Page 1

mipick MP

Pick-to-Light System

User Manual

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 2

mipick MP

User Manual

Index

1 GENERAL 4

2 SYSTEM OVERVIEW 5

3 COMPONENTS 6

3.1 Distribution unit 6

3.1.1 Distribution unit for Ethernet TCP/IP 6

3.1.2 Distribution unit for Profibus DP 6

3.2 Pick displays

4 WIRING 16

4.1 Distribution unit 17

4.2 Display shaft 18

4.3 mipick 18

4.4 Bus termination 18

5 ETHERNET 19

5.1 Configuration of the Ethernet Interface 19

5.2 Ethernet Communication 21

5.2.1 Sending commands 22

5.2.2 Receiving status messages 23

Page 2

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 3

mipick MP

User Manual

6 PROFIBUS DP 24

6.1 Configuration of the Profibus Interface 24

6.1.1 GSD file 24

6.1.2 Configuration data 24

6.1.3 User parameter data 25

6.1.4 Diagnostic data 25

6.2 DP communication 26

6.2.1 Transmitting commands 27

6.2.2 Receiving status messages 28

7 TELEGRAM STRUCTURE 30

7.1 Structure of commands 30

7.2 Structure of status messages 30

7.2.1 Command confirmation 30

7.2.2 Event message 30

7.2.3 Bus participant message 31

7.3 Control command mipick MP20 32

7.4 Control command mipick MP80 34

7.5 Additional commands 37

8 DISPLAYABLE CHARACTERS 40

9 DECLARATION OF CONFORMITY 42

10 VERSION OVERVIEW 43

Page 3

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 4

mipick MP

User Manual

1 General

Regarding small parts warehouses as well as manual assembly workstations, the

light-controlled picking and assembly reduces the error rate and the searching for

parts and facilitates the training of new employees. However, the limited space is

an unsolvable task for many pick-to-light systems. But with the development of

the “mipick MP”, microSYST has found a solution for exactly this problem.

"mipick MP" stands for easy installation thanks to simplified wiring and a newly

developed software-controlled programming.

The channel height of this display is only 30 mm and the width 80 mm - space

saving and efficient! When mounting “display to display” shelf widths of only 80

mm can be realized with Pick-to-Light!

The display is equipped with two LED indicators (red + multi-colored), a metal

confirmation push button and LED directional arrows. A double-digit 7 segment

LED display with a digit height of 14 mm ensures an excellent readability of the

displayed values. Furthermore, a membrane keypad for possible value corrections is available.

The displays communicate via a RS485 interface, the main control system will be

activated via Ethernet and ensures a fast and reliable data transfer.

We are pleased to be able to supply this display also as a complete system with

an individual assembly workplace and a software perfectly tailored to your application.

Page 4

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 5

mipick MP

User Manual

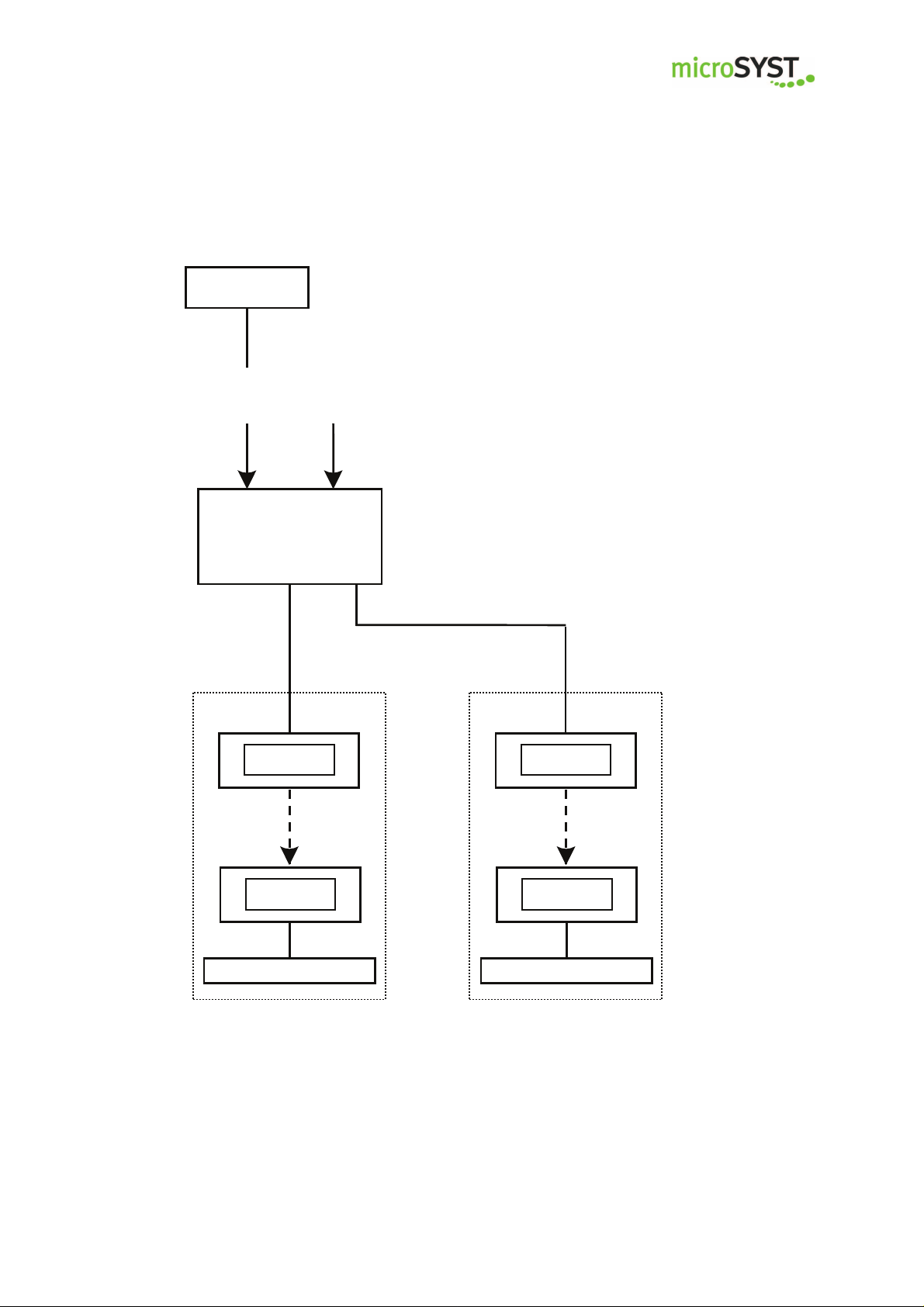

2 System Overview

Controller

Ethernet /

Profibus-DP

Profibus DP

Distribution Unit

230 VAC

The main components of the system are the distribution unit and the pick displays.

The distribution unit is the converter between the

system interface (Ethernet TCP/IP or Profibus DP)

and RS485 and provides the 24 VDC supply power

for the displays.

Two internal connections are available for up to 100

displays.

