Page 1

micros

®

Systems, Inc.

Workstation 4 LX

Field Service Guide

Workstation 4

and

Copyright 2004 - 2008

By MICROS Systems, Inc.

Columbia, Mary land USA

All Rights Reserved

Part Number 100016-118 (4th Edition)

Page 2

Declarations

Warranties

Trademarks

Although the best efforts are made to ensure that the information

contained in this manual is comple te and cor re ct, MICROS Systems, Inc.

makes no warranty of any kind with regard to this material, including but

not limited to the implied warranties of marketability and fitness for a

particular purpose. Information in this manual is subject to change

without notice. MICROS Systems, Inc. shall not be liable for errors

contained herein or for i ncidental or conse quential dama ges in connectio n

with the furnishing, performance, or use of this material.

MICROS is a registered trademark of MICROS Systems, Inc.

Microsoft, MS-DOS, Windows, Windows 95, and Windows CE are registered

trademarks of Microsoft Corporation in the U.S. and other countries.

AMD, the AMD logo, and combinations there of are trademarks of Advanced

Micro Devices, Inc.

General Software, the GS Logo, Embedded BIOS, CE Ready, the CE Ready

logo, and Firmbase are trademarks or registered trademarks of General

Software, Inc.

Printing History

New editions of this manual incorporate new and changed material since

the previous edition. Minor corrections and updates may be incorporated

into reprints of the current edition without changing the date or edition

number.

1st Edition: March 2004

2nd Edition: March 2005

3rd Edition: January 2007

4th Edition: January 2008

ii

Page 3

Table Of Contents

Table Of Contents

Preface

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Who Should Use This Manual?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Document Design and Production. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Daughter

Introduction to the WS4/WS4 LX FRUs

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Base Casework - WS4 and WS4 LX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

System Boards and Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

WS4 System Boards - A Short History. . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

The Workstation 4 LX System Board . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Workstation 4 System Board and Components. . . . . . . . . . . . . . . . . . . . . . . 1-8

Workstation 4 LX System Board and Components . . . . . . . . . . . . . . . . . . 1-10

Cables and Toroids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Cable, Samsung LCD Display, REV F/G . . . . . . . . . . . . . . . . . . . . . . . 1-12

Cable, Samsung LCD Display, REV I . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Cable, Sharp LCD Display, REV F/G. . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Cable, Sharp LCD Display, REV I . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Cable Inverter, F/G BD, WS4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Cable, Inverter to REV I BD, WS4 or WS4 LX . . . . . . . . . . . . . . . . . . 1-15

Touchscreen Extension Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Cable Kit, Power In - Power Out, AC Conn . . . . . . . . . . . . . . . . . . . . 1-16

Toroid Kit, Display, MSR and AC Power . . . . . . . . . . . . . . . . . . . . . . 1-16

AC Power Input Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Workstation 4 and 4 LX - LCD/Touchscreen/Mag Stripe Reader . . . . . . . 1-18

Samsung LCD Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Sharp LCD Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Touchscreen and Front Cover Plastic . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Top Cover - Mag Stripe Reader Assembly and Cover . . . . . . . . . . . . . 1-22

LCD Customer Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

LCD Interface Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

LCD Module, Optrex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Cable, LCD Pole and Rear Display Head . . . . . . . . . . . . . . . . . . . . . . 1-24

Cable Extension, LCD Pole Display . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Kit, Front/Rear Cover, /w Lens, Screws, Pole Mount Hinge . . . . . . . . 1-25

Kit, Front/Rear Cover, /w Lens, Screws, Rear Mount Hinge . . . . . . . . 1-25

iii

Page 4

Table of Contents

Workstation 4 Technical Overview

Workstation 4 System Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

SC3200 GX1 Processor, Video Processor, Core Logic and Super IO . . . . 2-5

GX1 Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Video Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Core Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

PCI and Sub-ISA Bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Sub-ISA Bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Boot Loader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Disk On Chip (DOC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

SC3200 Super I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

PC87360 Super IO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

General Purpose IO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Parallel Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Operator LED Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Keyboard and Mouse Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

ACCESS.bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Low Pin Count (LPC) Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

TFT LCD Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Touchscreen Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Optional PCMCIA Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Optional Mini-PCI Daughter Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Complex Programmable Logic Device (CPLD). . . . . . . . . . . . . . . . . . . . . 2-23

CPU Interface and Register Control . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Power Button (AB28 System Boards . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Power Button (ABRD36 System Board) . . . . . . . . . . . . . . . . . . . . . . . 2-26

Reset Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Wake On LAN Power Management Event . . . . . . . . . . . . . . . . . . . . . 2-29

LCD Backlight Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Cash Drawer Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

System Board Hardware Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

DP83815 10/100 Mbps PCI Ethernet Controller . . . . . . . . . . . . . . . . . . . . 2-33

EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

RS422 Port A and RS422 B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

RS422 Port A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

RS422 Port B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

Customer Display/Mag Card Reader Port (COM3) . . . . . . . . . . . . . . . . . . 2-38

COM3 Configuration - AB28-F and AB28-G . . . . . . . . . . . . . . . . . . . 2-38

COM3 Configuration - AB28-I or ABRD36-B . . . . . . . . . . . . . . . . . . 2-40

Multiplexer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

Optional LCD Customer Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

Casework . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

Interface Board and LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

iv

Page 5

Table Of Contents

Interface Board Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

Hardware Compatibility - System Board Hardware Revision . . . . . . . 2-47

Enabling the LCD Customer Display - WS4 . . . . . . . . . . . . . . . . . . . . 2-47

Enabling the LCD Customer Display - WS4 LX . . . . . . . . . . . . . . . . . 2-47

Workstation 4 Troubleshooting

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Software Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Operational Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Original Workstation 4 Boot Sequence . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Testing the Power Supply and System Board Voltage Regulators . . . . . . . 3-8

POST Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

LCD Display Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Touchscreen Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Local Area Network (LAN) Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Mechanical Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Peripheral Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

IDN Port Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

RS232 Peripheral Device Does Not Function. . . . . . . . . . . . . . . . . . . . 3-22

USB Peripherals Do Not Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

VFD Pole Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

LCD Customer Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Workstation Recovery Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Formatting the CF Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Using the CAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Workstation 4 Diagnostics Utility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

System Information Screen - Hardware Components. . . . . . . . . . . . . . 3-29

System Information Screen - Platform Software Components . . . . . . . 3-31

Other Platform Files and Folders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

v

Page 6

Table of Contents

Workstation 4 LX Technical Overview

Workstation 4 LX System Board Block Diagram . . . . . . . . . . . . . . . . . . . . 4-2

LX800 Processor and TFT Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Processor Core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

GeodeLink Interface Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

GeodeLink Memory Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

GeodeLink Control Processor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

GeodeLink PCI Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

GeodeLink General Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

CS5536 Companion Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

System Management Bus (SMB) Controller . . . . . . . . . . . . . . . . . . . . . 4-7

Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Real Time Clock (RTC) and CMOS RAM . . . . . . . . . . . . . . . . . . . . . . 4-7

ATA Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

LPC Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Audio Codec 97 Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

IDE Interface (ABRD86 - Sheet 18). . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

W83627HF Super IO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Low Pin Count Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

RS422 Port A and B Control Signals . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

COM3 Mux Control Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Hardware Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Cash Drawer Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

System Board Hardware Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

TFT LCD and Backlight Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

The Graphics Processor (GP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

The Display Controller (DC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Video Processor (VP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

LCD Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Backlight Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Companion Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

USB Flash Drive Power Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

USB Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Touchscreen Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Point Of Sale Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Customer Display/Mag Card Reader Port . . . . . . . . . . . . . . . . . . . . . . 4-18

Pole/Rear Customer Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Rear LCD Customer Display Firmware Programming . . . . . . . . . . . . 4-20

RS422-A and RS422-B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Cash Drawer Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

vi

Page 7

Table Of Contents

Cash Drawer Closed Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

System Board Hardware Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

RTL8110SC 10/100/1000Mbps PCI Ethernet Controller . . . . . . . . . . . . . 4-25

PCI Bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Link, Speed and Activity LED Control. . . . . . . . . . . . . . . . . . . . . . . . . 4-25

EEPROM Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

System Board Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Standby Power Domain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Working Power Domain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Workstation 4 LX Troubleshooting

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Operational Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Workstation 4 LX Boot Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Pre-boot Firmware Applications - Background . . . . . . . . . . . . . . . . . . . 5-7

Platform Updates - Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Testing the WS4 LX Power Supply and System Board Voltages . . . . . . . . 5-9

Standby Voltage Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Working Voltage Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Power On Self Test (POST) Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

LCD Display Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Touchscreen Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Local Area Network Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Mechanical Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Peripheral Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Workstation 4 LX Diagnostics Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

System Information Screen - Hardware Components . . . . . . . . . . . . . . . . 5-23

System Information Screen - Platform Files . . . . . . . . . . . . . . . . . . . . . . . 5-25

Workstation Recovery and Platform Update Procedures . . . . . . . . . . . . . . 5-29

Wiping the Compact Flash Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

Platform Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

Using Windows CE Factory Restore . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

Factory Restore Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

vii

Page 8

Table of Contents

Remove and Replace the WS4 and WS4 LX FRUs

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

General Precautions for Working Inside the Workstation . . . . . . . . . . . 6-2

ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Environmental Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Removing the Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Removing the RF Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Remove and Replace the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Remove and Replace the Workstation 4 System Board . . . . . . . . . . . . . . 6-11

Remove and Replace the Workstation 4 LX System Board. . . . . . . . . . . . 6-15

Remove and Replace the LCD panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Remove and Replace the Touchscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Remove and Replace the Magnetic Stripe Reader . . . . . . . . . . . . . . . . . . . 6-25

Reassembling the RF Shield. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

LCD Customer Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

Connector and Cable Diagrams

IO Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

RS422-A (COM4) and RS422-B (COM5). . . . . . . . . . . . . . . . . . . . . . . A-2

10/100 Ethernet Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

RS232 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Cash Drawer 1 and 2 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

PS2 Mouse/Keyboard Connectors (WS4 Only) . . . . . . . . . . . . . . . . . . . A-5

Pole Customer Display Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

System Board Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Magnetic Stripe Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

USB Flash Drive Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

LCD Customer Display Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

System Board Integrated Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

LCD Customer Display Assembly Interface Cable . . . . . . . . . . . . . . . . A-8

Pole LCD Customer Display Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Hook-up Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

RS232 from the RS422-A and RS422-B Ports . . . . . . . . . . . . . . . . . . . A-8

Ethernet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

8-Pin to 6-Pin Hook-up RS422 Cable (300319-001) . . . . . . . . . . . . . . A-11

Cash Drawer Extension Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

IDN(+) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

LCC(-). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

RS232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

viii

Page 9

Preface

In this preface, you’ll find information about this manual. Refer to the preface if

you have questions about the organization, conventions, or contents of this

manual.

In this section

Why Read This Manual?..........................................................................ix

How This Manual Is Organized...............................................................xi

Notation Conventions..............................................................................xii

Workstation 4 and 4 LX Field Service Guide ix

Page 10

Preface

Why Read This Manual?

Why Read This Manual?

Purpose

This hardware-only guide is intended for those who will be troubleshooting and

repairing the MICROS Workstation 4 and 4 LX.

Who Should Use This Manual?

This manual is intende d for qua lifi ed serv ice per son nel who hav e experi ence wit h

the configuration and troubleshooting of MICROS point of sale terminals. The

ability to read schematics and a working knowledge of microprocessor based

systems and related test equipment is required.

The circuit and detailed start-up descriptions contained in this manual are

intended to give the techn ician a working knowl edge of the hardwa re to be used as

an aid in the troubleshooting and repair of the equipment.

Bibliography

Workstation 4:

AMD Geode

AMD Geode

DiskOnChip Millennium Plus Data Sheet Rev. 1.7

National Semiconductor Corporation PC87360 Super IO Datasheet

National Semiconductor Corporation DP83815 Ethernet Controller Datasheet

Workstation 4 LX:

AMD Geode

AMD Geode

Realtec RTL8110SC Integrated Gigabit Ethernet Controller Data Sheet

SMSC Integrated USB 2.0 Compatible Hub Datasheet Revision 1.8

Winbond W83627HF/F Super IO Datasheet Version 2.0

™

SC3200 Processor Data Book - November 2004

™

SC3200 Processor Specification Update

™

LX Processor Databook - October 2005

™

CS5536 Companion Device Databook

x Workstation 4 and 4 LX Field Service Guide

Page 11

How This Manual is Organized

The fourth edition of this field service guide incorporates the Workstation 4 LX

System Board Field Replacement Units (FRUs), technical descriptions, and test

procedures.

