Page 1

micros

®

Systems, Inc.

Workstation 5

Field Service Guide

Copyright 2008, 2009

By MICRO S Systems, Inc.

Colu mbia, Ma r y l a n d USA

All Ri ghts Reserved

Part N umber 100016-166 (2nd Edition)

Page 2

ii

Declarations

Warranties

Although the best efforts are made to ensure that the information

contained in this manua l is complete and correct, MICROS Systems, Inc .

makes no warranty of any kind with r e gard to this material, including but

not limited to the implied warranties of marketability and fitness for a

particular purpose. Information in this manual is subject to change

without notice. MICROS Systems, Inc. shall not be liable for errors

contained here in or for incide ntal or c onsequenti al damages in c onnect ion

with the furnishing, performance, or use of this material.

Trademarks

MICROS is a reg istered trademark of MICROS Systems, Inc.

Microsoft, MS-DOS, Windows, Windows 95, and Windows CE are registered

trademarks of Microsoft Corporation in the U.S. and other countries.

AMD, the AMD logo, and combinations thereof are trademarks of Adva nced

Micro Devices, Inc.

General Software, the GS Logo, Embedded BIOS, CE Ready, the CE Ready

logo, and Firm b ase ar e tradem ark s or re g ister ed tradem ark s of G en e ral

Software, Inc.

Printing History

New editions of this manual incorp orate new and changed material since

the previous edition . Minor co rrections and updates may be incorporated

into reprints of the curr ent edition without changing the date or edition

number.

1st Edition: April 2008

2nd Edition: March, 2009

Page 3

iii

Table Of Content s

Table Of Contents

Preface

Purpo se . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Who Should Use This Manual? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Symbo l s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v i i

Document Design and Production . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Introd uction to the WS 5 FR U s

Introduction

Casework and Mag Card Reader

Touchs creen Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -3

Top Cov e r . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

IO Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -4

Workstation 5 B ase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Mag Card Reader Ass e m b l y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -4

Power B u t ton A c t u ator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -4

System Board and Components

Main Bo a rd , Bare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

USB Flash D ri v e , 4GB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

USB Flash Drive, 256M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

BIOS EE PROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Compact Flash Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Compa c t Fla sh Ca r d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -6

DDR333 DIMM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Battery, CR2032 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

LCD/Touchscreen Assembly

Touchs creen Pan e l . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

LCD and To u c h screen Bra ck et . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

LCD Pan e l , 1 5 ” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -8

Backl i g h t In v erter Boar d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -8

Cables

LCD Dat a Ca b l e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -9

Backl i g h t In v erter Boar d Ca b l e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Cable Kit , AC Power In - D C Pow e r O u t . . . . . . . . . . . . . . . . . . . . . . 1 -10

Dongle, RJ45-DB9, IDN Port to RS232 2-wire serial . . . . . . . . . . . . . 1-10

Serial Port Conversion Dongle, COM5 RJ45 to DB9 . . . . . . . . . . . . . 1-11

LAN Patch Ca b l es . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -11

Cash Drawer Extension Ca b l e s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Workstation 5 Adjustable Stand Accessories

USB Exten sion Cab l e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -1 2

Third P a rt y Mo u n t i n g Adapte r . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Page 4

iv

Table of Contents

LCD Customer Display

LCD Inte r fa ce Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

LCD Module, Optrex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Cable, LCD P o le and Rear Di sp lay Head . . . . . . . . . . . . . . . . . . . . . . 1- 1 4

Cable Exte n sion, LCD Pole Di sp l ay . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1 4

LCD Custo mer Display Poles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1- 1 4

Kit, Front/Rear Cover, /w Lens, Screws, Pole Mount Hinge . . . . . . . 1- 15

Hinge Set , LCD Custom er Displa y . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

WS System Board T e ch nical Overview

Worksta t i o n 5 Bl o ck D i a g ram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

LX800 Processor and TFT Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Processor Core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

GeodeL i n k In t e rf a c e Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

GeodeL i n k Me m o ry Co n t roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

GeodeL i n k Cont rol Proc essor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -6

GeodeL i n k In t e rf a ce Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

FIFO/Synchronous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Transa c t i o n Forwarding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

PCI Bus Int e rface Blo c k . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

PCI Bus Arb i t e r . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

GeodeL i n k In t e rface General Descript i o n . . . . . . . . . . . . . . . . . . . . 2-7

CS5536 Companion Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

System Ma n ag e m e n t Bu s Control l e r . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Real Time Clock (RTC) and CMO S RA M . . . . . . . . . . . . . . . . . . . . . . 2- 8

ATA Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

LPC Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Audio Co d e c In t e rface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Divers e Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Power Ma n a g e m en t Control ler (PMC). . . . . . . . . . . . . . . . . . . . . . . . . 2-10

IDE Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

TFT LCD an d Ba c k l i g h t In t e rface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 2

The Grap h i c s P ro c essor (GP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

The Displ ay Co n t roller (DC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2- 1 3

Video Pr o ce ssor (VP ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1 3

LCD Inte rface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Backlight Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Config u rat i o n Ju mpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Companion Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

USB Flash Dr i v e Pow er Contr o ll er . . . . . . . . . . . . . . . . . . . . . . . . 2 -16

CN6 Port Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

USB Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Page 5

v

Table Of Content s

CN8 Por t P o w er . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -1 8

Touchs creen In t e rf a c e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

LPC Inte r face . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -20

AC’97 A u d i o In t e r fa ce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Realtek ALC203E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Speaker and Lin e Out p u t s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Point Of Sale Inte rf a c es. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -2 3

Customer Display Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Sendin g D a t a to t h e C u st o m e r Display . . . . . . . . . . . . . . . . . . . . . . 2 -2 3

Receiving Data from the Rear Display . . . . . . . . . . . . . . . . . . . . . . 2-24

Receiving Data from the Pole Display . . . . . . . . . . . . . . . . . . . . . . 2-24

Customer Display VCC Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 4

The LCD Customer D i sp l a y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 4

Mag Str i pe Reader Int e rface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 5

IDN Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

IDN Transmit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

IDN Receive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

RS422 Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

IDN Port RS232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

RS232 Transmit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

RS232 Receive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

COM5 Modular RS232 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

COM1 DB9 Po r t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Cash Drawer Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Cash Drawer Clos e d De tection . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 0

+24V Regu l ator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

System Bo a rd Hardware Rev is i o n . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

RTL8110SC Ethernet Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Genera l D escription . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -3 2

PCI Bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Link, Speed and Activity LED Co n t rol . . . . . . . . . . . . . . . . . . . . . . . . 2-32

EEPROM In t e rface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 3

System Bo a rd Power D i st ributio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

Standby Domain Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

+12V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -35

VCC5SB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -3 5

VCC3SB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -3 5

VCORE SB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

VCC1.8S B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Workin g Dom a i n V o l t a g e s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

VCC12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

VCC3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

VCC5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

VCC -12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

VCORE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Page 6

vi

Table of Contents

Working, Standby and System Reset . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Worksta t i o n 5 Backlight In v e r t e r Board . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

Functi onal Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

Techni c a l De sc r iption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 8

Supply Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

Lamp Strike . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

Run Lam p . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

Bright ness Contro l . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Workstation 5 Troubleshoo tin g

Introduction

Operational Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Worksta t i o n 5 Boo t Sequen c e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Booting to Windows Embedded CE 6.0 . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Booting to W EP O S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Background Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Multiple Boot Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Windows Embedded CE 6.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3- 11

WEPOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Pre-boot Firmware Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Platform Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

CAL32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Power- On Self Test (P O ST) Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -14

Checking the Power Supply and System Board Voltages . . . . . . . . . . . . . 3-15

WS5 System Board - Standby Vo l t a g es . . . . . . . . . . . . . . . . . . . . . . . 3-15

WS5 System Board - Wo rk i n g V o l tages . . . . . . . . . . . . . . . . . . . . . . . 3 -17

Workstation Recovery and Platform Update Procedures

Windows Embedded CE 6.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Using WC F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Using th e CA L t o Configure a Workstati o n . . . . . . . . . . . . . . . . . . . . 3-20

The CAL Download s the POS Appli c at ion . . . . . . . . . . . . . . . . . . . . . 3 -20

Stand-A l o n e CA L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3- 2 0

Using Windows CE Factory Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Factory Re store Pr o ce d u r e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

WEPOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

LCD Display Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Dark LCD (N o Backlight) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3- 2 4

Blank LC D (No Vid e o ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Flickering LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

LCD Back l i g h t too D im . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

LCD Imag e Pr o b l e m . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

LCD Quality Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Config u ri n g the LCD Jump ers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Touchscreen Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Touchscreen Not Responding after the Operating System Starts . . . . 3-27

Page 7

vii

Table Of Content s

Touchscreen Ca lib ration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 7

False To u ch e s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 9

Local A rea Networ k . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -2 9

Workstation 5 Does not Conn e ct t o LA N . . . . . . . . . . . . . . . . . . . . . . 3-29

Workstation 5 Does not Conn e ct t o LA N (Link LED OFF ) . . . . . . . . 3-30

Workstation 5 Does not Conn e ct t o LA N (Link LED ON ). . . . . . . . . . 3 -30

Perip h eral Relat e d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3 1

IDN Port COM4 (RS422) Does Not Function . . . . . . . . . . . . . . . . . . . 3-31

RS232 COM4 Peripheral Device Does not Function . . . . . . . . . . . . . . 3-31

COM5 RS232 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

COM1 RS232 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Mag Str i pe Reader Int e rface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3 2

Customer Display Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

WS5 Diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Windows Embedded CE 6.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

WEPOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Starting the WS5DiagUtility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

System Information Screen - Hardware Components . . . . . . . . . . 3-35

Syste m I n fo rmatio n Screen - Platform Fi l e s . . . . . . . . . . . . . . . . . 3-37

Activity Counters, Dump Sys Info and Recovery Image Info . . . . 3-41

WEPOS Sy st em Infor m a t ion Screen . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

Remove and Replace the Workstation 5 FRUs

Disassembli n g th e Workstation 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Magnet ic Card Rea d er . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -5

The Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

LCD/T o u c h screen Proc edures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Touchs creen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

LCD Pan e l . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 2

Backl i g h t In v erter Boar d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Capacitive Touchscreen Interface Board . . . . . . . . . . . . . . . . . . . . . . . 4-16

The System Board

USB Flash D ri v e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

DDR Mem o ry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 0

Approv e d D IMMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

BIOS EE PROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Mini-P CI Wireless Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 3

The Inte g rated LCD Cu stomer Display . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 4

Reass embling the Wo rk stati o n 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -2 5

Connector and Cable Diagrams

IO Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

10/100 Ethernet Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

RS232 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Cash Drawer 1 and 2 Con n ec t o rs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

Page 8

viii

Table of Contents

PS2 Mouse/Keyboard Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Remote Cust o mer Disp l ay Co n n e ctor . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

System Board Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A- 7

Magnetic Stripe Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

Hook-up Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

RS232 from the RS422-A and RS422-B Ports . . . . . . . . . . . . . . . . . . .A-8

Ethern et. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

8-Pin to 6-Pin Hook-up RS422 Cable (300319-001) . . . . . . . . . . . . . .A-11

Cash Drawe r Extens io n Cab l e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Page 9

Workstation 5 Field Service Guide ix

Preface

In this preface, you’ll find information about this manual. Refer to the prefac e if

you have questions about the organization, conventions, or contents of this

manual.

In this sectio n

Why Re ad T h is Manual?....... .. .................................................................ix

How This Manual Is Organized ...............................................................xi

Notation Conventions................................... ...........................................xii

Page 10

x Workstation 5 F ield Serv ic e Guide

Preface

Why Read T his Manual?

Why Read Thi s Ma nu al?