RS485,

24 VDC

Line 1

Pick Display

Pick Display

Bus Termination

Line 2

Pick Display

Pick Display

Bus Termination

Page 5

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 6

Interface

mipick d

isplays

mipick d

isplays

mipick MP

User Manual

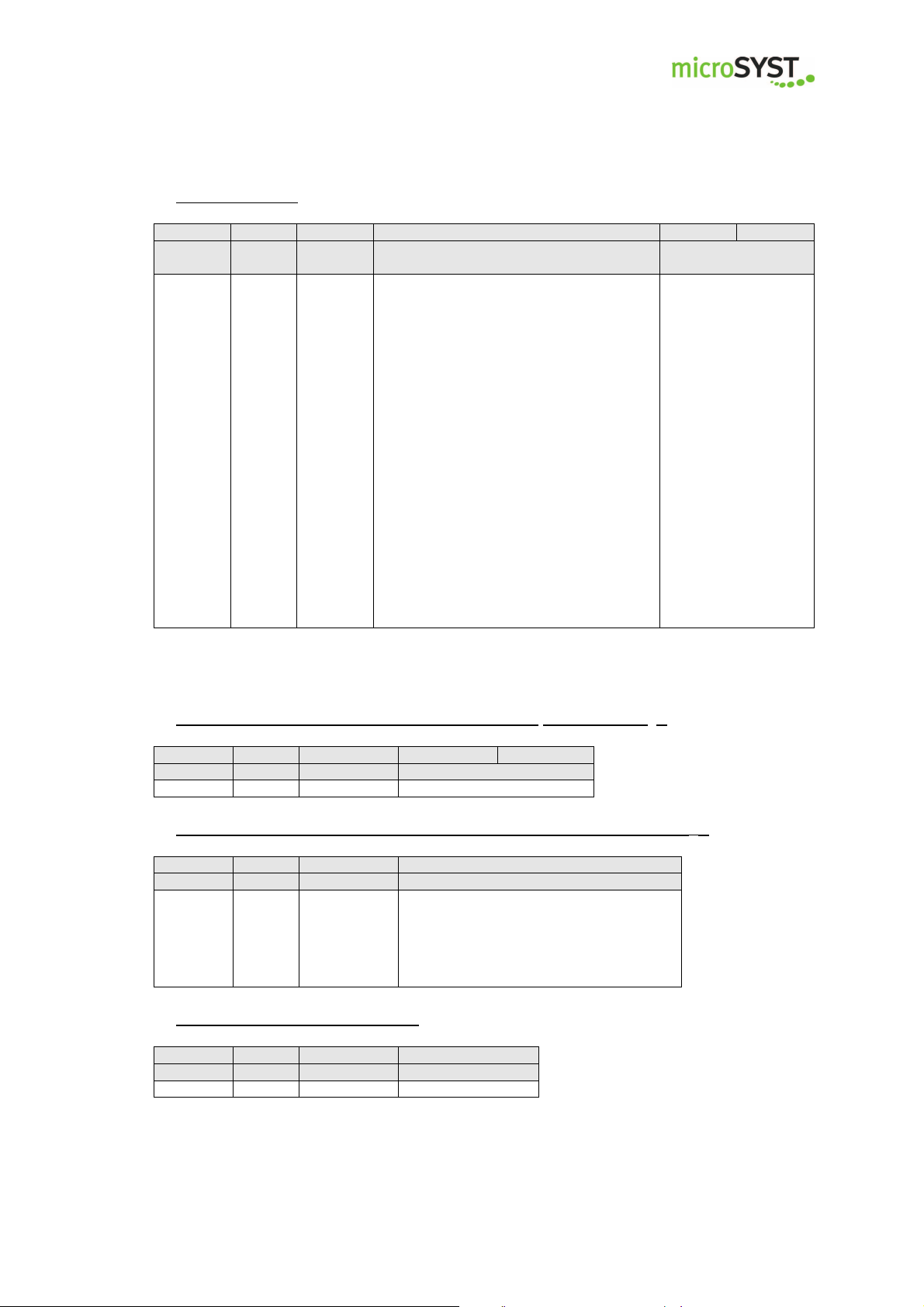

3 Components

3.1 Distribution unit

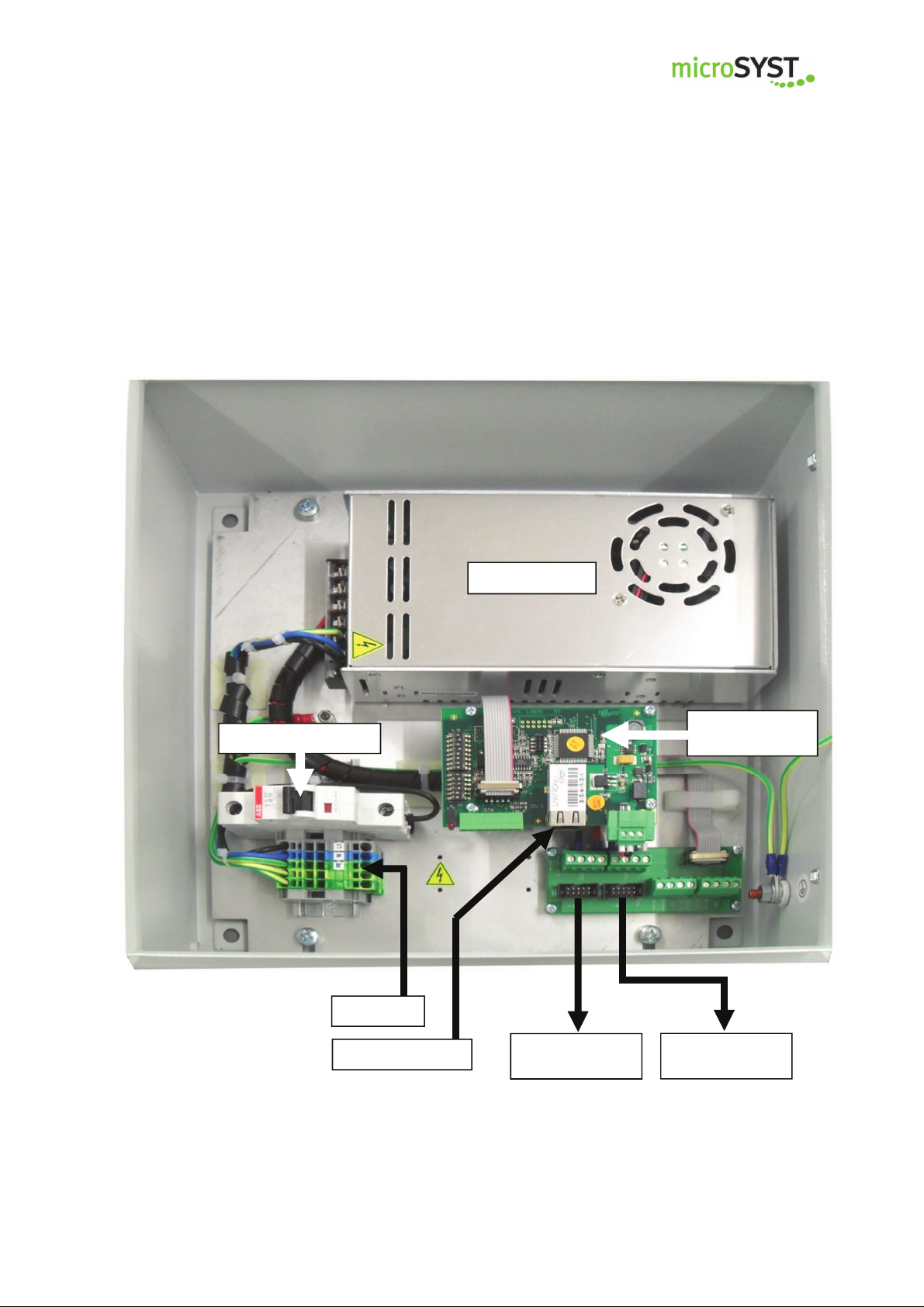

3.1.1 Distribution unit for Ethernet TCP/IP

Power Supply

Circuit Breaker

Ethernet/mipick

230 VAC

Ethernet TCP/IP

Line 2

Line 1

Page 6

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 7

LED Status

Meaning

mipick MP

User Manual

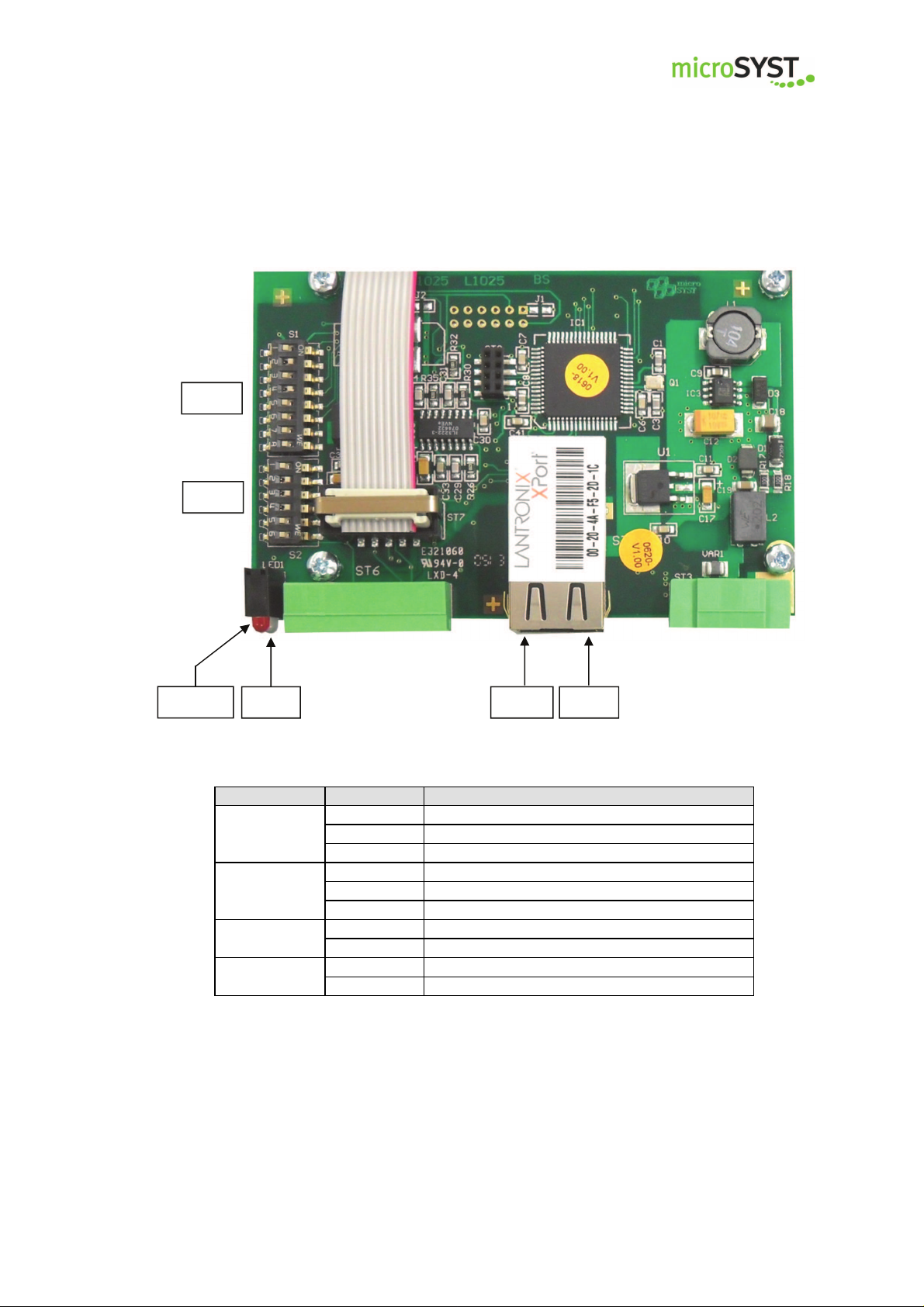

Interface Ethernet / mipick

S1

S2

FAULT

RUN LINK ACT

Green Full-Duplex

ACT

LINK

FAULT

RUN

Yellow Half-Duplex

Off No network activity

Green Physical network connection with 100 MBaud

Yellow Physical network connection with 10 MBaud

Off No physical network connection

Red No active TCP/IP connection

Off Active TCP/IP connection

Green No data traffic at the serial interface

Blinking Data traffic at the serial interface

Page 7

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 8

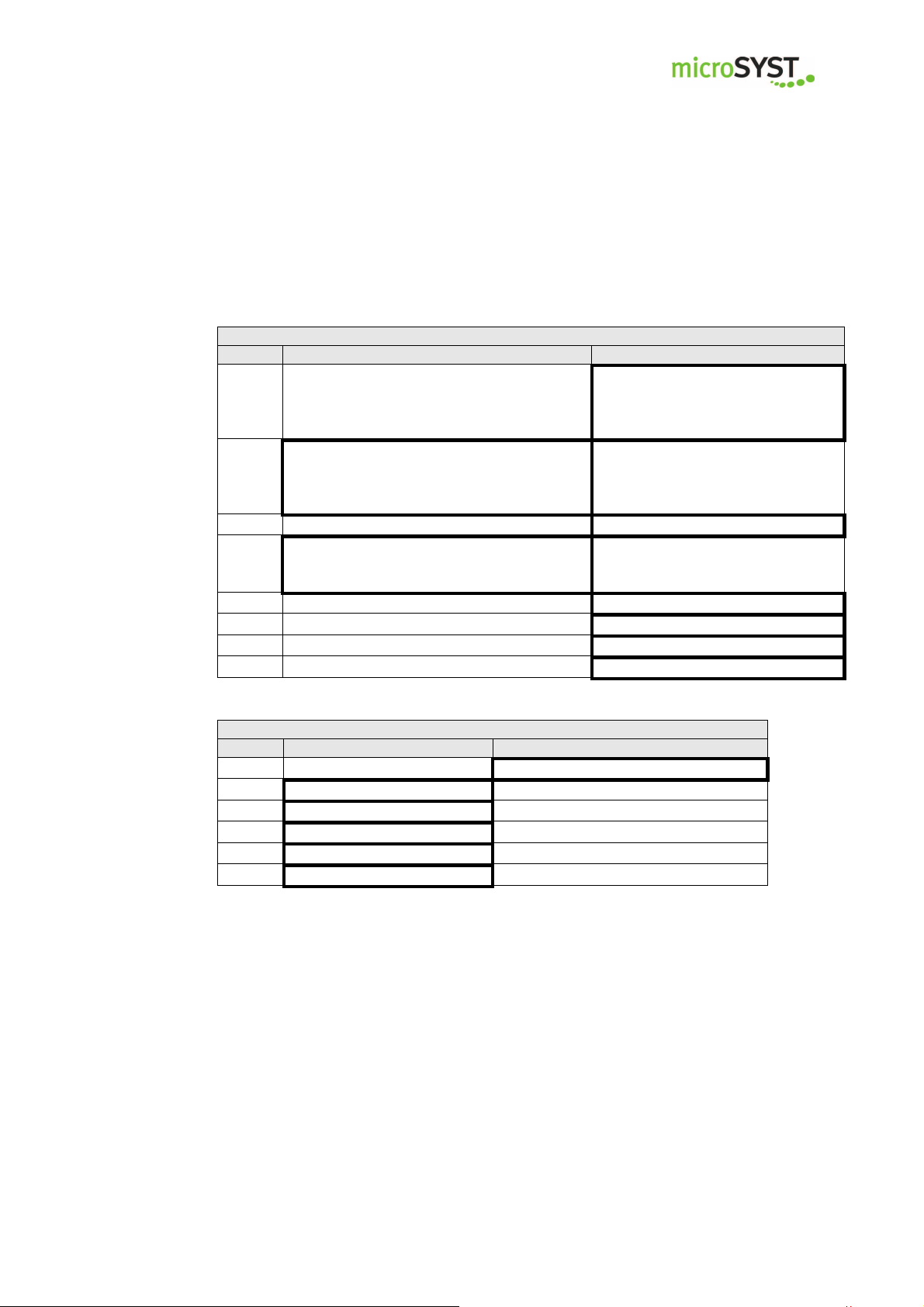

Switch S1: Options

DIP ON OFF

Switch S2: RS485 bus termination

DIP ON OFF

mipick MP

Positions marked with “

Bold-framed positions are the default.

Test mode:

Every display shows its own RS485 ad-

1

dress. There should be no Ethernet communication at the same time!

