNC Users Guide 2 - 1

Page 8

WinCNC Controller Screen Display

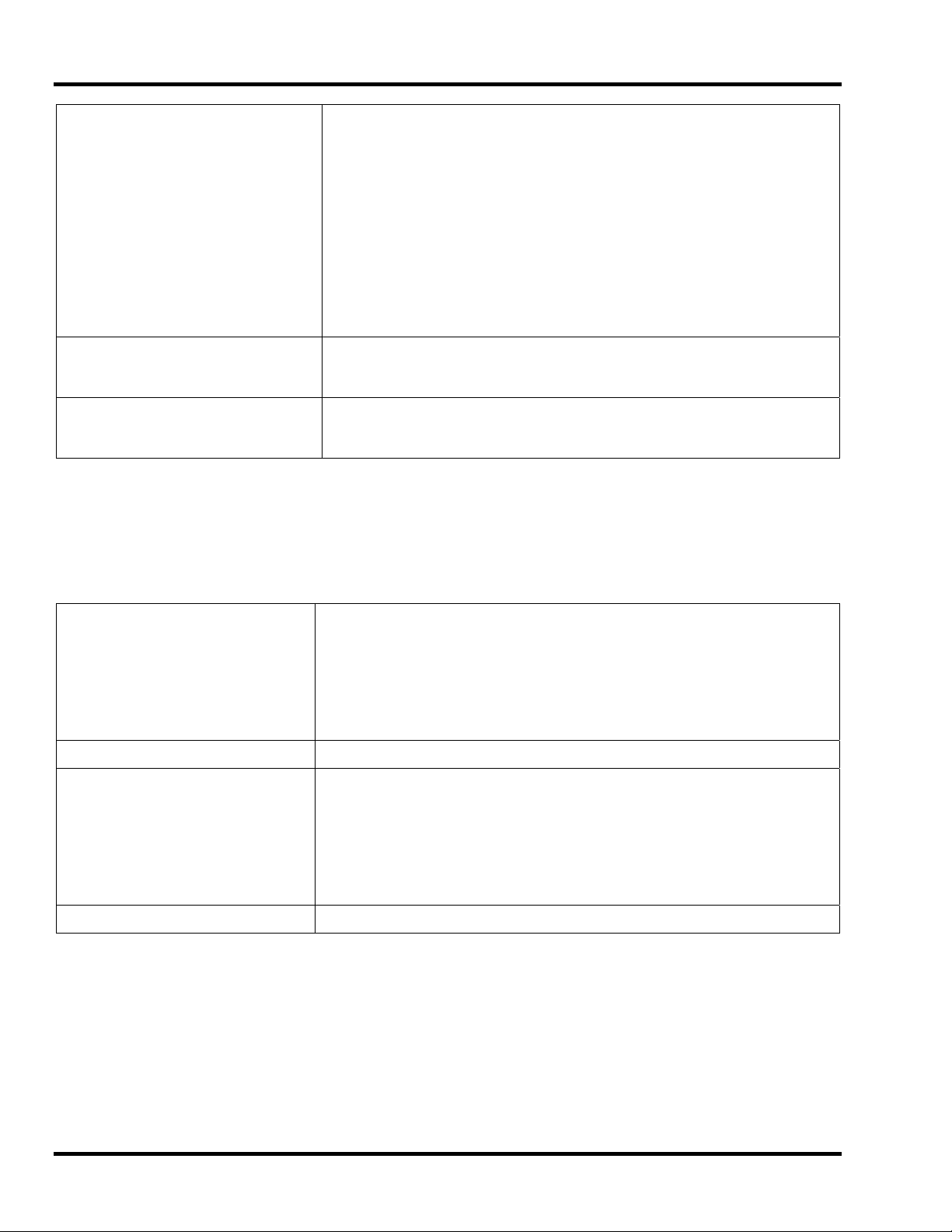

SCREEN DISPLAY COMPONENT BREAKDOWN:

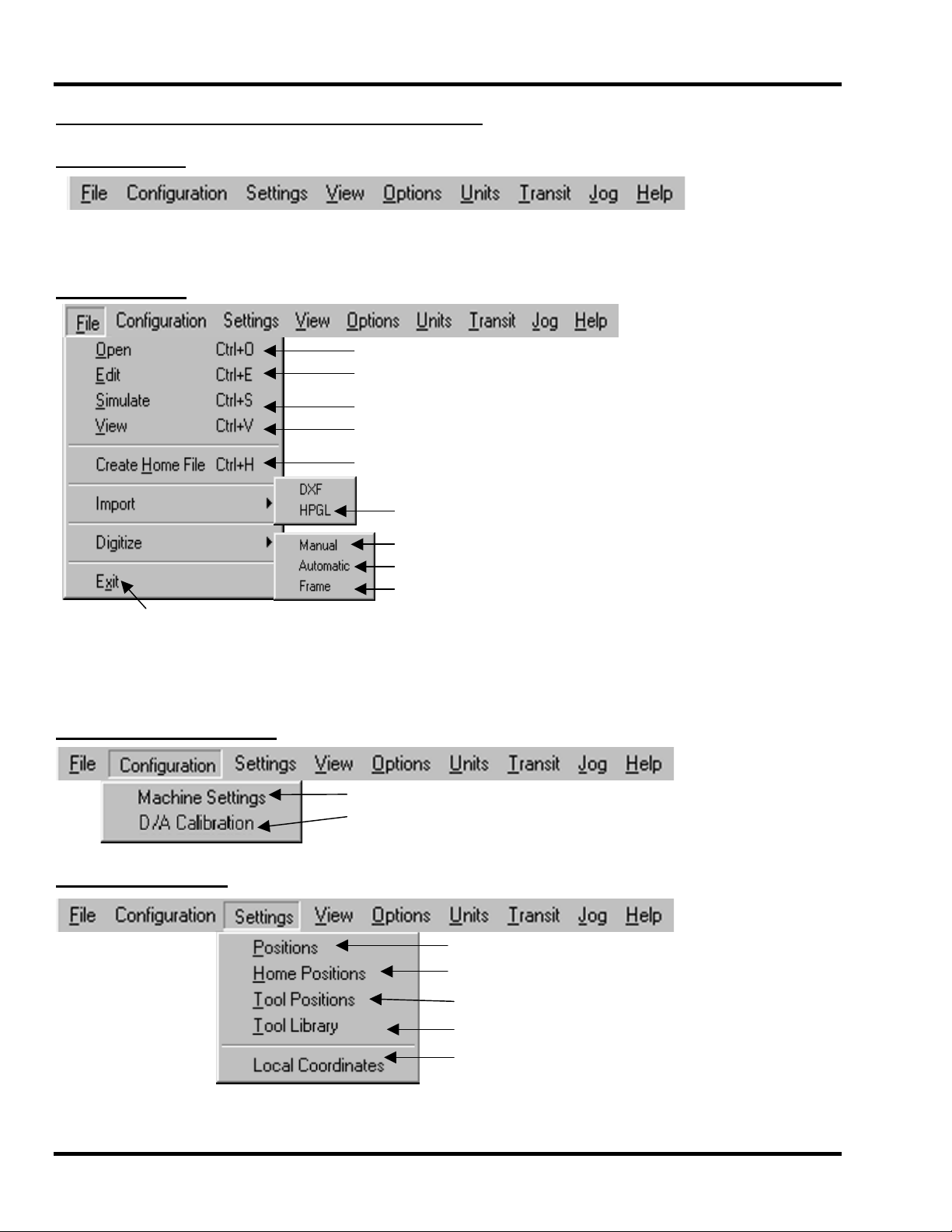

The Menu Bar:

The Menu Bar contains many of the main features of the WinCnc Software. It is broken down into several

generalized sections, as shown above. The following graphics display their options and uses under each section.

The File Menu:

*Note: You should only use the DXF and HPGL import feature of WinCNC for simple design. WinCNC does not

compensate for tool diameter when converting these files. For more complicated design, where intellegent tool

pathing is important, please use a compatible CAD/CAM program.

Quits

The Configuration Menu:

The Settings Menu:

WinCNC Users Guide 2 - 2

Opens a file

Opens the editor (if a filename is in the command line, editor opens that

file)

Simulates a file running to check for errors and time

Views a file in the viewer window

Creates a home file at the current machine position.

Allows the user to import DXF and HPGL files (* see Note)

Enable/Disable Manual Digitizing Toolbar

Automatic Digitizing (L802, L803)

Skeletal Digitizing (Uses L810)

Starts the WinCnc Ini File Editor

Calibration Settings for D/A

Views Positions

iews Home Positions

V

Views Tool Positions

Views Defined Tool Library

View XYZ Coordinates

Page 9

WinCNC Controller Screen Display

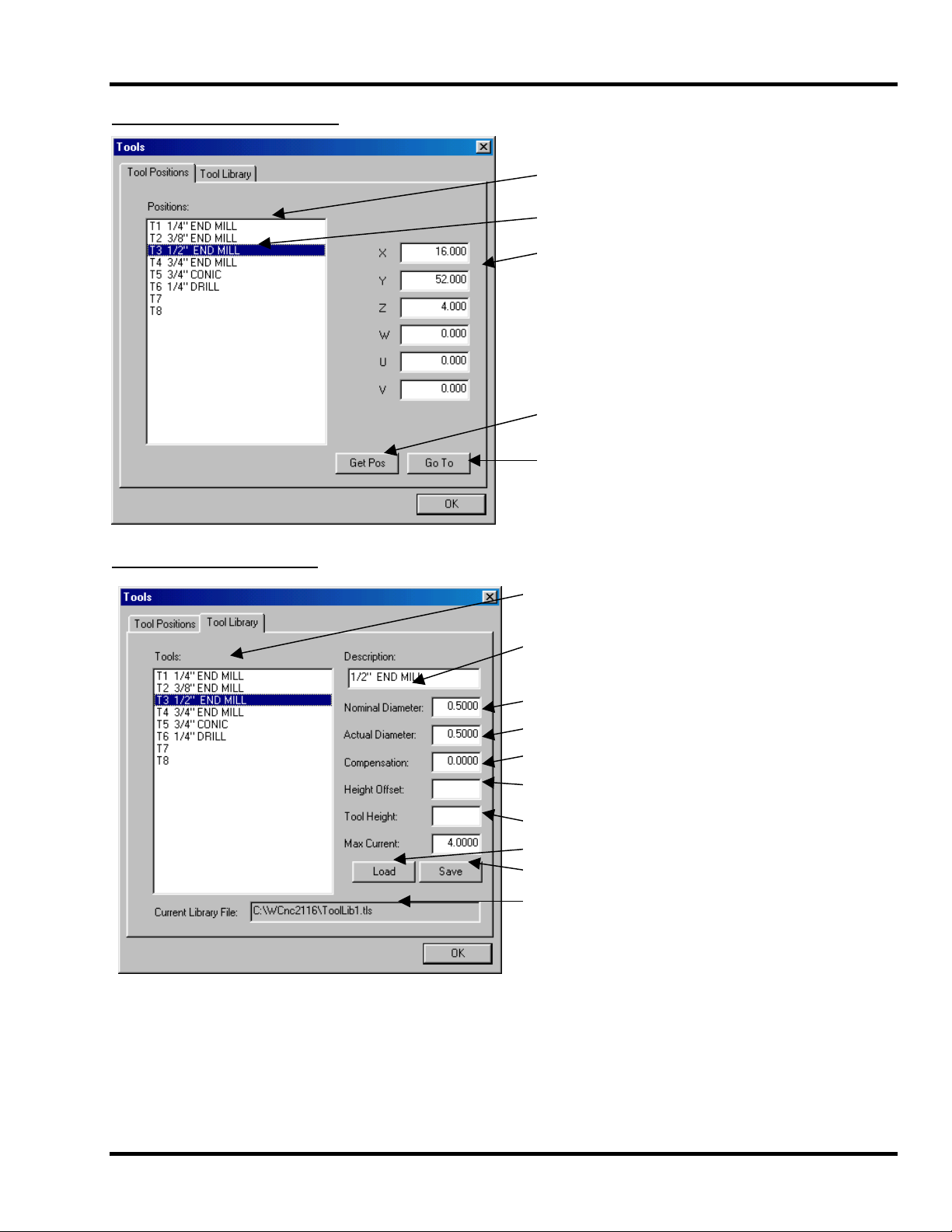

The Tool Positions Menu:

The Tool Library Menu:

Stored Tool Position list.

