Page 1

WLAN 802.11bgn 1T1R and BT2.1 EDR combo slim module

Combo slim Module

Rev 1.0

Application Note

APPLICATION NOTE

MS-3822

WLAN 802.11b/g/n 1T1R Slim Module

1

Micro-Star International Co., Copyright 2009

Proprietary and Confidential

Page 2

WLAN 802.11bgn 1T1R and BT2.1 EDR combo slim module

Combo slim Module

Rev 1.0

Application Note

Revision History

Revision Date Description Author/Revised by

1.0 2009/11/30 First version Benson

2

Micro-Star International Co., Copyright 2009

Proprietary and Confidential

Page 3

WLAN 802.11bgn 1T1R and BT2.1 EDR combo slim module

Combo slim Module

Rev 1.0

1. WLAN Module Block Diagram

Application Note

Figure1: WLAN Module Block Diagram

Micro-Star International Co., Copyright 2009

Proprietary and Confidential

3

Page 4

WLAN 802.11bgn 1T1R and BT2.1 EDR combo slim module

Combo slim Module

Rev 1.0

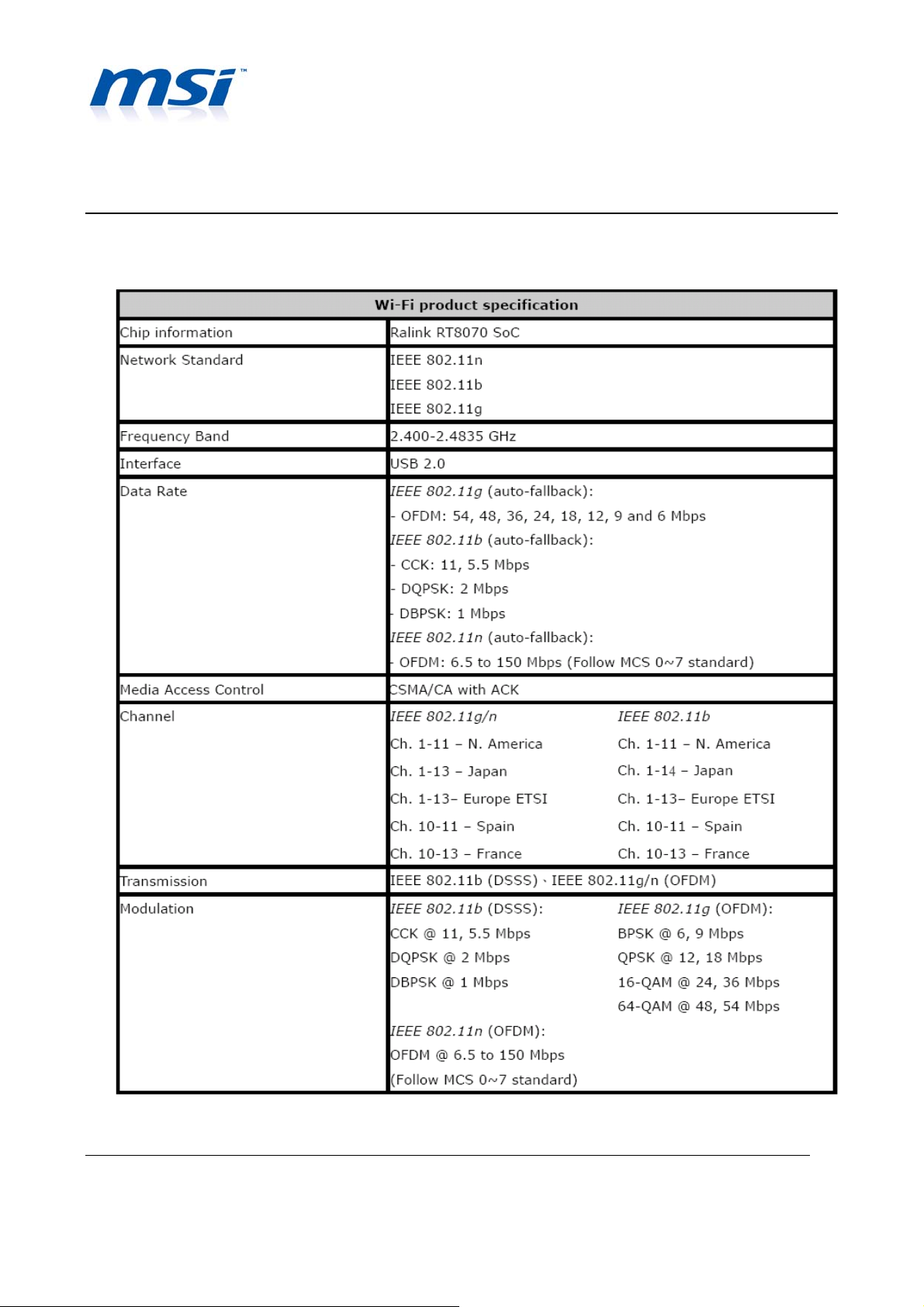

2. Product Specification

Application Note

Micro-Star International Co., Copyright 2009

Proprietary and Confidential

4

Page 5

WLAN 802.11bgn 1T1R and BT2.1 EDR combo slim module

Combo slim Module

Rev 1.0

Application Note

Micro-Star International Co., Copyright 2009

Proprietary and Confidential

5

Page 6

WLAN 802.11bgn 1T1R and BT2.1 EDR combo slim module

Combo slim Module

Rev 1.0

3. Module Pin Description

Pin 1 Pin 10

Table1: Combo Module Pin Description

Application Note

6

Micro-Star International Co., Copyright 2009

Proprietary and Confidential

Page 7

WLAN 802.11bgn 1T1R and BT2.1 EDR combo slim module

Combo slim Module

Rev 1.0

4. Mechanical Specifications

3.1 PCB Mechanical Drawing

Application Note

Figure2: WLAN Module Dimension

3.2 Connector Mechanical Drawing

Micro-Star International Co., Copyright 2009

Proprietary and Confidential

7

Page 8

WLAN 802.11bgn 1T1R and BT2.1 EDR combo slim module

Combo slim Module

Rev 1.0

Application Note

Figure3: Combo Module connector Dimension

4.3 Recommended Cable Length and Gauge

UL1571 32AWG HOOK UP WIRE OD=0.38mm, LENGTH=650mm (MAX.)