Use 128 RS485 addresses (0...127) for

the RS485 cycle, bus participant message

2

C2 allowed

3 ■

Send bus participant messages (C1, C2)

4

automatically when changing (and after

the Ethernet connection)

5 ■

6 ■

7 ■

8 ■

User Manual

■

” are fixed and may not be changed!

Standard mode

Use 64 RS485 addresses (0...63)

for the RS485 cycle,

bus participant message C2 not

allowed

Send bus participant messages

(C1, C2) on request only (C0, C1

or C2)

1 ■

2 ■

3 ■

4 ■

5 Bus termination is set no bus termination

6 Bus termination is set no bus termination

The bus termination must be set if the interface comes first in the RS485

bus.

Page 8

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 9

Power

Interface

Circuit Breaker

mipick displays

mipick

displays

mipick MP

User Manual

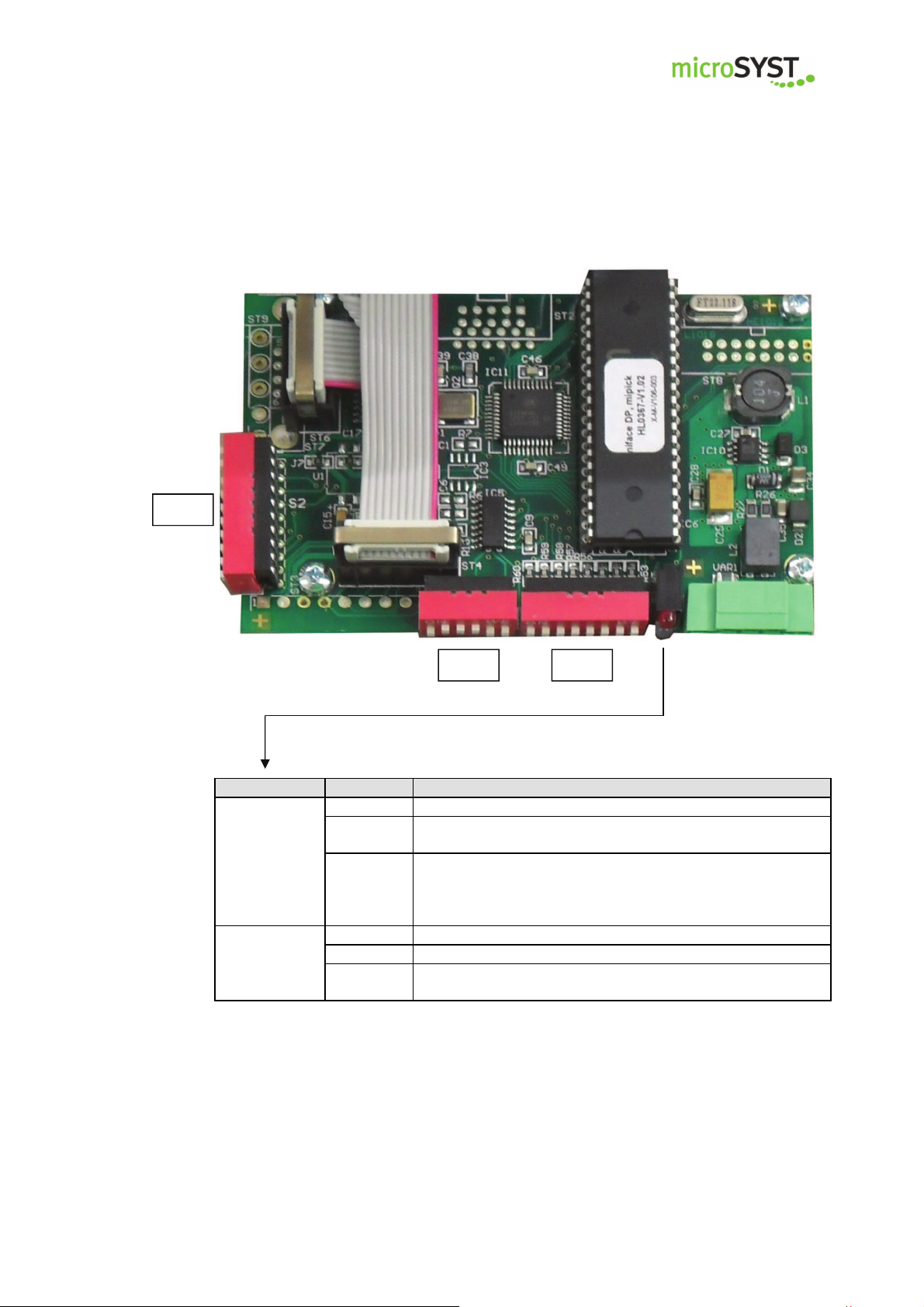

3.1.2 Distribution unit for Profibus-DP

supply

230 VAC

Profibus IN

line 2

Profibus OUT

Profibus/mipick

line 1

Page 9

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 10

LED Status

Meaning

mipick MP

User Manual

Interface Profibus / mipick

S2

S1 S3

off Profibus DP connection established

no cyclical Profibus DP communication

or RAM error (if green LED is off)

no RS485 response (within the last 500 ms) or RS485

communication stopped because a new status message is

available and the former status message has not yet been

confirmed (DP-OUT-QBS must be set to DP-IN-TBS)

