Page 1

Operating Instructions

Ultrasonic double sheet detection

with 2 switched outputs

dbk+5/3CDD/M18 E+S

dbk+5/3BEE/M18 E+S

Functional principle

The function of the double sheet detection is to detect two or more

sheets or other laminary materials lying one on top of the other. The sensor system consists of a transmitter

and a receiver complete with integrated evaluation electronics.

A high-frequency ultrasonic transmitter beams from the underside

against the sheet material. The emitted ultrasonic pulse excites the sheet

material into vibrations. The effect of

these vibrations is for a very small

sonic wave on the other side of the

sheet to spread. This wave is received

by the ultrasonic receiver located

there. In the case of sheet one on

top of the other (double sheet), the

receiver detects the difference in signal and sets its outputs accordingly.

Ultrasonic sensors

Product description

■ Assured detection of single, double and multiple sheet.

■ Scanning of sheet material

weights from 100 g/m2 to 2,000

g/m2, corrugated cards, sheet metals, printed circuit boards, films

and plastic sheets up to several

mm thickness possible.

■ Double sheet and missing sheet

output as pnp or npn switched

outputs.

■ Vertical mounting to the sheet running through permitted.

■ Three control inputs allow for an

external setting of sensitivity for

the material to be scanned.

■ Changes to sensitivity classes under ongoing operations can be undertaken.

■ Additional teach-in mode e.g. for

scanning wafers glued with a water film.

■ Optional trigger operation mode

e.g. for applications in the shingled stream.

■ Parameterization via LinkControl

■ 0.5 ms response time until a dou-

ble or missing sheet in the trigger

mode is detected.

■ Transmitter-receiver spacing can

be selected from 30 to 70 mm

Safety tips

■ Read the operating instructions

before start-up.

■ Only qualified personnel are to undertake connection, mounting and

settings.

■ Not a safety component in keeping with the EC Machinery Directive.

