Page 1

Operating Instructions

Ultrasonic proximity switch with

one switched output

pico+15/F pico+15/WK/F

pico+25/F pico+25/WK/F

pico+35/F pico+35/WK/F

pico+100/F pico+100/WK/F

Product description

The pico+sensor offers a non-contact

measurement of the distance to an

object which must be positioned

within the sensor’s detection zone.

The switched output is set conditional upon the adjusted detect distance.

Via the Teach-in procedure, the detect distance and operating mode

can be adjusted. Two LEDs indicate

operation and the state of the switched output.

The pico+sensors are IO-Link-capable

in accordance with IO-Link specification V1.0.

Safety instructions

Read the operating instructions

prior to start-up.

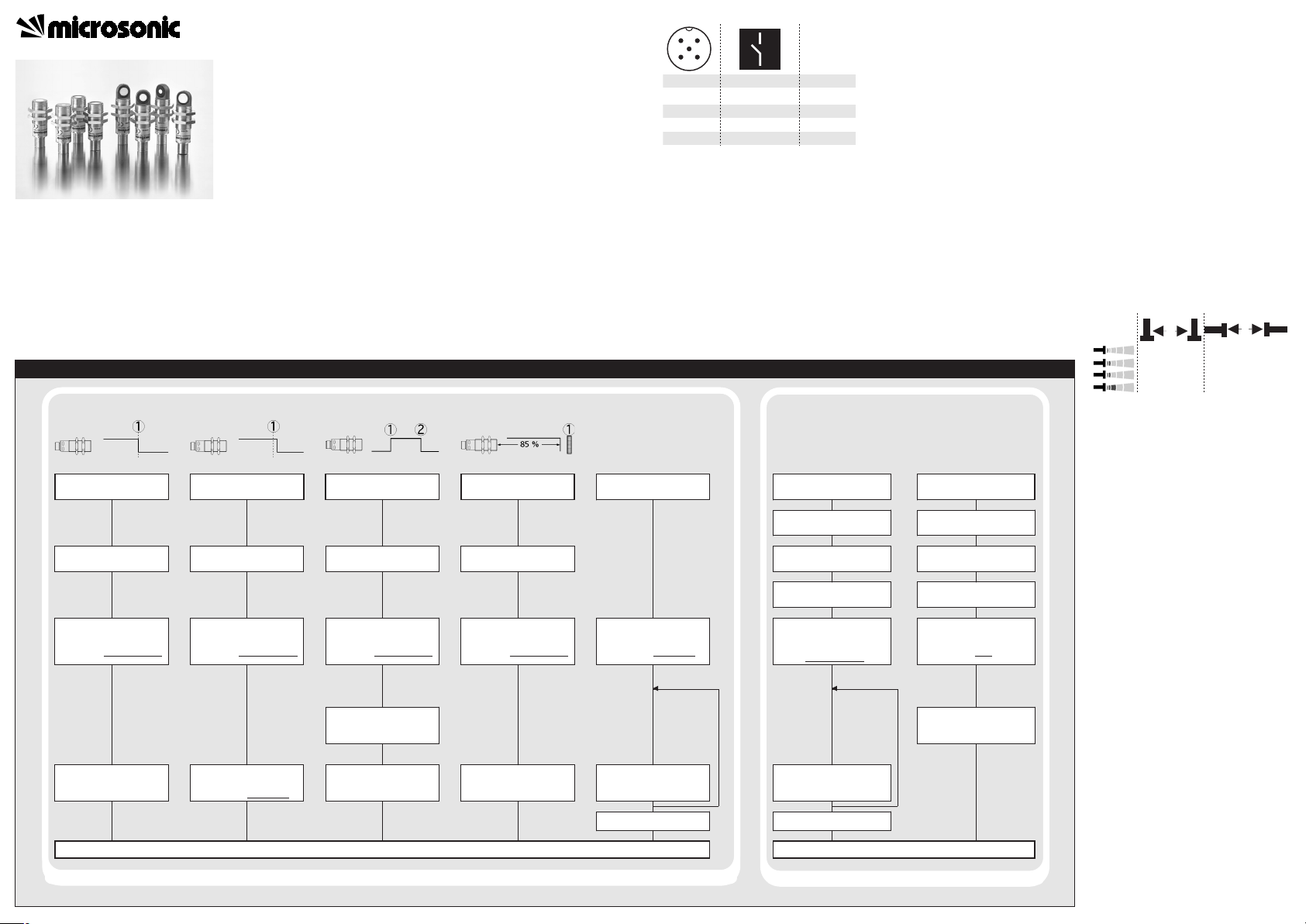

Sensor adjustment with Teach-in procedure

Set detect point

– method A

Place object at position

Connect Com for about

3 s to +U

B

, until both

LEDs flash simultaneously

Both LEDs:

flash alternately

Set detect point +8 %

– method B

Place object at position

Connect Com for about

3 s to +U

B

, until both

LEDs flash simultaneously

Both LEDs:

flash alternately

Set window mode

Set two way reflective

barrier

Set NOC/NCC

Place object at position

Install reflector at

position

Connect Com for about

3 s to +U

B

, until both

LEDs flash simultaneously

Both LEDs:

flash alternately

Connect Com for about

3 s to +U

B

, until both

LEDs flash simultaneously

Both LEDs:

flash alternately