Profibus DP toggle byte has been changed

(command or status message transmitted)

red (FAULT)

green (RUN)

on

flashing

off Controller is not working (hardware error)

on Controller is working

short off

(flickering)

Page 10

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 11

Switch S1: RS485 Bus Termination

DIP ON OFF

Switch S2: DP address, DP bus t

ermination

DIP Function

Switch S3: Options

DIP ON OFF

mipick MP

Positions marked with “

Bold-framed positions are the default.

1 ■

2 ■

3 ■

4 ■

5

6

1

2

3 DP address Bit 22 (ON = 4)

4 DP address Bit 23 (ON = 8)

5 DP address Bit 24 (ON = 16)

6 DP address Bit 25 (ON = 32)

7 DP address Bit 26 (ON = 64)

8 reserved (= OFF ■)

9 both ON: Profibus bus termination set

10

Bus termination is set no bus termination

both OFF: no Profibus bus termination set

User Manual

■

DP address Bit 20 (ON = 1)

DP address Bit 21 (ON = 2)

” are fixed and may not be changed!

Bus termination must

be set if the interface

comes first in the

RS485 bus.

Only DP addresses 0

to 126 are allowed.

Test mode:

Every display shows its own RS485 ad1

dress. There should be no Profibus commu-

nication at the same time!

Use 128 RS485 addresses (0...127) for the

RS485 cycle, bus participant message C2

2

allowed

Transmit every status message immediately

3

(separately) to the DP master

(-> easier handling but slower)

Send bus participant messages (C1, C2) au-

tomatically when changing (and after power4

up and every restart of the DP communica-

tion

5 ■

6 ■

7 ■

8 ■

Standard mode

Use 64 RS485 addresses (0...63)

for the RS485 cycle,

bus participant message C2 not allowed

Collect status messages until DP-IN

buffer is full or the current polling

cycle has been finished.

Send bus participant messages

(C1, C2) on request only (C0, C1 or

C2)

Page 11

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 12

mipick MP

User Manual

3.2 Pick displays

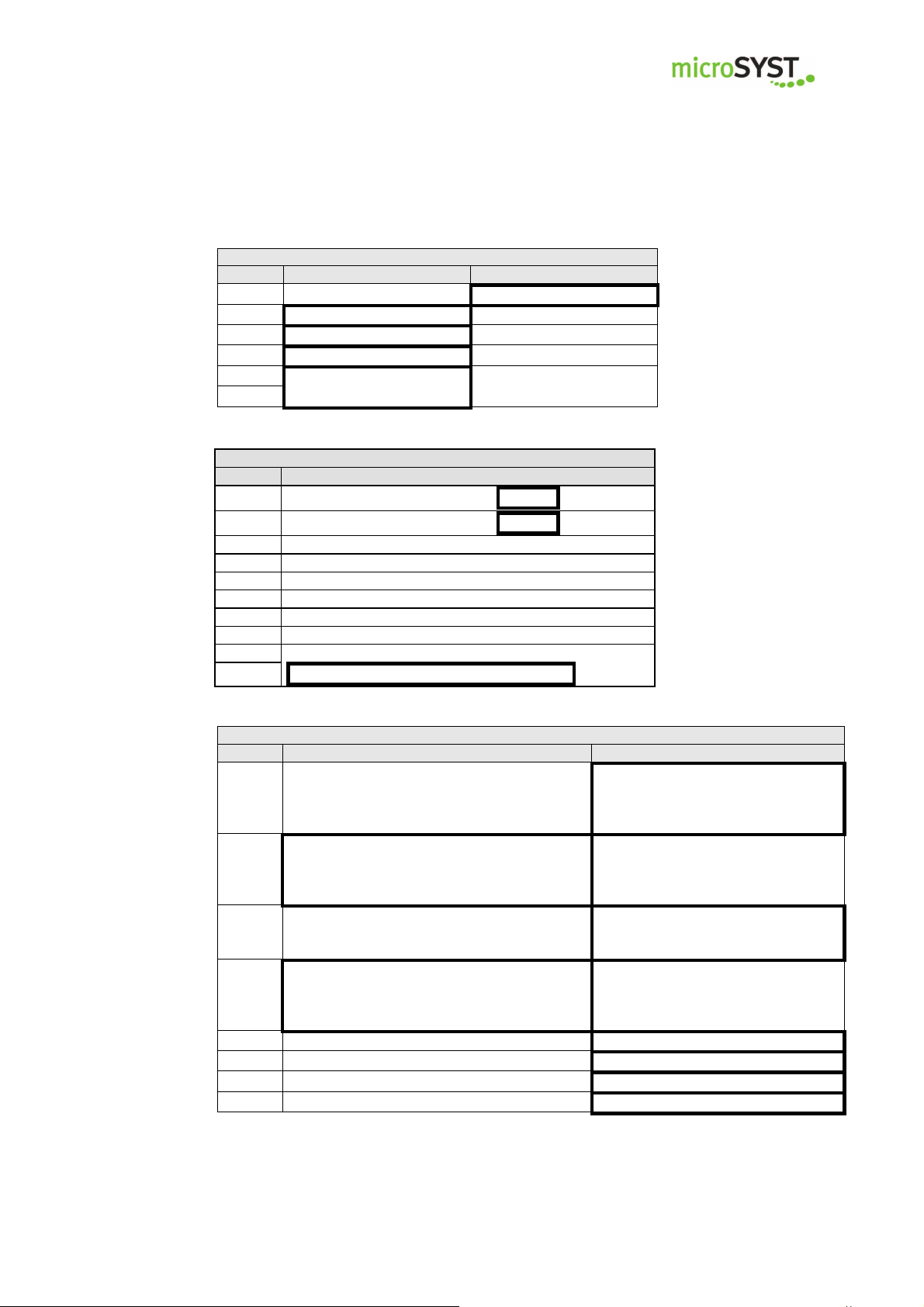

3.2.1 Pick display mipick MP20

Technical data

Display type:

Character height:

Digits:

Display colour:

Operating voltage:

Current consumption:

Data input:

Display:

Addresses:

Keypad:

Safety push button:

Signal lamp:

Housing:

Dimensions:

Shaft depth incl. display:

Housing colour:

Mounting:

Protection:

Operating temperature:

Storage temperature:

7 segment LED

14 mm

2 (numeric)

rot

24 VDC +/-20 %

32 mA at 24 V (0,77 W)

RS485 with 115 kBaud

see chapter “Displayable Characters”

0…99

membrane keypad with 2 buttons

metal design,

mechanical service life: > 1.000.000 cycles,

diameter 12 mm,

separately replaceable

1 x LED red, 1 x LED multicoloured,

LED diameter: 8 mm

aluminium, anodised

80 x 30 mm (w x h)