Currently selected Tool.

Machine Position of currently selected Tool

in Tool Holder.

Stores the current machine position. Should

be clicked when Tool is squarely in Tool

Holder.

Moves to the position of selected tool.

Current Tool Library.

Currently selected Tool.

Diameter this bit should be.

Actual diameter of this bit.

Amount toolpath must be shifted to

compensate for difference.

Distance, positive or negative, to

compensate for specialized Tool.

Distance head must travel from absolute

zero in order for Tool to touch the table.

Load a Tool Library.

Save a Tool Library

Current Library file and path.

WinCNC Users Guide 2 - 3

Page 10

WinCNC Controller Screen Display

The Home Positions Menu:

The Positions Menu:

Programmable Home Positions List

Selected Home Position (name optional)

Clearance after Z height adjustment

Axis positions for this Home Position.

WinCNC sets a G92.1 for these positions.

Stores these axis coordinates as a new

Home Position.

Moves to selected Home Position and sets

local zeros.

Programmable Positions List

Selected Position (name optional)

If G92 is set, “Local” moves machine relative

to G92 setting. Absolute moves machine to

coordinates specified regardless of G92

settings.

Axis coordinates for this stored Position.

Stores these coordinates as a Position.

Moves to selected Position.

WinCNC Users Guide 2 - 4

Page 11

WinCNC Controller Screen Display

The View Menu:

The Options Menu:

The Units Menu:

Sets units of measurement to Inches

Sets units of measurement to Centimeters

Sets units of measurement to Millimeters

The Transit Menu:

Sets Transit speed to Slow

Sets Transit speed to Medium

Sets Transit speed to Fast

View current Resolution settings for each axis

View current Acceleration settings for each axis

View current Limit settings for each axis

Views current input states (will also change in state)

Enable/Disable the Main Toolbar.

Refreshes the screen

Clears the message display window

Enable/Disable the Soft Limits Option

Enable/Disable the Keyboard Transit/Jog

Control

Used to Customize User Buttons

Auto populate the command line with last

command

Enables/Disables the Auto run feature

Enables/Disables the Auto preview feature

Enables/Disables single line execution of

G-Code files.

WinCNC Users Guide 2 - 5

Page 12

WinCNC Controller Screen Display

The Jog Menu:

The Help Menu:

The About box in the WinCnc Controller software contains important information about your specific software

package. The About Box displays your security key serial number, the software version number, your user level,

the maximum number of axis, the table size limitation, and which additional features you have enabled. If you do

not have a feature enable that you would like or need, you can contact your software vendor for an upgrade.

Sets Jog Increment to 0.001

Sets Jog Increment to 0.01

Sets Jog Increment to 0.1

Sets Jog Increment to 1

Sets Jog Increment to Custom

Activates the in Program help menu

Opens the Updating Utility

Opens the WinCnc About window

WinCNC Users Guide 2 - 6

Page 13

WinCNC Controller Screen Display

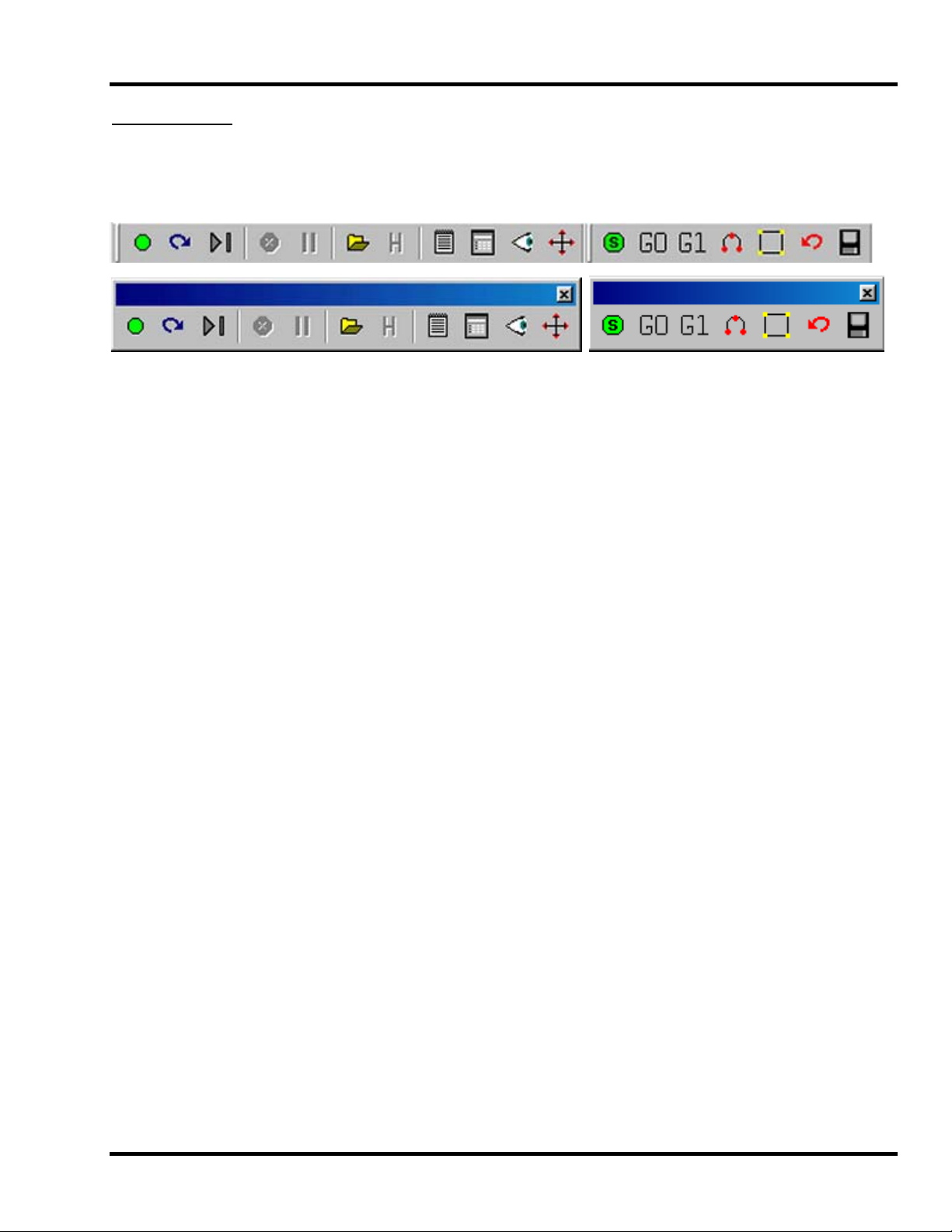

The Tool Bar:

The tool bar is a collection of shortcut buttons that perform specific actions. The Toolbars in WinCnc are floating

and can be positioned or docked to the user’s preference. The image below shows both the standard and manual

digitizing toolbars both docked in the normal toolbar area. The additional images show each toolbar separately as

a floating toolbar. The explanation of each button on the toolbar is as follows. The explanations move

sequentially from left to right along the toolbar.

Start Motion: This button will begin the command or job listed in the command line.

Restart: Allows you to pick a job file and the line to start that file on. This is useful if you want to skip over lines in

a job file, or if you have aborted a job and want to start back at the point you aborted from. You can also choose

to run the file in single step mode.

Single Step: When selected, this allows you to execute one line of a G-Code file each time you hit ENTER.

Abort Motion: Aborts a command or job that is running.

Pause/Continue Motion: Pauses/Continues a command or job that is running.

Open File: Opens a browse box that is used to open a job file.

View Hi story: Opens the command history box, which allows a user to execute a command used previously.

When an error is found in the WinCnc.ini file, the line containing the syntax error is displayed here in red when

WinCnc starts.

Edit: Opens the default editor specified in the WinCnc.ini file. WinCnc uses notepad by default. The editor can be

used to open job files, listed in the command line, in the editor.

Simulate: Simulates a file to check for errors and run-time

View: Opens a file for viewing in the viewer window

Soft Limits: Enables/Disables Softlimit features

Manual Digitize Buttons: The seven buttons on the manual digitization toolbar are for use only with the Manual

Digitize feature, and will only be visible after showing the manual digitize toolbar under the View->toolbars section

of the menu bar.

Start a Manual Digitized File: Starts a manual digitized file and enables the manual digitize mode.

Add a Rapid Move: Adds a rapid move to the manual digitized file.

Add a Feed Move: Adds a feed move to the manual digitized file.

Add an Arc Point: Used to add arcs into a manual digitized file.

Close Shape: Used to close the last move in a shape without moving the machine.

Undo: Used to undo previous moves.

Save: Allows you save the manual digitized file in either G-Code or DXF file format.