Chapter 1 combines the Workstation 4 and Workstation 4 LX spare Field

Replacement Units (FRUs). The FRUs are grouped into individual listings for

each system board. FRUs available for the optional LCD Customer Display are

included as well.

Chapter 2 provides technical descriptions of the original Workstation 4 System

Boards AB28 and ABRD36 with emphasis on the IDN and Customer Display/

Mag Stripe Reader interfaces, along with info on the TFT LCD interface, Super

IO, and voltage control.

Chapter 3 covers WS4 troubles hooting. The Cha pter star ts of f with a deta iled star t

up description, provides voltage test points for the internal power supply and

system board voltage regulators. Much of the troubleshooting information

contained in thi s chap ter is compiled from the experi enc e of the technicians at the

MICROS Board Repair Center.

Preface

How This Manual is Organized

Chapter 4 provides technical descriptions of the Workstation 4 LX System Board

ABRD86, with emphasis on the IDN and Customer Display/Mag Stripe Reader

interfaces, along with info on the TFT LCD interface, Super IO, and on-board

voltage regulators.

Chapter 5 covers WS4 LX Troubleshooting. The Workstation 4 LX is a new

system board that requires a new start up description and test procedure. Voltage

test points for the i ntern al power supp ly and sy stem boar d volt age regu lator s have

been updated to accommodate this update system board.

Chapter 6 includes the FRU remove/replace procedures with separate sections for

for each System Board.

Appendix A includes pin-out diagrams for all WS4 and WS5 LX connectors and

related hook-up cables.

Workstation 4 and 4 LX Field Service Guide xi

Page 12

Preface

Notation Conventions

Notation Conventions

Symbols

NOTE

This symbol brings special attention to a related item.

WARNING

This symbol indicates that specific handling instructions or

procedures are required to prevent damage to the hardware or

loss of data.

SHOCK HAZARD

This symbol calls attention to a potential hazard that requires

correct procedures in order to avoid personal injury.

STATIC SENSITIVE DEVICES

This symbol indicates that specific ESD handling procedures

are required.

Document Design and Production

Desktop Publishing: Adobe FrameMaker 6.0.

Images: Nikon CoolPix 990 or Canon PowerShot A80

Line Drawings: Corel Draw! 7.0.

Image Processing: Paint Shop Pro 8.0 - Corel Draw! 7.0.

xii Workstation 4 and 4 LX Field Service Guide

Page 13

Chapter 1

Introduction to the WS4/WS4 LX

FRUs

This section introduces the Workstation 4, Workstation 4 LX, and LCD

Customer Display FRUs. With the addition of the Workstation 4 LX, a new

section on how to distinguish each system board has been added.

In this chapter

Introduction...................................................................................................1-2

Base Casework - WS4 and WS4LX............................................................ 1-3

System Boards and Components................................................................. 1-5

Workstation 4 System Board and Components ........................................... 1-8

Workstation 4 LX System Board and Components................................... 1-10

Cables and Toroids..................................................................................... 1-12

Workstation 4 and 4 LX - LCD/Touchscreen/Mag Stripe Reader............. 1-18

LCD Customer Display ............................................................................. 1-23

Workstation 4 and 4 LX Field Service Guide 1-1

Page 14

Introduction to the WS4/WS4 LX FRUs

Introduction

Introduction

The Workstation 4 has been a very successful MICROS POS terminal - in fact, the

greatest selling unit in company history. It is now over four years old with over

172,000 units in the field. PMA 07-892 announces the WS4 end-of-life in July 2007,

with hardware support available through 2012.

This edition of th e Fiel d S ervic e Guide intr oduc es th e Workstation 4 LX system board

and related FRUs. All other components including casework, LCD, power supply,

touchscreen, and mag stripe reader are common to both workstations.

• Base Casework and Sheet Metal Components - WS4 and WS4 LX

This section contains base plastics, rear door and hinge, sheet metal components,

rubber feet, hardware and miscellaneous plastic. There are two bases available,

with usage is determined by the System Board Revision.

• System Boards, Components and Power Supply

This section begins wit h a brief hi story of t he Workstati on 4 system boar d through

the WS4 LX. To keep confusion to a minimum, each system board is referred to

by a model number designation.

• Workstation 4 System Board and Components

This section includes the original Workstation 4 System Board and major

components including a bare sys tem board, Power Supply, CF Daughter Card,

Boot Loader, Disk On Chip, DIMM, and CF card.

• WS4 LX System Board and Components

This section includes the WS4 LX System Board System Board, Power

Supply and major components including the bare system board, CF Daughter

Card, BIOS Chip, USB Flash Drive, and CF card.

• Cables and Toroids

This section include s all WS4 and WS4 LX repla cement cables and t oroid kit. The

WS4 LX system board retains compatibility with all cables used on the most

recent WS4 units.

• Top Cover - LCD, Touchscreen, and Mag Stripe Reader

This section includes top cover components such as the LCD panel, touchscreen,

and mag stripe reader. The Sharp LCD Panel recently changed from the

LQ121S1LG41 to the LQ121S1LG61, requiring an update to the INF file that

controls backlight bri ght ne ss levels. Units with the LG61 LCD ship wit h GR 2.3a

platform software.

• LCD Customer Display - WS4, WS4 LX, and WS5

Includes all replacement components for the Rear or Pole LCD based customer

display. This display may be found on the WS4, WS4 LX and the WS5.

1-2 Workstation 4 and 4 LX Field Service Guide

Page 15

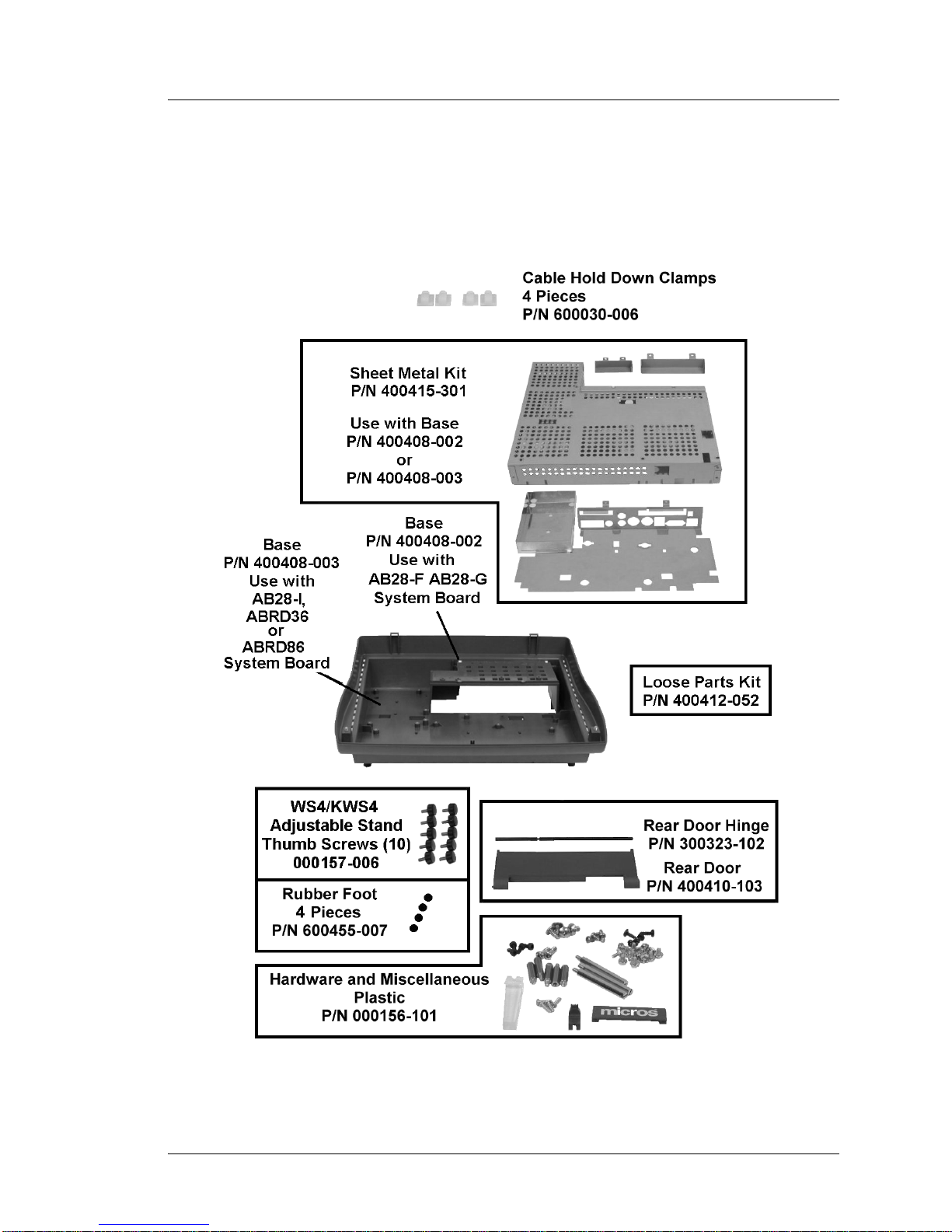

Base Casework - WS4 and WS4LX

Figure 1-1 shows the spare parts related to the WS4 or WS4 LX workstation base.

Includes plastic, sheet metal, hardware and miscellaneous components.

Introduction to the WS4/WS4 LX FRUs

Base Casework - WS4 and WS4LX

Figure 1-1: WS4/WS4LX Base Casework Related Spare Parts

Workstation 4 and 4 LX Field Service Guide 1-3

Page 16

Introduction to the WS4/WS4 LX FRUs

Base Casework - WS4 and WS4LX

• Clamp, Cable Hold Down - P/N 600030-006.

Kit of four pieces. Mounted on the RF Shield Cover, one pair is used for the

display cable and toro id an d the second pair is used for the magnetic stri pe reader

interface cable and toroid. Base P/N 400408-003 does not require a toroid on the

mag stripe interface cable, so more recent units will have only two cable clamps

installed.

• Base Sheet Metal Kit - P/N 400415-301.

The Base Sheet Meta l Kit consists of the power supply tray, system board top and

bottom shield, original WS4 IO pane l, as well as the CF and PCMCIA card

covers. Use with Base P/N 400408-002 or 003. The IO plate is not compatible

with the ABRD86 (WS4 LX) System Board.

• Workstation Base - P/N 400408-002.

This base should be used for the AB28-F and AB28-G System Boards. Includes

pre-installed power button actuator. Does not include sheet metal components or

hardware. Use with Base Sheet Metal Kit P/N 400415-301 and hardware kit P/N

000156-101.

• Workstation Base - P/N 400408-003.

This base can be used for the AB28-I, ABRD36 and ABRD86 System Boards.

Includes pre-installed power button actuator. Does not include sheet metal or

hardware. Use with Hardware and Miscellaneous Plastic Kit 000156-101.

• Door Hinge, Rear - P/N 300323-102.

Compatible with all Workstation 4 and 4LX units.

• Door, Rear - P/N 400410-103.

The Rear Door covers the IO panel. Compatible with all Workstation 4 and 4LX

units.

• Thumbscrews, WS4/KWS4 Stand - P/N 00157-006.

Kit of ten thumbscrews used to secure the unit to the WS4 Adjustable Stand.

• Foot, Rubber - P/N 600455-007.

Kit of 4 pieces. Fits all versions of the WS4 Base.

• Hardware and Miscellaneous Plastic Kit - P/N 000156-101.

This kit includes all hardware for the base and top cover as well as the Operator

LED light pipe, and the MICROS l ogo badge located between the top and b ott om

workstation covers. Compatible with all Works tation 4 and 4LX units.

• Loose Parts Kit - P/N 400412-052.

Similar to the kit included with each workstation, it includes five 6” Tie Wraps,

five Employee/Diagnost ics Mag Cards, and one 2.5mm hex wr ench f or use on the

PCMCIA and CF card covers. AC power cable not included. Compatible with all

Workstation 4 and 4LX units.

1-4 Workstation 4 and 4 LX Field Service Guide

Page 17

System Boards and Components

This section starts with a discussion of each system board revision from the first

generation, through the first ‘ROHS’ compliant revision, then on to latest system

board, the WS4 LX.

