Page 1

Technical data

fork width 60 mm

fork depth

working range

transducer frequency

resolution

73 mm

≥ 40 mm (± 20 mm)

ca. 310 kHz

0.02 mm

reproducibility

operating voltage U

B

voltage ripple

no-load current consumption

± 0.1 mm

20 to 30 V DC, reverse polarity protection

± 10 %

≤ 60 mA

housing

class of protection to EN 60 529

zinc die cast chromed, plastic parts: PBT

ultrasonic transducer : polyurethane foam,

epoxy resin with glass contents

IP 65

type of connection

controls

indicators

5-pin M12 initiator plug,

brass, nickel-plated

Teach-in-button

LED green: center or within switching window

programmable

synchronisation

operating temperature

LEDs yellow: deviation from centre/switching window

LCA-2 with LinkControl

internal synchronisation up to 10 sensors

+5°C to +60°C

storage temperature

weight

response time

repetition rate

-40°C to +85°C

280 g

6 ms

4 ms

time delay before availability

order no.

analogue output

< 300 ms

bks+6/FIU

current output 4-20 mA

voltage output 0-10 V

switched output

short-circuit-proof, switchable rising/falling

Push-Pull, UB-4V, -UB+2 V, I

max

= 100 mA

switchable NOC/NCC; short-circuit-proof

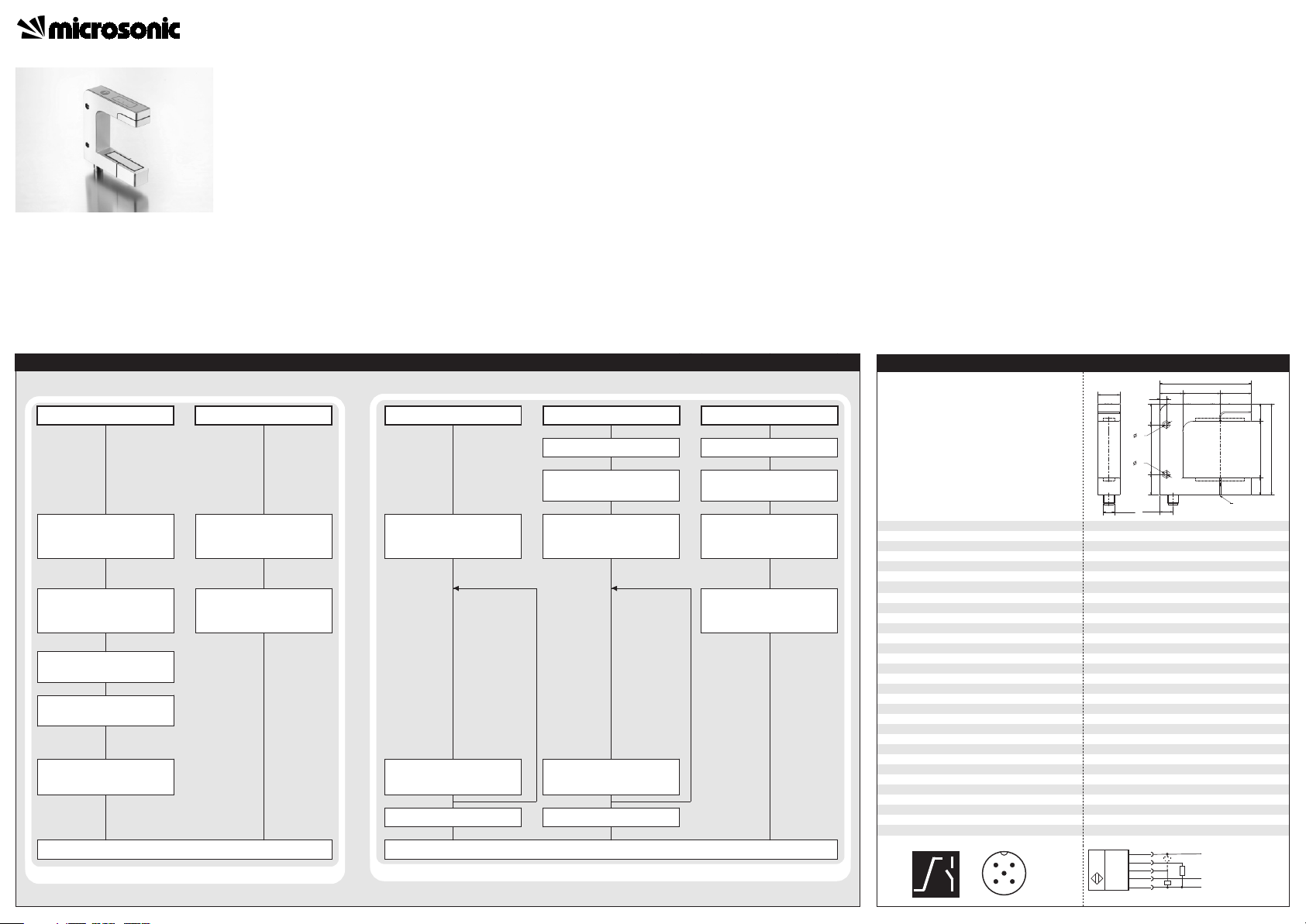

24.5 39.75 33.25

97.5

1

8

.

5

6

0

1

8

.

5

9

7

7

2

2

5

3

2

2

14.15

4.2

4.2

M12x1

23.5

zero position mark

1

5

2

34

1 Push-Pull switched output and analogue output

+U

B

-U

B

Sync/Com

1

2

4

5

3

U

R

L

F

I/U

Sensor adjustment with Teach-in procedure

2-point adjustment

Completely free the fork from

the web material.

Press push-button for ca. 3 s1),

until the LED »0» and LED »+«

flash simultaneously.

Wait for 10 s, until LED »0« and

LED »+« flash mutually.

Cover the sound path com-

pletely with web material.

1-point adjustment

Align the web edge inside the

fork with the mark to obtain a 50

% coverage of the sound path.