WinCNC Users Guide 2 - 7

Page 14

WinCNC Controller Screen Display

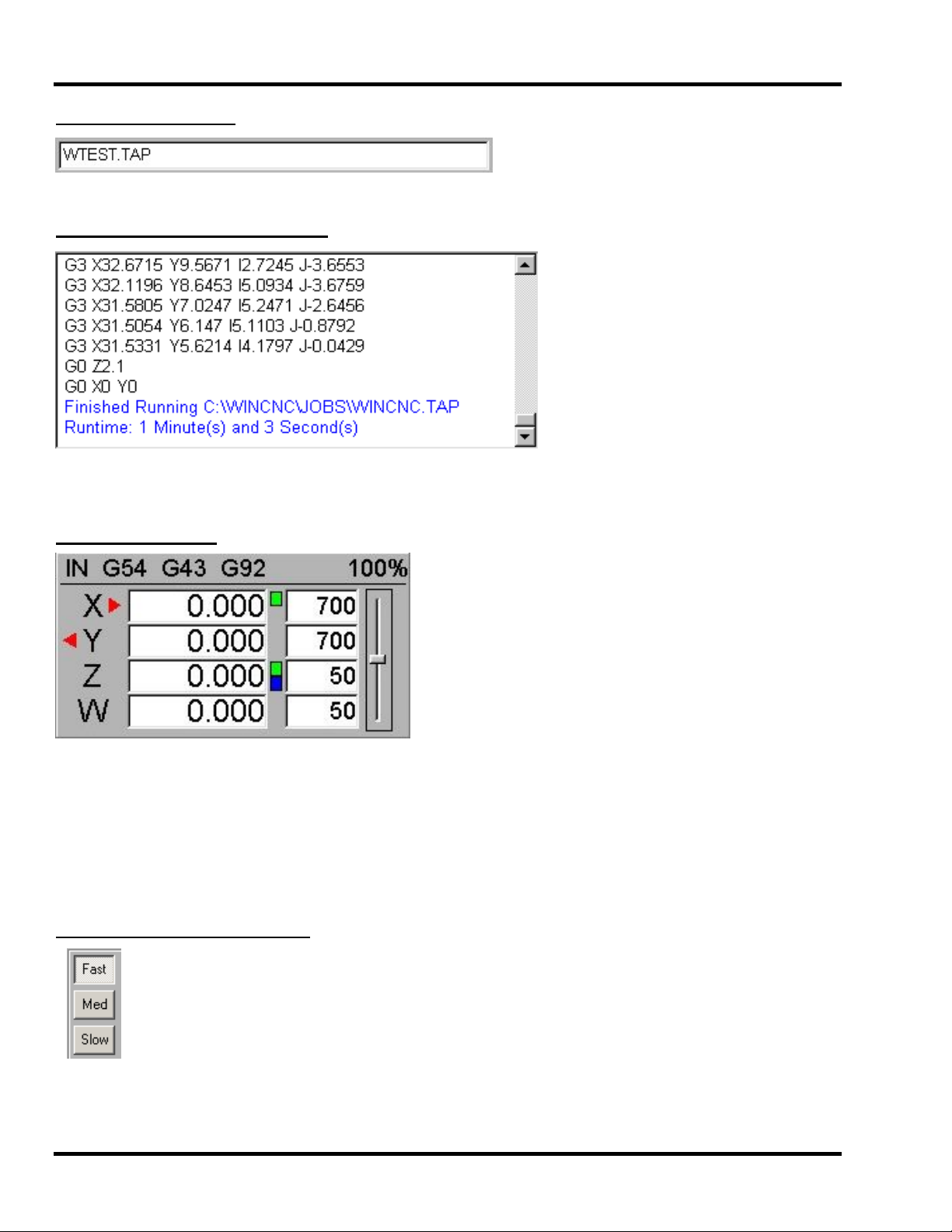

The Command Line:

Is the Input line for users to enter commands or job files to be executed.

The Message Display Window:

The message display window is the main output window displaying the commands that have been executed,

messages to the user, or errors that have occurred during an operation.

The Axis Window:

The axis window is the primary display for current information about each axis on your machine. The current

positions and velocities for each axis are displayed in the text boxes. Displayed above the position and velocity

boxes are the current units of measure, any currently active modes, and the current feed rate override

percentage. Red triangles to the left and right of each axis label indicate low or high limit switch hits. A red

triangle to the left of an axis label indicates a low limit switch hit, and to the right indicates a high limit switch hit. A

green box displayed to the right of the position box indicates a temporary workspace setting, and a blue box

indicates a tool length measure setting. To the far right side of the axis window is the feed rate override control

slide bar.

The Transit Speeds Buttons:

These buttons allow you to specify the transit speed of your machine.

WinCNC Users Guide 2 - 8

Page 15

WinCNC Controller Screen Display

The Jog Increment Buttons:

These buttons allow you to spe

cify the increment of a jog move.

he Transit/Jog Buttons:

T

what allow you to initiate a manual transit or jog movement from the console of the computer These buttons are

that runs the machine. In transit mode, holding the button down will continuously move the machine. In jog

mode, each time a button is pressed the machine will move according to the jog increment that has been

selected. Holding the button down in jog mode will move the machine only once.

The Custom Screen Buttons Section:

This section of controls is a customizable button section that allows the user to place shortcut buttons to activate

heavily used commands.

ote: See Section 4 Screen Configuration

N

he Status Bar:

T

label along the bottom of the WinCnc window that looks similar to the one shown below. The status bar is the

This bar provides the user with the status of several features in WinCnc. Each section in the example below is

labeled for clarity.

Curre

nt

Line in Job

F

ile

Elapsed Time for

Current File

G00/G01

Mode

Indicator

Current File

Percentage of

File Completion

Tool Changer ON/OFF

and current tool being

used

* Note: There are TWO

tool changer indicators

G90/G91

Mode

Indicator

WinCNC Users Guide 2 - 9

Page 16

WinCNC Controller Screen Display

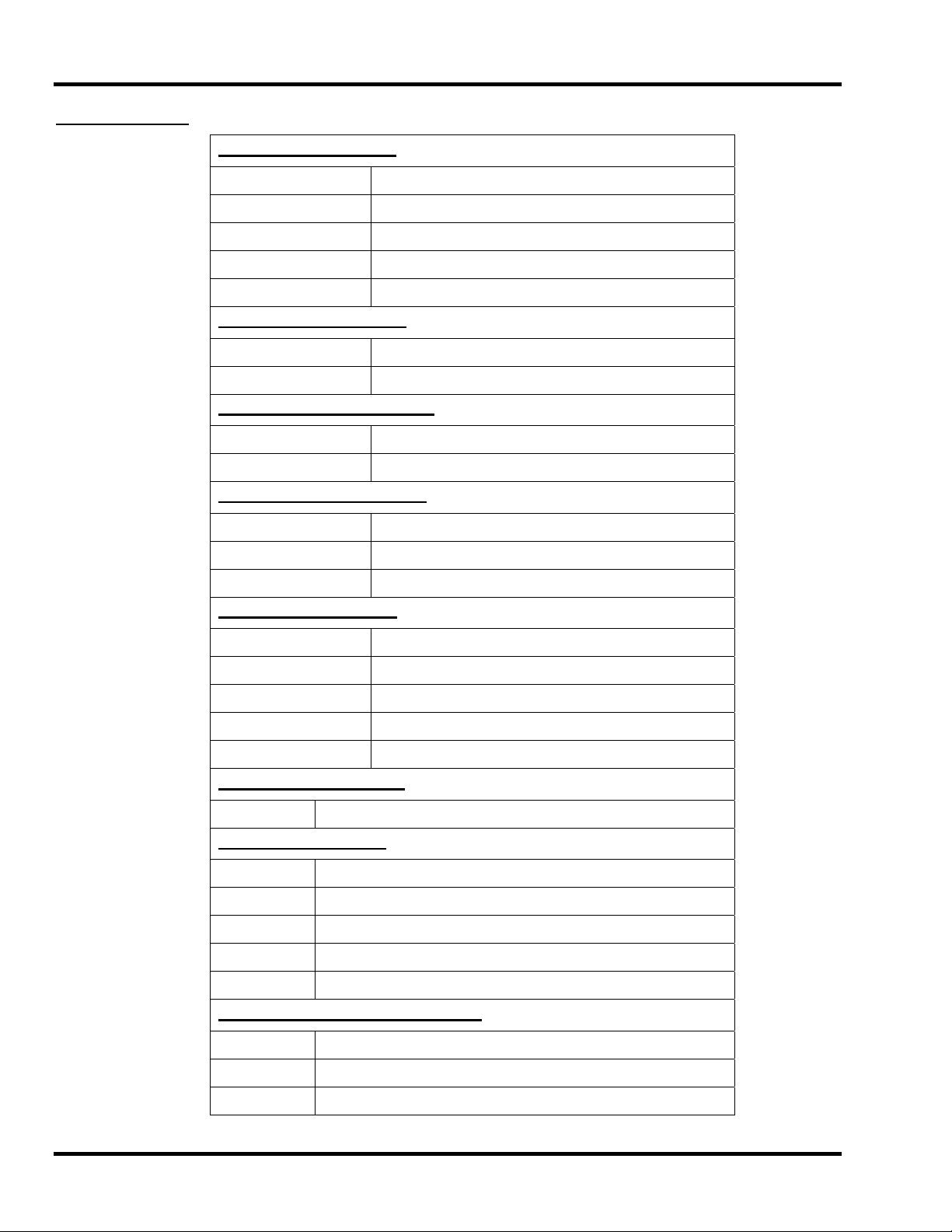

Shortcut Keys:

File Menu Shortcuts

Ente

Open

r(only when command line is blank), (Ctrl+0)

Edit

Simulate

View

Create Home File

(Ctrl+E)

(Ctrl+S)

(Ctrl+V)

(Ctrl+H).

View Menu Shortcuts

Refresh View

Clear Messages

(F5)

(Ctrl+

C)

Options Menu Shortcuts

Keyboard

Soft Limit

(Ctrl+K).

(Ctrl+L)

Transit Menu Shortcuts

Slow

Medium

Fast

(F2).

(F3)

(F4)

Jog Menu Shortcuts

(F6)

.001

.01

.1

1

Custom

(F7)

(F8)

(F9)

(F10)

Help Menu Shortcuts

Help

(F1)

Tool Bar Shortcuts

ESC

SPACE

ENTER

TAB

Ctrl+R

Aborts the

Pauses a file or command.

Starts/restarts a file or command.

Opens the command history box.

Opens the restart file box.

current file or command.

Feed Rate Override Shortcuts

Insert

Delete

Ctrl+either

Increases override rate

Decreases override rate

Resets feed rate to 100%.

No override settings

WinCNC Users Guide 2 - 10

Page 17

WinCNC Controller Screen Display

Shortcut Keys cont.:

Manual Digitize Shortcuts

olbar and clicking the green start button the following shortcut key After opening the Manual Digitize to

combinations become active for adding moves to the digitized file.

Add Rapid Move

CTRL+J

Add Feed Move

Add Arc Midpoint/Endpoint

Undo Last Move

Close Current Shape

Save

CTRL+F

CTRL+A

CTRL+U

CTRL+D

CTRL+W

Spindle Speed and Laser Power Shortcuts:

Spindle Speed Alone or

Laser Power Alone

Spindle Speed and

Laser Power Together

+ – (plus and minus)

Laser Power uses + - (plus and minus)

Spindle Speed uses Shift + - (shift, plus

and minus)

WinCNC Users Guide 2 - 11

Page 18

WinCNC Controller System Configuration

System Configuration:

WINCNC.INI is read on program startup. The preconfigured file is setup to work with minimal change for normal

installations. To change configuration use a text editor to edit WINCNC.INI. If the WINCNC.INI is changed while

WinCNC is running you must restart the program to activate your changes.

CAUTION!!