In order to keep confusion to a mini mum, each sys tem board is refe renced by a model

designation printed on the board.

WS4 System Boards - A Short History

The AB28-’n’ designation (where ‘n’ represents the hardware revision), indicates the

‘original’ non-ROHS compliant series of WS4 System Boards. Close to 100000 units

were produced with the AB28 Series, including AB28-F, AB28-G and AB28-I.

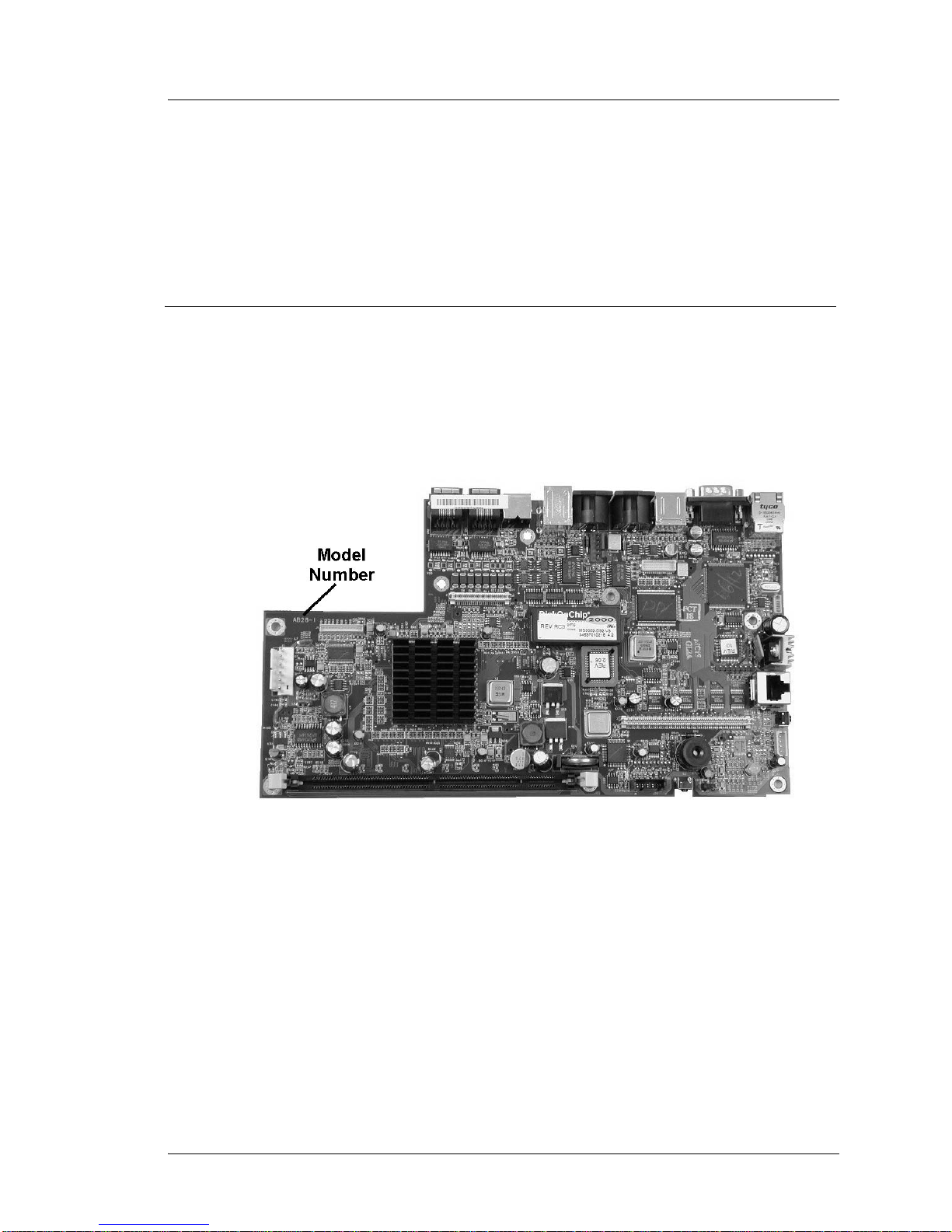

Figure 1-2 displays the AB28-I System Board, the most numerous example of the

AB28 series, and points out the location of the model number.

Introduction to the WS4/WS4 LX FRUs

System Boards and Components

Figure 1-2: The AB28 Series Workstation 4 System Board

The transition from AB28-F/G to AB28-I system boards combined with the change

from a Samsung LCD to a Sharp LCD forced changes in the LCD and backlight

cables. This is reflected in the section on replacement cables.

Another important change between the AB28-F/G, and AB28-I system boards is the

addition of a multiplexer on the COM 3 port, shared between the Mag Stripe Reader

and Customer Display port. The AB28-I System Board required updated platform

files in order for the mag stripe reade r and customer display interfaces to f unction

properly. Chapter 2 provides more detail about the multiplexer.

Workstation 4 and 4 LX Field Service Guide 1-5

Page 18

Introduction to the WS4/WS4 LX FRUs

System Boards and Components

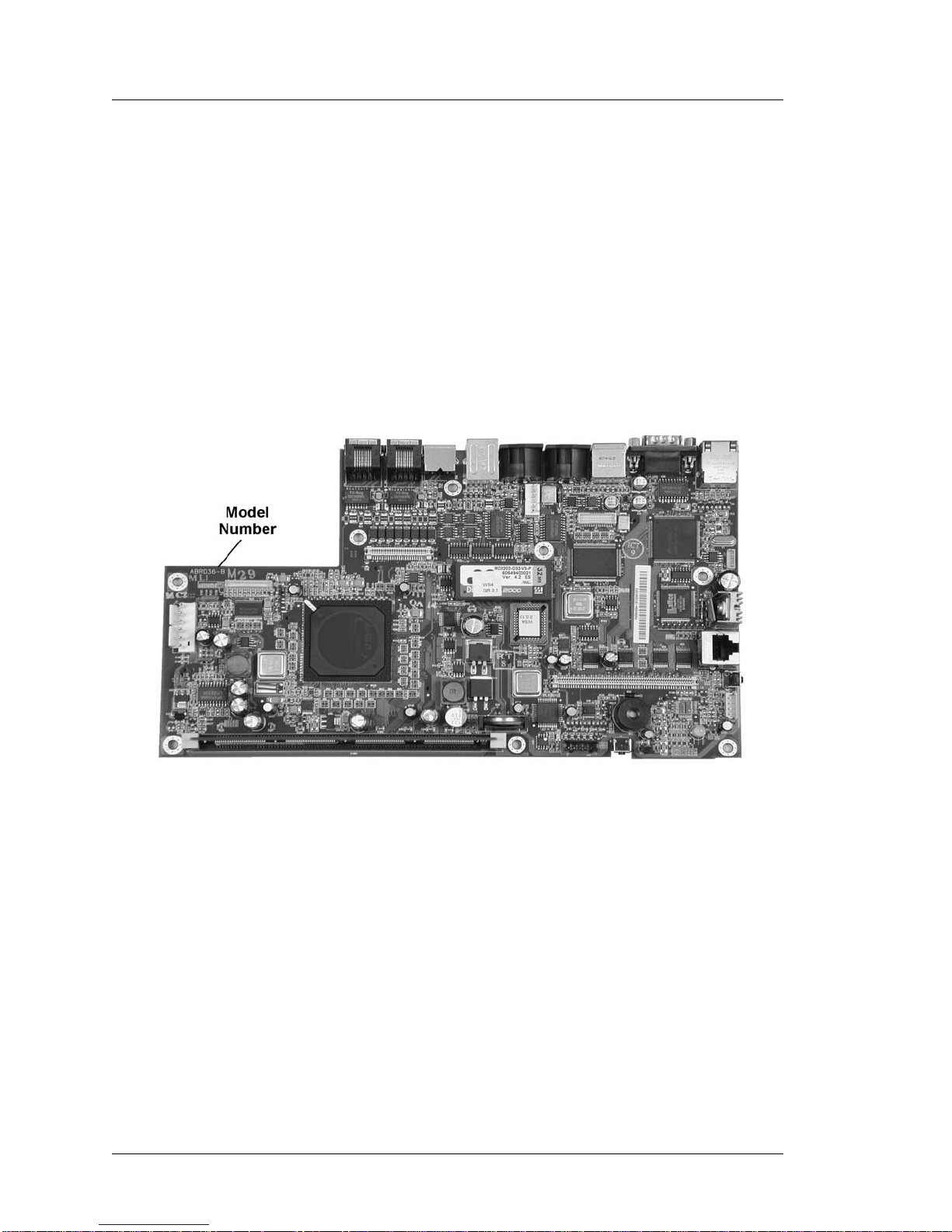

The first RoHS (Reduction of Hazardous Substances) compliant Workstation 4

System Board is designated ABRD36-B replacing the AB28 series. The Revision A

did not enter produ ction . The WS4 DiagUt ilit y views this bo ard as an ex tensi on of th e

AB28 series, displaying Revision ‘K’ in the ‘Hardware Revision’ field.

The primary difference between the ABRD36-B and AB28 series is the AMD Geode

SC3200 Processor packaging . Sever al ot her compone nts wer e also up dated to ‘ge t the

lead out,’ in addition to five other hazardous substances included in the RoHS

directive.

The ABRD36-B board is equivalent to the AB28-I board, using the same interface

cables, CF Card, DIMM, Boot Loader and Disk On Chip. Platform software GR2.2

(or GR2.3a if the LG61 LCD is used) is re qui red. Figure 1-3 displays a sample of this

board and the model number location.

Figure 1-3: The ABRD36-B or Rev K Workstation 4 System Board

The board pictured above doe s not i nclude a proce ssor he at si nk, b ut the first unit s did

include one. The AMD Geode SC3200 packaging used on the AB28 board series did

require a passive heat sink to maintain internal temp eratures and this carried o ver to

the initial production of the ABRD36 system board. However, subsequent testing in

the heat chamber indicated that the ROHS packaging offered improved heat

dissipation and heat sink was not required.

Production of the ABRD36 board ends with the int r oduc ti on of th e Workstation 4 LX

System Board.

