Page 1

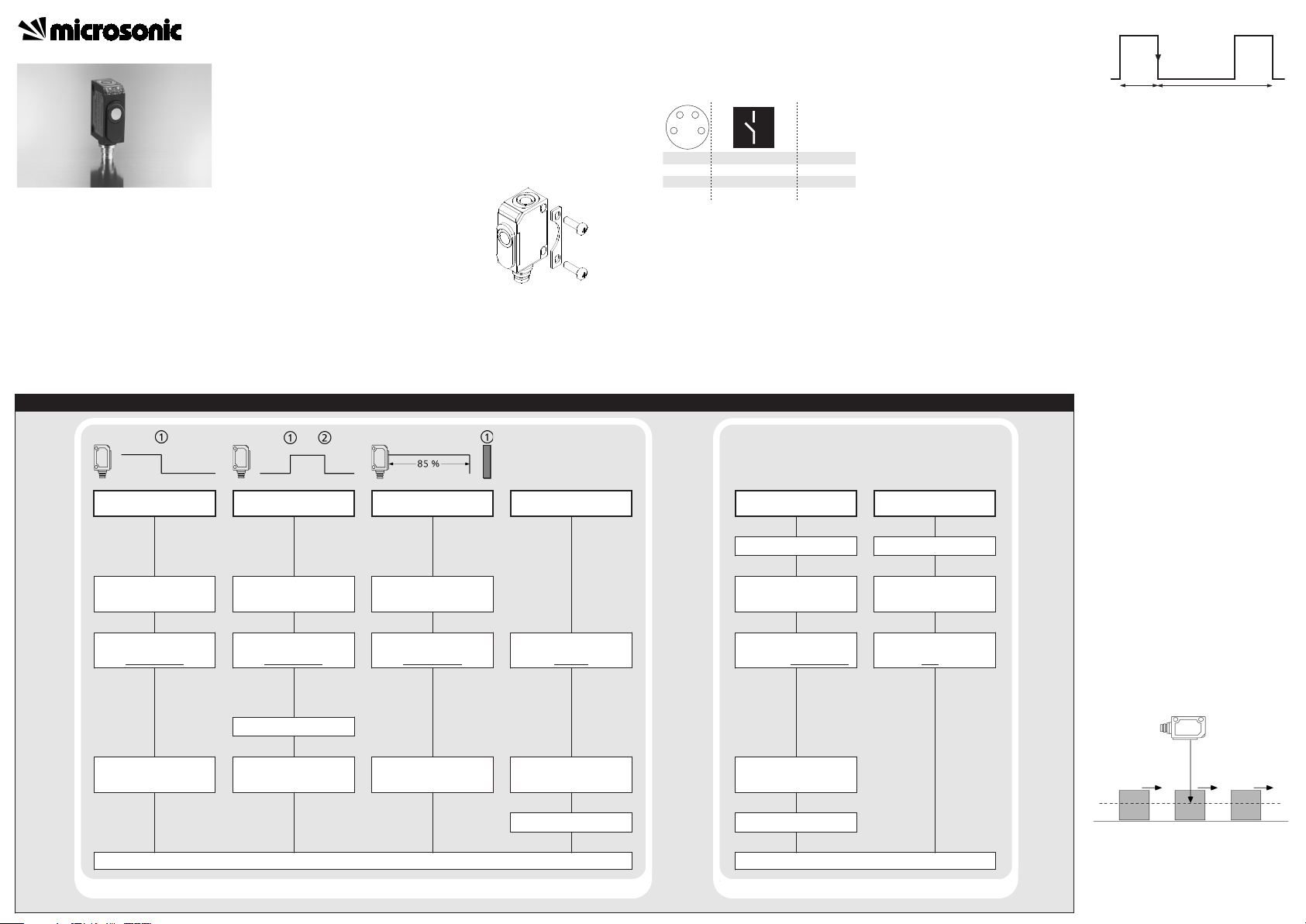

Sensor adjustment with Teach-in procedure

Set detect point

Place object at position

Press push-button for about

3 s until LEDs flash

simultaneously

both LEDs:

flash

mutually

Press push-button for

about 1 s

Set window mode

Place object at position

Press push-button for about

3 s until LEDs flash

simultaneously

both LEDs:

