Page 1

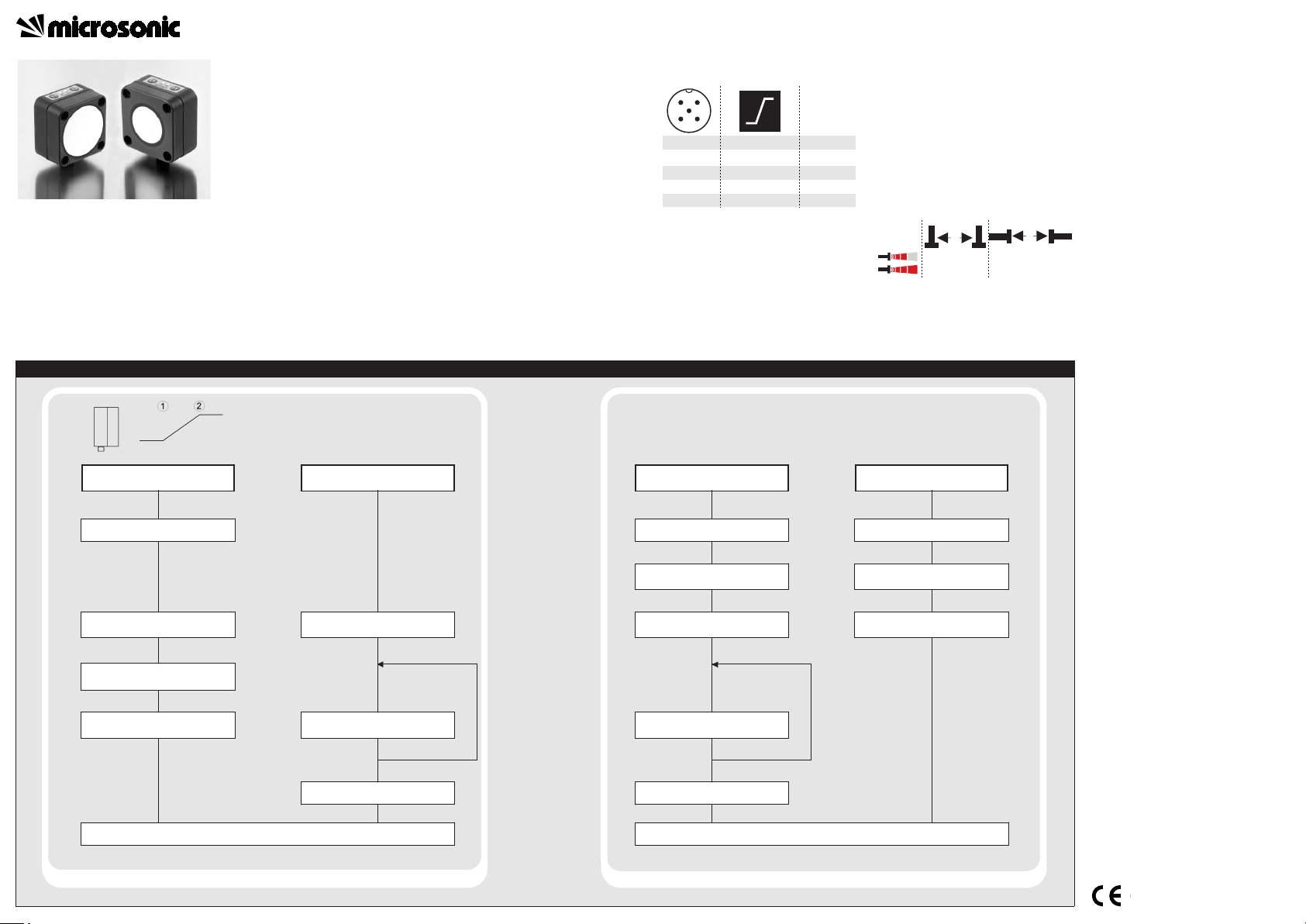

Sensor adjustment with Teach-in procedure

Set window margins

Place object at position 1.