1-6 Workstation 4 and 4 LX Field Service Guide

Page 19

Introduction to the WS4/WS4 LX FRUs

System Boards and Components

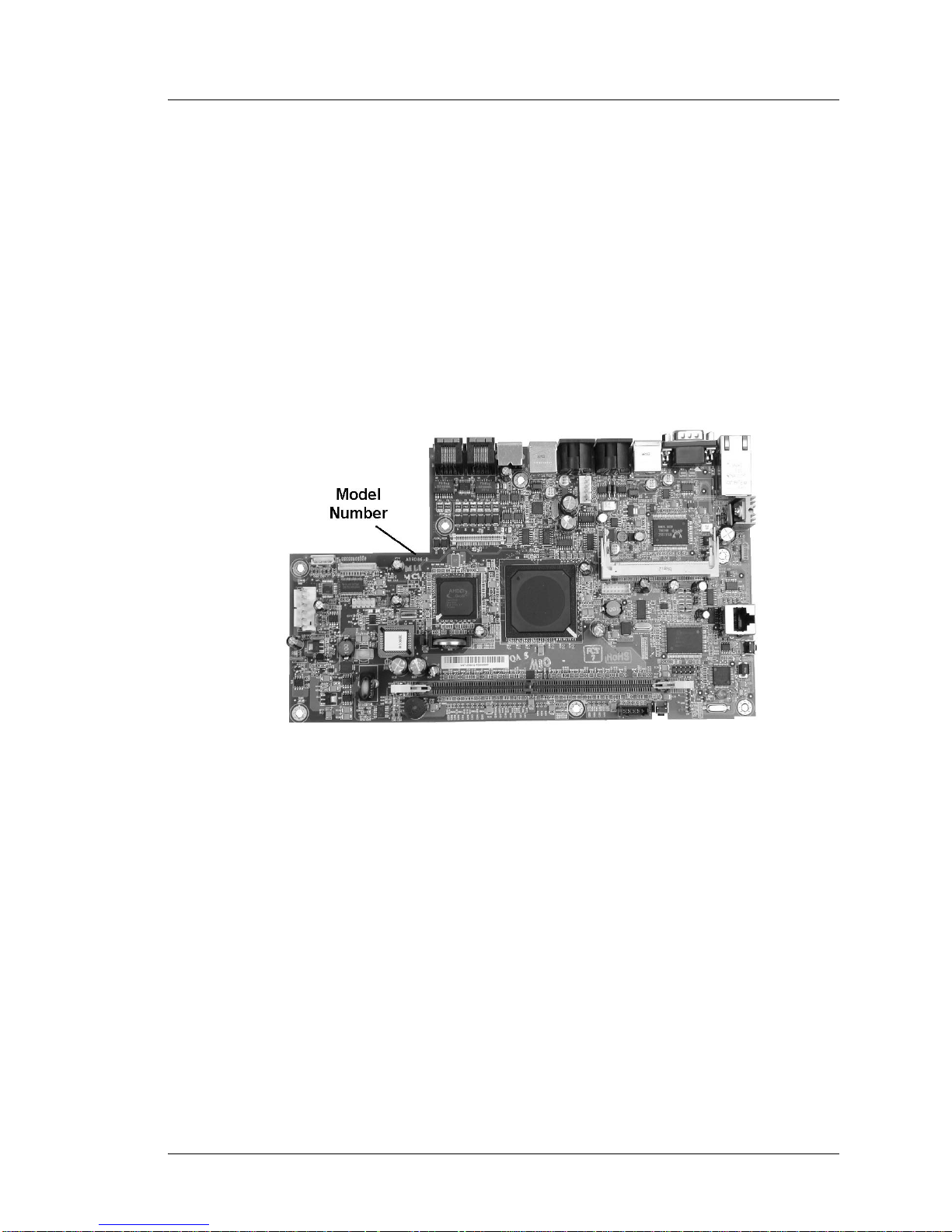

The Workstat ion 4 LX System Board

The Workstation 4 LX System Board is also ROHS compliant and uses the

designation ABRD86-n, where ‘n’ represents the hardware revision. More than just a

board ‘spin’, the LX is a new hardware architecture - requiring a new API, and

platform files. The CAL Client and MICROS applications consider it a new terminal.

Chapter 4 includes a technical overview of this board.

The LX System Board is based on the x86 compatible AMD Geode LX800 processor

and CS5536 Companion Device. This processor, when combined with USB Flash

Drive technology to replace the relativity slow (and soon to be EOL) Disk On Chip

results in a unit that benchmarks up to three times faster than the original WS4 with a

MICROS POS application. Figure 1-4 displays a sample of the ABRD86-D System

Board and model number location.

Figure 1-4: The Workstation 4 LX System Board - ABRD86

Highlighted Changes:

• Blue Operator LED distinguishes the WS4 LX from the original WS4.

• Disk On Chip replaced with USB based flash drive.

• The PCMCIA Socket is replaced by the Mini-PCI socket, to accommodate a

Mini-PCI wireless card. The WS4 LX IO Plate includes a cut-out for an SMA

style antenna connector included in the kit.

• The PS/2 Mouse and Keyboard connectors are replaced by two additional USB

Ports. This means that an IO plate fro m the original WS4 will not fit the LX

System Board.

• The Ethernet Controller supports 1Gbit LANs.

• General Software’s Embedded BIOS 2000 BIOS replaces the original WS4 Boot

Loader. It provides the environment for creating custom pre-boot firmware

utilities such Windows CE Factory Restore.

Workstation 4 and 4 LX Field Service Guide 1-7

Page 20

Introduction to the WS4/WS4 LX FRUs

Workstation 4 System Board and Components

Workstation 4 System Board and Components

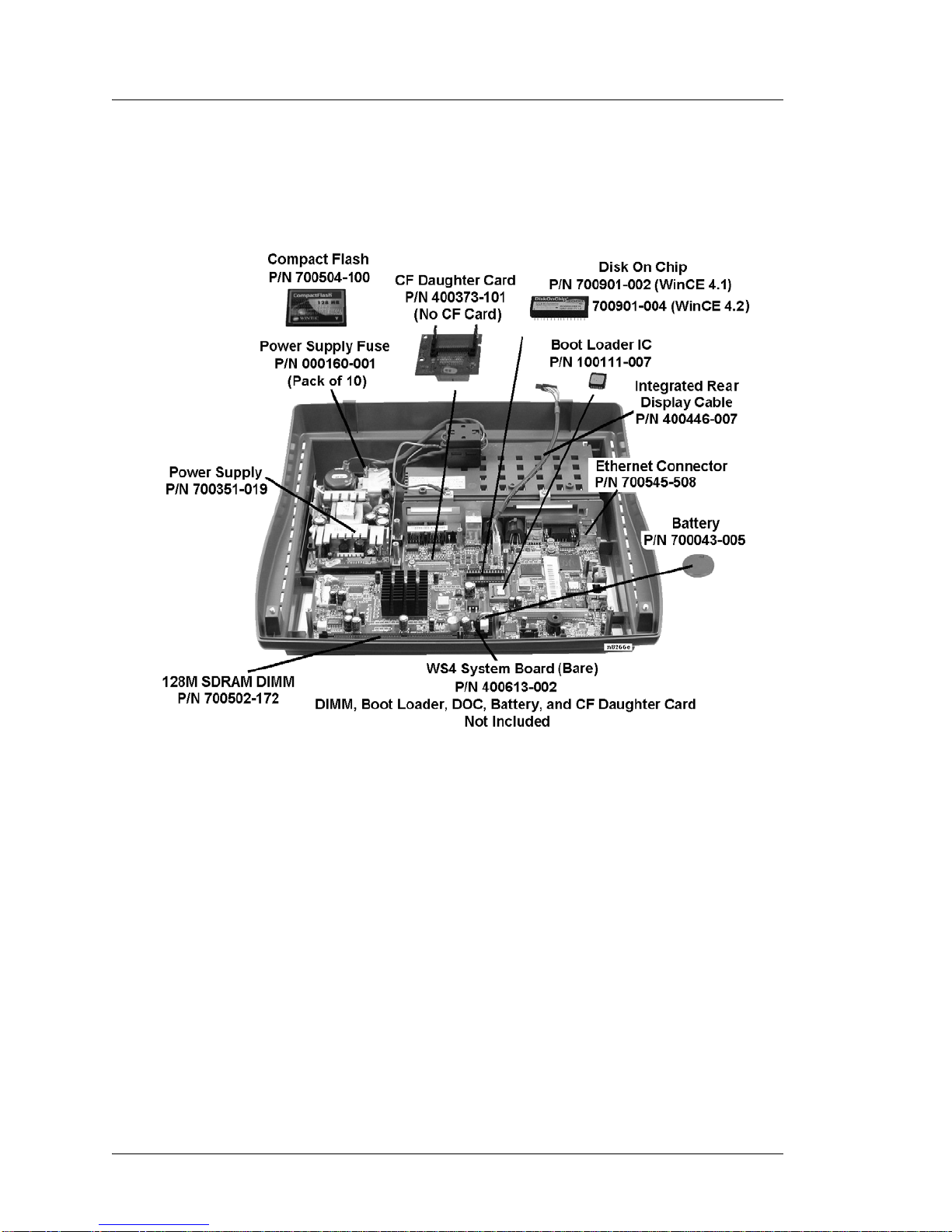

Figure 1-5 shows the original WS4 with the AB28 series or ABRD36 system board

and components.

Figure 1-5: Original Workstation 4 System Board and Components

• Bare Workstation 4 System Board - P/N 400613-002.

Bare ABRD36 system board does not inc lude DIMM, Boot Loader, Disk On Chip

Battery, CF Daughter Card and Processor heatsink. The ROHS compliant WS4

system board designated ABRD36-B, (Revision B) is the current replacement

board for the original WS4.

Physically, the ABRD36 system board is a drop-in replacement for the AB28-I

system board, using the same interface cables, DOC, boot loader, CF card, and

DIMMs. If this board replace s the AB28-F or AB28-G sys tem boards, see Cha pter

6 to install the LCD and backlight cables with the proper ‘offset.’

• DIMM, 128M SDRAM - P/N 700502-172.

Replacement 128M SDRAM DIMM. Compatible with the AB28 and ABRD36

boards, as well as the KW S4 system board. Not compatible with the LX Syste m

board.

1-8 Workstation 4 and 4 LX Field Service Guide

Page 21

Introduction to the WS4/WS4 LX FRUs

Workstation 4 System Board and Components

• Compact Flash Daughter Card - P/N 400373-101.

The CF Daughter Card attaches to J4 on AB28 and ABRD36 Sys tem Board s. The

CF Card, cover and mounti ng hardware not included. This part is a ls o compatible

with the KWS4, PCWS 2010, WS4 LX, and WS5.

• IC, Compact Flash Card - P/N 700504-100.

A blank, formatted 256M Compact Flash card. Can be used in any Workstation 4,

or Workstation 4 LX.

• IC, U19, Disk On Chip - P/N 700901-002 or P/N 700901-004.

32M Disk On Chip in 32-Pin DIP package. The -002 part includes a pre-loaded

WinCE 4.1 image and the -004 part includes a pre-loaded WinCE 4.2 image.

Installs in socket U19 on the AB28 board or U18 on th e ABRD36 System Boards.

Not compatible with the ABRD86 System board.

• IC, U24, Boot loader, Preprogrammed - P/N 100111-007.

39VF020 256M Flash Memory Device contains workstation 4 boot loader.

Installs in socket U24. Compatible with AB28 and ABRD36 System Boards. Not

compatible with the ABRD86 (WS4 LX) System board.

• Cable, Rear LCD Customer, Integrated - P/N 400446-007.

This cable connects to J1 on the system board and attaches to the cable from the

optional Integrated LCD Customer Display. See page 1-24 for more LCD

Customer Display cables. Can als o be used in the KWS4 and WS4 LX.

• Ethernet Connector - P/N 700545-508.

Replacement System Board Connector CN9, for the 10/100 Ethernet Interface.

Compatible with the AB28 and ABRD3 6 sy st em boa rds . Not co mp at ibl e wi th th e

ABRD86 System Board.

• Battery - P/N 700043-005.

CR2032 3V Lithium Coin Cell. This battery is also used on the WS4 LX, PCWS

2010, KWS4, and PCWS Eclipse system boards.

• Power Supply - P/N 700351-019.

65W open frame power supply with +5V, +12V and -12V outputs. This power

supply is compatible with Workstation 4 and Workstation 4 LX units.

• Power Supply Fuse, Kit of 10 pcs. - P/N 000160-001.

3.15A, 250V AC Input fuse with pigtail leads for WS4 and WS4 LX Power

Supply P/N 700351-019.