Connect Com for about

13 s to +U

B

, until both

LEDs flash alternately

Green LED:

Yellow LED:

flashes

on: NOC

off: NCC

Switch-over

Teach-in / synchronisation

Switch off operating

voltage

Reset to factory setting

Switch off operating

voltage

Connect Com to -U

B

Switch on

operating voltage

Keep Com connected to

-U

B

for about 3 s, until

both LEDs flash

simultaneously

Green LED:

Yellow LED:

flash

on: Teach-in

off: Synchronisation

Connect Com to -U

B

Switch on

operating voltage

Keep Com connected to

-U

B

for about 13 s, until

both LEDs stop

flashing

Connect Com for about

1 s to +U

B

Normal operating mode

Connect Com for about

3 s to +U

B

, until both

LEDs flash alternately

Place object at position

Both LEDs:

flash mutually

Connect Com for about

1 s to +U

B

Connect Com for about

10 s to +U

B

To change output

characteristic connect

Com for about 1 s to +U

B

Wait for 10 s

To change operation

mode connect

Com for about 1 s to -U

B

Wait for 10 s

Normal operating mode

Disconnect Com from -U

B

before switching off

supply voltage

Connection, installation and ad-

justments may only be carried out

by qualified staff.

No safety component in

accordance with the EU Machine

Directive

Use for intended purpose only

pico+ultrasonic sensors are used for

non-contact detection of objects.

Installation

Mount the sensor at the place of

fitting.

Connect a connection cable to the

M12 device plug.