Make sure you have some idea of what you are doing before changing WINCNC.INI. All input and output is

controlled by these settings. Improper settings will cause limit switches to not work, wrong axis movement in the

wrong directions, and/or other bad and potentially dangerous or damaging incorrect operation.

Please call for help instead of experimenting if you are not very familiar with motion control concepts and

computer configuration.

Use a text editor (such as EDIT.COM or NOTEPAD.EXE) to edit WINCNC.INI. Change values for parameters as

specified below. WINCNC.INI is read every time the program is started. Make sure the file gets saved as ASCII

text (without formatting).

WINCNC.INI Settings:

Unit Settings:

The default unit of measure is inches. If you want to use this WINCNC.INI setting to set the unit of measure, it

must be the first line in the ini file. No other line matters in placement except the Unit= line. You can also set

units by choosing Units from the menu bar and selecting the desired unit of measure.

Unit= (unit) (Unit) is the unit of measurement you want to use.

IN – sets unit= to Inches

CM – sets unit= to Centimeters

MM – sets unit= to Millimeters

Example: unit=IN would set up your configuration to use Inches as

the unit of measurement.

Many WINCNC.INI settings are similar except for the axis specifier, the port number, etc. In this case the

reference below will specify the parameter to be changed in <>. For example:

Timer Card Setup:

Timertype=<#> # Must be 7200.

Maxstepv=<#> # is the maximum number of pulses per second per axis. The default

value is 30000, and can safely be increased to 50000 when using the

2801 or 7200 timer type.

Accel=S<#> S<#>sets the max velocity increment during acceleration. Can be 0

to 50000. The default value is 50.

WinCNC Users Guide 3 - 1

Page 19

WinCNC Controller System Configuration

Port Settings:

NOTE: See the Appendix for the default port settings.

Portin=<#, *> # is the number of the port, can be 0-7. * is the hexadecimal memory

address to the port.

Portout=<#, *> # is the number of the port, can be 0-7. * is the hexadecimal memory

address to the port.

Comment characters:

Comchars=<###> ### represents characters to use to designate comments in a GCode

file. When one of the listed characters is found at the beginning of a

line, WinCnc skips the entire line. The characters “[(%” are regarded

as comments by WinCnc by default. Warning: Any character listed

here will be considered as a comment character, therefore

everything that follows that character on any line will be ignored.

Override Settings:

Gives the user the options of enabling of disabling the feed rate override, and setting the low and high limitations

for the feed rate.

Override=E# L# H#

Pause/Abort from any unassigned keyboard key:

By default, the Spacebar is the Pause key and the Escape key is the abort key. By including the anykey= line in

the WinCNC.INI file, the user can set WinCNC to read any unassigned key as a pause key or an abort key.

Anykey=A#P# A# enables or disables abort on any unassigned key. 0 is disabled, 1

E# enables or disables the feed rate override. Can be set to 0 or 1. 0

is disabled, 1 is enabled. The default is enabled. L# sets the lower

limitation of the override percentage. Can be 1 to 200, but must be

lower than the high value. H# sets the high limitation for the override

percentage. Can be 1 to 200, but must be higher than the low value.

is enabled.

P# enables or disables pause on any unassigned key. 0 is disabled, 1

is enabled.

If both a1 and p1 are included, any unmapped key will be read as an

abort.

WinCNC Users Guide 3 - 2

Page 20

WinCNC Controller System Configuration

Axis Settings:

Axischar=<###> # is desired alpha axis label. Example: axischar=XYZ

Axisspec=P<#>S<#>D<#>R<#>

A<#>O<#>E<#>T<#>B<#>K<#>

Altaxisspec=P<#>S<#>D<#>O<#>

E<#>

Axisvel=R<#>F<#>S<#>M<#>H<#>

A<#>C<#>

Backlash=B<#>S<#>F<#> B# sets initial backlash compensation to on or off, can be 0 or 1.

[SEE DIAGRAMS IN APPENDIX]

P# is port number.

S# is the bit for the step signal, can be 0-7.

D# is the bit for the direction signal, can be 0-7.

R# is the actual resolution in steps per unit.

A# is the actual acceleration in units per minute per second.

O# changes motor direction, can be 0 or 1.

E# sets the step signal for negative edge triggered drives, can be 0 or 1.

E0 is default, a negative going pulse, E1 is positive going.

T# sets the type of axis. 1 is first horizontal. 2 is second horizontal. 3 is

vertical. 4 is rotational.

B# is the amount of backlash to compensate for on this axis.

K# is used for keyboard mapping to this axis.

Ignores Scroll Lock

1 Left/Right Arrow Keys

2 Up/Down Arrow Keys

3 PageUp/PageDown Keys

4 Home/End Keys

Works Only with Scroll Lock Off

5 Left/Right Arrow Keys

6 Up/Down Arrow Keys

7 PageUp/PageDown Keys

8 Home/End Keys

Works Only with Scroll Lock On

9 Left/Right Arrow Keys

10 Up/Down Arrow Keys

11 PageUp/PageDown Keys

12 Home/End Keys

See Axisspec= documentation on the previous page. This setting is

used for an axis that has two motors, and specifies the step and

direction settings for the second motor. Uses the same resolution,

acceleration, type, and backlash as axis specified in the previous

Axisspec= line

NOTE: axisvel is associated with the preceding axisspec line.

R# sets the rapid or G0 velocity for the axis.

F# sets the feed or G1 velocity for the axis.

S# sets the velocity for slow transit.

M# sets the velocity for medium transit.

H# sets the velocity for fast transit.

A# specifies an acceleration factor for transit moves.

C# sets minimum velocity used in velocity matching. Using this setting

improves smoothing and reduces cutting times.

S# sets the smoothing factor for backlash compensation moves.

F# sets the “slow down” feed rate setting to eliminate “clicking” during

arc backlash compensation moves. Example: backlash=b1 f100 means

enable backlash, slowdown feedrate of 100 units per minute.

WinCNC Users Guide 3 - 3

Page 21

WinCNC Controller System Configuration

Vgroup=<F><###> F is only used for the feedrate command group. It normally locks the X

and Y axes together. It isn’t used on any other vgroup line.

#’s are the desired alpha axis labels to group velocity.

Examples:

Vgroup=FXY is the special feedrate command group; If the command

F300 is given on the command line, it forces the X and Y axes to use

300 as their feedrate.

Vgroup=XY would lock the X and Y axes, so that if the command G1

X15 F50 is entered, both axes would be set to 50. Otherwise, Y would

remain at whatever feedrate it had previously been set to.

Other than the X and Y axes, each axis should have its own vgroup; i.e.

Vgroup=Z.

Axismode=A<#>V<#> NOTE: axismode is associated with the preceding axisspec line.

A# is the acceleration factor to use for smoothing on this axis.

V# is the increment used during acceleration in steps/second.

Steppulse=P<#>D<#> P# is the length of each step pulse in microseconds.

D# is the amount of time before each step that the direction signal is set.

NOTE: These settings default to 5, and are generally unused.

Axislo and Axishi:

Are used if the channel specs are not used in the preceding Axisspec or if the limit switch is non-standard for

channel specs.

Axislo=P<#>B<#>O<#>A<#> P# is the input port for limit switch, can be 0-3.

B# is the bit on the port used with the switch, can be 0-7.

O# sets the switch polarity, can be 0 or 1.

A# sets the alternate bit.

Axislo=P0 B2 A4 [bit 2, alternate bit 4]

Altaxislo=P<#>B<#>O<#>A<#> Low limit for Altaxis. See Axislo= documentation above.

Axishi=P<#>B<#>O<#>A<#> P# is the input port for limit switch, can be 0-3.

B# is the bit on the port used with the switch, can be 0-7.

O# sets the switch polarity, can be 0 or 1.

A# sets the alternate bit.

Axishi=P0 B0 A1 [bit 0, alternate bit 1]

Altaxishi=P<#>B<#>O<#>A<#> High limit for Altaxis. See Axishi= documentation above.

Limit Switches:

The default channel settings will normally provide proper interfacing with the machine’s limit switches. Before

attempting to move the machine verify that all limit switches are functioning properly. Limit switch status is

displayed in the position window using a red triangular indicator to the left or right of the axis label. The indicator

to the left of the axis label shows low limit status for that axis, the indicator to the right of the label shows high limit

status. If the indicator is present then the limit switch is closed otherwise it is open.

The lim_mode setting is used to control how WinCnc responds to limit switch triggers.

WinCNC Users Guide 3 - 4

Page 22

WinCNC Controller System Configuration

Lim_mode=<#> # can be one of the following:

0 = same debounce for on and off, any limit switch causes an abort.

1 = same debounce for on and off, only limit switch in the direction of

motion causes an abort.

2 = less debounce for change to off, any limit switch causes an abort.

3 = less debounce for change to off, only limit switch in the direction of

motion causes an abort.

Lim_cnt=<#> # sets the debounce for limit switches.

First toggle your limit switches by hand. Verify that the appropriate limit display toggles. If it does not toggle then

you need to adjust WINCNC.INI. See the WINCNC.INI reference sections of the manual if the default settings are

incorrect for your machine.

It is recommended that you verify limit switch operation at the beginning of each session. Do not attempt

movement until the limit switch displays toggle correctly. Once the limits are working try a small move. If nothing

moves, the wrong axis moves, or movement is in the wrong direction then adjust WINCNC.INI.

Perhaps the easiest way to do preliminary testing of movement is with the Jog mode. Select Jog .1”, and select

the KEYBOARD option under the OPTIONS menu. If you are using the default jog key configuration, use the

LEFT and RIGHT arrow keys to move X, the UP and DOWN arrows to move Y, the PAGEUP and PAGEDOWN

keys to move Z and U, and the HOME and END keys. Otherwise use the buttons that are defined for your

system.

Auxout, Autoaux, and Auxin:

Auxout=C<#>P<#>B<#>O<#>S<#>

E<#>T<#>X<#>W<#> T<#>

[SEE DIAGRAMS IN APPENDIX]

AuxOutVel=# # is the velocity percentage to use (0-100). If the machine velocity,

C# is the channel number, 1-32. Numbers should not be skipped.

P# is the port number, refers to a port specified in a portout spec.

B# is the bit number, can be 0-7.

O# changes the output polarity, can be 0 or 1.

S# set output state on WinCnc startup, can be 0 or 1.

e# set output state on WinCnc exit, can be 0 or 1.

X# set output state on abort, can be 0 or 1.

W# set output state on pause, can be 0 or 1.

T# sets the type of auxout. # can be 2 or 3. T2 sets the auxout

channel to be a motion only auxout. This will result in the auxout only

working while the machine is moving and will turn off when the

machine stops. To use this feature you must also have the S# set to

1 to start up with the software. You can then change it off and on

using the M11 and M12 commands. You must have it enabled to

work correctly during motion. The T2 setting only works with a PCI

card, it does not work with an ISA card or a parallel port connection.

T3 sets the auxout to a programmed velocity percentage auxout type.

during motion, drops below the specified percentage of the

programmed velocity then the auxout signal will be on, otherwise the

auxout signal will be off.