Press push-button for ca. 6 s,

until the LED »0« and LED »-«

flash simultaneously.

Set analogue output

Lock push-button

Turn supply voltage OFF.

While pressing the push-button

turn supply voltage ON

2)

.

Press push-button for ca. 13 s1),

until the LED »0« and LEDs

»+«/»-« flash simultaneously.

LED »0«:

The function of

the analogue

output is

displayed:

flashes

LED »+« on, LED »-«

on: 0-10 V, rising

LED »+« on, LED »-«

off: 0-10 V, falling

LED »+« off, LED »-«

on: 4-20 mA, rising

LED »+« off, LED »-«

off: 4-20 mA, fallin

g

Keep push-button pressed for ca.

3 s

2)

, until LED »0« and LED »+«

simultaneously flash quickly.

LED »0«:

LED »-«:

LED »+«:

flashes

off

on: push-button

active

off: push-button

locked

Factory setting

Turn supply voltage OFF.

While pressing the push-button

turn supply voltage ON

2)

.

Keep push-button press for

ca. 13 s

2)

, until the LED »0«

flashes quickly.

Release push-button within

10s

3)

, whilst supply voltage

is ON.

Press push-button for ca. 1 s.

Normal mode operation

To change output function press

push-button for ca. 1 s

1)

.

Wait for 10 s.

Normal mode operation

To change setting press

push-button for ca. 1 s

2)

.

Wait for 10 s.

Ultrasonic Sensors

Further settings

Operating Instructions

bks+6/FIU

Ultrasonic web edge sensor with

analogue output and

IO-Link interface

Product Description

The bks+ ultrasonic web edge sensor

is a fork sensor for scanning the

edges of sound-impermeable and

slightly sound-permeable materials

such as foil or paper.

The fork’s lower leg is equipped with

an ultrasonic sensor which cyclically

emits short sound impulses, which

are detected by the ultrasonic

receiver accommodated in the upper

fork leg. Material immersing into the

fork covers this sound path and thus

attenuates the receive signal, which is

evaluated by the internal electronics.