30 mm

natural with grey foil

snap-on mounting

front panel IP40

0...+50°C

-25...+70°C

Page 12

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 13

mipick MP

User Manual

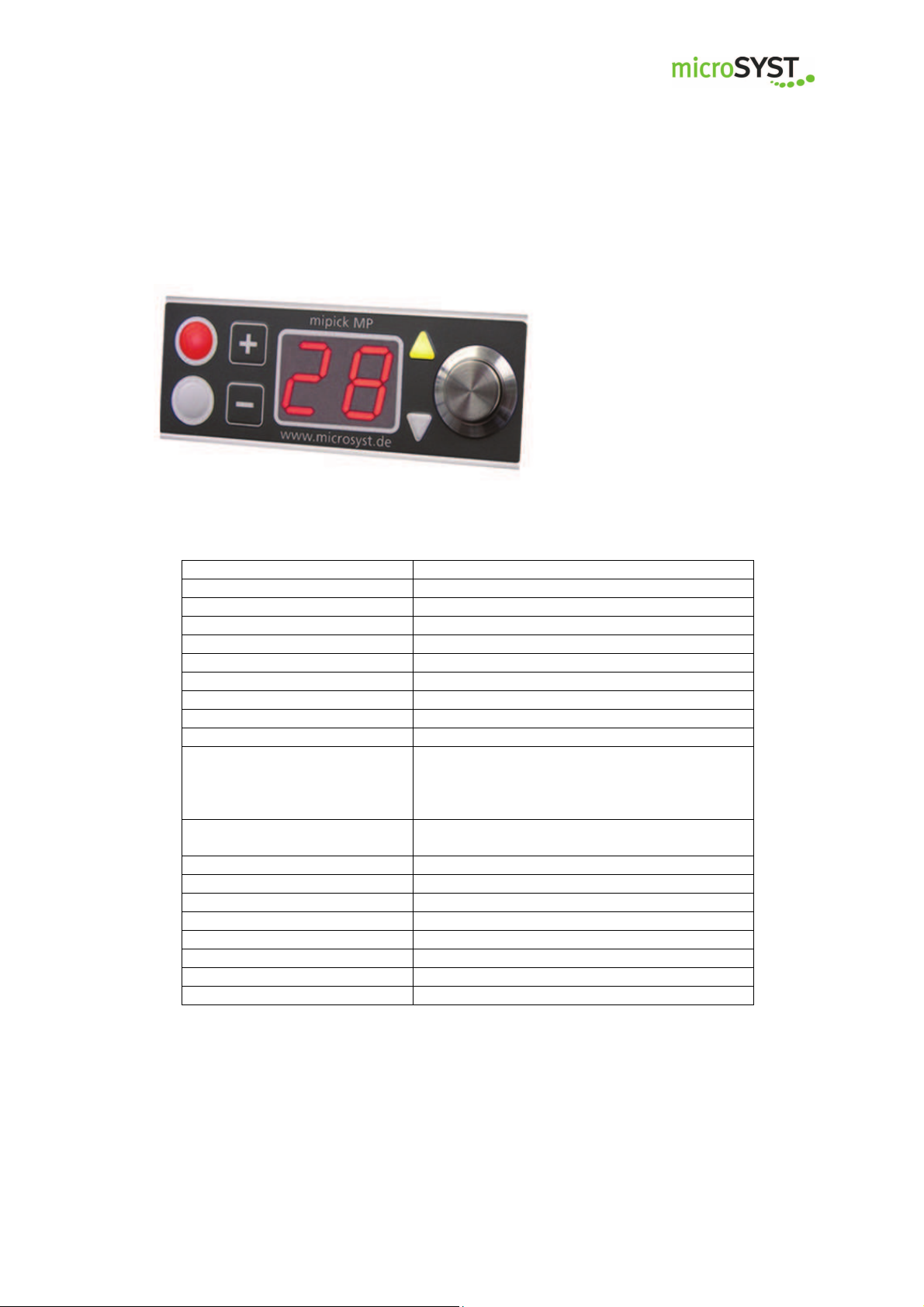

3.2.2 Pick display mipick MP80

Technical data

Display type:

Character height:

Digits:

Display colour:

Operating voltage:

Current consumption:

Data input:

Display:

Addresses:

Keypad:

Safety push button:

Signal lamp:

Housing:

Dimensions:

Shaft depth incl. display: 30 mm

Housing colour:

Mounting:

Protection:

Operating temperature:

Storage temperature:

SMD-LED-Dot-Matrix

14 mm

8 (alphanumerisch)

red

24 VDC +/-20 %

90 mA bei 24 V (2,16 W)

RS485 with 115 kBaud

see chapter “Displayable characters”

0…99

Membrane keypad with 2 buttons

Metal design,

mechanical service life: > 1.000.000 cycles,

diameter 12 mm,

separately replacable

1 x LED rot,

1 x LED mulitcoloured (red, green, blue, yellow, cyan, magenta,

white),

LED diameter: 8 mm

aluminium, anodised

170 x 30 mm (w x h)

natural with grey foil

snap-on mounting

front panel IP40

0...+50°C

-25...+70°C

Page 13

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 14

mipick MP

3.2.3 Addressing

The address settings can be made either manually via buttons or automatically

with the help of the software “miprog”.

Addressing via buttons

In case that only individual displays have to be programmed (e.g. when replacing

a display) the addressing via buttons is the easiest way. No data connection has

to be available, the pick display has only to be supplied with voltage.

• Please press the enter button and „+“ at the same time.

• Plug in the power supply.

• Please set the required address with the buttons „+“ and „-“.

• Press the enter button.

Addressing via software

This is used for the programming of complete picking systems. All displays on the

RS485 sub bus can be programmed easily.

Regarding systems with Ethernet the addressing will be done via the Ethernet interface.

Regarding systems with Profibus the addressing is done via RS485. For this, disconnect the RS485 bus between distribution unit and the displays and connect it

again with the configuration PC via an USB/RS485 converter.

• Please select the interface and press the button “Verbindung herstellen/create connection”

User Manual

Page 14

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 15

mipick MP

• Select the start address of the first pick display and (if you have more displays) the option “automatisch weiter Adressieren” (= continue automatically with addressing).

• By pressing the button “Adressierung starten” (= start addressing), the

currently assigned RS485 address will be indicated.

User Manual

• Now, the LEDs of all displays are flashing and the currently assigned address will be indicated everywhere. Please press this confirmation button

of the display, which shall receive this current address.

• The current address will now be indicated in the software.

Continue until all displays of the bus have been assigned.

You can stop the programming with the button “Adressierung beenden” (= stop

addressing).

Page 15

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 16

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

mipick MP User Manual

4 Wiring

Page 16

Page 17

mipick MP

4.1 Distribution Unit

Power supply (230 VAC)

System Interface

Ethernet: Profibus DP

User Manual

Display Interface

RS485 bus and power supply are provided for each display line.

line 2 line 1

to the display shaft

IN OUT

Page 17

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 18

mipick MP

4.2 Display shaft

In the side shaft cover a screw joint is mounted. Through a slotted protective hose

the flat ribbon cable will be inserted into the shaft.

4.3 mipick

User Manual

from distribution unit

4.4 Bus termination

After the last display of the line the bus termination board will be connected:

Page 18

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 19

mipick MP

User Manual

5 Ethernet

5.1 Configuration of the Ethernet Interface

The distribution unit is preset with the following network settings:

IP address: 192.168.4.200

Net mask: 255.255.255.0

Port: 10001

In order to change these parameters please proceed as follows:

Information for Windows 7 users:

The Telnet client must be activated:

Start Control Panel Programs Activate or deactivate Windows features

Telnet Client

• Switch the supply power on and connect the distribution unit to a network

hub by using a RJ45 cable (1:1 cable) or directly to a PC (crosslink cable).

• Start the “MS DOS entry prompt” at your Windows PC.

Please note that with Windows 7 you must have extended rights:

Start All Programs Accessories right mouse click on Command

Prompt Run as Administrator

•

Enter the desired IP address of the interface into the ARP table:

ARP -S XXX.XXX.XXX.XXX xx-xx-xx-xx-xx-xx <CR>

XXX.XXX.XXX.XXX : required IP address

xx-xx-xx-xx-xx-xx : Ethernet MAC address of the interface

(see label on the RJ45 socket)

Page 19

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 20

mipick MP

• Create a Telnet connection to port 1:

TELNET XXX.XXX.XXX.XXX 1 <CR>

This connection will fail (disconnection within 3 seconds). However, the IP

address of the interface has been temporarily changed.

Close the Telnet window after acknowledging the error message.

• Create a Telnet connection to port 9999:

TELNET XXX.XXX.XXX.XXX 9999 <CR>

After the connection, press immediately the enter key (within 5 seconds) in

order to enter the setup mode.

• Please do never select “7” (Defaults).

These settings do not fit the system.

• Enter “0” (Server).

• Enter the required IP address and press the enter key.

• Please press the enter key until

”Netmask: Number of Bits for Host Part (…)“ is selected.

Enter here the number of free bits for the IP address,

e.g. “8“ for a netmask of 255.255.255.0

(=11111111.11111111.11111111.00000000) or

“11“ for the netmask of 255.255.248.0

(=11111111.11111111.11111000.00000000) and press the enter key.

• Please press the enter key until “Your choice?” is selected.

• Press “9” to save all settings ( the Telnet connection will be interrupted).

The configuration of the Ethernet interface is now completed.

The telegram for controlling can now be transmitted via the selected IP address

(TCP/IP connection via port 10001).

User Manual

Page 20

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 21

A L D

A

L

D

mipick MP

5.2 Ethernet Communication

The Ethernet interface of the distribution unit allows communication between a controller (for example PC or PLC) and the mipick devices.

“Commands” will be sent from the controller to the interface via Ethernet and will

then be transmitted to the respective mipick devices.

“Status messages” will be sent from the mipick devices to the interface via RS485

and will then be transmitted to the controller via Ethernet.

The Ethernet interface represents the “bus master” at the RS485 level.

Should there be no “commands”, the bus-sharing units (mipick devices) will cycli-

cally be polled (address order 0 to 63, 0 to 63, … or 0 to 127, 0 to 127,…). If an

event occurs (e.g. “button has been pressed”), the bus-sharing unit (mipick devices)

replies accordingly and a related “status message” will be sent via Ethernet.