PS: This is the very minimum cable selection requirement. Performance could be more optimized if

cable length is shorter or premium cable is adopted.

5. Recommended Assembly for WLAN Module

8

Micro-Star International Co., Copyright 2009

Proprietary and Confidential

Page 9

WLAN 802.11bgn 1T1R and BT2.1 EDR combo slim module

Combo slim Module

Rev 1.0

Applying insulating tape or other insulator and adhere it onto the module or LCD panel. This is to

prevent the module touching on the panel ground.

’

Giving at least 1-2mm gap or applying insulators (insulating tap) in between module & panel for

Application Note

1~2mm gap

better isolation. (please note: This gap or isolation is only necessary when there is noise inducing

from the LCD panel)

6. Solution for Thermal Red uction and Improving Antenna Gain

Adopting copper /aluminum foil or heat sink and then adhere it onto the top of combo module

shielding case. The bigger the foil/heat sink, the better the thermal conduction. Please note that

9

Micro-Star International Co., Copyright 2009

Proprietary and Confidential

Page 10

WLAN 802.11bgn 1T1R and BT2.1 EDR combo slim module

Combo slim Module

Rev 1.0

Application Note

the size of foil/heat sink should just fit properly onto the shielding case. Foil/ heat sink size larger

than shielding area will impact the antenna performance. See below picture as a reference for

correct cutting size. Copper foil is highly recommended as it will enhance antenna performance.

7. Recommended Placement for Combo Module’s Antennas.

0.5mm GAP ( BT)

Leaving a gap between the combo module and NB housing ( the screw hole) for better antenna

10mm GAP ( Wi-Fi)

performance.

10

Micro-Star International Co., Copyright 2009

Proprietary and Confidential

Page 11

WLAN 802.11bgn 1T1R and BT2.1 EDR combo slim module

Combo slim Module

Rev 1.0

For Wi-Fi side, 10mm gap is recommended.

For Bluetooth side, 0.5mm gap is recommended.

Note: please avoid any metal parts to cover, touch or surround with antenna.