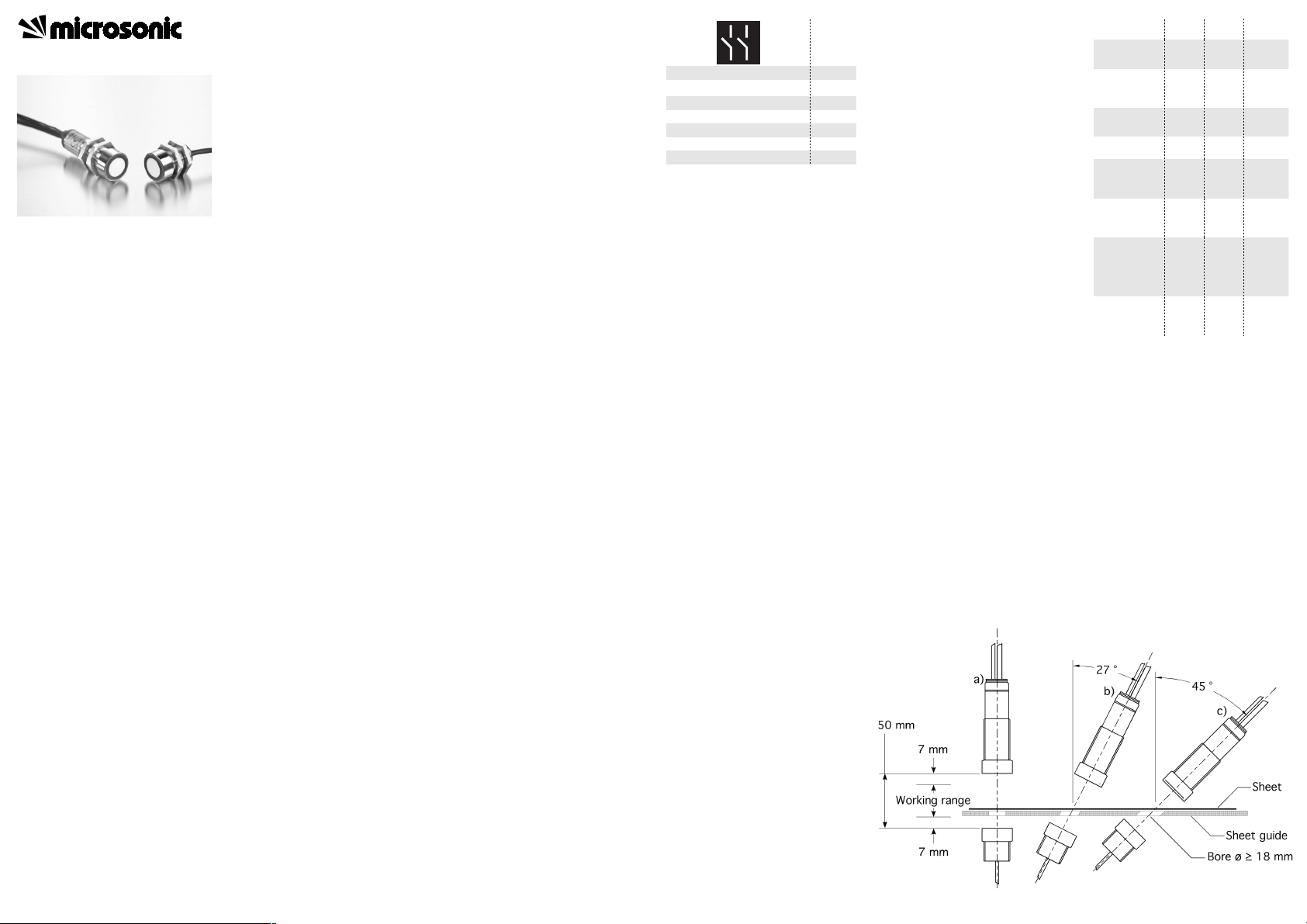

Mounting

▸ Mount transmitter and receiver in

keeping with Fig 1 at the recommended spacing of 50 mm ± 3

mm .

dbk+5 can be fitted at any position .

▸ Connect the transmitter to the re-

ceiver using the M8 connector.

▸ Connect the receiver 7-strand con-

trol line in keeping with Fig 2.

Pointer

■ If required, spacing between trans-

mitter and receiver can be adjusted to the local circumstances in

the 30 to 70 mm range; see under

»Teach-in spacing between transmitter and receiver«.

■ The coaxiality of transmitter and

receiver must be ≤ 0.5 mm.

■ Transmitter and receiver are not to

be inclined to each other in excess

of 2°.

■ Vertical mounting to the sheet is

recommended for papers (Fig 1a).

■ In case of vertical mounting to the

sheet, the spacing between transmitter and/or receiver and the

sheet running through is not to be

under 7 mm.

■ In case of certain sheet metals or

thicker plastic films, the dbk has to

be mounted at an inclination to

sheet normal depending on the

material (Fig. 1b). If necessary the

optimum mounting position has

to be determined in a test.

■ Thick papers and paperboard responsible for faulty switching in

case of vertical mounting can often be scanned at a 27° to 45°

mounting angle to sheet normal.

Corrugated cards have to be measured obliquely to the waves (Fig

1c).

■ Other materials may make a special

fitting position necessary. Do contact microsonic when you work

with these special materials.

■ The max. torque of the nuts is 15

Nm for the M18 sleeves.

■ The drill hole must be ≥ 12 mm

given that the transmitter is recess-mounted or a sheet feed is

envisaged between transmitter

and receiver. The recommendation

is for a 18 mm diameter (see Fig

1).

■ The line between transmitter and

receiver is not to be bridged with

an external potential.

Fig. 2: Colour coding of the control line

Start-up

▸ Select the »Standard« sensitivity

class by placing all the 3 control

inputs onto logic 0 (see Figs 3 and

4) or leave them unconnected.

Switch on the dbk+5 voltage supply.

Pointer

■ The »Standard« sensitivity class

corresponds to the setting of

predecessor model dbk-5.

Check the function with a test sheet.

▸ Hold a single test sheet within the

working range between transmitter and receiver.

The LED must light up green for

"Single sheet detected«. (Should the

LED light up red, then check on the

dbk+5 fitting dimension and the selected test sheet.)

▸ Hold a double test sheet within

the working range between transmitter and receiver.

The LED must light up red for "Double sheet detected«.

▸ Remove all the sheets between

transmitter and receiver.

The LED must flash red for "Missing

sheet detected«.