WinCNC Users Guide 3 - 5

Page 23

WinCNC Controller System Configuration

Autoaux=C<#>I<#>S<#>E<#>

Auxin=C<#>P<#>B<#>O<#>D<#>

F<#> M<”error message”>

[SEE DIAGRAMS IN APPENDIX]

C# is the auxiliary output channel number

I# is the initial state of the AutoAuxOut mode (0=off, 1=on).

S# sets the amount of dwell time in seconds used when the

AutoAuxOut channel is set to on.

E# sets the amount of dwell time in seconds used when the

AutoAuxOut channel is set to off.

This feature allows the user to setup an auxiliary output that will turn

on during G1/G2/G3 moves, and will turn off for all other moves, only

if the “AutoAuxOut” mode is set to on. The “AutoAuxOut” mode can

be enabled using the L34 command and disabled using the L35

command.

C# is the channel number, 1-32. Numbers should not be skipped.

P# is the port number, refers to a port specified in a portin spec.

B# is the bit number, can be 0-7.

O# changes the input polarity, can be 0 or 1.

D# specifies debounce. When the input is a switch, debounce should

be used. D100 is a typical value.

F# specifies the function type of the auxin. Can be set to the same

function types as enab, or signal below. When sets to 0, no special

function types are enabled.

M<error message> denotes a custom error message. The me ssage

must be enclosed in double quotes – “”.

Watchdog:

The “watch” feature in WinCnc generates a square wave using an Aux-Out channel, timer chip out 0, or timer chip

out 1.

Watch=T# D# C#

Examples:

Watch=T1 Timer Out 0 (Startup=Low, Exit=High)

Watch=T2 Timer Out 1 (Startup=Low, Exit=High)

Watch=T3 Timer Out 0 and Timer Out 1 (Startup=Low, Exit=High)

Watch=T4 D50 Timer Out 0 (50 ms Square Wave)

Watch=T5 D50 Timer Out 1 (50 ms Square Wave)

Watch=T6 D20 Timer Out 0 and Timer Out 1 (20 ms Square Wave)

Watch=T7 C1 D20 Aux-Out Channel 1 (20 ms Square Wave)

T# is type (1-7)

D# is delay

C# is aux-out channel number

T# can be 0 for pin 11, 1 for pin 15, or 3 for both

The feature can only be enabled if the “pumpcont” feature is not

used. Output pins 11 and 15 will go high when the PC is powered up.

When the “watch” feature is enabled, one or both of these outputs will

go low while WinCnc is running and high again when WinCnc exits.

WinCNC Users Guide 3 - 6

Page 24

WinCNC Controller System Configuration

Signal:

Is used to setup control pushbuttons. First setup an auxin line for the input. Then specify signal as follows to use the input channel as a control signal.

Signal=C<#>M<”error message”> T<#> C# specifies the input channel to be used for the signal.

C<error message> denotes a custom error message. The

message must be enclosed in double quotes – “”.

T# specifies the signal type.

*100 Abort

*101 Pause/Continue

*102 Pause

*103 Continue

*110 Start Cycle

*201 Run command stored with L201 command

*202 Run command stored with L202 command

Enable:

Is used to setup emergency stops. First setup an auxin line for input. Then specify the enable as follows to use

the input channel as an enable switch.

Enab=C<#>C<”error message”>T<#> C# specifies the input channel to be used for the enable.

M<error message> denotes a custom error message. The

message must be enclosed in double quotes – “ “.

T# auxin enable type. 1 is default and will abort from any

command when the enable switch is triggered. 2 will abort only

from commands that would result in machine motion when the

enable switch is triggered.

Abort Cushions:

Lim_step=<#> # is the number of steps to compress limits after switch hit.

Esc_step=<#> # is the number of steps to move after ESC key pushed.

Some machines may be damaged if stopped suddenly at higher speeds. Abort cushions provide a method of

decelerating quickly but not instantly when a limit is hit or the escape button is pushed.

Lim_step specifies the number of steps to continue after a limit is hit. This number must be calculated from the

distance your switches may be compressed without damage and the lowest axis resolution of your machin e.

For instance if your X and Y resolution are 1018.592, your Z and W resolution are 2000 and your limit switches

may be compressed .1” then you would set lim_step as follows:

Lim_step=1018.592*.1=100 steps

Esc_step may be set to any value that results in a quick stop without moving too far. A 200 setting is suggested.

G28 Settings:

G28move=X<#>Y<#>Z<#>E<#>R<#>

T<#> A<#>M<#>F<#>

G28altmove=X<#>Y<#>Z<#>W<#> Used to square a machine with two motors on the gantry.

G28coord=X<#>Y<#>Z<#>W<#> Specifies a position after a G28, not used if all positions are zero.

G37 Settings:

G37=X<#>Y<#>D<#>F<#> X# is the X position of the tool measure switch.

Y# is the Y position of the tool measure switch.

D# is the rapid decent distance.

F# is the feed rate for the remaining decent distance after rapid rate.

WinCNC Users Guide 3 - 7

XYZW specifies the distance to move from each limit switch while

homing. The R specifies the distance to move off the limit switch

after the first contact. F is the approach speed to use for the initial

contact. T is the approach speed to use to for second contact. A is

used to specify that an alternate limit switch is to be used. M

specifies that each axis will home individually.

Page 25

WinCNC Controller System Configuration

Soft Limits:

Lolim=X<#>Y<#>Z<#>W<#> X# is the low soft limit value for X.

Y# is the low soft limit value for Y.

Z# is the low soft limit value for Z.

W# is the low soft limit value for W.

Hilim=X<#>Y<#>Z<#>W<#> X# is the high soft limit value for X.

Y# is the high soft limit value for Y.

Z# is the high soft limit value for Z.

W# is the high soft limit value for W.

Lobound=X<#>Y<#>Z<#>W<#> X# is the low boundary value for X.

Y# is the low boundary value for Y.

Z# is the low boundary value for Z.

W# is the low boundary value for W.

Hibound=X<#>Y<#>Z<#>W<#> X# is the high boundary value for X.

Y# is the high boundary value for Y.

Z# is the high boundary value for Z.

W# is the high boundary value for W.

Softlim=T<#>M<#> T# can be one of the following. 0=disable 1=enabled and active

2=enabled but inactive.

M# is to tell whether or not to show the softlim’s toolbar icon. 1 will result

in the toolbar icon being shown, 0 for not shown. Boundaries and Soft

limits are linked, so the state of 1 represents the state of the other. So the

boundary= line is not needed.

Arc Settings:

Arc_err=<#> # Is the value (in units of measure) of allowable errors in arc

specifications.

Default value is .01. If you get radius errors from your files increase in .002 steps. If errors persist with larger

values the problem is probably in your program.

Arc Radius errors indicate that the distance from the start point to the center point is not the same as the distance

from the end point to the center point.

Arc_min=<#> # is the value (in units of measure) for smallest arc radius to be cut as an

arc. Arcs with radius smaller than this value will be cut as a G1 move.

Default value is .002.

Arc_tol=<#> # is the value (in steps) for full circle. If the distance from the start point to

the end point (in steps) is less than arc_tol then a full circle will be cut.

Default value is 3 steps.

Arcfeed=<#> # can be 0 for Auto Mode or the velocity desired.

Arc_feed_lock=<#> # can be one of the following values. 0, 1, or 2 as above.

G2modal=<#> # can be 0 or 1, if 0 G2 and G3 commands are non-modal, if 1 G2 and

G3 commands are modal. The default is non-modal.

Arc Feed rates may be set to Automatic Mode or set to an initial rate. In Automatic Mode arcs are run at the

current XY feed velocity unless the radius is too small to support that velocity, in which case the maximum arc

velocity is calculated based on the acceleration settings for the X and Y axis’s. Arc Feed rate may also be locked

as above. Smoothest motion is usually obtained using Auto Mode.

Rapidjog Settings:

Rapidjog=<#> # can be 0 or 1. If 0, jog moves use G1 speed (this is the default). If set

to 1, jog moves use G0 speed.

WinCNC Users Guide 3 - 8

Page 26

WinCNC Controller System Configuration

Workspace:

G54=X<#>Y<#>T<#>A<#>R<#>

O<#>

G55=X<#>Y<#>T<#>A<#>R<#>

O<#>

G56=X<#>Y<#>T<#>A<#>R<#>

O<#>

G57=X<#>Y<#>T<#>A<#>R<#>

O<#>

G81 Settings:

G81dwell=<#> # is the value (in seconds) of the desired dwell at the end of the plunge

Laser Settings:

Laser=P<#>D<#> P# is the initial power scale.

D/A Settings:

Da=T<#>A<#>V<#>I<#> T# is the type of D/A port used. Can be 0 (parallel port) or 1 (PCI

Tool Changer Settings:

X# is the workspace shift value for the X axis.

Y# is the workspace shift value for the Y axis

T# is the type of workspace shift. Use 0 for vertical head swapping and

use 1 for rotational axis

A# is the axis number. This setting is used only for type 1.

R# is the radius, which is used for type 1’s which have an off center bit

O# is the offset value, which is used for correcting the 0 degrees

position. The 0 degrees position should point toward the positive X

direction

move. The default value is 0.

D# is the laser power duty cycle.

daughter board).

A# is the parallel port address and is only used when t is set to 0.

V# is the maximum voltage - generally 5 or 10 volts.

I# is the value to which you wish the port to be initialized when WinCNC

starts. It can be set from 0 to the maximum set in V#.

Atc1=H<#>O<#>Z<#>A<#>L<#>

N<#>M1

Atc2=H<#>O<#>Z<#>A<#>L<#>

N<#>M1

SST Servo Drive:

Sst= C# R# V# C# is the COM port number being used.

Sstnode=A#D# A# sets the axis number for this node (servo drive). 0=X, 1=Y, 2=Z, ….

Add a “SSTNODE=” line for each servo drive on the serial loop. If there is a drive connected for which you DO

NOT wish to change resolution specify “D0”

H# is the height at which the tool is unloaded.

O# is the offset to the tool sensor.

Z# is height of the bottom of the tool changing spindle.

A# is the axis number for the tool changing spindle. X=0, Y=1, etc.

L# is the lowest tool number.

N# is the total number of tools in the spindle

M1 allows the use of the new library option.

R# sets the division for resolution when switched to rapid mode. Can

be 2,4,6, or 8.

V# sets if each command sent to a servo drive is validated. 0=not

validated, 1=validated (default).

D# sets the division for this node (servo drive). Can be 0, 2, 4, 6, or 8.

WinCNC Users Guide 3 - 9

Page 27

WinCNC Controller System Configuration

Pump Control Settings:

Pumpcont=T<#>L<#>H<#>A<#>

B<#>I<#>R<#>

KeyPad Settings:

Keypad=C<#>B<#>P<#> C# is the number of the com port used with the keypad.

Keypaddir=c:\wincnc\keypad Specifies the directory where file that can be ran from the keypad type

AutoRun Settings:

T# sets the pump control type. The available types are:

T0 pulse width

T1 pulse width with auto reverse.

