Page 1

Operating Instructions

Ultrasonic label ans splice sensor

with 2 switched outputs

esp-4/3CDD/M18 E+S

esp-4/3BEE/M18 E+S

esp-4/M12/3CDD/M18 E+S

esp-4/M12/3BEE/M18 E+S

Functional principle

With a rapid pulse sequence, an

ultrasonic transmitter beams

upwards against the backing

material. The effect of the sound

pulses inducing the backing material

to vibrate is for a markedly

weakened sonic wave to be emitted

on the opposite side. The receiver

receives this sonic wave and analyses

it.

The backing material signal level is

different to that of the label or

splice. And this difference in signal is

analysed by the esp-4. The difference

between backing material and label

and/or between sheeting and splice

can be very slight indeed. To ensure

certainty with the difference, teachin for the esp-4 sensor must firstly

revolver around the signal level for

the backing material/sheeting.

The esp-4 sensors can be used as a

label and splice sensor. The 3 teachin methods permit the esp-4 sensor

to be optimally set for each and

every assignment.

Ultrasonic sensors

Product description

■ Assured detection of labels made

of paper, metal or (transparent)

plastic.

■ Detection of splices of paper web,

plastic web or metal web.

■ Label/splice and web break output

as pnp or npn switched outputs.

■ Scanning of material weights from

<60 g/m2 to >>600 g/m2; sheet

metals and plastic films up to 0,6

mm thickness.

■ 3 Teach-in modes.

■ Synchronisation.

■ Parametrization via LinkControl.

■ Response time of 300 µs until

lable/splice is detected.

■ Transmitter - receiver spacing can

be selected from 20 to 40 mm

Safety tips

■ Read the operating instructions

before start-up.

■ Only qualified personnel are to

undertake connection, mounting

and settings.

■ Not a safety component in

keeping with the EC Machinery

Directive.

Mounting

▸ Mount transmitter and receiver in

keeping with Fig 1 at the

recommended spacing of 40 mm

± 3 mm (or 20 mm ± 2 mm with

esp-4/M12/...E+S).

esp-4 can be fitted at any position.

▸ Connect the transmitter to the

receiver using the M8 connector.

▸ Connect the receiver 7-strand

control line in keeping with Fig 2.

Fig. 2: Colour coding of the control line

Pointer

■ The coaxiality of transmitter and

receiver must be ≤ 0.5 mm.

■ Transmitter and receiver are not to

be inclined to each other in excess

of 2°.

■ In case of thicker plastic films the

esp-4 is to be mounted at a 27°

inclination to sheet normal (Fig.

1b).

■ Other materials may make a special fitting position necessary. Do

contact microsonic when you

work with these special materials.

■ The max. torque of the nuts is 15

Nm for the M18 and 8 Nm for the

M12 sleeves respectively.

■ The drill hole must be ≥ 12 mm

given that the transmitter is

recess-mounted or a sheet feed is

envisaged between transmitter

and receiver.

■ The line between transmitter and

receiver is not to be bridged with

an external potential.

Start-up

▸ For normal opperation mode leave

all the 3 control inputs

unconnected (see Figs 3 and 4).

▸ Switch on the esp-4 voltage sup-

ply.

Fig. 3: Function of control inputs

+U

B

-U

B

Colour

Brown

Blue

lable/splice output D1

web break output D2

control input C1

control input C2

White

Black

Violet

Pink

control input C3 Grey

Input

C1

C2

Function

Teach-in

Automatic tracking on/off

C3 Synchronization/communication

1) C3 must not be connected to -U

B

Fig. 4: Assignment of control inputs

Teach-in

Teach-in is carried out via contol input C1.

There are 3 Teach-in methods:

■ Dynamic teach-in of backing material and label

■ Separate teach-in for backing material and labels

■ Teach-in only for sheeting

▸ Place the web material between

transmitter and receiver of the

esp-4 and carry out one of the 3

Teach-in methods.

Pointer

■ During Teach-in the control input

C2 has to be left unconnected or

connected to -UB and C3 has to

be unconnected.

Operation

The esp-4 performs measurements

cyclically and depending on the

measurement result it sets the two

switched outputs.

The automatic tracking can be put

on/off during runnig operation.

The conditions of LED 1 and 2 are

shown in Fig. 6.