+U

B

-U

B

Colour

Brown

Blue

Single/missing sheet output

Double sheet output

Control input C1

Control input C2

Black

White

Violet

Pink

Control input C3/Com Grey

Pointer

■ You can use a material of a high

sheet weight as the test sheet or

the test sheet itself obtainable as

an accessory with the »dbk test

sheet« article name. This test

sheet works as critical material at

the ambient temperature in the

»Standard« sensitivity class and

can be used to examine the correct adjustment and function.

Factory setting

The dbk+5 are delivered with the following factory settings:

■ Free-run mode with 3 sensitivity

classes and teach-in

■ Missing sheet output on NCI

■ Double sheet output on NCI

■ 50 mm spacing

Fig. 9: LED displays

Condition

single sheet

single sheet

overmodulation

LED 1 LED 2

Green

Green

Green

Green

+ Red =

Orange

static on

static on

double sheet

missing sheet

Teach-in

activated

Teach-in

dismissed

Red

Red

Red

Red

Green

Red

Green

Red

static on

flashing

flashing

mutually

flashing

mutually

Teach-in spacing transmitter-receiver

Teach-in

dismissed

Red

Red

Green

Red

flashing

mutually

flashing

mutually

Fig. 1: Mounting and installation positions

Page 2

2004/108/EC

Operation in the free-run

mode

The dbk+5 operates in the free-run

mode ex-works. In the free-run

mode, the dbk+5 performs measurements cyclically.

Pointer

■ If measurements should be taken

in the shingled stream, then an external trigger signal can individually trigger each measurement. To

this end, the trigger mode can be

parameterized with the help of

the LCA-2 LinkControl adapter

available as an accessory and the

LinkControl software.

Fig. 3: Voltage level of the logic states at

the control inputs

Sensitivity classes

The fact that the dbk+5 control inputs are unconnected or on logic 0

points to pre-selection of the »Standard« sensitivity class where the

range of sheet material weights from

a typical 100 g/m2 up to 2,000 g/m

2

can be scanned.

■ The 3 control inputs allow the sensitivity classes to be pre-selected in

keeping with the Fig 4 table.

■ The »Thin« setting has to be selected for thin materials.

■ The working range can be enlarged to thicker materials by

choosing the setting »Thick«.

■ Changes between sensitivity

classes can be undertaken under

on-going operations.

■ Pre-selecting an over-low sensitivity class can result – even with a

single sheet – in a double sheet

signal appearing. In such an instance, the next-higher sensitivity

class is to be pre-selected.

■ Pre-selecting an over-high sensitivity class results – given a single

sheet – in the double-sheet detection indicating overmodulation at

the LEDs: one LED lights up green

and the other green-red (orange

Logical state

0

Voltage level

pnp

-U

B

npn

+U

B

1

+UB-U

B

blend). In such an instance, the

next-lower sensitivity class is to be

pre-selected.

Pointer

Parameterization of the D1 switched

output onto the »Overmodulation«

output function achieved with LinkControl software results in the overmodulation signal being additionally

outputted on D1.

Teach-in

The teach-in mode is also available

for materials glued to each other

across their full extent (e.g. two wafers bonded with a water film, a

spline on a paper web) and special

materials which cannot be scanned

with one of the 3 sensitivity classes

▸ Select the teach-in mode (C1 and

C2 on logic 1) in keeping with the

table in Fig 4.

This is the way to teach-in a material:

▸ Place a single sheet of the material

in the working range of the double sheet detection.

▸ Place the C3 control input on logic

1 for a minimum of 3 seconds.

Materials with inhomogeneities

must be moved during the teachin phase so that dbk+5 can detect

them.

Success with a teach-in operation is

shown by a green LED. In instances

of where no material teach-in was

possible, dbk+5 flashes in red. Then

repeat the operation.

▸ On finishing the teach-in opera-

tion, either place the C3 control

input on logic 0 or leave it unconnected.

The material can now be scanned.

Pointer

■ C3 must not be on logic 1 when

the supply voltage is connected.

Fig. 4: Free-run mode: selection of the sen-

sitivity class and Teach-in

Parameterization with LinkControl

The dbk+5 can be extensively parameterized under LinkControl. Here

you need the optionally available

LinkControl adapter LCA-2 and the

LinkControl software for Windows©.