Purpose

This hardware-only gui de is intended for those who will be troubleshooting and

repairing the MICROS Workstation 5.

Who Should Use This Manual?

This manual is intended for qual ified service personnel who have experience with

the configuration an d troubleshooting of MICROS point of sale terminals. The

ability to read schemati cs and a working knowledge of microprocessor based

systems and related test equipment is required.

The circuit and detaile d start- up descriptions contained in this manual are

intended to give the technician a working knowledge of the hardware to be used as

an aid in the troubleshooting and repair of the equipment.

Bibliography

AMD Geode™ LX Processor Databook - October 2005

AMD Geode

™

CS5536 Companion Device Databook

Realtec RTL8110SC Integrated Gigabit Ethernet Controller Data Sheet

SMSC Integrated USB 2.0 Compatible Hub Datasheet Revision 1.8

Winbond W83627HF/F Super IO Datasheet Version 2.0

Page 11

Workstation 5 Field Se rv ic e Guide xi

Preface

How This Manual is Or ganized

How This Manual is Organize d

W elcome to the 1st Edition of the Workstation 5 Field Service Guide.

Chapter 1 list s the Workstation Fiel d Rep l ace me nt U n its (FR U s) . This inclu d es

casework, LCD and Touchscreen components, the Workstat ion 5 system board

and components. Images of each FRU are included to avoid confusion.

Chapter 2 provides tec hnical de scriptions of the Workstati on 5 Syste m Board with

emphasis on the POS Interfaces includ ing IDN, Customer Display, Mag Stripe

Reader and Cash Drawer int erfaces. Other to pics include a des cription of the USB

Interfaces and the System Board Power Distribution.

Chapter 3 covers WS5 trouble shooting. The Chapter st arts of f with a detai led star t

up description of the support ed operating syst ems and provid es volta ge test points

for the internal power supply and system board voltage regulators.

Chapter 4 in clude s th e FRU rem o ve/ repl ac e pr oc edu res .

Appendix A includes pin- out dia grams fo r all WS5 IO Po rt conn ectors and r elate d

hook-up cables.

Page 12

xii Workstatio n 5 F ie ld Servic e Guide

Preface

Notation Conventions

Notation Conventions

Symbols

Document Design and Production

Desktop Publishing: Adobe FrameMaker 6.0.

Images: Nikon CoolPix 990/Canon PowerS hot A80

Line Drawings: Corel Draw! 7.0.

Image Processing: Paint Shop Pro 8.0/ Corel Draw! 7.0.

NOTE

This symbol brings special attention to a related item.

WARNING

This symbol indicates that specif ic handling instructions or

procedures are required to prevent damage to the hardware or

loss of data.

SHOCK HAZARD

This symbol calls attention to a potential hazard that requires

correct procedures in orde r to avoid personal injury.

STATIC SENSITIVE DEVICES

This symbol indicates that specif ic ESD handling procedures

are required.

Page 13

Workst at ion 5 Field S erv ic e Guide 1-1

Chapter 1

Introduction to the WS5 FRUs

This section introduces the Workstation 5 Field Replaceable Units, or spare

parts. Also, spa re parts f or the LCD Customer Displ ay can be found at the end

of this Chapter.

In this chapter

Introduction...................................................................................................1-2

Casework and Mag Card Reader ................................................................. 1-3

System Board and Components................................................. .................. 1-5

Power Supply............................................................................................... 1-7

LCD and Touchscreen Assembly ................................................................ 1-8

Cables........................................................................................................... 1-9

Workstation 5 Adjustable Stand Accessories ............................................ 1-13

LCD Cus t o m e r Dis p lay . ... ......................................................................... 1-14

Page 14

1-2 Works tat ion 5 Fiel d Servi ce Gui de

Introduction to the WS5 FRUs

Introduction

Introduction

This chapter introduces the Workstation 5 Field Replacement Units (FRUs).

The FRUs are grouped into the following categories.

Casework and Mag Stripe Reader

This section contains the available casework FRUs and the fully assembled

Mag Stripe Reader. The Mag Card Reader is now a complete assembly /w

cable and ready to install.

System Board and Components

This section contains the replacement system board and primary components

such as the USB Flash Drive, BIOS EEPROM, and DIMM.

Power Supply

This section lists the replacement WS5 Power Supply.

LCD Touchscreen Assembly

This section details the LCD Touchscreen Assembly components and includes

the Backlight Inverter Board.

Cables

This section contains all internal cable assemblies as well as several optional

serial port conversion cables.

Workstation 5 Ad j ustable Stand Acce ssories

This section lists optional available of the Workstation 5 Adjustable Stand.

LCD Customer Display

This sections lists FRUs available for the Optional Integrated and Pole mount

LCD Customer Display.

Page 15

Workst at ion 5 Field S erv ic e Guide 1-3

Introduction to the WS5 FRUs

Casework and Mag Card Reader

Casework and Mag Card Reader

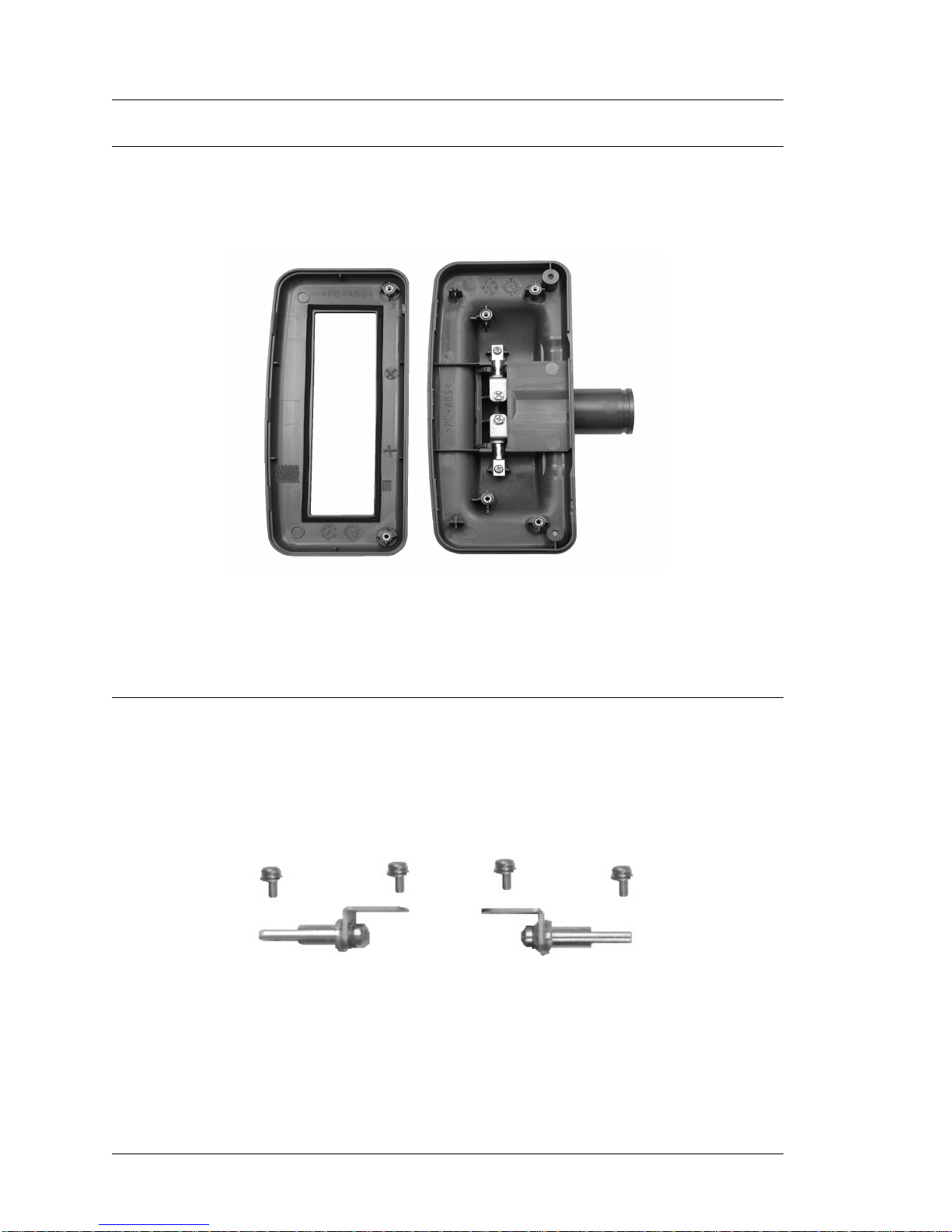

Figure 1-1, below illustrates all plastic components and the Mag Stripe Reader

Assembly.

Figure 1-1: Workstation 5 Casework and Mag Card Reader

• Touchscreen Gasket, Workstation 5 - P/N 600537-128

The touchscreen gasket is pressed into a groove around the inside of the

Top Cover.

• Top Cover, Workstation 5 - P/N 400409-005

Includes Operator LED lens and captive mounting screws pre-installed.

Touchscreen Gasket not included.

Page 16

1-4 Works tat ion 5 Fiel d Servi ce Gui de

Introduction to the WS5 FRUs

Casework and Mag Card Reader

• Door, /w Logo Insert , Work station 5 - P/N 300323-105

Snap-in IO Door with removable MICROS logo insert.

• Base, Workstation 5 - P/N 400408-005

The plastic base holds the chassis, system board, power supply and Mag

Card Reader assembly. Mounting hardware, Mag Card Reader assembly

and power button actuator not included.

• Mag Card Reader Assembly, MCR /w Cable and Cover - P/N 700293-125

Fully assembled Magnetic Card Reader /w cable and plastic mounting

bracket.

• Power Button Actuator, /w Light Pipe and Screw - P/N 300103-011

Power button actuator assembly includes light pipe and mounting screw.

Mounts to the base to activate the System Board power switch.