Should there be a “command” for a certain RS485 address, it will be sent to the bussharing unit (mipick devices) instead of the polling telegram. The reply of the mipick

device will be reported via the Ethernet.

Should there be a new added bus-sharing unit or a former existing bus sharing unit

which does not respond (correctly), a special telegram via Ethernet will be sent. The

controller can explicitly request this “bus participant telegram” in order to receive the

current bus status.

For further information on commands and “status messages” please see chapter

“Telegram Structure”.

Their structure is as follows:

User Manual

ddress of the pick display

1 byte 1 byte n bytes

Page 21

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

ength of the data

ata

Page 22

mipick MP

5.2.1 Sending commands

The commands are transmitted from the control computer to the Ethernet interface

and from there via an RS485 bus to the respective mipick device.

With each TCP/IP telegram, one or more commands (completely) can be transmitted to the Ethernet interface. Every command has the following structure “address”,

“length” and “data”.

Please note that it is not possible to send a new command to a certain address before the last command has been answered or at least approximately 1 second has

passed (in this case, the bus participant has not answered or has not answered correctly.

After a “broadcast command” please wait for the command confirmations (one per

existing bus participant) before sending a new command. A waiting period of 1 second will be enough.

Note: If more than one command confirmations are pending, they do not necessarily

have to arrive in the same order as the commands have been sent. It can also be

possible to receive an “event message” or “bus participant message”!

Example:

The value “12“ shall appear on display 4:

Send the command via TCP/IP (in HEX format):

04 08 80 20 20 31 32 00 00 00

(address = 4, length = 8 bytes, data = 80 20 20 31 32 00 00 00)

User Manual

Page 22

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 23

mipick MP

5.2.2 Receiving Status Messages

There are three types of status messages:

1. Command confirmations (= command responses)

2. Event messages (e.g. “button was pressed“)

3. Bus participant messages (“device was removed/added”)

Status messages are sent to the control computer with a TCP/IP telegram. Every

TCP/IP telegram can contain one or more status messages (completely). Every status message has the following structure “address”, “length” and “data”.

Examples:

a) Command confirmation concerning above mentioned command:

Receiving the command confirmation via TCP/IP (in HEX format):

04 01 80

(address = 4, length = 1, data = 80)

b) Press the button of display 4:

04 03 00 81 0C

c) Release the button of display 4:

04 03 00 80 0C

Important: With regard to above mentioned example only one status message is transferred but should there be more than one status messages they will be transmitted at

the same time.

User Manual

Page 23

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 24

Byte no.

Data identifier

Number of bytes

Function / Description

mipick MP

User Manual

6 Profibus DP

6.1 Configuration of the Profibus Interface

6.1.1 GSD file

The device database file „micr05D0“, which is part of the delivery is used for the

integration of the Profibus DP interface (DP slave) into the Profibus. This file

contains the necessary identifiers for the configuration of the input/output data

widths (please see next chapter).

6.1.2 Configuration data

Via the configuration the data width of the cyclic data exchange can be set individually. Therefore, the following identifiers (max. 30) must be selected in any

order.

The DP master transmits the identifier to the DP slave before it starts the cyclic

data exchange.

x 0x10 1 Input Data

x 0x11 2 Input Data

: :

x 0x1F 16 Input Data

x 0x20 1 Output Data

x 0x21 2 Output Data

: :

x 0x2F 16 Output Data

x 0x30 1/1 Input/Output Data (1 byte each)

x 0x31 2/2 Input/Output Data (2 bytes each)

: :

x 0x3F 16/16 Input/Output Data (16 bytes each)

The minimum number of input or output bytes is 6 bytes each.

The maximum number of input or output bytes is 200 bytes each, but the length

of 300 bytes (input + output) may not be exceeded.

Standard configuration: 0x3F, 16 input / output bytes.

Page 24

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 25

mipick MP

6.1.3 User parameter data

The „User_Prm_Data“ is not used by the interface. But nevertheless it will be

checked if the Profibus master transfers any User_Prm_Data. If

User_Prm_Data is transferred, the Profibus initialization will be rejected and the

slave’s parameters must be reconfigured.

Note:

Standard parameters configuration is necessary and is normally added by the

used DP configurators.

6.1.4 Diagnostic data

The interface does not support any extended diagnostic data. Default diagnosis

is used.

User Manual

Page 25

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 26

DP-OUT:

DP-IN:

mipick MP

6.2 DP Communication

For the DP master the Profibus interface (DP slave) is a standard I/O device. This

means, there are DP output data which are cyclically transmitted to the slave and

DP input data which are cyclically received from the slave.

The structure of the I/O data is as follows:

TBK: Toggle byte for the commands

QBK: Confirmation byte for the commands (= TBK after data transfer)

LBK: Length byte for the commands

TBS: Toggle byte for the status messages

QBS: Confirmation byte for the status messages (= TBS after data transfer)

LBS: Length byte for the status messages

A: Address of the pick displays

L: Length of the data

D: Data (max. 20 bytes)

For more information on commands and status messages please see chapter “Telegram structure”.

Information:

After the (re)start of the Profibus DP communication all DP-OUT bytes and all DP-IN

bytes have the value 0.

With the help of the configuration, the number of DP IN bytes and DP OUT bytes

has to be defined in such a way that the longest possible command or the longest

possible status message has enough space. The maximum I/O width may not be

exceeded (please see chapter „configuration data“).

User Manual

TBK QBS LBK A L D A L D … A L D

QBK TBS LBS A L D A L D … A L D

Commands

Status messages

Page 26

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 27

mipick MP

6.2.1 Transmitting commands

Commands are used to define what the displays should indicate or what they should

do. The commands will be transmitted from the DP master to the Profibus interface

(DP slave) and from here via the RS485 bus to the respective displays.

Instructions:

1. Enter the command or also more commands (completely) in the DP OUT “commands. Every command consists of “address“, “length“ and “data“.

2. Enter the length of all command bytes into “LBK“.

3. Then, “TBK“ will be increased by one.

4. Now, the DP slave starts to evaluate the commands and transmit them to the

corresponding displays. Once this process is completed, the “QBK“ is set to the

value of the previous changed “TBK“.

5. If there are further commands available please continue with item 1.

Example:

The value “12“shall appear on display 4:

1. Enter the command:

DP OUT(hex) = 00 XX 00 04 08 80 20 20 31 32 00 00 00

2. Set “LBK“: ▼

DP OUT(hex) = 00 XX 0A 04 08 80 20 20 31 32 00 00 00

3. Increase “TBK“: ▼

DP OUT(hex) = 01 XX 0A 04 08 80 20 20 31 32 00 00 00

4. Wait for “QBK“:

DP IN(hex) = 00 XX XX XX ...

DP IN(hex) = 01 XX XX XX ...

User Manual

▼

Page 27

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 28

mipick MP

6.2.2 Receiving status messages

There are three types of status messages:

1. Command confirmations (= command responses)

2. Event messages (e.g. “button has been pressed“)

3. Bus participants messages (“device has been removed/added“)

This status messages has to be retrieved from the DP master in the shortest possible time, otherwise the RS485 communication with the displays can slow down or

even stop (until the status messages are retrieved)!

Instructions:

1. If the “TBS“changes, there are status messages which must be retrieved.

2. The status messages which must be retrieved are available in the DP IN “status

messages“(completely, in total “LBS“ bytes). Every status message consists of

“address“, “length“and “data“.

3. After the status messages have been retrieved out the DP master must set the

“QBS“to the same value of “TBS“. This should made made as quick as possible

(not to slow down the RS485 communication).

4. Continue with item 1.

Examples:

a) Command confirmations concerning the above mentioned command:

1. “TBS“ has been changed:

DP IN(hex) = XX 00 XX XX XX ...

▼

DP IN(hex) = XX 01 03 04 01 80

2. Read out the status message:

“LBS” = 3

“Address“ = 4

“Length“ = 1

“Data“ = 80H (command confirmation)

3. Set “QBS” to the value of “TBS”:

DP OUT(hex) = XX 01 XX XX XX ...

User Manual

▼

Page 28

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 29

mipick MP

b) Press the button of display 4:

1. “TBS“ has been changed:

DP IN(hex) = XX 01 XX XX XX ...

DP IN(hex) = XX 02 05 04 03 00 81 0C

2. Read out the status message:

“LBS” = 5

“Address“ = 4

“Length“ = 3

“Data“ = 00H 81H 0CH (event message: button pressed, display value = “12“)

3. Set “QBS” to the value of “TBS”:

DP OUT(hex) = XX 02 XX XX XX ...

Note:

In the above mentioned examples only one status message has been transmitted.

If there are more than one status messages available they are transmitted at the

same time in order to use the available DP IN bytes in the best possible way and to

speed up the communication.

If the DIP switch S3-3 is set to ON every status message will be reported separately

(in order to simplify the evaluation of the DP master).

User Manual

▼

▼

Page 29

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 30

Address

Length

Command

1.

Parameter

... n. Parameter

s

Address

Length

Command confirmation

Possible reply data

Event

n th

Parame-

mipick MP

User Manual

7 Telegram structure

7.1 Structure of commands

Data

0…127,

255*

Number of bytes

to be transferred

*Address = 255: broadcast command:

This command will be sent to all possible bus addresses (0...63 or 0...127). Only

the really existing MIPICKS of the bus which support the command will evaluate it

and respond with a “command confirmation”.