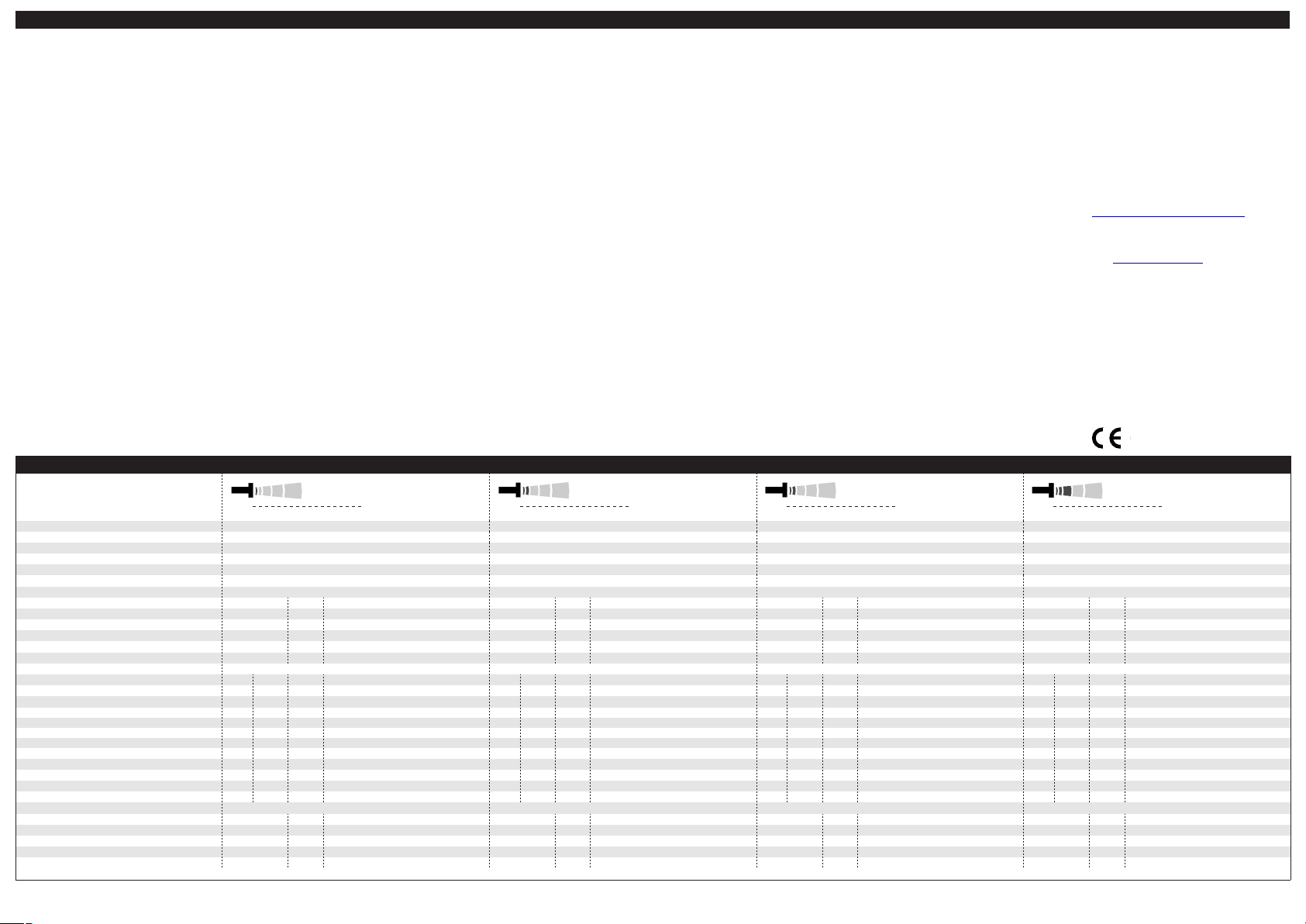

Fig. 1: Pin assignment with view onto sensor

plug and colour coding of the

microsonic connection cables

Start-up

Connect the power supply.

Carry out sensor adjustment in

accordance with the diagram.

1

3

colour

+U

B

-U

B

brown

blue

4

2

5

F

-

black

white

Com grey

1

5

2

34

Factory setting

Detect point operation

Switched output on NOC

Detect distance at operating range

Multi-function input »Com« set to

»Teach-in«

Filter at F01

Filter strength at P01

Operating modes

Three operating modes are available

for the switched output:

Operation with one detect point

The switched output is set when the

object falls below the set detect

point.

Window mode

The switched output is set when the

object is within the set window.

Two-way reflective barrier

The switched output is set when the

object is between sensor and fixed

reflector.

Synchronisation

If under multiple sensor operation

the assembly distance falls below the

values shown in Fig. 2, the internal

synchronisation should be used. For

this purpose set the switched outputs of all sensors in accordance with

the diagram »Sensor adjustment

with the Teach-in procedure«. Then

change the multi-function output

»Com« to »synchronisation« (see

»Further settings«). Finally interconnect each pin 5 of the sensors to be

synchronised.

Fig. 2: Assembly distances

Maintenance

microsonic sensors are maintenancefree. In case of excess caked-on dirt

we recommend cleaning the white

sensor surface

Notes

The sensors of the pico+ family

have a blind zone, within which a

distance measurement is not possible.

The pico+ sensors are equipped

with an internal temperature compensation. Due to the sensors self

heating, the temperature compensation reaches its optimum working-point after approx. 20 minutes

of operation.

In the normal operating mode, an il-

luminated yellow LED signals that the

switched output is switched

through.