Page 17

Workst at ion 5 Field S erv ic e Guide 1-5

Introduction to the WS5 FRUs

System B oard and Components

System Board and Compo ne nt s

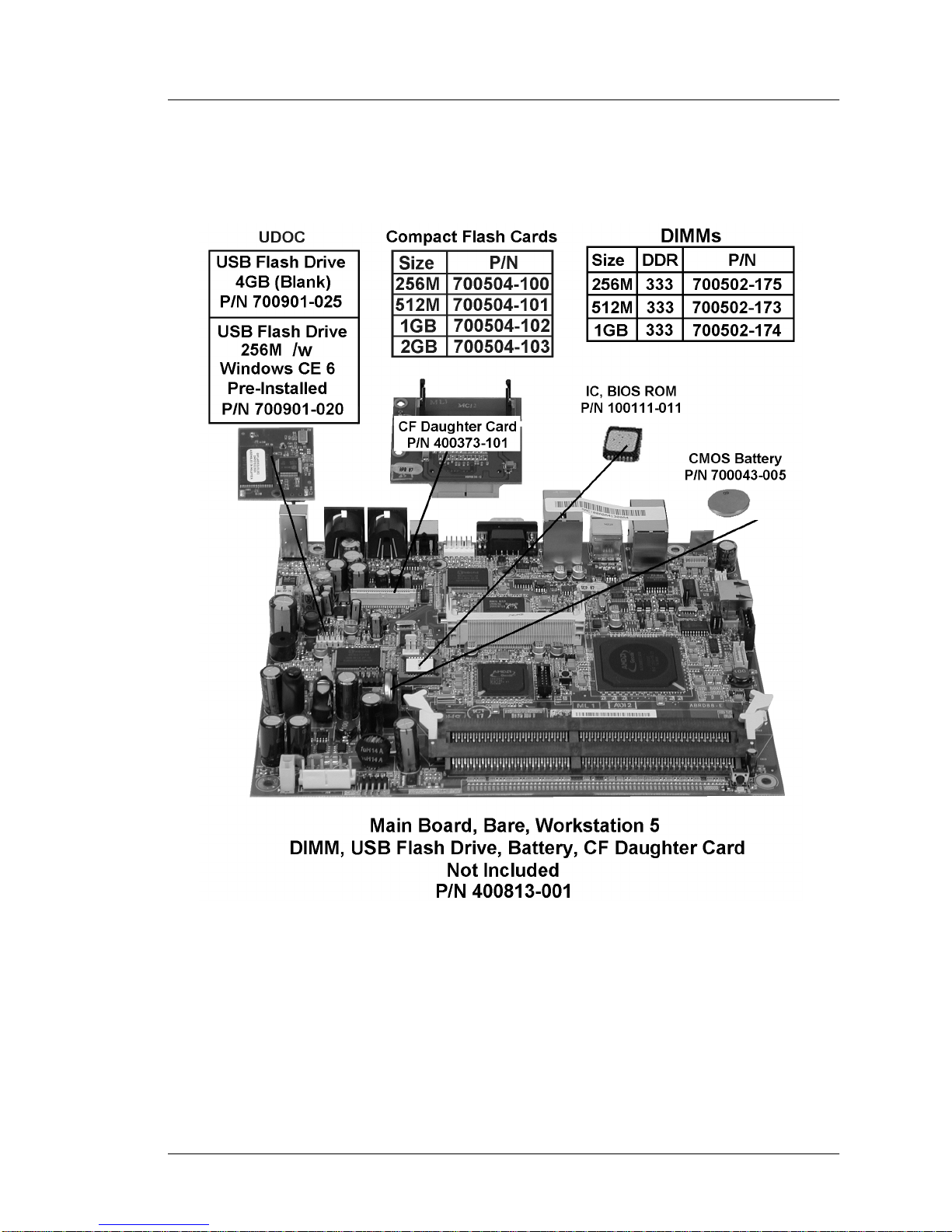

Figure 1-2, below lists the System Board FRU and available components.

Figure 1-2: Workstation 5 System Board and Components

• Main Board, Bar e, Workstation 5 - P/N 400813-001

Bare ABRD88 system board supplied without DIMM, BIOS ROM, USB

Flash Drive, CMOS Battery, or CF Daughter Card.

• USB Flash Drive, 4GB - P/N 700901-025

Blank 4GB USB Flash Drive for WEPOS. Kit P/N 000218-050, the

WEPOS Recovery Kit can be used to restore the WEPOS Flash Drive.

Page 18

1-6 Works tat ion 5 Fiel d Servi ce Gui de

Introduction to the WS5 FRUs

System B oard and Co m ponents

See chapter 3 for more information about recovering the WEPOS image.

• USB Flash Drive, 256M - P/N 700901-020

256M USB Flash Drive is pre-loaded with the Windows Embedded CE 6.0

operating system, platform files and the CAL client utility. Installs on

system board header J9. Not compatible with the Workstation 4 LX System

Board.

• IC, BIOS ROM, WS5 - P/N 100111-011

The pre-programmed 1M BIOS ROM installs in system board socket U36.

Not compatible with the Workstation 4 or Workstation 4 LX.

• Compact Flash Daughter Card - P/N 400373-101

The CF Daughter Card attaches to IDE1 the CF Riser Socket on the

Workstation 5 System Board. Does not include CF Card, cover and

mounting screws. Also compatible with the KWS4, PCWS 2010, the

Workstation 4 and Wor kstation 4 LX.

• Compact Flash Cards - See Figure 1-2

Blank formatted Compact Flash Card in sizes of 256M, 512M, 1GB, and

2GB. The 256M CF is standard for Windows CE, but a WEPOS unit ships

without a CF card installed. Compatible with all CF based MICROS

workstations.

• DIMM, DDR333 256M - P/N 700502-175

DDR3 DIMM suitable for Windows Embedded CE 6.0. Approved devices

include Wintec WD1UN256X808-333B-PH,

WD1UN256X808-333B-PJ-M01, and Unigen

UG732D6688KV-DHFMSS. Also compatible with the Workstation 4 LX.

Please note that the Windows Embedded CE image is limited to 512M of

RAM.

• DIMM, DDR333 512M - P/N 700502-173

Suitable for WEPOS configurations. Wintec part numbers include

WD1UN512X808-333B-QC and WD1UN512X816-333B-PJ-M01.

• DIMM, DDR333, 1GB - P/N 700502-174

Suitable for WEPOS configurations. Wintec Part Number

WD1UN01GX816-333C-QC.

• Battery , CR2032 - P/N 7000043-005

CR2032 Lithium Coin Cell. This battery is also used on the WS4, WS4

LX, PCWS 2010, PCWS Eclipse and KWS4 System Boards.

Page 19

Workst at ion 5 Field S erv ic e Guide 1-7

Introduction to the WS5 FRUs

Power Supply

Power Suppl y

• Power Supply - P/N 700351-022

The +12V 100W open frame power supply is shown in Figure 1-3. Power

Supply vendor and appearance may vary. Not compatible with the

Workstation 4/4 LX.

Figur e 1-3: Workstation 5 Power Supply

Page 20

1-8 Works tat ion 5 Fiel d Servi ce Gui de

Introduction to the WS5 FRUs

LCD and Touchscreen Ass em bly

LCD and Touchscreen Assembly

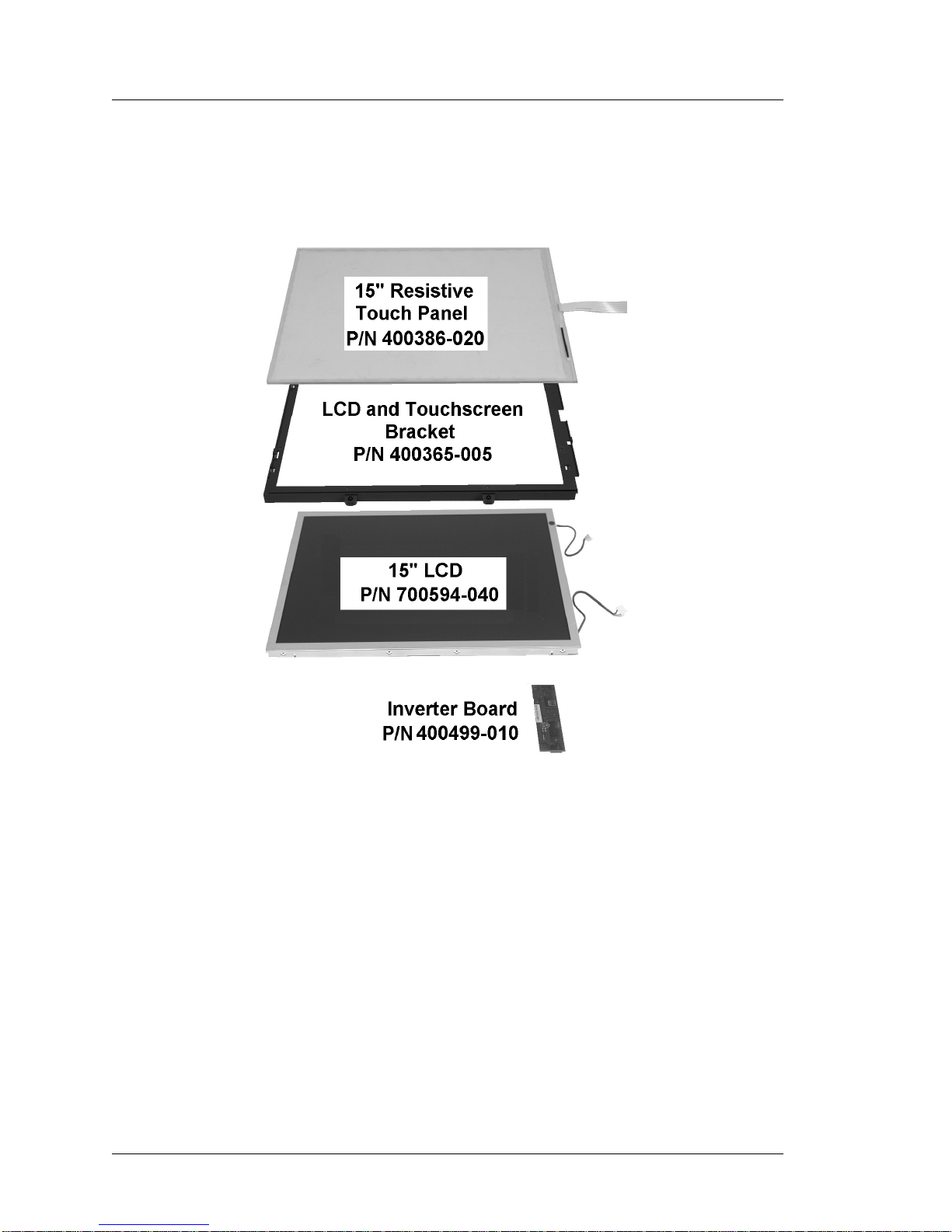

Figure 1-4, displays the FRUs associated with Workstation 5 LCD and

Touchscreen Assembly.

Figure 1-4: LCD and Touchscreen Assembly FRUs

• Touchscreen Panel, 15.0” R esistive, E LO E055550 or EL O E457626 - P/N

400386-020

Five-wire resistive touch panel.

• Bracket, LCD and Touchscreen Assy, /w captive screws - P/N 400365-005

This bracket houses the touchscreen glass and the LCD panel.

• Display 15” LCD, WS5 - P/N 700594-040

Replacement 15” Sharp or AUO LCD Panel. See Chapter 3 for jumper

configurations.

• Inverter Board, WS5 - P/N 400499-010

Workstation 5 compatible push-pull Backlight Inverter Board. Mounts to

the LCD plate. Compatible only with the Workstation 5.

Page 21

Workst at ion 5 Field S erv ic e Guide 1-9

Introduction to the WS5 FRUs

Cables

Cables

This section contains all Workstation 5 internal and external cables.

LCD Data Cable - P/N 300331-305

This cable connects between the System Board J8 and the LCD panel data

connector.

Figure 1-5 : Workstation 5 LCD Data Cable

Cable, Inverter Board - P/N 300331-210

This cable connects between the System Board J3 and J1 on the Backlight

Inverter Board.

Figur e 1-6: Workstation 5 Backlight Inverter Board Cable

Page 22

1-10 Workst at ion 5 F ield S ervi ce Gui de

Introduction to the WS5 FRUs

Cables

Cable Kit, AC Power In - DC Power Out - P/N 000170-015

Kit consisting of the AC input connector and wiring harness and Power Supply

to the System Board Cable.

Figure 1- 7: Workstation 5 AC In - DC Out Cable Kit

WS5, AC Power Cable, RT Angle - P/N 200153-009

Replacement Power Cable for the Low Profile Workstation 5. Not compatible

with the W orkstation 4/4LX or the Workstation 5 Adjustable Stand.