7.2 Structure of status messages

z.B. 80H

= “controlling the

display”

7.2.1 Command confirmation

Data

0…127 >= 1 z.B. 80H

Every command will be acknowledged by sending a command confirmation. This

ensures the complete communication cycle, from the control computer to the

MIPICKS and back. If necessary, reply data from the MIPICK will be transmitted.

7.2.2 Event message

Data

Address Length

Number of

0…127

bytes to be

transferred

message

00H

Status byte 1 th Parameter ...

Contains (bit-coded) in-

formation to the event

Additional event information

if the space of status byte is not

enough

All existing MIPICKs on the RS485 bus (addresses 0 to 63 or 0 to 127) will always

be polled. If a status byte will be unequal 0 OR at least one additional “parameter

byte” will be received an event occurs. It will then be transmitted from the interface

to the control computer.

ter

Page 30

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 31

Bus participant

Adresse

Länge

“Interface Command“

mipick MP

User Manual

7.2.3 Bus participant message

If the related DIP switch is set to “ON“ the bus participants messages will be sent

automatically ...

• after every change (new bus participant identified or not available anymore)

• after every communication restart = start of the cyclic DP data exchange or the

TCP/IP connection (after completion of the currently running polling cycle).

Data

Adress Length

255 9

message

C1H

(bus addresses

0…63)

C2H

(bus addresses

64…127,

only if 128 ad-

dresses are set

via DIP switch)

Bus participant status of

the addresses 0…7 or

64… 71:

(bit 0…7)

1 = device available,

0 = device not available

BTN0 ... BTN7

... Bus participants status of

the addresses 56…63 or

120…127:

Bit 0…7:

1 = device available,

0 = device not available

The bus participant messages can be requested by transmitting the following command:

Data

C1H : Request a bus participant message C1H

255 1

C2H : Request a bus participant message C2H (if 128 addresses)

C0H : Request a bus participant messages C1H and C2H (if 128 addresses)

Page 31

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 32

1 2 3

Address

Length

Command

4 5 6 7

Text of digit 1

Text of digit 2

Value of digit 1

Value of digit 2

8 9

Options 1

Options 2

10

Optionen 3

mipick MP

User Manual

7.3 Control command mipick MP20

Command (10 bytes):

0…127, 255 = Broadcast 8 80H

ASCII code (20...7FH) ASCII code (30...39H, 20H = empty)

+ Bit 7 = 1, if decimal point is required

Bit 0=0: LED 1 (on the top) off

=1: LED 1 (on the top) on*

Bit 1=1: LED 1 slowly flashing

Bit 2=1: LED 1 fast flashing

Bit 5-3: 000 = LED 2 (below) off

001 = blue*

010 = green*

100 = red*

110 = yellow*

011 = cyan*

101 = magenta*

111 = white*

Bit 6=1: LED 2 slowly flashing

Bit 7=1: LED 2 fast flashing

*Bit must be set for flashing

Bit 0=1: Arrow “up“ on

Bit 1=1: Arrow “down“ on

Bit 2=1: Display slowly flashing

Bit 3=1: Display fast flashing

Bit 4=1: LEDs will be deleted automatically,

if one of the two inputs will be closed

Bit 5=1: LEDs will be deleted automatically,

if one of the two inputs will be closed

Bit 7, 6: Brightness:

00 = bright

01 = :

10 = :

11 = dark

Bit 0=0: Suppress leading zeros

=1: Display leading zeros

Bit 1=1: +/- keys locked

Bit 2=1: +/- counts endlessly (0 to 99)

=0: +/- counts from 0 to preset value

Bit 4, 3: cycle duration until change

value – text

00 = 2 s

01 = 1.5 s

10 = 1.1 s

11 = 0.8 s

Bit 5=0 do not report keystrokes +/ 5=1: report keystrokes +/-

Bit 7, 6: reserved (=0)

Page 32

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 33

1 2 3

Address

Length

Command confirmations

1 2 3 4 5

Event

mipick MP

User Manual

Command confirmation (3 bytes):

0…127 1 80H

Event message (5 bytes):

Address Length

0…127 3 00 H

Message

Bit 0 : Input 1 (ST3)

0: Contact OPEN

1: Contact CLOSED

Bit 1 : Input 2 (ST5)

0: Contact OPEN

1: Contact CLOSED

Bit 2: Status arrow UP

Bit 3: Status arrow DOWN

Bit 4 : Input button “–“

0: Contact OPEN

1: Contact CLOSED

Bit 5 : Input button “+“

0: Contact OPEN

1: Contact CLOSED

Bit 6=1: Display error reported

Bit 7=1: Change flag for bit 0,1,4 and 5

Status Byte Value

0…99

Notes:

Bytes 6 and 7 (value) of the command determine the real display value of the pick

display. After pressing the confirmation button this value will be reported to the event

message telegram. Also the correction keys “+” and “-“run solely with this value.

Only numbers (30H .. 39H) or space characters (20H) can be used as “value”.

With the bytes 4 and 5 (text) it is possible to display two characters as an additional

text or labeling. The fields “value” and “text” are then displayed alternatively. The cycle time can be adjusted with byte 10 (options 3).

If one of the fields “text” or “value” will not be used two space characters (20H) must

be set in the corresponding position in the telegram. Then, there will be no change

between the two fields on the display.

Page 33

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 34

1 2 3

Address

Length

Command

4 5 6 7 8 9

Text of digit

1

Text of digit

2

Text of digit

3

Text of digit

4

Text of digit

5

Text of digit

6

10 11 12 13 14 15

Value of

digit

1 Value of

digit

2 Value of

digit

3 Value of

digit

16 17

Options

1

Options

2

mipick MP

User Manual

7.4 Control command mipick MP80

Command (18 bytes)

0…127

255 = Broadcast

16 88H

ASCII code

20…7FH

ASCII code

20…7FH

ASCII code

20…7FH

ASCII code

20…7FH

ASCII code

20…7FH

ASCII code

20…7FH

Text of digit 7 Text of digit 8

ASCII code

20…7FH

ASCII code

20…7FH

Bit 0=0: LED 1 (on the top) off

=1: LED 1 (on the top) on*

Bit 1=1: LED 1 slowly flashing

Bit 2=1: LED 1 fast flashing

Bit 5-3: 000 = LED 2 (below) off

001 = blue*

010 = green*

100 = red*

110 = yellow*

011 = cyan*

101 = magenta*

111 = white*

Bit 6=1: LED 2 slowly flashing

Bit 7=1: LED 2 fast flashing

*Bit must be set for flashing

Only the following bits will be evaluated:

Option 1 (byte 16): all bits

Option 2 (byte 17): bit 0,1,4,5,6,7

Option 3 (byte 18): bit 5

Text and vaue (bytes 4-15) will be ignored

4

0…9 0…9 0…9 0…9

Bit 0=1: Arrow “up“ on

Bit 1=1: Arrow “down“ on

Bit 2=1: Display slowly flashing

Bit 3=1: Display fast flashing

Bit 4=1: LEDs will be deleted automatically,

if one of the two inputs will be closed

Bit 5=1: LEDs will be deleted automatically,

if one of the two inputs will be closed

Bit 7, 6: Brightness:

00 = bright

01 = :

10 = :

11 = dark

Page 34

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 35

18

Options

3

1 2 3

Address

Length

Command

confirmation

mipick MP

User Manual

Bit 0=0: Suppress leading zeros

=1: Display leading zeros

Bit 1=1: +/- keys locked

Bit 2=1: +/- counts endlessly (0 to 9999)

=0: +/- counts from 0 to preset value

Bit 4, 3: cycle duration until change

value – text

00 = 2 s

01 = 1.5 s

10 = 1.1 s

11 = 0.8 s

Bit 5=0 do not report keystrokes +/ 5=1: report keystrokes +/-

Bit 6: reserved (=0)

Bit 7=1 only evaluate options

Command Confirmation:

0…127 1 88H

Page 35

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 36

1 2 3 4 5 6

Event

1 2 3 5 6

Address

Length

Command

Value

1 2 3 4

Address

Length

Command

Status of the inputs

1 2 3 4

Address

Length

Command

Start checking

mipick MP

User Manual

Event message:

Address Length

0…127 4 00 H

message

Bit 0 : Input 1 (ST3)

0 : Contact OPEN

1 : Contact CLOSED

Bit 1 : Input 2 (ST5)

0 : Contact OPEN

1 : Contact CLOSED

Bit 2: Arrow up status

Bit 3: Arrow down status

Bit 4 : Input key „–“

0 : Contact OPEN

1 : Contact CLOSED

Bit 5 : Input key „+“

0 : Contact OPEN

1 : Contact CLOSED

Bit 6=1: Display error has been detected

Bit 7=1: Change flag for bit 0,1,4 and 5

Status byte Value

Reply to the query regarding the display content (command 05 H):

0…9999

0…127 3 05H 0…9999

Reply to the query regarding the status of the inputs (Kommando 07 H):

Bit 0 = 1: input 1 closed (ST3)

Bit 1 = 1: input 2 closed (ST5)

0…127 2 07H

Bit 2 = 1: „+“ key is pressed

Bit 3 = 1: „-“ key is pressed

Bit 4...7 : reserved (= 0)

Starting the LED error checking:

0…127 2 08H 01

Page 36

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 37

1 2 3

Address

Length

Command

1 2 3 4

Address

Length

Command

Reading error

1 2 3 4 5

Address

Length

Command

Total number of LED errors

6 7 8 9 10 11 12 13 14 15

Position

error

1

Position

error

2

Position

error

3

Position

error

4

Position

error

5

Address

Length

Command

mipick MP

User Manual

Starting reply to LED error checking:

0…127 2 08H

Reading an LED error

Before reading an LED error a checking must be started.