Fig. 5: Voltage level of the logic states at

the control inputs

Mode

normal

operation

Teach-in

C1 C2

open

or -U

B

See »Te-

ach-in

modes«

open

or -U

B

open

or -U

B

C3

open

1

open

1

automatic

tracking

sychronization

automatic

tracking

and synchronization

open

or -U

B

open

or -U

B

+U

B

open

or -U

B

open

or -U

B

+U

B

open

1

C3 con-

nected

with

each

other

C3 con-

nected

with

each

other

Logical state

0

Voltage level

pnp

-U

B

npn

+U

B

1

+UB-U

B

Fig. 6: LED displays

Factory setting

The esp-4 are delivered with the

following factory settings:

■ Output label/splice output D1 on

NOC.

■ Output D2 on fuction web break.

■ Ouput web break on NOC.

■ 40 or 20 mm spacing.

■ Operation mode on automatic

tracking on/off via input C2.

Automatic tracking

After a Teach-in the esp-4 can track

the working point automatically. In

this way variations in the material to

be scanned and fluctuation in the

ambient temperature can be compensated.

Via control input C2 the automatic

tracking can be put on and off.

Condition

operation

backing

material

LED 1 LED 2

Green

Green

Green

Green

label/splice

web break

Teach-in

Teach-in

dismissed

Red

Green

Green

Red flashing

See »Teach-in methods«

Green Red flashing

Synchronization

If two or more esp-4 shall work close

together they may influence one

another. To avoid this the esp-4 can

be synchronized. To do this all contol

inputs C3 have to be connected with

each other.

Parameterization with

LinkControl

The esp-4 can be extensively

parameterized under LinkControl.

Here you need the optionally

available LinkControl adapter LCA-2

and the LinkControl software for

Windows©.

Operation onto LinkControl

▸ Install the LinkControl software

onto your PC.

Connect the LinkControl adapter

to your PC with the USB cable.

▸ Connect esp-4 to the LCA-2 in

keeping with the Fig 7 table. For

this, use the adapter cable in the

LCA-2 case.

▸ Connect the voltage supply cable

to the LCA-2 on the other side of

the T connector.

▸ Start the LinkControl software and

follow the instructions on the

screen.