Figure 1- 8: Workstation 5 Replacement AC Power Cable

Page 23

Workst at ion 5 Field S erv ic e Guide 1-11

Introduction to the WS5 FRUs

Cables

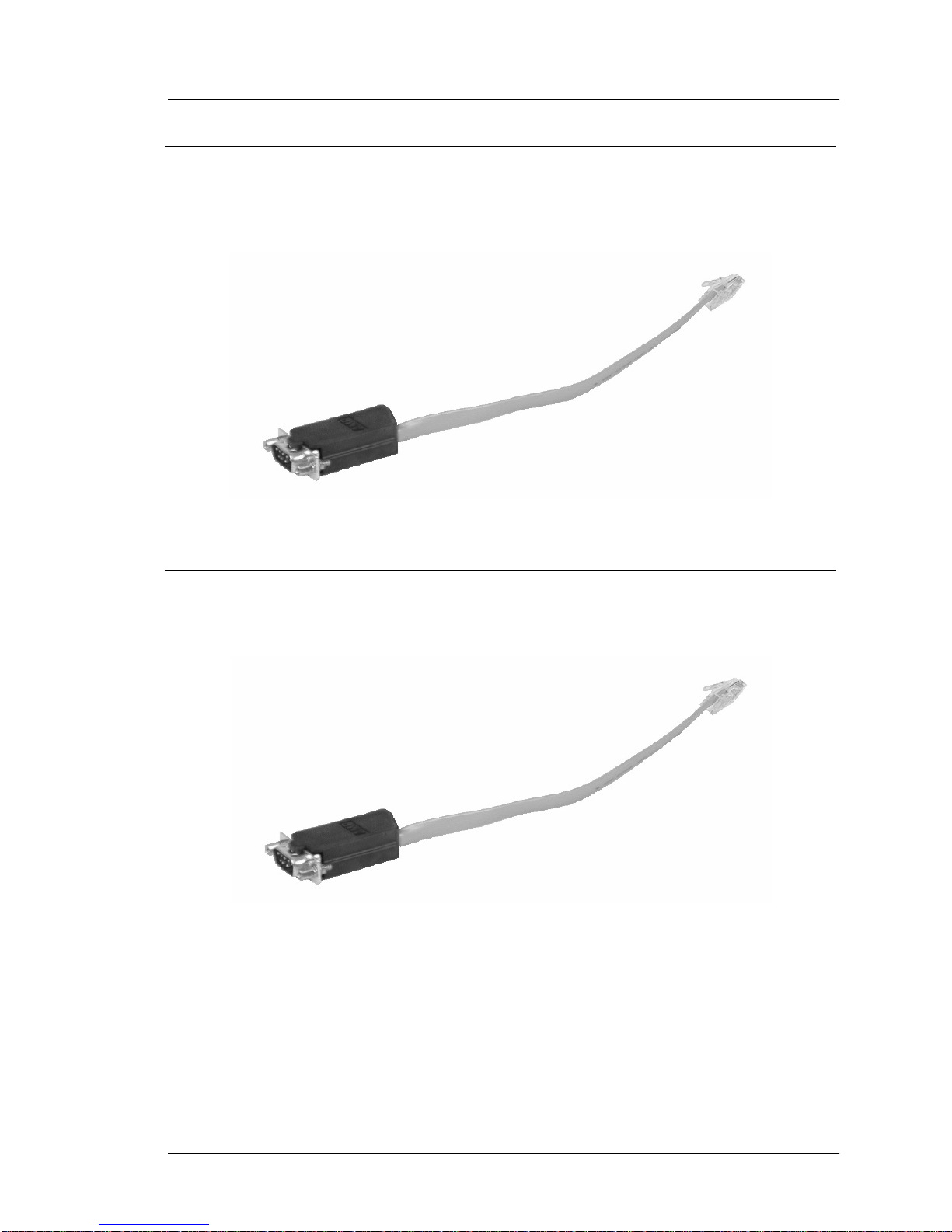

Dongle, RJ45-DB9, IDN Port to RS232 2-Wire Serial - P/N 300319-102

This cable brings out the RS232 conductors from the IDN port to a DB9

connector.

Figure 1-9: Conve rting the IDN Port to RS232 DB9

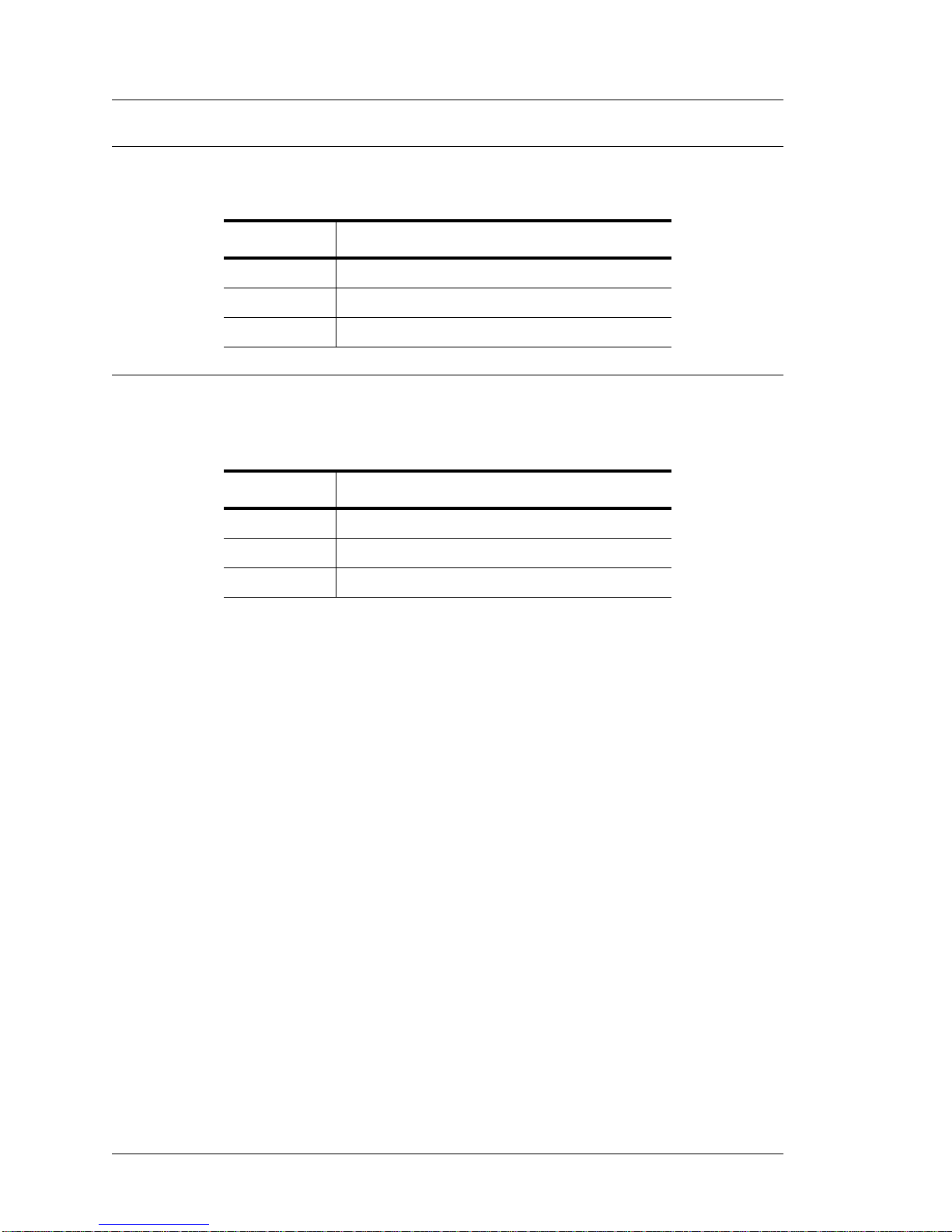

Serial Port Conversion Dongle, COM5, RJ45 to DB9 - P/N 300319-103

This cable converts the modular COM5 serial connector to a DB9 connector.

Figure 1-1 0: Converting the Modular COM5 Port to RS232 DB9

Page 24

1-12 Workst at ion 5 F ield S ervi ce Gui de

Introduction to the WS5 FRUs

Cables

LAN Patch Cables

The table below displays Category 5 Patch Cables in three lengths.

Cash Drawer Extension Cables

For upgrades or under-the-counter installations, the following extended length

cables are available.

Part Number Description

700834-003 Category 5 Patch Cable, Bl ue, 3 Feet

700834-006 Category 5 Patch Cable, Bl ue, 6 Feet

700834-012 Category 5 Patch Cable, Bl ue, 12 Feet

Part Number Description

300029-006 6 Foot Cash Drawer Extender Cable

300029-012 12 Foot Cash Drawer Extende r Cabl e

300029-018 18 Foot Cash Drawer Extende r Cabl e

Page 25

Workst at ion 5 Field S erv ic e Guide 1-13

Introduction to the WS5 FRUs

Workstation 5 Adjustable Stand Acce s s ories

Workstation 5 Adjustable Stand Accessories

USB Extension Cable and Bracket - P/N 400431-305

Optional USB Extension Cable connects between the Workstation 5 IO panel

and the base of the adjustable stand. Cable appearance may vary.

Figure 1-11: Adjustable Stand USB Extension Cable

Third Party Mounting Adapter for Workstation 5 Stand - P/N 600526-050

The mounting adapter installs in place of the WS5 Adjustable Stand Logo

Badge as shown in the Figure below . It can be used to mount a variety

customer facing devices.

Figure 1-12 : Adjustable Stand Third Party Mounting Adapter

Page 26

1-14 Workst at ion 5 F ield S ervi ce Gui de

Introduction to the WS5 FRUs

LCD Customer Display

LCD Customer Display

This section lists the available FRU’s for the LCD Customer Display. See

Chapter 6 for instructions on removing and replacing these items. The WS4,

KWS4, WS4 LX and WS5 support this display.

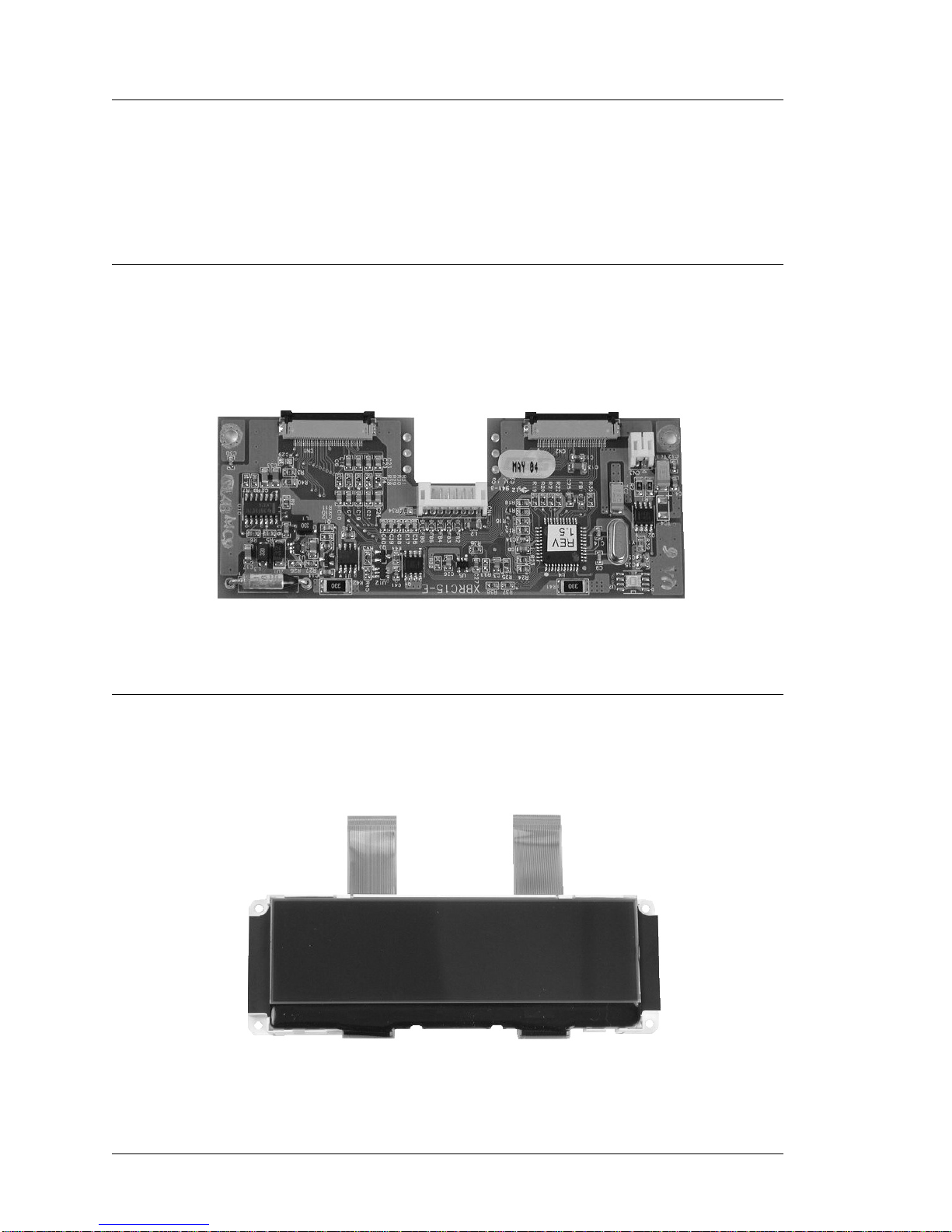

LCD Interface Board - P/N 400702-001

The LCD Customer Display Interface Board is used for the Integrated, Pole

and Adjustable Stand Pole mounted display. This board also drives the

Operator Display in the KWS4.