An analogue signal and a binary

value via IO-Link is output in dependence of the coverage degree.

The bks+6/FIU optional can be programmed using the LinkControlAdapter LCA-2 and LinkControl soft-

ware.

The bks+6/FIU sensors are IO-Link-capable in accordance with IO-Link

specification V1.1.

Via the Teach-in button on the

edge sensor’s top or via Pin 5 on

the device plug, the sensor can

be adjusted to the material to be

controlled.

Choosing between rising and

falling output characteristic is

possible.

Three LEDs indicate the position

of the web material inside the

fork.

Safety Notes

Read the operating instructions

prior to start-up.

Connection, installation and ad-

justment works may only be carried out by expert personnel.

No safety component in ac-

cordance with the EU Machine

Directive.

Installation

Mount the sensor at the installa-

tion site.

Connect a connection cable to

the M12 device plug.

Start-Up

Connect the power supply.

Carry out the adjustment to the

web material in accordance with

the diagram.

Synchronisation

If two or more edge sensors are

mounted in a distance < 50 mm the

internal synchronisation should be

used. Connect Sync-channels (Pin 5

at the units receptacle) of all sensors.

Factory setting

Analogue output on voltage out-

put

Rising analogue characteristic

(0 V at maximum coverage)

Switched output on NOC

Switched output window is

± 4,5 mm around zero position.

Maintenance

microsonic sensors are maintenancefree. With heavy dirt deposits, we recommend a cleaning of the white

sensor surface.

1)

or connect Pin 5 (Sync/Com) to +U

Adjust sensor to web edge

B

2)

or connect Pin 5 (Sync/Com) to -UB

3)

or disconnect Pin 5 (Sync/Com) from -U

B

Page 2

microsonic GmbH | Hauert 16 | 44227 Dortmund | Germany | Tel: +49 2 31 / 97 51 51-0 | Fax: +49 2 31 / 97 51 51-51 | E-Mail: info@microsonic.de | www.microsonic.de The content of this document is subject to technical changes. Specifications in this document are presented in a descriptive way only. They do not warrant any product features.