Fig. 1: Mounting and installation positions

Page 2

Fig. 7: Connecting dbk+4 to the LCA-2

+UB-U

B

Colour

esp4

Colour

adapter cable

Brown

Blue

Brown

Blue

Pin

1

3

C3/Com Grey Grey 5

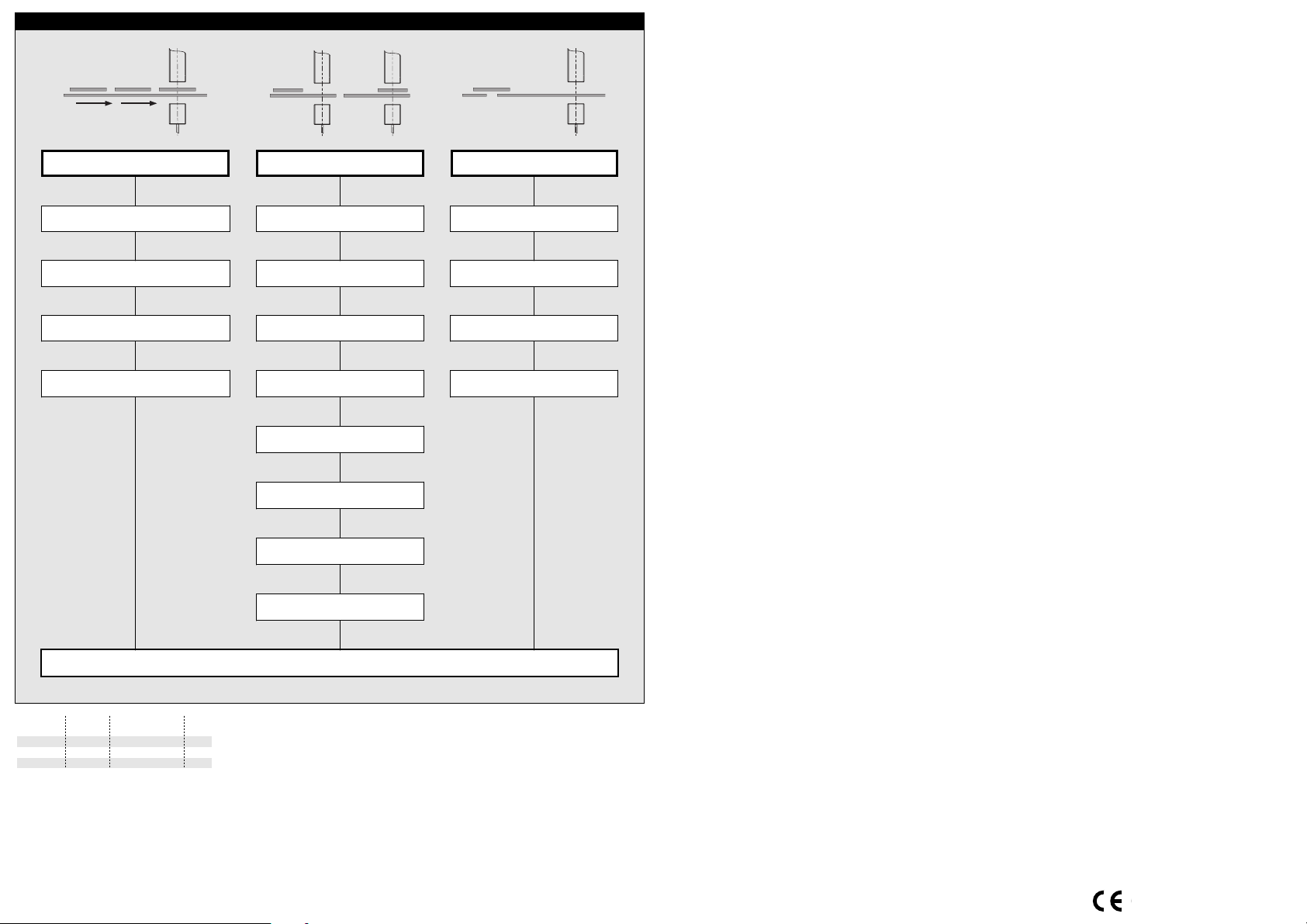

Teach-in methods

Teach-in label dynamic

Place backing material with label between transmitter

and receiver.

Teach-in label static

a) Place only backing material between

transmitter and receiver.

Teach-in only for sheeting

(splice sensor)

Place web material between transmitter

and receiver.

Place control input C1 on logic 1 for 3 s until both LED

flash mutualy.

Pull backing material with labels among transmitter

and receiver with constant speed.

both LED flash green

simultaneously

Place control input C1 on logic 1 for 1 s.

one LED flashes green briefly,

one LED is static green

one LED is static green,

one LED flashes green

Place control input C1 on logic 1 for 6 s until

one LED turns off and one LED is on.

Pull only backing material among transmitter

and receiver.

one LED flashes green,

one LED is static green

Place control input C1 on logic 1 for 1 s.

b) Place backing material with label between

transmitter and receiver.

one LED flashes green briefly,

one LED is static green

one LED is static green,

one LED flashes green

Place control input C1 on logic 1 for 9 s until

both LEDs turn off.

Pull web material among transmitter

and receiver.

one LED flashes green briefly,

one LED is static green

Place control input C1 on logic 1 for 1 s.

one LED flashes green briefly,

one LED is static green

one LED is static green,

one LED flashes green

Normal operation

Place control input C1 on logic 1 for 1 s.

Move backing material with label between

transmitter and receiver.

one LED flashes green briefly,

one LED is static red

one LED flashes green,

one LED is static green

Place control input C1 on logic 1 for 1 s.

one LED flashes green briefly,

one LED is static green

one LED flashes green,

one LED is static green

!"

#"

The following settings can be

undertaken:

■ Teach-in of web or label material.

■ Spacing between transmitter and

receiver.

■ NOC/NCC function of the

switched outputs.

■ Function of switched output D2.

some isopropanol onto a cotton

cloth and then wipe the surface

clean. Make sure that the reaction

Also available is a diagrammatic

representation of the readings.

time of the cleaner is kept down.

That means quickly wiping dry the

transducer surfaces.

Maintenance

No maintenance is need on the esp-

4. We would recommend cleaning

the sensor surfaces at the transmitter

and receiver should they become

very dirty. The best thing is to apply

2004/108/EC

Page 3

Technical data

esp-4/3.../M18 E+S esp-4/M12/3.../M18 E+S

Spacing transmitter-receiver

Optimum spacing transmitter-receiver

Blind zone (in front of transmitter and receiver)