Figur e 1-13: LCD Customer Display Interface Board

LCD Module, Optrex - P/N 700594-117

The 240x64 Monochrome LCD Module is used for the Rear and Pole Mount

LCD Customer Display . It is also used for the Operator Display on the KWS4.

Figur e 1-14: Optrex LCD Module for the LCD Customer Display

Page 27

Workst at ion 5 Field S erv ic e Guide 1-15

Introduction to the WS5 FRUs

LCD Customer Display

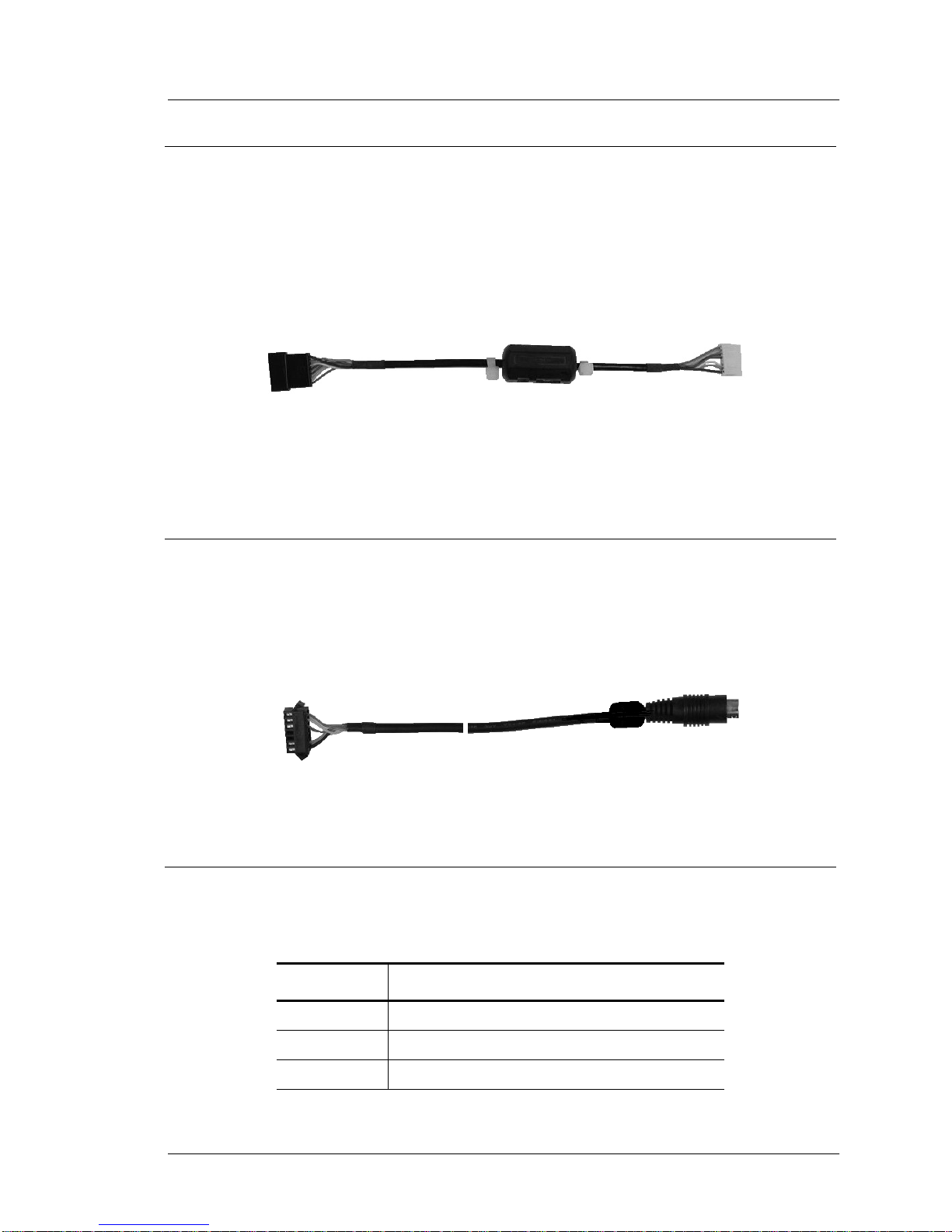

Cable, LCD Pole and Rear Display Head - P/N 300331-251

This replacement cable connects between the LCD Interface Board in the rear

or pole LCD display housing to cable 400446-007 (Integrated/Rear) or

300331-250 (Pole).

Figure 1-15 : Replacement LCD Customer Display Cable

Cable Extension, LCD Pole Display - P/N 300331-250

This cable is installed in the pole and connects between 300331-251 (above)

and the WS4, WS4 LX, WS5 or KWS4 I/O Panel.

Figure 1-16: Replacement LCD Pole Extension Cable

LCD Customer Display Poles

Three sizes are available, they can be used as a replacement or conversion for

kit 500827-007, or 700827-105.

Part Number Description

600568-031 Replacement 6 Inch Pole

600568-032 Replacement 12 Inch Pole

600568-033 Replacement 18 Inch Pole

Page 28

1-16 Workst at ion 5 F ield S ervi ce Gui de

Introduction to the WS5 FRUs

LCD Customer Display

Kit, Front/Rear Cover, /w Lens, Screws, Pole Mount Hinge - P/N 000160-010

LCD Customer Display housing kit with Front and Rear Plastic covers, pole

mount and pre-installed 2nd generation hinge assembly.

Figure 1-17: Pole Display Plastic Replacement Kit

Workstation 5 Integrated LCD Bracket is not yet available. The WS4 WS4LX

bracket is not compatible.

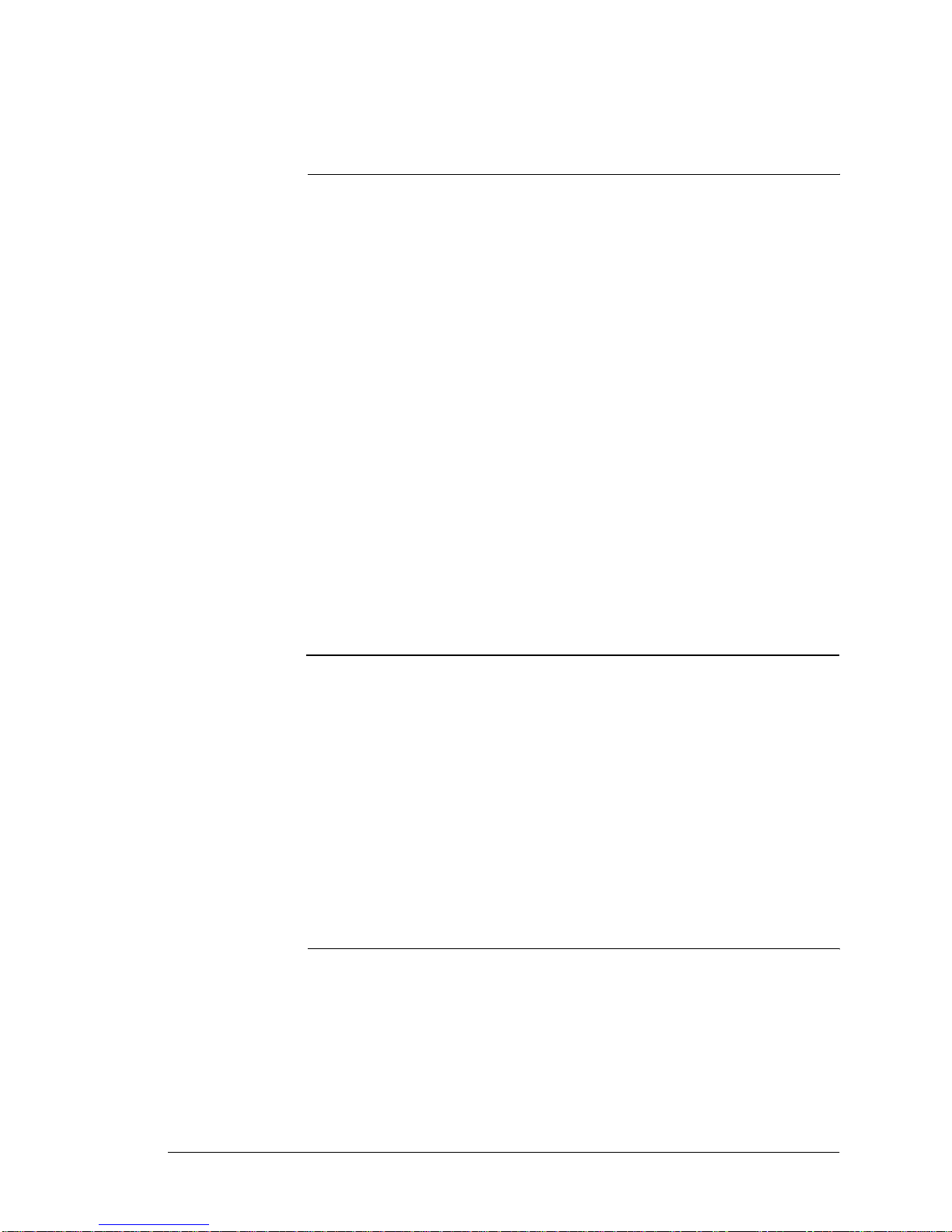

Hinge Set, LCD Customer Display - P/N 400456-020

The hinge set can be used on the updated LCD Customer Display housing rear

cover.

Figure 1-18: Rea r/Pole Hinge Set /w Mounting Screws

Page 29

Workstation 5 Field Ser vic e Guide 2-1

Chapter 2

Workstation 5 System Board

Technical Descriptions

This chapter provides technical descriptions of the Workstation 5

System Board and accessories.