The pico+sensors have a push-pull

switched output.

In the »Two-way reflective barrier«

operating mode, the object has to

be within the range of 0-85 % of

the set distance.

≥0,25 m ≥1,30 m

≥0,35 m

≥0,40 m

≥2,50 m

≥2,50 m

≥0,70 m

≥4,00 m

A

B

Ultrasonic Sensors

Set switched output

Further Settings

Page 2

Technical data

blind zone

operating range

maximum range

angle of beam spread

20 mm

150 mm

30 mm

250 mm

250 mm

see detection zone

350 mm

see detection zone

transducer frequency

resolution

reproducibility

380 kHz

0.069 mm

320 kHz

0.069 mm

± 0.15 %

± 0.15 %

accuracy

operating voltage U

B

voltage ripple

no-load current consumption

±1 % (temperature drift internally compensated)

10 - 30 V DC, reverse polarity protection

±1 % (temperature drift internally compensated)

10 - 30 V DC, reverse polarity protection

±10 %

< 40 mA

±10 %

< 40 mA

housing

max. tightening torque of nuts

brass sleeve, nickel-plated, plastic parts: PBT;

ultrasonic transducer: polyurethane foam,

brass sleeve, nickel-plated, plastic parts: PBT;

ultrasonic transducer: polyurethane foam,

class of protection per EN 60 529

type of connection

controls

indicators

IP 67

IP 67

Teach-in via pin 5 (Com)

LED green (operation)

Teach-in via pin 5 (Com)

LED green (operation)

programmable

synchronisation

operating temperature

LED yellow (state of output)

Teach-in, LinkControl

LED yellow (state of output)

Teach-in, LinkControl

internal synchronisation up to 10 sensors

-25°C to +70°C

internal synchronisation up to 10 sensors

-25°C to +70°C

storage temperature

switched output

switching hysteresis

1)

-40°C to +85°C

Push-Pull, I

max

= 100 mA

-40°C to +85°C

Push-Pull, I

max

= 100 mA

switchable NOC/NCC, short-circuit-proof

2 mm

switchable NOC/NCC, short-circuit-proof

3 mm

switching frequency

1)

response time

1)

time delay before availability

1)

norm conformity

25 Hz

32 ms

25 Hz

32 ms

< 300 ms

EN 60947-5-2

< 300 ms

EN 60947-5-2

order no. directly radiating

weight

pico+15/F

pico+25/F

30 g

30 g

order no. angular head

weight

1) Can be programmed with LinkControl

pico+15/WK/F

35 g

pico+25/WK/F

35 g

65 mm

350 mm

120 mm

1,000 mm

600 mm

see detection zone

1,300 mm

see detection zone

400 kHz

0.069 mm

200 kHz

0.069 mm

± 0.15 %

± 0.15 %

±1 % (temperature drift internally compensated)

10 - 30 V DC, reverse polarity protection

±1 % (temperature drift internally compensated))

10 - 30 V DC, reverse polarity protection

±10 %

< 40 mA

±10 %

< 40 mA

brass sleeve, nickel-plated, plastic parts: PBT;

ultrasonic transducer: polyurethane foam,

brass sleeve, nickel-plated, plastic parts: PBT;

ultrasonic transducer: polyurethane foam,

IP 67

IP 67

Teach-in via pin 5 (Com)

LED green (operation)

Teach-in via pin 5 (Com)

LED green (operation)

LED yellow (state of output)

Teach-in, LinkControl

LED yellow (state of output)

Teach-in, LinkControl

internal synchronisation up to 10 sensors

-25°C to +70°C

internal synchronisation up to 10 sensors

-25°C to +70°C

-40°C to +85°C

Push-Pull, I

max

= 100 mA

-40°C to +85°C

Push-Pull, I

max

= 100 mA

switchable NOC/NCC, short-circuit-proof

5 mm

switchable NOC/NCC, short-circuit-proof

20 mm

12 Hz

64 ms

10 Hz

80 ms

< 300 ms

EN 60947-5-2

< 300 ms

EN 60947-5-2

pico+35/F

pico+100/F

30 g

30 g

pico+35/WK/F

35 g

pico+100/WK/F

35 g

+U

B

-U

B

F

Com

1

2

4

5

3

Push-Pull output in pnp circuit

U

+U

B

-U

B

F

Com

1

2

4

5

3

Push-Pull output in npn circuit

U

pico+15...

pico+25...

pico+35...

pico+100...