The review process takes approximately up to 500 ms.

After that the errors can be read.

0…127 2 08H 00

Reply to reading LED errors:

0…127 13 08H

0 = No error

> 0 = Error

Position Position Position Position Position

A maximum of 5 errror positions will be reported, but the total number of LED errors

can be higher. The error positions are only valid if there are a corresponding numbers

of errors. Otherwise, the reported value will not be valid (=0)

The meaning of the positions is as follows:

0 RGB green

1 RGB red

2 RGB blue

3 LED red

4 LED arrow down

5 LED arrow up

6-334 LED Matrix (47x7 LEDs, line-by-line from top left to the bottom right)

7.5 Additional commands

Displaying addresses

Data

0…127, 255 = Broadcast 1 01H

Page 37

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 38

Address

Length

Command

Address

Length

Command

Address

Length

Command

Address

Length

Command

Lamp test

Address

Length

Command

Address

Length

Command

Address

Length

Command

Value

Address

Length

Command

mipick MP

User Manual

Command confirmation:

0...127 1 01H

Deleting a display

0…127, 255 = Broadcast 1 02H

Command confirmation:

0...127 1 02H

Lamp test

Data

Data

Data

Data

0…127, 255 = Broadcast 2 04H

Command confirmation:

Daten

0…127 1 04H

Querying display content

0…127, 255 = Broadcast 1 05H

Command confirmation:

0…127 2 05H 0…99

Querying software version

01H = start

00H = stop

Data

Data

Data

0…127, 255 = Broadcast 1 06H

Command confirmation:

Page 38

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 39

Address

Length

Command

SW version (12 bytes)

Address

Length

Command

Address

Length

Command

Input status

mipick MP

User Manual

0…127 13 06H HLxxxx-Vx.xx

Querying input status

0…127, 255 = Broadcast 1 07H

Command confirmation:

0…127 2 07H

Data

Data

Data

Bit 0 = 1: input 1 closed (ST3)

Bit 1 = 1: input 2 closed (ST5)

Bit 2 = 1: „+“ key pressed

Bit 3 = 1: „-“ kex pressed

Bit 4...7: reserved (= 0)

Page 39

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 40

Lower

Higher

mipick MP

User Manual

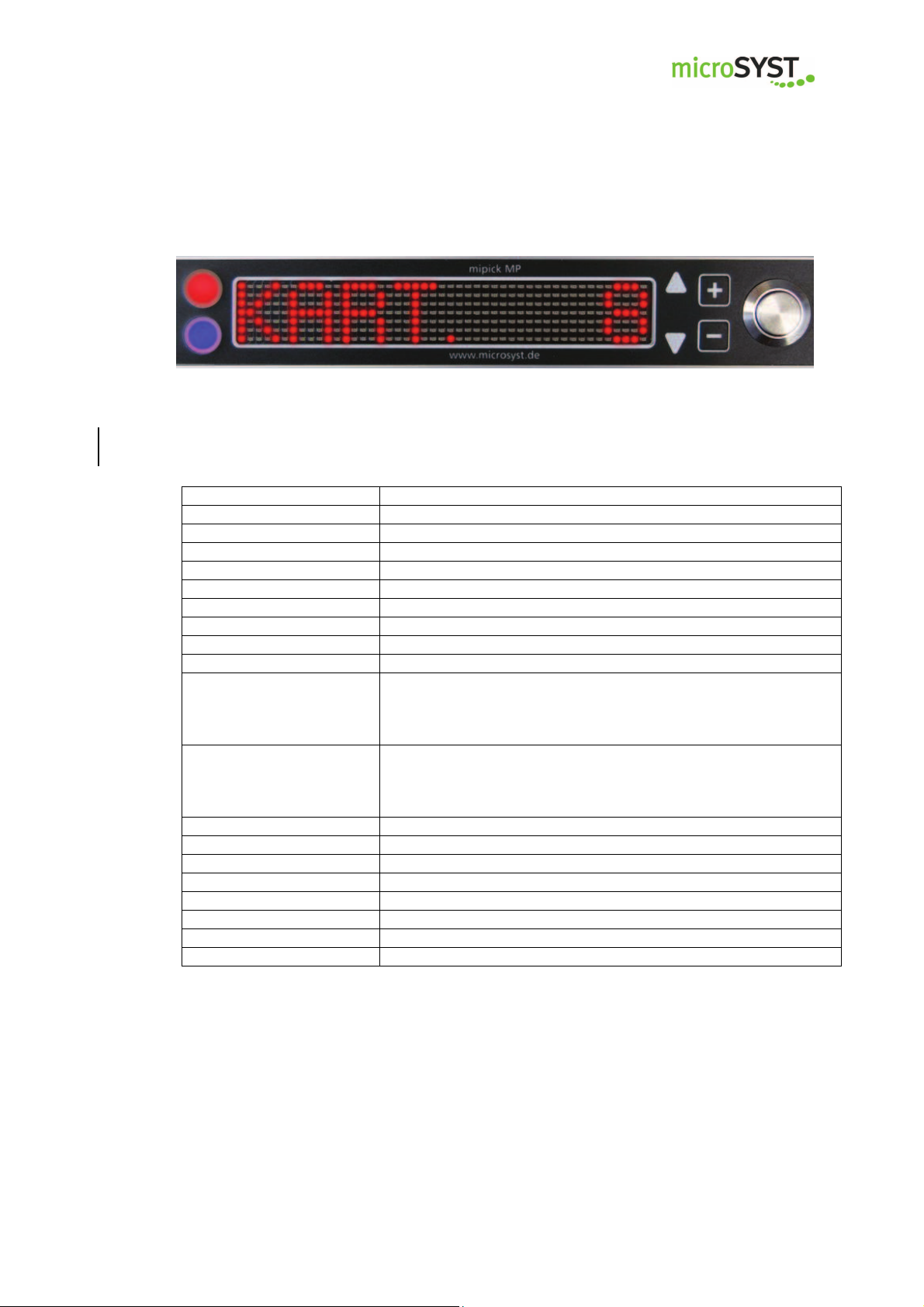

8 Displayable characters

8.1 Pick display MP20

0

1

2

3

4

5

6

7

8

9

A

B

0 1 2 3 4 5 6 7

Segment a* Space

Segment b*

Segment c*

Segment d*

Segment e*

Segment f*

Segment g*

Punkt dp*

C

D

E

F

*Assignment of segments

Page 40

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 41

mipick MP

8.2 Pick display MP80

With regard to the pick display MP80 a large part of the ASCII character set (bytes 32

until 127) can be displayed (letters, numbers, special characters).

User Manual

Page 41

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 42

Das bezeichnete Produkt stimmt mit

Die Übereinstimmung des bezeichneten Produk-

Richtlinien /

Europäische Norm /

mipick MP

User Manual

9 Declaration of Conformity

EU-Konformitätserklärung

EU Declaration of Conformity

Produktbezeichnung: mipick MP

Product name:

Typenreihe: Controller Box

Type code: mipick MP20

mipick MP80

mipick MP80T

Hersteller: microSYST Systemelectronic GmbH

Manufacturer: Am Gewerbepark 11

92670 Windischeschenbach

der folgenden Europäischen Richtlinie

überein:

We herewith confirm that the above mentioned product meets the requirements of

the following standard:

Directives

EMV Richtlinie

EMC Directive

NiederspannungsRichtlinie

Low Voltage Directive

RoHS Richtlinie

RoHS Directive

Windischeschenbach, 16.11.2016

Manuel Raß

Geschäftsführer / General Manager

2014/30/EU

2014/35/EU

2011/65/EU

tes mit den Vorschriften der angewandten

Richtlinie(n) wird nachgewiesen durch die Einhaltung folgender Normen / Vorschriften:

The conformity of the product described above with

the provisions of the applied Directive(s) is demonstrated by compliance with the following standards /

regulations:

Standard

EN61000-6-2:2005

EN61000-6-3:2007 +A1:2011

EN60950-1:2006 +A11:2009 +A1:2010 +A12:2011

+A2:2013

EN50581:2012

Page 42

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Page 43

mipick MP

User Manual

10 Version overview

Version Date Remarks, Descriptions

1.00

1.10

1.20

Certified per DIN EN ISO 9001.

29.04.14

03.05.16

13.09.17

Document created

Declaration of conformity

Display MP80 has been added

Page 43

microSYST Systemelectronic GmbH, Am Gewerbepark 11, 92670 Windischeschenbach

Tel. +49 9681 91960-0, Fax +49 9681 91960-10, www.microsyst.de, info@microsyst.de

Loading...

Loading...