In this chapter

Workst a t i o n 5 Sys t e m Bo a rd Block Diagram.................................... 2-2

LX800 Processor and TFT Controller ...............................................2-4

CS5536 Companion Device...............................................................2-8

TFT LCD an d Ba cklight Int e rface...... .............................................2-12

USB Interface ..................................................................................2-16

T ouchscreen Interface......................................................................2-19

LPC Inte rface.... ...............................................................................2-20

AC 97 Audio In t e rface.. ...................................................................2 -21

Point Of Sale Interfaces.... .... ........... .... ...... .... ...... .... ...... .... ...... .... ....2- 23

RTL8110SC Ethernet Controller .....................................................2-32

System Board Power Distribution ...................................................2-34

Page 30

2-2 Workstat io n 5 Fie ld S ervice Guide

Workstation 5 System Board Technical De scriptions

Workstation 5 System Board Block Diagram

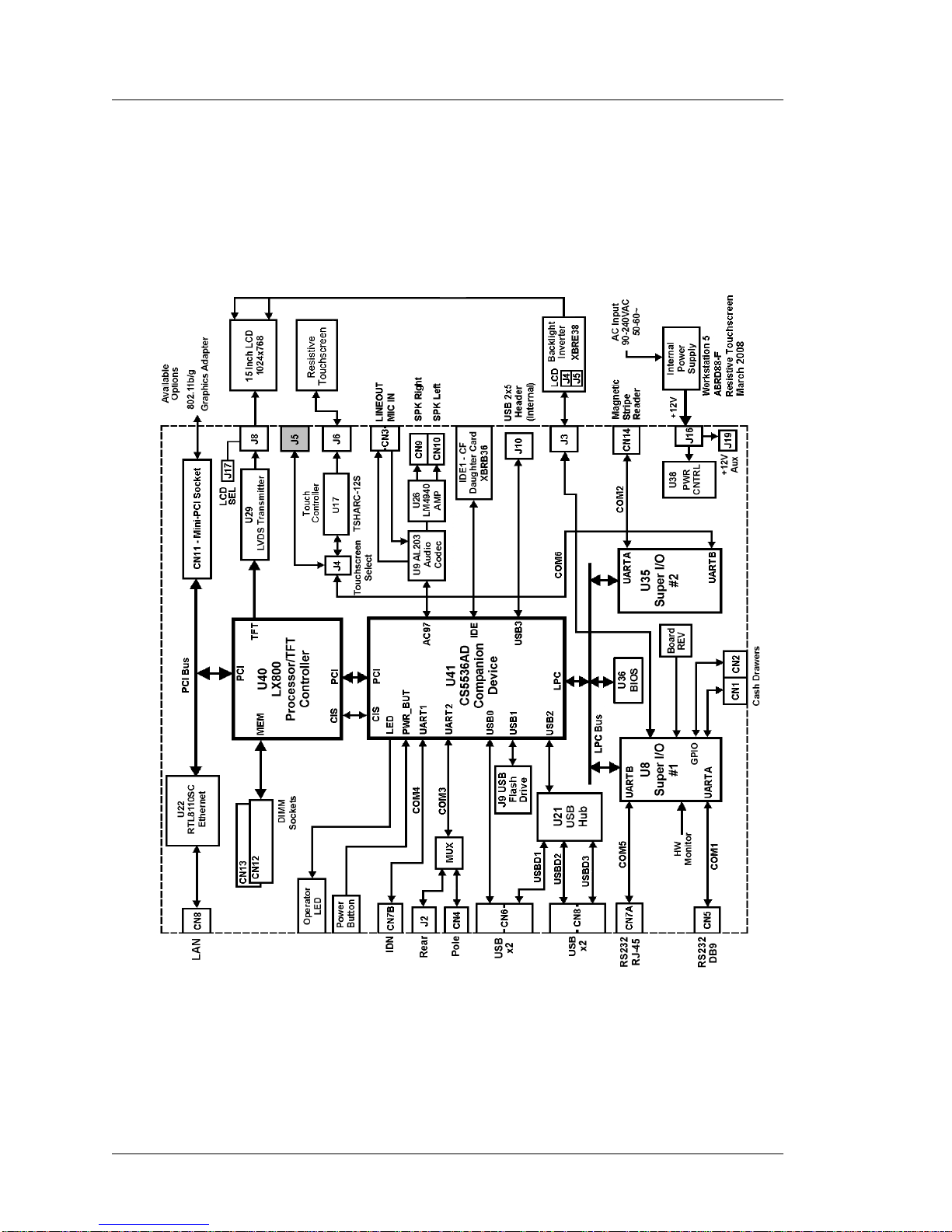

Workstation 5 System Board Block Diagram

Figure 2-1 displays a block diagram of the Workstation 5 with the standard

resistive touchscreen. This configuration represents production units from

January 2008 to February 2009.

Figure 2-1: Workstation 5 Block Diagram /w Resistive Touchscreen

Page 31

Workstation 5 Field Ser vic e Guide 2-3

Workstation 5 System Board Technical Descriptions

Workstation 5 System Board Block Diagram

Figure 2-2 below displays a block diagram of the Workstati on 5 with an

optional capacitive touchscreen installed. This configuration adds the

Capacitive Touchscreen Interface Board. This configuration is not in

production,

Figure 2-2 : Workstation 5 Block Diagram /w Capacitive Touchscreen

Page 32

2-4 Workstat io n 5 Fie ld S ervice Guide

Workstation 5 System Board Technical De scriptions

LX800 Processor and T FT Co nt roller

LX800 Processor and TFT Controlle r

REF: ABRD88 - Sheets 1, 2, 5 and 6

Figure 2-3 displays a block diagram of the LX800 processor.

Figure 2-3: AMD Geode LX800 Processor/TFT Controller Block Diagram

Page 33

Workstation 5 Field Ser vic e Guide 2-5

Workstation 5 System Board Technical Descriptions

LX800 Process o r a n d TFT C on trolle r

Processor Core

The processor core consists of an integer unit, cache memory subsystem, and

an x87 compatible floating point unit. The integer unit contains the instruction

pipelines and associated logic. The memory subsystem contains the instruction

and data caches, translation look-aside buffers (TLBs) and an interface to the

GeodeLink Interface Units (GLIUs).

The LX800 instruction set is based on a combination of Intel’s Pentium®, the

AMD K6® processor, and the Athlon™ Floating point unit, and the AMD

Geode™ LX processor specific instructions.

GeodeLink Interface Units

The pair of GeodeLink Interface Units (GLIU0 and GLIU1 in the LX800 block

diagram, Figure 2-3) form the heart of GeodeLink architecture. Each features a

built-in arbiter that enables dynamic allocation of memory bandwidth, with

on-the-fly prioritization.

Internally each GLIU includes seven channels, with channel 0 reserved for the

GLIU itself and not considered a physical port. Together, GLIU0 and GLIU1

make up the internal bus comprised of the GeodeLink architecture. GLIU0

connects to the five modules that require high bandwidth, and GLIU1 connects

to the five low bandwidth modules.

GLIU0 is connected to modules with high-bandwidth requirements:

•CPU Core

• GeodeLink Memory Controller (GLMC)

• Graphics Processor

• Display Controller

• GLIU1 (GeodeLink Interface Unit 1).

GLIU1 is connected to modules with lower bandwidth requirements:

• GeodeLink Control Processor (GLCP)

• Video Input Port

• GeodeLink PCI Bridge

• TFT Controller/Video Output Port (VOP)

• Security Block.

Page 34

2-6 Workstat io n 5 Fie ld S ervice Guide

Workstation 5 System Board Technical De scriptions

LX800 Processor and T FT Co nt roller

GeodeLink Memory Controller

The GeodeLink Memory Controller provides all of the LX800 memory needs.

The GLMC is capable of ha ndling multiple requests for memory data fr om the

CPU core, the Graphics Processor, the Display Controller and the external PCI

bus via the GeodeLink Interface Units (GLIUs). Contention for memory

bandwidth between the various modules is minimized by extensive buffering

logic.

Because the GLMC supports the memory requirements of both the CPU core

and display sub-system, it is classified as a Unified Memory Architecture

(UMA) subsystem.

• The 64-bit DDR SDRAM Interface as implemented on the LX System

Board, supports unbuffered DDR 333/400 DIMMs up to 2GB.

• Unified Memory Architecture (UMA), UMA enables up to 2GBps memory

bandwidth while using single memory interface. The DDR Memor y array

contains both the main system memory and the graphics frame buffer.

GeodeLink Control Processor

The GeodeLink Control Processor is used for software debugging and

performance analysis.

GeodeLink PCI Bridge

The GeodeLink PCI Bridge (GLPCI) module provides the PCI interface for the

LX800 system. It is comprised of five major sections or blocks, briefly

described below.

GeodeLink Interface Block

The GeodeLink Interface Block provides a conversion layer between the

GeodeLink Interface Unit 1 (GLIU1) and the Transaction Forwarding

Block.

FIFO/Synchronous Block

The FIFO module consists of a group of in-bound and out-bound FIFOs.

Each FIFO provides a simple, synchronous interfaces to read and write

requests.

Transaction Forwarding

The Transaction Forwarding block receives, processes and forwards

transaction requests and responses between the GeodeLink Interface and

PCI Bus Blocks. Transaction ordering rules are implemented and write

gathering and read pre-fetching are performed as required.

Page 35

Workstation 5 Field Ser vic e Guide 2-7

Workstation 5 System Board Technical Descriptions

LX800 Process o r a n d TFT C on trolle r

PCI Bus Interface Block

The PCI Bus Interface provides a protocol conversion layer between the

transaction forwarding block and the PCI bus. The master and target

portions of this block operate independently.

The PCI Bus Interface Block impl ement s the logic to generate PCI

configuration cycles. The standard mechanism for generating PCI

Configuration cycles (as described in the PCI 2.2 Specification) is used.

PCI Bus Arbiter

The PCI Arbiter implements a fair arbitration scheme with special support

for the CD5536 companion device. By default it operates as a simple round

robin arbiter that rotates three request/grant prioritie s in a circular fas hion.

GeodeLink Interface General Description

The GeodeLink Interface is a non-traditional high bandwidth packetized

uni-directional bus for internal peripherals. The GeodeLink architecture

connects the internal modules of the LX800 and companion device using

the data ports defined by GeodeLink Interface Units. Transactions between

GeodeLink Devices and the GLIU are conducted with packets.

The GLIU accepts request packets from masters and routes them to slaves.

Similarly, slave response packets are routed back to the master. The bus is

non-blocking. Several requests can be pending, but order is not guaranteed.

All packets have one source and one destination, broadcasts are not

allowed.

The existence of the GeodeLink architecture is generally invisible to the

user or even a system programmer. All GeodeLink initialization and

support is handled at the BIOS level, and additionally provides a Virtual

PCI Configuration Space to abstract the GeodeLink architectur e to

industry standard interfaces. Through the V irtual PCI Configuration Space,

all GeodeLink devices appear in one PCI multi-function configuration

space header on the external PCI bus.

Page 36

2-8 Workstat io n 5 Fie ld S ervice Guide

Workstation 5 System Board Technical De scriptions

CS5536 Co m p anion Device

CS5536 Companion Device

REF: ABRD88 - Sheets 8, 9 and 10

The CS5536 Companion Device is designed to work with the LX800, a

processor with an integrated memory controller. Together, the LX800

processor and CS5536 Companion Device provide a low power, high

performance embedded solution for both the Workstation 4 LX and the

Workstation 5.

The internal architecture is based on the high-performance GeodeLink

architecture that yields high internal speed (over 4 GB/s) data movement and

versatile power management.

Communications with the AMD LX800 processor is over the 66Mhz PC I Bus.

The Geode Companion device includes many IO functions on-chip. These

include:

System Management Bus (SMB) Controller

The SMB is a two-wire synchronous serial interface compatible with the

System Management Bus physical layer. On the WS5 system board, the

SMB controller in the Companion Device is connected to Ethernet

Controller U22, as well as each DDR DIMM socket.

Serial Interface

The CS5536 includes two high-speed industry standard serial ports,

configured to support the Customer Display and IDN Interfaces. The

UAR Ts are 16550 and 16450 software compliant and support baud rates up

to 115.2 kbps.