Press T1 until both LEDs flash

simultaneously

(ca. 3 s).

Both LEDs:

Place object at position 2

flash

mutually

Press T1 for about 1 s

Set rising/falling output

characteristic curve

Press T1 until both LEDs flash

mutually

(ca. 13 s).

LED D2:

LED D1:

To change output characteristic press T1

for about 1 s.

flashes

on: rising /

off: falling output

characteristic curve

Activate/deactivate Teach-in

Turn OFF power supply.

Reset to factory setting

Turn OFF power supply.

While pressing T1 turn ON power suply.

Keep T1 pressed until both LEDs flash

simultaneously

(ca. 3 s).

LED D2:

LED D1:

To activate or deactivate Teach-in press

T1 for about 1 s.

flashes

on: Teach-in activated

off: Teach-in deactivated

While pressing T1 turn ON power suply.

Keep T1 pressed until both LEDs flash

mutually

(ca. 13 s).

Normal mode operation

Wait for 10 s.

Wait for 10 s.

Normal mode operation

1

3

colour

+U

B

-U

B

brown

blue

4

2

5

-

I|U

black

white

Com grey

1

5

2

34

≥ 2,00 m ≥ 18,00 m

≥ 4,00 m

≥ 30,00 m

A

B

Ultrasonic Sensors

Set analogue output

Further Settings

2004/108/EC

Operating Instructions

Ultrasonic sensor with one

analogue output

lcs+340/IU

lcs+600/IU

Product description

The lcs+ sensor offers a non-contact

measurement of the distance to an object that has to be present within the

sensor’s detection zone. Depending on

the set window limits, a distance-proportional analogue signal is output.

The window limits of the analogue

output and its characteristic can be

adjusted with the Teach-in procedure.

One 2-colour LED indicates the state

of the analogue output.

The sensor automatically detects the

load put to the analogue output and

switches to current output or voltage

output respectively.

Optionally all Teach-in and additional

sensor parameter settings can be

made using the LinkControl Adapter

LCA-2 (optional accessory) and the

LinkContol software for windows.

Safety instructions

Read the operating instructions

prior to start-up.

Connection, installation and ad-

justments may only be carried out

by qualified staff.

No safety component in

accordance with the EU Machine

Directive

Use for intended purpose only

lcs+ ultrasonic sensors are used for

non-contact detection of objects.

Installation

Mount the sensor at the place of

fitting.

Connect a connection cable to the

M12 device plug

Start-up

Connect the power supply.

Carry out sensor adjustment in

accordance with the diagram.

Fig. 1: Pin assignment with view onto sensor

plug and colour coding of the

microsonic connection cable

Factory Setting

Rising analogue characteristic

curve.

Window limits between blind

zone and operating range.

Synchronisation

If under multiple sensor operation

the assembly distance falls below the

values shown in Fig. 2, the internal

synchronisation should be used. For

this purpose interconnect each pin 5

of maximum 10 sensors to be synchronised.

Fig. 2: Assembly distances

Maintenance

microsonic sensors are maintenancefree. In case of excess caked-on dirt

we recommend cleaning the white

sensor surface.

Notes

The sensors of the lcs+ family have

a blind zone, within which a distance measurement is not possible.

The lcs+ sensors are equipped

with an internal temperature compensation. Due to the sensors self

heating, the temperature compensation reaches its optimum working-point after approx. 30 minutes

of operation.

The load put to the analogue out-

put is detected automatically

when turning power supply on.

If an object is within the set

window margins of the analogue

output, then LED D1 lights up

green, if the object is outside the

window margins, then LED D1

lights up red.

If no push-buttons are pressed for

20 seconds during parameter setting mode the made changes are

stored and the sensor returns to

normal mode operation.

The sensor can be reset to its fac-

tory setting (see »Sensor adjustment with Teach-in procedure«).

Optionally all Teach-in and addi-

tional sensor parameter settings

can be made using the LinkControl adapter (optional accessory)

and the LinkControl software for

windows.