T2 pulse width without auto reverse, double scaled.

T3 frequency mode.

L# sets the low value of the output range in units per minute.

H# sets the high value of the output range in units per minute.

A# sets the low value of the frequency range in pulses per second.

B# sets the high value of the frequency range in pulses per second.

I# is the initial value of the pump control output. (0-99)

R# is the initial value of the pump reverse output. (0-15)

B# is the baud rate used with the specified port. Should be 9600.

P# is the type of keypad used. Type 1 is the standard serial keypad,

type 2 is the Q-Term brand keypad with LCD display, and type 3 is the

2Tech brand keypad with LCD display and optional emergency stop.

2 will be stored.

Autodir=c:\wincnc\auto Specifies the directory where files to be automatically ran are copied.

Autofdir=c:\wincnc\done Specifies the directory where files are copied after auto run.

Automode=<#> The autorun mode 0 is disabled, mode 1 will copy name and path to

command bar, mode 2 will automatically execute the found file.

Log File Settings:

Logdir=c:\wincnc\log Specifies the directory where the log file is written.

Logfile=c:\wcnc.csv Specifies the name of the log file.

Home File Settings:

Homedir=c:\wincnc\homes Specifies the directory where created home files are written.

Bitmap Button File Settings:

Bitmapdir=c:\wincnc\bitmaps Specifies the directory where bitmaps used with the splash screen and

screen buttons are kept.

Editor Settings:

Editor=<filename> Filename is the full path and filename of any text editor that will accept

files names as a command line parameter.

Example: Editor=write.exe

WinCNC Users Guide 3 - 10

Page 28

WinCNC Controller System Configuration

File Types:

Filetype=.tap;*.nc Specifies file extensions that are recognized by WinCNC as job files.

Command Settings: *

CmdStart=<command> <command> is the command that will run at the start of every file.

Example: CmdStart=M11C1

CmdEnd=<command> <command> is the command that will run at the end of every file.

Example: CmdEnd=M12C1

CmdAbort=<command> <command> is the command that will run when a file is aborted.

Example: CmdAbort=M12C1

*NOTE: These settings can also be used to call a subroutine to use multiple commands

G-Code Viewer Settings:

Table=X<#>Y<#>W<#>H<#>B<#>

Z<#>

Rapid_Lock for G00 Speed:

Rapid_lock=<#> # can be either:

Spindle Speed Control:

Spindle=T<#>A<”#”>R<#>V<#>

O<#>D<#>

Drillbank:

X# low X coordinate to start viewer area

Y# low Y coordinate to start viewer area

W# width of the table area to view in viewer

H# height of the table area to view in viewer

B# border size in units (Keeps table outline viewable)

Z# auto-zoom for the G-Code Viewer. 1 (default) - auto-zoom out only.

2 - auto zoom in and out. 3 - no auto zoom.

0 – Unlocked status and can change G00 feedrates.

1 – Locked status and can not change G00 feedrates.

The default setting for this feature if not specified in the ini file is 1, the

locked status.

Support for D/A card for spindle speed control.

T<#> is the type of spindle. 1=D/A type 2=auxout type

A<”#”> is the base address of the D/A card

R<#> is the max revs per second of the spindle

V<#> is the value to express the max voltage for the card type.

O<#> is the offset if using a D/A type to shift the low point.

D<#> is the initial default rpm value

Example: Spindle=t1 a”0x2a0” r18000 v4095

*Note this example is based on a 12 bit D/A card. The values will vary

depending on the card type used. I.e. 12 bit, 16 bit, 32 bit card, etc.

Once this line is in the ini file the spindle speed can be set by using S#

where # is the desired revs per second of the spindle.

Drillbank=C<#>N<#> C# - aux out channel, first one that lowers a drill.

Note: Aux Out channels need to be in numerical order

N# - number of channels.

See also the M11 command.

WinCNC Users Guide 3 - 11

Page 29

WinCNC Controller System Configuration

3D Digitizing:

Scan=T<#>A<#>C<#>S<#>H<#>

F<#>P<#>R<#>

Scanfile=T<#>F<#>O<#>A<#> T# is the threshold that is to be used. The accuracy that is used for the

ComDll:

T# is the probe type. 1 is an up/down probe. 2 is an up/down/side to side.

This setting is required.

A# is the axis # the probe is on. 2 for Z. Optional setting. Defaults to 2.

C# is the auxin channel the probe is connected to. This setting is

required.

S# is the # steps to decelerate the probe. Optional setting that defaults to

50 if not specified.

H# is the height to lift when the probe comes into contact with something.

Optional setting that defaults to .005 if not specified.

F# is the feed rate to scan with. Optional setting that defaults to 30 if not

specified.

P# is the plunge for the a#. Optional setting that defaults to 30 if not

specified.

R# is the tolerance.

Example: scan=t2 a2 c8 s50 h.005 f30 p30 r#

STL file. The higher the number the smaller the STL file will be, the

smaller the number the larger the STL file will be. Using 0 for this value

will result in points. Defaults to .003

F# sets the file type. 0 is ASCII, 1 is binary. 0 is the default.

O# sets the output file format. 0 is STL, 1 is DXF. 0 is the default.

A# sets the algorithm used to generate the output file. 0 uses the original

algorithm, which includes all scan data. 1 uses the new algorithm, which

eliminates unneeded data points to reduce the size of the output file. 0 is

the default. This setting is used only with STL files.

Comdll= (path) (path) is the directory to where the comdll file is located.

Positions:

Positions=P<#>H<#>T<#> P# - maximum number of stored positions.

H# - maximum number of stored home positions.

T# - maximum number of stored tool positions.

Knife Mode:

Knifemode=T<#>A<#>L<#>I<#>

Z<#>

Saw Mode:

Sawmode=T<#>A<#>R<#>

O<#>Z<#>

T# – type of knife. This setting must be 1. It is reserved for future use.

A# - is the lift angle. If the angle of change is greater than this value then

the head will lift before rotating.

L# - is the XYW rotation length. At the start of each move XYW will rotate

this distance simultaneously, if there is no Z lift. This setting can be used

to smooth corners.

I# - Arc interpolation chord accuracy.

Z# - is the lift amount used when the auto-lift is used for knife rotation.

T# - type of saw. This setting must be 1. It is reserved for future use.

A# - is the rotational axis number, 0 is X, 1 is Y, etc.

R# - is the radius of the saw blade.

O# - is the offset, in degrees, from the home position to the 0 degree cutting

direction.

Z# - is the lift amount used when the auto-lift is used for saw blade rotation.

WinCNC Users Guide 3 - 12

Page 30

WinCNC Controller System Configuration

G09:

G09=S<#> S# - smoothing factor to be used.

Arctype:

Arctype=T<#>I<#>M<#> T# use 1 for normal arc an d 2 for interpolated arcs.

I# is the length of the segment to interpolate.

M# if set to 1 makes G2/G3 commands modal.

HelpFile:

Helpfile=(path) Path= directory for the manufacturers help file.

Spindle Character:

Spinchar=<#> # - Character used for spindle speed control.

Skip Line Characters: Specifies a character or group of characters that indicate a block of GCode that should be skipped or ignored.

Skipchars=C<”#”>N<#>

Example: Skipchars=c”#%” n10 Sets WinCnc to skip 10 lines of GCode each time that it reads a ‘#’or a ‘%’

character at the beginning of a line in a GCode file.

PCI48H and PCI24H: These are optional PCI cards that support additional IO. Please call Microsystems for

pricing, availability and compatibility.

PCI48H=A<#>B<#>

PCI24H=A<#>

WinCNC Users Guide 3 - 13

C”# “ - # represents the character or characters that mark the beginning of the

code block to be skipped. Characters must be placed within quotes.

N# - # represents the number of lines to skip.

A# - Sets IO for ports A1, B1, and C1. (PCI48H and PCI24H)

B# - Sets IO for ports A2, B2, and C2. (PCI48H only)

WinCnc IO port numbers are automatically assigned to ports 8-12.

A# or B# can be set to 0-15 from the following table.

0 - A=out/B=out/CU=out/CL=out

1 - A=out/B=out/CU=out/CL=in

2 - A=out/B=in/CU=out/CL=out

3 - A=out/B=in/CU=out/CL=in

4 - A=out/B=out/CU=in/CL=out

5 - A=out/B=out/CU=in/CL=in

6 - A=out/B=in/CU=in/CL=out

7 - A=out/B=in/CU=in/CL=in

8 - A=in/B=out/CU=out/CL=out

9 - A=in/B=out/CU=out/CL=in

10 - A=in/B=in/CU=out/CL=out

11 - A=in/B=in/CU=out/CL=in

12 - A=in/B=out/CU=in/CL=out

13 - A=in/B=out/CU=in/CL=in

14 - A=in/B=in/CU=in/CL=out

15 - A=in/B=in/CU=in/CL=in

Page 31

WinCNC Controller Screen Configuration

CNCSCRN.INI Settings:

Program Icon:

“Icon”,”c:\wincnc\icons\msicons.ico”

Display Sections:

"Display", "Viewer", 370, 145, 265, 180

“Display”, ”ButtonSet”, 0, 200, 680, 520

“Display”, “Command”, 0, 0, 425, 195

“Display”, “Position”, 430, 0, 235, 150

"Display", "StoredPosition", 5, 330

“Display”, “Main Window”, 0, 0, 680, 435

“Display”, “Main Color”, 180, 180, 180

“Display”, “Title”, “MicroSystems WinCNC Controller”

"Display", "FileStatWindow", XStart, Ystart

"Display", "JobWindow", 5, 350

"Display", "Position", 527, 0, 260, 140 Uses the standard G92 display

"Display", "Position", 527, 0, 260, 140, 1 Uses the new “ABS” and “LCL” display.