Real Time Clock (RTC) and CMOS RAM

The companion device contains the equivalent of Motorola MC146818A

compatible real time clock. The clock performs two functions. It keeps

track of the time and date when the system is not connected to AC power,

and provides 242 bytes of non-volatile memory for storing BIOS and

system data.

The clock contains separate registers for seconds, minutes, hours, days

(both day of week and day of month), months, and years. The RTC

operates from a 32.768 Khz crystal and is powered from a 3V lithium

battery that can maintain operation for several years.

ATA Interface

The IDE Interface is an ATA-5 specification compatible IDE controller

(ATAC). Two devices are supported, using PIO Modes 0 through 4,

MDMA modes 0 to 2, and UDMA/66 mode 0 through 4.

Page 37

Workstation 5 Field Ser vic e Guide 2-9

Workstation 5 System Board Technical Descriptions

CS5536 Com p an io n D evic e

The interface provides a variety of features to optimize system

performance, including 32-bit disk access, post write buffers, bus master,

look-ahead read buffer, and pre-fetch mechanism.

On the WS5 System Board, the CF Card resides on the ATA Interface in

socket IDE1.

USB Interface

The CS5536 Companion Device includes four Universal Serial Bus (USB)

2.0 compliant ports, supporting low speed, full speed, and high-speed

connections.

Each port supports wake-up events and feature over-current and power

control support. The ports can be enabled individually to react to

over-current events.

Port 4 supports the USB 2.0 On-The-Go supplement version 1.0

specification, but this feature is not supported on the WS5 system board.

One USB output from the Companion Device is fed to an on-board USB

hub controller. See the System Board USB Interface Section for more

information.

LPC Interface

The LPC is based on Intel’s Low Pin Count (LPC) specification version

1.0. The controller can convert an internal local bus memory or IO cycle to

an external LPC cycle. It receives serial IRQs from the LPC bus and

converts them to parallel form so they can be routed to the IRQ mapper and

interacts with the Legacy DMA logic to perform DMA between on-chip

and off-chip devices.

The LPC interface supports memory, I/O, DMA, and firmware hub based

devices.

Audio Codec Interface

The codec interface is AC97 V2.3 compliant and contains support for any

AC97 audio codec with Sample Rate Conversion (SRC). The WS5 S ystem

board uses a Realtek ALC203 Audio Codec and audio amplifier to drive a

pair of internal speakers. See the AC 97 Audio Interface section for more

information.

Diverse Device

The Diverse Device is comprised of the legacy PC functionality required

for most designs.

Page 38

2-10 Workstat io n 5 Fie ld S ervice Guide

Workstation 5 System Board Technical De scriptions

CS5536 Co m p anion Device

Power Management Controller (PMC)

This module is a GeodeLink Device whose functio n is to control all aspects

of power management. Power Management is event driven - any action the

PMC carries out is predicated on some event. Those events can originate

from other GeodeLink Devices, such as the LX800 processor, or from

other external sources such as the power button.

The PMC consists of three internal sections: Working, Standby, and Real

Time Clock.

o The Working block includes all circuits and functions associated with

the W orking power domain. The primary function of the Wor king block

is to transition the system to the sleep mode.

o Standby block contains all circuits and functions associated with the

Standby power domain. The primary function f the Standby block is to

control power to the Working domain.

o The RTC block contains the timing circuits required to maintain a real

time clock and calender functions. The R T C block is powered by

VBAT, from a board mounted CR2032 battery.

Page 39

Workstation 5 Field Ser vic e Guide 2-11

Workstation 5 System Board Technical Descriptions

CS5536 Com p an io n D evic e

IDE Interface (REF: ABRD88 - Sheet 18)

Figure 2-4 displays a block diagram of the WS5 System Board IDE Interface

coupled to the CF Daughter Card.

Figur e 2-4: Workstation 5 IDE Interface Block Diagram

Like the Workstation 4, the CF Daughter card is positioned to make the CF

card available at the IO panel where it can serve as a ‘personality’ module in

Windows Embedded CE 6.0 configurations.

LED1 is the hard disk activity indicator and is located just to the left of the

mini-DIN pole customer display connector.

The CF card is an intelligent solid state storage device containing a micro

controller and firmware positioned in front of a block of flash memory. The

firmware responds to file IO requests from the operating system file driver and

maps file data to/from the flash memory array.

Page 40

2-12 Workstat io n 5 Fie ld S ervice Guide

Workstation 5 System Board Technical De scriptions

TFT LCD a n d B acklig ht In terface

TFT LCD and Backlight Interface

REF: ABRD88 - Sheets 27

Figure 2-5 displays a block diagram of the LX800 Processor with the TFT

controller sections highlighted. The LX800 graphics interface consists of the

Graphics Processor (GP), the Display Controller (DC) and the V ideo P rocessor

(VP).

Figur e 2-5: LX800 Graphics Processor Block Diagram

The Graphics Processor (GP)

The Graphics Processor is based on the Graphics processor used in the Geode

Processor, but adds the GeodeLink memory interface and other features to

support improved performance and functionality.

The GP is a BitBL T/vector graphics engine, that supports pattern generation,

source expansion, pattern/source transparency, 256 ternary raster operations,

alpha blenders to support alpha-BLTs, incorporated BLT FIFOs, and

GeodeLink interface.

Page 41

Workstation 5 Field Ser vic e Guide 2-13

Workstation 5 System Board Technical Descriptions

TFT LCD and Back light Interface

The Display Controller (DC)

The DC module is similar to that found in the Geode GX processor line with

additional hardware for graphics filter functions. It consists of a memory

retrieval system (GLIU0), Graphical User Interface (GUI) block, a VGA

interface block, and back-end filter/scaling. The GUI and VGA blocks share a

single display FIFO and display refresh memory interface to the GeodeLink

Memory Controller (GLMC).

The DC module retrieves graphics, video, and overlay streams from the frame

buffer, serializes the streams, performs any necessary color look-ups and

output formatting, and interfaces to the Video Processor for driving the display

device.

Video Processor (VP)

The VP interfaces with the processor core via a GLIU master/slave interface to

provide three main functions, the V ideo Processor, the TFT controller, and the

V ideo Output Port (VOP). The VP mixes the graphics and video streams, and

outputs digital RGB data to the TFT Controller.

The TFT Controller converts the digital RGB output of the V ideo Mixer block

to the digital output suitable for driving a TFT flat panel LCD. The panel

interface supports most SVGA TFT panels and meets the VESA FPDI (Flat

Panel Display Interface) Revision 1 Specification including the correct power

sequencing.

Page 42

2-14 Workstat io n 5 Fie ld S ervice Guide

Workstation 5 System Board Technical De scriptions

TFT LCD a n d B acklig ht In terface

LCD Interface (REF: ABRD88 - Sheets 5, 16 and 27)

Figure 2-6 displays a block diagram of the Workstation 5 LCD and Backlight

Interfaces.

LX800 Pixel Data outputs DRGB[23:2] are fed to U29, a THC63LVDM83R

LVDS Trans mitter. This device contains four seven-bit parallel-load serial-out

shift registers coupled to low voltage differential signalling (LVDS) line

drivers. Its primary function is to convert the 28-bits of Low Voltage TTL level

pixel, control and clock data from the LX800 TFT Controller into four data

streams and a single clock stream. The output of U29 drives LCD connector

J8.

The primary reasons for converting the TTL/CMOS level video signals to the

LVDS format are reduced noise and cable pin count. The LVDS compatible

signals are converted back into Low V olt age TTL/CMOS voltage levels within

the LCD Panel.

LCD Panel power sequencing is provided by the VDDEN_VIPSYNC output of

the LX800 TFT controller. This signal drives a switch consisting of Q9 and

Q10. VDDEN_VIPSYNC does not go active until all system voltages and

busses have become stable and the processor is executing instructions.

Figure 2-6: WS5 Syst em Board TFT LCD and Backlight Interface

Page 43

Workstation 5 Field Ser vic e Guide 2-15

Workstation 5 System Board Technical Descriptions

TFT LCD and Back light Interface

Backlight Interface

The backlight enable signal, DISPEN originates in the LX800 TFT controller.

This enable signal is ANDed with

SIO_PWM at U6 to produce PWMBL which

drives the backlight inverter board mounted to the LCD plate. SIO_PWM

originates from an unused fan controller (FANPWM2) in Super I/O #1, U8.

Inverter Board power, VCC_BL is supplied by VCC12 through F1 and FB8. A

pre-regulator circuit is not implemented on the WS5 System Board.

Configuration Jumpers

A total of three jumpers, one on the system board and two on the inverter

board are required to configure the LCD panel type.

System Board jumper J17 is used for LCD Panel configuration. At this

time, one of two possible LCD panels may be used. Production started with

the Sharp LQ150X1LG45 15” LCD Panel and J17 includes a jumper

placed between Pins 1 and 2. Note that Pin-1 faces the rear of the unit. On

later units with an AUO LCD Panel is installed, no jumper will be installed

on J17.

The Backlight Inverter Board contains a pair of jumpers J4 and J5, factory

configured to match the LCD panel installed. The jumper setting is routed

through the interface cable to the system board as BL_MOD0 and

BL_MOD1 and fed to a pair of general purpose (GPIO28 and GPIO29)

inputs on Super IO #1, U8.

At power-up, the WS5 API reads this pair of bits to determine the LCD

panel type. When it determines the LCD panel type, for example the Sharp,

it references the \DOC\HWInf folder and loads the file

‘lxvideo_Sharp.inf.’ This file contains backlight brightness and brightness

range values optimized for the Sharp LCD. If the AUO panel is used, the

jumpers are set accordingly and the API would load the ‘lxvideo_auo.inf

file from the \DOC\HWInf folder.

Page 44

2-16 Workstat io n 5 Fie ld S ervice Guide

Workstation 5 System Board Technical De scriptions

USB Interface

USB Interface

REF: ABRD88 - Sheets 9, 16, 21, and 29

The Workstation 5 System Board includes a total of seven USB ports, four of

which are available at the IO Panel. A fifth USB port is accessible at the front

of the chassis for the integrated finger print reader or other optional device.

Figure 2-7 displays a block diagram of the system board USB interface

including the USB port assignments and the power management scheme.

Figure 2-7: Workstation 5 System Board USB Configu ration

Page 45

Workstation 5 Field Ser vic e Guide 2-17

Workstation 5 System Board Technical Descriptions

USB Interf ace

Companion Device

U41, the CS5536 companion device supplies four USB ports. One port, USB0

is fed to IO panel connector CN6A.

The USB1 output drives J9, the USB Flas h Drive Connector.

USB Flash Drive Power Control

In the Windows Embedded CE 6.0 and current WEPOS configuration, the

USB Flash Drive is the primary boot device. A pre-boot POST test ensures

the device is installed.

However, to provide the flexibility of booting from the CF Card, a BIOS

field is available that removes power from J9, the USB Flash Drive

connector.

A GPIO signal from U8, Super IO #1 called UDOC_ON is controlled by

the ‘Boot Test Image’ field of the Special Configuration screen of BIOS

Setup. UDOC_ON drives a switch consisting of Q6 and Q8. The default

setting of ‘Normal’ sets UDOC_ON high, enabling the switch and

providing VCC5_UDOC to power the USB Flash Drive.

When the Boot Test image field is set to ‘Alternate,’ UDOC_ON goes low,

and turns off switch, cutting power to the USB Flash Drive socket.

Using the ‘Reset BIOS to WI NCE or WINXPE defaults’ automatically s ets

the Boot Test Image field to ‘Normal,’ to allow booting from the USB

Flash Drive.