2004/108/EC

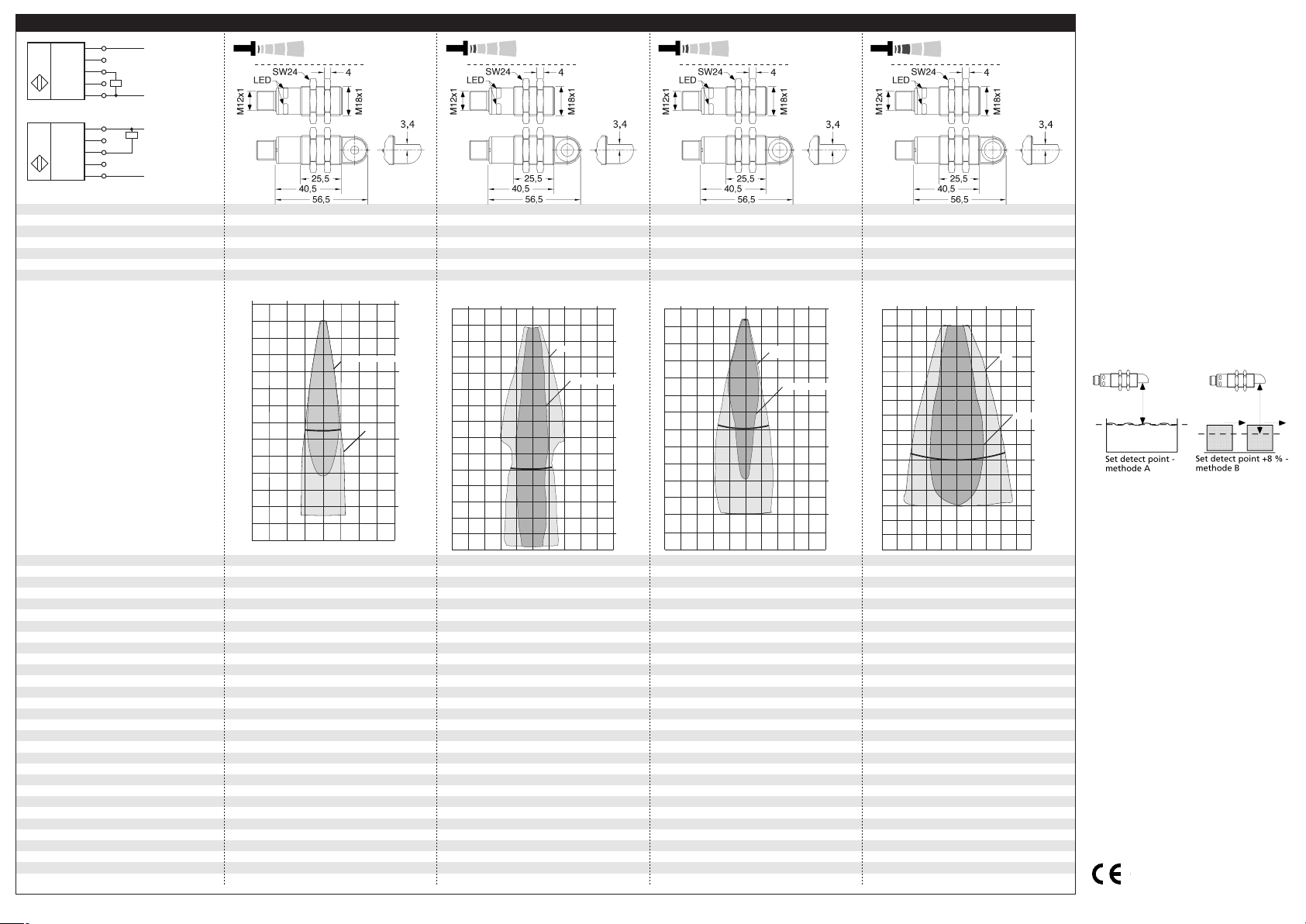

detection zones

The dark grey areas represent the zone

where it is easy to recognise the normal

reflector (round bar). This indicates the typical

operating range of the sensors. The light

grey areas represent the zone where a

very large reflector – for instance a

plate – can still be regognized. The

requirement here is for an optimum

alignment to the sensor. It is not

for different objects:

possible to evaluate ultrasonic

reflections outside this area.