Page 2

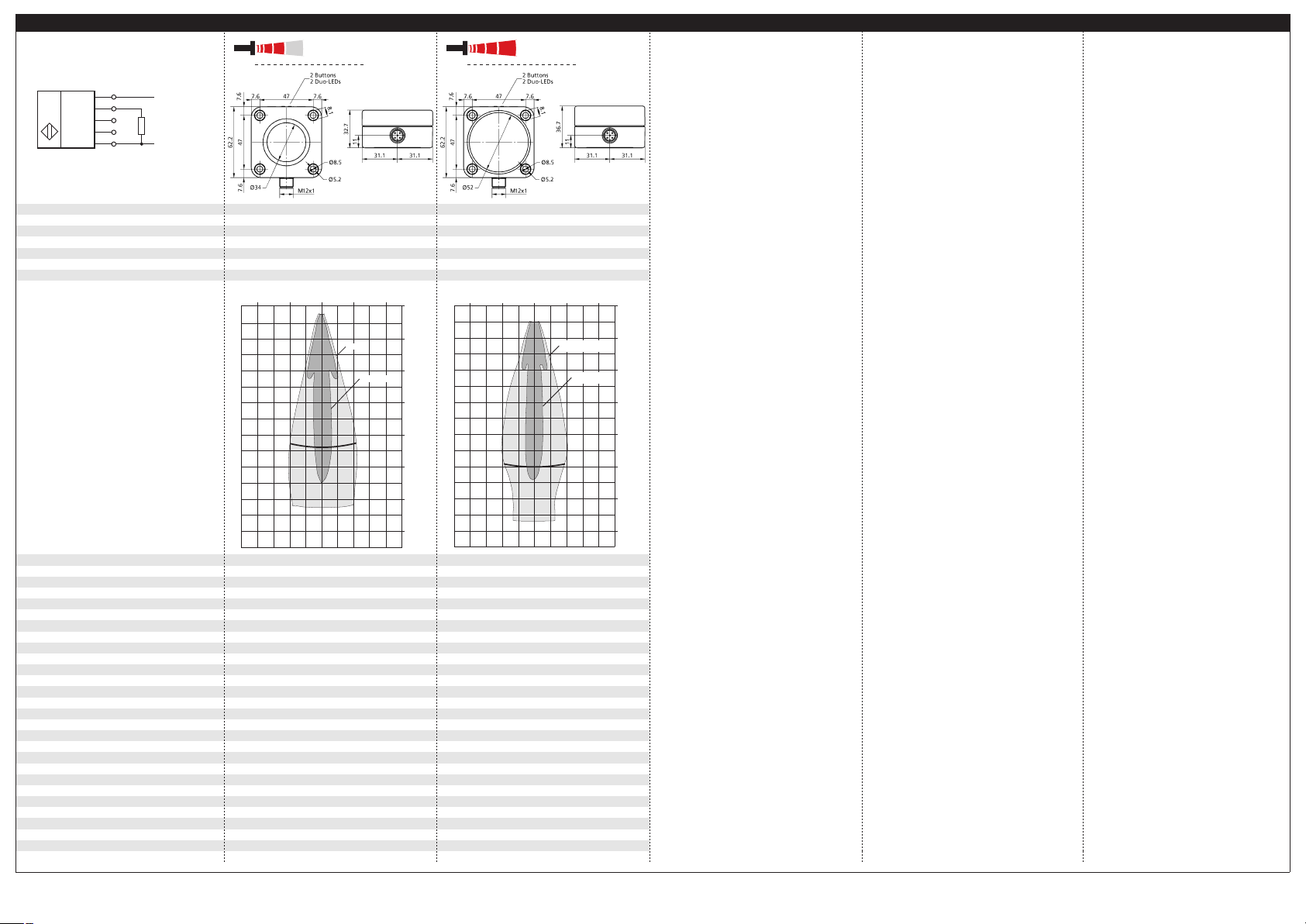

Technical data

blind zone

operating range

maximum range

angle of beam spread

0 to 350 mm

3,400 mm

5,000 mm

see detection zone

transducer frequency

resolution

detection zones

for different objects:

The dark grey areas represent the zone

where it is easy to recognise the normal

reflector (round bar). This indicates the typical

operating range of the sensors. The light

grey areas represent the zone where a

very large reflector – for instance a

plate – can still be recognized. The

requirement here is for an optimum

alignment to the sensor. It is not

possible to evaluate ultrasonic

reflections outside this area.