Workstation 4 and 4 LX Field Service Guide 1-9

Page 22

Introduction to the WS4/WS4 LX FRUs

Workstation 4 LX System Board and Component s

Workstation 4 LX System Board and Components

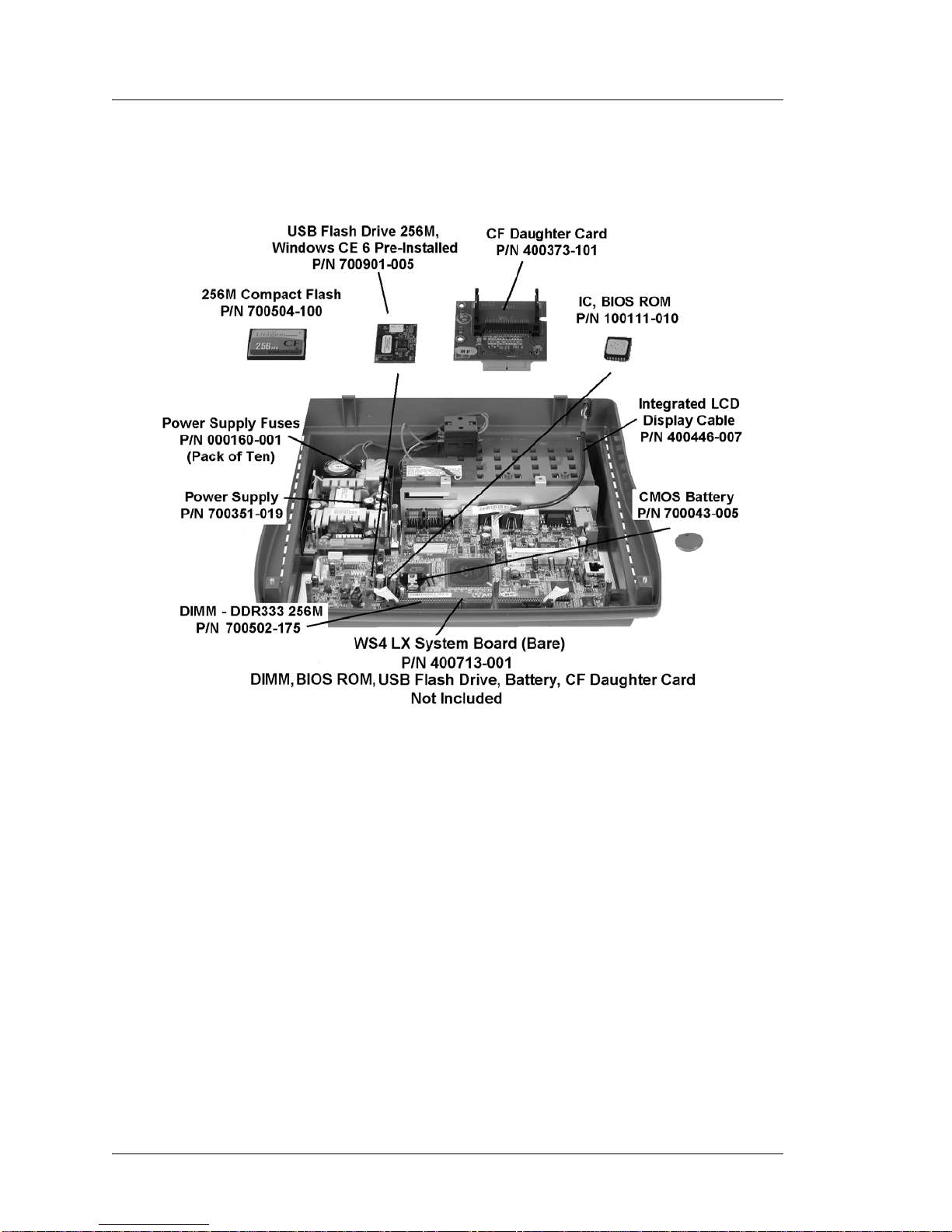

Figure 1-6 shows the WS4 LX System Board ABRD86 and components.

Figure 1-6: WS4 LX System Board and Components

• Main Board, Bare, WS4 LX System Board, P/N 400713-001.

Bare ABRD86 system board does not include DIMM, BIOS ROM, USB Flash

Drive, CMOS battery, or CF Daughter Card.

As discussed in the previous section, the ABRD86 System Board is not a direct

replacement for the original Workstation 4 system boards, AB28 or ABRD36.

• USB Flash Drive, 256M, Pre-Programmed, WS4 LX - P/N 700901-005.

256M USB Flash Drive is pre-loaded with the Windows Embedded CE 6.0

operating system, platform files and utilities. Installs on system board header J5.

Not compatible with the AB28 or ABRD36 System Boards.

• IC, BIOS ROM, WS4 LX - P/N 100111-010.

The pre-programmed 1M BIOS ROM installs in socke t U35. Not compatibl e with

the AB28 and ABRD36 System Boards.

1-10 Workstation 4 and 4 LX Field Service Guide

Page 23

Introduction to the WS4/WS4 LX FRUs

Workstatio n 4 LX System Board and Components

• Compact Flash Daughter Card - P/N 400373-101.

The CF Daughter Card plugs into socket IDE1 on the LX Sys tem Board a nd J 4 on

older System Boards. Cover and mounting hardware not included.

• IC, Compact Flash Card - P/N 700504-100.

A blank, formatted 256M Co mpact Fl ash Card. Can be used in any Workstation 4

or Workstation 4 LX.

• DIMM, DDR333 256M - P/N 700502-175.

Replacement DIMM. Approved devices include Wintec

WD1UN256X808-333B-QC-RA and Unigen UG732D6688KK-DHFMSE. Not

compatible with AB28 and ABRD36 System Boards.

• Cable, Rear LCD Customer, Integrated - P/N 400446-007.

This cable is pre-installed on all Workstation 4 LX System Boards. It attaches

between J1 on the System Board to the optional Integrated LCD Customer

Display. Compatible with the WS4 and KWS4.

• Battery - P/N 7000043-005.

CR2032 3V Lithium Coin Cell. This battery is also used on the WS4, WS5,

PCWS 2010, KWS4, and PCWS Eclipse System Boards.

• Power Supply - P/N 700351-019.

65W open frame power supply with +5V, +12V and -12V outputs. Compatible

with the WS4 and WS4 LX.

• Power Supply Fuse, Kit of 10 pcs. - P/N 000160-001.

3.15A, 250V AC Input fuse with pigtail leads for P/N 700351-019.

Workstation 4 and 4 LX Field Service Guide 1-11

Page 24

Introduction to the WS4/WS4 LX FRUs

Cables and Toroids

Cables and Toroids

This section presents the cables available for the WS4 and adds the WS4 LX.

Considering the original AB28 series system board connector changes, three LCD

panels and the recent introduction of the WS4 LX System board, a total of four LCD

interface cable s and two ba cklig ht int erfac e cable s are av ail able. The WS4 LX sys tem

board (ABRD86) uses the same LCD and bac klight ca bles as the WS4 Rev I (AB28-I)

or ABRD36-B system boards. The table below summarizes the LCD and backlight

cable part numbers, based on the system board type, revision and the Samsung or

Sharp CD panels.

System

Board

AB28-F

AB28-G

AB28-I

ABRD36-B

ABRD86

Samsung

LCD

300331-204 300331-202 300331-103

300331-201 300331-203 300331-200

300331-201 300331-203 300331-200

N/A 300331-203 300331-200

Sharp LCD

(LG41,

LG61)

Backlight

Inverter

Each cable is listed individually in the following pages.

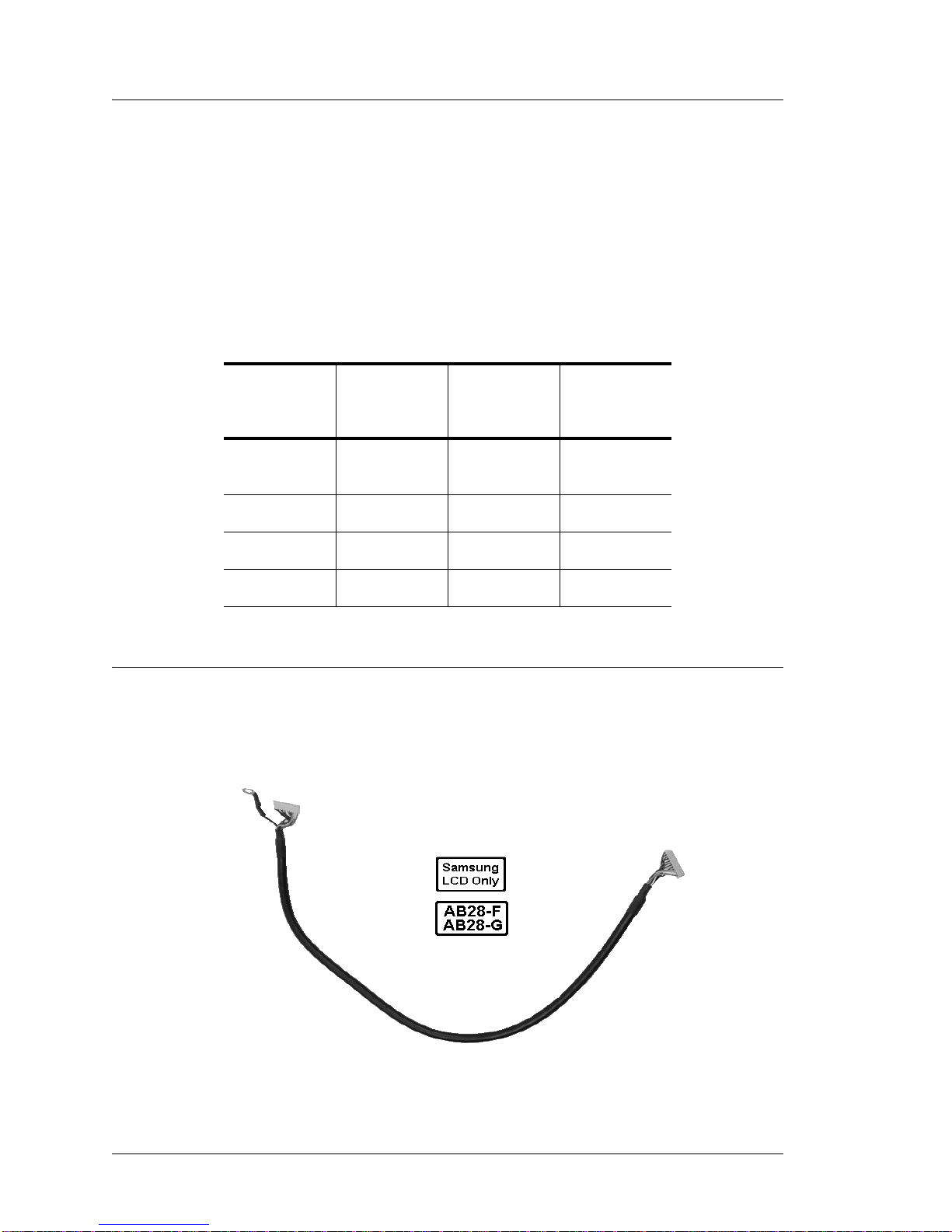

Cable, Assembly LCD Display, REV F/G, BD, WS4 - P/N 300331-204

The cable shown in Figure 1-7 connects between the EOL Samsung LCD LVDS

Board and system boards AB28-F and AB28-G. This cable is not compatible with a

Sharp LCD.

Figure 1-7: Samsung LCD Cable for AB28-F and AB28-G System Boards

1-12 Workstation 4 and 4 LX Field Service Guide

Page 25

Introduction to the WS4/WS4 LX FRUs

Cables and Toroids

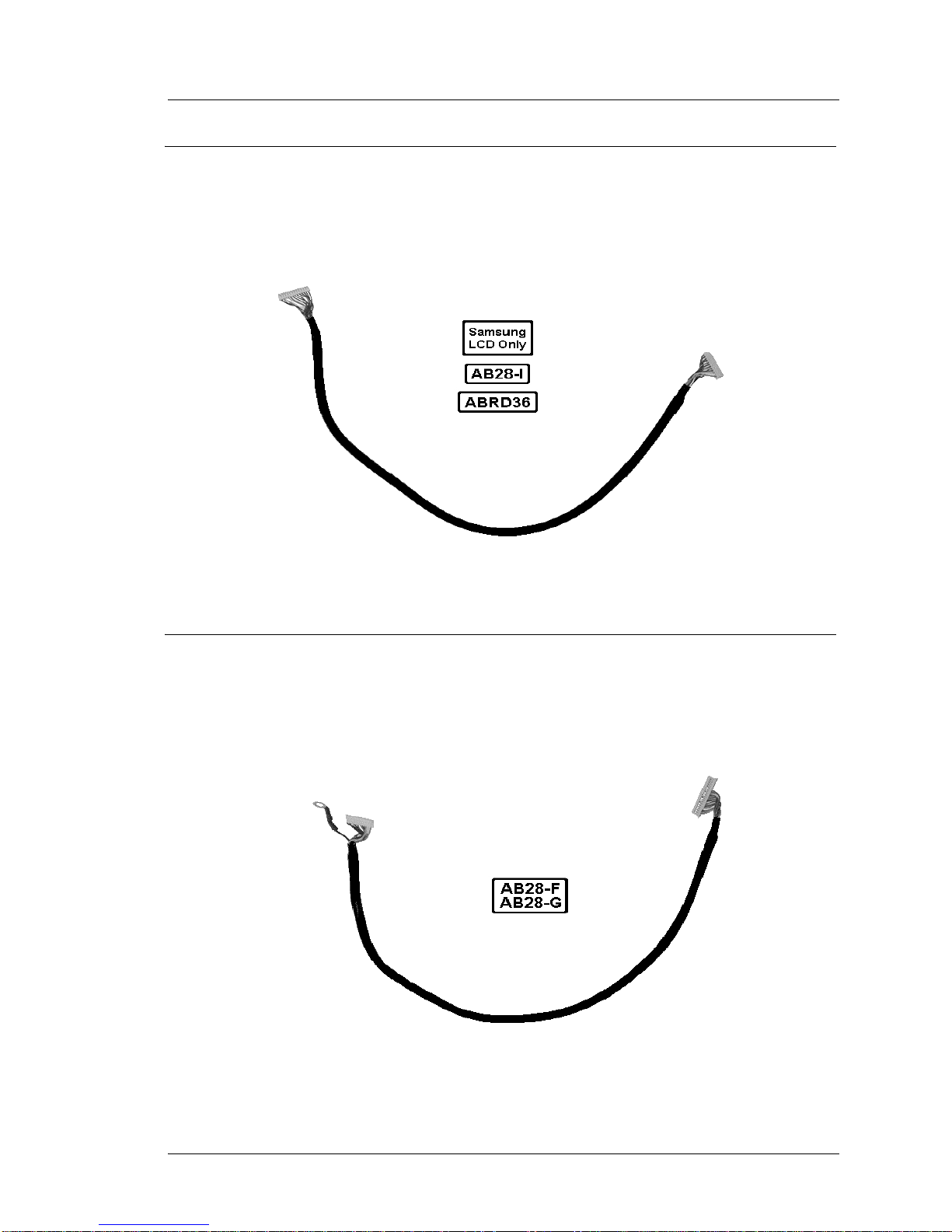

Cable, Samsung LCD Display, WS4 REV I, WS4 ROHS - P/N 300331-201

The cable shown in Figure 1-8 connects between the EOL Samsung LCD LVDS

Board and System Boar d AB28 -I . This cable is not compatible with a Sharp LCD and

system boards AB28-F and AB28-G.