MV-DO-120904-441970

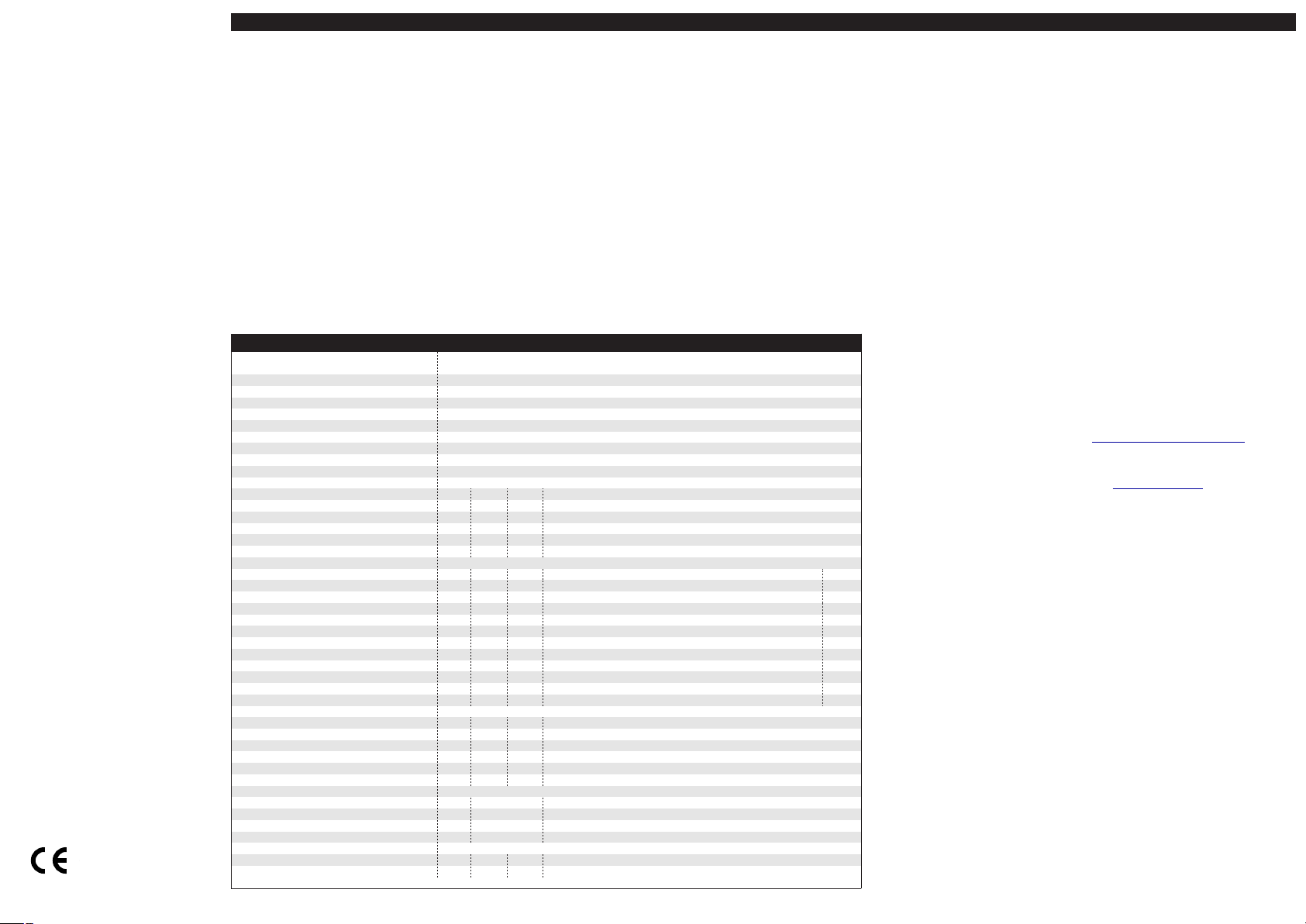

IO-Link Mode

IO-Link Data

physical layer

bks+6/FIU

IO-Link revision

compatibilty

block parameter

data storage

V1.1

V1.0

yes

yes

SIO mode support

min cycle time

baud rate

format of process data

yes

4 ms

COM 2

16 Bit, R, UNI16

content of process data

service data IO-Link specific

vendor name

Bit 0-15: degree of coverage with 0.01 mm resolution

index

0x10

vendor text

product name

product ID

product text

0x11

0x12

0x13

0x14

service data sensor specific

Teach-in via push-button

linearisation of the output characteristic

index

format

0x40

0x41

UINT8

UINT8

temperature compensation

analogue output mode

rising/falling output characteristic curve

NCC/NOC

0x42

0x44

UINT8

UINT8

0x45

0x46

UINT8

UINT8

automatic turning-off LEDs

measurement filter

filter strength

centre of switching window

0x48

0x4D

UINT8

UINT8

0x4E

0x4F

UINT8

UINT16

width of switching window

system commands

restore IO-Link parameter

0x50

UINT16

index

0x02

sensor adjustment: fork cleared

sensor adjustment: fork 50 % covered

sensor adjustment: fork 100 % covered

reset to factory setting

0x02

0x02

0x02

0x02

events

code typ

0x8ca0

0x8ca1

Notification

Notification

observe

measurement value

0x8ca2

Notification

index

0x54

format

UINT16

1)

The value range 0-4,095 corresponds with the working range of the sensor.

accessRvalue

microsonic GmbH

R

R

www.microsonic.de

bks+

RRbks+6/FIU

Ultraschall-Sensor

access range

R/W

R/W

0: activated; 1: deactivated

0: parameter without function

default

0

0

R/W

R/W

0: deactivated; 1: activated

2: current output, 3: voltage output

R/W

R/W

0: rising characteristic curve; 1: falling characteristic curve

0: NOC; 1: NCC

1

3

1

1

R/W

R/W

0: deactivated; 1: activated

0-2: F00-F02

R/W

R/W

0-9: P00-P09

0-4,095

1)