Place object at position

Press push-button for

about 1 s

flash

mutually

Set two way reflective

barrier

Set NOC/NCC

Enable/disable Teach-in

push-button

Switch off power supply

Place reflector at position

Press push-button for about

3 s until LEDs flash

simultaneously

Press button for about 13 s

until LEDs flash

mutually

both LEDs:

flash

mutually

Press push-button for

about 10 s

green LED:

yellow LED:

To change output characte-

ristic press push-button

for about 1 s

While pressing the push-

button switch on power

supply

Keep push-button pressed

for about 3 s until both

LEDs flash simultaneously

flashes

on: NOC

off: NCC

green LED:

yellow LED:

flashes

on: push-button

enabled

off: push-button

disabled

To enable/disable Teach-in

press push-button

for about 1 s

Reset to factory setting

Switch off power supply

While pressing the push-

button switch on power

supply

Keep push-button pressed

for about 13 s until both

LEDs stop

flashing

Normal operating mode

Wait for 10 s

Wait for 10 s

Normal operating mode

Operating Instructions

Ultrasonic Sensors

1

3

colour

+U

B

-U

B

brown

blue

4

2

D

Sync

black

white

143

2

Sensor disabled Sensor disabled

Start

+U

B

-U

B

ti

tp

Further settings

Set switched output

zws-7/CD/QS zws-7/CE/QS

zws-15/CD/5ms.a zws-15/CE/5ms.a

Fast ultrasonic proximity switch

with one switched output

Product Description

The zws sensor offers a non-contact

measurement of the distance to an

object which must be positioned

within the sensor’s detection zone.

The switched output is set in dependence of the adjusted detect distance.

Due to the short response time and

the high switching frequency these

zws sensors are applicable to the detection of quick processes. For the

zws-7, the faster variant, please see

the notes for installation and operation.

Via the push-button, the detect distance and operating mode can be

adjusted (teach-in). Two LEDs indicate operation and the state of the

switched output.

Safety Notes

Read the operating instructions

prior to start-up.

Connection, installation and

adjustment works may only be

carried out by expert personnel.

No safety component in accor-

dance with the EU Machine Directive.

Installation

Mount the sensor at the installa-

tion site with the aid of the

enclosed mounting plate.

Maximum torque of attachment

screw: 0,5 Nm

Fig. 1: Attachment with mounting plate

Connect a connection cable to the

M8 device plug.

Avoid mechanical load on the con-

nector.

Start-Up

Connect the power supply.

Carry out the adjustment in

accordance with the diagram.

Fig. 2: Pin assignment with view onto sensor

plug and colour coding of the

microsonic connection cable

Factory Setting

Operation with one detect point

Switched output on NOC

Detect points at operating range

Operating modes

Three operating modes are available

for the switched output:

Operation with one detect point

The switched output is set if the object falls below the set detect point.

Window mode

The switched output is set if the object is within the set window margins.

Two-way reflective barrier

The switched output is set if the object is between sensor and reflector.

Synchronization

You can synchronize as many sensors

as you like.

Apply a square-wave signal to the

sync-input with pulse width ti and

repetition rate tp (Fig.3 and

technical data).

Fig.3: External synchronization signal

A high level on the sync-input will

deactivate the sensor.

Checking operation mode

In normal mode shortly press the

push-button.

The green LED stops shining for one

second, then it will show the current

operating mode:

1 x flashing = operation with one

switching point

2 x flashing = window mode

3 x flashing = reflective barrier

After a break of 3 s the green LED

shows the output function:

1 x flashing = NOC

2 x flashing = NCC

Maintenance

microsonic sensors are maintenancefree. In case of excess caked-on dirt

we recommend cleaning the white

sensor surface

Notes

The zws sensor has a blind zone,

within which distance measurements are not possible.

In the normal operating mode, an il-

luminated yellow LED signals the

switched output is switched

through.

The sensor got to know the

distance to the object at the teachin stage. For objects that move into

the sound field from the side, an 810 % greater distance should be

set for reliable object detection by

the sensor.

Fig. 4: Setting the switching point

The zws-7 has a very short measu-

rement cycle time of only 2 ms.