120 kHz

0.18 mm to 1.5 mm, depending on the

analogue window

reproducibility

accuracy

operating voltage U

± 0.15 %

±1 % (temperature drift internally compensated; may

be deactivated, 0,17 %/K without compensation)

9 V to 30 V DC, reverse polarity protection

voltage ripple

no-load current consumption

housing

±10 %

≤ 60 mA

PBT, Polyester; ultrasonic transducer:

polyurethane foam, epoxy resin with glass content

class of protection per EN 60 529

type of connection

controls

programmable

IP 67

5-pin M12 circular plug, PBT

2 push-buttons

• Teach-in via push-buttons

indicator

synchronisation

operating temperature

• LCA-2 with LinkControl

LED D1

green/red (object within/outside margins)

internal synchronisation up to 10 sensors

-25°C to +70°C

storage temperature

weight

response time

1)

time delay before availability

1)

-40°C to +85°C

180 g

172 ms

< 450 ms

norm conformity

order no.

current output 4 - 20 mA

EN 60947-5-2

lcs+340/IU

RL ≤ 100 Ω at 9 V ≤ UB ≤ 15 V;

voltage output 0 - 10 V

RL ≤ 500 Ω at UB ≥ 15 V

rising/falling output characteristic

RL ≥ 100 kΩ at UB ≥ 15 V, short-circuit-proof

rising/falling output characteristic

1) Can be programmed with LinkControl

analogue output

+U

B

-U

B

IU

Sync/Com

1

2

4

5

3

U

lcs+340...

0 m

0,8 m

1,6 m

2,4 m

3,2 m

4 m

4,8 m

5,6 m

3,4 m

plate

round bar

1,6 m

0,8 m

0 m

0,8 m

1,6 m

MV-DO-121025-438274

microsonic GmbH | Hauert 16 | 44227 Dortmund | Germany | telefone +49 2 31 / 97 51 51-0 | telefax +49 2 31 / 97 51 51-51 | e-mail: info@microsonic.de | www.microsonic.eu

The content of this document is subject to technical changes. Specifications in this document are presented in a descriptive way only. They do not confirm any product features.

lcs+600...

0 to 600 mm

6,000 mm

8,000 mm

see detection zone

80 kHz

0.18 mm to 2.4 mm, depending on the

analogue window

1,2 m

0 m

1,2 m

2,4 m

2,4 m

0 m

plate

± 0.15 %

±1 % (temperature drift internally compensated; may

be deactivated, 0,17 %/K without compensation)

9 V to 30 V DC, reverse polarity protection

±10 %

≤ 60 mA

PBT, Polyester; ultrasonic transducer:

polyurethane foam, epoxy resin with glass content

IP 67

5-pin M12 circular plug, PBT

2 push-buttons

• Teach-in via push-buttons

• LCA-2 with LinkControl

LED D1

green/red (object within/outside margins)

internal synchronisation up to 10 sensors

-25°C to +70°C

-40°C to +85°C

240 g

240 ms

< 450 ms

EN 60947-5-2

lcs+600/IU

≤ 100 Ω at 9 V ≤ UB ≤ 15 V;

R

L

RL ≤ 500 Ω at UB ≥ 15 V

rising/falling output characteristic

RL ≥ 100 kΩ at UB ≥ 15 V, short-circuit-proof

rising/falling output characteristic

round bar

1,2 m

2,4 m

3,6 m

4,8 m

6 m

7,2 m

8,4 m

Loading...

Loading...