Viewer Sections:

Syntax: "Viewer", "Table", Red (0-255), Green (0-255), Blue (0-255), 0=Solid/1=Dash, Width (Pixels)

Default Settings: "Viewer", "Table", 255, 0, 0, 0, 2

Syntax: "Viewer", "FeedLine", Red (0-255), Green (0-255), Blue (0-255), 0=Solid/1=Dash, Width (Pixels)

Default Settings: "Viewer", "FeedLine", 0, 0, 255, 0, 1

Syntax: "Viewer", "RapidLine", Red (0-255), Green (0-255), Blue (0-255), 0=Solid/1=Dash, Width (Pixels)

Default Settings: "Viewer", "RapidLine", 0, 0, 0, 1, 1

Syntax: "Viewer", "PreFeedLine", Red (0-255), Green (0-255), Blue (0-255), 0=Solid/1=Dash, Width

(Pixels)

Default Settings: "Viewer", "PreFeedLine", 180, 180, 180, 0, 1

Syntax: "Viewer", "PreRapidLine", Red (0-255), Green (0-255), Blue (0-255), 0=Solid/1=Dash, Width

(Pixels)

Default Settings: "Viewer", "PreRapidLine", 180, 180, 180, 1, 1

Syntax: "Viewer", "BackGround", Red (0-255), Green (0-255), Blue (0-255)

Default Settings: "Viewer", "BackGround", 255, 255, 255

Syntax: "Viewer", "Grid", Red (0-255), Green (0-255), Blue (0-255), 0=Solid/1=Dash, Width (Pixels)

Default Settings: "Viewer", "Grid", 210, 210, 210, 0, 1

Syntax: "Viewer", "PosIndicator", Red (0-255), Green (0-255), Blue (0-255), 1 [Indicator Enabled]

Default Settings: "Viewer", "PosIndicator", 255, 0, 0, 1

Syntax: "Viewer", "Local", Red (0-255), Green (0-255), Blue (0-255), 0=Solid/1=Dash, Width (Pixels)

Default Settings: "Viewer", "Local", 0, 0, 0, 0, 1

WinCNC Users Guide 4 - 1

Page 32

WinCNC Controller Screen Configuration

Slider Controls:

“SlideControl”, Left, Top, Width, Height, Output, Unused, Unused, Unused, Unused, ScanOn, ScanOff

The Output value can be 0 for D/A, 1 for Spindle Speed, 2 for Laser Power, 3 for Maximum Pump Output

percentagte, and 4 for Pump Reverse Time percentage. If using Spindle Speed alone, or Laser Power alone, the

+- (plus and minus) keys are used to adjust values up or down. If using Spindle Speed and Laser Power

together, Laser Power uses the +- (plus and minus) keys and the Spindle Speed uses the Shift +- (Shift, plus and

minus) key combination.

“SlideControl”,425,5,235,50,0,0,’’’’,’’’’,’’’’,-1,-1

Axis Controls:

“AxisControl”, Left, Top, Width, Height, Axis, Direction, Unused, Unused, Unused, ScanOn, ScanOff, Bitmap

Axis numbers are zero-based. The letter displayed is determined by the axis given. You can change these letters

in WINCNC.INI.

“AxisLabel”,50,37,35,13,0,0,’’’’,’’’’,’’’’,-1,-1,”x.bmp”

“AxisLabel”,90,37,35,13,1,0,’’’’,’’’’,’’’’,-1,-1,”y.bmp

Jog Mode Buttons:

“JogMode”, Left, Top, Width, Height, Mode, Unused, Label, Unused, Unused, ScanOn, ScanOff, Bitmap

These buttons allow you to switch jog mode and transit speeds. The mode number can be one of the following:

8 = Custom (Uses the label value)

7 = Fast Transit

6 = Medium Transit

5 = Slow Transit

4 = Jog 1”

3 = Jog 0.1”

2 = Jog 0.01”

1 = Jog 0.001”

Label sets the text you will actually see on the button when it is drawn on the screen.

“JogMode”,0,5,35,25,7,0,”Fast”,’’’’,’’’’,-1,-1,”fast.bmp”

“JogMode”,0,35,35,25,6,0,”Med”,””,””,-1,-1,”med.bmp”

“JogMode”,0,65,35,25,5,0,”Slow”,””,””,-1,-1,”slow.bmp”

“JogMode”,50,95,35,25,4,0,”1”,””,””,-1,-1,”1.bmp”

“JogMode”,90,95,35,25,3,0,”.1”,””,’’”,-1,-1,”p1.bmp”

“JogMode”,130,95,35,25,2,0,”.01”,””,””,-1,-1,”p01.bmp”

“JogMode”,170,95,35,25,8,0,”10”,””,””,-1,-1,”10.bmp”

Frames:

“Frame”, Left, Top, Width, Height, FrameType, Unused, Unused, Unused, Unused, ScanOn, ScanOff, Unused,

Group #

Using group frames allows the user to position buttons, labels, and indicators inside of a frame using the upper

left corner of the frame as the (0,0) location. When the frame is moved all buttons in the same group move with it.

Groups can be assigned by adding a group number to the end of a “Frame” line, and then adding the group

number to the end of any "AxisControl", "AxisLabel", “JogMode”, “UserBtn”, “StateBtn”, "AuxOut", “ShellCmd”, or

"AuxIn" line. Allows user to draw boxes around screen elements to organize them. The appearance of the frame

is determined by FrameType: 1 = Etched Frame.

WinCNC Users Guide 4 - 2

Page 33

WinCNC Controller Screen Configuration

Following are some examples of how to use the group frames.

"Frame",210,0,115,125,1,0,"","","",-1,-1,"",1 [Group 1 Frame]

"UserBtn",5,5,50,25,0,0,"G90","G90","",-1,-1,"",1 [Group 1]

"UserBtn",5,35,50,25,1,0,"G91","G91","",-1,-1,"",1 [Group 1]

"UserBtn",5,65,50,25,2,0,"Home","G28","",-1,-1,"",1 [Group 1]

"Frame",325,0,45,170,1,0,"","","",-1,-1,"",2 [Group 2 Frame]

“AuxIn", 0, 5, 5, 20, 18, 1, 1, "C1",2 [Group 2]

"AuxIn", 0, 5, 25, 20, 18, 2, 1, "C2",2 [Group 2]

User Buttons:

“Userbtn”, Left, Top, Width, Height, ButtonNum, Unused, Label, Command, Unused, ScanOn, ScanOff, Bitmap

Userbtn is used to create customized push buttons that send G-Code whenever they are pressed The ButtonNum

is used internally to identify the button. It is recommended that you use sequential integers starting with 0. The

Label parameter determines the text that is actually printed on the button. The Command parameter is G-Code

that is executed whenever the button is pressed.

“Userbtn”,225,5,50,25,0,0,”G90”,”G90”,””,-1,-1,”g90.bmp”

Aux Out Buttons:

“AuxOut”, Left, Top, Width, Height, Channel, Unused, Label, AuxOn, AuxOff, ScanOn, ScanOff, Bitmap

AuxOut creates buttons used to control auxiliary outputs. Channel should be set to the auxiliary channel you want

to control. Label determines the text that is displayed on the button. AuxOn is a G-Code command that turns on

your auxiliary output and may utilize macros. AuxOff is the G-Code command that turns off the auxiliary output.

Note: The 0 channel is reserved for laser enable control only! Standard auxout do not use 0.

“AuxOut”,280,35,50,25,0,0,”Laser”,”L251”,”L250”,-1,-1,”Laser.bmp”

“AuxOut”,280,65,50,25,1,0,”AuxOut 1”,”M11C1”,”M12C1”,-1,-1,”Auxout.bmp”

Job Command Buttons:

“JobCmd”, Left, Top, Width, Height, Command, Unused, Label, Unused, Unused, ScanOn, ScanOff

JobCmd buttons represent non G-code commands you want to send to CNC Controller. The Command

parameter can be one of the following:

1 = Abort motion

2 = Run current command

3 = Pause motion

4 = Refresh keypad file list

“JobCmd”,0,0,0,0,1,0,”Abort”,””,””,17,0,””

“JobCmd”,0,0,0,0,3,0,”Pause”,””,””,13,0,””

Shell Command Buttons:

Shell command buttons allow you to create buttons inside the WinCnc window, which execute outside commands

or programs. Any command that can be executed from the Windows START->RUN line can also be ran from a

shell command button. The following example shows how to create a shell command button for the calculator

application that is included in all versions of Windows.

["ShellCmdBtn", Left, Top, Width, Height, ButtonNum, Unused, Label, Command, Directory, ScanOn,

[ ScanOff, Bitmap

"ShellCmdBtn",215,95,50,25,0,0,"Calc.","calc.exe","",-1,-1,""

WinCNC Users Guide 4 - 3

Page 34

WinCNC Controller Screen Configuration

Repeat Command Buttons:

"RptCmd", Left, Top, Width, Height, Command, Unused, Label, Unused, Unused, ScanOn, ScanOff

RptCmd buttons represent non G-code commands you want to send to CNC Controller, using the serial keypad.

These buttons are not shown on the main window.

The Command parameter can be one of the following:

RptCmd commands should be used for JobCmds that need repeating key messages

1 = Increase override

2 = Decrease override

3 = Increase laser power

4 = Decrease laser power

"RptCmd",0,0,0,0,1,0,"Inc Override","","",7,0,""

"RptCmd",0,0,0,0,2,0,"Dec Override","","",8,0,""

"RptCmd",0,0,0,0,3,0,"Inc Laserp","","",6,0,""

"RptCmd",0,0,0,0,4,0,"Dec Laserp","","",5,0,""

Key Pad Out Buttons:

“KeyPadOut”,Left, Top, Width, Height, Command, Unused, Label, Unused, Unused, ScanOn, ScanOff

KeyPadOut buttons represent commands you want to send to the Qterm II Console. The command parameter

can be one of the following.

1 = Scroll keypad file list up

2 = Scroll keypad file list down

3 = Run current keypad file

4 = Refresh keypad file list

“KeyPadOut”,0,0,0,0,1,0,”Up”,””,””,2,0,””

“KeyPadOut”,0,0,0,0,2,0,”Down”,””,””,3,0,””

AuxIn Indicators:

“AuxIn”, Type(0), Left, Top, Height, Width, Channel(1-32), Color(1-6), Label

Auxin Indicators represent auxiliary inputs for which you want a status display. Channel corresponds to channel

number in wincnc.ini.

AuxIn color settings: The following is the color schemes for the color section of the AuxIn screen line 1 - On=Green, Off=Red

2 - On=Green, Off=Gray

3 - On=Red, Off=Gray

4 - On=Red, Off=Green

5 - On=Gray, Off=Green

6 - On=Gray, Off=Red

Example:

“AuxIn”,0, 340, 60, 18, 1, 1, “Aux-In 1”,””

State Buttons:

State buttons represent the state of a feature on or off. The buttons will stay down when clicked until clicked

again to disable the feature. The type sets the class of the feature. The example below displays type 8 which is

for the scanner feature. If an L800 or L801 command it typed into the command line, the button will change

states to represent the command. The commands are represented left to right, with the left command, L801 in

the example, to represent what happens when the feature is disable, the state button is out in a normal state and

can be clicked to turn on the feature. The second command “L800” is the command that is issued when the

button is up and is clicked to the down state.

["StateBtn",Left,Top,Width,Height,Type,Unused,Label,Command,Unused,ScanOn,ScanOff

"StateBtn",335,25,50,20,8,0,"Scanner","L801","L800",-1,-1,""

WinCNC Users Guide 4 - 4

Page 35

WinCNC Controller Screen Configuration

State button types are as follows:

0 – Reserved

1 – Reserved

2 – Reserved

3 – Reserved

4 – Velocity mode for pump On/Off

5 – Reverse Mode for pump indicator. Indicates if running in reverse mode.

6 – Purge Mode for pump

7 – Tangential Knife mode On/Off

8 – 3D Probe Scanning On/Off

9 – Smart Bitmap engraving

10 – AutoAuxOut

Menu Buttons:

The Menu button can be used to add buttons to the main screen and serve as shortcuts to menu options. The

syntax for the Menu button is as follows:

["MenuBtn",Left,Top,Width,Height,Function#,Unused,Label,Unused,Unused,ScanOn,ScanOff, [Bitmap,Group

"MenuBtn",5,95,50,25,1,0,"Set Local","","",-1,-1,"",1

The Function # can only be set to 1 for the Settings->Local Coordinates menu option. Function numbers for other

menu options will be added in future WinCnc versions.