Permissible angular deviation

20 to 40 mm

40 mm ± 3 mm

20 to 30 mm

20 mm ± 3 mm

7 mm

10°-27° from the perpendicular of the sheet

5 mm

10°-27° from the perpendicular of the sheet

Ultrasonic frequency

Working range

Operating voltage U

B

400 kHz

web material with grammages of < 20 g/m2 to

500 kHz

web material with grammages of < 20 g/m2 to

>>600 g/m2; paper, metal, plastic

20 V to 30 V DC

>>600 g/m2; paper, metal, plastic

20 V to 30 V DC

Voltage ripple

No-load current consumption

Type of connection

Transmitter-receiver connection

± 10 %

≤ 50 mA

± 10 %

≤ 50 mA

2 m PUR cable, 7 x 0,25 mm

2

At receiver: PUR, 1,2 m;

2 m PUR cable, 7 x 0,25 mm

2

At receiver: PUR, 1,2 m;

Controls

at transmitter: 1 m, PUR; both with M8 connector at transmitter: 1 m, PUR; both with M8 connector

Connection cable to external ultrasonic transducer:

3 Control inputs: C1 to C3

PVC, 1,2 m

3 Control inputs: C1 to C3

Programmable

Response time

Teach-in, LinkControl

300 µs - 2,25 ms, depending on the grammages

Teach-in, LinkControl

300 µs - 2,25 ms, depending on the grammages

Indicator

Housing

Green: working/backing material

Red: label/splice

Green: working/single sheet

Red: double sheet

Red flashing: web break

Brass sleeve, nickel-plated; plastic parts: PBT, PA;

Red flashing: missing sheet

Brass sleeve, nickel-plated; plastic parts: PBT, PA;

Max. tightening torque of nuts

Class of protection to EN 60529

Cable: PUR; ultrasonic transducer:

Polyurethane, epoxy resin with glass content

Cable: PUR/PVC; ultrasonic transducer:

Polyurethane, epoxy resin with glass content

M18: 15 Nm

IP 65

M18: 15 Nm; M12: 8 Nm

IP 65

Operating temperature

Storage temperature

Weight

Norm conformity

+5 °C to +60 °C

-40 °C to +85 °C

+5 °C to +60 °C

-40 °C to +85 °C

130 g

EN 60947-5-2

160 g

EN 60947-5-2

Order no.

Double sheet output

esp-4/3CDD/M18 E+S esp-4/M12/3CDD/M18 E+S

pnp, +UB-2 V, I

max.

= 200 mA, short circuit proof,

switchable NOC/NCC

pnp, +UB-2 V, I

max.

= 200 mA, short circuit proof,

switchable NOC/NCC

Missing sheet output

UE at control inputs C1-C

3

pnp, +UB-2 V, I

max.

= 200 mA, short circuit proof,

switchable NOC/NCC

pnp, +UB-2 V, I

max.

= 200 mA, short circuit proof,

switchable NOC/NCC

> -UB+18 V: logical 1

< -UB+13 V or control input open: logical 0

> -UB+18 V: logical 1

< -UB+13 V or control input open: logical 0

Time delay before availibility

Order no.

Double sheet output

< 300 ms < 300 ms

esp-4/3BEE/M18 E+S

npn, -UB+2 V, I

max.

= 200 mA, short circuit proof,

esp-4/M12/3BEE/M18 E+S

npn, -UB+2 V, I

max.

= 200 mA, short circuit proof,

Missing sheet output

UE at control inputs C1-C

3

switchable NOC/NCC

npn, -UB+2 V, I

max.

= 200 mA, short circuit proof,

switchable NOC/NCC

npn, -UB+2 V, I

max.

= 200 mA, short circuit proof,

switchable NOC/NCC

< -UB+6 V: logical 1

switchable NOC/NCC

< -UB+6 V: logical 1

Time delay before availibility

1)

Can be programmed with LinkControl

> -UB+10 V or control input open: logical 0

< 750 ms

> -UB+10 V or control input open: logical 0

< 750 ms

Brown

White

Black

Violet

Blue

2 pnp switched outputs

U

Pink

Grey

+UB

D2

D1

C1

C2

C3

-UB

Brown

White

Black

Violet

Blue

2 npn switched outputs

U

Pink

Grey

+UB

D2

D1

C1

C2

C3

-UB

MV-DO-108284-290059

microsonic GmbH • Hauert 16 • D-44227 Dortmund • Tel: +49 2 31 / 97 51 51-0 • Fax: +49 2 31 / 97 51 51-51 • E-Mail: info@microsonic.de • www.microsonic.deThe content of this document is subject to technical changes. Specifications in this document are presented in a descriptive way only. They do not warrant any product features.

Loading...

Loading...