■ In the »Set detect point – method

A« Teach-in procedure the actual

distance to the object is taught to

the sensor as the detect point. If

the object moves towards the

sensor (e.g. with level control) then

the taught distance is the level at

which the sensor has to switch the

output.

If the object to be scanned moves

into the detection area from the

side, the »Set detect point +8 % –

method B« Teach-in procedure

should be used. In this way the

switching distance is set 8 % further than the actual measured distance to the object. This ensures a

4 cm

0 cm

0 cm

0 cm

0 cm

4 cm

4 cm

4 cm

Rohr ø 10 mm

Rohr ø 10 mm

Rohr ø 10 mm

Round bar ø 10 mm

ausgerichtete Platte

ausgerichtete Platte

Plate

8 cm

8 cm

8 cm

8 cm

0 cm

0 cm

0 cm

4 cm

4 cm

4 cm

8 cm

8 cm

8 cm

12 cm

12 cm

12 cm

16 cm

16 cm

16 cm

20 cm

20 cm

20 cm

24 cm

24 cm

24 cm

10 cm

5 cm

0 cm

5 cm

Plate

Round bar ø 10 mm

10 cm

0 cm

5 cm

10 cm

15 cm

20 cm

25 cm

30 cm

35 cm

20 cm

10 cm

0 cm

10 cm

Plate

Round bar ø 27 mm

20 cm

0 cm

10 cm

20 cm

30 cm

35 cm

40 cm

50 cm

60 cm

0,4 m

0,2 m

0 m

0 m

0,2m

Plate

0,4 m

0,6 m

Round bar ø 27 mm

0,8 m

1,0 m

1,0 m

1,3 m

1,4 m

0,4 m

0,2 m

reliable switching distance even if

the height of the objects varies

slightly.

Fig. 4: Setting the detect point for different

directions of movement of the object

4 cm

4 cm

8 cm

8 cm

4 cm

4 cm

8 cm

8 cm

epoxy resin with glass content

15 Nm

5-pin M12 circular plug

epoxy resin with glass content

15 Nm

5-pin M12 circular plug

epoxy resin with glass content

15 Nm

5-pin M12 circular plug

epoxy resin with glass content

15 Nm

5-pin M12 circular plug

If synchronization is activated the

Teach-in is disabled (see »Further

settings«).

The sensor can be reset to its fac-

tory setting (see »Further settings«).

Using the LinkControl adapter (op-

tional accessory) and the LinkControl software for Windows, all

Teach-in and additional sensor parameter settings can be optionally

undertaken.

Page 3

IO-Link mode

The pico+ sensors are IO-Link-capable in accordance with IO-Link specification V1.0.

Pointer

In IO-Link mode Teach-in, Link-

Control and synchronization via

pin 5 are not available.

In IO-Link mode pin 5 must not be

connected to any potential.

For current information about IO-

Link please contact the microsonic

sales department.

Synchronisation in IO-Link mode

In IO-Link mode each sensor is synchronized on the protocol of the IOLink master.

In multiple sensor operation the sensors are synchronous if the master

protocols are synchronous.

Process data

The pico+ cyclically transmits the

measured distance value with a resolution of 0,1 mm and the state of

the switched output.

Service data

The following sensor parameters

may be set via IO-Link interface using

the IO-Link device description (IODD).

Detect point 1

The switched output is activated

when the distance to an object is under that of the present detect point.

Return detect point 1

The switched output is reactivated

when the distance to an object is

greater than the present return detect point (detect point + hysteresis).

Pointer

The return detect point 1 must al-

ways be greater than the detect

point 1.

Detect point 2, return detect point 2

By programming these two detect

distances the window mode is activated.