Figure 1-8: Samsung LCD Cable for AB28-I or ARBD36 System Boards

Cable, Sharp LCD Display, REV F/G BD, WS4 - P/N 300331-202

The cable shown in Figur e 1 -9 c onnects a Sharp LCD to older system boards AB28-F

and AB28-G. This cable is not compatible with the Samsung LCD, the AB28-I,

ABRD36 and ABRD86 system boards.

Figure 1-9: Sharp LCD Cable for AB28-F or AB28-G System Boards

Workstation 4 and 4 LX Field Service Guide 1-13

Page 26

Introduction to the WS4/WS4 LX FRUs

Cables and Toroids

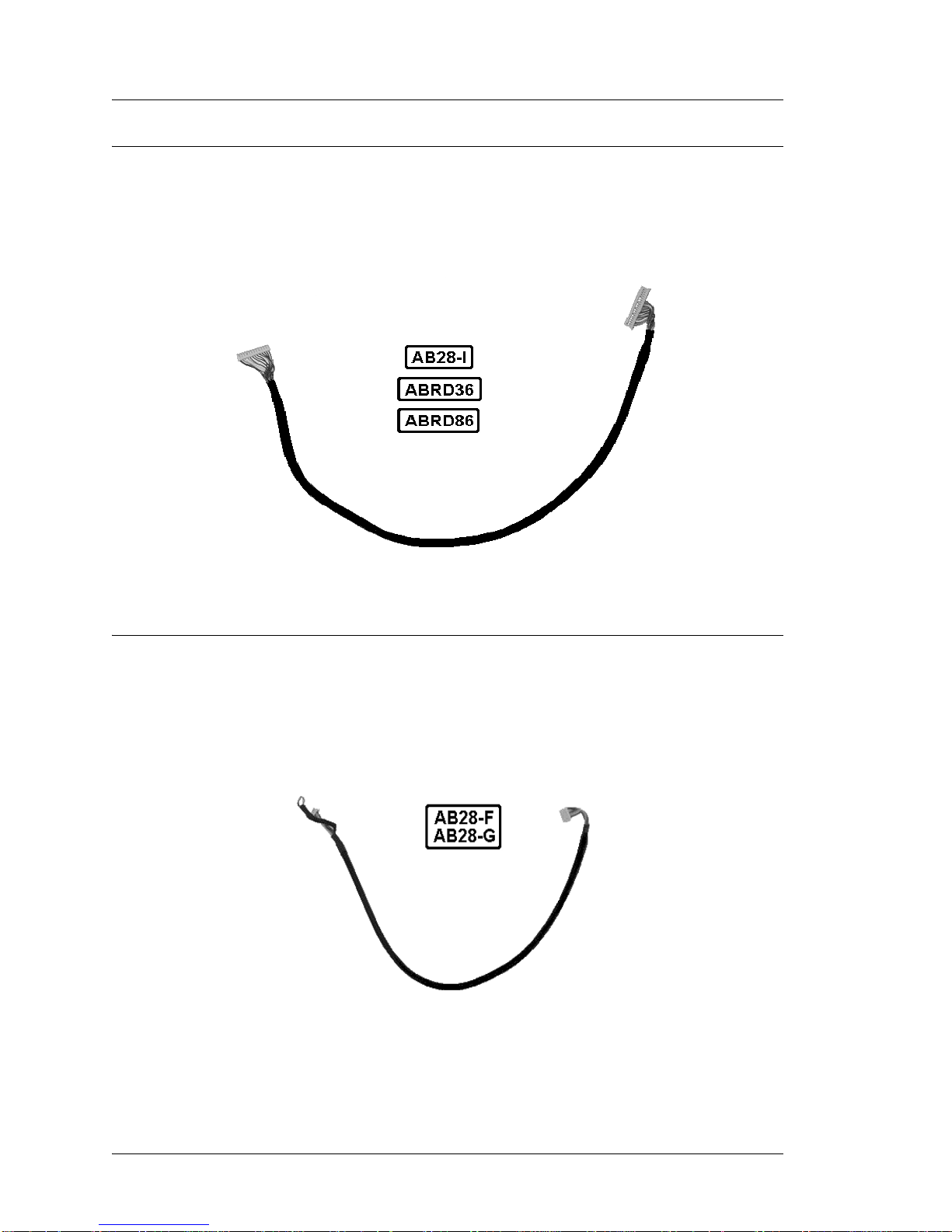

Cable, Sharp LCD Display, WS4 Rev I, ROHS, or WS4 LX - P/N 300331-203

The cable shown in Figure 1-10 con nects a Sharp LCD to WS4 System Board AB28- I,

ABRD36, and ABRD86. Not compatible with Samsung LCDs and the AB28-F/G

System Boards.

Figure 1-10: Sharp LCD Cable for AB28-I and later System Boards

Cable, Inverter, F/G BD, WS4 - P/N 300331-103

The cable shown in Figure 1-11 connects between the backlight inverter board and

system boards AB28-F and AB28-G only. Not compatible with AB28-I, ABRD36 and

ABRD86 system boards.

Figure 1-11: Inverter Cable for WS4 AB28-F and AB28-G System Boards

1-14 Workstation 4 and 4 LX Field Service Guide

Page 27

Introduction to the WS4/WS4 LX FRUs

Cable, Inverter to REV I BD, WS4 or WS4 LX - P/N 300331-200

The cable shown in Figure 1-12 connects between the backlight inverter board and

system boards AB28-I, ABRD36, and ABRD86. This cable is not compatible with

WS4 System Boards AB28-F and AB28-G.

Cables and Toroids

Figure 1-12: Inverter Cable for WS4 Rev I, ROHS and WS4 LX System Boards

Touchscreen Extension Cable - P/N 300331-350

This cable connects between the system board and the touchscreen ribbon cable. The

cable shown in the illustration below is an improved version of the original extension

cable and is compatible with all WS4 and WS4 LX system boards.

Figure 1-13: Touchscreen Extension Cable

Workstation 4 and 4 LX Field Service Guide 1-15

Page 28

Introduction to the WS4/WS4 LX FRUs

Cables and Toroids

Cable Kit, Power In - Power Out, AC Conn - P/N 000170-003

Figure 1-14 displays the Power In and Power Out Cable Kit. It consists of the AC

input cable assembly and the power supply to syst em board cable. The Power -In cab le

does not include a toroid. It is part of toroid kit P/N 700791-001, below. Both cables

are compatible with all WS4s including the WS4 LX .

Figure 1-14: WS4 and WS4 LX AC Input and Power Supply Cable Kit

Toroid Kit, Display, MSR, and AC Power - P/N 700791-001

Kit of three toroids. One each for the LCD interface cable, mag stripe reader cable,

and AC Power In cable assembly. WS4s that use the AB28-I, ABRD36 or ABRD86

system boards and the 400408-003 base do not require a toroid on the MSR cable.

Figure 1-15: WS4 and WS4 LX Toroid Kit

1-16 Workstation 4 and 4 LX Field Service Guide

Page 29

AC Power Input Cable - P/N 200153-001

Replacement AC Power Cable for Workstation 4 and Workstation 4 LX.

Figure 1-16: Replacement AC Power Cable

Introduction to the WS4/WS4 LX FRUs

Cables and Toroids

Workstation 4 and 4 LX Field Service Guide 1-17

Page 30

Introduction to the WS4/WS4 LX FRUs

Workstation 4 and 4 LX - LCD/Touchscreen/Mag Stripe Reader

Workstation 4 and 4 LX - LCD/Touchscreen/Mag Stripe Reader

This section lists all components in the WS4 or WS4 LX top cover, including the

LCD, touchscreen, and mag stripe reader.

Samsung LCD Related

The Samsung LTM121SI-T01 LCD panel is no longer av ailab le, EOL in l ate 2 004. To

replace the Samsung LCD panel, order kit P/N 000160-100. More information about

the kit contents is listed below.

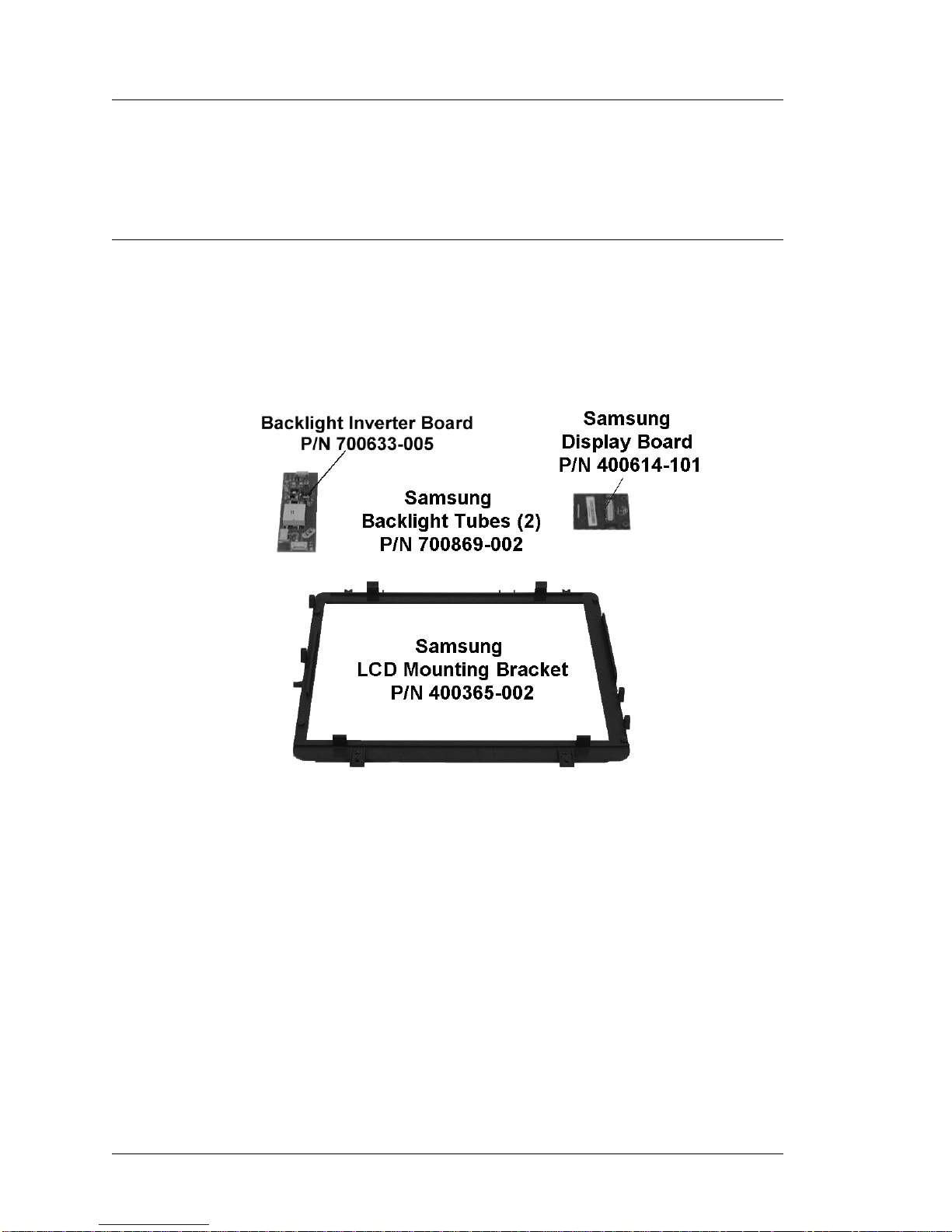

While the Samsung LCD panel itse lf is no longer available, the components shown in

Figure 1-17 are available.