The USB2 port drives the input of USB Hub U21, a device that adds three US B

ports to the System Board. See below.

The USB3 port drives J10. This is a right angle 2x5 connector positioned at the

front edge of the system board and accessed through a cut-out in the cage.

Currently the optional Integrated Finger Pr int Reade r is connecte d to this port.

Future options could also use this USB Port.

CN6 Port Power

U30, an LM3526 Dual Port USB Power Switch handles the power and

current-limiting requirements of dual USB connector CN6. The device

contains a pair of P-channel MOSFETS (one for each port) with separate

enables and fault outputs. In a typical application, current flows from the

IN(put) pins through the MOSFET and OUT towards the load.

The device employes a two-stage thermal protection circuit. If the internal

temperature is greater than 150°C, both MOSFETs are turned off and the

fault outputs, FLAGA# and FLAGB# go active. These outputs have a 1 ms

delay to prevent false over-current reporting from the in-rush current

caused by hot plug events. Shorted switches will continue to cycle off and

on, due to the rising and falling die temper ature, until the s hort is removed.

Page 46

2-18 Workstat io n 5 Fie ld S ervice Guide

Workstation 5 System Board Technical De scriptions

USB Interface

USB Hub

The USB2 port from the Companion Device is fed to USBDP0, the upstream

port of U21, an SMSC 2503 3-port hub. The device is fully compatible with

the USB 2.0 specification. It adds three additional USB Ports, assigned to the

following connectors.

The USBDP1 port is fed to IO port connector CN6B.

The USBDP2 and USBDP3 ports are fed to IO Port Connector CN8.

CN8 Port Power

U16, an LM3526 Dual Port USB Power Switch handles the power and

current-limit requirements for dual USB connector CN8. The device

contains a pair of P-channel MOSFETS (one for each port) with separate

enables and fault outputs. In a typical application, current flows from the

IN(put) pins through the MOSFET and OUT towards the load.

The device employes a two-stage thermal protection circuit. If the internal

temperature is greater than 150°C, both MOSFETs are turned off and the

fault outputs, FLAGA# and FLAGB# go active. These outputs have a 1 ms

delay to prevent false over-current reporting from the in-rush current

caused by hot plug events. Shorted switches will continue to cycle off and

on, due to the rising a nd falling die temperature, until the short is removed.

Page 47

Workstation 5 Field Ser vic e Guide 2-19

Workstation 5 System Board Technical Descriptions

Touchscreen Int er face

Touchscreen Interface

Figure 2-8 shows a block diagram of the system board resistive touchscreen

interface.

Figur e 2-8: WS5 5-Wire Resistive Touchscreen Interface

U17, the Hampshire TSHARC-12S resistive touchscreen controller is a single

chip design, incorporating a microprocessor, A/D converter, UART, and

firmware. It supports only 5-wire resistive touchscreen and serial interface to

the host system.

The serial Receive/Transmit signals from U17 are routed to jumper block J4.

When a resistive touchscreen is inst all ed, J4 is configured to route RES_TXD

to F_TXD2 and RES_RXD to F_RXD2 which are fed to UART2 in U35 Super

IO #2.

When the optional Capacitive Touchscreen Interface Board is installed, the

jumpers are configured to route CAP_TXD and CAP_RXD to U35 instead of

the resistive touchscreen controller.

Page 48

2-20 Workstat io n 5 Fie ld S ervice Guide

Workstation 5 System Board Technical De scriptions

LPC Interface

LPC Interface

The Low Pin Count Interface is a PCI like-bus comprised of seven signals lines

and is used to replace the legacy ISA bus as the interface between the

Companion Device and Super IO and BIOS devices. Figure 2-9 below displays

a block diagram of the LPC Bus as implemented on the Workstation 5 System

Board.

Figure 2-9: LPC Bus Block Diagram

A total of three devices and the LPC Debug slot are attached to the LPC Bus.

Because the LPC Bus is a replacement for th e legacy for the ISA Bus, the

BIOS redirects Port 80H POST Codes to the LPC Bus.

Two lines from the Companion Device, BOS0 and BOS1 specify location of

the Boot Device after a hardware reset. These pins are configured to ‘Boot

from a Memory Device on the LPC Bus,’ in this case BIOS EEPROM U36.

Page 49

Workstation 5 Field Ser vic e Guide 2-21

Workstation 5 System Board Technical Descriptions

AC 97 Audio Interface

AC 97 Audio Interface

Figure 2-10 displays a block diagram of the WS5 System Board AC’97 Audio

Interface.

Figure 2-10: Workstation 5 Audio Circuit Block Diagram

Realtek ALC203E Features

• Compliant with AC97, 2.3 Specification

• Meets performance requirements for audio on PC99/2001 systems.

• Meets Microsoft WQHL/WLP 2.0 audio requirements.

• 20-bit DAC and 18-bit ADC resolution

AC’97 Audio is comprised of a two-chip solution with a digital component

(the Companion Chip) and an analog component (the AL203E). The AL203E

contains Digital to Analog Converters (ADC), mixers, jack detection and I/O.

The Companion Chip and the Codec communicate over the AC’97 link

interface, a serial bi-directional, pulse coded modulation digital stream.

Page 50

2-22 Workstat io n 5 Fie ld S ervice Guide

Workstation 5 System Board Technical De scriptions

AC 97 Audio Interface

The AC’97 architecture provides for data transfer through individual frames

transmitted in a serial data stream. A Time Division Multiplexed (TDM)

scheme is used to allow multiple input and output streams as well as access to

the internal control registers. Each frame is divided into 12 out going and 12

incoming data frames or slots.

The Table below describes the function of each audio link signal at U9, the

audio codec.

Speaker and Line Outputs (REF: ABRD88, Sheet 28)

The speaker outputs of the codec drive U26, a LM4940 ‘Boomer’ series audio

amplifier. The LM4940 outputs, SPK_R_OUT and SRK_L_OUT drive system

board connectors CN9 and CN10 respectively. The speakers are mounted

internally, at the left and right sides of the case.

AUD_PWRON, from a GPIO pin on Super IO #1, is pulled to ground by R405

and fed to the SHUTDOWN input of U9. The BIOS sets AUD_ PWR ON low

during a warm or cold boot to reduce speaker ‘pop.’

The LINE_OUT_R and LINE_OUT_L outputs are fed through a low-pass filter

to Line Out Jack CN3. The internal speakers remain active when the Line-Out

jack is used.

Signal Name I/O Description

AC97_SYNC Input/Output 48 Khz sync pulse that indicates the

beginning of a serial transfer on

AC97_DATA_OUT and

AC97_DATA_I N.

AC97_BITCLK Output 12.888 Mhz Serial Data Clock from

the codec. Derived from the

CLK_14_CODEC input at Pin-2.

AC97_DATA_O U T Output Audio Controller Serial Data Out.

Transmits audio data to the codec.

Data stream consists of both control

data and audio data. Data valid on

rising the rising edge of

AC97_BITCLK.

AC97_DATA_I N Input Audio Controller Serial Data In. Data

stream consists of both control data

and audio data. Data valid on rising

the rising edge of AC97_BITCLK.

PCI_RST# Input Working Domain Master Reset.

Page 51

Workstation 5 Field Ser vic e Guide 2-23

Workstation 5 System Board Technical Descriptions

Point Of Sale Inte r faces

Point Of Sale Interfaces

Customer Display Interface (REF: ABRD88 - Sheets 8, 16, and 31)

Figure 2-11 displays a block diagram of the WS5 System Board Customer

Display Interface. The Customer Display Interface is not shared with the MSR

Interface.

Figure 2-11: Workstation 5 System Board Customer Display Interface

The Interface Supports the MICROS LCD Customer Display which is capable

of returning information to the host workstation.

Sending Data to the Customer Display(s)

TXD4 from UART 2 in the Companion Device U41 is fed to U3, a

PI74STX2G4245 2-Bit Level Shifting/Buffer Transceiver /w Dual Voltage

Supply. This device is required because the Customer Display Interface

operates at VCC5, while the Companion Device operates at VCC3. Note

that the device has both VCC5 and VCC3 power supply inputs.

The output of U3, F_TXD4 drives both the Pole (CN4) and Rear (J2)

customer display connectors simultaneously through NOR gates U4A and

U4C.

Page 52

2-24 Workstat io n 5 Fie ld S ervice Guide

Workstation 5 System Board Technical De scriptions

Point Of Sale Interfaces

Receiving Data from the Rear Display

T o selectively receive data from a Rear Display attached to J2, the API sets

GPIO output REAR_OE# low at U10-3 to gate REAR_RX from J2-2 onto

U10-2, F_RXD4.

Receiving Data from the Pole Display

To selectively receive data from a Pole Display attached to CN4, the API

sets GPIO output POLE_OE# low at U10-4 to gate POLE_RX from CN4-3

onto U10-6, F_RXD4.

Customer Display VCC Switch

The VCC supply to customer display connectors J2 and CN4 is controlled

by a switch consisting of Q15 and Q27. VCC5 is fed through F2 to the

switch, controlled by the GPIO signal VCC5_DISP.

Normally, VCC5_DISP is high enabling the switch and s upplying VCC5 to

the customer display connectors. In the WS5 Diagnostics Utility LCD tab,

the [Reset] button toggles VCC5_DISP low, then high to provide a true

hardware reset for the LCD Display. The [Reset] button is intended to reset

the LCD customer display after it receives a firmware update.

The LCD Customer Display

The MICROS LCD Customer Display is a graphics capable display t hat

interfaces to the host workstation through a 115Kbaud serial interface. The

display is an intelligent device, using an 8-bit controller with

programmable firmware.

Two versions of the LCD Customer Display are available for the

workstation 5.

o A Rear or Integrated version that physically attaches to the workstation

through a cut-out in the IO door . Power and data are supplied through a

IO panel connector, attached to system board connector J2. The Rear

and Pole version share a common housing. The Workstation 5 version

uses a bracket that is not physically compatible with the Workstation 4

and W orkstation 4 LX.

o A Pole Mount version that receives power and data from IO Panel

connector CN4. When used with the Workstation 5 Stand, the pole is 6”

and can be mounted to the left, right or rear of the stand. An 18” pole

mounted to a counter surface is also available.

Page 53

Workstation 5 Field Ser vic e Guide 2-25

Workstation 5 System Board Technical Descriptions

Point Of Sale Inte r faces

Mag Stripe Reader Interface (REF: ABRD88 - Sheets 17, 19, 33)

Figure 2-12, displays a simplified block diagram of the WS5 Mag Stripe

Interface.

The MSR is assigned to UART A in U35, Super IO #2 and occupies COM2.

The reader connects to CN14, an 8-pin modular connector mounted along the

right side of the system board.

The serial reader operates at VCC3 (3.3V) voltage levels. However, UART A

in Super IO #2 operates at

VCC5. This requires level shifters U13 and U14 to

interface the reader to the UART.

MSR_DTR supplies operating power to the Mag Stripe Reader. It also can be

used to reset the reader. In the Mag Stripe Reader Test of the DiagUtility,

pressing the [Reset Mag Reader] causes the API to bring MSR_DTR low, then

high, effectively resetting the controller in the MSR.

Figure 2-12: Workstation 5 System Board Magne tic Stripe Interface

Page 54

2-26 Workstat io n 5 Fie ld S ervice Guide

Workstation 5 System Board Technical De scriptions

Point Of Sale Interfaces

IDN Port (REF: ABRD88 - Sheets 16, 32, and 33)

The IDN Port is a multi-purpose RS422/232 port based on an 8-Pin RJ-45

modular connector. This port is functionally identical to the RS422-A and

RS422-B ports on the Workstation 4 and 4 LX, the PCWS 2010 ‘COM4 IDN’