Operation onto LinkControl

▸ Install the LinkControl software

onto your PC.

Connect the LinkControl adapter

to your PC with the USB cable.

▸ Connect dbk+5 to the LCA-2 in

keeping with the Fig 5 table. For

this, use the adapter cable in the

LCA-2 case.

▸ Connect the voltage supply cable

to the LCA-2 on the other side of

the T connector.

▸ Start the LinkControl software and

follow the instructions on the

screen.

Fig. 5: Connecting dbk+5 to the LCA-2

The following settings can be undertaken:

■ Numeric input of the spacing between transmitter and receiver

■ Function for the D1 switched output

Missing sheet = NCC (single sheet

= NCO) or

Missing sheet = NCO (single sheet

= NCC) or

Overmodulation = NCC or

Overmodulation = NOC

Standard

Thick

C1 C2

000

1

C3

0

0

Thin

Teach-in-Mode

Teach-in active

110

1

1 1

0

0

1

+UB-U

B

Colour

dbk+5

Colour

adapter cable

Brown

Blue

Brown

Blue

Pin

1

3

C3/Com Grey Grey 5

■ Function for the D2 switched output

Double sheet = NCI or

Double sheet = NCO

■ Operating mode

Free-run mode with 3 pre-defined

sensitivity classes and additional

teach-in mode or

Free-run mode with 4 independent teach-in classes or

Trigger mode with 2 pre-defined

sensitivity classes and additional

teach-in mode or

Edge- or level-controlled trigger

mode

Also available is a diagrammatic representation of the readings.