Figure 1-17: Samsung LCD Related Spares

• LCD Conversion Kit - P/N 000160-100.

The kit consists of a Sharp LQ121S1LG41 or LG61 Panel, LCD mounting

bracket, and interface cable. MD0011-003, included in the kit provides

installatio n instructio ns.

• Samsung LCD Mounting Bracket - P/N 400365-002.

This LCD Mounting bracket is specific to the Samsung LTM121SI-T01 12.1”

TFT LCD Panel.

• Samsung Video Display Board - P/N 400614-101.

Also known as the LVDS Receiver Board, XB34. This board attaches directly to

the input connector of the Samsung LCD. This board is not required for Sharp

LCDs; the LVDS receiver is built-in.

1-18 Workstation 4 and 4 LX Field Service Guide

Page 31

Introduction to the WS4/WS4 LX FRUs

Workstation 4 and 4 LX - LCD/Touchscreen/Mag Stripe Reader

• Backlight Inverter Board - P/N 700633-005.

This board attaches to the LCD bracket and powers the Samsung or Sharp LCD

backlight tubes. Two versions of the backlight inverter board now exist. The

original board can be identified by the number ‘XB33’ located near the input

connector J1.

The ROHS compliant version of the backlight inverter is the same MICROS P/N

as the previous board, but includes a new transformer that operates at a higher

frequency. This board can be identified by the model number ‘XBRB33’

silk-screened near the input connector J1.

The increased operating frequency of the inverter circuit is optimized for the

Sharp LG41 and later the LG61 LCD, and results in diminished backlight

brightness if used with the EOL Samsung LCD and GR 2.0 platform software.

The low brightness levels affect the DIM and NORMAL brightness settings and

are inherent to the new transformer’s operating characteristics. See the ‘Other

Platform Fil es and Folders’ section of Chapter 3 for more informatio n.

Workstation 4 and 4 LX Field Service Guide 1-19

Page 32

Introduction to the WS4/WS4 LX FRUs

Workstation 4 and 4 LX - LCD/Touchscreen/Mag Stripe Reader

Sharp LCD Related

Figure 1-18 shows the spare parts available for the Sharp LCD. These items are

compatible with both the WS4 and WS4 LX

.

Figure 1-18: Sharp LCD Related FRUs - WS4 and WS4 LX

• Sharp LCD Panel - P/N 700594-030.

The Sharp LCD Model LQ121S1LG61 (LG61) replaces the Sharp Model

LQ121S1LG41 (LG41). Each i s phy sic ally and e lectr ical ly compa tibl e - u sing the

same interface cable and bracket. Software or driver changes are not required.

Vermont LCD Notice

This product contains mercury and may only be disposed of

after the proper removal and disposal of the lamps.

• Sharp LCD Bracket - P/N 300264-301.

This bracket is unique to the Sharp LQ121S1LG41 or LG61 TFT LCD Panel.

• Backlight Inverter Board - P/N 700633-005.

This board attaches to the LCD bracket and powers the LCD backlight tubes. Two

versions of the backlight inverter board now exist. The ROHS compliant version

of the backlight invert er introduc ed at the same time as the ABRD36 system board

uses the same MICROS P/N as the previous board. Howeve r this board has a new

transformer that operates at a higher frequency optimized for the Sharp LG41 or

LG61 LCD. This board is designated by the model number ‘XBRB33’ located

near input connector J1.

1-20 Workstation 4 and 4 LX Field Service Guide

Page 33

Workstation 4 and 4 LX - LCD/Touchscreen/Mag Stripe Reader

Touchscreen and Front Cover Plastic

Figure 1-19, shows the part numbers for the touch screen glass, gasket, and the top

cover plastic. These items are compatible with the WS4 and WS4 LX.

Introduction to the WS4/WS4 LX FRUs

Figure 1-19: WS4 and WS4 LX Touchscreen and Top Cover

• Touchscreen Glass - P/N 400386-011.

EloTouch Systems 5-wire resistive touchscreen glass.

• Touchscreen Gasket - P/N 600537-127.

The touchscreen gasket fits in a groove in the top cover. The same gasket is used

in the PCWS Eclipse and 2010 12.1” LCD Head.

• Top Cover - P/N 400409-002.

The Top Cover Plastic. Does not include hardware or Operator LED light pipe.

All hardware and the light pipe are included with kit P/N 000156-101.

Workstation 4 and 4 LX Field Service Guide 1-21

Page 34

Introduction to the WS4/WS4 LX FRUs

Workstation 4 and 4 LX - LCD/Touchscreen/Mag Stripe Reader

Top Cover - Mag Stripe Reader Assem b ly and Cover - WS4 and WS4 LX

Figure 1-20 shows the MSR and related components installed in the top cover.

Figure 1-20: Magnetic Stripe Reader FRUs - WS4 and WS4 LX

• Mag Stripe Reader Assembly - P/N 700293-110.

Three-track 90mm RS232 compati ble reader assembly. This is the sam e reader

used by the PCWS Eclipse and 2010. Compatible with the WS4 and WS4 LX.

System Boards prior to AB28-I and Base P/N 400408-002 use a toroid on this

cable.

• Mag Stripe Reader Mounting Kit - P/N 700789-101.

The kit consists of the black plastic spill cover, end brackets and hardware.

Compatible with the WS4 and WS4 LX.

1-22 Workstation 4 and 4 LX Field Service Guide

Page 35

LCD Customer Display

This section lists the available FRU’s for the LCD Customer Display. See Chapter 6

for instructions on removing and replacing these items. The WS4, KWS4, WS4 LX

and WS5 support this display.

LCD Interface Board - P/N 400702-001

The LCD Customer Display Interface Board is used for the Integr ated, Pole and

Adjustable S tand Pole mounted dis play. This board is also drives t he Operat or Displa y

in the KWS4.

Introduction to the WS4/WS4 LX FRUs

LCD Customer Display

Figure 1-21: LCD Customer Display Interface Board

LCD Module, Optrex - P/N 700594-117

The 240x64 Monochrome LCD Module is used for the Rear and Pole Mount LCD

Customer Display. It is also used for the Operator Display on the KWS4.

Figure 1-22: Optrex LCD Module for the LCD Customer Display

Workstation 4 and 4 LX Field Service Guide 1-23

Page 36

Introduction to the WS4/WS4 LX FRUs

LCD Customer Display

Cable, LCD Pole and Rear Display Head - P/N 300331-251

This replacement cable connects between the LCD Interface Board in the rear or pole

LCD display housing to cable 400446-007 (Integrated/Rear) or 300331-250 (Pole).

Figure 1-23: Replacement LCD Customer Display Cable

Cable Extension, LCD Pole Display - P/N 300331-250

This cable is installed in the pole and connects between 300331-251 (above) and the

WS4, WS4 LX, WS5 or KWS4 I/O Panel. It is approximately 6 feet (183 cm) in

length.

Refer to Figure 1-5 for the P/N of the Customer Display cable that attache s to the

system board.

Figure 1-24: Replacement LCD Pole Extension Cable

1-24 Workstation 4 and 4 LX Field Service Guide

Page 37

Introduction to the WS4/WS4 LX FRUs

LCD Customer Display

Kit, Front/Rear Cover, /w Lens, Screws, Pole Mount Hinge - P/N 000160-010

LCD Customer Display housing kit with Front and Rear Plastic covers, pole mount

and pre-installed 2nd generation hinge assembly.

Figure 1-25: Pole Display Plastic Replacement Kit

Kit, Front/Rear Cover, /w Lens, Screws, Rear Mount Hinge - P/N 000160-011

LCD Customer Display housing kit with Front and Rear Plastic covers, integrated

mounting bracket, and pre-installed 2nd generation hinge assembly.

Workstation 4 and 4 LX Field Service Guide 1-25

Figure 1-26: Rear Display Plastic Replacement Kit

Page 38

Introduction to the WS4/WS4 LX FRUs

LCD Customer Display

1-26 Workstation 4 and 4 LX Field Service Guide

Page 39

WS4 Technical Overview

This Chapter contains the Workstation 4 System Board AB28 and ABRD36

technical descriptions. Refer to Chapter 4 for more information about the

Workstation 4 LX System Board, ABRD86.

Chapter 2

In this chapter

Workstation 4 System Block Diagrams........................................................2-2

SC3200 GX1 Processor, Video Processor, Core Logic and Super IO......... 2-5

PCI and Sub-ISA Bus Interface ................................................................... 2-8

SC3200 Super I/O.......................................................................................2-11

PC87360 Super IO..................................................................................... 2-12

TFT LCD Interface.................................................... ......... ......... .............. 2-17

Touchscreen Interface................................................................................ 2-20

Optional PCMCIA Daughter Card ............................................................ 2-21

Optional Mini PCI Daughter Card............................................................. 2-22

Complex Programmable Logic Device (CPLD)........................................ 2-23

DP83815 10/100 Mbps PCI Ethernet Controller....................................... 2-32

RS422 Port A and RS422 B....................................................................... 2-35

Customer Display/Mag Card Reader Port (COM3).................................. 2-38

Optional LCD Customer Display .............................................................. 2-44

Workstation 4 and 4 LX Field Service Guide 2-1

Page 40

WS4 Technical Overview

Workstation 4 System Block Diagrams

Workstation 4 System Block Diagrams

In the following pages, the three major configurations of the original Workstation 4

are presented. Each highlights the system board and LCD configuration as it changes

over time. Figure 2-1 shows the initial configuration of the WS4 with System Board

AB28-F/G and a Samsung LCD panel.

Figure 2-1: WS4 Block Diagram /w System Boards AB28-F or AB28-G and Samsung LCD Panel

Functionally, there is very little difference between AB28-F and AB28-G. The

majority of changes were implemented to improve EMI emissions, and lower

manufacturing costs.

The illustration also shows the Samsung LCD panel and companion LVDS Receiver

Board, designated XB34.

This configuration was produced up to August 2004.

2-2 Workstation 4 and 4 LX Field Service Guide

Page 41

WS4 Technical Overview

Workstation 4 System Block Diagrams

Figure 2-2 shows a block diagram of the WS4 based on th e AB28-I System Board and

the Sharp ‘LG41’ LCD.

Figure 2-2: WS4 Block Diagram /w AB28-I System Board and Sharp LCD Panel

The AB28-I System Board int roduce s the COM3 Mult iple xer in order to ful ly sup port

the MICROS LCD Customer Display, introduced in late 2004. More information on

this change can be found on page 2-38.

This configuration, cons isting of the AB28-I System Board, Backlight Invert er Board

XB33, and CF Daughter Card XB36, and Shar p LCD were produced between August

2004 and June 2006.

The Sharp LCD includes a built-in LVDS receiver, and does not require the XB34

LVDS Receiver Board. The AB28-I System Board uses different LCD and Backlight

interfaces cables than the AB28-F and AB28-G System Boards. See Chapter 1.

T o sup port th e COM3 Multiple xer for the MSR an d customer displ ays, the GR 1.2 (or

later) platform files must be installed on the works t ation. The m ajority of these units

were shipped with the GR 2.0 or 2.1 platform.

Workstation 4 and 4 LX Field Service Guide 2-3

Page 42

WS4 Technical Overview

Workstation 4 System Block Diagrams

Figure 2-3 displays the third variation of the original WS4, based on the ABRD36

System Board and Sharp LG41 LCD.