WinCNC Users Guide 4 - 5

Page 36

WinCNC Controller Program Operation

Program Operation:

WinCNC Controller has advanced features to provide the smoothest possible cuts. G-Code input is constantly

buffered to ‘vector match’ moves. This means your machine only slows down when it needs to and then only as

much as needed to stay within the acceleration parameters programmed. WinCNC Controller also does S-Curve

acceleration through arcs and matches arc tangential velocities with straight moves to provide smooth arc moves.

The result of these features is simply smoother cuts and less need for finishing operations. WinCNC Controller

has a user-friendly interface that lets you take control of your machine providing features previously only found on

custom industrial controllers.

Run the program by double clicking the WinCNC icon on your Windows desktop. Program options may be

selected from the pull down menu using the mouse, alt + menukey, or function keys while the machine is stopped.

Files can either be typed into the command line or you can use the File menu’s open option to bring the file name

to the command line. Using the open command does not automatically run the file, it just brings the name to the

command line.

Homing the Machine:

When WinCNC Controller is started the display is set to the last known position. If the machine has been moved

manually or has drifted while powered down this position will not be accurate. The G28 command must be used to

home the machine. G28 moves the WZ motors up to the hi limits, then moves the XY motors to their low limits.

The heads are then moved away from the limits by the values specified in WINCNC.INI and each axis is set to

zero. This position is Machine Zero.

It is important to use G28 to set Machine Zero since many CNC Controller features are calculated from this

position. Soft Limits and Boundaries cannot be used if Machine Zero is not properly set. G28 will search for the

limits at 50” per minute. The lim_step setting in WINCNC.INI can help minimize the impact to the machine when

stopping at the limit switches.

G28 can also be used to home only specified axis. (i.e. G28Z homes only the Z axis)

Normal machine operation using WinCNC Controller would to be:

Start the program.

Enter G28. Push ENTER. (Machine Goes Home)

Enter Name of Part Program To Be Cut. Push ENTER. (Job File Runs)

Coordinate System:

The Machine Zero (MZ) set by homing the machine becomes the anchor point for all positions specified in

subsequent G Code commands.

Local Zeros (LZ) are set using the G92, G92.1 and G92.2 commands

The position display box displays the current axis coordinates and the axis coordinate modes. The axis coordinate

mode is displayed to the right of the axis position.

A green box indicates that the axis has a Local Zero applied.

A blue box on a horizontal axis indicates that a workspace other than G54 is in effect.

A blue box on a vertical axis indicates that tool length measure is in effect.

The coordinate modes show how the axis values in a given G code command will be interpreted.

MZ Coordinates Values are relative to MZ

G92 Coordinates Values are relative to LZ specified by G92

G55,G56,G57 Coords for horizontal

axes.

Horizontal axes values are offset for vertical axes heads

G43 Coords for vertical axes Vertical axes values are offset for M37 tool measure values

G92 and G55,G56,G57,G43 Values are offset for both

WinCNC Users Guide 5 - 1

Page 37

WinCNC Controller Program Operation

G91 Mode:

G91 mode is called relative or incremental mode. In G91 mode values specify distances. For instance if the X

position is currently 20 and G0 X8 is specified the machine would move +8 units of measure in X to X28.

A G Code program written in G91 mode may be run from any position. Since the moves are relative, the starting

position does not matter, the program will run properly from any starting position. However to get the proper

results the machine must be set to the proper position in relation to the workpiece before the piece is run.

The axis coordinate status does not have any effect on how the program runs. It does however affect the

coordinate display while the program runs.

G90 Mode:

G90 mode is called absolute mode. In G90 mode values specify positions. If the X position is 20 and G0 X8 is

specified the machine would move –12 units of measure in X to X8.

In G90 mode the situation is different. The initial of the machine position will not affect where the part runs since

the first move will go to the absolute position specified on the table. Instead of setting the machine position

properly before running a G90 program.

The G92 commands are used to change the coordinate system so that any position may be temporarily made to

be Local Zero (LZ).

Most G90 programs are written relative to a starting position of X0Y0 with Z0W0 being either the bottom or top of

the workpiece. All that is then necessary to run the program is to insure that the current LZ is set to match the

program before running. There are several ways to do this.

The machine maybe positioned to the proper position and the G92 command used to set the proper coordinates

for running.

Example:

The workpiece is fixtured at X20Y20, is 1” thick and Z0 in the part file refers to the top of the workpiece:

G90 Commands in G90 Mode

G92 Turn off any current G92’s

G0Z2 Set Z 2” above the table 1” above the workpiece

G0X20Y20 Go to corner of workpiece

G92X0Y0Z1 Set this position to be 1” above LZ

The Axis Window shows:

Alternately LZ may be set by shifting MZ the desired amount using G92.1 Using G92.1 it is not necessary to move

to the workpiece first.

Example:

G90 Commands in G90 mode

G92.1 X20Y20Z1 Move LZ 20” in XY and 1” above the table

WinCNC Users Guide 5 - 2

Page 38

WinCNC Controller Program Operation

The coordinate display shows the current position relative to the work piece.

When writing a G Code program there must always be a starting point. Typically it would be the lower left corner

(in XY) of the piece to be machined and either the upper or lower surface of the workpiece or a position a known

distance above the workpiece (ZW). In a G91 mode program this point does not need to be given a coordinate

value.

In G90 mode this point is assigned a coordinate value (usually 0,0,0) and all positions are specified relative to this

starting point.

When running the program the machine is positioned to this starting point and G92 is used to set position to the

start position for the program. Alternately G92.1 may be used to shift MZ.

Workspace:

The G54/G55/G56/G57 functions are used to allow for easy switching between workspace coordinates. Each

G54/G55/G56/G57 line you wish to use must be specified in the wincnc.ini file.

WinCnc.ini Setup: For descriptions see the Systems Configuration Section of the manual

G54=X# Y# T# A# R# O#

After configuring the G54/G55/G56/G57, the G54/G55/G56/G57 commands can be used to switch workspace

coordinates, or for rotating a rotational axis.

If using the type 0 G54/G55/G56/G57 for switching vertical heads just use the G54/G55/G56/G57 command alone

to switch workspace coordinates.

If using the type 1 G54/G55/G56/G57 for a rotational axis command G54/G55/G56/G57 X# Y#, where X and Y

are the positions to rotate towards.

Head Swap:

L12 provide a means of cutting with a head not specified within a program and of using multiple heads

simultaneously.

Example:

L12WZ moves Z whenever W is specified and moves W when Z is specified.

L12ZZ moves Z and W together whenever Z is specified.

L12 alone or L12ZW sets normal operation.

Tool Length Offset:

M37 is used to measure tool length and set ZWUV workspace.

By using M37 it is not necessary to measure tool length for every workpiece thickness change. Using M37 in

combination with Soft Limits and Boundaries also provides a means of protecting the table from being routed

accidentally. After M37 is set G28 will set the ZW to the actual position of the tool tip above the table.

Example:

Move the Z head tool tip to the table.

Command M37 Z0.

M37 turns on G43 mode, indicating that tool length offsets are active. Tool length offsets can be disabled using

G49 and re-enabled with G43 without re-measuring.

Soft Limit / Boundaries:

Soft Limits are used to keep programs and command from moving into the limit switches. Values must be set in

WINCNC.INI before using.

WinCNC Users Guide 5 - 3

Page 39

WinCNC Controller Program Operation

Lolim=X#Y# Distance from MZ to XY low limit switches less .1”

Hilim=X#Y#Z#W# Distance from MZ to XYZW high limit switches less .1”

ZW low limits should not be specified since desired positions vary with tool length.

Lobound=X#Y#Z#W# Distance from MZ to XY table edge and top

Hibound=X#Y# Distance from MZ to XY table edge

ZW high boundaries should not be specified since desired positions vary with tool length.

Soft Limits check absolute position command against the limit switch positions. If a position is commanded that

would result in a limit switch being hit a limit error will be displayed and the move will not be run.

Boundaries check workspace positions. In G54 mode the Z head will not be allowed to leave the table. In G55

mode the Z head might move off the table but the W head will be kept on the table.

ZW low boundary checking is available if M37 is used. Use M37 to set Z0W0 to the tabletop. The ZW hi limits

and low boundaries are then both set to 0. This allows movement between the limits and the table.

Limits and Boundaries may be enabled or disabled in the Settings Menu and in WINCNC.INI using softlim=0 or 1

and boundary=0 or 1.

Repeat Command:

The command or file name history may be viewed by pushing the TAB key.

To repeat a command from the history list select the desired command or file name using the mouse, and then

click OK.

Keypad:

WinCNC Controller Level 4 and above includes a keypad to allow transit and jog of the machine from up to 20

feet from the computer. Plug the keypad into the COM2: port on your computer or change settings in WINCNC.INI

to select another available COM port.

There are three types of keypads that can be used with the WinCNC Controller. Type one is an input only keypad,

which is a serial number pad, just like the one found on the far right of a standard keyboard. Each key can be

configured individually in the CNCSCRN.INI file, using the ScanOn and ScanOff parameters. The type two

keypad is an input/output keypad with a 20x4 LCD screen display. When this type of keypad is defined X,Y, and Z

axis information is displayed on the keypad screen. This keypad can also be configured to browse and select files

from the directory last used by the WinCNC Controller. Configuration for this keypad is done in the CNCSCRN.INI

file, just as for keypad type one. To use the file browsing capabilities of keypad type two you will need to setup

three “KeyPadOut” buttons, as shown in the previous CNCSCRN.INI Settings section. The type 3 is the 2Tech

brand keypad with LCD display and optional emergency stop. This keypad would be configured the same way as

the type 2 keypads.

NOTE: When defining keypad buttons it is important to set the ScanOff code to zero, only for buttons that you

wish to use with the keypad. If this is not done properly a button can be pressed, but will not be released. When

configuring the keypad for use with jog or transit keys this is particularly important because the motion will not

stop when the key is released. It is recommended that the keypad setup is done after you have verified that all

limit switches are working properly.

Below is a list of scan codes for both types of compatible keypads.

WinCNC Users Guide 5 - 4

Page 40

WinCNC Controller Program Operation

Keypad Type 1 : w/out LCD

WINCNC.INI Setting: keypad=c [com port #] b1200 p1

Key: OnCode: OffCode:

1 96 64

2 97 65

3 98 66

4 99 67

5 100 68

6 101 69

7 102 70

8 103 71

9 104 72

ESC 105 73

/ 106 74

* 107 75

- 108 76

+ 109 77

. 110 78

0 111 79

ENTER 116 84

NUMLOCK 121 89

Keypad Type 2: w/ LCD

WINCNC.INI Setting: keypad=c [COM port #] b9600 p2

Key: OnCode: OffCode: Key: OnCode: OffCode