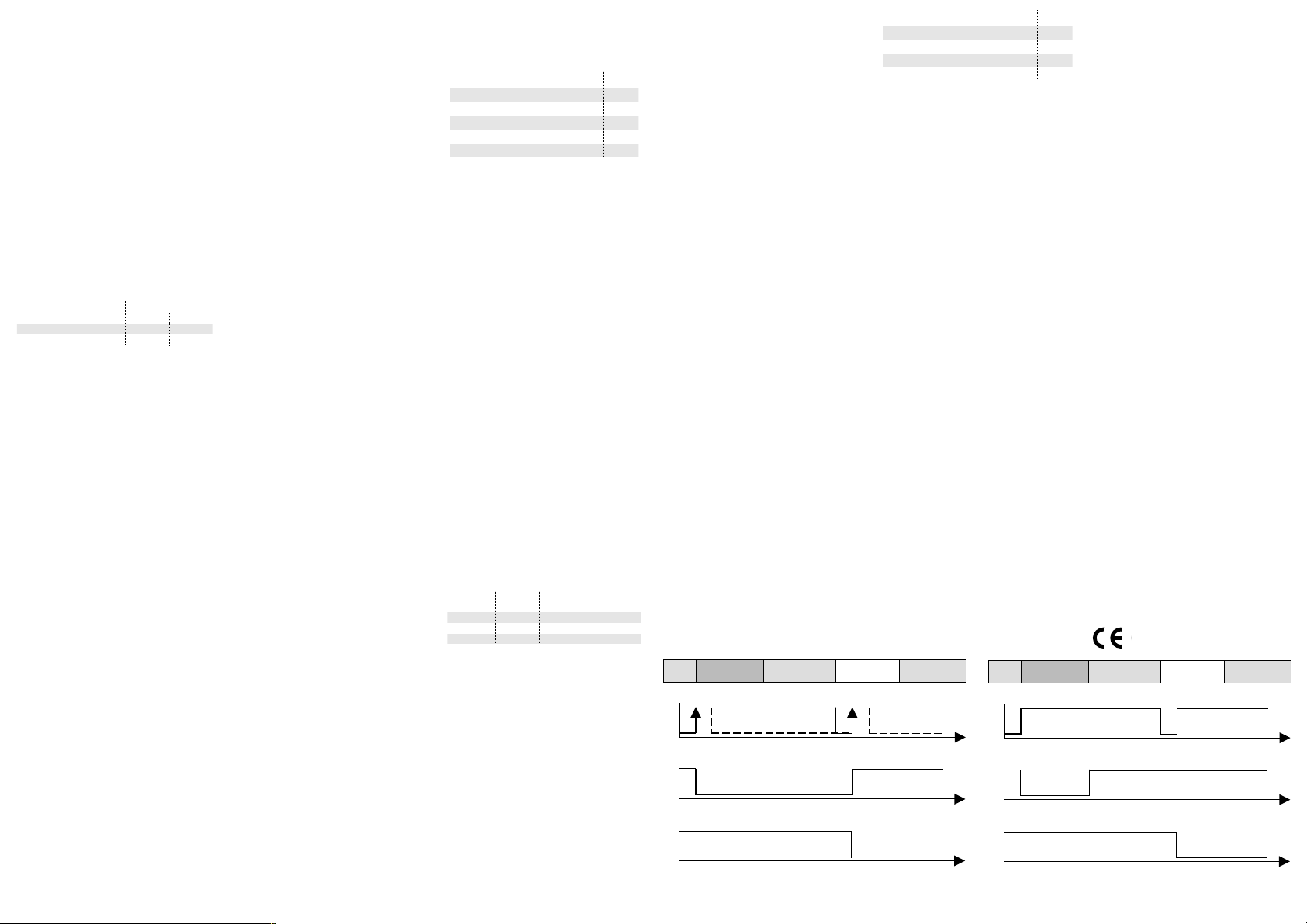

Operation in the trigger

mode

If LinkControl was used to parameters the trigger mode, then the external trigger signal is to be placed on

the C2 control input.

Available in the trigger mode are

sensitivity classes »Standard«, »Thin«

and the teach-in mode in keeping

with the Fig 6 table.

In the edge-controlled trigger setting

(see Fig 7), the double sheet detection takes a measurement with every

edge from 0 to 1. The finding is then

stored until the next trigger edge.

Fig. 6: Trigger mode: selection of the sensi-

tivity class and teach-in mode

In the level-controlled trigger mode,

dbk+5 keeps on taking measurements for as long as the trigger signal is on hand. With dbk+5 deactivated (C2 control input to logic 0),

the reading of the last measurement

at the switched outputs is frozen (see

Fig 8).

Free-run mode with 4 independent teach-in classes

Parameterization with the aid of

LinkControl of the free-run mode

with 4 independent teach-in classes

makes teach-in possible for up to 4

different materials. As a result, the

»Standard«, »Thick«, »Thin« and

»Teach-in mode« sensitivity classes

can be individually adjusted (see online help in LinkControl).

Teach-in spacing between

transmitter and receiver

Teach-in of the selected spacing between transmitter and receiver must

be undertaken should you not have

mounted transmitter and receiver at

the recommended 40 mm or 30 mm

spacing.

▸ Clear the measuring section of

sheet materials between transmit-

Standard

Thick

C1 C2

00Trigger

Trigger

C3

0

1

Teach-in-Mode

Teach-in active11

Trigger

Trigger01

ter and receiver.

Place all the 3 control inputs on

logic 1.

Switch on the supply voltage: The

LEDs flash alternately red and

green.

Wait at least 2 seconds.

Place the C3 control input on logic

0.

Pointer

■ Any failure to teach-in the set

spacing results in dbk+5 flashing

in red for 3 seconds.

dbk+5 is operating normally. Finally,

select the requested type of operation through the control inputs.

Maintenance

No maintenance is need on the double sheet detection. We would recommend cleaning the sensor surfaces at the transmitter and receiver

should they become very dirty. The

best thing is to apply some isopropanol onto a cotton cloth and then

wipe the surface clean. Make sure

that the reaction time of the cleaner

is kept down. That means quickly

wiping dry the transducer surfaces.

Double sheet Missing sheetSingle sheet

Assingnment

1

0

t

1

0

t

1

0

t

Control input C2

Double sheet output

Missing sheet output

Double sheet Missing sheetSingle sheet

Assingnment

1

0

t

1

0

t

1

0

t

Control input C2

Double sheet output

Missing sheet output

Fig.7: Trigger mode edge-controlled Fig. 8: Trigger-mode level-controlled

Page 3

Te ch n ic a l d at a

dbk+5/3CDD/M18 E+S dbk+5/3BEE/M18 E+S

Spacing transmitter-receiver

Optimum spacing transmitter-receiver

Blind zone (in front of transmitter and receiver)