Pointer

The return detect point 2 must al-

ways be smaller than the detect

point 2.

NOC/NCC operation

The NCC or NOC output function can

be present for the switched output.

Measurement filter

pico+ ultrasonic sensors provide for a

choice of 3 filter settings:

F00

No filter, each ultrasonic measurement acts in an unfiltered manner

on the output.

F01

Standard filter, on the object continuously approaching the sensor,

the ongoing interval is immediately taken on and the output

correspondingly activated. The effect of the object abruptly moving

away from the sensor is for the

existing distance to be saved for a

retaining time dependent on the

filter strength and for the switched

output state to be maintained.

F02

Average value filter, forms the

arithmetic mean across a number

of measurements. The output is

activated in keeping with the average value. The number of measurements, from which the average

value is formed, depends on the

selected filter strength.

Filter strength

A filter strength between 0 – weak

filter effect – and 9 – pronounced filter effect – can be selected for each

measurement filter.

Foreground suppression

Spurious reflections, caused by objects in the foreground of the sensor

may be blocked out by the foreground suppression.

Pointer

Check that the object in the fore-

ground does not cause multiple

reflections.

The object in the foreground must

not cover the sensor in a way that

the detection zone is influenced.

System commands

With 4 system commands the following settings may be carried out:

Teach-in detect point – method A.

Teach-in detect point – method B.

Teach-in two way reflective barrier.

Reset sensor to factory settings.

Pointer

To achieve the maximum resolution

the Master Cycle Time has to comply

with the following requirements:

Min Cycle Time ≤ Master Cycle

Time ≤ Min Cycle Time + 1.2 ms.

If this condition can not be full-

filled, sporadic discontinuities of

the measurement value can occur.

In this case the Master Cycle Time

has to be increased in 400 µs steps

until the discontinuities of the

measurement disappear.

Pointer

If the pico+ sensor was set using

Teach-in or LinkControl it is recommended to reset the sensor

to the factory setting prior to

using it in IO-Link mode (s.

»Further settings«).

IODD file

The latest IODD file you will find

on

the internet under

www.microsonic.de/en/IODD.

For further informations on IO-Link

see www.io-link.com.

index

index

format

UINT16

UINT16

UINT16

UINT16

index

format

UINT16

UINT16

UINT16

UINT16

format

UINT16

466-65,512 (32 - 350 mm) 1)

> 5,094: window mode deactivated

451-65,512 (31 - 349 mm) 1)

UINT16

UINT16

UINT16

format

UINT16

975-65,512 (67 - 600 mm) 1)

> 8,733: window mode deactivated

961-65,512 (66 - 599 mm) 1)

UINT16

UINT16

UINT16

> 5,094: window mode deactivated

> 8,733: window mode deactivated

1,776-65,512 (122 - 1,300 mm) 1)

> 18,922: window mode deactivated

1,761-65,512 (121 - 1,299 mm) 1)

> 18,922: window mode deactivated

pico+15...

pico+35...

pico+100...

IO-Link mode

MV-DO-108322-372394

microsonic GmbH | Hauert 16 | 44227 Dortmund | Germany | telefone +49 2 31 / 97 51 51-0 | telefax +49 2 31 / 97 51 51-51 | e-mail: info@microsonic.de | www.microsonic.eu

The content of this document is subject to technical changes. Specifications in this document are presented in a descriptive way only. They do not confirm any product features.

IO-Link data

physical layer

SIO mode support

min cycle time

format of process data

content of process data

service data IO-Link specific

service data sensor specific

return detect point 1

return detect point 2

foreground suppression

Teach-in via Pin 5 in SIO mode

Teach-in detect point – method A

Teach-in detect point – method B

Teach-in two way reflective barrier

reset to factory settings

baud rate

Vendor name

Vendor text

Product name

Product ID

Product text

detect point 1

detect point 2

switching mode

filter strength

system commands

yes

8 ms

COM 2 (38.400 Bd)

16 Bit, R, UNI16

Bit 0: state of switched output;