Under unfavourable conditions

this can lead to the sensor wrongly

Page 2

Technical data

Blind zone

Operating range

Maximum range

Angle of beam spread

20 mm

70 mm

20 mm

150 mm

100 mm

See detection zone

250 mm

See detection zone

Transducer frequency

Resolution, sampling rate

Reproducibility

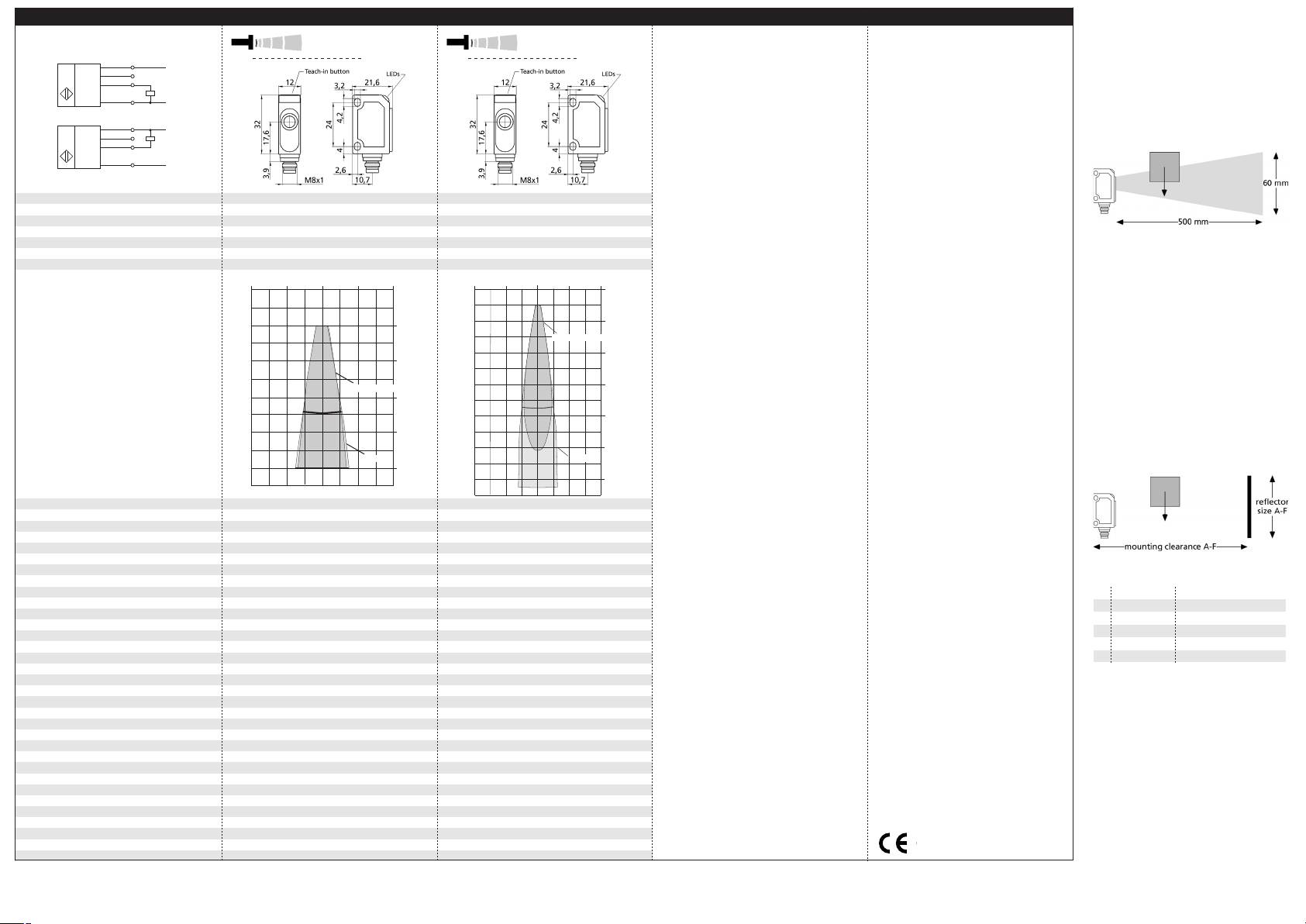

Detection zones

for different objects:

The dark grey areas are determined

with a thin round bar (10 mm dia.)

and indicate the typical operating range

of a sensor. In order to obtain the light grey

areas, a plate (100 x 100 mm) is introduced

into the beam spread from the side.

In doing so, the optimum angle between

plate and sensor is always employed.

This therefore indicates the maximum

detection zone of the sensor.

It is not possible to evaluate ultrasonic

reflections outside this area.