Permissible angular deviation

30 to 70 mm

50 mm ± 3 mm

30 to 70 mm

50 mm ± 3 mm

7 mm

±45° from the perpendicular of the sheet

7 mm

±45° from the perpendicular of the sheet

Ultrasonic frequency

Working range

200 kHz

papers with grammages of 100 g/m2 to

200 kHz

papers with grammages of 100 g/m2 to

2,000 g/m2; metal-laminated sheets and films

up to 5 mm thickness, self-adhesive films, sheet

2,000 g/m2; metal-laminated sheets and films

up to 5 mm thickness, self-adhesive films, sheet

Operating voltage U

B

Voltage r ip ple

metals up to 2 mm thickness, corrugated

cardboard, wafer, printed circuit boards

metals up to 2 mm thickness, corrugated

cardboard, wafer, printed circuit boards

20 V to 30 V DC

± 10 %

20 V to 30 V DC

± 10 %

No-load current consumption

Ty pe of co n ne c ti o n

Tra ns mi tt er -r ec ei ve r con ne ct io n

≤ 50 mA

2 m PUR cable, 7 x 0,25 mm

2

≤ 50 mA

2 m PUR cable, 7 x 0,25 mm

2

At receiver: PUR, 1,2 m;

at transmitter: 1 m, PUR; both with 3-pin M8 plug

At receiver: PUR, 1,2 m;

at transmitter: 1 m, PUR; both with 3-pin M8 plug

Controls

Programmable

3 Control inputs: C1 to C3

Selection of sensitivity classes, Teach-in, LinkControl

3 Control inputs: C1 to C3

Selection of sensitivity classes, Teach-in, LinkControl

< 500 µs

5,5 ms

< 500 µs

5,5 ms

Release delay Trigger-Mode

Indicator

Until next edge

5,5 ms

Until next edge

5,5 ms

Green: working/single sheet

Red: double sheet

Green: working/single sheet

Red: double sheet

Housing

Red flashing: missing sheet

Brass sleeve, nickel-plated; plastic parts: PBT, PA;

Red flashing: missing sheet

Brass sleeve, nickel-plated; plastic parts: PBT, PA;

Cable: PUR; ultrasonic transducer:

Polyurethane, epoxy resin with glass content

Cable: PUR; ultrasonic transducer:

Polyurethane, epoxy resin with glass content

Max. tightening torque of nuts

Class of protection to EN 60529

Operating temperature

Storage temperature

15 Nm

IP 65

15 Nm

IP 65

+5 °C to +60 °C

-40 °C to +85 °C

+5 °C to +60 °C

-40 °C to +85 °C

Weight

Norm conformity

Order no.

150 g

EN 60947-5-2

150 g

EN 60947-5-2

dbk+5/3CDD/M18 E+S dbk+5/3BEE/M18 E+S

Double sheet output

Missing sheet output

pnp, +UB-2 V, I

max.

= 200 mA, short circuit proof,

switchable NCO/NCI

npn, -UB+2 V, I

max.

= 200 mA, short circuit proof,

switchable NCO/NCI

pnp, +UB-2 V, I

max.

= 200 mA, short circuit proof,

switchable NCO/NCI

npn, -UB+2 V, I

max.

= 200 mA, short circuit proof,

switchable NCO/NCI

UE at control inputs C1-C

3

Time delay before availibility

Pin assignment

> -UB+18 V: logical 1

< -UB+13 V or control input open: logical 0

< -UB+6 V: logical 1

> -UB+10 V or control input open: logical 0

< 300 ms < 750 ms

1)

Can be programmed with LinkControl

Brown

White

Black

Violet

Blue

U

Pink

Grey

+UB

Missing sheet

Double sheet

C1

C2

C3

-UB

Brown

White

Black

Violet

Blue

U

Pink

Grey

+UB

Missing sheet

Double sheet

C1

C2

C3

-UB

MV-DO-108329-324993

microsonic GmbH • Hauert 16 • D-44227 Dortmund • Tel: +49 2 31 / 97 51 51-0 • Fax: +49 2 31 / 97 51 51-51 • E-Mail: info@microsonic.de • www.microsonic.deThe content of this document is subject to technical changes. Specifications in this document are presented in a descriptive way only. They do not warrant any product features.

Loading...

Loading...