Application Note

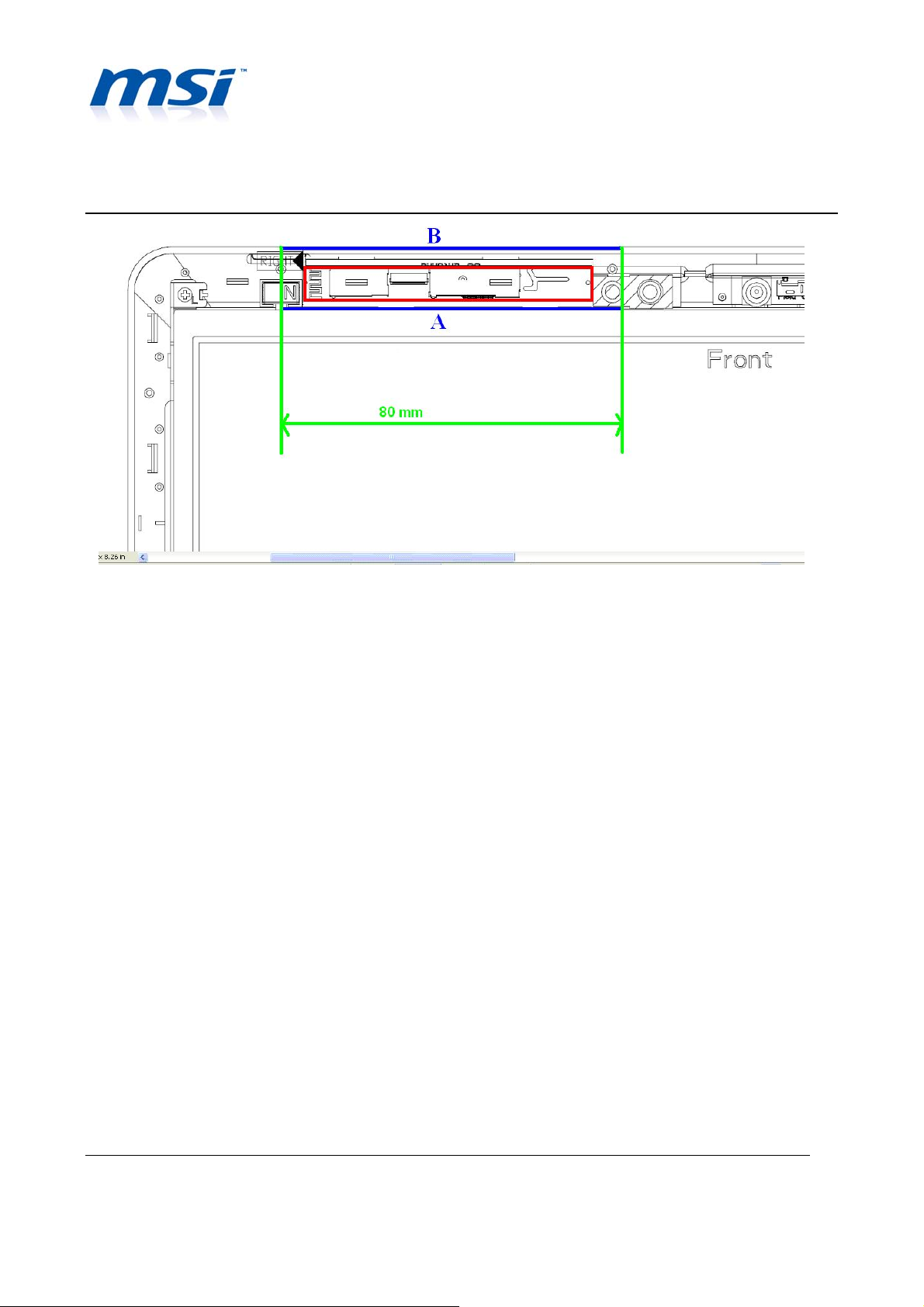

8. Recommended The Size Of Copper /Aluminum Foil

9. Recommended The EMI Coating Ar ea

We suggest the area of EMI Coating must be within the length of Green line :100mm and the

width between blue line A and B (from the end of panel to end of A side). Don't Coating exceed

this area.

11

Micro-Star International Co., Copyright 2009

Proprietary and Confidential

Page 12

WLAN 802.11bgn 1T1R and BT2.1 EDR combo slim module

Combo slim Module

Rev 1.0

Application Note

12

Micro-Star International Co., Copyright 2009

Proprietary and Confidential

Loading...

Loading...