380 kHz

0,20 mm

380 kHz

0,20 mm

± 0,15 %

± 0,15 %

Accuracy

Operating voltage U

B

Voltage ripple

No-load current consumption

Temperature drift 0,17 % / °C

20 - 30 V DC, reverse polarity protection

Temperature drift 0,17 % / °C

20 - 30 V DC, reverse polarity protection

±10 %

< 30 mA

±10 %

< 30 mA

Housing

Class of protection to EN 60 529

ABS

ultrasonic transducer: polyurethane foam,

ABS

ultrasonic transducer: polyurethane foam,

epoxy resin with glass content

IP 67

epoxy resin with glass content

IP 67

Type of connection

Controls

Indicators

4-pin M8 initiator plug

Yes, Teach-in push-button

4-pin M8 initiator plug

Yes, Teach-in push-button

LED green (operation)

LED yellow (state of output)

LED green (operation)

LED yellow (state of output)

Programmable

Synchronisation

Pulse width synchronization signal t

p

Repetition rate synchronization signal t

p

No

Yes, external

No

Yes, external

> 150 µs

2 ms < tp < 1 s

> 150 µs

5 ms < tp < 1 s

Operating temperature

Storage temperature

Weight

Switching hysteresis

-25°C to +70°C

-40°C to +85°C

-25°C to +70°C

-40°C to +85°C

10 g

2 mm

10 g

2 mm

Switching frequency

Response time

Switch-off delay time

Time delay before availability

250 Hz

< 3 ms

100 Hz

< 7 ms

< 3 ms

< 300 ms

< 7 ms

< 300 ms

Norm conformity

Order no.

Switched output

EN 60947-5-2

EN 60947-5-2

zws-7/CD/QS

pnp, UB-2 V, I

max

= 200 mA

zws-15/CD/5ms.a

pnp, UB-2 V, I

max

= 200 mA

Order no.

Switched output

switchable NOC/NCC, short-circuit-proof

switchable NOC/NCC, short-circuit-proof

zws-7/CE/QS

npn, -UB+2 V, I

max

= 200 mA

zws-15/CE/5ms.a

npn, -UB+2 V, I

max

= 200 mA

switchable NOC/NCC, short-circuit-proof switchable NOC/NCC, short-circuit-proof

1

2

4

3

+U

B

-U

B

Sync

U

1

2

4

3

+U

B

-U

B

Sync

U

1 pnp switched output

1 npn switched output

zws-7...

zws-15...

2 cm 0 cm 2 cm

0 cm

2 cm

4 cm

6 cm

7 cm

8 cm

10 cm

Plate

Round bar ø 10 mm

4 cm 4 cm

8 cm 4 cm 0 cm 4 cm 8 cm

0 cm

4 cm

8 cm

12 cm

16 cm

20 cm

24 cm

Round bar ø 10 mm

Plate

microsonic GmbH • Hauert 16 • D-44227 Dortmund • Tel: +49 2 31 / 97 51 51-0 • Fax: +49 2 31 / 97 51 51-51 • E-Mail: info@microsonic.de • www.microsonic.de

The content of this document is subject to technical changes. Specifications in this document are presented in a descriptive way only. They do not warrant any product features.

MV-DO-085271-408188

responding to echoes from existing measurements. To avoid this,

there has to be an unobstructed

space extending to a depth of 500

mm in front of the sensor. Only

the objects to be detected are to

be within the sensor's 20-100 mm

operating area.

Fig. 5: Unobstructed space in front of the

sensor

With the zws-7, it is vital that the

objects to be detected enter the

sound fields from the sides..

If the unobstructed 500 mm space

cannot be provided or should the

sensor be used in the «Two-way

reflective barrier» mode, then a

plane reflector at a specific distance to the sensor must be fitted.

The size of the reflector and its

working clearance from the sensor

can be taken from the table in

Fig.7.

Fig. 6: Sensor/reflector working clearance

Fig. 7: Working clearance and reflector sizes

In the »Two-way reflective barrier«

operating mode, the object has to

be within the range of 0-85 % of

the set distance.

The zws-7 sensor has no tempera-

ture compensation.

If the push-button is not pressed

for 2 minutes during the teach-in

setting, the settings made hitherto

are deleted.

The sensor can be reset to its fac-

tory setting.

A

B

C

D

E

F

366 mm 60 mm x 60 mm

194 mm

137 mm

60 mm x 60 mm

50 mm x 50 mm

108 mm

91 mm

40 mm x 40 mm

40 mm x 40 mm

79 mm 30 mm x 30 mm

89/336/EEC

Loading...

Loading...