Bit 1-15: distance value with 0,1 mm resolution

0x10

0x11

0x12

0X13

0x14

0x40

0x41

0x47

0x48

0x42 UINT8

0x43

filter

0x44

0x49

0x4A

0x02

0x02

0x02

0x02

1)

Distance values, e.g. detect points, are given as multiple of the internal resolution of the measurement value = 0,069 mm (example: 320 ≙ 22 mm). The values in the table are decimal.

access value

RRmicrosonic GmbH

RRpico+

R Ultraschall-Sensor

access

R/W

R/W

R/W

R/W

R/W

UINT8

R/W

UINT8

R/W

UINT8

R/W

R/W

UINT8

access value

WW161

WW164

www.microsonic.de

15/F;15/WK/F

range (dez)

306-3,609 (21-248 mm) 1)

320-3,624 (22-249 mm) 1)

335-65,512 (23 - 250 mm) 1)

> 3,638: window mode deactivated

320-65,512 (22 - 250 mm) 1)

> 3.638: window mode deactivated

00: NCC, 02: NOC

00-02: F00 - F02

00-09: P00 - P09

0-1,878 (0-129 mm) 1)

00: deactivated, 16: activated

162

168

yes

8 ms

COM 2 (38.400 Bd)

16 Bit, R, UNI16

Bit 0: state of switched output;

Bit 1-15: distance value with 0,1 mm resolution

index

0x10

0x11

0x12

0X13

0x14

index

0x40

0x41

0x47

0x48

0x42 UINT8

0x43

0x44

0x49

0x4A

index

0x02

0x02

0x02

0x02

access value

RRmicrosonic GmbH

RRpico+

R Ultraschall-Sensor

access

R/W

R/W

R/W

R/W

R/W

UINT8

R/W

UINT8

R/W

UINT8

R/W

R/W

UINT8

access value

WW161

WW164

pico+25...

www.microsonic.de

25/F;25/WK/F

range (dez)

436-5,065 (30 - 348 mm) 1)

451-5,080 (31 - 349 mm) 1)

00: NCC, 02: NOC

00-02: F00 - F02

00-09: P00 - P09

0-3,246 (0-223 mm) 1)

00: deactivated, 16: activated

162

168

yes

16 ms

COM 2 (38.400 Bd)

16 Bit, R, UNI16

Bit 0: state of switched output;

Bit 1-15: distance value with 0,1 mm resolution

index

0x10

0x11

0x12

0X13

0x14

index

0x40

0x41

0x47

0x48

0x42 UINT8

0x43

0x44

0x49

0x4A

index

0x02

0x02

0x02

0x02

access value

RRmicrosonic GmbH

RRpico+

R Ultraschall-Sensor

access

R/W

R/W

R/W

R/W

R/W

UINT8

R/W

UINT8

R/W

UINT8

R/W

R/W

UINT8

access value

WW161

WW164

www.microsonic.de

35/F;35/WK/F

range (dez)

946-8,704 (65 - 598 mm) 1)

961-8,718 (66 - 599 mm) 1)

00: NCC, 02: NOC

00-02: F00 - F02

00-09: P00 - P09

0-4,236 (0-291 mm) 1)

00: deactivated, 16: activated

162

168

yes

20 ms

COM 2 (38.400 Bd)

16 Bit, R, UNI16

Bit 0: state of switched output;

Bit 1-15: distance value with 0,1 mm resolution

index

0x10

0x11

0x12

0X13

0x14

index

0x40

0x41

0x47

0x48

0x42 UINT8

0x43

0x44

0x49

0x4A

index

0x02

0x02

0x02

0x02

access value

RRmicrosonic GmbH

RRpico+

R Ultraschall-Sensor

access

R/W

R/W

R/W

R/W

R/W

UINT8

R/W

UINT8

R/W

UINT8

R/W

R/W

UINT8

access value

WW161

WW164

www.microsonic.de

100/F;100/WK/F

range (dez)

1,747-18,892 (120 - 1,298 mm) 1)

1,761-18,907 (121 - 1,299 mm) 1)

00: NCC, 02: NOC

00-02: F00 - F02

00-09: P00 - P09

0-12,969 (0-891 mm) 1)

00: deactivated, 16: activated

162

168

Loading...

Loading...