Figure 2-3: WS4 Block Diagram /w ABRD36 System Board and Sharp LCD Panel

The ABRD36 System Board is combined with Backlight Inverter Board XBRB33,

and CF Daughter Card XBRB36 to complete a ROHS compliant WS4.

The ABRD36 system board is compatible with the AB28-I board as a drop-in

replacement (each uses the same LCD and Backlight Inverter cables), but it requires

the GR2.2 Platform software to fun ction correctly.

The configuration shown above entered production in approximately June 2006 and

continued until the release of the Workstation 4 LX in July 2007. Non-ROHS

compliant Workstation 4s were also produced during this period.

Over 172,000 Workstation 4s were produced in one of the three basic configurations

presented here. Workstation 4 EOL occurred in July 2007, with hardware support

continuing through late 2012. See Chapter 4 for more information about the WS4 LX

System Board.

2-4 Workstation 4 and 4 LX Field Service Guide

Page 43

WS4 Technical Overview

SC3200 GX1 Processor, Video Processor , Core Logi c and Super IO

SC3200 GX1 Processor, Video Processor, Core Logic and Super IO

REF: AB28/ABRD36 - Sheets 1, 2 and 3

The SC3200 was originally a member of National Semiconductor Corp. ‘WebPad On

A Chip’ family of highly integrated x86 system devices. In mid-2003, Advanced

Micro Devices (AMD) purchased t he Geo de line fr om Nationa l. The SC3200 consist s

of a GX1 processor integrated with a TFT LCD video controller, x86 compatible PC

core logic block, and Super IO component shown in the Figur e 2-4 below. Features of

each section are highlighted in the paragraphs that follow.

Workstation 4 and 4 LX Field Service Guide 2-5

Figure 2-4: Geode SC3200 Block Diagram

Page 44

WS4 Technical Overview

SC3200 GX1 Processor, Video Processor, Core Logic and Super IO

GX1 Processor

The Geode GX1 combines advanced CPU performance with MMX™ support,

accelerated 2D graphics, a 64-bit syn chronou s DRAM (SDRAM) interfac e contr oller,

PCI Bus Controller, and a display controller.

• 32-bit, x86, 266Mhz clock speed, with MMX™ compatible instruction set.

• 16 KB unified L1 cache

• Integrated floating point unit (FPU)

• Re-entrant SMM enhanced for VSA.

2D Graphics Accelerator

• Accelerates BitBLTs, line draw and text

• Supports all 256 raster operations

• Supports transparent BLTs

• Runs at the same frequency as the GX1

Memory Controller

• 64-Bit SDRAM Interface

• 66Mhz to 100 Mhz frequency range. The Workstation 4 runs at 78Mhz.

• Direct interface to CPU/cache, display controller and 2D graphics accelerator

• Supports clock suspend and power-down/self refresh

• Up to 8 SDRAM devices or one DIMM/SODIM socket.

Display Controller

• Hardware graphics frame buffer compress/decompress

• Hardware cursor, up to 32 x 32 pixels.

Video Processor

The TFT video processor includes hardware for scaling, filtering, and color space

conversion.

• Hardware video accelerator with video shaping and image enhancing

• Flexible video scaling support of up to 800% (horizontally and vertically)

• Bilinear interpolation filters (with two taps, and eight phases) to smooth video

output

• TFT Interface supports non-interlaced 800x600 or 1024x768 TFT LCD panels.

The Workstation 4 uses a 12.1” TFT (Active) LCD panel operating at a fixed

resolution of 800x600.

2-6 Workstation 4 and 4 LX Field Service Guide

Page 45

Core Logic

The Core Logic of the SC3200 device includes the following PC AT functionality: a

USB interface, IDE interface, PCI Bus Interface, LPC (Low Pin Count) interface,

ACPI 1.0 compliant power management, Video Input Port (VIP), and support for an

audio codec.

WS4 Technical Overview

SC3200 GX1 Processor, Video Processor , Core Logi c and Super IO

Audio Interface (Not Supported)

• AC97/AMC97 (Rev 2.0) codec interface

• Legacy audio emulation using XpressAUDIO

• 6 DMA Channels.

PC AT Functionality

This block consists of the following components:

• Programmable Interrupt Controller (PIC), compatib le with 8259A

• Programmable Interval Timer (PIT), compatible with 8254

• DMA Controller (DMAC) compatible with 8237.

Video Input Port

• Not Implemented on the WS4

Power Management

• ACPI 1.0 Compliant

• Sx state control of three power planes

• Gx/Sx state control of clocks and PLLs

• Wake-up event support.

General Purpose IO (GPIO) Ports

The SC3200 GPIO ports are use d for a var iety of task s, incl uding IDE bu s contr ol

signals, and RS232 COM1 handshake signals.

• 27 multiplexed GPIO signals.

Low Pin Count (LPC) Interface

The LPC Interface is base d on the Intel® Low Pin Count Interface Specification.

It is a PCI-like bus composed of seven signal lines and is used to replace the

legacy ISA bus. Other features include:

• Specification Rev 1.0 compatible

• Reduce the cost of traditional ISA bus devices

• Performs the same bus cycle types as ISA: memory, I/O, DMA, and Bus

Master

• Interrupts are communicated with the serial interrupt (SERIRQ) protocol.

Workstation 4 and 4 LX Field Service Guide 2-7

Page 46

WS4 Technical Overview

PCI and Sub-ISA Bus Interface

PCI and Sub-ISA Bus In terface

REF: AB28/ABRD36 - (Sheets 2, 5, 6 and 10)

Figure 2-5 shows a block diagram of the SC3200 PCI and Sub-ISA Bus as

implemented on the original Workstation 4 System Boards.

Figure 2-5: SC3200 PCI/Sub-ISA Bus Interface

In order to re duce t he number of p ins on the S C3200 dev ice, t he PCI and Sub-IS A bus

pins are shared. Sharing occurs on a bus-cycle by bus-cycle basis, where the Core

Logic PCI bridge arbitrates between PCI and Sub-ISA cycles.

PCI Bus Interface Feature Summary

• PCI 2.1 with wake-up capability

• 32-bit data path, up to 33Mhz

• +3.3V signal support only

• Glue-less interface for a n external PCI device

• Fixed priority of PCI devices.

2-8 Workstation 4 and 4 LX Field Service Guide

Page 47

WS4 Technical Overview

PCI and Sub-ISA Bus Interface

As shown in Figure 2-5, two device s are located on the PCI Bus. U1 2 is a National

Semiconductor Corp DP83815 10/100 Ethernet Controller, and the optional

PCMCIA Daughter Card XB37 or XBRB37 includes a RL5C475II PCI to Card

Bus Controller. The PCMCIA Daughter Card was replaced by the Mini-PCI

Daughter Card XBRD68 in 2006.

Sub-ISA Bus Interface

Some features of the Sub-ISA Bus are listed below.

Two devices are attached to the Sub-ISA Bus. These are U24, a 39LF020 2Mbit

(256 x 8) Flash EEPROM Boot Loader installed in a 32-pin PLCC socket, and

U19, a 32M Disk On Chip installed in a 32-pin DIP socket.

• Supports the ROMCS output to select Flash EPROM boot loader chip

• Includes d irect support for the M-Sy stems DiskOnChip

®

2000.

Boot Loader

The Boot Loader code is stored in Flash EEPROM U24. Simila r in function to

the BIOS in Personal Computers, the boot loader is specific to the x86

compatible SC3200 processor. Executing at power-up, it contains all

power-up initalization code for each of the system board devices.

Once initalization is complete, the boot loader performs a custom Power On

Self Test of the primary system board components and copies the operating

system image from the Disk On Chip in to system RAM.

The boot loader also co ntains c ustom ext ensions u nique to the WS4 hardware .

These functions permit access to platform specific features such as persisting

the registry to the CF card and checking the CF card for an updated copy of

the operating system at boot time.

Disk On Chip (DOC)

The Disk On Chip 2000 is part of M-Systems third generation of Disk On

Chip produc ts. It combines disk controller firmware with Flash Memory on a

single die, providing a cost effective solid state alternative to conventional

rotating media.

The DOC includes a copy of the Windows CE image contained in a hidden

partition. Each time the workstation starts, the Windows CE image is

transferred from the Disk On Chip to system RAM and started.

All Workstation 4s use a 32M DOC in a 32-pin Dual In Line (DIP) package.

The SC3200 is programmed to enable DOCCS#, the DOC chip select output

in an 8K memory window starting at C8000H.

Workstation 4 and 4 LX Field Service Guide 2-9

Page 48

WS4 Technical Overview

PCI and Sub-ISA Bus Interface

IDE Interface (AB28/ABRD36 - Sheets 1 and 13)

The core logic module integrates a PCI bus mastering ATA-4 compatible IDE

Controller. This controller supports Ultra DMA, Multi-word DMA and

Programmable I/O (PIO) modes. Two IDE devices are supported by the SC3200.

However, on the WS4 system board only a single Compact Flash card is attached

to this interface. A block diagram is shown in Figure 2-6.

Figure 2-6: Workstation 4 IDE Interface Block Diagram

The CF Daughter card is pos it ioned to make the CF card available at the IO panel

and serve as the ‘personality’ module.

The CF card is an intelligent solid state storage device containing a micro

controller and firmware positioned in front of a block of flash memory. The

firmware responds to file IO requests from the Windows CE FAT file system

driver and maps file data into the flash memory.

Compact Flash Cards with capacities of 32M, 64M, 128M, and 256M have been

used at various stages of production.

USB Interface (AB28 - Sheets 1 and 14)

The SC3200 includes three independent USB ports. Each port has a Data “+” and

a Data “-” signal. Two of these ports are available at connector CN7 on the I/O

panel and the third is not used. The USB ports are Open Host Controller Interface

(OpenHCI) Rev 1.0 (1.1) compliant. The OpenHCI specification provides a

register level description for a host controller, as well as common industry

hardware/software interface and drivers.

2-10 Workstation 4 and 4 LX Field Service Guide

Page 49

SC3200 Super I/O

REF: AB28/ABRD36 - Sheets 1 and 2

The SC3200 Super IO module comprises a collection of 8 functional blocks, host

interface, and a central configuration register set, all attached to the internal 8-bit data

bus.

The host interface serves a bridge between the external ISA bus and the internal bus

and supports 8-bit I O rea d, 8- bi t I O wri te and 8 -bi t DMA t ran sac ti ons . The r emai ni ng

functional blocks are briefly described below.

Parallel Port

The SC3200 Super IO parallel port includes an IEEE 1284 compatible parallel

port interface. However, the SC3200 parallel port interface is not implemented.

ACCESS.bus (ACB) Interface

The ACB is a two-wire synchronous serial interface compatible with the

ACESS.bus physical layer. The ACB is also compatible with the Intel SMBus

(System Management Bus) and Phillips I

bi-directional Serial Data Line (SDL), and Seri al Clock Line (SCL) which allows

easy interfacing to a wide range of memories and IO devices, including

EEPROMs, SDRAMs, timers, ADCs, DAC, clock chips and peripheral devices.

WS4 Technical Overview

SC3200 Super I/O

2

C bus. The interface is composed of a

As shown in the block diagram, ACB2 is not used. However, ACB1 is connected

to socket DIMM1 and is imple mente d as a Seria l Pre sen ce Dete ct (SP D) I nterf ace

to the DIMM. The Boot Loader utilizes DRAM timing parameters stored in the

EEPROM to op timize the SC3 200 memory co ntroller.

Serial Interface

The SC3200 block diagram in Figure 2-4 shows three serial ports, labeled

UART1, UART2, and UART3. Each UART contains the equivalent of a 16550

UART with 16 byte FIFO buffer.

UART1 is assigned to the touchscreen interface located on COM2. The interface

is a simple two-wire TX/RX interface and is connected to touchscreen controller

U38 without the use of RS232 level converters.

UART2 is assigned to the rear panel DB9 connector designated as COM1.

Handshake signals required for this interface are supplied by General Purpose IO

pins on the SC3200. These pins are shared with IDE control signals.

UAR T3 is assigned to COM5 and dedicated to RS422 Port B. The cont ro l signals

required to manage the RS422/RS232 selection and TX enable for this port are

supplied from GPIO ports on Super IO chip, U15.

Real Time Clock (RTC)

The RTC provides timekeeping and calendar management functions. It also

includes 242 bytes of battery backed RAM for general-purpose use.