1

0

0

2,047

R/W

0-4,095

1)

accessWvalue

130

1,023

WW161

162

WW163

164

name

parameter was changed

sensor adjustment successful

sensor adjustment failed

accessRrange

0-4,095

1)

The bks+6/FIU sensors are IO-Link-capable in accordance with IO-Link

specification V1.1 and compatible to

specification V1.0.

Note

In IO-Link mode Teach-in and Link-

Control are not available.

Process data

The bks+ cyclically transmits the

value corresponding to the measured

coverage degree with a resolution of

0.01 mm.

Service data

The following sensor parameters

may be set via IO-Link.

Teach-in via push-button

The push-button can be activated/

deactivated for sensor settings with

Teach-in.

Temperature compensation

The temperature compensation is

used for measurement value correction for varying ambient temperatures and can be disabled.

Analogue output mode

For the analogue output either the

function output voltage or current

output can be selected.

Rising / falling analogue characteristic

The analogue characteristic can be

set on rising (0 V / 4 mA at full coverage) or falling characteristic.

Set NOC/NCC

The NCC or NOC output function can

be present for the switched output.

Switching off the LEDs

When activated, the LEDs are switched off 30 seconds after a key

press. After a new key press they will

run for 30 seconds. This automatic

shutdown can be deactivated.

Measurement filter

bks+ ultrasonic sensors provide for a

choice of 3 filter settings:

F00 (no filter)

Each ultrasonic measurement acts

on the output in an unfiltered

manner.

F01 (average value filter)

Forms approximately the arithmetic

mean of several measurements.

According to the mean value the

output is set. The number of measurements, from which the mean is

formed is dependent on the chosen filter strength.

F02 (median filter)

Finds the median of several measurements. According to the median

the output is set. The number of

measurements, for which the median is determined is dependent on

the selected filter strength.

Filter strength

For both measurement value filters, a

filter strength between P00 (weak filter effect) and P09 (strong filter effect) can be selected.

Switching window

If the web edge is within the switching window the switching output

is set. The switching window is defined by the adjusted center and the

width.

Note

The switching window has to be

within the operating range.

System commands

With 5 system commands the following settings may be carried out:

restore IO-Link parameters to their

factory settings

sensor adjustment: fork cleared.

sensor adjustment: fork 50 % co-

vered

sensor adjustment: fork 100 %

covered

reset all sensor parameters includ-

ing the IO-Link parameters to their

factory settings.

Events

The bks+ sensor sends the following

events:

parameter was changed

sensor adjustment successful

sensor adjustment failed

IODD file

The latest IODD file you will find

on

the internet under

www.microsonic.de/en/IODD

.

For further informations on IO-Link

see www.io-link.com.

Note

Working range and gradient of

the analogue output curve depend on the ultrasonic transducers and cannot be adjusted. The

working range always is ≥ 40

mm.

For

sound-impermeable materi-

als

the sensor can be adjusted

to the environmental conditions

by the 1-point adjustment procedure.

For slightly s

ound-permeable

materials the sensor has to be

set up to the material and the

environmental conditions

by us-

ing the 2-point adjustment.

Carry out a practical test to find out

whether a material is slightly

sound-permeable.

For optimum measurement re-

sults the material to be detected

should be kept in a range of ± 5

mm around the centre between

the upper and lower fork leg.

The sensor can be reset to its

factory settings (see »Sensor adjustment with Teach-in procedure, further settings«).

Using the LinkControl-Adapter

LCA-2 (optional accessory) and

the LinkControl-Software V7.6

all Teach-in- and additional sensor parameter settings may be

made.

Depending on the function the

ultrasonic transducers in the upper and lower fork leg are

mounted with a slope of 2°.

2004/108/EWG

Loading...

Loading...